Fire Retardancy of Cementitious Panels with Larch and Spruce Bark as Bio-Admixtures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

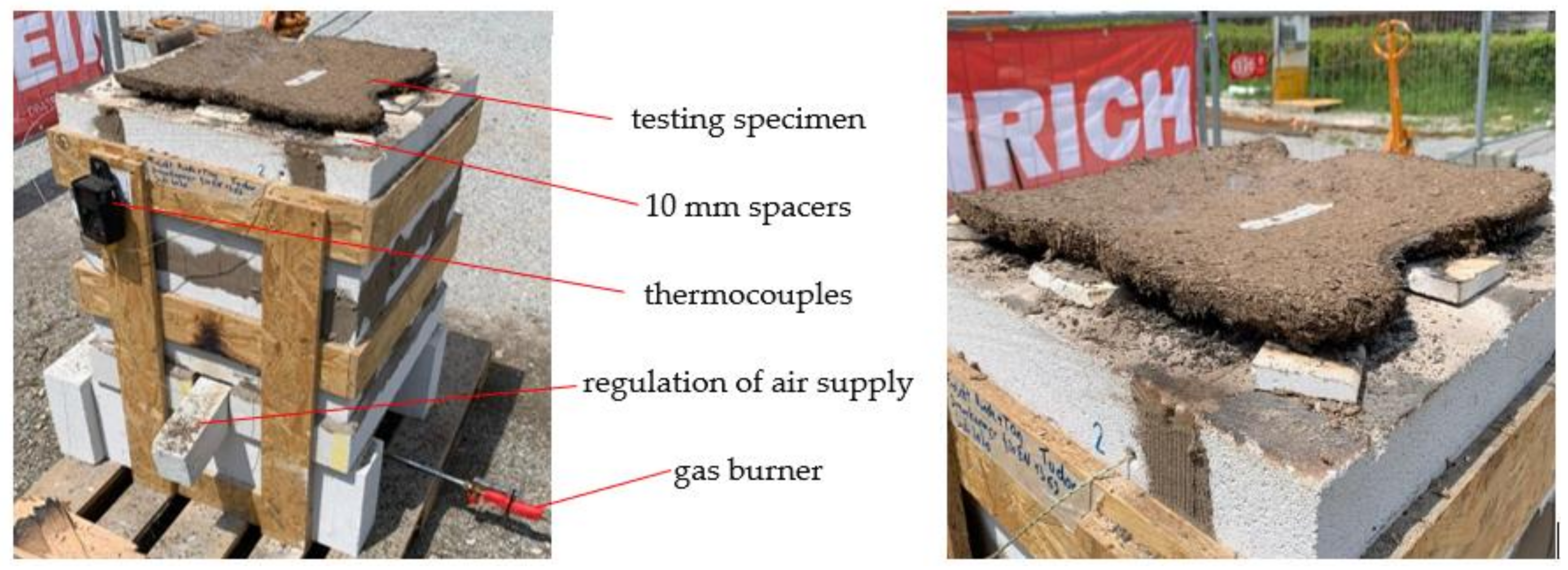

2.2. Fire-Resistance Test

3. Results

3.1. Determination of the Physical Properties

3.1.1. Moisture Content (MC)

3.1.2. Thickness Swelling (TS) after 24 h Water Soaking

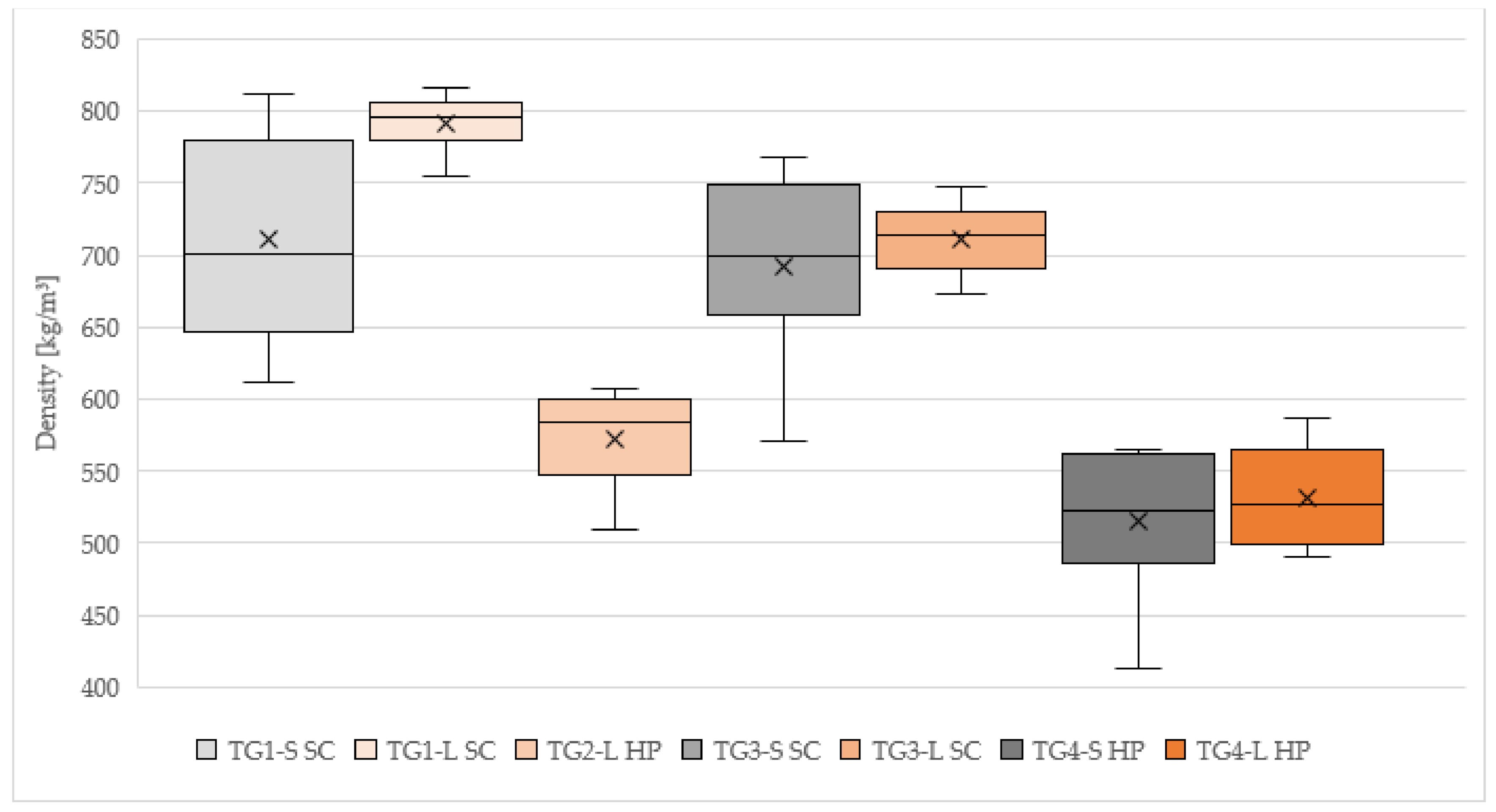

3.1.3. Density

3.2. Determination of the Mechanical Properties

3.2.1. Compressive Strength

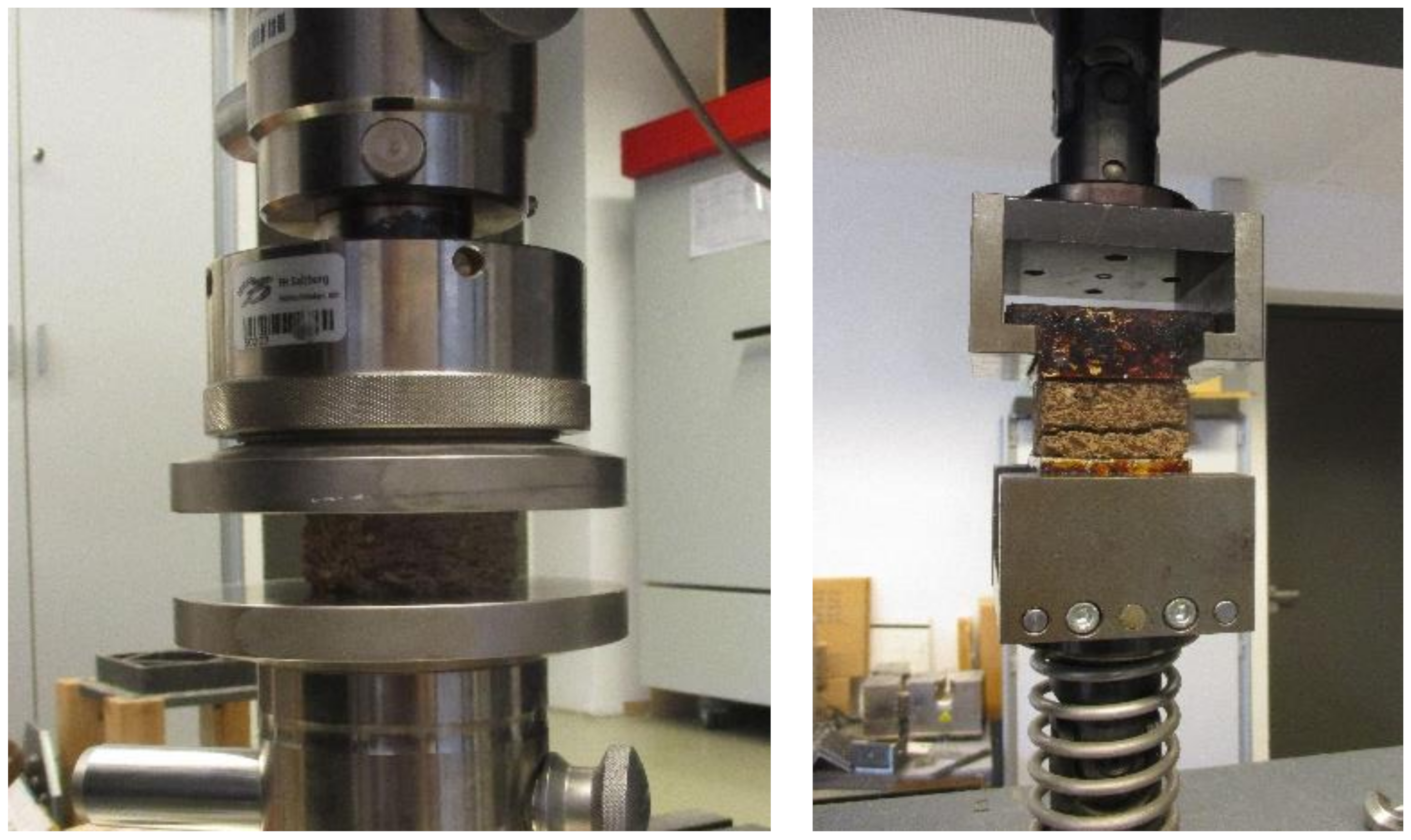

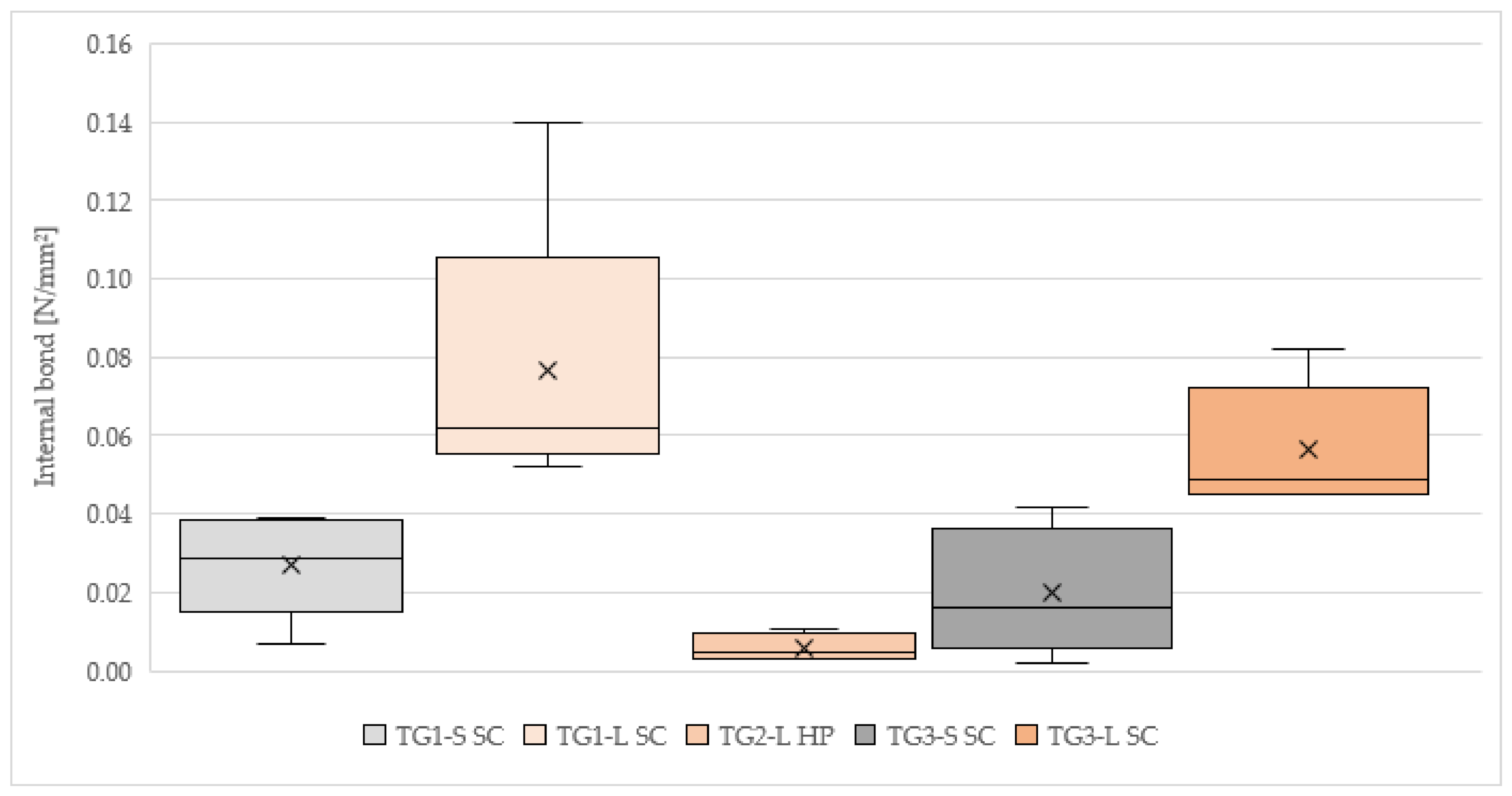

3.2.2. Internal Bond (IB)

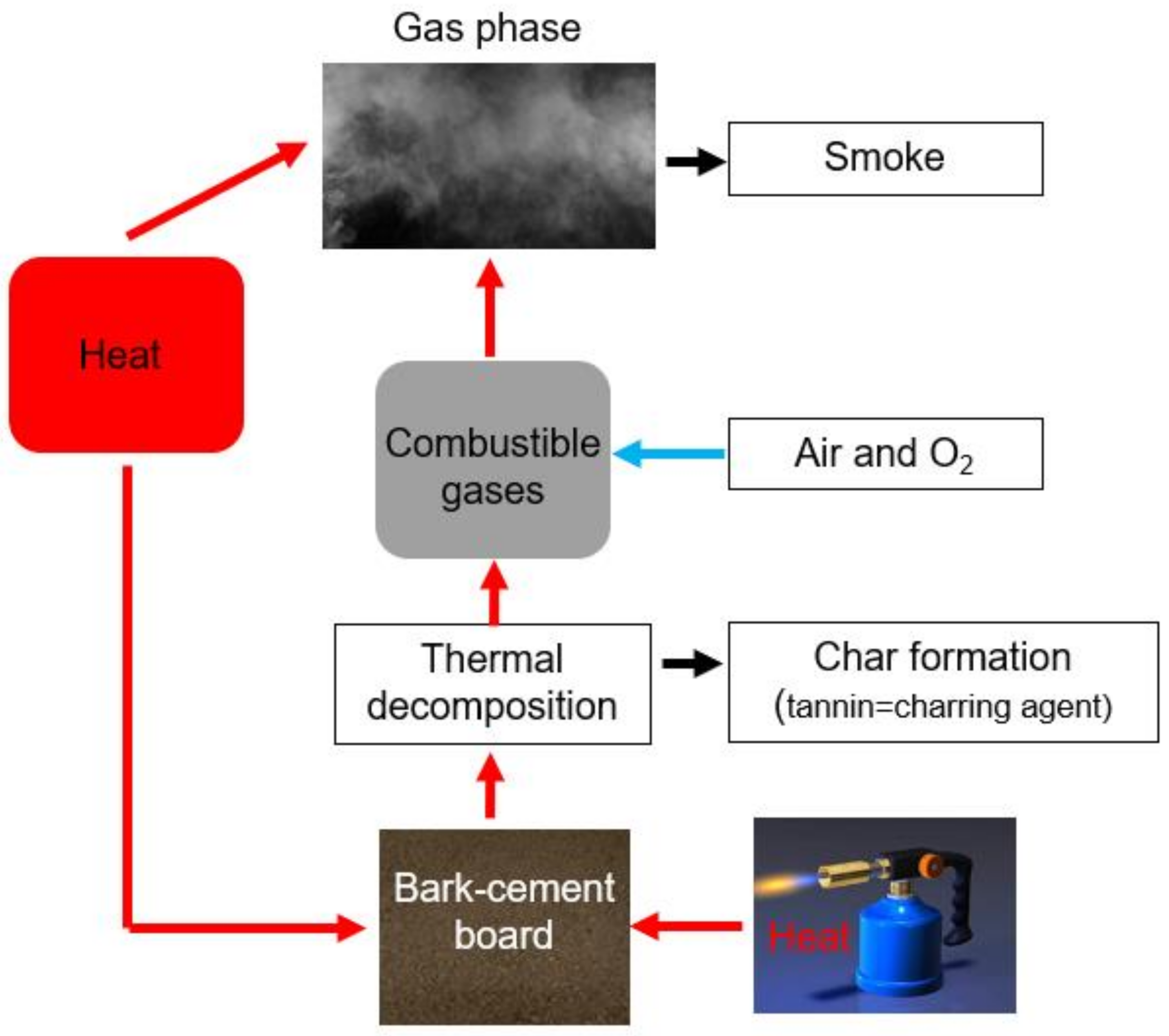

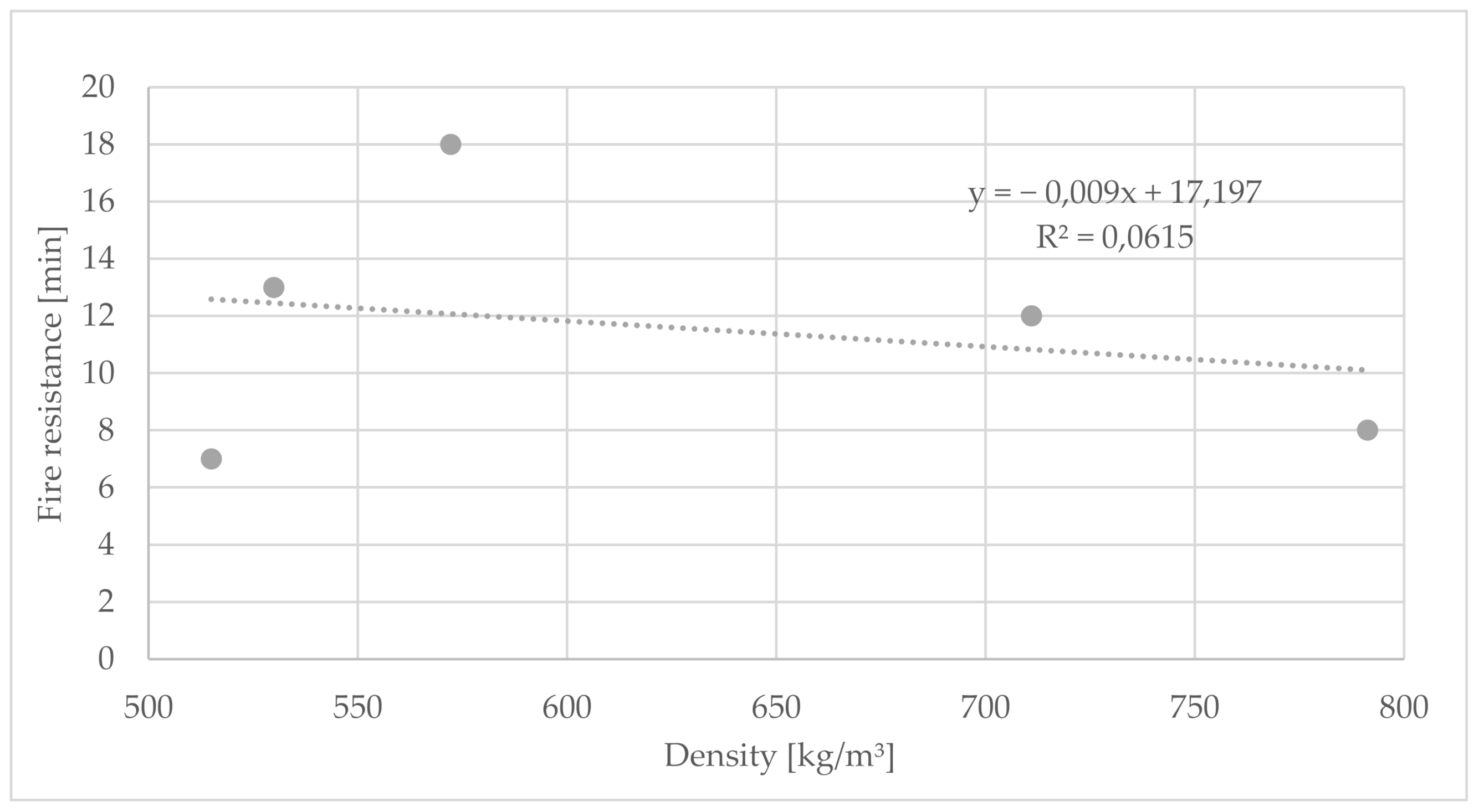

3.2.3. Fire Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ebner, G. Es brummt wieder. Starke Nachfrage hebt Preise markant. Holzkurier 2022, 1, 3–6. [Google Scholar]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- European Commission. Bioeconomy: The European Way to Use our Natural Resources. Available online: https://op.europa.eu/en/publication-detail/-/publication/775a2dc7-2a8b-11e9-8d04-01aa75ed71a1 (accessed on 10 February 2022).

- Verkerk, P.J.; Hassegawa, M.; van Brusselen, J.; Cramm, M.; Chen, X.; Imparato Maximo, Y.; Koç, M.; Lovrić, M.; Tekle Tegegne, Y. The Role of Forest Products in the Global Bioeconomy—Enabling Substitution by Wood-Based Products and Contributing to the Sustainable Development Goals; FAO: Rome, Italy, 2021. [Google Scholar]

- Kader, A.H.A.; Dacrory, S.; Khattab, T.A.; Kamel, S.; Abou-Yousef, H. Hydrophobic and Flame-Retardant Foam Based on Cellulose. J. Polym. Environ. 2022. [Google Scholar] [CrossRef]

- Segev, O.; Kushmaro, A.; Brenner, A. Environmental impact of flame retardants (persistence and biodegradability). Int. J. Environ. Res. Public Health 2009, 6, 478–491. [Google Scholar] [CrossRef] [PubMed]

- Ashraf, M.A.; Zwawi, M.; Taqi, M.M.; Kanthasamy, R.; Bahadar, A. Jute Based Bio and Hybrid Composites and Their Applications. Fibers 2019, 7, 77. [Google Scholar] [CrossRef]

- Rubino, C.; Bonet Aracil, M.; Gisbert-Payá, J.; Liuzzi, S.; Stefanizzi, P.; Zamorano Cantó, M.; Martellotta, F. Composite Eco-Friendly Sound Absorbing Materials Made of Recycled Textile Waste and Biopolymers. Materials 2019, 12, 4020. [Google Scholar] [CrossRef] [PubMed]

- Carosio, F.; Kochumalayil, J.; Cuttica, F.; Camino, G.; Berglund, L. Oriented clay nanopaper from biobased components--mechanisms for superior fire protection properties. ACS Appl. Mater. Interfaces 2015, 7, 5847–5856. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.H.; Kim, H.S.; Kim, S.; Kim, H.J.; Lee, B.; Deng, Y.; Feng, Q.; Luo, J. Evaluating the flammability of wood-based panels and gypsum particleboard using a cone calorimeter. Constr. Build. Mater. 2011, 25, 3044–3050. [Google Scholar] [CrossRef]

- Yi, D.; Yang, R.; Wilkie, C.A. Full scale nanocomposites: Clay in fire retardant and polymer. Polym. Degrad. Stab. 2014, 105, 31–41. [Google Scholar] [CrossRef]

- Horrocks, R.; Price, A.; Limited, W.P. (Eds.) Introduction: Polymer Combustion, Condensed Phase Pyrolysis and Smoke Formation: Fire Retardant Materials; Elsevier Science, Woodhead Publishing: Cambridge, UK, 2011. [Google Scholar]

- Tudor, E.M.; Scheriau, C.; Barbu, M.C.; Réh, R.; Krišťák, L.; Schnabel, T. Enhanced Resistance to Fire of the Bark-Based Panels Bonded with Clay. Appl. Sci. 2020, 10, 5594. [Google Scholar] [CrossRef]

- Urstöger, J.; Barbu, M.C.; Pacher, T.; Petutschnigg, A.; Jorda, J.; Tudor, E.M. Selected Properties of Cement Bound Spruce and Larch Bark Bio-Aggregates. Polymers 2021, 13, 4438. [Google Scholar] [CrossRef] [PubMed]

- Giannotas, G.; Kamperidou, V.; Barboutis, I. Tree bark utilization in insulating bio-aggregates: A review. Biofuels Bioprod. Bioref. 2021, 15, 1989–1999. [Google Scholar] [CrossRef]

- Scherer, R. Verfahren Zur Herstellung Eines Feuersicheren, Leichten, Porösen Materiales. Patent AT37223B, 1907. (Switzerland). [Google Scholar]

- Bauer, G.; Speck, T.; Blömer, J.; Bertling, J.; Speck, O. Insulation capability of the bark of trees with different fire adaptation. J. Mater. Sci. 2010, 45, 5950–5959. [Google Scholar] [CrossRef]

- Réh, R.; Krišťák, L.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Vozárová, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of Birch Bark as an Eco-Friendly Filler in Urea-Formaldehyde Adhesives for Plywood Manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef]

- Barbu, M.C.; Lohninger, Y.; Hofmann, S.; Kain, G.; Petutschnigg, A.; Tudor, E.M. Larch Bark as a Formaldehyde Scavenger in Thermal Insulation Panels. Polymers 2020, 12, 2632. [Google Scholar] [CrossRef]

- Gößwald, J.; Barbu, M.C.; Petutschnigg, A.; Tudor, E.M. Binderless Thermal Insulation Panels Made of Spruce Bark Fibres. Polymers 2021, 13, 1799. [Google Scholar] [CrossRef]

- Tudor, E.M.; Krišťák, L.; Barbu, M.C.; Gergeľ, T.; Němec, M.; Kain, G.; Réh, R. Acoustic Properties of Larch Bark Panels. Forests 2021, 12, 887. [Google Scholar] [CrossRef]

- Xing, C.; Deng, J.; Zhang, S.Y. Effect of thermo-mechanical refining on properties of MDF made from black spruce bark. Wood Sci. Technol. 2007, 41, 329–338. [Google Scholar] [CrossRef]

- Muszinsky, Z.; McNatt, J. Investigations on the use of spruce bark in the manufacture of particleboard. For. Prod. J. 1984, 34, 28–35. [Google Scholar]

- Filbakk, T.; Jirjis, R.; Nurmi, J.; Høibø, O. The effect of bark content on quality parameters of Scots pine (Pinus sylvestris L.) pellets. Biomass Bioenergy 2011, 35, 3342–3349. [Google Scholar] [CrossRef]

- Pásztory, Z.; Mohácsiné, I.R.; Gorbacheva, G.; Börcsök, Z. The utilization of tree bark. Bioresources 2016, 11, 7859–7888. [Google Scholar] [CrossRef]

- Frybort, S.; Mauritz, R.; Teischinger, A.; Müller, U. Cement bonded composites—A mechanical review. Bioresources 2008, 3, 602–626. [Google Scholar]

- Lin, X.; Silsbee, M.R.; Roy, D.M.; Kessler, K.; Blankenhorn, P.R. Approaches to improve the properties of wood fiber reinforced cementitious composites. Cem. Concr. Res. 1994, 24, 1558–1566. [Google Scholar] [CrossRef]

- Karade, S.R. Potential of Cork Cement Composite as a Thermal Insulation Material. KEM 2015, 666, 17–29. [Google Scholar] [CrossRef]

- Merabti, S.; Kenai, S.; Belarbi, R.; Khatib, J. Thermo-mechanical and physical properties of waste granular cork composite with slag cement. Constr. Build. Mater. 2021, 272, 121923. [Google Scholar] [CrossRef]

- Karade, S.R.; Irle, M.; Maher, K. Influence of granule properties and concentration on cork-cement compatibility. Holz Roh Werkst. 2006, 64, 281–286. [Google Scholar] [CrossRef]

- Mansilla, C.; Pradena, M.; Fuentealba, C.; César, A. Evaluation of Mechanical Properties of Concrete Reinforced with Eucalyptus globulus Bark Fibres. Sustainability 2020, 12, 10026. [Google Scholar] [CrossRef]

- Eusebio, D.A.; Yamauchi, H.; Sasaki, H.; Kawai, S. (Eds.) Bark Cement Composites. In Proceedings of the Third Pacific Rim Bio Based Composites Symposium, Kyoto, Japan, 15–16 November 1996. [Google Scholar]

- EN 1363-1:2020; Fire Resistance Tests. European Committee for Standardization: Brussels, Belgium, 2020.

- Reiner, F. Einfluss des Tonanteiles auf die Festigkeits- und Brandeigenschaften von Mineralgebundenen Holzwerkstoffplatten. Bachelor’s Thesis, Fachhochschule Salzburg, Kuchl, Austria, 2020. [Google Scholar]

- Schintlmeister, A. Der Einfluss des Klebstoffanteiles auf die Festigkeits- und Brandeigenschaften von Rinde-Ton-Plattenwerkstoffen. Bachelor’s Thesis, Fachhochschule Salzburg, Kuchl, Austria, 2020. [Google Scholar]

- EN 326-1:2005; Wood-Based Panels—Sampling, Cutting and Inspection. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 322:2005; Wood-Based Panels—Determination of Moisture Content. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 317:2005; Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 2005.

- EN 323:2005; Wood-Based Panels—Determination of Density. European Committee for Standardization: Brussels, Belgium, 2005.

- Vangeel, T.; Neiva, D.M.; Quilhó, T.; Costa, R.A.; Sousa, V.; Sels, B.F.; Pereira, H. Tree bark characterization envisioning an integrated use in a biorefinery. Biomass Conv. Bioref. 2021. [Google Scholar] [CrossRef]

- Čabalová, I.; Bélik, M.; Kučerová, V.; Jurczyková, T. Chemical and Morphological Composition of Norway Spruce Wood (Picea abies, L.) in the Dependence of Its Storage. Polymers 2021, 13, 1619. [Google Scholar] [CrossRef]

- Niemz, P.; Sonderegger, W.U. Holzphysik: Physik des Holzes und der Holzwerkstoffe; Fachbuchverlag Leipzig im Carl Hanser Verlag: München, Germany, 2017; ISBN 978-3-446-44526-0. [Google Scholar]

- EN 826:2013; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour. European Committee for Standardization: Brussels, Belgium, 2013.

- EN 319:2005; Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 2005.

- Gwon, S.; Choi, Y.C.; Shin, M. Internal curing of cement composites using kenaf cellulose microfibers. J. Build. Eng. 2022, 47, 103867. [Google Scholar] [CrossRef]

- Fengel, D. Wood: Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany; New York, NY, USA, 1989; ISBN 9780899255934. [Google Scholar]

- Struble, L.; Skalny, J.; Mindess, S. A review of the cement-aggregate bond. Cem. Concr. Res. 1980, 10, 277–286. [Google Scholar] [CrossRef]

- Hestermann, U.; Rongen, L. Baukonstruktionslehre. Springer Vieweg: Wiesbaden, Germany, 2015; Volume 36, ISBN 978-3-8348-2564-3. [Google Scholar]

- DIN 4102-4:2004; Fire Behaviour of Building Materials and Building Components—Part 4: Synopsis and Application of Classified Building Materials, Components and Special Components. Deutsches Institut für Normung e.V, Beuth: Berlin, Germany, 2004.

- Tributsch, H.; Fiechter, S. The material strategy of fire-resistant tree barks. WIT Trans. Built Environ. 2008, 97, 43–52. [Google Scholar] [CrossRef]

- Hemingway, R.W.; Lacks, P.E. Plant Polyphenols: Synthesis, Properties, Significance; Plenum Press: New York, NY, USA, 1992. [Google Scholar]

| Bark | Comp. | Particle Size (%) | Cement (%) | Water (%) | RM (%) | Press Parameter | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| <3 mm | 3–7 mm | 7–12 mm | <1–4 mm | Pressure (N/mm2) | Temp. (°C) | Time | |||||

| TG1 <3–12 mm | spruce | SC | 9.86 | 12.30 | 12.30 | 39.26 | 19.64 | 6.64 | - | 20 | ~168 h |

| larch | |||||||||||

| TG2 <3–12 mm | spruce | HP | 9.86 | 12.30 | 12.30 | 39.26 | 19.64 | 6.64 | 0.8–2.0 | 20 | 6–8 min |

| larch | |||||||||||

| TG3 <3–7 mm | spruce | SC | 9.86 | 24.60 | - | 39.26 | 19.64 | 6.64 | - | 20 | ~168 h |

| larch | |||||||||||

| TG4 <3–7 mm | spruce | HP | 9.86 | 24.60 | - | 39.26 | 19.64 | 6.64 | 0.75 | 20 | 6–8 min |

| larch | 1.10 | ||||||||||

| Bark | Compaction | Moisture Content (%) | Thickness Swelling (%) | Density (kg/m3) | |

|---|---|---|---|---|---|

| TG1 <3–12 mm | spruce | SC | 13.06 | 2.69 (0.10) | 710 (74) |

| larch | 15.89 | 2.36 (0.61) | 791 (20) | ||

| TG2 <3–12 mm | spruce | HP | - | - | - |

| larch | 14.65 | 3.43 (0.48) | 572 (32) | ||

| TG3 <3–7 mm | spruce | SC | 13.34 | 5.48 (1.72) | 692 (66) |

| larch | 16.07 | 2.47 (0.59) | 711 (25) | ||

| TG4 <3–7 mm | spruce | HP | 13.06 | - | 515 (56) |

| larch | 14.06 | 3.52 (0.94) | 530 (37) |

| Bark | Compaction | Test Samples | Compressive Strength (N/mm2) | Internal Bond (N/mm2) | |

|---|---|---|---|---|---|

| TG1 <3–12 mm | spruce | SC | n = 5 | 1.83 (0.69) | 0.03 (0.01) |

| larch | n = 5 | 3.167 (0.320) | 0.08 (0.036) | ||

| TG2 <3–12 mm | spruce | HP | n = 5 | - * | - * |

| larch | n = 5 | 0.221 (0.032) | 0.006 (0.003) | ||

| TG3 <3–7 mm | spruce | SC | n = 5 | 1.795 (0.52) | 0.020 (0.016) |

| larch | n = 5 | 2.870 (0.45) | 0.057 (0.016) | ||

| TG4 <3–7 mm | spruce | HP | n = 5 | 0.268 (0.02) | - * |

| larch | n = 5 | 0.321 (0.06) | - * |

| Fire Resistance According to EN 1363-1:2020 | TG1-L SC | TG2-L HP | TG3-L SC | TG4-L HP | TG4-S HP | Gypsum Reference |

|---|---|---|---|---|---|---|

| Furnace temp.—start (combustion chamber ≈ 100 °C) | 110.0 °C | 109.6 °C | 113.5 °C | 121.4 °C | 121.3 °C | 91.4 °C |

| Surface temp—start | 32 °C | 34 °C | 35 °C | 37 °C | 34 °C | 25 °C |

| Thermal insulation (surface temp. + 140 °C) | 8 min | 18 min | 12 min | 13 min | 7 min * | 8 min |

| Integrity (surface temp. = 260 °C) | 9 min | 20 min | 12 min | 14 min | - | 9 min |

| End (surface temp. = 300 °C) | 10 min | 22 min | 13 min | 15 min | - | 10 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pacher, T.; Barbu, M.C.; Urstöger, J.; Petutschnigg, A.; Tudor, E.M. Fire Retardancy of Cementitious Panels with Larch and Spruce Bark as Bio-Admixtures. Polymers 2022, 14, 1469. https://doi.org/10.3390/polym14071469

Pacher T, Barbu MC, Urstöger J, Petutschnigg A, Tudor EM. Fire Retardancy of Cementitious Panels with Larch and Spruce Bark as Bio-Admixtures. Polymers. 2022; 14(7):1469. https://doi.org/10.3390/polym14071469

Chicago/Turabian StylePacher, Thomas, Marius Cătălin Barbu, Johannes Urstöger, Alexander Petutschnigg, and Eugenia Mariana Tudor. 2022. "Fire Retardancy of Cementitious Panels with Larch and Spruce Bark as Bio-Admixtures" Polymers 14, no. 7: 1469. https://doi.org/10.3390/polym14071469