Effect of PMMA Coupling Layer in Enhancing the Ultrasonic Weld Strength of Novel Room Temperature Curable Acrylic Thermoplastic to Epoxy Based Composites

Abstract

:1. Introduction

2. Materials and Manufacturing

2.1. Materials

Energy Director (ED) and Coupling Layer

2.2. Manufacturing of Composites

3. Experimental Methods

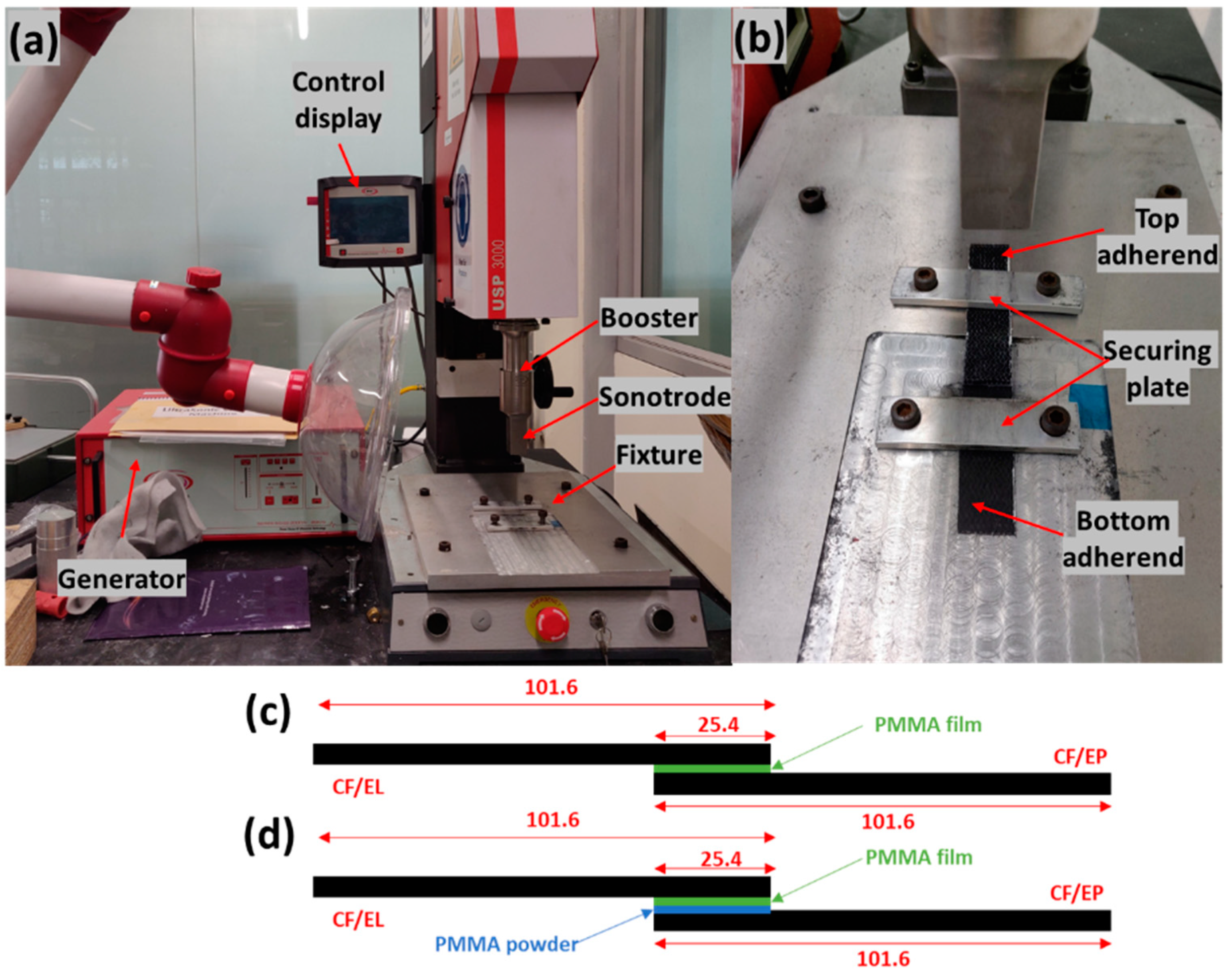

3.1. Ultrasonic Welding

3.2. Lap Shear Testing

3.3. Initial Trials

Elium Composite to Epoxy Composite

4. Results and Discussion

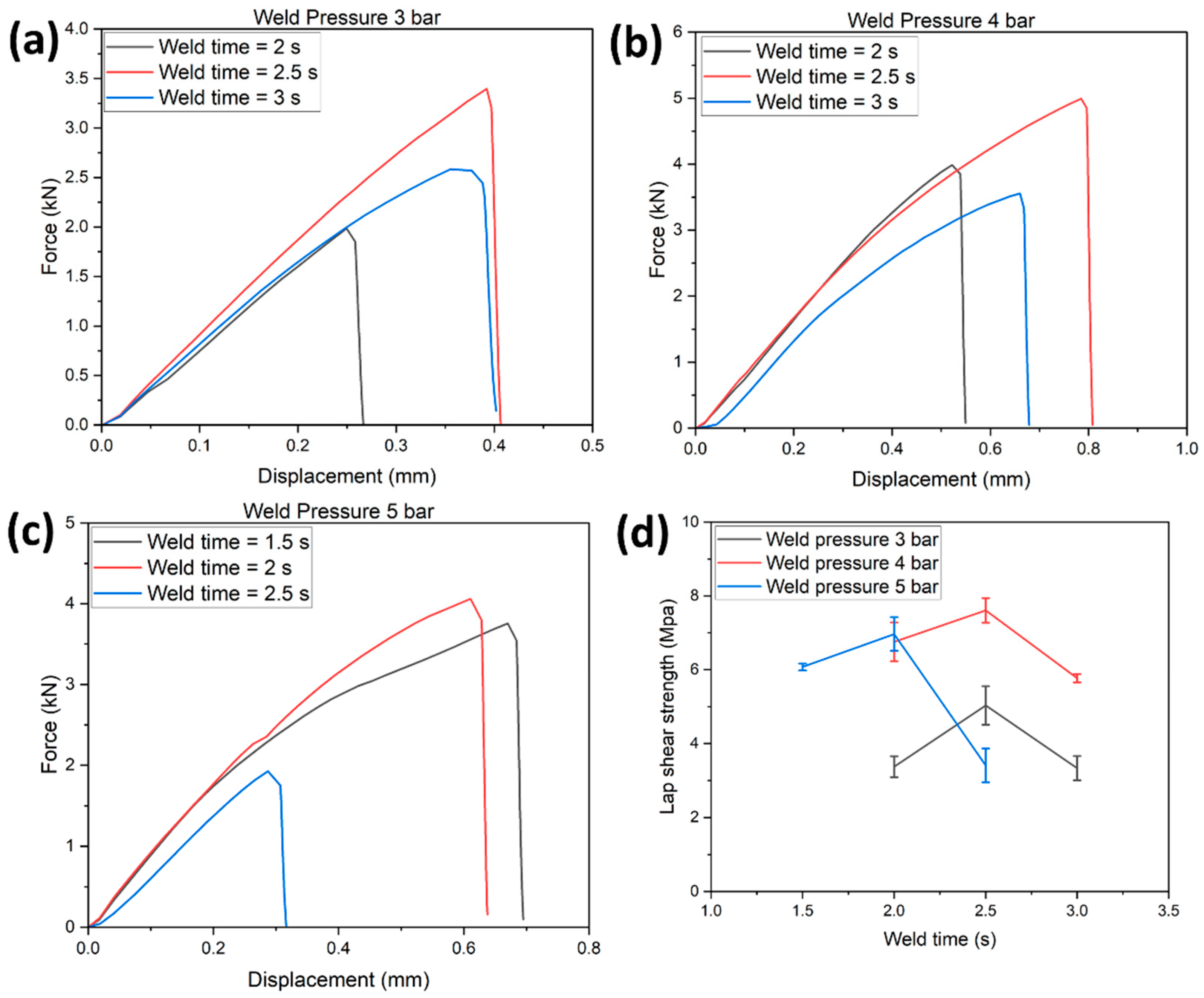

4.1. Lap Shear Testing of EL-EP Composites with Coupling Layer

4.2. Microscopic Investigation of Cross-Sectional Interfaces of the Welded Adherends

4.3. Fractography of Failed Surfaces

5. Conclusions

- The EL-EP_0.25_0.25 configuration yielded the highest maximum LSS of 8.56 MPa when welded with a weld time of 2 s and weld pressure of 5 bar. The fracture surfaces indicated that the failure mode was a partial cohesive/near interfacial failure, as there were areas of failure within the resin and interfacial failure between the coupling layer and carbon fiber due to shearing.

- The EL-EP_0.125_0.125, EL-EP_0.25, EL-EP_0.5, and EL-EP_ELP configurations yielded the maximum LSS values of 7.61 MPa, 7.78 MPa, 7.47 MPa, and 6.88 MPa, respectively.

- The LSS of EL-EP_0.25_0.25 was 190% higher than that of EL-EP, signifying the effectiveness of the coupling layer. However, the obtained LSS was lower by 13% and 35%, respectively, compared to those of EL-EP-ED and EL-EP SAF 30 5. The use of semi-circular EDs is known to yield higher weld strength. The time required for welding was 2 s, as compared to 10 min for adhesives to cure, showing the time effectiveness of ultrasonic welding. These results confirmed the feasibility of welding dissimilar polymer composites using a coupling layer and provided the possibility of selecting thermoplastic and thermoset composites for different parts that are ultrasonically welded to form a product.

- In SEM images, epoxy and PMMA/Elium matrix interphase were observed to have a rough surface and remained largely unaffected by welding. There was an interphase change further away from the interphase to a rougher texture. There was little to no effect from the penultimate layer on the weld strength, as no interphase change could be observed after welding.

- From the fractography investigations, shear cusps, matrix plastic deformation, fiber imprints, fiber pull-out, and good adhesion between matrix and fiber were observed as features of configurations with maximum LSS, whereas voids, poor adhesion at the matrix/fiber interface, fiber breakage, and smooth surfaces were observed as features of configurations with minimum LSS.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barbosa, L.C.M.; Bortoluzzi, D.B.; Ancelotti, A.C. Analysis of Fracture Toughness in Mode II and Fractographic Study of Composites Based on Elium® 150 Thermoplastic Matrix. Compos. Part B Eng. 2019, 175, 107082. [Google Scholar] [CrossRef]

- Tsai, J.L.; Guo, C.; Sun, C.T. Dynamic Delamination Fracture Toughness in Unidirectional Polymeric Composites. Compos. Sci. Technol. 2001, 61, 87–94. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Joshi, S.C.; Leong, K.F. Vibration Damping and Dynamic Mechanical Attributes of Core-Shell Particles Modified Glass Epoxy Prepregs Cured Using Microwave Irradiations. Compos. Commun. 2020, 21, 100412. [Google Scholar] [CrossRef]

- Gohel, G.; Bhudolia, S.K.; Leong, K.F.; Gerard, P. On the Structural Damping Response of Hollow Carbon Composite Shafts with Room Temperature Curable Novel Acrylic Liquid Thermoplastic Resin. Compos. Commun. 2021, 29, 100990. [Google Scholar] [CrossRef]

- Stewart, R. Thermoplastic Composites—Recyclable and Fast to Process. Reinf. Plast. 2011, 55, 22–28. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Islam, A. Advances in Ultrasonic Welding of Thermoplastic Composites: A Review. Materials 2020, 13, 1284. [Google Scholar] [CrossRef] [Green Version]

- Yeh, H.J. Ultrasonic Welding of Medical Plastics. In Joining and Assembly of Medical Materials and Devices; Zhou, Y., Breyen, M.D., Eds.; Woodhead Publishing: Sawston, UK, 2013; pp. 296–323e. [Google Scholar]

- Choudhury, M.R.; Debnath, K. Analysis of Tensile Failure Load of Single-Lap Green Composite Specimen Welded by High-Frequency Ultrasonic Vibration. Mater. Today Proc. 2020, 28, 739–744. [Google Scholar] [CrossRef]

- Pramanik, A.; Basak, A.; Dong, Y.; Sarker, P.; Uddin, M.; Littlefair, G.; Dixit, A.R.; Chattopadhyaya, S. Joining of Carbon Fibre Reinforced Polymer (CFRP) Composites and Aluminium Alloys—A Review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef] [Green Version]

- Gilmore, C.M. Advanced Composites Manufacturing by Timothy G. Gutowski. Mater. Manuf. Process. 1998, 13, 626. [Google Scholar] [CrossRef]

- Niu, C.; Niu, M.C.Y. Airframe Structural Design: Practical Design Information and Data on Aircraft Structures; Adaso Adastra Engineering Center: Granada Hills, CA, USA, 1999. [Google Scholar]

- Stavrov, D.; Bersee, H.E.N. Resistance Welding of Thermoplastic Composites-An Overview. Compos. Part A Appl. Sci. Manuf. 2005, 36, 39–54. [Google Scholar] [CrossRef]

- Villegas, I.F.; Moser, L.; Yousefpour, A.; Mitschang, P.; Bersee, H.E. Process and Performance Evaluation of Ultrasonic, Induction and Resistance Welding of Advanced Thermoplastic Composites. J. Thermoplast. Compos. Mater. 2013, 26, 1007–1024. [Google Scholar] [CrossRef]

- Brassard, D.; Dubé, M.; Tavares, J.R. Resistance Welding of Thermoplastic Composites with a Nanocomposite Heating Element. Compos. Part B Eng. 2019, 165, 779–784. [Google Scholar] [CrossRef]

- Ahmed, T.J.; Stavrov, D.; Bersee, H.E.N.; Beukers, A. Induction Welding of Thermoplastic Composites—An Overview. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1638–1651. [Google Scholar] [CrossRef]

- Mahdi, S.; Kim, H.-J.; Gama, B.A.; Yarlagadda, S.; Gillespie, J.W. A Comparison of Oven-cured and Induction-cured Adhesively Bonded Composite Joints. J. Compos. Mater. 2003, 37, 519–542. [Google Scholar] [CrossRef]

- Troughton, M.J. Chapter 11—Induction Welding. In Handbook of Plastics Joining, 2nd ed.; William Andrew Publishing: Boston, MA, USA, 2009; pp. 113–120. [Google Scholar]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Barsotti, J.R.J. Investigation on Ultrasonic Welding Attributes of Novel Carbon/Elium® Composites. Materials 2020, 13, 1117. [Google Scholar] [CrossRef] [Green Version]

- Tao, W.; Su, X.; Wang, H.; Zhang, Z.; Li, H.; Chen, J. Influence Mechanism of Welding Time and Energy Director to the Thermoplastic Composite Joints by Ultrasonic Welding. J. Manuf. Process. 2019, 37, 196–202. [Google Scholar] [CrossRef]

- Zweifel, L.; Brauner, C. Investigation of the Interphase Mechanisms and Welding Behaviour of Fast-Curing Epoxy Based Composites with Co-cured Thermoplastic Boundary Layers. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106120. [Google Scholar] [CrossRef]

- Tsiangou, E.; de Freitas, S.T.; Villegas, I.F.; Benedictus, R. Investigation on Energy Director-Less Ultrasonic Welding of Polyetherimide (PEI)- To Epoxy-Based Composites. Compos. Part B Eng. 2019, 173, 107014. [Google Scholar] [CrossRef]

- Villegas, I.F.; Rubio, P.V. On Avoiding Thermal Degradation during Welding of High-Performance Thermoplastic Composites to Thermoset Composites. Compos. Part A Appl. Sci. Manuf. 2015, 77, 172–180. [Google Scholar] [CrossRef]

- Liu, S.-J.; Lin, W.-F.; Chang, B.-C.; Wu, G.-M.; Hung, S.-W. Optimizing the Joint Strength of Ultrasonically Welded Thermoplastics. Adv. Polym. Technol. 1999, 18, 125–135. [Google Scholar] [CrossRef]

- Stokes, N.K. Joining Methods for Plastics and Plastic Composites. An Overview. Polym. Eng. Sci. 1989, 29, 1310–1324. [Google Scholar] [CrossRef]

- Laessig, R.; Eisenhut, M.; Mathias, A.; Schulte, R.T.; Peters, F.; Kuehmann, T.; Waldmann, T.; Begemann, W. Series Production of High-Strength Composites Perspectives for the German Engineering Industry; Roland Berger Strategy Consultants: Munchen, Germany, 2012. [Google Scholar]

- Murray, R.E.; Roadman, J.; Beach, R. Fusion Joining of Thermoplastic Composite Wind Turbine Blades: Lap-Shear Bond Characterization. Renew. Energy 2019, 140, 501–512. [Google Scholar] [CrossRef]

- Rudolf, R.; Mitschang, P.; Neitzel, M.; Rueckert, C. Welding of High-Performance Thermoplastic Composites. Polym. Polym. Compos. 1999, 7, 309–315. [Google Scholar]

- Reincke, T.; Hartwig, S.; Dilger, K. Improvement of the Adhesion of Continuously Manufactured Multi-Material Joints by Application of Thermoplastic Adhesive Film. Int. J. Adhes. Adhes. 2019, 93, 102321. [Google Scholar] [CrossRef]

- Tsujino, J.; Hongoh, M.; Yoshikuni, M.; Miura, H.; Ueoka, T. Frequency Characteristics of Ultrasonic Plastic Welding: (27 kHz to 180 kHz Ultrasonic Plastic Welding Systems). JSME Int. J. Ser. C 2006, 49, 634–641. [Google Scholar] [CrossRef] [Green Version]

- Villegas, I.F.; van Moorleghem, R. Ultrasonic Welding of Carbon/Epoxy and Carbon/PEEK Composites through a PEI Thermoplastic Coupling Layer. Compos. Part A Appl. Sci. Manuf. 2018, 109, 75–83. [Google Scholar] [CrossRef]

- Lionetto, F.; Morillas, M.N.; Pappadà, S.; Buccoliero, G.; Villegas, I.F.; Maffezzoli, A. Hybrid Welding of Carbon-Fiber Reinforced Epoxy Based Composites. Compos. Part A Appl. Sci. Manuf. 2018, 104, 32–40. [Google Scholar] [CrossRef]

- Gohel, G.; Bhudolia, S.K.; Kantipudi, J.; Leong, K.F.; Barsotti, R.J. Ultrasonic Welding of Novel Carbon/Elium® with Carbon/Epoxy Composites. Compos. Commun. 2020, 22, 100463. [Google Scholar] [CrossRef]

- Tsiangou, E.; De Freitas, S.T.; Villegas, I.F.; Benedictus, R. Ultrasonic Welding of Epoxy- To Polyetheretherketone- Based Composites: Investigation on the Material of the Energy Director and the Thickness of the Coupling Layer. J. Compos. Mater. 2020, 54, 3081–3098. [Google Scholar] [CrossRef] [Green Version]

- Bhudolia, S.K.; Joshi, S.C.; Di Boon, Y. Experimental and Microscopic Investigation on Mechanical Performance of Textile Spread-tow Thin Ply Composites. Fibers Polym. 2019, 20, 1036–1045. [Google Scholar] [CrossRef]

- Kazemi, M.E.; Shanmugam, L.; Dadashi, A.; Shakouri, M.; Lu, D.; Du, Z.; Hu, Y.; Wang, J.; Zhang, W.; Yang, L.; et al. Investigating the Roles of Fiber, Resin, and Stacking Sequence on the Low-Velocity Impact Response of Novel Hybrid Thermoplastic Composites. Compos. Part B Eng. 2021, 207, 108554. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C.; Bert, A.; Gohel, G.R.; Raama, M. Energy Characteristics and Failure Mechanisms for Textile Spread Tow Thin Ply Thermoplastic Composites under Low-velocity Impact. Fibers Polym. 2019, 20, 1716–1725. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Joshi, S.C.; Leong, K.F. Quasi-Static Indentation Response of Core-Shell Particle Reinforced Novel NCCF/Elium® Composites at Different Feed Rates. Compos. Commun. 2020, 21, 100383. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Leong, K.F.; Joshi, S.C. Damping, Impact and Flexural Performance of Novel Carbon/Elium® Thermoplastic Tubular Composites. Compos. Part B Eng. 2020, 203, 108480. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Gohel, G.; Joshi, S.C.; Gerard, P.; Leong, K.F. Optimizing Bladder Resin Transfer Molding Process to Manufacture Complex, Thin-Ply Thermoplastic Tubular Composite Structures: An Experimental Case Study. Polymers 2021, 13, 4093. [Google Scholar] [CrossRef] [PubMed]

- Bhudolia, S.K.; Gohel, G.; Vasudevan, D.; Leong, K.F.; Gerard, P. Behaviour of Rectangular Hollow Thin Ply Carbon Thermoset and Thermoplastic Composite Tubes Subjected to Bending. Polymers 2022, 14, 1386. [Google Scholar] [CrossRef]

- Taillemite, S. Arkema Gains Ground in Composites and Launches a Revolutionary Range of Elium Liquid Resins. 2014. Available online: http://www.arkema.com/en/media/news/news-details/Arkema-gains-ground-in-composites-and-launches-a-revolutionary-range-of-Elium-liquid-resins/ (accessed on 12 February 2017).

- Bhudolia, S.K.; Gohel, G.; Joshi, S.C.; Leong, K.F. Manufacturing Optimization and Experimental Investigation of Ex-situ Core-shell Particles Toughened Carbon/Elium® Thermoplastic Composites. Fibers Polym. 2021, 22, 1693–1703. [Google Scholar] [CrossRef]

- Boumbimba, R.M.; Coulibaly, M.; Khabouchi, A.; Kinvi-Dossou, G.; Bonfoh, N.; Gerard, P. Glass Fibres Reinforced Acrylic Thermoplastic Resin-Based Tri-Block Copolymers Composites: Low Velocity Impact Response at Various Temperatures. Compos. Struct. 2017, 160, 939–951. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kantipudi, J.; Leong, K.F.; Gerard, P. Mechanical Performance and Damage Mechanisms of Thin Rectangular Carbon/Elium® Tubular Thermoplastic Composites under Flexure and Low-Velocity Impact. Thin-Walled Struct. 2021, 165, 107971. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Subramanyam, E.S.B.; Leong, K.F.; Gerard, P. Enhanced Impact Energy Absorption and Failure Characteristics of Novel Fully Thermoplastic and Hybrid Composite Bicycle Helmet Shells. Mater. Des. 2021, 209, 110003. [Google Scholar] [CrossRef]

- Gohel, G.; Bhudolia, S.K.; Elisetty, S.B.S.; Leong, K.F.; Gerard, P. Development and Impact Characterization of Acrylic Thermoplastic Composite Bicycle Helmet Shell with Improved Safety and Performance. Compos. Part B Eng. 2021, 221, 109008. [Google Scholar] [CrossRef]

- Grigoriev, M.M.; Han, J.; Woo, R.; Cheng, D. Effect of Atmospheric Pressure Plasma Treatment on Surface Porosity of OOA Composites. In Proceedings of the SAMPE 2013 Conference and Exhibition: Education and Green Sky—Materials Technology for a Better World, Long Beach, CA, USA, 6–9 May 2013. [Google Scholar]

- Khalili, P.; Blinzer, B.; Kádár, R.; Bisschop, R.; Försth, M.; Blomqvist, P. Flammability, Smoke, Mechanical Behaviours and Morphology of Flame Retarded Natural Fibre/Elium® Composite. Materials 2019, 12, 2648. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Barbosa, L.C.M.; de Souza, S.D.B.; Botelho, E.C.; Cândido, G.; Rezende, M. Fractographic Evaluation of Welded Joints of PPS/Glass Fiber Thermoplastic Composites. Eng. Fail. Anal. 2019, 102, 60–68. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Gohel, G.; Kantipudi, J.; Leong, K.F.; Barsotti, R.J., Jr. Ultrasonic Welding of Novel Carbon/Elium Thermoplastic Composites with Flat and Integrated Energy Directors: Lap Shear Charactersation and Fractographic Investigation. Materials 2020, 13, 1634. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhudolia, S.K.; Gohel, G.; Fai, L.K.; Barsotti, R.J. Fatigue Response of Ultrasonically Welded Carbon/Elium® Thermoplastic Composites. Mater. Lett. 2020, 264, 127362. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Optimizing Polymer Infusion Process for Thin Ply Textile Composites with Novel Matrix System. Materials 2017, 10, 293. [Google Scholar] [CrossRef] [Green Version]

- Van Rijswijk, K.; Bersee, H.E.N. Reactive Processing of Textile Fiber-Reinforced Thermoplastic Composites—An Overview. Compos. Part A Appl. Sci. Manuf. 2007, 38, 666–681. [Google Scholar] [CrossRef]

- Guide To US Plastic Assembly; Dukane: St. Charles, IL, USA, 2011.

- Kairouz, K.C.; Matthews, F.L. Strength and Failure Modes of Bonded Single Lap Joints between Cross-Ply Adherends. Composites 1993, 24, 475–484. [Google Scholar] [CrossRef]

- ASTM D5868-01; Standard Test Method for Lap Shear Adhesion for Fiber Resinforced Plastic (FRP) Bonding. ASTM: West Conshohocken, PA, USA, 2014.

- Saunders, R.; Lekakou, C.; Bader, M. Compression and Microstructure of Fibre Plain Woven Cloths in the Processing of Polymer Composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 443–454. [Google Scholar] [CrossRef]

- Naik, N.; Sirisha, M.; Inani, A. Permeability Characterization of Polymer Matrix Composites by RTM/VARTM. Prog. Aerosp. Sci. 2013, 65, 22–40. [Google Scholar] [CrossRef]

- Mathews, P.G. Design of Experiments with MINITAB; ASQ Quality Press: Milwaukee, WI, USA, 2005. [Google Scholar]

- Purslow, D. Matrix fractography of fibre-reinforced thermoplastics, part 1. peel failures. Composites 1987, 18, 365–374. [Google Scholar] [CrossRef]

- Purslow, D. Some Fundamental Aspects of Composites Fractography. Composites 1981, 12, 241–247. [Google Scholar] [CrossRef]

- Greenhalgh, E.S. Failure Analysis and Fractography of Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2009. [Google Scholar]

- Defects and Damage and Their Role in the Failure of Polymer Composites. In Failure Analysis and Fractography of Polymer Composites; Greenhalgh, E.S. (Ed.) Elsevier: Amsterdam, The Netherlands, 2009; pp. 356–440. [Google Scholar]

| Code Name | Top Layer (Grams Per Welded Area) | Penultimate Layer (Grams Per Welded Area) |

|---|---|---|

| EL-EP_0.125_0.125 | 0.125 | 0.125 |

| EL-EP_0.25 | 0.25 | 0 |

| EL-EP_0.25_0.25 | 0.25 | 0.25 |

| EL-EP_0.5 | 0.5 | 0 |

| EL-EP_0.5_0.5 | 0.5 | 0.5 |

| EL-EP_1 | 1 | 0 |

| Configuration | Weld Time (s) | Weld Pressure (bar) |

|---|---|---|

| EL-EP_0.125_0.125 | 1.5, 2, 2.5 | 3, 4, 5 |

| EL-EP_0.25 | 2, 2.5, 3, 3.5 | 3, 4, 5 |

| EL-EP_0.25_0.25 | 1.5, 2, 2.5, 3 | 3, 4, 5 |

| EL-EP_0.5 | 1.5, 2, 2.5, 3 | 3, 4, 5 |

| Type of Weld | LSS (MPa) | SD (MPa) | % Change with Respect to | ||

|---|---|---|---|---|---|

| EL-EP | 2.95 | 0.80 | |||

| EL-EP SAF 30 5 | 13.1 | 0.75 | EL-EP | EL-EP-ED | EL-EP SAF 30 5 |

| EL-EP_0.125_0.125 | 7.6096 | 0.53 | 158% | −23% | −42% |

| EL-EP_0.25 | 7.7751 | 0.44 | 164% | −21% | −41% |

| EL-EP_0.25_0.25 | 8.5597 | 0.09 | 190% | −13% | −35% |

| EL-EP_0.5 | 7.4718 | 0.81 | 153% | −24% | −43% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gohel, G.; Soh, C.Z.; Leong, K.F.; Gerard, P.; Bhudolia, S.K. Effect of PMMA Coupling Layer in Enhancing the Ultrasonic Weld Strength of Novel Room Temperature Curable Acrylic Thermoplastic to Epoxy Based Composites. Polymers 2022, 14, 1862. https://doi.org/10.3390/polym14091862

Gohel G, Soh CZ, Leong KF, Gerard P, Bhudolia SK. Effect of PMMA Coupling Layer in Enhancing the Ultrasonic Weld Strength of Novel Room Temperature Curable Acrylic Thermoplastic to Epoxy Based Composites. Polymers. 2022; 14(9):1862. https://doi.org/10.3390/polym14091862

Chicago/Turabian StyleGohel, Goram, Chun Zhi Soh, Kah Fai Leong, Pierre Gerard, and Somen K. Bhudolia. 2022. "Effect of PMMA Coupling Layer in Enhancing the Ultrasonic Weld Strength of Novel Room Temperature Curable Acrylic Thermoplastic to Epoxy Based Composites" Polymers 14, no. 9: 1862. https://doi.org/10.3390/polym14091862