Dielectric Characteristics of Crosslinked Polyethylene Modified by Grafting Polar-Group Molecules

Abstract

:1. Introduction

2. Experimental and Theoretical Methods

2.1. Material Preparation

2.2. Characterization and Test

2.3. Molecular Simulation

3. Results and Discussion

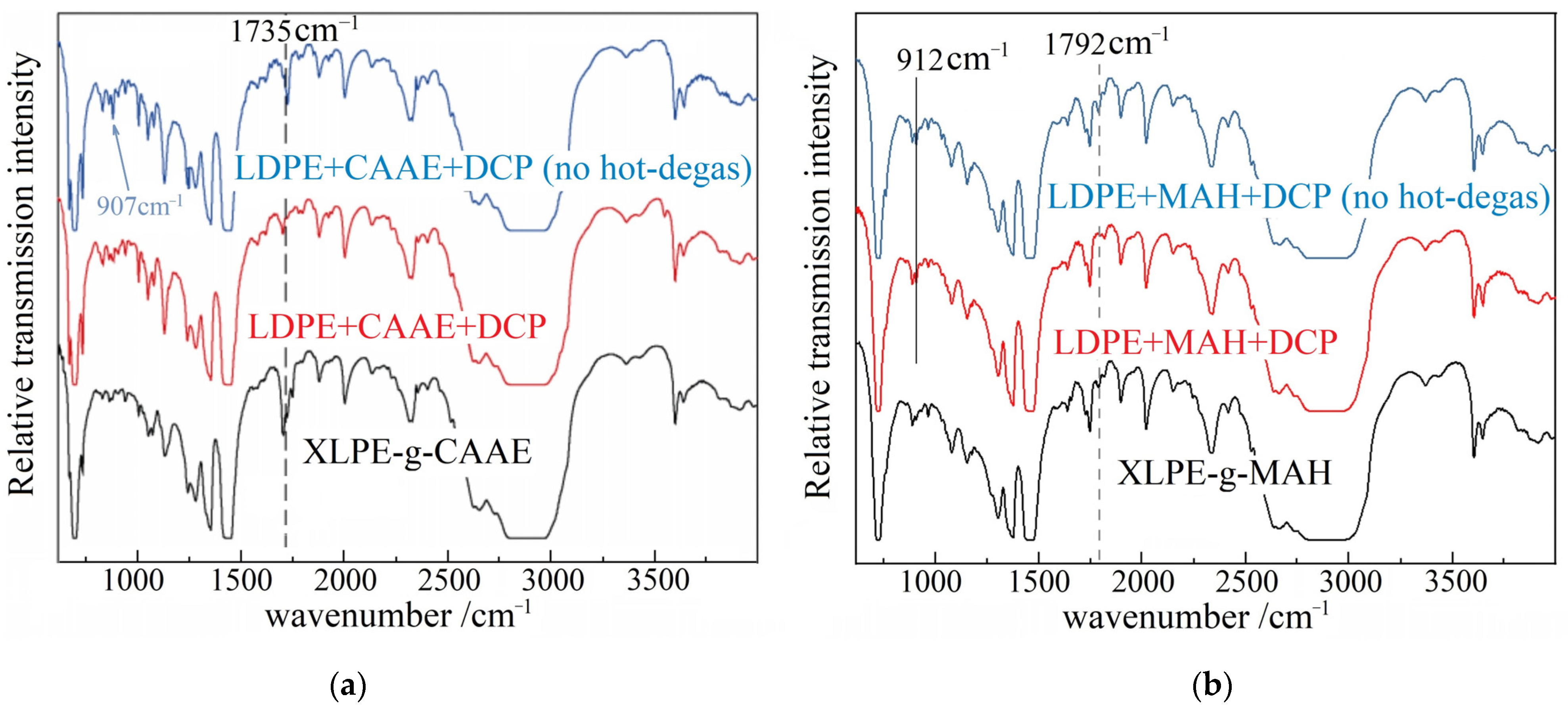

3.1. Infrared Spectroscopy

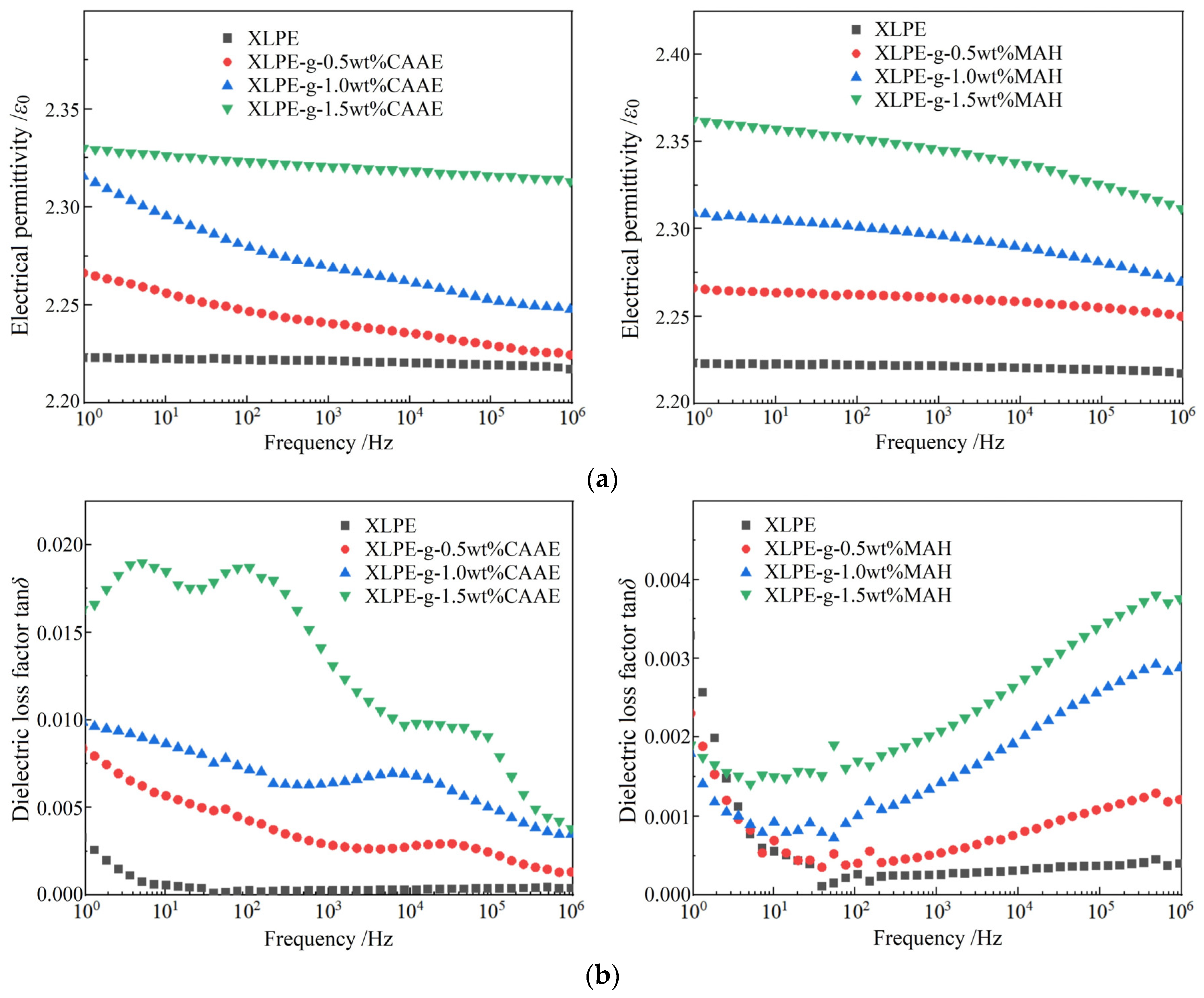

3.2. Dielectric Frequency Spectra

3.3. Dielectric Breakdown Strength

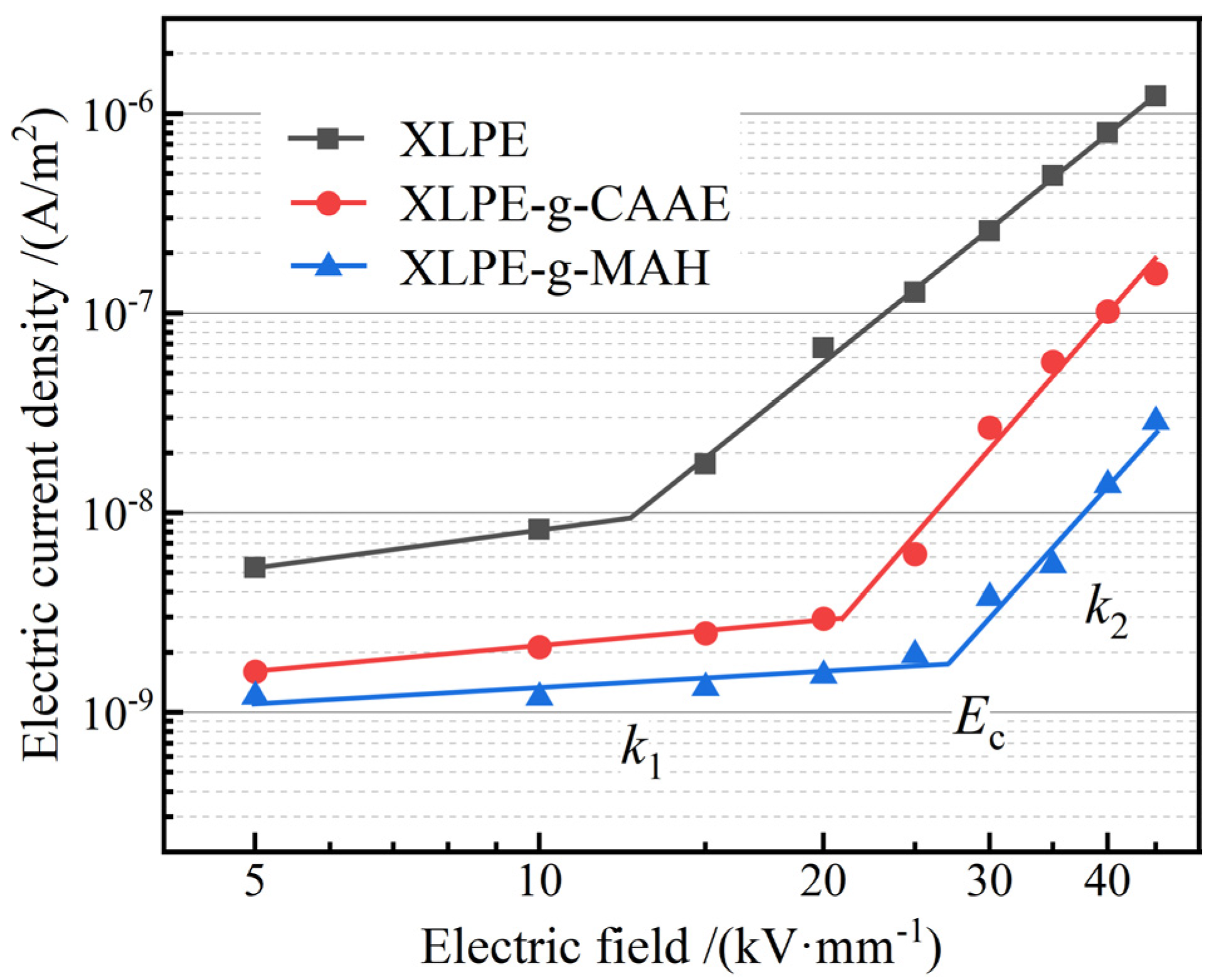

3.4. Electric Conductivity

3.5. Charge Trap Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, J.; Peng, L.; Zhou, Y. Research progress of environment-friendly HVDC power cable insulation materials. High Volt. Eng. 2017, 43, 337–343. [Google Scholar]

- Alassi, A.; Bañales, S.; Ellabban, O.; Adam, G.; MacIver, C. HVDC Transmission: Technology Review, Market Trends and Future Outlook. Renew. Sustain. Energy Rev. 2019, 112, 530–554. [Google Scholar] [CrossRef]

- Chen, G.; Hao, M.; Xu, Z.Q.; Vaughan, A.; Cao, J.Z.; Wang, H.T. Review of High Voltage Direct Current Cables. CSEE J. Power Energy Syst. 2015, 1, 9–21. [Google Scholar] [CrossRef]

- Teyssedre, G.; Laurent, C. Advances in high-field insulating polymeric materials over the past 50 years. IEEE Electr. Insul. Mag. 2018, 29, 26–36. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, J.; Liu, R.; Chen, Z. Key technical analysis and prospect of high voltage and extra-high voltage power cable. High Volt. Eng. 2014, 40, 2593–2612. [Google Scholar]

- Pleşa, I.; Noţingher, P.V.; Schlögl, S.; Sumereder, C.; Muhr, M. Properties of Polymer Composites Used in High-Voltage Applications. Polymers 2016, 8, 173. [Google Scholar] [CrossRef]

- Montanari, G.C. Bringing an Insulation to Failure: The Role of Space Charge. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 339–364. [Google Scholar] [CrossRef]

- Ohki, Y. Development of XLPE-insulated cable for high-voltage dc ubmarine transmission line. IEEE Electr. Insul. Mag. 2013, 29, 65–67. [Google Scholar] [CrossRef]

- Mazzanti, G.; Chen, G.; Fothergill, J.C.; Hozumi, N.; Li, J.; Marzinotto, M.; Mauseth, F.; Morshuis, P.; Reed, C.; Tzimas, A.; et al. A Protocol for Space Charge Measurements in Full-size HVDC Extruded Cables. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 21–34. [Google Scholar] [CrossRef] [Green Version]

- Kubota, T.; Takahashi, Y.; Sakuma, S.; Watanabe, M.; Kanaoka, M.; Yamanouchi, H. Development of 500-kV XLPE cables and accessories for long distance underground transmission line—Part I: Insulation design of cables. IEEE Trans. Power Deliv. 1994, 9, 1741–1749. [Google Scholar] [CrossRef]

- Kubota, T.; Takahashi, Y.; Hasegawa, T.; Noda, H.; Yamaguchi, M.; Tan, M. Development of 500-kV XLPE cables and accessories for long distance underground transmission lines—Part II: Jointing techniques. IEEE Trans. Power Deliv. 1994, 9, 1750–1759. [Google Scholar] [CrossRef]

- Fukawa, N.; Kawai, T.; Okano, Y.; Sakuma, S.; Asai, S.; Kanaoka, M.; Yamanouchi, H. Development of 500-kV XLPE cables and accessories for long distance underground transmission line. III. Electrical properties of 500-kV cables. IEEE Trans. Power Deliv. 1996, 11, 627–634. [Google Scholar] [CrossRef]

- Takeda, N.; Izumi, S.; Asari, K.; Nakatani, A.; Noda, H.; Yamaguchi, M.; Tan, M. Development of 500-kV XLPE cables and accessories for long-distance underground transmission lines. IV. Electrical properties of 500-kV extrusion molded joints. IEEE Trans. Power Deliv. 1996, 11, 635–643. [Google Scholar] [CrossRef]

- Kaminaga, K.; Ichihara, M.; Jinno, M.; Fujii, O.; Fukunaga, S.; Kobayashi, M.; Watanabe, K. Development of 500-kV XLPE cables and accessories for long-distance underground transmission lines. V. Long-term performance for 500-kV XLPE cables and joints. IEEE Trans. Power Deliv. 1996, 11, 1185–1194. [Google Scholar] [CrossRef]

- Lau, K.; Vaughan, A.; Chen, G.; Hosier, I.; Holt, A.; Ching, K. On the space charge and DC breakdown behavior of polyethylene/silica nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 340–351. [Google Scholar] [CrossRef]

- Sharad, P.A.; Kumar, K.S. Application of surface-modified XLPE nanocomposites for electrical insulation partial discharge and morphological study. Nanocomposites 2017, 3, 30–41. [Google Scholar] [CrossRef] [Green Version]

- Sharad, P.A.; Kumar, K.S.; Ahmad, M.H.; Piah, M.A. Space charge and conductivity measurement of XLPE nanocomposites for HVDC insulation–permittivity as a nanofiller selection parameter. IET Sci. Meas. Technol. 2018, 12, 1058–1065. [Google Scholar] [CrossRef]

- Chen, Q.G.; Xi, B.G.; Zhang, J.F.; Wang, X.Y.; Yang, H.D. Dielectric and space charge characteristics of nano-modified liquid silicone rubber for high-voltage DC cable accessories. J. Mater. Sci. Mater. Electron. 2020, 31, 16819–16829. [Google Scholar] [CrossRef]

- Li, G.C.; Zhou, X.G.; Li, X.J.; Wei, Y.H.; Hao, C.C.; Li, S.T.; Lei, Q.Q. DC breakdown characteristics of XLPE/BNNS nanocomposites considering BN nanosheet concentration, space charge and temperature. High Volt. 2020, 5, 280–286. [Google Scholar] [CrossRef]

- Pourrahimi, A.M.; Olsson, R.T.; Hedenqvist, M.S. The Role of Interfaces in Polyethylene/Metal-Oxide Nanocomposites for Ultrahigh-Voltage Insulating Materials. Adv. Mater. 2018, 30, 1703624. [Google Scholar] [CrossRef]

- Sun, W.F.; Wang, X. Molecular dynamics simulation study of polyimide/copper-nanoparticle composites. Acta Phys. Sin. 2013, 62, 186202. [Google Scholar]

- Gao, J.G.; Zhao, H.; Sun, W.F. Molecular Dynamics Simulation Study of Parallel Orientation Structure and Gas Transport in Graphite-Nanoplatelet/Polyethylene Composites. Mater. Today Commun. 2017, 13, 57–64. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Yu, P.L.; Sun, W.F.; Wang, X. Ameliorated Electrical-Tree Resistant Characteristics of UV-Initiated Cross-Linked Polyethylene Nanocomposites with Surface-Functionalized Nanosilica. Processes 2021, 9, 313. [Google Scholar] [CrossRef]

- Green, C.D.; Vaughan, A.S.; Stevens, G.C.; Sutton, S.J.; Geussens, T.; Fairhurst, M.J. Recyclable power cable comprising a blend of slow-crystallized polyethylenes. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1–9. [Google Scholar] [CrossRef]

- Li, L.; Zhong, L.; Zhang, K.; Gao, J.; Xu, M. Temperature Dependence of Mechanical, Electrical Properties and Crystal Structure of Polyethylene Blends for Cable Insulation. Materials 2018, 11, 1922. [Google Scholar] [CrossRef] [Green Version]

- Hosier, I.L.; Vaughan, A.S.; Swingler, S.G. An investigation of the potential of ethylene vinyl acetate/polyethylene blends for use in recyclable high voltage cable insulation systems. J. Mater. Sci. 2010, 45, 2747–2759. [Google Scholar] [CrossRef]

- Suh, K.S.; Kim, J.Y.; Lee, C.R.; Takada, T. Charge distribution in polyethylene/ethylene vinylacetate laminates and blends. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 201–206. [Google Scholar] [CrossRef]

- Wang, X.; He, H.Q.; Tu, D.M.; Lei, C.; Du, Q.G. Dielectric Properties and Crystalline Morphology of Low Density Polyethylene Blended with Metallocene Catalyzed Polyethylene. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 319–326. [Google Scholar] [CrossRef]

- Zhao, X.D.; Sun, W.F.; Zhao, H. Enhanced Insulation Performances of Crosslinked Polyethylene Modified by Chemically Grafting Chloroacetic Acid Allyl Ester. Polymers 2019, 11, 592. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Xi, C.; Zhao, X.D.; Sun, W.-F. Elevated-Temperature Space Charge Characteristics and Trapping Mechanism of Cross-Linked Polyethylene Modified by UV-Initiated Grafting MAH. Molecules 2020, 25, 3973. [Google Scholar] [CrossRef]

- Fu, Y.W.; Zhang, Y.Q.; Sun, W.F.; Wang, X. Functionalization of Silica Nanoparticles to Improve Crosslinking Degree, Insulation Performance and Space Charge Characteristics of UV-initiated XLPE. Molecules 2020, 25, 3794. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.Q.; Wang, X.; Sun, W.F.; Zhao, H. Water-Tree Resistability of UV-XLPE from Hydrophilicity of Auxiliary Crosslinkers. Molecules 2020, 25, 4147. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.X.; Pan, Y.C.; Sun, W.F. Water-Tree Characteristics and Its Mechanical Mechanism of Crosslinked Polyethylene Grafted with Polar-Group Molecules. Int. J. Mol. Sci. 2022, 23, 9450. [Google Scholar] [CrossRef] [PubMed]

- Dong, W.; Wang, X.; Tian, B.; Liu, Y.; Jiang, Z.; Li, Z.; Zhou, W. Use of Grafted Voltage Stabilizer to Enhance Dielectric Strength of Cross-Linked Polyethylene. Polymers 2019, 11, 176. [Google Scholar] [CrossRef]

- Li, C.Y.; Zhao, H.; Han, B.Z.; Zhang, H.; Zhang, C.C.; Ai, Y. Effect of Voltage Stabilizer on the DC Insulation Properties of XLPE. Proc. Chin. Soc. Electr. Eng. 2018, 38, 7071–7079. [Google Scholar]

- Zhao, X.D.; Zhao, H.; Sun, W.F. Significantly Improved Electrical Properties of Crosslinked Polyethylene Modified by UV-Initiated Grafting MAH. Polymers 2020, 12, 62. [Google Scholar] [CrossRef] [Green Version]

- Rigby, D.; Roe, R.J. Molecular Dynamics Simulation of Polymer Liquid and Glass. II. Short Range Order and Orientation Correlation. J. Chem. Phys. 1988, 89, 5280. [Google Scholar] [CrossRef]

- Yang, J.M.; Wang, X.; Han, B.Z.; Zhao, H. DC conductivity characteristic of LDPE nanocomposite and its effect on electric field distribution in HVDC cables. Proc. Chin. Soc. Electr. Eng. 2014, 34, 1454–1461. [Google Scholar]

- Tian, F.Q.; Bu, W.B.; Shi, L.S.; Yang, C.; Wang, Y.; Lei, Q.Q. Theory of modified thermally stimulated current and direct determination of trap level distribution. J. Electrost. 2011, 69, 7–10. [Google Scholar] [CrossRef]

| Material | Eb /(kV/mm) | β | Material | Eb /(kV/mm) | β |

|---|---|---|---|---|---|

| XLPE | 122.3 | 12.30 | |||

| XLPE-g-0.5wt%CAAE | 126.0 | 11.54 | XLPE-g-0.5wt%MAH | 134.7 | 15.24 |

| XLPE-g-1.0wt%CAAE | 142.8 | 17.62 | XLPE-g-1.0wt%MAH | 139.6 | 19.50 |

| XLPE-g-1.5wt%CAAE | 131.6 | 14.61 | XLPE-g-1.5wt%MAH | 135.4 | 29.17 |

| Material | Ec /(kV/mm) | k1 | k2 |

|---|---|---|---|

| XLPE | 12.54 | 0.64 | 3.80 |

| XLPE-g-CAAE | 21.15 | 0.43 | 5.41 |

| XLPE-g-MAH | 27.14 | 0.27 | 5.15 |

| Molecular Model | Band-gap /eV | Electron Trap Level /eV |

|---|---|---|

| PE-g-CAAE | 8.24 | 1.18, 2.13 |

| PE-g-MAH | 8.05 | 2.31, 2.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, J.-G.; Liu, L.-W.; Sun, W.-F. Dielectric Characteristics of Crosslinked Polyethylene Modified by Grafting Polar-Group Molecules. Polymers 2023, 15, 231. https://doi.org/10.3390/polym15010231

Gao J-G, Liu L-W, Sun W-F. Dielectric Characteristics of Crosslinked Polyethylene Modified by Grafting Polar-Group Molecules. Polymers. 2023; 15(1):231. https://doi.org/10.3390/polym15010231

Chicago/Turabian StyleGao, Jun-Guo, Li-Wei Liu, and Wei-Feng Sun. 2023. "Dielectric Characteristics of Crosslinked Polyethylene Modified by Grafting Polar-Group Molecules" Polymers 15, no. 1: 231. https://doi.org/10.3390/polym15010231

APA StyleGao, J.-G., Liu, L.-W., & Sun, W.-F. (2023). Dielectric Characteristics of Crosslinked Polyethylene Modified by Grafting Polar-Group Molecules. Polymers, 15(1), 231. https://doi.org/10.3390/polym15010231