High-Strength Heat-Elongated Thermoplastic Polyurethane Elastomer Consisting of a Stacked Domain Structure

Abstract

1. Introduction

2. Experimental Section

2.1. Preparation of the Specimen

2.2. Tensile Tests

2.3. SAXS and WAXD Measurement

2.4. DSC Measurement

2.5. AFM Observation

3. Results and Discussion

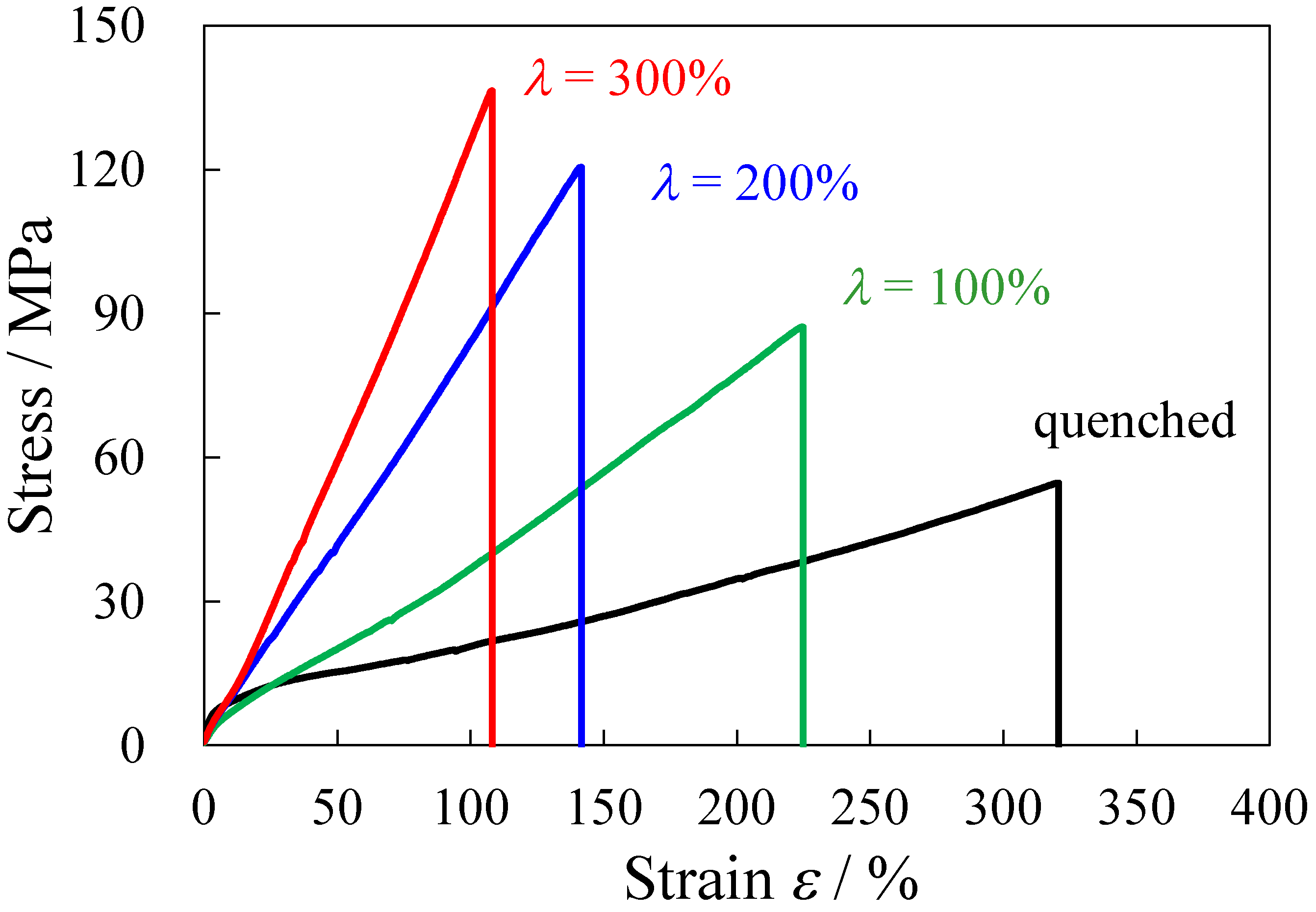

3.1. Tensile Properties of the Elongated TPU

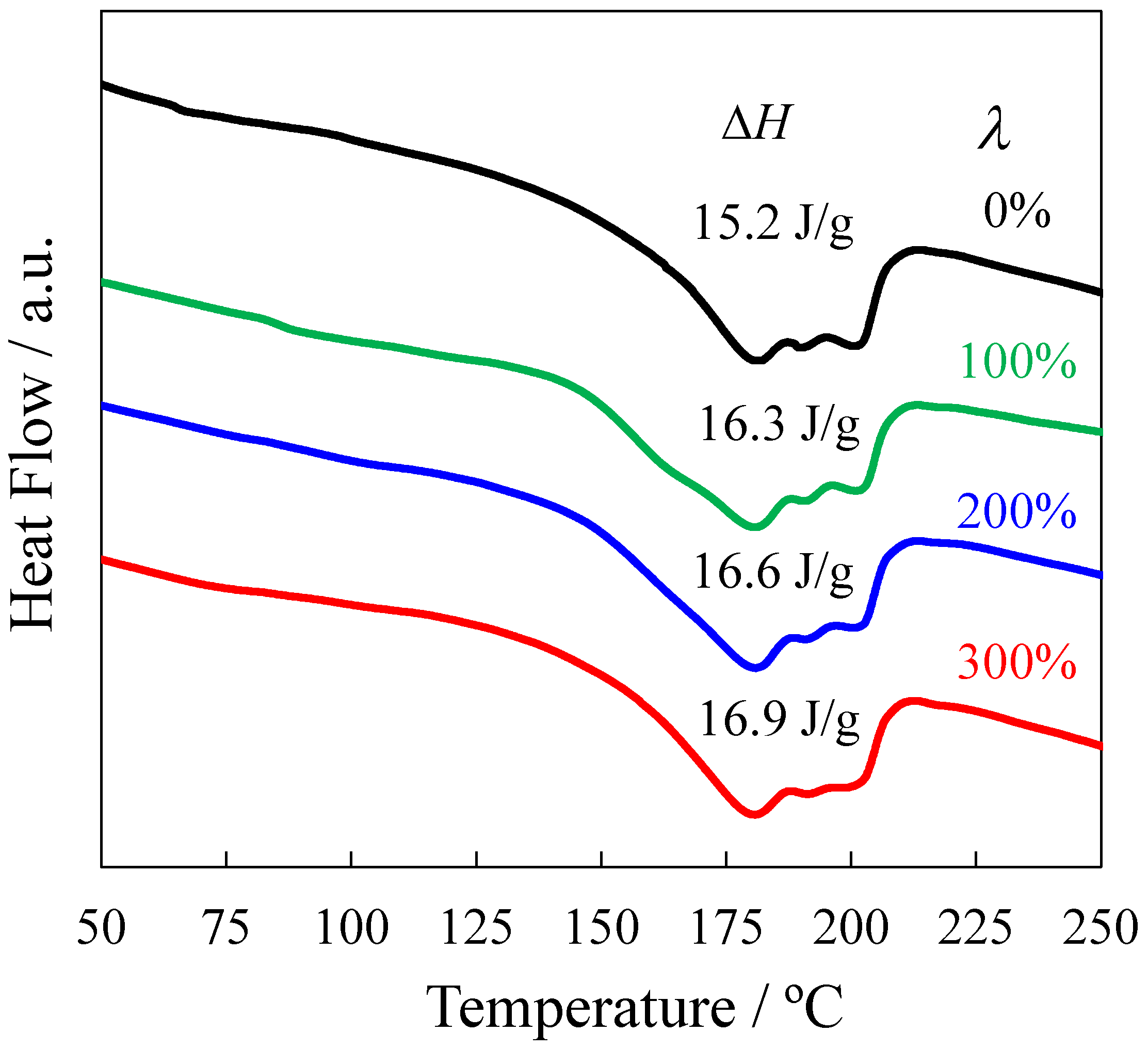

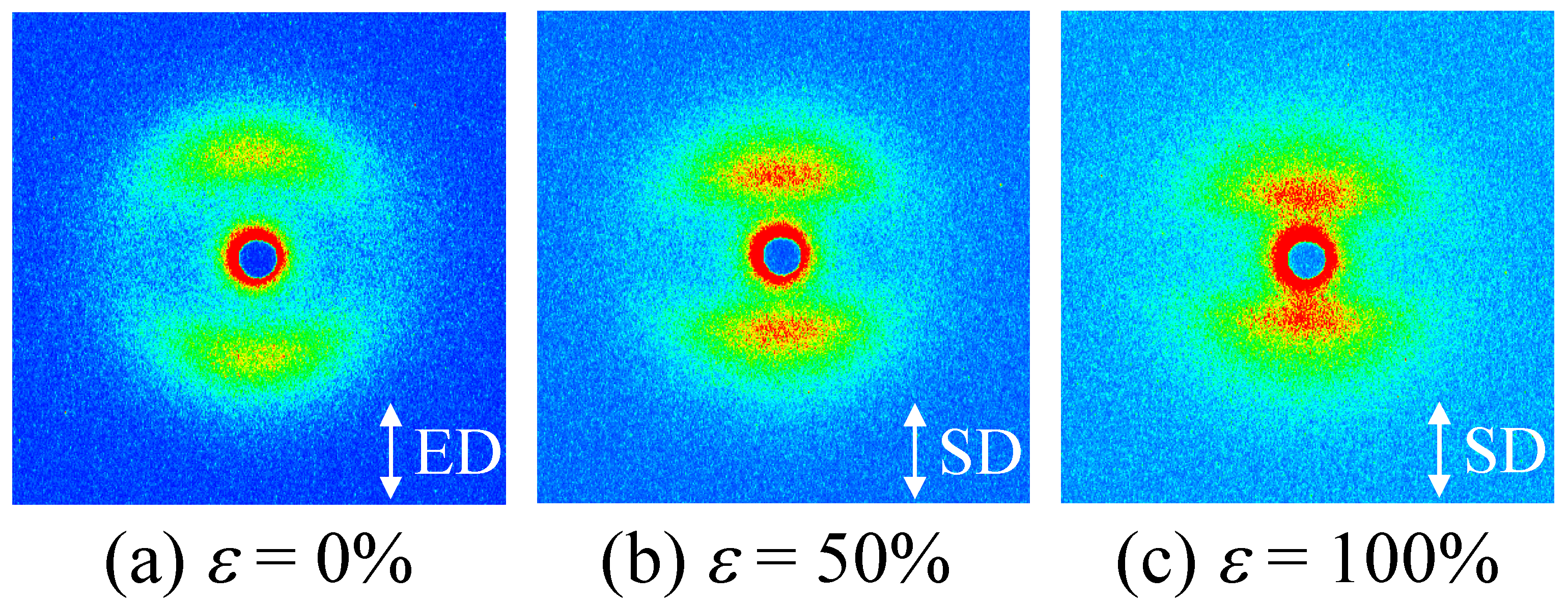

3.2. Structure Change during the Heat Elongation

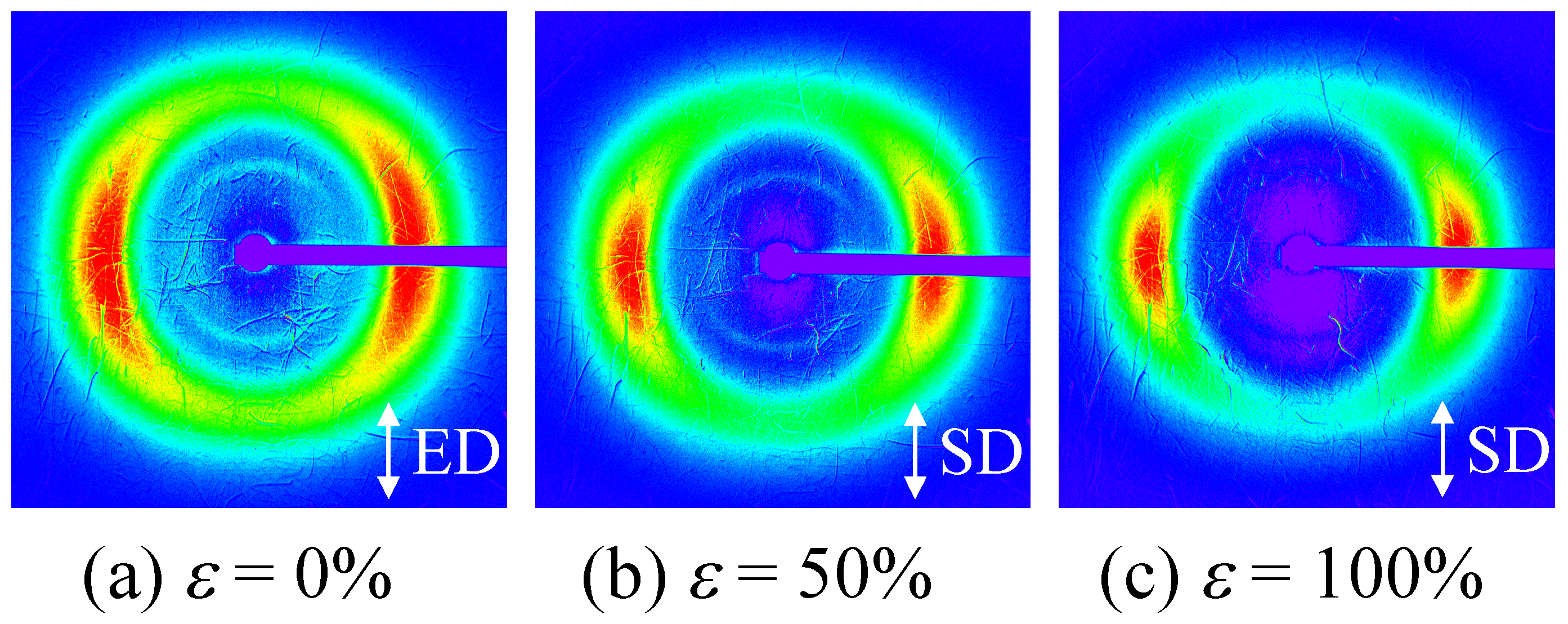

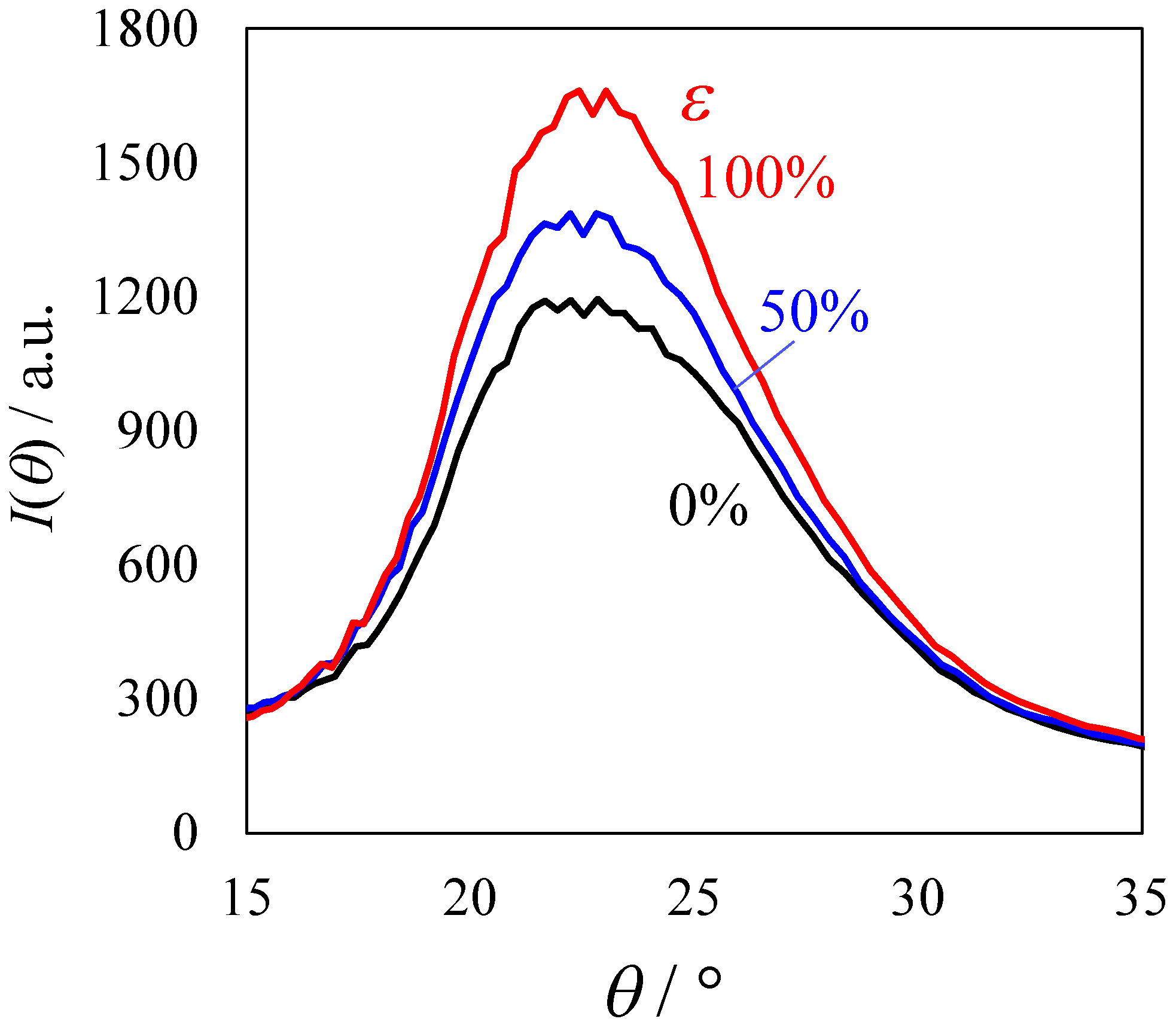

3.3. Structure Change in the Elongated TPU during Stretching

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, A.; Peng, X.; Turng, L.-S. In-situ fibrillated polytetrafluoroethylene (PTFE) in thermoplastic polyurethane (TPU) via melt blending: Effect on rheological behavior, mechanical properties, and microcellular foamability. Polymer 2018, 134, 263–274. [Google Scholar] [CrossRef]

- Yanagihara, Y.; Suenaga, A.; Kondo, H.; Saito, H. Structure and deformation recovery of the thermoplastic polyurethane spherulite. J. Polym. Sci. Part B Polym. Phys. 2017, 55, 1585–1594. [Google Scholar] [CrossRef]

- Hepburn, C. Polyurethane Elastomers; Springer Science & Business Media: Berlin, Germany, 2012. [Google Scholar]

- Curgul, S.; Yilgor, I.; Yilgor, E.; Erman, B.; Cakmak, M. Effect of chemical composition on large deformation mechanooptical properties of high strength thermoplastic poly(urethane urea)s. Macromolecules 2004, 37, 8676–8685. [Google Scholar] [CrossRef]

- Bhowmick, A.K.; Stephens, H. Handbook of Elastomers; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Wang, C.B.; Cooper, S.L. Morphology and properties of segmented polyether polyurethaneureas. Macromolecules 1983, 16, 775–786. [Google Scholar] [CrossRef]

- Saiani, A.; Rochas, C.; Eeckhaut, G.; Daunch, W.; Leenslag, J.-W.; Higgins, J. Origin of multiple melting endotherms in a high hard block content polyurethane. 2. Structural investigation. Macromolecules 2004, 37, 1411–1421. [Google Scholar] [CrossRef]

- Garrett, J.; Runt, J.; Lin, J. Microphase separation of segmented poly (urethane urea) block copolymers. Macromolecules 2000, 33, 6353–6359. [Google Scholar] [CrossRef]

- Velankar, S.; Cooper, S.L. Microphase separation and rheological properties of polyurethane melts. 1. Effect of block length. Macromolecules 1998, 31, 9181–9192. [Google Scholar] [CrossRef]

- Koberstein, J.T.; Galambos, A.F.; Leung, L.M. Compression-molded polyurethane block copolymers. 1. Microdomain morphology and thermomechanical properties. Macromolecules 1992, 25, 6195–6204. [Google Scholar] [CrossRef]

- Kojio, K.; Nakashima, S.; Furukawa, M. Microphase-separated structure and mechanical properties of norbornane diisocyanate-based polyurethanes. Polymer 2007, 48, 997–1004. [Google Scholar] [CrossRef]

- Eceiza, A.; Martin, M.; De La Caba, K.; Kortaberria, G.; Gabilondo, N.; Corcuera, M.; Mondragon, I. Thermoplastic polyurethane elastomers based on polycarbonate diols with different soft segment molecular weight and chemical structure: Mechanical and thermal properties. Polym. Eng. Sci. 2008, 48, 297–306. [Google Scholar] [CrossRef]

- He, Y.; Xie, D.; Zhang, X. The structure, microphase-separated morphology, and property of polyurethanes and polyureas. J. Mater. Sci. 2014, 49, 7339–7352. [Google Scholar] [CrossRef]

- Kojio, K.; Furukawa, M.; Motokucho, S.; Shimada, M.; Sakai, M. Structure-Mechanical property relationships for poly(carbonate urethane) elastomers with novel soft segments. Macromolecules 2009, 42, 8322–8327. [Google Scholar] [CrossRef]

- Saralegi, A.; Rueda, L.; Fernández-d’Arlas, B.; Mondragon, I.; Eceiza, A.; Corcuera, M.A. Thermoplastic polyurethanes from renewable resources: Effect of soft segment chemical structure and molecular weight on morphology and final properties. Polym. Int. 2013, 62, 106–115. [Google Scholar] [CrossRef]

- Kohjiya, S.; Ikeda, Y.; Yamashita, S.; Shibayama, M.; Kotani, T.; Nomura, S. Infrared Dichroism Study of Segmented Polyurethaneurea with Triblock Polyether Soft Segments. Polym. J. 1991, 23, 991–998. [Google Scholar] [CrossRef][Green Version]

- Li, Y.; Gao, T.; Chu, B. Synchrotron SAXS studies of the phase-separation kinetics in a segmented polyurethane. Macromolecules 1992, 25, 1737–1742. [Google Scholar] [CrossRef]

- Martin, D.J.; Meijs, G.F.; Gunatillake, P.A.; McCarthy, S.J.; Renwick, G.M. The effect of average soft segment length on morphology and properties of a series of polyurethane elastomers. II. SAXS-DSC annealing study. J. Appl. Polym. Sci. 1997, 64, 803–817. [Google Scholar] [CrossRef]

- Leung, L.M.; Koberstein, J.T. DSC annealing study of microphase separation and multiple endothermic behavior in polyether-based polyurethane block copolymers. Macromolecules 1986, 19, 706–713. [Google Scholar] [CrossRef]

- Koberstein, J.T.; Russell, T.P. Simultaneous SAXS-DSC study of multiple endothermic behavior in polyether-based polyurethane block copolymers. Macromolecules 1986, 19, 714–720. [Google Scholar] [CrossRef]

- Saiani, A.; Novak, A.; Rodier, L.; Eeckhaut, G.; Leenslag, J.W.; Higgins, J.S. Origin of multiple melting endotherms in a high hard block content polyurethane: Effect of annealing temperature. Macromolecules 2007, 40, 7252–7262. [Google Scholar] [CrossRef]

- Yanagihara, Y.; Osaka, N.; Murayama, S.; Saito, H. Thermal annealing behavior and structure development of crystalline hard segment domain in a melt-quenched thermoplastic polyurethane. Polymer 2013, 54, 2183–2189. [Google Scholar] [CrossRef]

- Nallicheri, R.A.; Rubner, M.F. Thermal and mechanical-properties of polyurethane diacetylene segmented copolymers.1. molecular-weight and annealing effects. Macromolecules 1990, 23, 1005–1016. [Google Scholar] [CrossRef]

- Lee, B.S.; Chun, B.C.; Chung, Y.-C.; Sul, K.I.; Cho, J.W. Structure and thermomechanical properties of polyurethane block copolymers with shape memory effect. Macromolecules 2001, 34, 6431–6437. [Google Scholar] [CrossRef]

- Rueda-Larraz, L.; d’Arlas, B.F.; Tercjak, A.; Ribes, A.; Mondragon, I.; Eceiza, A. Synthesis and microstructure–mechanical property relationships of segmented polyurethanes based on a PCL–PTHF–PCL block copolymer as soft segment. Eur. Polym. J. 2009, 45, 2096–2109. [Google Scholar] [CrossRef]

- Nakamae, K.; Nishino, T.; Asaoka, S. Microphase separation and surface properties of segmented polyurethane—Effect of hard segment content. Int. J. Adhes. Adhes. 1996, 16, 233–239. [Google Scholar] [CrossRef]

- Yanagihara, Y.; Osaka, N.; Iimori, S.; Murayama, S.; Saito, H. Relationship between modulus and structure of annealed thermoplastic polyurethane. Mater. Today Commun. 2015, 2, e9–e15. [Google Scholar] [CrossRef]

- Fernández-d’Arlas, B.; Corcuera, M.; Runt, J.; Eceiza, A. Block architecture influence on the structure and mechanical performance of drawn polyurethane elastomers. Polym. Int. 2014, 63, 1278–1287. [Google Scholar] [CrossRef]

- Fernandez-d’Arlas, B.; Ramos, J.A.; Saralegi, A.; Corcuera, M.; Mondragon, I.; Eceiza, A. Molecular Engineering of Elastic and Strong Supertough Polyurethanes. Macromolecules 2012, 45, 3436–3443. [Google Scholar] [CrossRef]

- Kaursoin, J.; Agrawal, A.K. Melt spun thermoresponsive shape memory fibers based on polyurethanes: Effect of drawing and heat-setting on fiber morphology and properties. J. Appl. Polym. Sci. 2007, 103, 2172–2182. [Google Scholar] [CrossRef]

- Christenson, E.M.; Anderson, J.M.; Hiltner, A.; Baer, E. Relationship between nanoscale deformation processes and elastic behavior of polyurethane elastomers. Polymer 2005, 46, 11744–11754. [Google Scholar] [CrossRef]

- Yeh, F.; Hsiao, B.S.; Sauer, B.B.; Michel, S.; Siesler, H.W. In-situ studies of structure development during deformation of a segmented poly(urethane-urea) elastomer. Macromolecules 2003, 36, 1940–1954. [Google Scholar] [CrossRef]

- Higaki, Y.; Suzuki, K.; Ohta, N.; Takahara, A. Strain-induced molecular aggregation states around a crack tip in a segmented polyurethane film under uniaxial stretching. Polymer 2017, 116, 458–465. [Google Scholar] [CrossRef]

- Kojio, K.; Matsuo, K.; Motokucho, S.; Yoshinaga, K.; Shimodaira, Y.; Kimura, K. Simultaneous small-angle X-ray scattering/wide-angle X-ray diffraction study of the microdomain structure of polyurethane elastomers during mechanical deformation. Polym. J. 2011, 43, 692–699. [Google Scholar] [CrossRef]

- Unsal, E.; Yalcin, B.; Yilgor, I.; Yilgor, E.; Cakmak, M. Real time mechano-optical study on deformation behavior of PTMO/CHDI-based polyetherurethanes under uniaxial extension. Polymer 2009, 50, 4644–4655. [Google Scholar] [CrossRef]

- Koerner, H.; Kelley, J.J.; Vaia, R.A. Transient microstructure of low hard segment thermoplastic polyurethane under uniaxial deformation. Macromolecules 2008, 41, 4709–4716. [Google Scholar] [CrossRef]

- Blundell, D.; Eeckhaut, G.; Fuller, W.; Mahendrasingam, A.; Martin, C. Time-Resolved SAXS/Stress–Strain Studies of Thermoplastic Polyurethanes during Mechanical Cycling at Large Strains. J. Macromol. Sci. Part B 2004, 43, 125–142. [Google Scholar] [CrossRef]

- Blundell, D.; Eeckhaut, G.; Fuller, W.; Mahendrasingam, A.; Martin, C. Real time SAXS/stress–strain studies of thermoplastic polyurethanes at large strains. Polymer 2002, 43, 5197–5207. [Google Scholar] [CrossRef]

- Desper, C.; Schneider, N.; Jasinski, J.; Lin, J. Deformation of microphase structures in segmented polyurethanes. Macromolecules 1985, 18, 2755–2761. [Google Scholar] [CrossRef]

- Sup Lee, H.; Ra Yoo, S.; Won Seo, S. Domain and segmental deformation behavior of thermoplastic elastomers using synchrotron SAXS and FTIR methods. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 3233–3245. [Google Scholar] [CrossRef]

- Laity, P.R.; Taylor, J.E.; Wong, S.S.; Khunkamchoo, P.; Norris, K.; Cable, M.; Andrews, G.T.; Johnson, A.F.; Cameron, R.E. A 2-dimensional small-angle X-ray scattering study of the microphase-separated morphology exhibited by thermoplastic polyurethanes and its response to deformation. Polymer 2004, 45, 5215–5232. [Google Scholar] [CrossRef]

- Kawamura, Y.; Hayashi, K.; Inoue, A.; Masumoto, T. Rapidly solidified powder metallurgy Mg97Zn1Y2Alloys with excellent tensile yield strength above 600 MPa. Mater. Trans. 2001, 42, 1172–1176. [Google Scholar] [CrossRef]

- Hagihara, K.; Kinoshita, A.; Sugino, Y.; Yamasaki, M.; Kawamura, Y.; Yasuda, H.Y.; Umakoshi, Y. Effect of long-period stacking ordered phase on mechanical properties of Mg97Zn1Y2 extruded alloy. Acta Mater. 2010, 58, 6282–6293. [Google Scholar] [CrossRef]

- Abe, E.; Ono, A.; Itoi, T.; Yamasaki, M.; Kawamura, Y. Polytypes of long-period stacking structures synchronized with chemical order in a dilute Mg–Zn–Y alloy. Philos. Mag. Lett. 2011, 91, 690–696. [Google Scholar] [CrossRef]

- Hagihara, K.; Li, Z.; Yamasaki, M.; Kawamura, Y.; Nakano, T. Strengthening mechanisms acting in extruded Mg-based long-period stacking ordered (LPSO)-phase alloys. Acta Mater. 2019, 163, 226–239. [Google Scholar] [CrossRef]

- Emura, S.; Ji, X. Introduction of Mille-Feuille-Like α/β Layered Structure into Ti–Mo Alloy. Mater. Trans. 2020, 61, 856–861. [Google Scholar] [CrossRef]

- Egami, M.; Ohnuma, I.; Enoki, M.; Ohtani, H.; Abe, E. Thermodynamic origin of solute-enriched stacking-fault in dilute Mg-Zn-Y alloys. Mater. Design 2020, 188, 108452. [Google Scholar] [CrossRef]

- Murayama, T.; Abe, E.; Saito, H. Strengthening of mille-feuille structured high-density polyethylene by heat elongation. Polymer 2021, 236, 124343. [Google Scholar] [CrossRef]

- Nguyen-Tri, P.; Ghassemi, P.; Carriere, P.; Nanda, S.; Assadi, A.A.; Nguyen, D.D. Recent applications of advanced atomic force microscopy in polymer science: A review. Polymers 2020, 12, 1142. [Google Scholar] [CrossRef]

- Tahara, D.; Ninh, T.H.; Yamamoto, H.; Tashiro, K. Metropolis Monte Carlo simulation of two-dimensional small-angle X-ray scattering patterns of oriented polymer materials. Macromolecules 2019, 53, 276–287. [Google Scholar] [CrossRef]

- Ivanov, D.; Amalou, Z.; Magonov, S. Real-time evolution of the lamellar organization of poly(ethylene terephthalate) during crystallization from the melt: High-temperature atomic force microscopy study. Macromolecules 2001, 34, 8944–8952. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takano, M.; Takamatsu, K.; Saito, H. High-Strength Heat-Elongated Thermoplastic Polyurethane Elastomer Consisting of a Stacked Domain Structure. Polymers 2022, 14, 1470. https://doi.org/10.3390/polym14071470

Takano M, Takamatsu K, Saito H. High-Strength Heat-Elongated Thermoplastic Polyurethane Elastomer Consisting of a Stacked Domain Structure. Polymers. 2022; 14(7):1470. https://doi.org/10.3390/polym14071470

Chicago/Turabian StyleTakano, Mutsumi, Koudai Takamatsu, and Hiromu Saito. 2022. "High-Strength Heat-Elongated Thermoplastic Polyurethane Elastomer Consisting of a Stacked Domain Structure" Polymers 14, no. 7: 1470. https://doi.org/10.3390/polym14071470

APA StyleTakano, M., Takamatsu, K., & Saito, H. (2022). High-Strength Heat-Elongated Thermoplastic Polyurethane Elastomer Consisting of a Stacked Domain Structure. Polymers, 14(7), 1470. https://doi.org/10.3390/polym14071470