Behavior Study of Commercial Polyurea under Monotonic, Rate Dependent, Cyclic, and Fatigue Tensile Loading for Potential Structural Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polyurea Material

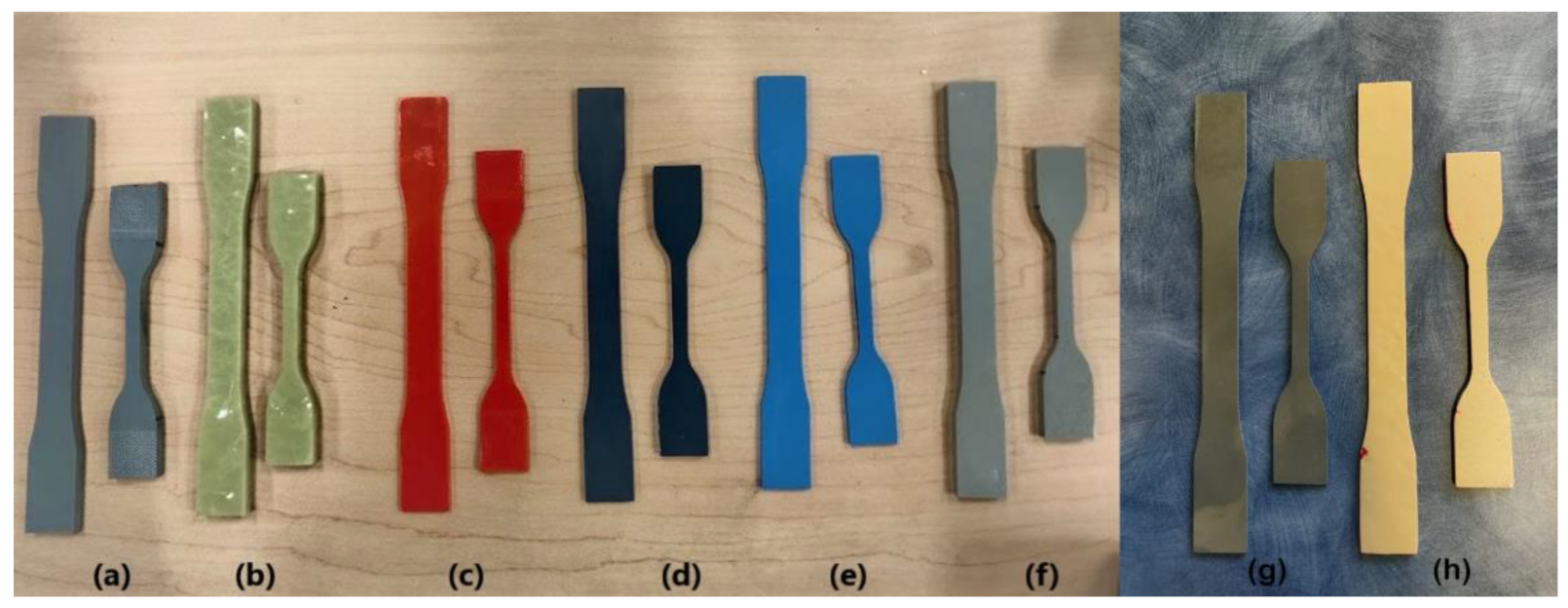

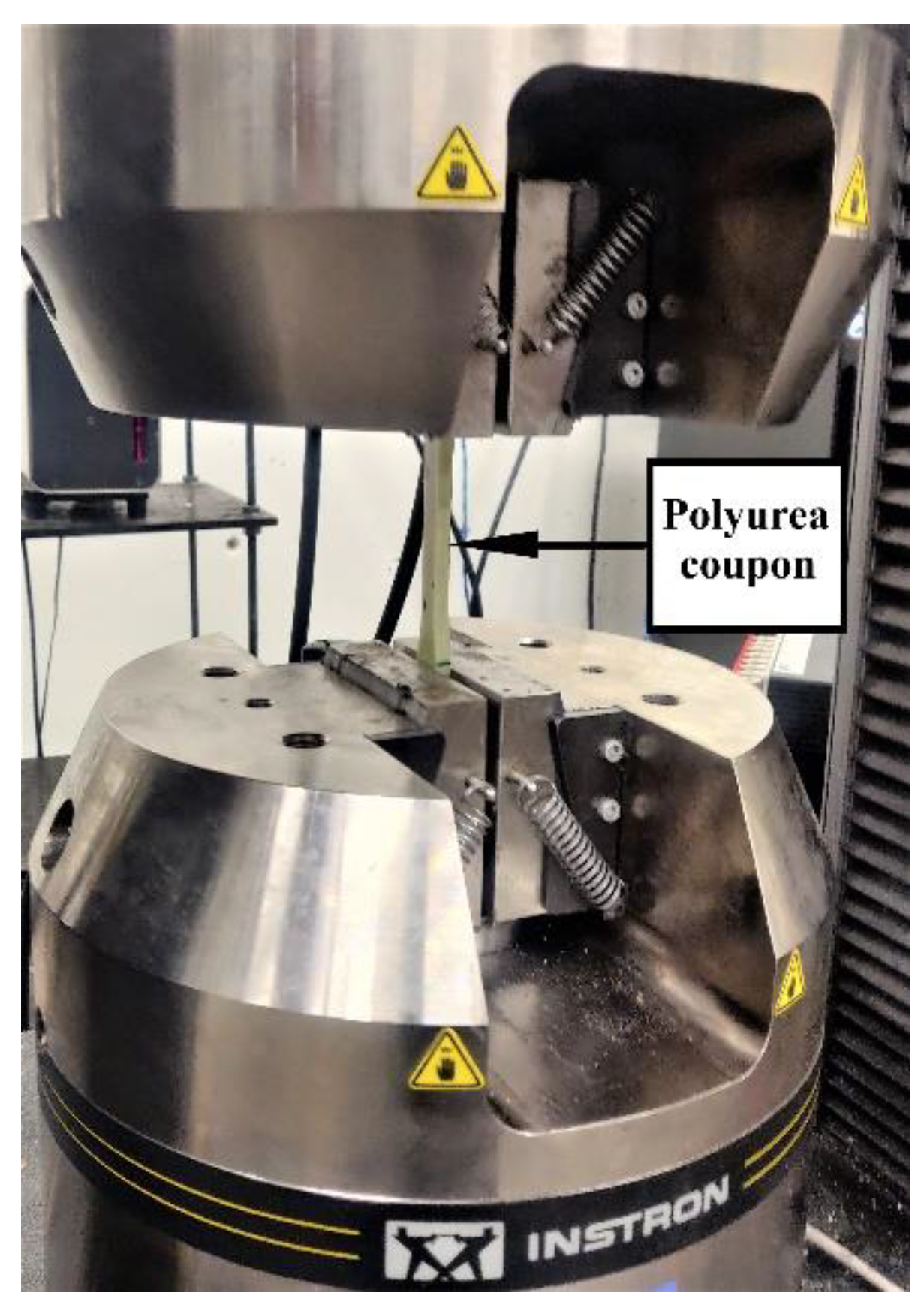

2.2. Coupon Preparation and Test Setup

2.3. Monotonic Tensile Tests

2.4. Rate Dependent Tensile Tests

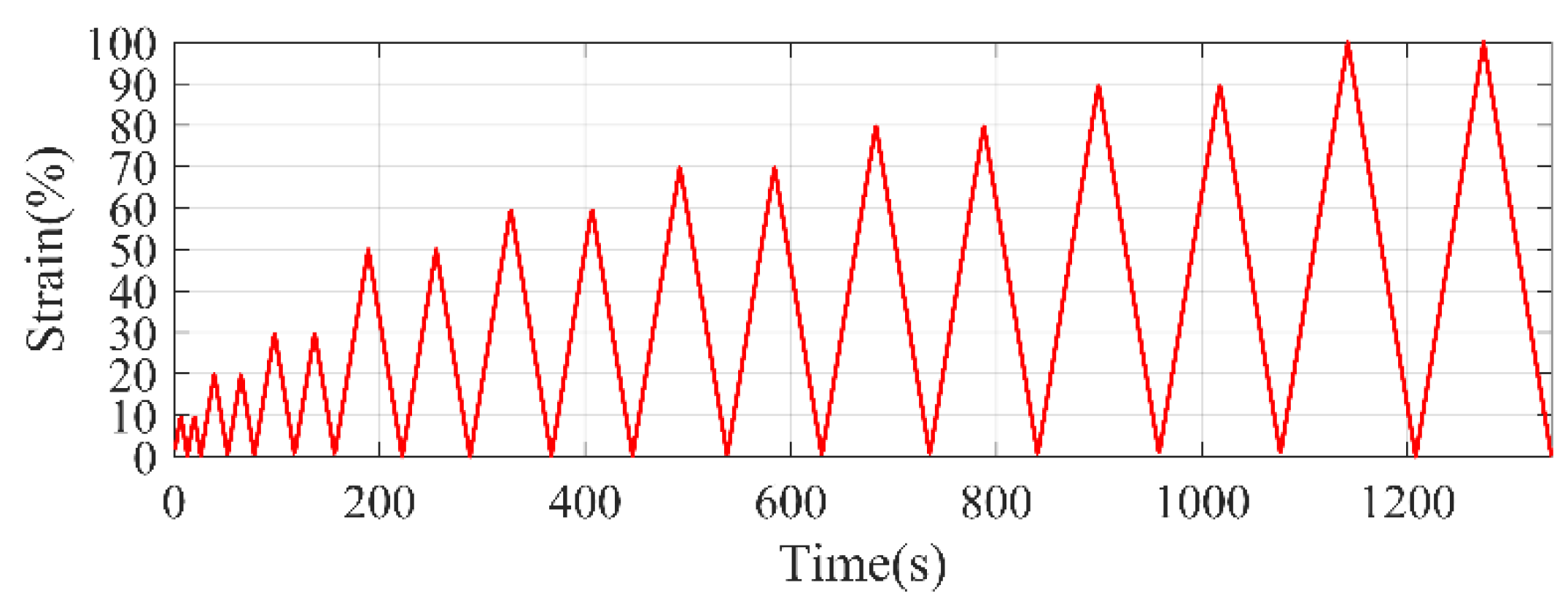

2.5. Cyclic Tensile Test

2.6. Tensile Fatigue Test

3. Results and Discussions

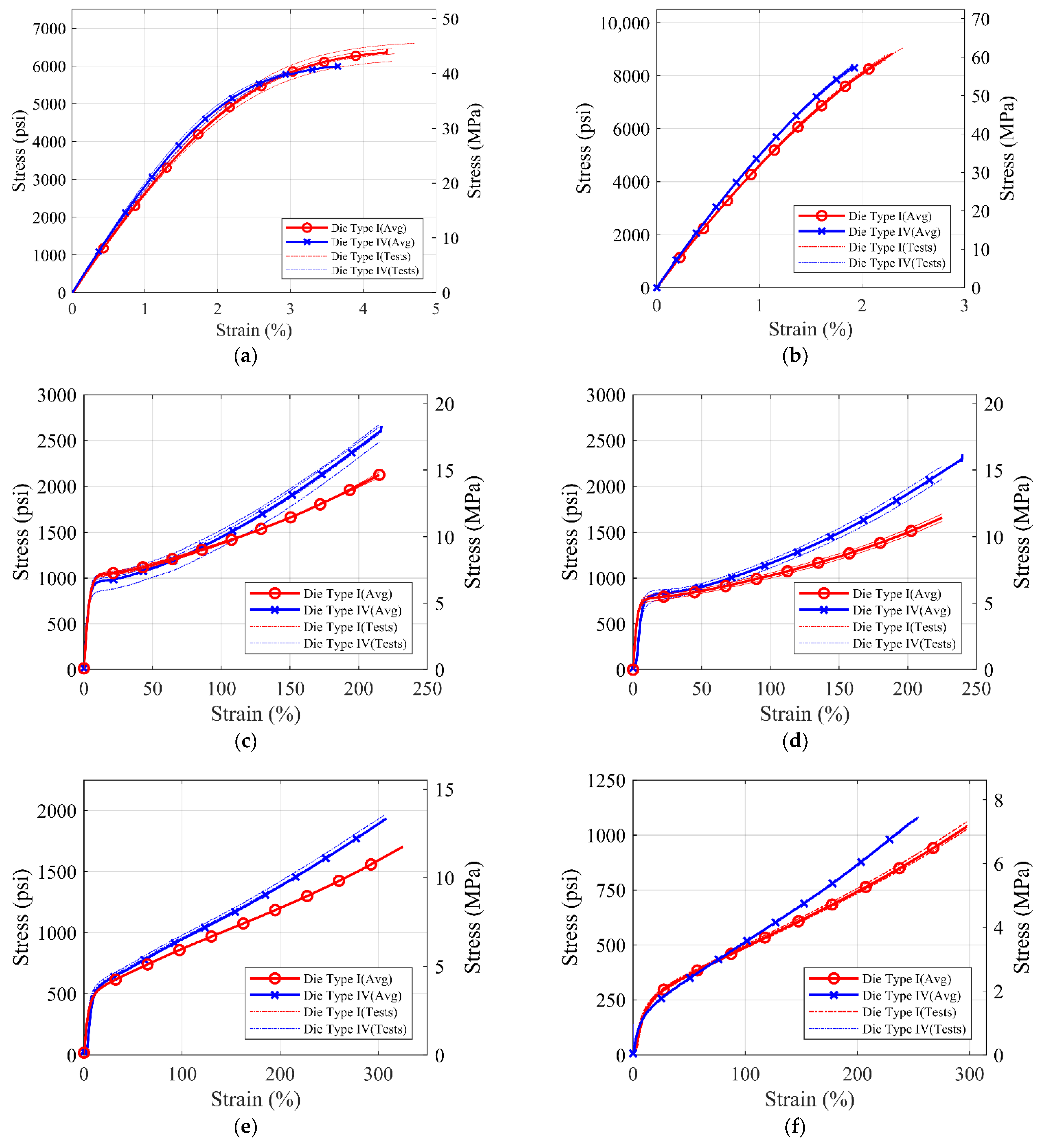

3.1. Tensile Behavior of Different Material Types

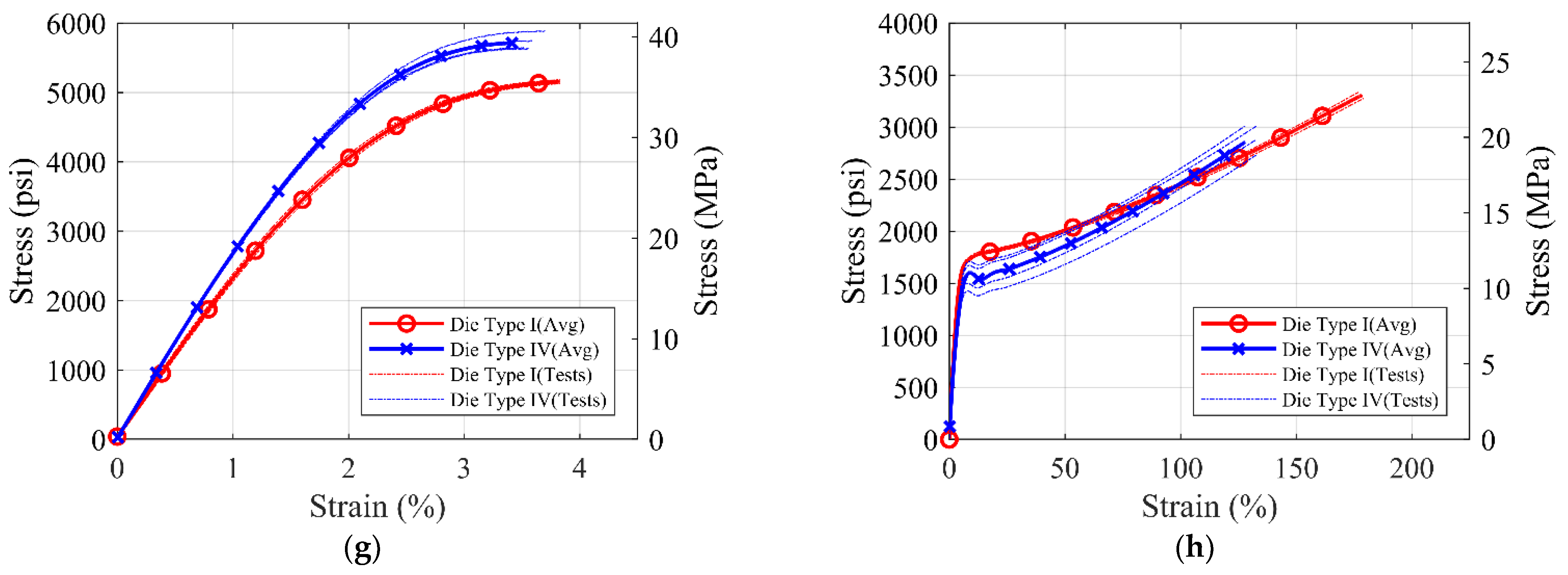

3.2. Tensile Behavior Comparison of Different Material Types

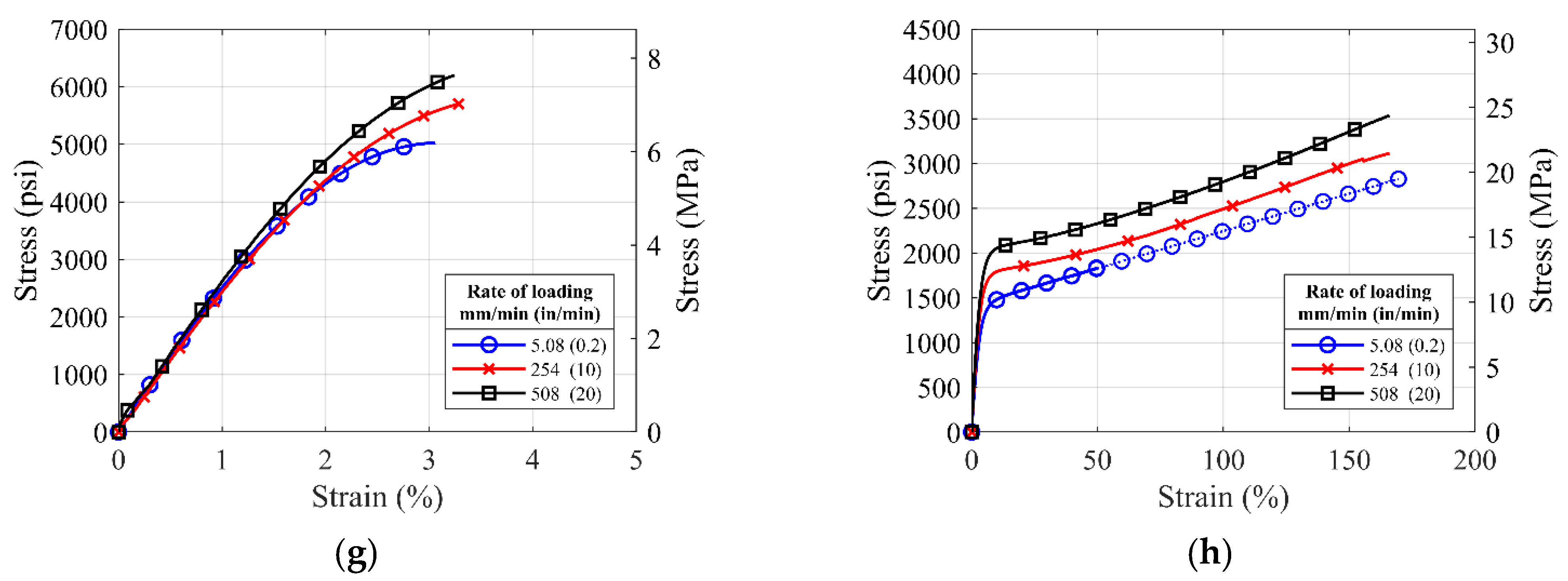

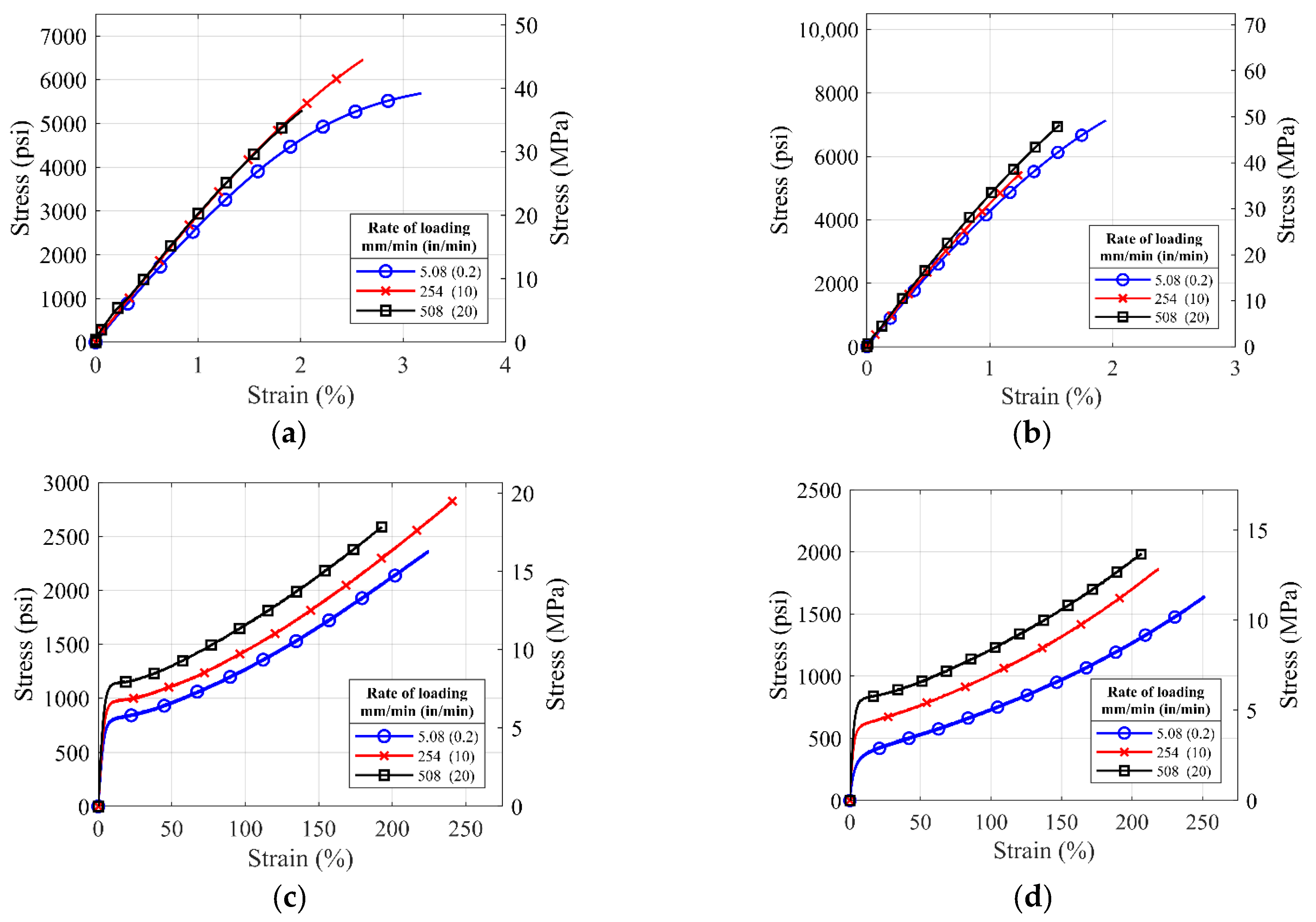

3.3. Rate Dependent Behavior of Different Material Types

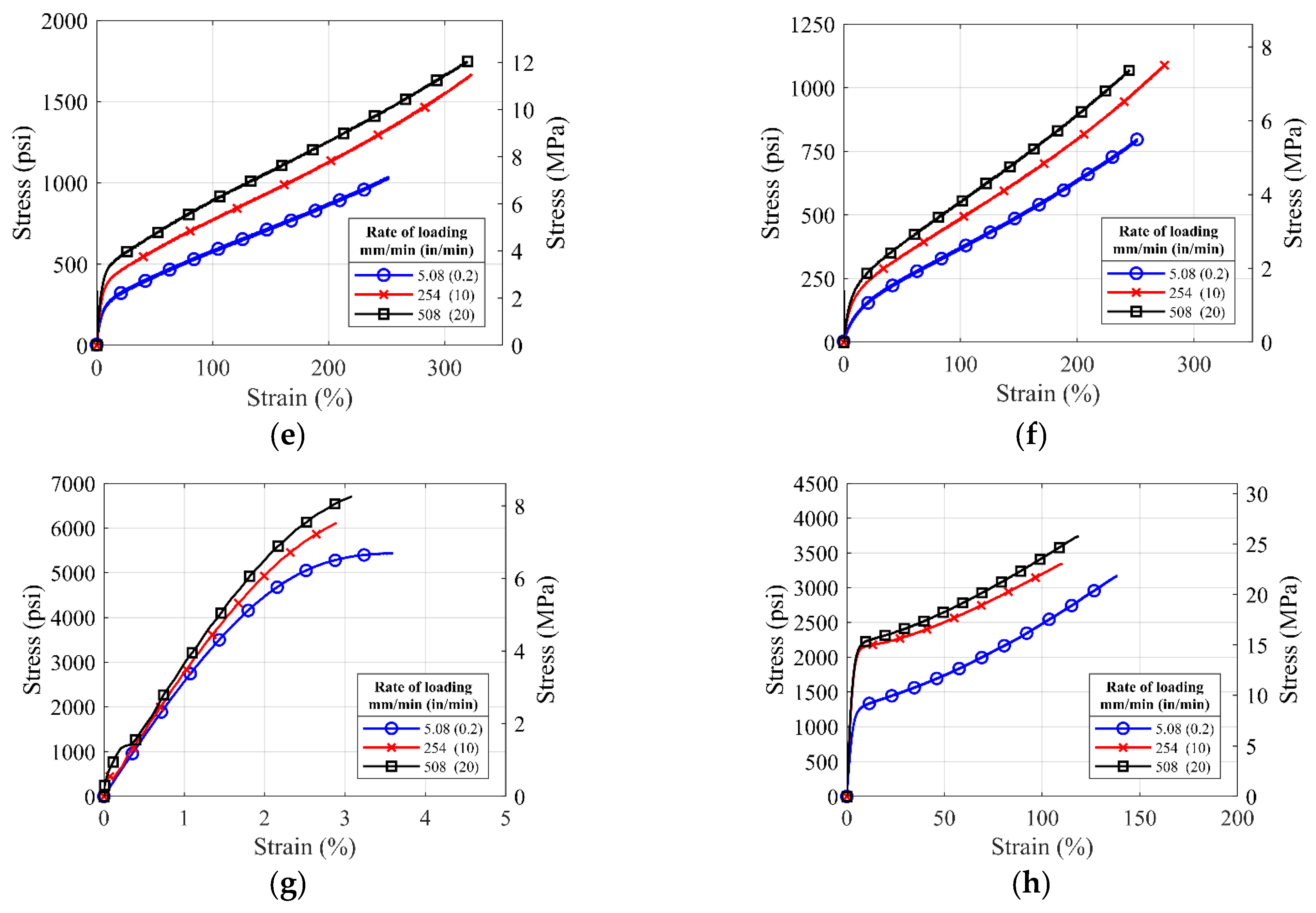

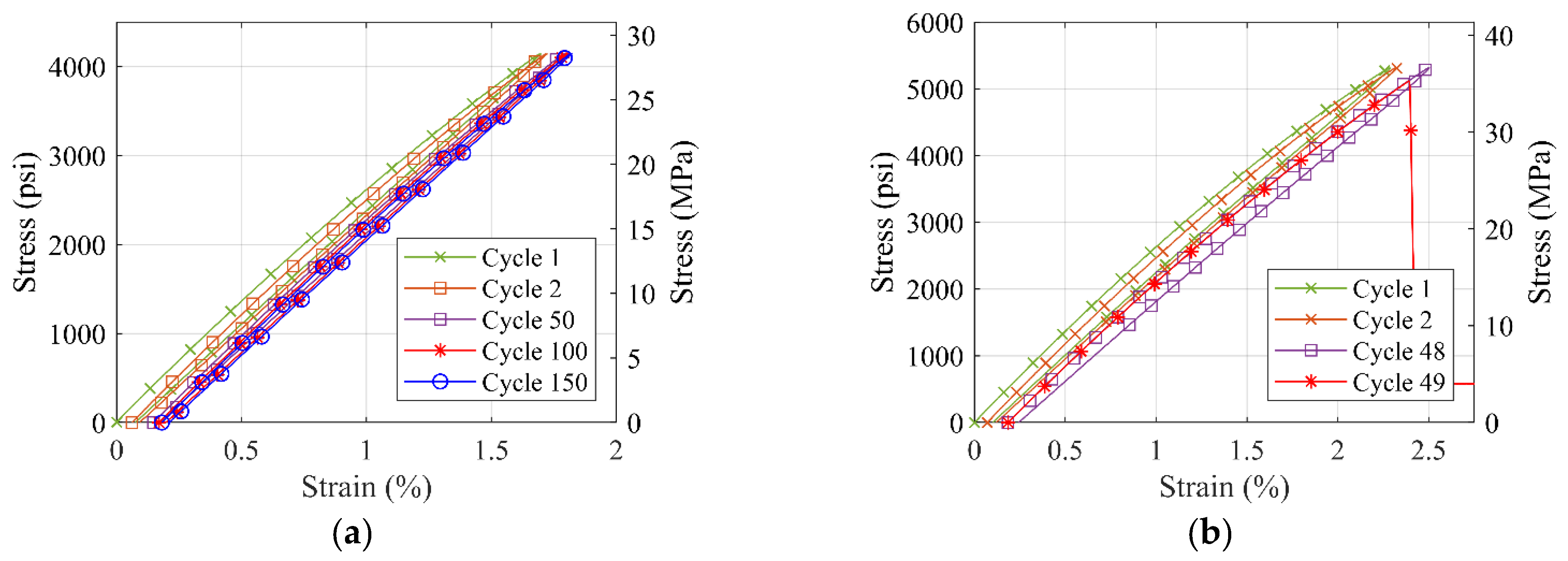

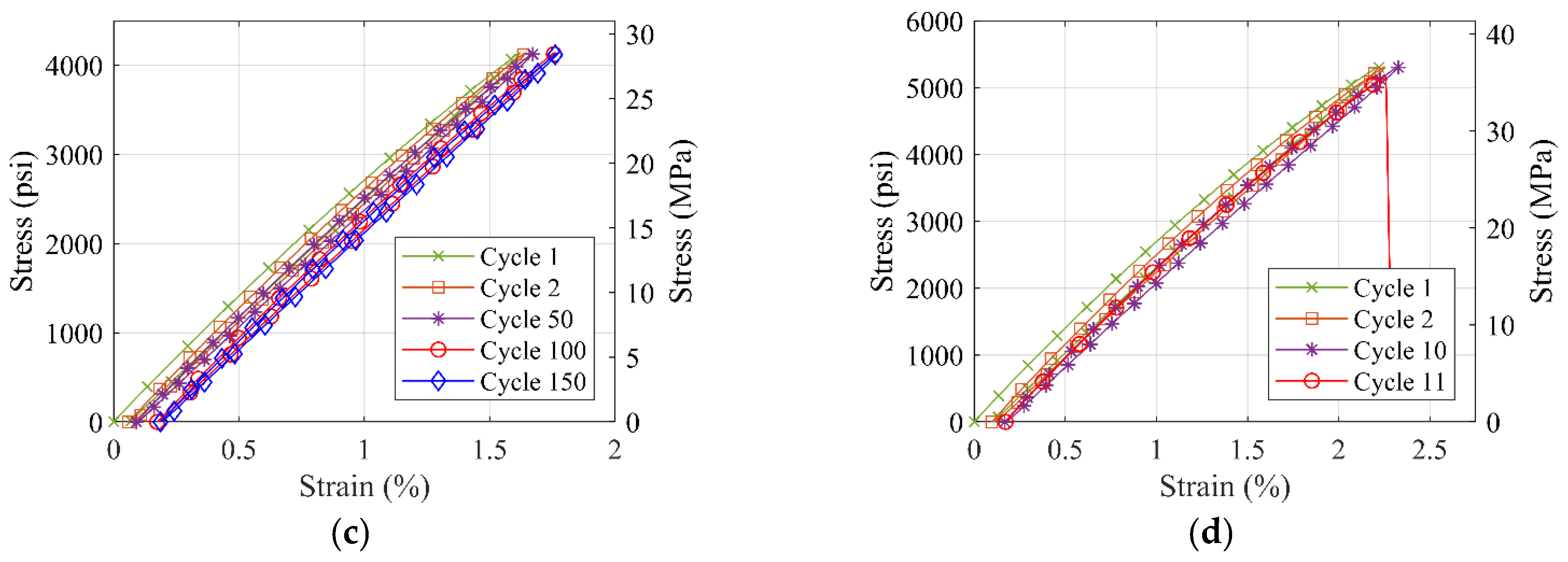

3.4. Cyclic Tensile Behavior of Selected Material Types

3.5. Tensile Fatigue Behavior of Selected Material Types

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghaffary, A.; Moustafa, M.A. Synthesis of Repair Materials and Methods for Reinforced Concrete and Prestressed Bridge Girders. Materials 2020, 13, 4079. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.F.; Liu, T.; Oehlers, D.J. Fundamental Principles That Govern Retrofitting of Reinforced Concrete Columns by Steel and FRP Jacketing. Adv. Struct. Eng. 2016, 9, 507–532. [Google Scholar] [CrossRef]

- Szafran, J.; Matusiak, A. Polyurea Coating Systems: Definition, Research, Applications; University of Warmia and Mazury in Olsztyn: Olsztyn, Poland, 2016; pp. 103–110. [Google Scholar]

- Davidson, J.S.; Porter, J.R.; Dinan, R.J.; Hammons, M.I.; Connell, J.D. Explosive Testing of Polymer Retrofit Masonry Walls. J. Perform. Constr. Facil. 2004, 18, 100–106. [Google Scholar] [CrossRef]

- Grujicic, M.; Bell, W.C.; Pandurangan, B.; He, T. Blast-Wave Impact-Mitigation Capability of Polyurea When Used as Helmet Suspension-Pad Material. Mater. Des. 2010, 31, 4050–4065. [Google Scholar] [CrossRef]

- Iqbal, N.; Sharma, P.K.; Kumar, D.; Roy, P.K. Protective Polyurea Coatings for Enhanced Blast Survivability of Concrete. Constr. Build. Mater. 2018, 175, 682–690. [Google Scholar] [CrossRef]

- Beyer, M.E.; Myers, P.J.J. Durability Performance of Polyurea Based Systems for Concrete Member Rehabilitation. Available online: https://citeseerx.ist.psu.edu/viewdoc/summary?doi=10.1.1.689.4970 (accessed on 24 February 2021).

- Tuhin, I.; Tazarv, M. Stress-Strain Relationship for Polyurea-Confined Circular Concrete Columns under Static Loads. ACI Mater. J. 2020, 117, 81–94. [Google Scholar]

- Akın, E.; Tunaboyu, O.; Avşar, Ö. Axial Behavior of FRP Confined Low-Strength Concrete with Polyurea. Structures 2020, 28, 1774–1784. [Google Scholar]

- Yi, J.; Boyce, M.C.; Lee, G.F.; Balizer, E. Large Deformation Rate-Dependent Stress-Strain Behavior of Polyurea and Polyurethanes. Polymer 2006, 47, 319–329. [Google Scholar] [CrossRef]

- Sarva, S.S.; Deschanel, S.; Boyce, M.C.; Chen, W. Stress–Strain Behavior of a Polyurea and a Polyurethane from Low to High Strain Rates. Polymer 2007, 48, 2208–2213. [Google Scholar] [CrossRef]

- Raman, S.N.; Ngo, T.; Lu, J.; Mendis, P. Experimental Investigation on the Tensile Behavior of Polyurea at High Strain Rates. Mater. Des. 2013, 50, 124–129. [Google Scholar] [CrossRef]

- Wang, H.; Deng, X.; Wu, H.; Pi, A.; Li, J.; Huang, F. Investigating the Dynamic Mechanical Behaviors of Polyurea through Experimentation and Modeling. Def. Technol. 2019, 15, 875–884. [Google Scholar] [CrossRef]

- Holzworth, K.; Jia, Z.; Amirkhizi, A.V.; Qiao, J.; Nemat-Nasser, S. Effect of Isocyanate Content on Thermal and Mechanical Properties of Polyurea. Polymer 2013, 54, 3079–3085. [Google Scholar] [CrossRef]

- Mohotti, D.; Ali, M.; Ngo, T.; Lu, J.; Mendis, P. Strain Rate Dependent Constitutive Model for Predicting the Material Behaviour of Polyurea under High Strain Rate Tensile Loading. Mater. Des. 2014, 53, 830–837. [Google Scholar] [CrossRef]

- Guo, H.; Guo, W.; Amirkhizi, A.V.; Zou, R.; Yuan, K. Experimental Investigation and Modeling of Mechanical Behaviors of Polyurea over Wide Ranges of Strain Rates and Temperatures. Polym. Test. 2016, 53, 234–244. [Google Scholar] [CrossRef] [Green Version]

- Hrynyk, T.D.; Myers, J.J. Out-of-Plane Behavior of URM Arching Walls with Modern Blast Retrofits: Experimental Results and Analytical Model. J. Struct. Eng. 2008, 134, 1589–1597. [Google Scholar] [CrossRef]

- Natalia, L.C.; John, J.M.; Domenico, A.; Costantino, M.; Andrea, P. Polyurea Coated and Plane Reinforced Concrete Panel Behavior under Blast Loading: Numerical Simulation to Experimental Results. Trends Civ. Eng. Archit. 2018, 119, 1–12. [Google Scholar]

- Amini, M.R.; Isaacs, J.B.; Nemat-Nasser, S. Experimental Investigation of Response of Monolithic and Bilayer Plates to Impulsive Loads. Int. J. Impact Eng. 2010, 37, 82–89. [Google Scholar] [CrossRef]

- Toutanji, H.A.; Choi, H.; Wong, D.; Gilbert, J.A.; Alldredge, D.J. Applying a Polyurea Coating to High-Performance Organic Cementitious Materials. Constr. Build. Mater. 2013, 38, 1170–1179. [Google Scholar] [CrossRef]

- Greene, C.E.; Myers, J.J. Flexural and Shear Behavior of Reinforced Concrete Members Strengthened with a Discrete Fiber-Reinforced Polyurea System. J. Compos. Constr. 2013, 17, 108–116. [Google Scholar] [CrossRef]

- Marawan, A.E.; Debaiky, A.S.; Khalil, N.N. Shear and Flexural Behavior of RC Beams Strengthened with Polyurea Spray. Int. J. Adv. Res. Sci. Eng. 2015, 4, 12–26. [Google Scholar]

- Parniani, S.; Toutanji, H. Monotonic and Fatigue Performance of RC Beams Strengthened with a Polyurea Coating System. Constr. Build. Mater. 2015, 101, 22–29. [Google Scholar] [CrossRef]

- Carey, N.L.; Myers, J.J. Discrete Fiber Reinforced Polyurea for Hazard Mitigation; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Song, J.-H.; Lee, E.-T.; Eun, H.-C. A Study on the Improvement of Structural Performance by Glass Fiber-Reinforced Polyurea (GFRPU) Reinforcement. Adv. Civ. Eng. 2019, 2019, 2818219. [Google Scholar] [CrossRef]

- Rizwan, M.; Khaleequzzaman, S.; uz Zaman, U.K.; Fida, S.A.; Shahzad, A.; Rehman, M.; Sulaiman, M.O. Tensile Strength Improvement of Concrete Slabs Using Polyurea Spray. Pract. Period. Struct. Des. Constr. 2021, 26, 4020048. [Google Scholar] [CrossRef]

- Szafran, J.; Matusiak, A. Crushing Strength of Concrete Rings with a Polyurea Reinforce System. Tunn. Undergr. Space Technol. 2020, 101, 103407. [Google Scholar] [CrossRef]

- PPG VersaFlex|Arostruct®—VersaFlex. Available online: https://versaflex.com/products/industrial/arostruct-spray-polyurea/ (accessed on 9 November 2021).

- Bridge Deck Membrane Technical Data Sheet. Available online: https://bridgepreservation.com/docs/prod/Data_BPbdm.pdf (accessed on 9 November 2021).

- Bridge Deck Membrane Topcoat Technical Data Sheet. Available online: https://bridgepreservation.com/docs/prod/Data_BPbdmtopcoat.pdf (accessed on 9 November 2021).

- VersaFlex|AquaVers-405 Technical Data Sheet. Available online: https://versaflex.com/wp-content/uploads/2020/11/TDS-AquaVers-405-072420-V.6.5.pdf (accessed on 9 November 2021).

- VersaFlex|SL-75 Technical Data Sheet. Available online: https://versaflex.com/wp-content/uploads/2020/11/SL75-TDS-080720-V.6.5.pdf (accessed on 9 November 2021).

- Nukote PP 300 TDS—Nukote Coating Systems. Available online: https://nukoteglobal.com/technical-sheets/nukote-pp-300-tds/ (accessed on 9 November 2021).

- Nukote HTD TDS—Nukote Coating Systems. Available online: https://nukoteglobal.com/technical-sheets/nukote-htd-tds/ (accessed on 9 November 2021).

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics; ASTM International: West Conshohocken, PA, USA, 2014.

- Bischoff, P.H.; Perry, S.H. Compressive Behaviour of Concrete at High Strain Rates. Mater. Struct. 1991, 24, 425–450. [Google Scholar] [CrossRef]

- Li, M.; Li, H. Effects of Strain Rate on Reinforced Concrete Structure under Seismic Loading. Adv. Struct. Eng. 2012, 15, 461–475. [Google Scholar] [CrossRef]

- Philpot, T.A. Mechanics of Materials: An Integrated Learning System, 2nd ed.; John Wiley: Hoboken, NJ, USA, 2011; ISBN 9780470565148. [Google Scholar]

| Material Type (S#) | Commercial Name | Rupture Strength MPa (psi) | Elongation at Rupture | Gel Time | Tack Free Time |

|---|---|---|---|---|---|

| S1 | Arostruct® | 41.4 (6000) | 2.5–3.5% | 10–12 s | 2 min |

| S2 | Arostruct® with fibers * | n/a | n/a | n/a | n/a |

| S3 | Bridge Deck Membrane | 13.8 (2000) | >250% | 10 s | 30 s |

| S4 | Bridge Deck Membrane Topcoat | 13.8 (2000) | >250% | 90 s | 2 min |

| S5 | AquaVersTM-405 | 15.2 (2200) | >500% | 25 s | 180 s |

| S6 | SL/75TM | 8.9 (1295) | >406% | 1 min | 10 min |

| S7 | Nukote PP300 | 55 ± 3 (8000 ± 500) | 2 ± 1% | 15–20 s | 60–90 s |

| S8 | Nukote HTD | 26 ± 2 (3550 ± 250) | 200–300% | 5–15 s | 30–45 s |

| Material Type | Die Type | Loading Rate Used mm/min (in/min) | Average Coupon Thickness mm (in) | Number of Coupons Tested | |

|---|---|---|---|---|---|

| Die Type I | Die Type IV | ||||

| S1 | I, IV | 5.08 (0.2) | 5 (0.197) | 4 | 2 |

| S2 | 5.08 (0.2) | 6 (0.236) | 4 | 2 | |

| S3 | 254 (10) | 2 (0.079) | 2 | 4 | |

| S4 | 254 (10) | 2 (0.079) | 2 | 4 | |

| S5 | 254 (10) | 2 (0.079) | 2 | 4 | |

| S6 | 254 (10) | 4 (0.157) | 4 | 2 | |

| S7 | 5.08 (0.2) | 2.5 (0.098) | 2 | 4 | |

| S8 | 254 (10) | 2 (0.079) | 2 | 4 | |

| Material Type | Die Types | Loading Rates Used mm/min (in/min) | Average Coupon Thickness mm (in) | Number of Coupons Tested | |

|---|---|---|---|---|---|

| Die Type I | Die Type IV | ||||

| S1 | I, IV | 5.08 (0.2) 254 (10) 508 (20) | 5 (0.197) | 2 | 2 |

| S2 | 6 (0.236) | 2 | 2 | ||

| S3 | 2 (0.079) | 2 | 2 | ||

| S4 | 2 (0.079) | 2 | 2 | ||

| S5 | 2 (0.079) | 2 | 2 | ||

| S6 | 4 (0.157) | 2 | 2 | ||

| S7 | 2.5 (0.098) | 2 | 2 | ||

| S8 | 2 (0.079) | 2 | 2 | ||

| Polyurea Material | ASTM D638 Die Type | 0.2% Offset Yield Strength MPa (ksi) | Initial Stiffness MPa (ksi) | Rupture Strength MPa (ksi) | Strain at Rupture (%) |

|---|---|---|---|---|---|

| S1 | Die Type I | 27.7 (4.02) | 1903 (276) | 43.4 (6.29) | 4.09 |

| Die Type IV | 28.5 (4.14) | 2013 (292) | 40.1 (5.81) | 2.99 | |

| S2 | Die Type I | 52.5 (7.61) | 3199 (464) | 60.7 (8.80) | 2.29 |

| Die Type IV | 54.6 (7.92) | 3454 (501) | 57.9 (8.40) | 1.92 | |

| S3 | Die Type I | 6.0 (0.87) | 110 (16) | 19.3 (2.79) | >339 * |

| Die Type IV | 6.1 (0.88) | 110 (16) | 17.9 (2.59) | >216 * | |

| S4 | Die Type I | 4.3 (0.63) | 110 (16) | 15.9 (2.30) | >331 * |

| Die Type IV | 4.6 (0.66) | 103 (15) | 15.9 (2.30) | >339 * | |

| S5 | Die Type I | 2.8 (0.41) | 48 (7) | 11.7 (1.70) | >376 * |

| Die Type IV | 2.5 (0.36) | 48 (7) | 12.4 (1.80) | >284 * | |

| S6 | Die Type I | 1.0 (0.15) | 14 (2) | 6.6 (0.96) | >274 * |

| Die Type IV | 1.1 (0.16) | 14 (2) | 7.6 (1.10) | >248 * | |

| S7 | Die Type I | 25.65 (3.72) | 1689 (245) | 36.34 (5.27) | 4.03 |

| Die Type IV | 23.99 (3.48) | 1827 (265) | 39.44 (5.72) | 3.51 | |

| S8 | Die Type I | 10.5 (1.53) | 310 (45) | 23.9 (3.46) | 179 |

| Die Type IV | 9.8 (1.42) | 296 (43) | 21.9 (3.17) | 137 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acharya, P.; Ebrahimian, H.; Moustafa, M.A. Behavior Study of Commercial Polyurea under Monotonic, Rate Dependent, Cyclic, and Fatigue Tensile Loading for Potential Structural Applications. Polymers 2022, 14, 1878. https://doi.org/10.3390/polym14091878

Acharya P, Ebrahimian H, Moustafa MA. Behavior Study of Commercial Polyurea under Monotonic, Rate Dependent, Cyclic, and Fatigue Tensile Loading for Potential Structural Applications. Polymers. 2022; 14(9):1878. https://doi.org/10.3390/polym14091878

Chicago/Turabian StyleAcharya, Pawan, Hamed Ebrahimian, and Mohamed A. Moustafa. 2022. "Behavior Study of Commercial Polyurea under Monotonic, Rate Dependent, Cyclic, and Fatigue Tensile Loading for Potential Structural Applications" Polymers 14, no. 9: 1878. https://doi.org/10.3390/polym14091878

APA StyleAcharya, P., Ebrahimian, H., & Moustafa, M. A. (2022). Behavior Study of Commercial Polyurea under Monotonic, Rate Dependent, Cyclic, and Fatigue Tensile Loading for Potential Structural Applications. Polymers, 14(9), 1878. https://doi.org/10.3390/polym14091878