Multi-Band Polarization-Insensitive Metamaterial Absorber for Microwave Based on Slotted Structure and Magnetic Rubber

Abstract

1. Introduction

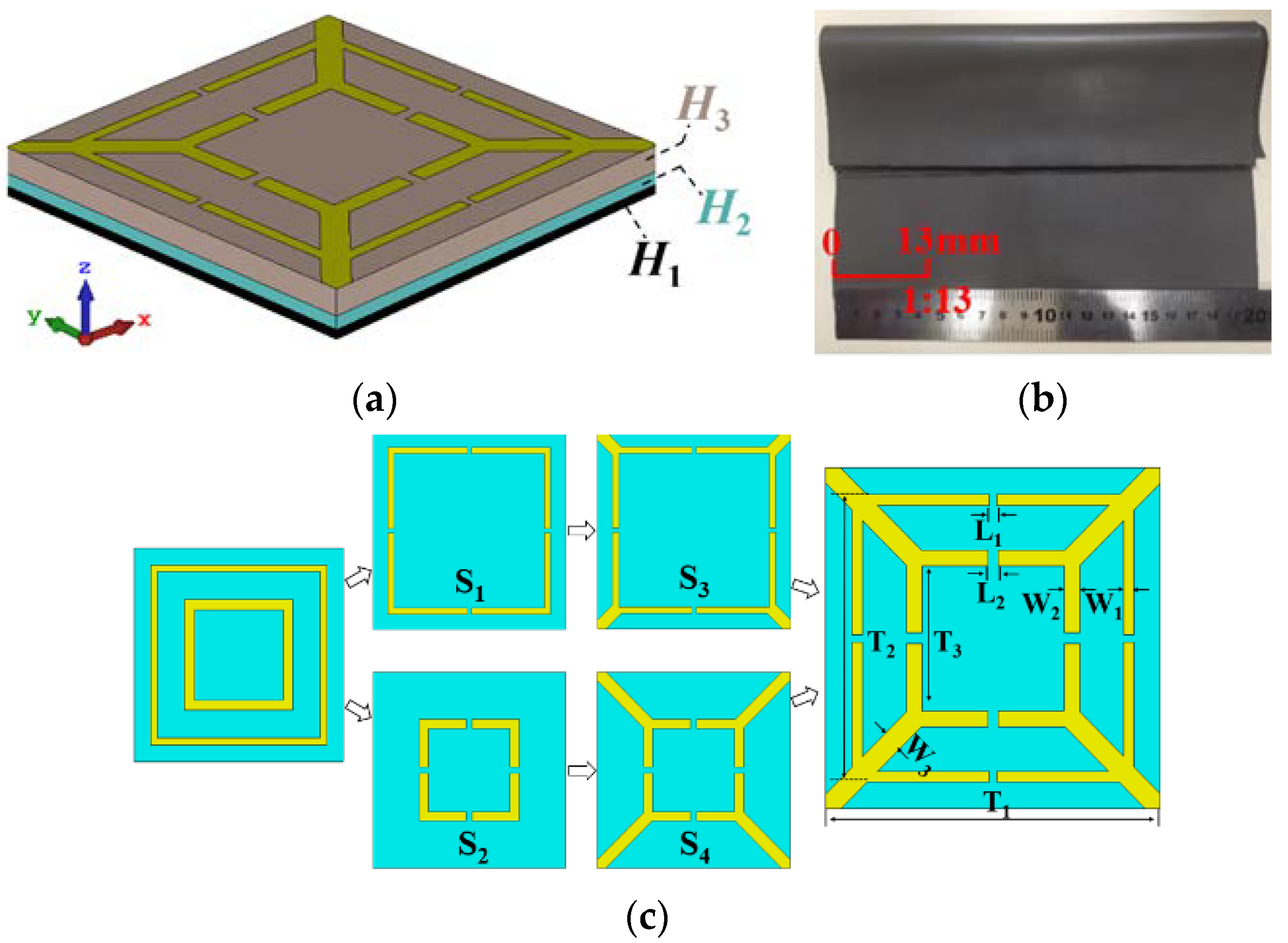

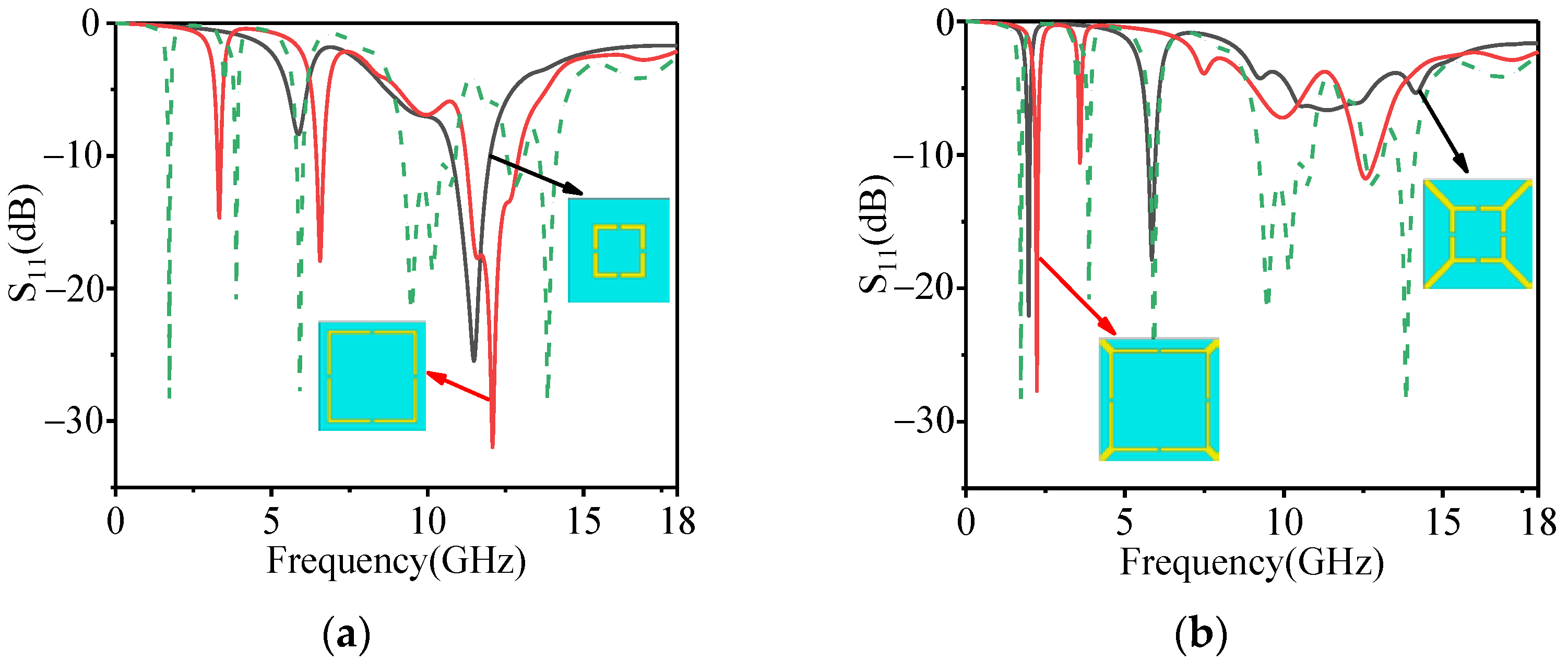

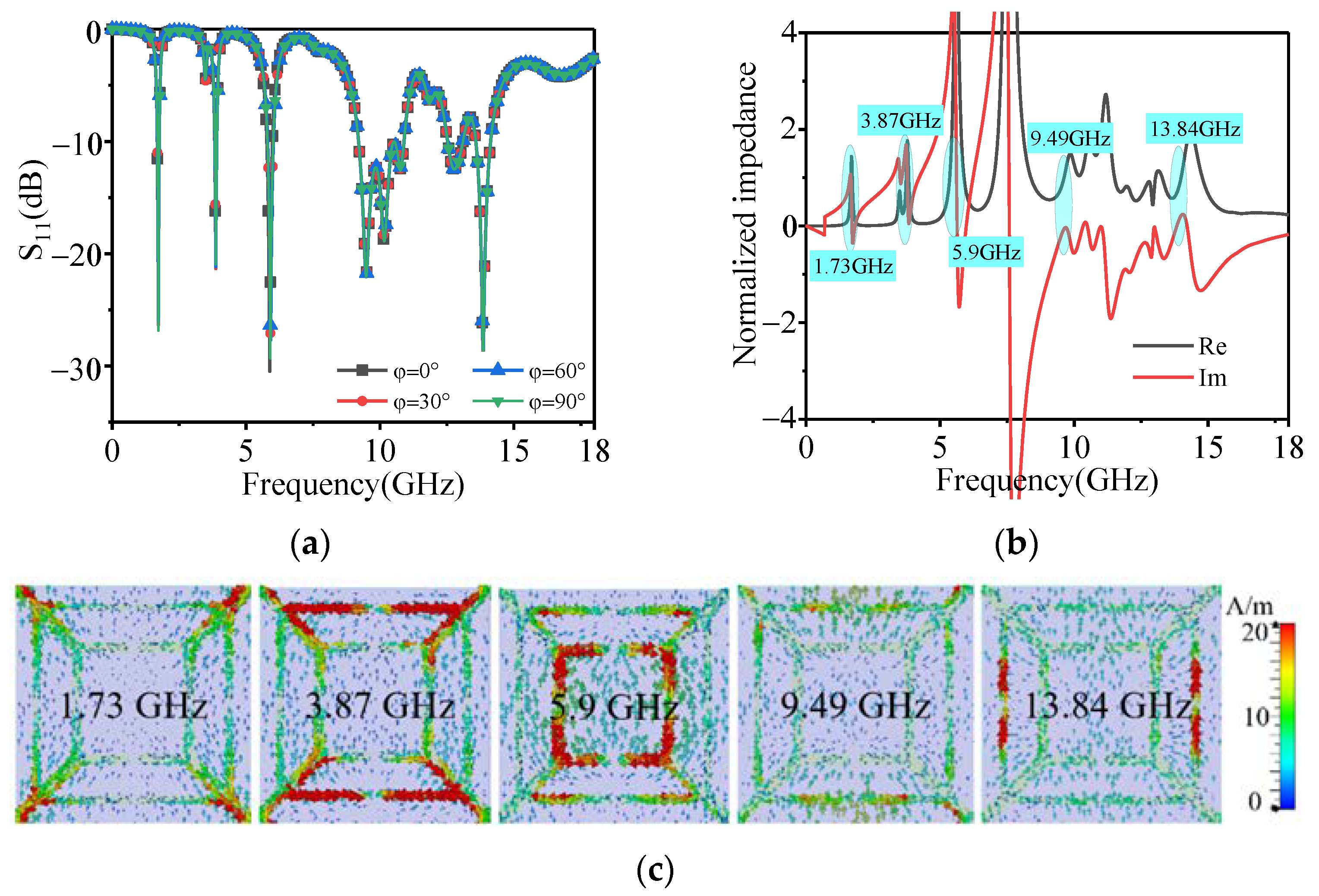

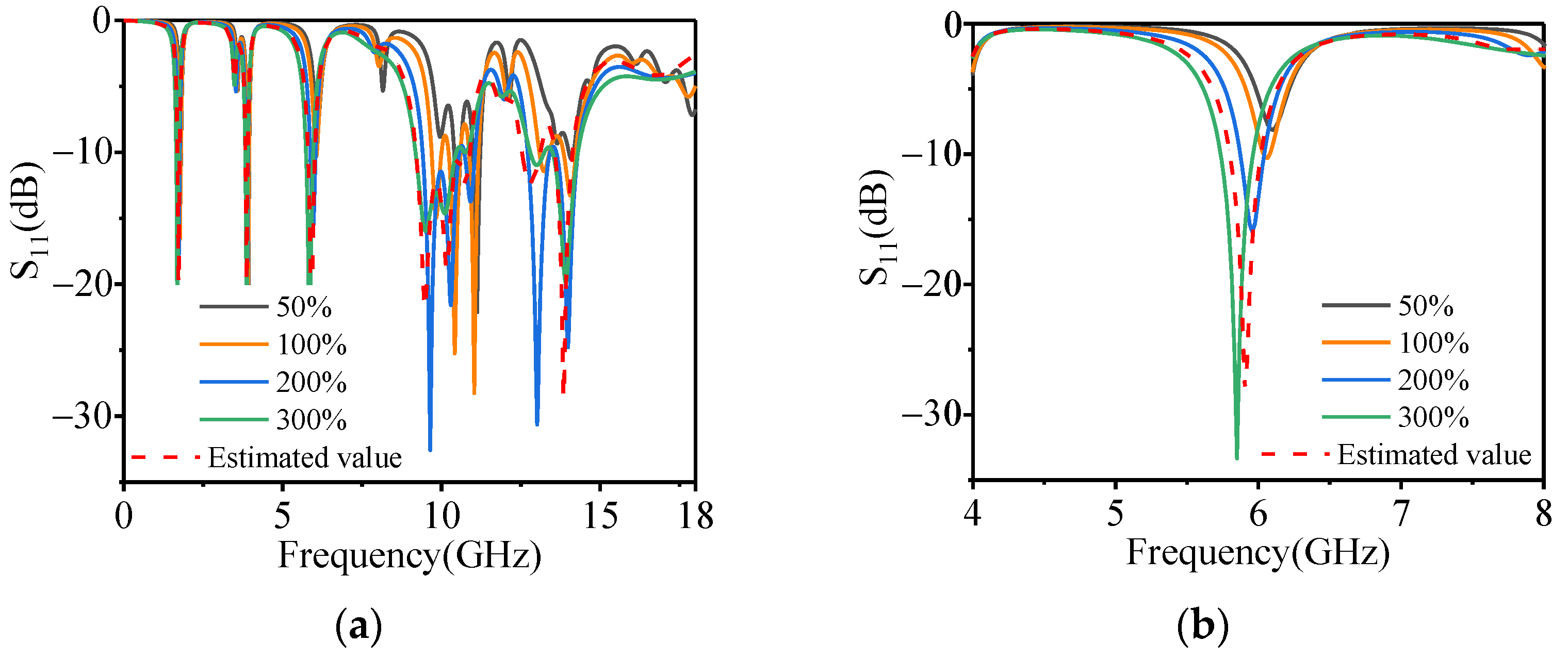

2. Design and Analysis of the Unit Structure

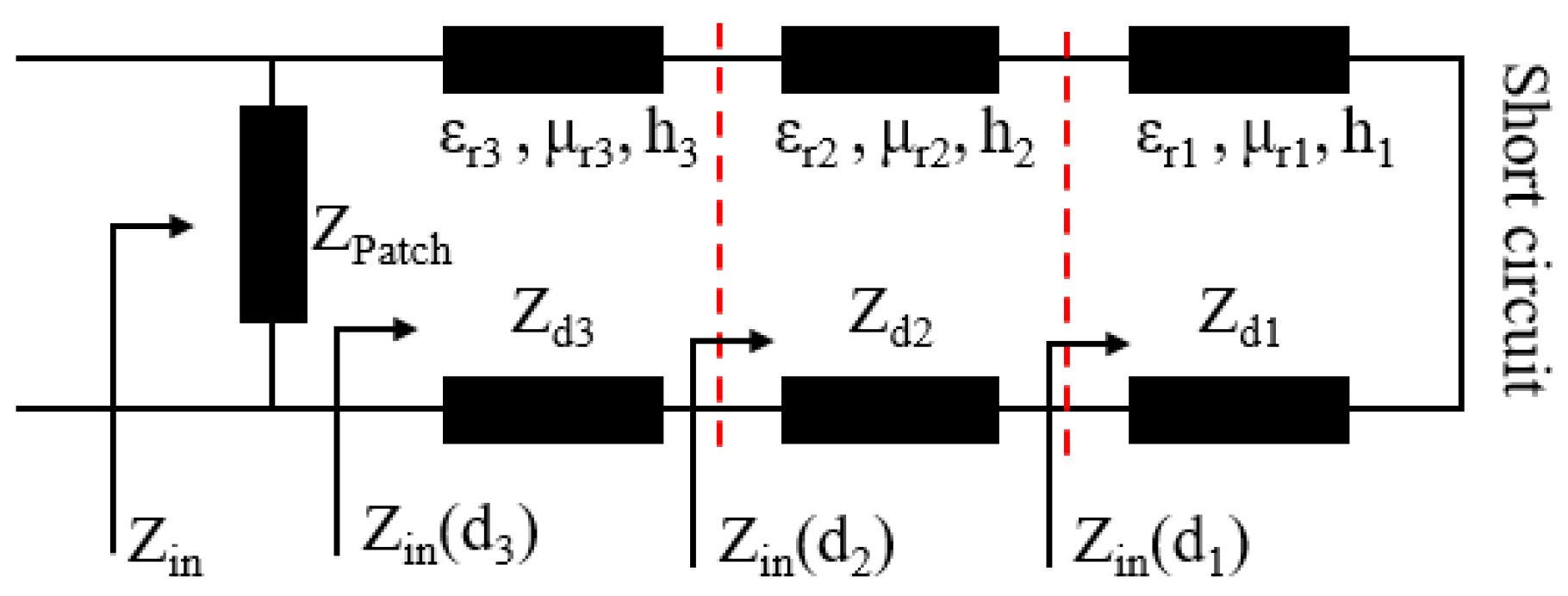

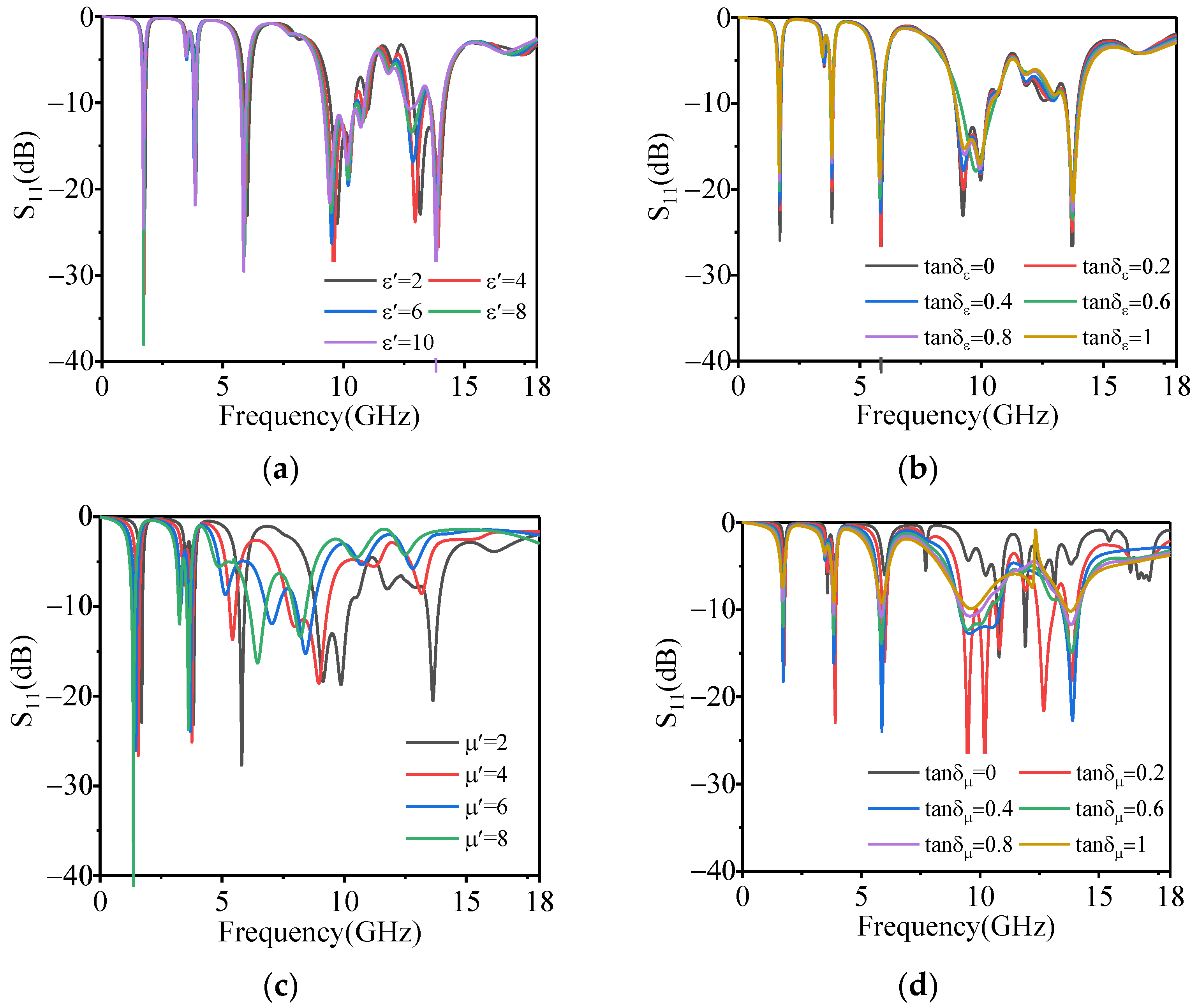

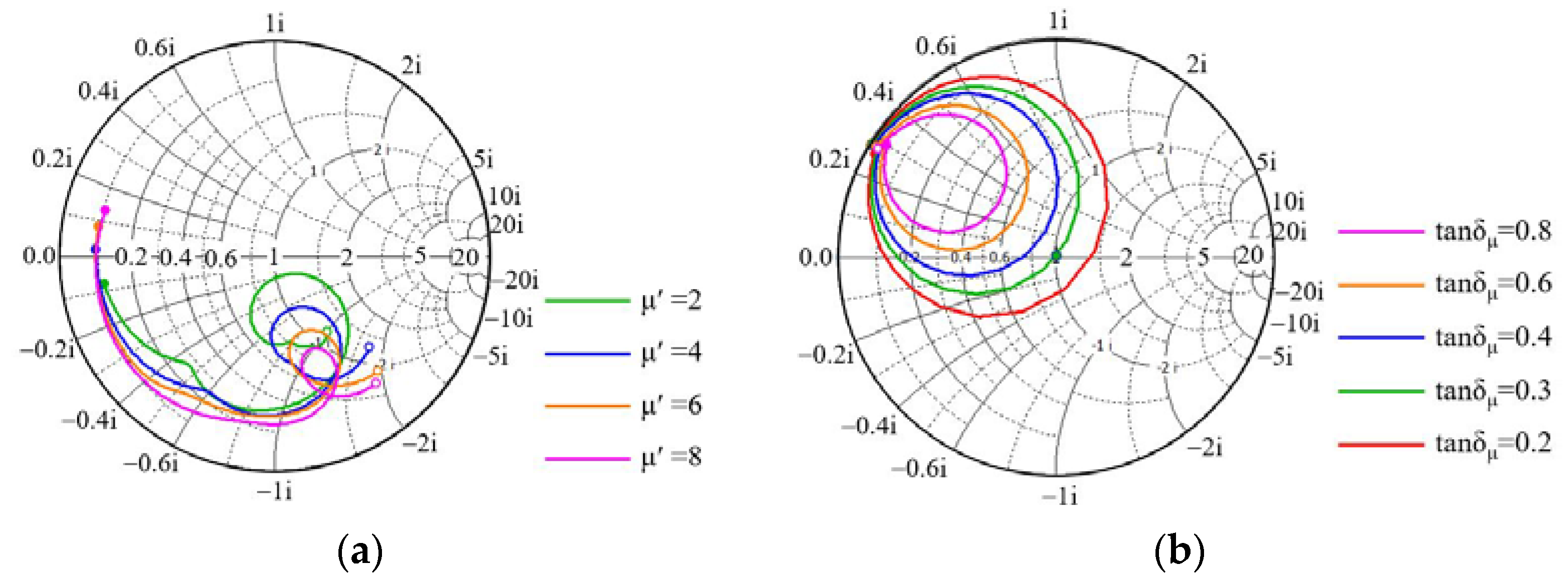

3. Study of EM Parameters Matching Characteristics

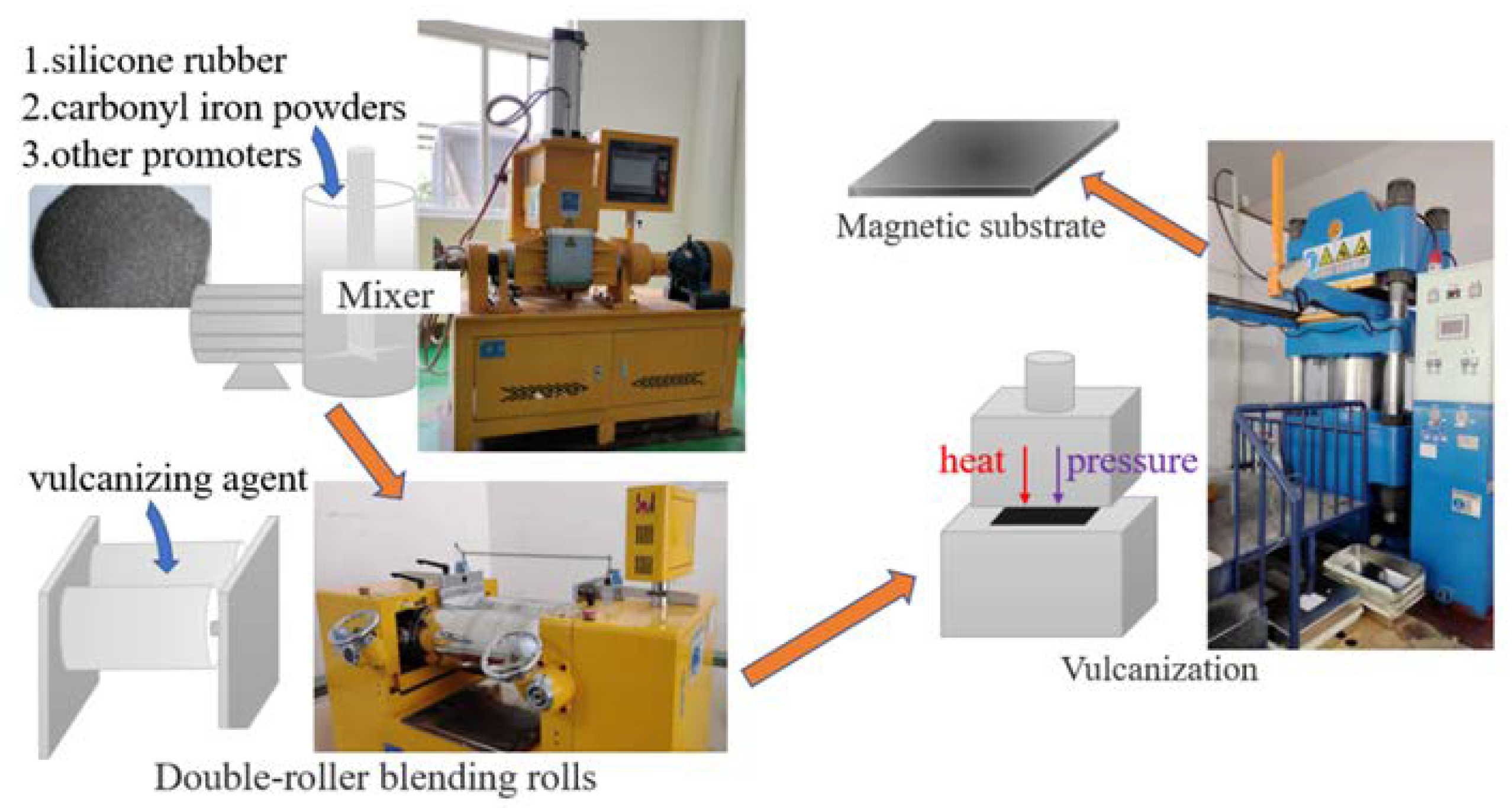

4. Fabrication and Analysis of Magnetic Rubber Substrates

4.1. Materials

4.2. Preparation of Magnetic Rubber Substrates

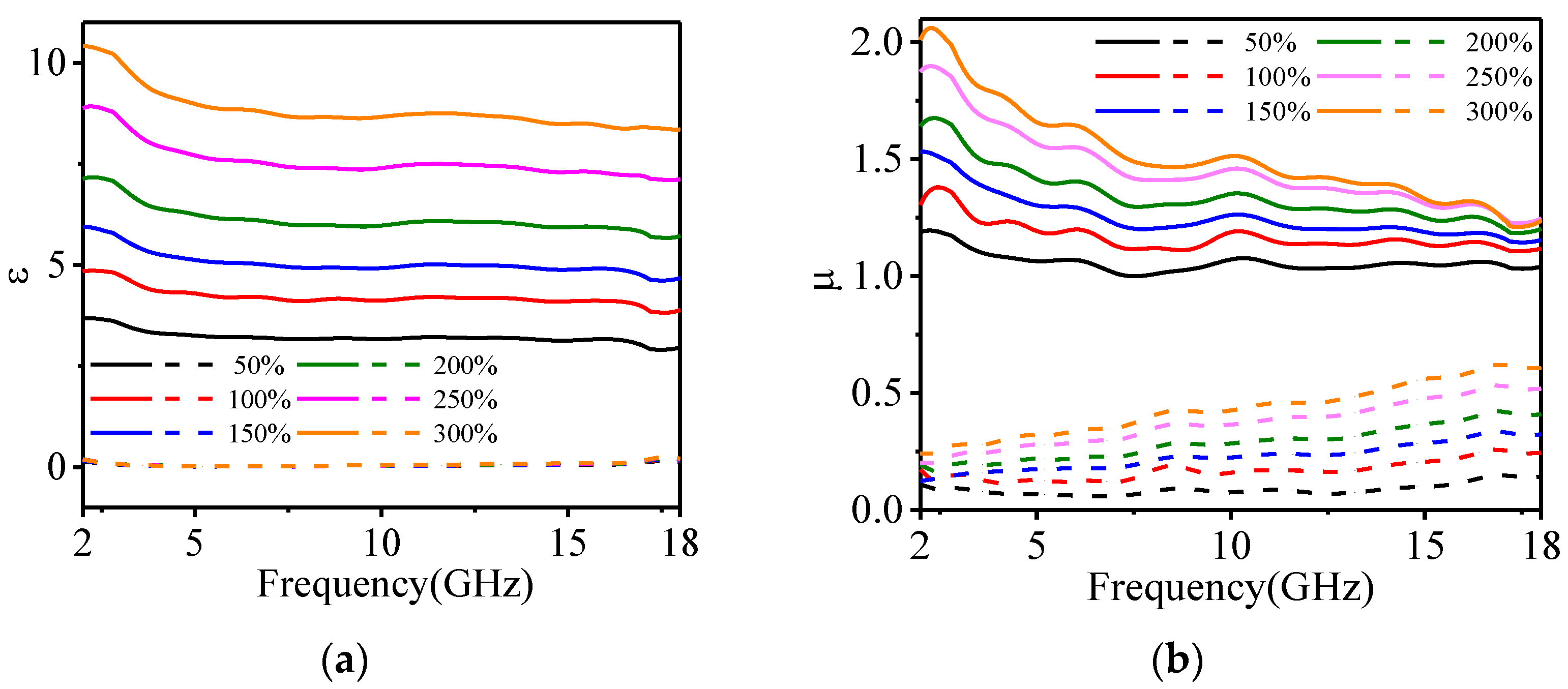

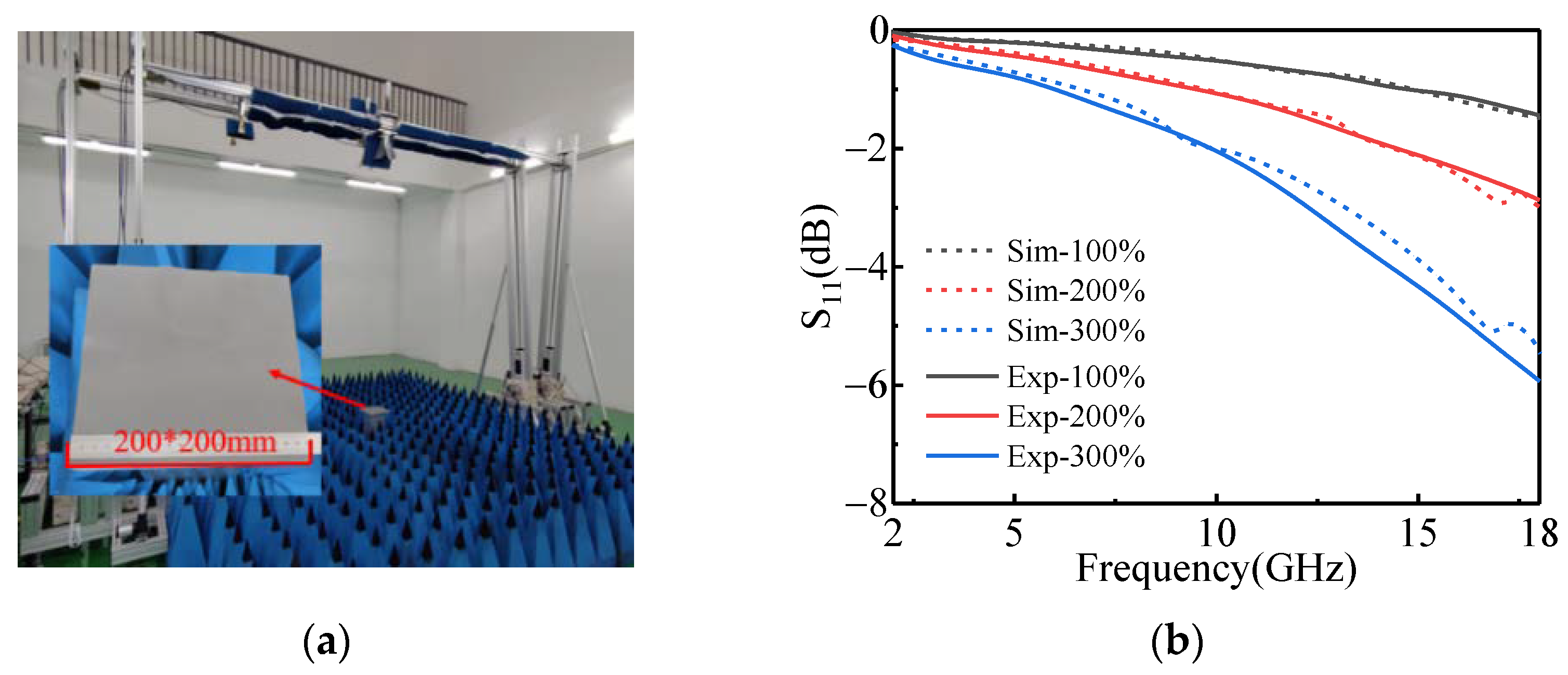

4.3. Measurement and Results of the EM Properties

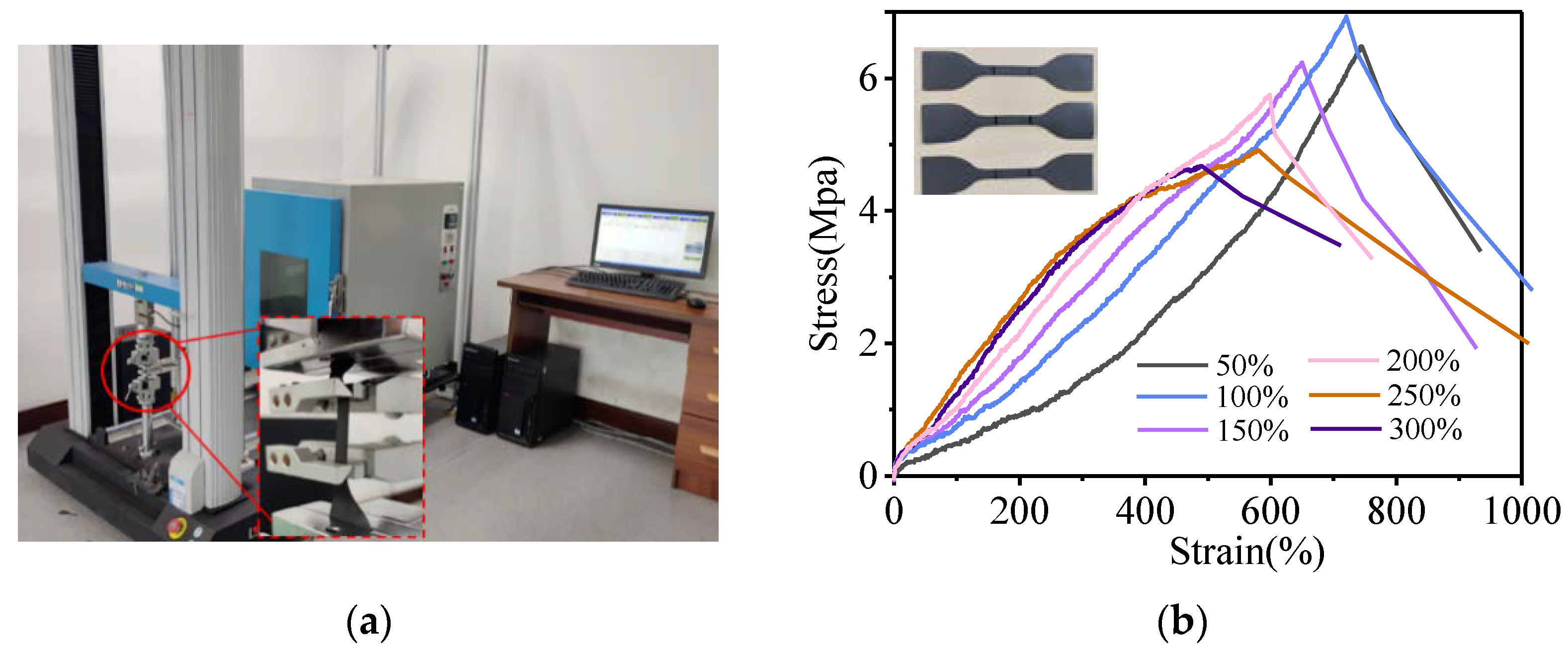

4.4. The Influence of the Carbonyl Iron Powder Content on Mechanical Properties of Magnetic Substrate

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Zhou, D.; Wang, P.J.; Du, C.; Liu, W.F.; Su, J.Z.; Pang, L.X.; Cao, M.S.; Kong, L.B. Recent progress in two-dimensional materials for microwave absorption applications. Chem. Eng. J. 2021, 425, 131558. [Google Scholar] [CrossRef]

- Huang, Q.Q.; Wang, G.H.; Zhou, M.; Zheng, J.; Tang, S.L.; Ji, G.B. Metamaterial electromagnetic wave absorbers and devices: Design and 3D microarchitecture. J. Mater. Sci. Technol. 2022, 108, 90–101. [Google Scholar] [CrossRef]

- Sista, K.S.; Dwarapudi, S.; Kumar, D.; Sinha, G.R.; Moon, A.P. Carbonyl iron powders as absorption material for microwave interference shielding: A review. J. Alloys Compd. 2021, 853, 157251. [Google Scholar] [CrossRef]

- Cui, T.J.; Smith, D.R.; Liu, R.P. Metamaterials-Theory, Design and Applications; Springer: New York, NY, USA, 2009; pp. 1–4. [Google Scholar]

- Chen, H.T. Interference theory of metamaterial perfect absorbers. Opt. Express 2012, 20, 7165–7172. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.B.; Kim, B.S.; Byun, J.H.; Hwang, B.S.; Um, M.K.; Park, J.S. Electromagnetic Wave Absorber Using a Dielectric Loss Sheet, Method for Forming the Electromagnetic Wave Absorber, and Rotary Blade for a Wind Turbine Having an Electromagnetic Wave Function Using Same. U.S. Patent EP11839878A, 18 September 2013. [Google Scholar]

- Wang, Q.; Cheng, Y.Z. Compact and low-frequency broadband microwave metamaterial absorber based on meander wire structure loaded resistors. AEU-Int. J. Electron. Commun. 2020, 120, 153198. [Google Scholar] [CrossRef]

- Chambers, B. Optimum design of a Salisbury screen radar absorber. Electron. Lett. 1994, 30, 1353–1354. [Google Scholar] [CrossRef]

- Du Toit, L.J. The design of Jauman absorbers. IEEE Antennas Propag. Mag. 1994, 36, 17–25. [Google Scholar] [CrossRef]

- Chambers, B.; Tennant, A. Active Dallenbach radar absorber. In Proceedings of the IEEE Antennas and Propagation Society International Symposium, Albuquerque, NM, USA, 9–14 July 2006; pp. 381–384. [Google Scholar]

- Landy, N.I.; Sajuyigbe, S.; Mock, J.J.; Smith, D.R.; Padilla, W.J. Perfect metamaterial absorber. Phys. Rev. Lett. 2008, 100, 207402. [Google Scholar] [CrossRef]

- Zhou, P.H.; Wang, L.Y.; Zhang, G.R.; Jiang, J.G.; Chen, H.Y. A stretchable metamaterial absorber with deformation compensation design at microwave frequencies. IEEE Trans. Antennas Propag. 2019, 67, 291–297. [Google Scholar] [CrossRef]

- Li, S.J.; Gao, J.; Cao, X.Y.; Zheng, C. Polarization-insensitive and thin stereometamaterial with broadband angular absorption for the oblique incidence. Mater. Sci. Process. 2015, 119, 371–378. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, C.X.; Yang, H.Y.; Wang, P.D.; Chen, M.J.; Lei, H.S.; Fang, D.N. Broadband radar absorbing composites: Spatial scale effect and environmental adaptability. Compos. Sci. Technol. 2020, 197, 108262. [Google Scholar] [CrossRef]

- Luo, G.Q.; Yu, W.; Yu, Y.; Zhang, X.H.; Shen, Z. A three-dimensional design of ultra-wideband microwave absorbers. IEEE Trans. Microw. Theory Tech. 2020, 68, 4206–4215. [Google Scholar] [CrossRef]

- Yu, J.W.; Cai, Y.; Lin, X.Q.; Wang, X. Perforated multilayer ultrawideband absorber based on circuit analog absorber with optimal air spaces. IEEE Antennas Wirel. Propag. Lett. 2019, 19, 34–38. [Google Scholar] [CrossRef]

- Li, S.J.; Wu, P.X.; Xu, H.X.; Zhou, Y.L.; Cao, X.Y.; Han, J.F.; Zhang, C.; Yang, H.H.; Zhan, Z. Ultra-wideband and polarization-insensitive perfect absorber using multilayer metamaterials. Nanoscale Res. Lett. 2018, 13, 386. [Google Scholar] [CrossRef] [PubMed]

- Rozanov, K.; Konstantin, N. Ultimate Thickness to Bandwidth Ratio of Radar absorbers. IEEE Trans. Antennas Propag. 2000, 48, 1230. [Google Scholar] [CrossRef]

- Chen, H.Y.; Zhang, H.B.; Deng, L.J. Design of an ultra-thin magnetic-type radar absorber embedded with FSS. IEEE Antennas Wirel. Propag. Lett. 2010, 9, 899–901. [Google Scholar] [CrossRef]

- Duan, B.F.; Zhang, J.M.; Wang, P.; He, D.L.; Qiao, L.; Wang, T. Design and Preparation of an Ultrathin Broadband Metamaterial Absorber with a Magnetic Substrate Based on Genetic Algorithm. J. Magn. Magn. Mater. 2020, 501, 166439. [Google Scholar] [CrossRef]

- Gil1, N.; Puthucheri, S.; Singh, D.; Agarwala, V. Critical analysis of frequency selective surfaces embedded composite microwave absorber for frequency range 2–8 GHz. J. Mater. Sci. Mater. Electron. 2017, 28, 1259–1270. [Google Scholar] [CrossRef]

- Zhou, J.; Bie, S.W.; Wan, D.; Xu, H.B.; Xu, Y.S.; Jiang, J.J. Realization of thin and broadband magnetic radar absorption materials with the help of resistor FSS. IEEE Antennas Wirel. Propag. Lett. 2014, 14, 24–27. [Google Scholar] [CrossRef]

- Gao, H.T.; Wang, J.J.; Xu, B.C.; Li, Z.; Suo, Q.T. Broadband metamaterial absorber based on magnetic substrate and resistance rings. Mater. Res. Express 2018, 6, 045803. [Google Scholar]

- Peymanfar, R.; Ghorbanian-Gezaforodi, S. Functionalized carbonized monarch butterfly wing scales (FCBW) ornamented by β-Co(OH)2 nanoparticles: An investigation on its microwave, magnetic, and optical characteristics. Nanotechnology 2021, 32, 195201. [Google Scholar] [CrossRef] [PubMed]

- Peymanfar, R.; Javanshir, S.; Naimi-Jamal, M.R.; Tavassoli, S.H. Morphology and medium influence on microwave characteristics of nanostructures: A review. J. Mater. Sci. 2021, 56, 17457–17477. [Google Scholar] [CrossRef]

- Amand, S.K.; Peymanfar, R. Fabrication of clay soil/CuFe2O4 nanocomposite toward improving energy and shielding efciency of buildings. Sci. Rep. 2021, 11, 20832. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.M.; Liao, X.; Li, J.S.; He, G.J.; Zhang, Y.; Tang, W.Y.; Wang, G.; Li, G.X. Light-weight and flexible silicone rubber/MWCNTs/Fe3O4 nanocomposite foams for efficient electromagnetic interference shielding and microwave absorption. Compos. Sci. Technol. 2019, 181, 107670. [Google Scholar] [CrossRef]

- Beeharry, T.; Selemani, K.; Diakhoumpa, K.; Ouslimani, H.H. Theoretical analysis for systematic design of flexible broadband radar absorbers using the least-square method. Prog. Electromagn. Res. C 2018, 87, 175–186. [Google Scholar] [CrossRef][Green Version]

- Ghodgaonkar, D.K.; Varadan, V.V.; Varadan, V.K. A free-space method for measurement of dielectric constants and loss tangents at microwave frequencies. IEEE Trans. Instrum. Meas. 1989, 38, 789–793. [Google Scholar] [CrossRef]

- Han, M.Y.; Zhou, M.; Wu, Y.; Zhao, Y.; Cao, J.M.; Tang, S.L.; Zou, Z.Q.; Ji, G.B. Constructing angular conical FeSiAl/SiO2 composites with corrosion resistance for ultra-broadband microwave absorption. J. Alloys Compd. 2022, 902, 163792. [Google Scholar] [CrossRef]

- Zhang, H.B.; Cheng, J.Y.; Wang, H.H.; Huang, Z.H.; Zheng, Q.B.; Zheng, G.P.; Zhang, D.Q.; Che, R.C.; Cao, M.S. Initiating VB-Group Laminated NbS2 Electromagnetic Wave Absorber toward Superior Absorption Bandwidth as Large as 6.48 GHz through Phase Engineering Modulation. Adv. Funct. Mater. 2021, 32, 2108194. [Google Scholar] [CrossRef]

- Jin, C.; Wu, Z.C.; Yang, C.D.; Wang, L.Y.; Zhang, R.X.; Xu, H.L.; Che, R.C. Impedance amelioration of coaxial-electrospun TiO2@Fe/C@TiO2 vesicular carbon microtubes with dielectric-magnetic synergy toward highly efficient microwave absorption. Chem. Eng. J. 2022, 433, 133640. [Google Scholar] [CrossRef]

- Ge, J.W.; Cui, Y.; Qian, J.X.; Liu, L.; Meng, F.D.; Wang, F.H. Morphology-controlled CoNi/C hybrids with bifunctions of efficient anti-corrosion and microwave absorption. J. Mater. Sci. Technol. 2022, 102, 24–35. [Google Scholar] [CrossRef]

- Dvurechenskaya, N.; Zielinski, R.J. Advantages and disadvantages of the free-space arch method used for investigation of shielding materials at low gigahertz frequencies. In Proceedings of the 10th International Symposium on Electromagnetic Compatibility (EMC Europe 2011), York, UK, 26–30 September 2011; pp. 26–30. [Google Scholar]

- Wang, A.X.; Qu, S.B.; Yan, M.B.; Wang, W.J.; Wang, J.F.; Zheng, L.; Wang, J.L. Six-band polarization-insensitive perfect metamaterial absorber using L-shaped resonator. Appl. Phys. A 2019, 125, 331. [Google Scholar] [CrossRef]

- Cao, H.L.; Shan, M.; Chen, T.; Lei, J.M.; Yang, L.H.; Tan, X.H. Triple-band polarization-independent ultrathin metamaterial absorber. Prog. Electromagn. Res. M 2019, 77, 93–102. [Google Scholar] [CrossRef]

- Mao, Z.W.; Liu, S.B.; Bian, B.R.; Wang, B.Y.; Ma, B.; Chen, L.; Xu, J.Y. Multi-band polarization-insensitive metamaterial absorber based on Chinese ancient coin-shaped structures. J. Appl. Phys. 2014, 115, 204505. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Y.Z.; Wu, T.L.; Cao, J.; Chen, Z.H.; Guan, J.G. Broadband radar cross section reduction by in-plane integration of scattering metasurfaces and magnetic absorbing materials. Results Phys. 2019, 12, 1964–1970. [Google Scholar] [CrossRef]

- Zhang, H.B.; Zhou, P.H.; Zhang, L.; Cheng, D.M.; Liang, D.F.; Deng, L.J. Low frequency needlepoint-shape metamaterial absorber based on magnetic medium. J. Appl. Phys. 2013, 113, 509. [Google Scholar]

| Ref. | Absorption Frequency (GHz) | Absorption Bands |

|---|---|---|

| [35] | 5.55, 6.51, 7.71, 9.45, 11.31, 13.11 | C-, X-, Ku- |

| [36] | 8.115, 11.4, 15.12 | X-, Ku- |

| [37] | 2.538, 7.092, 9.702, 13.302, 15.588 | S-, C-, X-, Ku- |

| Proposed Absorber | 1.7, 3.87, 5.96, 9.4–10.4, 14 | L-, S-, C-, X-, Ku- |

| Ref. | Absorption Bands | Thickness of Magnetic Material (mm) |

|---|---|---|

| [20] | S-, C-, X-, Ku- | 3.1 |

| [38] | C-, X-, Ku-, K-, Ka- | 2 |

| [39] | S-, C- | 3 |

| Proposed Absorber | L-, S-, C-, X-, Ku- | 0.7 |

| Doping Amount of Carbonyl Iron Powder (%) | Tensile Strength (Mpa) | Elongation at Break (%) | Elongation at Yield Point (%) |

|---|---|---|---|

| 50 | 6.486 | 744.51 | 477.68 |

| 100 | 6.933 | 720.36 | 408.86 |

| 150 | 6.238 | 649.62 | 309.81 |

| 200 | 5.752 | 598.4 | 243.92 |

| 250 | 4.914 | 580.35 | 166.75 |

| 300 | 4.676 | 487.84 | 165.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Lu, H.; Bi, M.; He, W.; Qi, L.; Zhou, Z.; Weng, X. Multi-Band Polarization-Insensitive Metamaterial Absorber for Microwave Based on Slotted Structure and Magnetic Rubber. Polymers 2022, 14, 1576. https://doi.org/10.3390/polym14081576

Li K, Lu H, Bi M, He W, Qi L, Zhou Z, Weng X. Multi-Band Polarization-Insensitive Metamaterial Absorber for Microwave Based on Slotted Structure and Magnetic Rubber. Polymers. 2022; 14(8):1576. https://doi.org/10.3390/polym14081576

Chicago/Turabian StyleLi, Kai, Haipeng Lu, Mei Bi, Wentao He, Lun Qi, Zhangrong Zhou, and Xiaolong Weng. 2022. "Multi-Band Polarization-Insensitive Metamaterial Absorber for Microwave Based on Slotted Structure and Magnetic Rubber" Polymers 14, no. 8: 1576. https://doi.org/10.3390/polym14081576

APA StyleLi, K., Lu, H., Bi, M., He, W., Qi, L., Zhou, Z., & Weng, X. (2022). Multi-Band Polarization-Insensitive Metamaterial Absorber for Microwave Based on Slotted Structure and Magnetic Rubber. Polymers, 14(8), 1576. https://doi.org/10.3390/polym14081576