High Mechanical Properties of Stretching Oriented Poly(butylene succinate) with Two-Step Chain Extension

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

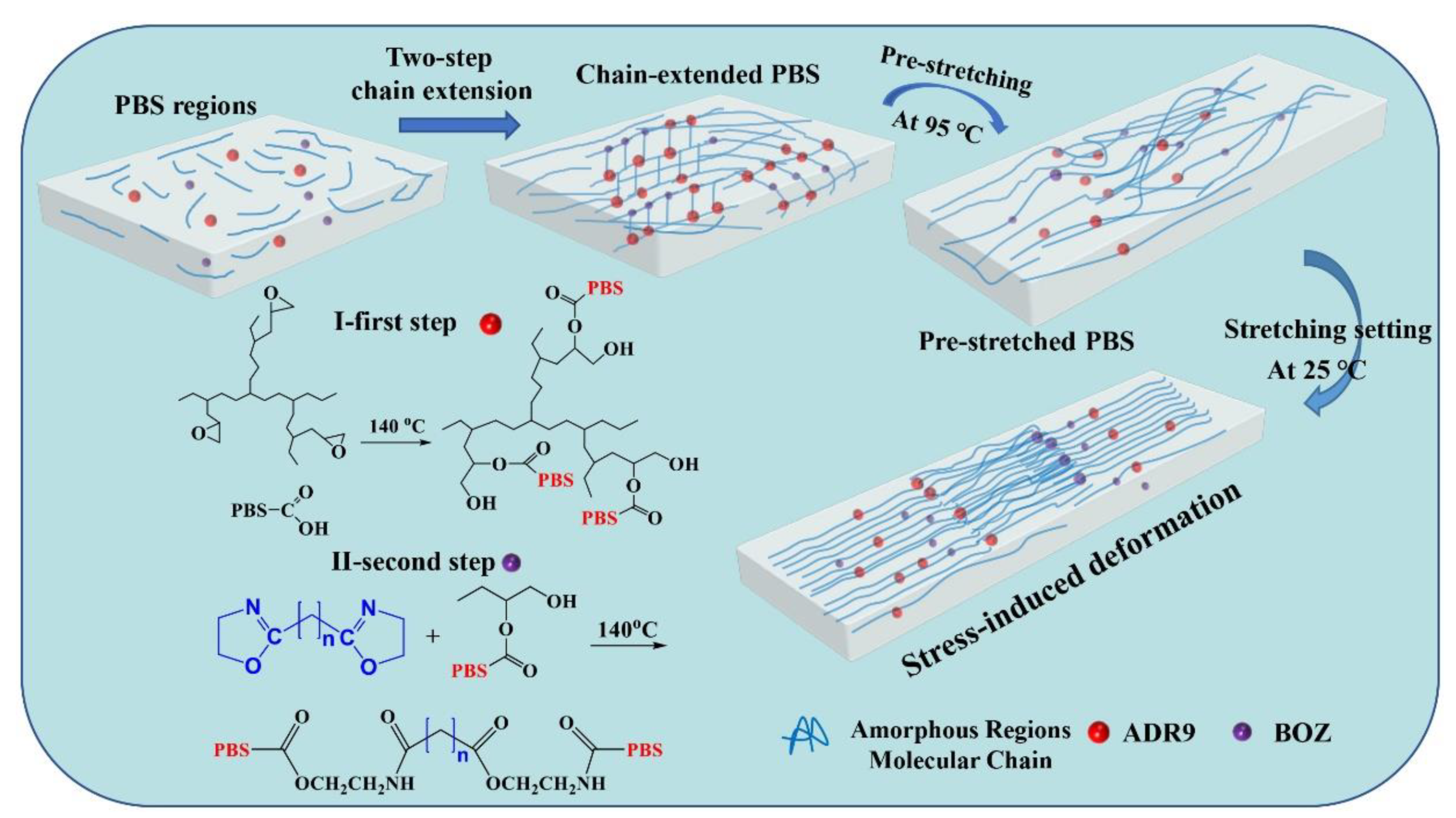

2.2. Preparation of Two-Step Chain-Extended and Pre-Stretched Sample

2.2.1. Mechanical Properties

2.2.2. Crystallization Process and Crystalline Structure Characterization

2.2.3. Morphological Characterization

2.2.4. Rheological Analysis

2.2.5. Infrared Spectroscopic Analysis

3. Results and Discussion

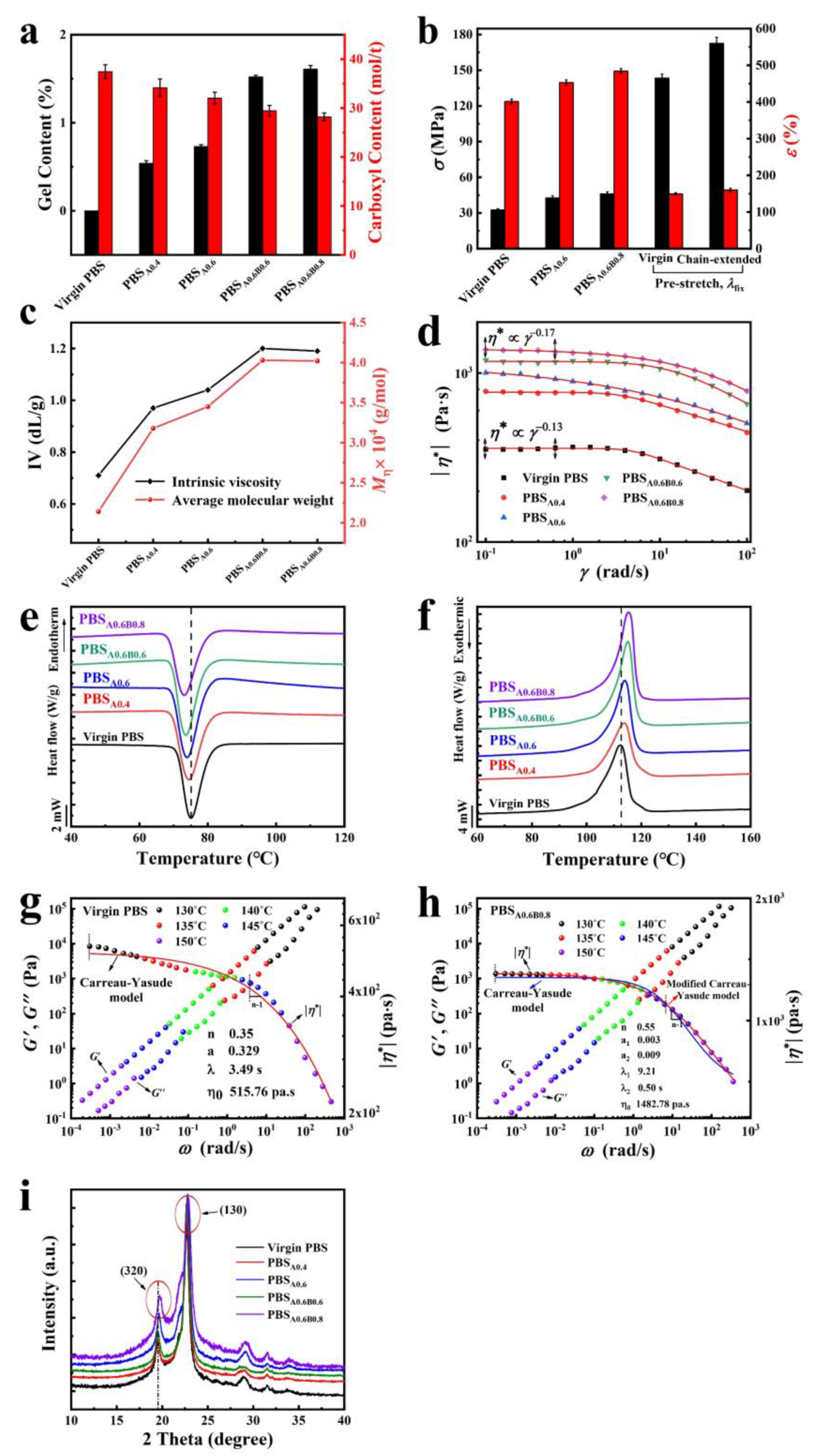

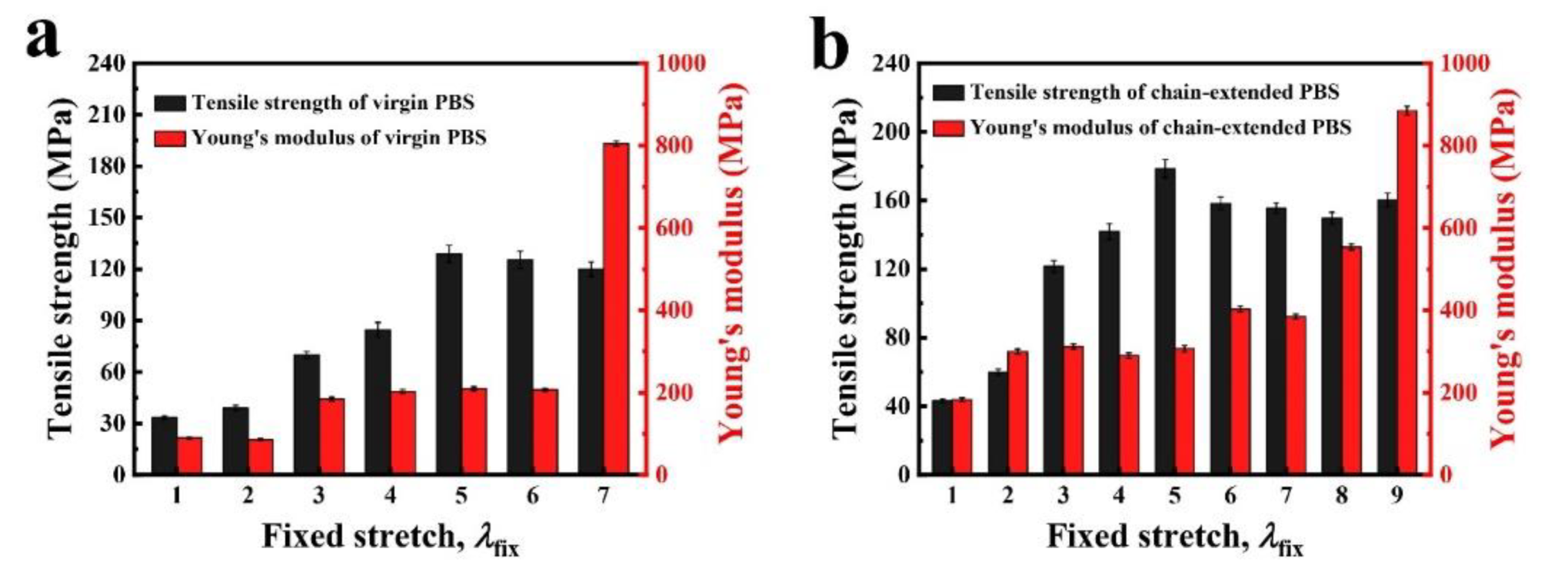

3.1. The Influence of Chain Extension Reaction on PBS

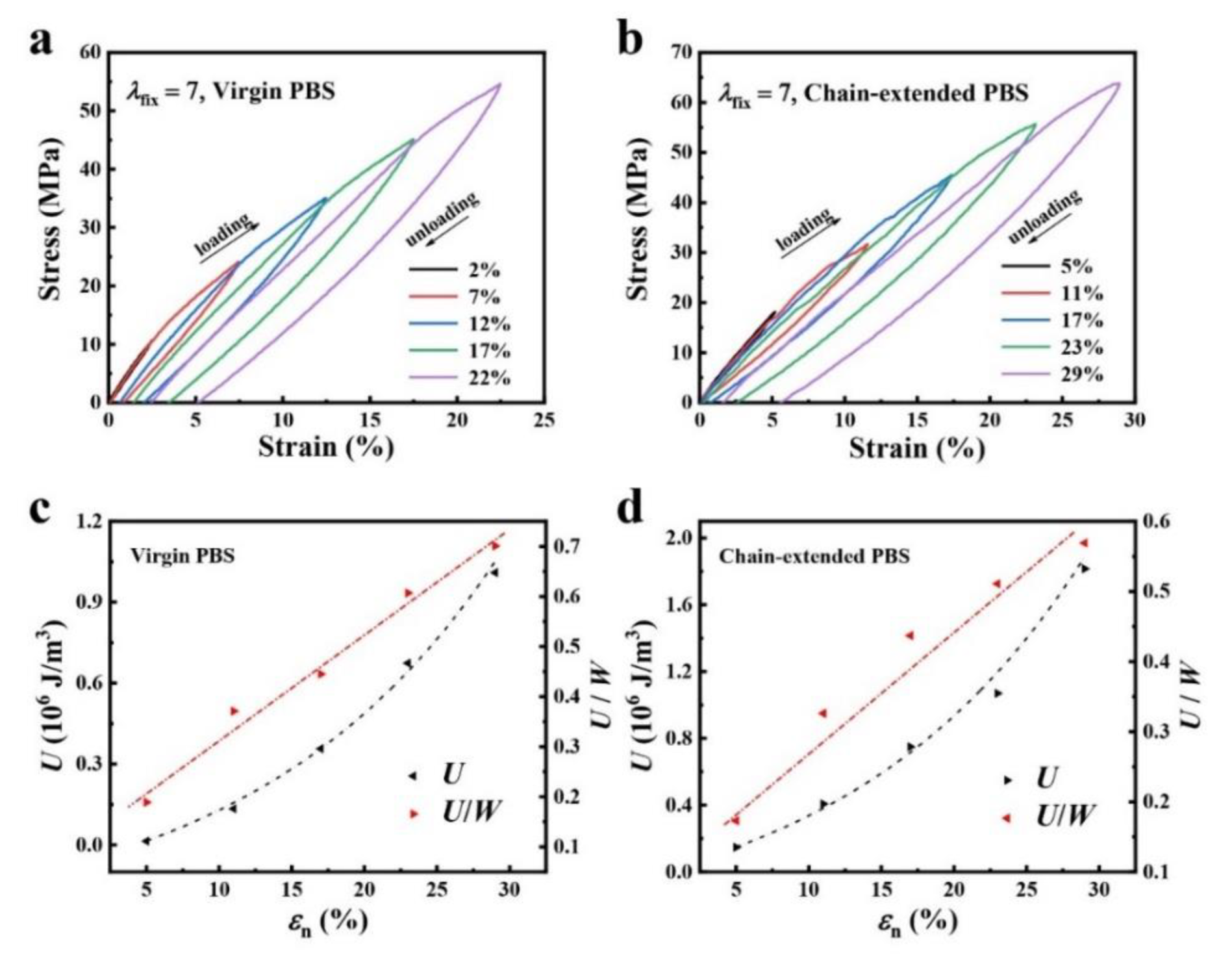

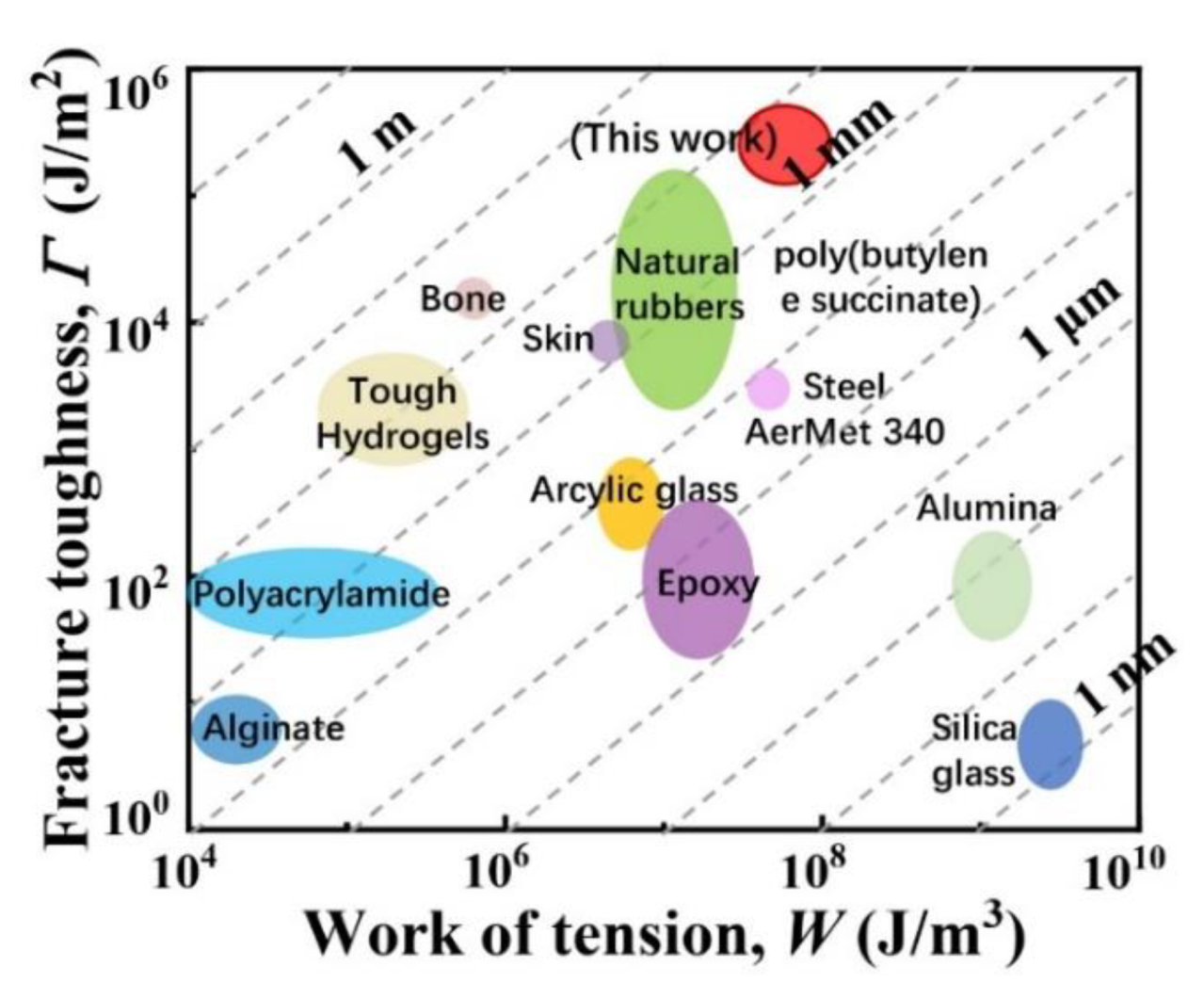

3.2. The Energy Release Rate of PBS Samples

3.3. Characterization of the Crystalline Morphology in PBS Samples

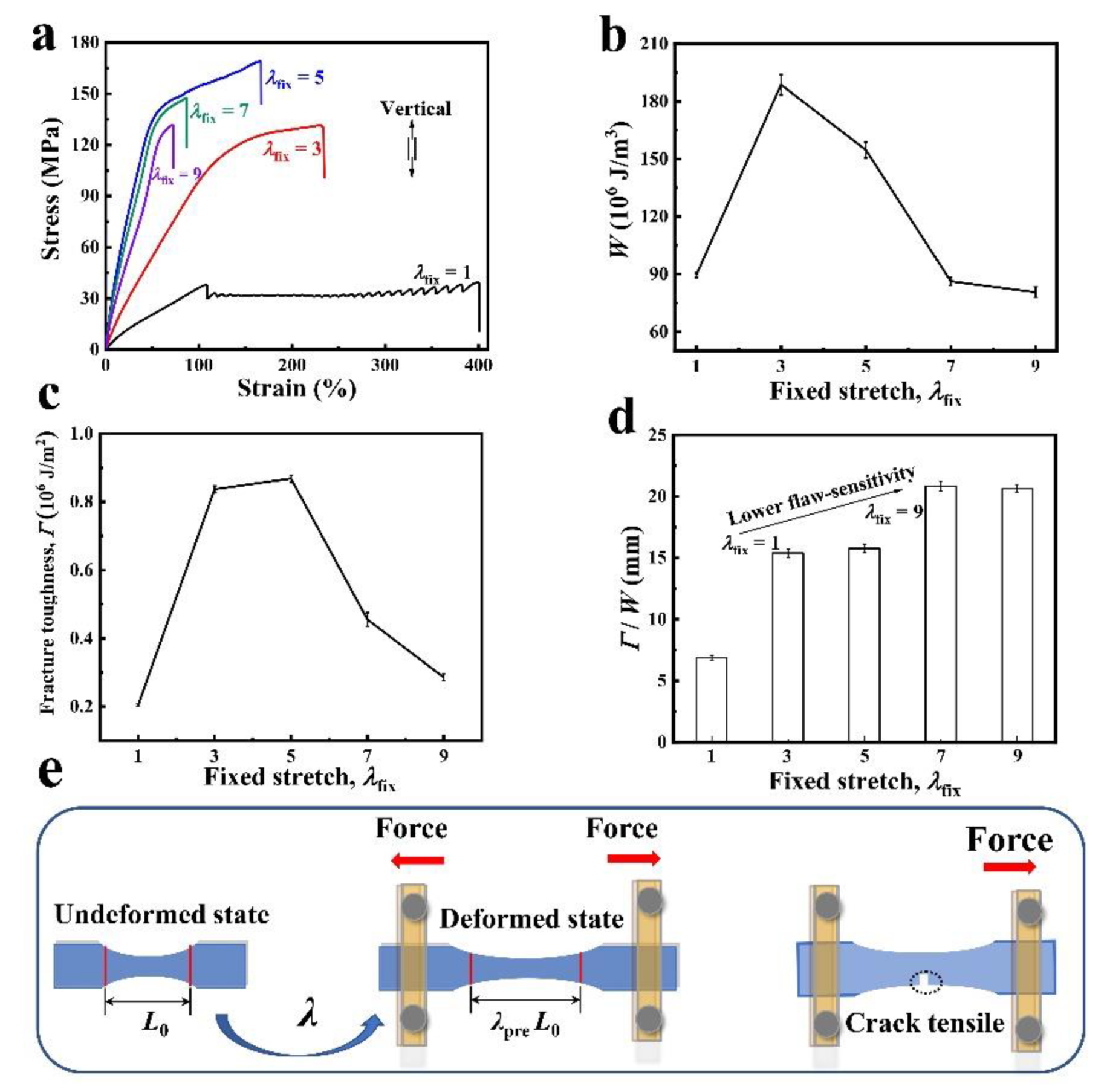

3.4. Characterization of Flaw Sensitivity Properties of PBS

3.5. Spherulite Morphology and Crystal Structure

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Marek, A.A.; Verney, V.; Totaro, G.; Sisti, L.; Celli, A.; Cionci, N.B.; Di Gioia, D.; Massacrier, L.; Leroux, F. Organo-modified LDH fillers endowing multi-functionality to bio-based poly(butylene succinate): An extended study from the laboratory to possible market. Appl. Clay. Sci. 2020, 188, 105502. [Google Scholar] [CrossRef]

- Sonseca, A.; McClain, A.; Puskas, J.E.; El Fray, M. Kinetic studies of biocatalyzed copolyesters of poly (butylene succinate) (PBS) containing fully bio-based dilinoleic diol-sciencedirect. Eur. Polym. J. 2019, 116, 515–525. [Google Scholar] [CrossRef]

- Liu, G.; Zheng, L.; Zhang, X.; Li, C.; Jiang, S.; Wang, D. Reversible lamellar thickening induced by crystal transition in poly(butylene succinate). Macromolecules 2012, 45, 5487–5493. [Google Scholar] [CrossRef]

- Dean, K.M.; Pas, S.J.; Yu, L.; Ammala, A.; Hill, A.J.; Wu, D.Y. Formation of highly oriented biodegradable polybutylene succinate adipate nanocomposites: Effects of cation structures on morphology, free volume, and properties. J. Appl. Polym. Sci. 2020, 113, 3716–3724. [Google Scholar] [CrossRef]

- Huang, M.; Dong, X.; Wang, L.; Zheng, L.; Liu, G.; Gao, X.; Li, C.; Müller, A.J.; Wang, D. Reversible Lamellar Periodic Structures Induced by Sequential Crystallization/Melting in PBS-co-PCL Multiblock Copolymer. Macromolecules 2018, 51, 1100–1109. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.K.; Bhattacharya, S.N.; Choi, H.J. Compatibility of biodegradable poly(lactic acid) (PLA) and poly(butylene succinate) (PBS) blends for packaging application. Korea-Aust. Rheol. J. 2007, 19, 125–131. [Google Scholar]

- Siracusa, V.; Lotti, N.; Munari, A.; Dalla Rosa, M. Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: Gas barrier properties after stressed treatments. Polym. Degrad. Stabil. 2015, 119, 35–45. [Google Scholar] [CrossRef]

- Platnieks, O.; Gaidukovs, S.; Barkane, A.; Gaidukova, G.; Grase, L.; Thakur, V.K.; Filipova, I.; Fridrihsone, V.; Skute, M.; Laka, M. Highly loaded cellulose/poly(butylene succinate) sustainable composites for woody-like advanced materials application. Molecules 2020, 25, 121. [Google Scholar] [CrossRef]

- Lei, H.; Dong, L.; Li, Y.; Zhang, J.; Chen, H.; Wu, J.; Zhang, Y.; Fan, Q.; Xue, B.; Qin, M.; et al. Stretchable hydrogels with low hysteresis and anti-fatigue fracture based on polyprotein cross-linkers. Nat. Commun. 2020, 11, 4032. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Leejarkpai, T.; Kashima, D.P.; Chuayjuljit, S. Poly(Lactic Acid)/Poly(Butylene Succinate) Blends Filled with Epoxy Functionalised Polymeric Chain Extender. Adv. Mat. Res. 2013, 664, 644–648. [Google Scholar] [CrossRef]

- Liu, X.; Li, C.; Zhang, D.; Xiao, Y. Melting behaviors, Melting behaviors, crystallization kinetics, and spherulitic morphologies of poly(butylene succinate) and its copolyester modified with rosin maleopimaric acid anhydride. J. Polym. Sci. Part B Polym. Phys. 2010, 44, 900–913. [Google Scholar] [CrossRef]

- Huang, C.Q.; Luo, S.Y.; Xu, S.Y.; Zhao, J.B.; Jiang, S.L.; Yang, W.T. Catalyzed chain extension of poly(butylene adipate) and poly(butylene succinate) with 2, 2′-(1, 4-phenylene) -bis (2-oxazoline). J. Appl. Polym. Sci. 2010, 115, 1555–1565. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, T.; Xie, Z.; Han, J.; Xu, J.; Guo, B. Synthesis and properties of biobased multiblock polyesters containing poly(2, 5-furandimethylene succinate) and poly(butylene succinate) blocks. Ind. Eng. Chem. Res. 2017, 56, 3937–3946. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Wang, X.L.; Wang, Y.Z.; Yang, K.K.; Li, J. A novel biodegradable polyester from chain-extension of poly(p-dioxanone) with poly(butylene succinate). Polym. Degrad. Stabil. 2005, 88, 294–299. [Google Scholar] [CrossRef]

- Zou, J.; Qi, Y.; Su, L.; Wei, Y.; Li, Z.; Xu, H. Synthesis and characterization of poly(ester amide)s consisting of poly(L-lactic acid) and poly(butylene succinate) segments with 2, 2′-bis (2-oxazoline) chain extending. Macromol. Res. 2018, 26, 1212–1218. [Google Scholar] [CrossRef]

- Baker, J.L.; Jimison, L.H.; Mannsfeld, S.; Volkman, S.; Yin, S.; Subramanian, V.; Salleo, A.; Alivisatos, A.P.; Toney, M.F. Quantification of Thin Film Crystallographic Orientation Using X-ray Diffraction with an Area Detector. Langmuir 2010, 26, 46–51. [Google Scholar] [CrossRef] [Green Version]

- Deb Nath, S.K. Effects of Fiber Orientation and Material Isotropy on the Analytical Elastic Solution of a Stiffened Orthotropic Panel Subjected to a Combined Loading. Adv. Mater. Sci. Eng. 2013, 30, 162–167. [Google Scholar] [CrossRef] [Green Version]

- Monakhova, K.Z.; Bazhenov, S.L.; Kechek’yan, A.S. The Influence of Planar Orientation on Mechanical Properties of Filled Poly(butylene succinate). Polym. Sci. Ser. A. 2019, 61, 499–503. [Google Scholar] [CrossRef]

- Bai, R.; Yang, J.; Morelle, X.P.; Suo, Z. Flaw-Insensitive Hydrogels under Static and Cyclic Loads. Macromol. Rapid Commun. 2019, 40, e1800883. [Google Scholar] [CrossRef]

- Li, X.; Xia, M.; Qiu, D.; Long, R.; Huang, Z.; Li, J.; Long, S.; Li, X. Fabrication and properties of modified poly(butylene terephthalate) with two-step chain extension. Macromol. Mater. Eng. 2021, 306, 2000638. [Google Scholar] [CrossRef]

- Karobi, S.N.; Sun, T.L.; Kurokawa, T.; Luo, F.; Nakajima, T.; Nonoyama, T.; Gong, J.P. Creep behavior and delayed fracture of tough polyampholyte hydrogels by tensile test. Macromolecules 2016, 49, 5630–5636. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Xue, J.; Li, D.; Li, H.; Huang, Z.; Huang, Y.; Gong, C.; Long, S.; Li, X. Tough hydrogels with tunable soft and wet interfacial adhesion. Polym. Test. 2021, 93, 106976. [Google Scholar] [CrossRef]

- Papageorgiou, G.Z.; Achilias, D.S.; Bikiaris, D.N. Crystallization kinetics of biodegradable poly(butylene succinate) under isothermal and non-isothermal conditions. Macromol. Chem. Phys. 2010, 208, 1250–1264. [Google Scholar] [CrossRef]

- Li, X.; Xu, H.; Long, S.; Yuan, Y.; Wang, P.; Qiu, D.; Ke, K. Improved compatibility in Recycled-PE/LDPE using glycidyl methacrylate, acrylic acid grafted mPE. Polym. Test. 2018, 69, 508–513. [Google Scholar] [CrossRef]

- Lin, S.; Liu, X.; Liu, J.; Yuk, H.; Loh, H.C.; Parada, G.A.; Settens, C.; Song, J.; Masic, A.; McKinley, G.H.; et al. Anti-fatigue-fracture hydrogels. Sci. Adv. 2019, 5, eaau8528. [Google Scholar] [CrossRef] [Green Version]

- Ihn, K.J.; Yoo, E.S.; Im, S.S. Structure and Morphology of Poly(tetramethylene succinate) Crystals. Macromolecules 1995, 28, 2460–2464. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, Q.; Ji, Y.; Su, F.; Meng, L.; Qi, Z.; Lin, Y.; Li, X.; Chen, X.; Lv, F.; et al. Stretch-induced complexation reaction between poly(vinyl alcohol) and iodine: An in-situ synchrotron radiation small- and wide-angle X-ray scattering study. Soft Matter. 2018, 14, 2535–2546. [Google Scholar] [CrossRef]

- Chen, C.; Wang, Z.; Suo, Z. Flaw sensitivity of highly stretchable materials. Extreme Mech. Lett. 2018, 14, 2535–2546. [Google Scholar] [CrossRef] [Green Version]

- Rivlin, R.S.; Thomas, A.G. Rupture of rubber. I. Characteristic energy for tearing. J. Polym. Sci. 1953, 10, 291–318. [Google Scholar] [CrossRef]

- Wegst, U.G.K.; Ashby, M.F. The mechanical efficiency of natural materials. Phil. Mag. 2004, 84, 2167–2186. [Google Scholar] [CrossRef]

- Sun, J.Y.; Zhao, X.; Illeperuma, W.R.; Chaudhuri, O.; Oh, K.H.; Mooney, D.J.; Vlassak, J.J.; Suo, Z. Highly stretchable and tough hydrogels. Nature 2012, 489, 133–136. [Google Scholar] [CrossRef] [PubMed]

- Drury, J.L.; Dennis, R.G.; Mooney, D.J. The tensile properties of alginate hydrogels. Biomaterials 2004, 25, 3187–3199. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.H.; Wang, M.X.; Haider, H.; Yang, J.H.; Sun, J.Y.; Chen, Y.M.; Zhou, J.; Suo, Z. Strengthening alginate/polyacrylamide hydrogels using various multivalent cations. ACS Appl. Mater. Interfaces. 2013, 5, 10418–10422. [Google Scholar] [CrossRef]

- Li, J.; Illeperuma, W.R.; Suo, Z.; Vlassak, J.J. Hybrid hydrogels with extremely high stiffness and toughness. ACS Macro Lett. 2014, 3, 520–523. [Google Scholar] [CrossRef]

- Sun, T.L.; Luo, F.; Kurokawa, T.; Karobi, S.N.; Nakajima, T.; Gong, J.P. Molecular structure of self-healing polyampholyte hydrogels analyzed from tensile behaviors. Soft Matter 2015, 11, 9355–9366. [Google Scholar] [CrossRef] [PubMed]

| Sample Code | Chain Extension for PBS a) | Pre-Stretching b) | |||||

|---|---|---|---|---|---|---|---|

| PBS | ADR9 | BOZ | λpre | λfix | ε (%) | L0 (mm) | |

| Virgin PBS | 100 | 0 | 0 | 1.2 | 1 | 120 | 20 |

| PBSA0.4 | 99.6 | 0.4 | 0 | 3.2 | 3 | 320 | 20 |

| PBS A0.6 | 99.4 | 0.6 | 0 | 5.3 | 5 | 530 | 20 |

| PBS A0.6B0.6 | 98.8 | 0.6 | 0.6 | 7.5 | 7 | 750 | 20 |

| PBS A0.6B0.8 | 98.6 | 0.6 | 0.8 | 9.8 | 9 | 980 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Xia, M.; Dong, X.; Long, R.; Liu, Y.; Huang, Y.; Long, S.; Hu, C.; Li, X. High Mechanical Properties of Stretching Oriented Poly(butylene succinate) with Two-Step Chain Extension. Polymers 2022, 14, 1876. https://doi.org/10.3390/polym14091876

Li X, Xia M, Dong X, Long R, Liu Y, Huang Y, Long S, Hu C, Li X. High Mechanical Properties of Stretching Oriented Poly(butylene succinate) with Two-Step Chain Extension. Polymers. 2022; 14(9):1876. https://doi.org/10.3390/polym14091876

Chicago/Turabian StyleLi, Xun, Min Xia, Xin Dong, Ren Long, Yuanhao Liu, Yiwan Huang, Shijun Long, Chuanqun Hu, and Xuefeng Li. 2022. "High Mechanical Properties of Stretching Oriented Poly(butylene succinate) with Two-Step Chain Extension" Polymers 14, no. 9: 1876. https://doi.org/10.3390/polym14091876