Effect of Air-Polishing and Different Post-Polishing Methods on Surface Roughness of Nanofill and Microhybrid Resin Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Surface Morphology Analysis

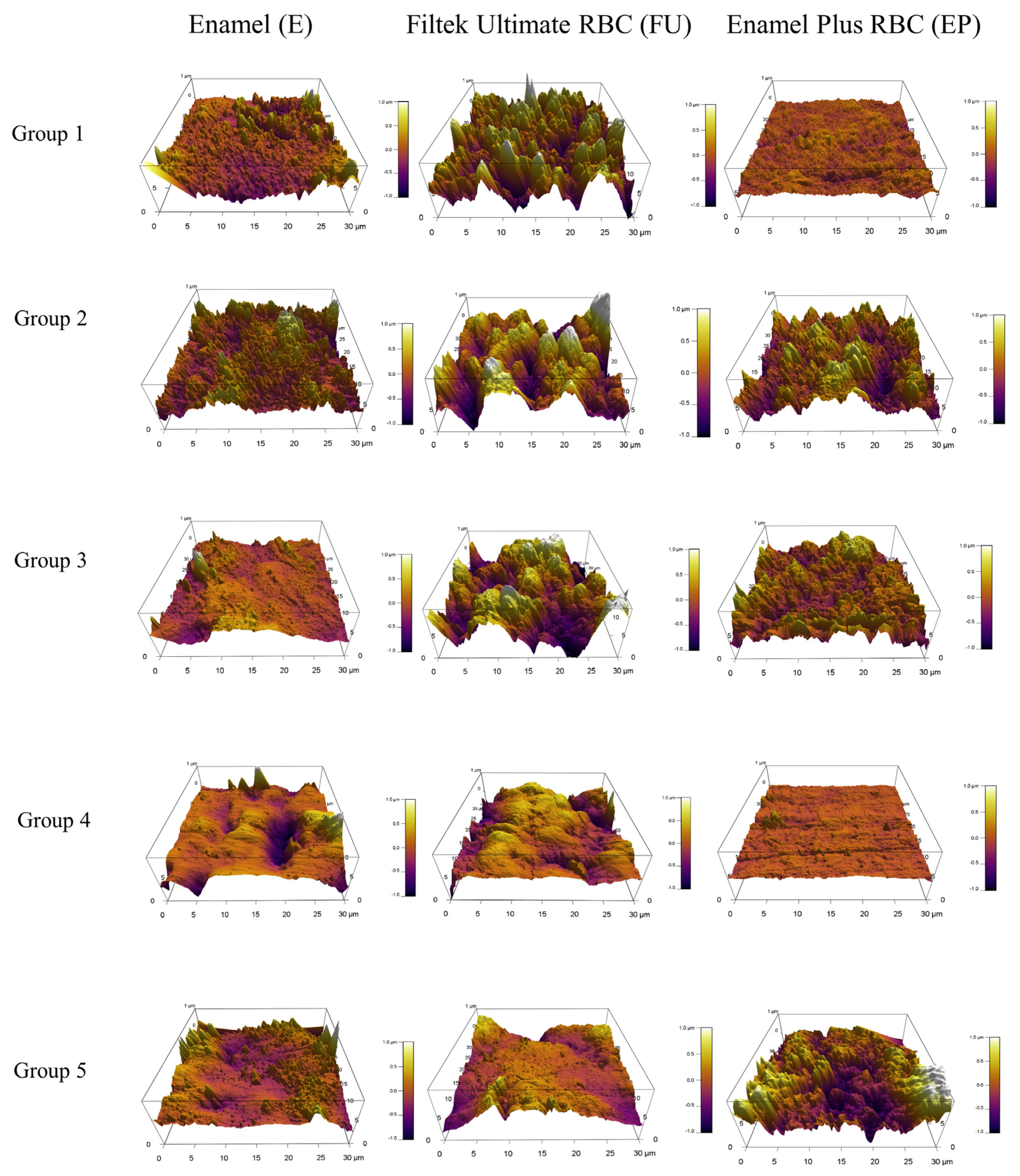

2.3. 3D Surface Topography Analysis

2.4. Evaluation and Statistical Analysis

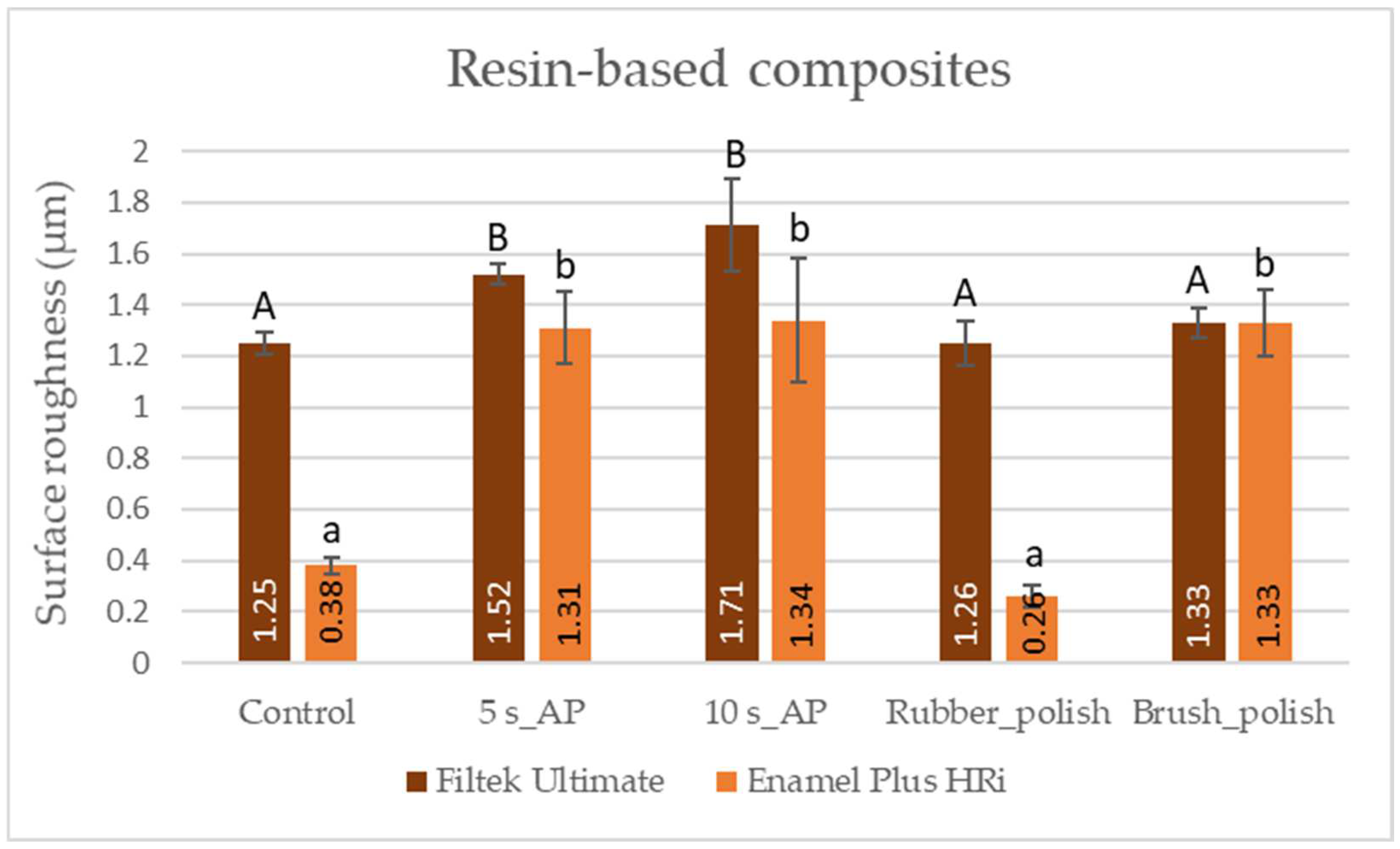

3. Results

4. Discussion

5. Conclusions

- (1)

- Air-polishing with calcium carbonate powder can cause abrasions on the enamel surface and can increase the surface roughness of both nanofill and microhybrid RBCs.

- (2)

- The destructive effect of the extended air-polishing time (10 s) is more significant on the enamel compared to the 5 s air-polishing; however, this did not influence the surface roughness of the resin-based composites.

- (3)

- The effect size of factors Material (type of resin-based composites) and Treatment (air-polishing and post-polishing) on the surface roughness is large.

- (4)

- Post-polishing with rubber polisher series can decrease the surface roughness of resin-based composites after air-polishing in a significant manner; thus, the post-polishing of resin-based composites with rubber polisher series is recommended after air-polishing.

- (5)

- Post-polishing with a series of rubber polishers has no beneficial effect on enamel which has been air-polished; however, polishing with brushes containing silicon carbide particles increased the surface roughness significantly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barnes, C.M.; Covey, D.A.; Walker, M.P.; Johnson, W.W. Essential selective polishing: The maintenance of aesthetic restorations. J. Pract. Hyg. 2003, 12, 18–24. [Google Scholar]

- Ritter, A.V. Direct resin-based composites: Current recommendations for optimal clinical results. Compend. Contin. Educ. Dent. 2005, 26, 481–482, 484–490. [Google Scholar]

- Roeder, L.B.; Powers, J.M. Surface roughness of resin composite prepared by single-use and multi-use diamonds. Am. J. Dent. 2004, 17, 109–112. [Google Scholar]

- Giti, R.; Dabiri, S.; Motamedifar, M.; Derafshi, R. Surface roughness, plaque accumulation, and cytotoxicity of provisional restorative materials fabricated by different methods. PLoS ONE 2021, 16, e0249551. [Google Scholar] [CrossRef]

- Sculean, A.; Bastendorf, K.D.; Becker, C.; Bush, B.; Einwag, J.; Lanoway, C.; Platzer, U.; Schmage, P.; Schoeneich, B.; Walter, C.; et al. A paradigm shift in mechanical biofilm management? Subgingival air polishing: A new way to improve mechanical biofilm management in the dental practice. Quintessence Int. 2013, 44, 475–477. [Google Scholar]

- Graumann, S.J.; Sensat, M.L.; Stoltenberg, J. Air polishing: A review of current literature. J. Dent. Hyg. 2013, 87, 173–180. [Google Scholar]

- Barnes, C.M. An in-depth look at airpolishing. Dimens. Dent. Hyg. 2010, 32, 34–36, 40. [Google Scholar]

- Muthukuru, M.; Zainvi, A.; Esplugues, E.O.; Flemmig, T.F. Non-surgical therapy for the management of peri-implantitis: A systematic review. Clin. Oral Implant. Res. 2012, 23, 77–83. [Google Scholar] [CrossRef]

- Müller, N.; Moëne, R.; Cancela, J.A.; Mombelli, A. Subgingival air-polishing with erythritol during periodontal maintenance: Randomized clinical trial of twelve months. J. Clin. Periodontol. 2014, 41, 883–889. [Google Scholar] [CrossRef] [Green Version]

- Flemmig, T.F.; Hetzel, M.; Topoll, H.; Gerss, J.; Haeberlein, I.; Petersilka, G. Subgingival debridement efficacy of glycine powder air polishing. J. Clin. Periodontol. 2007, 78, 1002–1010. [Google Scholar] [CrossRef]

- Buhler, J.; Amato, M.; Weiger, R.; Walter, C. A systematic review on the effects of air polishing devices on oral tissues. Int. J. Dent. Hyg. 2016, 14, 15–28. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Wang, C.; Zhou, J.; Jiang, L.; Xue, J.; Li, W. Influence of surface properties on adhesion forces and attachment of streptococcus mutans to zirconia in vitro. BioMed Res. Int. 2016, 2016, 8901253. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kuper, N.K.; van de Sande, F.H.; Opdam, N.J.M.; Bronkhorst, E.M.; de Soet, J.J.; Cenci, M.S.; Huysmans, M.C.D.J.N.M. Restoration materials and secondary caries using an in vitro biofilm model. J. Dent. Res. 2015, 94, 62–68. [Google Scholar] [CrossRef] [PubMed]

- Aykent, F.; Yondem, I.; Ozyesil, A.G.; Gunal, S.K.; Avunduk, M.C.; Ozkan, S. Effect of different finishing techniques for restorative materials on surface roughness and bacterial adhesion. J. Prosthet. Dent. 2010, 103, 221–227. [Google Scholar] [CrossRef]

- Mei, L.; Busscher, H.; Van Der Mei, H.C.; Ren, Y. Influence of surface roughness on Streptococcal adhesion forces to composite resins. Dent. Mater. 2011, 2, 770–778. [Google Scholar] [CrossRef]

- Glauser, S.; Astasov-Frauenhoffer, M.; Müller, J.A.; Fischer, J.; Waltimo, T.; Rohr, N. Bacterial colonization of resin composite cements: Influence of material composition and surface roughness. Eur. J. Oral Sci. 2017, 125, 294–302. [Google Scholar] [CrossRef]

- Bashetty, K.; Joshi, S. The effect of one-step and multi-step polishing systems on surface texture of two different resin composites. J. Conserv. Dent. 2010, 13, 34–38. [Google Scholar] [CrossRef]

- Barnes, C.M.; Covey, D.; Watanabe, H.; Simetich, B.; Schulte, J.R.; Chen, H. An in vitro comparison of the effects of various air polishing powders on enamel and selected esthetic restorative materials. J. Clin. Dent. 2014, 25, 76–87. [Google Scholar]

- Yang, K.I.; Park, D.Y.; Kim, B.O.; Yu, S.J. Clinical and microbiological study about efficacy of air-polishing and scaling and root-planing. Int. J. Oral Biol. 2015, 40, 93–101. [Google Scholar] [CrossRef]

- Karacaoglu, F.; Tuzcel, N.Y.; Akkaya, M. A comperative evaluation of 3 different polishing methods on tooth surface roughness. J. Biomed. Sci. 2016, 6, 1–6. [Google Scholar]

- King, O.J.; Milly, H.; Boyes, V.; Austin, R.; Festy, F.; Banerjee, A. The effect of air-abrasion on the susceptibility of sound enamel to acid challenge. J. Dent. 2016, 46, 36–41. [Google Scholar] [CrossRef] [PubMed]

- Aschmann, F.; Von Weissenfluh, B.A. Brush for Use in Restorative Dentistry. U.S. Patent 6,312,257, 6 November 2001. [Google Scholar]

- Petersilka, G.J.; Schenck, U.; Flemmig, T.F. Powder emission rates of four air polishing devices. J. Clin. Periodontol. 2002, 29, 694–698. [Google Scholar] [CrossRef] [PubMed]

- Sahrmann, P.; Ronay, V.; Schmidlin, P.R.; Attin, T.; Paqué, F. Three-dimensional defect evaluation of air polishing on extracted human roots. J. Periodontol. 2014, 85, 1107–1114. [Google Scholar] [CrossRef] [PubMed]

- Yap, A.U.; Mok, B.Y. Surface finish of a new hybrid aesthetic restorative material. Oper. Dent. 2002, 27, 161–166. [Google Scholar]

- Marghalani, H.Y. Effect of filler particles on surface roughness of experimental composite series. J. Appl. Oral Sci. 2010, 18, 59–67. [Google Scholar] [CrossRef] [Green Version]

- Moda, M.D.; de L Godas, A.G.; Fernandes, J.C.; Suzuki, T.Y.U.; Guedes, A.P.A.; Briso, A.L.F.; Bedran-Russo, A.K.; dos Santos, P.H. Comparison of different polishing methods on the surface roughness of microhybrid, microfill, and nanofill composite resins. J. Investig. Clin. Dent. 2018, 9, e12287. [Google Scholar] [CrossRef]

- Drummond, J.L. Degradation, fatigue and failure or resin dental composite materials. J. Dent. Res. 2008, 87, 710–719. [Google Scholar] [CrossRef] [Green Version]

- Almeida, G.S.; Poskus, L.T.; Guimarães, J.G.A.; da Silva, E.M. The effect of mouthrinses on salivary sorption, solubility and surface degradation of a nanofilled and a hybrid resin composite. Oper. Dent. 2010, 35, 105–111. [Google Scholar] [CrossRef] [Green Version]

- Lempel, E.; Lovász, B.V.; Meszarics, R.; Jeges, S.; Tóth, Á.; Szalma, J. Direct resin composite restorations for fractured maxillary teeth and diastema closure: A 7 years retrospective evaluation of survival and influencing factors. Dent. Mater. 2017, 33, 467–496. [Google Scholar] [CrossRef] [Green Version]

- Yap, A.U.; Lye, K.W.; Sau, C.W. Surface characteristics of tooth-colored restoratives polished utilizing different polishing systems. Oper. Dent. 1997, 22, 260–265. [Google Scholar]

- Pelka, M.A.; Altmaier, K.; Petschelt, A.; Lohbauer, U. The effect of air-polishing abrasives on wear of direct restoration materials and sealants. J. Am. Dent. Assoc. 2010, 141, 63–70. [Google Scholar] [CrossRef]

- Powder Therapy Guide—NSK Dental. Available online: https://www.nsk-dental.com/admin/wp-content/uploads/POWDER_THERAPY_GUIDE.pdf (accessed on 3 March 2017).

- Pelka, M.; Trautmann, S.; Petschelt, A.; Lohbauer, U. Influence of air–polishing devices and abrasives on root dentin–An in vitro confocal laser scanning microscope study. Quintessence Int. 2010, 41, 141–148. [Google Scholar]

- Yadav, R.D.; Raisingani, D.; Jindal, D.; Mathur, R. A Comparative Analysis of Different Finishing and Polishing Devices on Nanofilled, Microfilled, and Hybrid Composite: A Scanning Electron Microscopy and Profilometric Study. Int. J. Clin. Pediatr. Dent. 2016, 9, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Kaizer, M.R.; de Oliveira-Ogliari, A.; Cenci, M.S.; Opdam, N.J.; Moraes, R.R. Do nanofill or submicron composites show improved smoothness and gloss? A systematic review of in vitro studies. Dent. Mater. 2014, 30, 41–78. [Google Scholar] [CrossRef] [PubMed]

- Jefferies, S.R. Abrasive finishing and polishing in restorative dentistry: A state-of-the-art review. Dent. Clin. N. Am. 2007, 51, 379–397. [Google Scholar] [CrossRef] [PubMed]

- Antonson, S.A.; Yazici, A.R.; Kilinc, E.; Antonson, D.E.; Hardigan, P.C. Comparison of different finishing/polishing systems on surface roughness and gloss of resin composites. J. Dent. 2011, 39, 9–17. [Google Scholar] [CrossRef]

- Jaramillo-Cartagena, R.; López-Galeano, E.J.; Latorre-Correa, F.; Agudelo-Suárez, A.A. Effect of Polishing Systems on the Surface Roughness of Nano-Hybrid and Nano-Filling Composite Resins: A Systematic Review. Dent. J. 2021, 9, 95. [Google Scholar] [CrossRef]

- Erdemir, U.; Sancakli, H.S.; Yildiz, E. The effect of one-step and multi-step polishing systems on the surface roughness and microhardness of novel resin composites. Eur. J. Dent. 2012, 6, 198–205. [Google Scholar] [CrossRef] [Green Version]

- Alfawaz, Y. Impact of Polishing Systems on the Surface Roughness and Microhardness of Nanocomposites. J. Contemp. Dent. Pract. 2017, 18, 647–651. [Google Scholar] [CrossRef]

- Buchgraber, B.; Kqiku, L.; Allmer, N.; Jakopic, G.; Stadtler, P. Surface roughness of one nanofill and one silorane composite after polishing. Coll. Antropol. 2011, 35, 879–883. [Google Scholar]

| Material | Manufacturer | Type | Resin System | Filler | Filler Loading |

|---|---|---|---|---|---|

| Filtek Ultimate | 3M ESPE, St. Paul, MN, USA | Nanofill | Bis-GMA, UDMA, TEGDMA, Bis-EMA | non-agglomerated/non-aggregated 20 nm silica filler, non-agglomerated/ non-aggregated 4 to 11 nm zirconia filler, aggregated Zr/silica cluster filler; average cluster particle size 0.6–10 µm | 72.5 wt% 55.6 vol% |

| Enamel Plus HRi | Micerium S.p.A. Avegno, Italy | Microhybrid | UDMA, Bis-GMA, 1,4-butandiol dimethacrylate | glass filler mean size 1.0 µm, nano ZrO2 particles 20 nm; average filler size 0.04–3 µm | 80 wt% 63 vol% |

| Group 1 | Group 2 | Group 3 | Group 4 | Group 5 |

|---|---|---|---|---|

| Native Enamel (NE) Control | 5 s Air-polishing NE_5s_AP | 10 s Air-polishing NE_10s_AP | 10 s Air-polishing + Rubber polishing NE_RP | 10 s Air-polishing + Brush polishing NE_BP |

| Filtek Ultimate (FU) Control | 5 s Air-polishing FU_5s_AP | 10 s Air-polishing FU_10s_AP | 10 s Air-polishing + Rubber polishing FU_RP | 10 s Air-polishing + Brush polishing FU_BP |

| Enamel Plus HRi (EP) Control | 5 s Air-polishing EP_5s_AP | 10 s Air-polishing EP_10s_AP | 10 s Air-polishing+ Rubber polishing EP_RP | 10 s Air-polishing + Brush polishing EP_BP |

| Comparison between Different Treatments | Mean Difference (µm) | p-Value | 95% Confidence Interval | |

|---|---|---|---|---|

| Lower | Upper | |||

| Group 1 vs. Group 2 | 0.09 | 0.55 | −0.09 | 0.27 |

| Group 1 vs. Group 3 | 0.35 | <0.001 | 0.17 | 0.53 |

| Group 1 vs. Group 4 | 0.41 | <0.001 | 0.23 | 0.58 |

| Group 1 vs. Group 5 | −0.09 | 0.62 | −0.26 | 0.09 |

| Group 2 vs. Group 3 | 0.25 | <0.01 | 0.07 | 0.43 |

| Group 2 vs. Group 4 | 0.31 | <0.001 | 0.13 | 0.49 |

| Group 2 vs. Group 5 | −0.18 | 0.05 | −0.36 | 0.001 |

| Group 3 vs. Group 4 | 0.059 | 0.86 | −0.12 | 0.24 |

| Group 3 vs. Group 5 | −0.43 | <0.001 | −0.61 | −0.25 |

| Group 4 vs. Group 5 | −0.49 | <0.001 | −0.67 | −0.31 |

| Comparison between Different Treatments | Mean Difference (µm) | p-Value | 95% Confidence Interval | |

|---|---|---|---|---|

| Lower | Upper | |||

| Group 1 vs. Group 2 | −0.28 | <0.01 | −0.46 | −0.09 |

| Group 1 vs. Group 3 | −0.46 | <0.001 | −0.65 | −0.28 |

| Group 1 vs. Group 4 | −0.003 | 1.00 | −0.19 | 0.18 |

| Group 1 vs. Group 5 | −0.09 | 0.63 | −0.27 | 0.09 |

| Group 2 vs. Group 3 | −0.18 | 0.05 | −0.37 | −0.002 |

| Group 2 vs. Group 4 | 0.28 | <0.01 | 0.09 | 0.46 |

| Group 2 vs. Group 5 | 0.19 | 0.04 | 0.04 | 0.38 |

| Group 3 vs. Group 4 | 0.46 | <0.001 | 0.27 | 0.65 |

| Group 3 vs. Group 5 | 0.38 | <0.001 | 0.19 | 0.56 |

| Group 4 vs. Group 5 | −0.08 | 0.68 | −0.27 | 0.10 |

| Comparison between Different Treatments | Mean Difference (µm) | p-Value | 95% Confidence Interval | |

|---|---|---|---|---|

| Lower | Upper | |||

| Group 1 vs. Group 2 | −0.93 | <0.001 | −1.18 | −0.67 |

| Group 1 vs. Group 3 | −0.96 | <0.001 | −1.22 | −0.70 |

| Group 1 vs. Group 4 | 0.12 | 0.64 | −0.14 | 0.38 |

| Group 1 vs. Group 5 | −0.95 | <0.001 | −1.21 | −0.69 |

| Group 2 vs. Group 3 | −0.03 | 0.99 | −0.29 | 0.23 |

| Group 2 vs. Group 4 | 1.05 | <0.001 | 0.79 | 1.31 |

| Group 2 vs. Group 5 | −0.02 | 0.99 | −0.28 | 0.24 |

| Group 3 vs. Group 4 | 1.08 | <0.001 | 0.82 | 1.34 |

| Group 3 vs. Group 5 | 0.01 | <0.001 | −0.25 | 0.27 |

| Group 4 vs. Group 5 | −1.07 | <0.001 | 0.81 | 1.33 |

| Factor | Surface Roughness | |

|---|---|---|

| p-Value | Partial ƞ2 | |

| Material | <0.001 | 0.862 |

| Treatment | <0.001 | 0.885 |

| Material × Treatment | <0.001 | 0.805 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Németh, K.D.; Haluszka, D.; Seress, L.; Lovász, B.V.; Szalma, J.; Lempel, E. Effect of Air-Polishing and Different Post-Polishing Methods on Surface Roughness of Nanofill and Microhybrid Resin Composites. Polymers 2022, 14, 1643. https://doi.org/10.3390/polym14091643

Németh KD, Haluszka D, Seress L, Lovász BV, Szalma J, Lempel E. Effect of Air-Polishing and Different Post-Polishing Methods on Surface Roughness of Nanofill and Microhybrid Resin Composites. Polymers. 2022; 14(9):1643. https://doi.org/10.3390/polym14091643

Chicago/Turabian StyleNémeth, Kinga Dorottya, Dóra Haluszka, László Seress, Bálint Viktor Lovász, József Szalma, and Edina Lempel. 2022. "Effect of Air-Polishing and Different Post-Polishing Methods on Surface Roughness of Nanofill and Microhybrid Resin Composites" Polymers 14, no. 9: 1643. https://doi.org/10.3390/polym14091643

APA StyleNémeth, K. D., Haluszka, D., Seress, L., Lovász, B. V., Szalma, J., & Lempel, E. (2022). Effect of Air-Polishing and Different Post-Polishing Methods on Surface Roughness of Nanofill and Microhybrid Resin Composites. Polymers, 14(9), 1643. https://doi.org/10.3390/polym14091643