Catalytic Pyrolysis of PET Polymer Using Nonisothermal Thermogravimetric Analysis Data: Kinetics and Artificial Neural Networks Studies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Catalytic Thermal Decomposition of PET

2.3. Kinetic Theory

2.4. Topology of ANNs

3. Results and Discussion

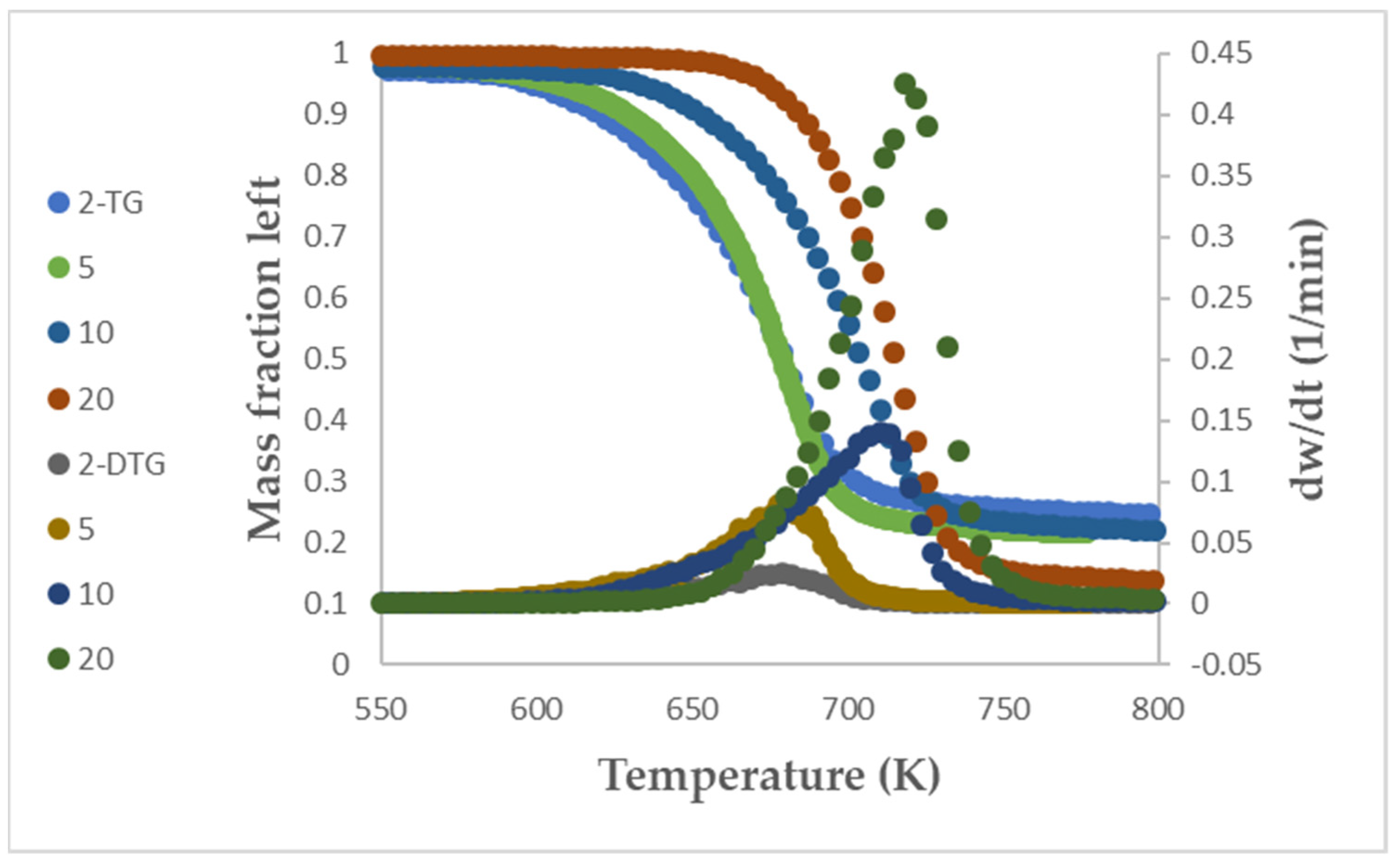

3.1. TG–DTG Analysis of PET

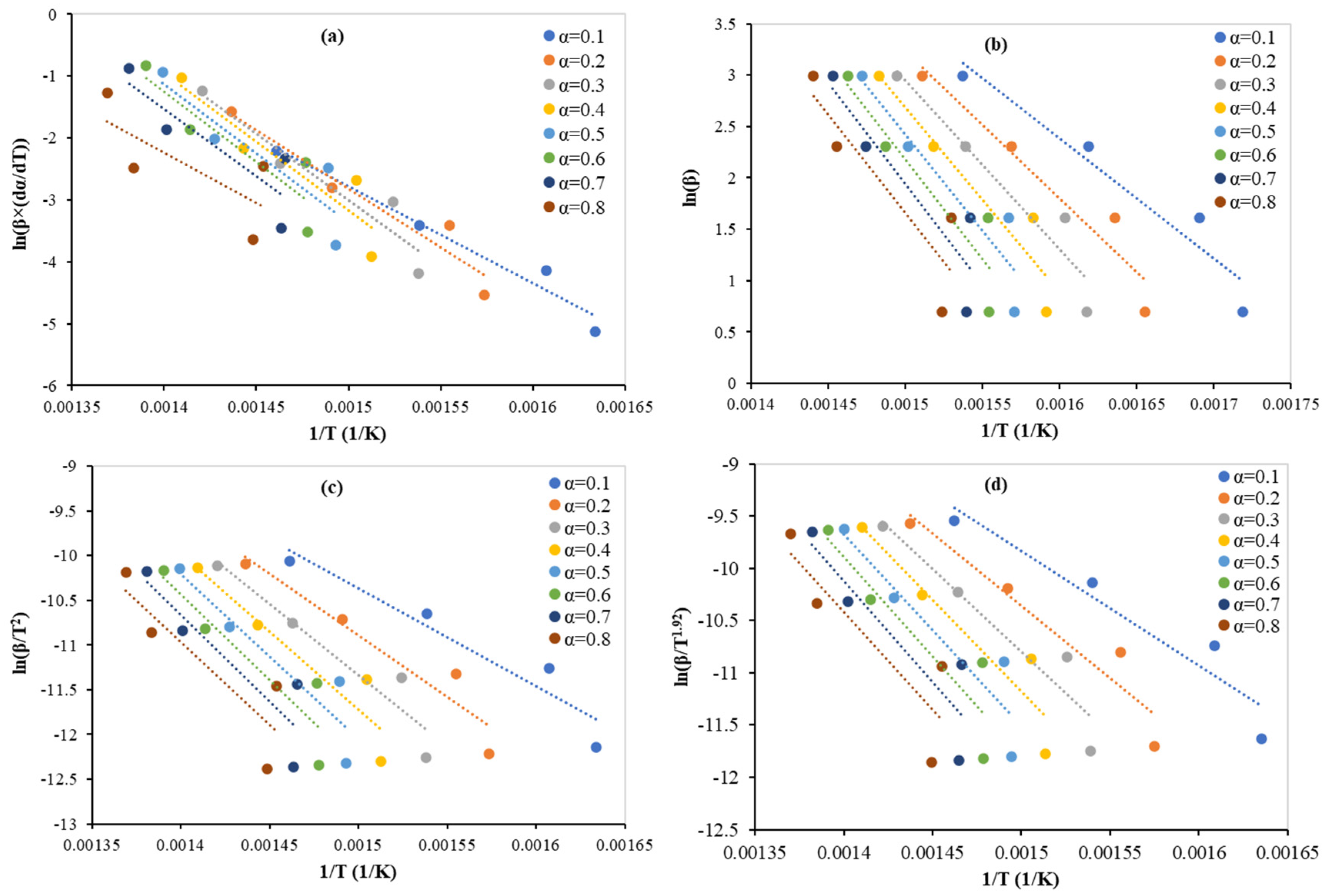

3.2. Model-Free Kinetics Calculation

3.3. Model-Fitting Kinetics Calculation

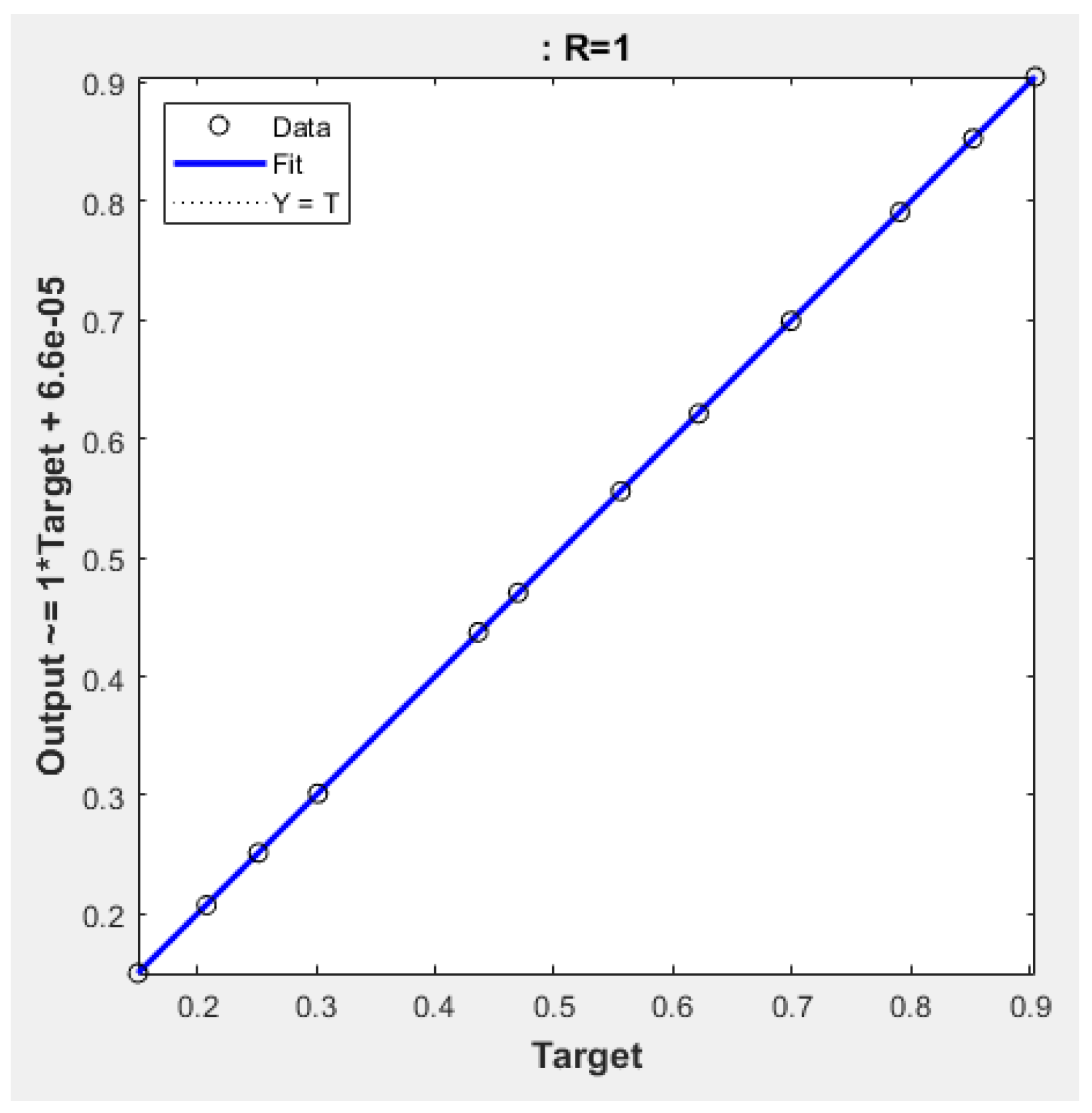

3.4. Catalytic Pyrolysis Prediction by ANN Model

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Dubdub, I.; Al-Yaari, M. Pyrolysis of Low Density Polyethylene: Kinetic Study using TGA Data and ANN Prediction. Polymers 2020, 12, 891. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martín-Gullón, I.; Esperanza, M.; Font, R. Kinetic model for the pyrolysis and combustion of poly-(ethylene terephthalate) (PET). J. Anal. Appl. Pyrolysis 2001, 58–59, 635–650. [Google Scholar] [CrossRef]

- Diaz-Silvarrey, L.S.; McMahon, A.; Phan, A.N. Benzoic acid recovery via waste poly(ethylene terephthalate) (PET) catalytic pyrolysis using sulphated zirconia catalyst. J. Anal. Appl. Pyrolysis 2018, 134, 621–631. [Google Scholar] [CrossRef] [Green Version]

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A review on thermal and catalytic pyrolysis of plastic solid waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef] [PubMed]

- Das, P.; Tiwari, P. Thermal degradation study of waste polyethylene terephthalate (PET) under inert and oxidative environments. Thermochim. Acta 2019, 679, 178340. [Google Scholar] [CrossRef]

- Yang, J.; Miranda, R.; Roy, C. Using the DTG curve fitting method to determine the apparent kinetic parameters of thermal decomposition of polymers. Polym. Degrad. Stab. 2001, 73, 455–461. [Google Scholar] [CrossRef]

- Girija, B.G.; Sailaja, R.R.N.; Madras, G. Thermal degradation and mechanical properties of PET blends. Polym. Degrad. Stab. 2005, 90, 147–153. [Google Scholar] [CrossRef]

- Saha, B.; Ghoshal, A.K. Thermal degradation kinetics of poly (ethylene terephthalate) from waste soft drinks bottles. Chem. Eng. J. 2005, 111, 39–43. [Google Scholar] [CrossRef]

- Aguado, J.; Serrano, D.P.; San Miguel, G.; Castro, M.C.; Madrid, S. Feedstock recycling of polyethylene in a two-step thermo-catalytic reaction system. J. Anal. Appl. Pyrolysis 2007, 79, 415–423. [Google Scholar] [CrossRef]

- Moltó, J.; Font, R.; Conesa, J.A. Kinetic model of the decomposition of a PET fibre cloth in an inert and air environment. J. Anal. Appl. Pyrolysis 2007, 79, 289–296. [Google Scholar] [CrossRef]

- Halász, J.; Vőneki, K.; Krajkó, J. Degradation OF Pure and Waste PVC and PET in the Presence of Modified Porous Catalysts. J. Eng. Ann. Fac. Eng. Hunedoara 2009, 174, 1021–1026. [Google Scholar]

- Çepelioğullar, Ö.; Pütün, A. Thermal and kinetic behaviors of biomass and plastic wastes in co-pyrolysis. Energy Convers. Manag. 2013, 75, 263–270. [Google Scholar] [CrossRef]

- Lee, H.W.; Kim, Y.; Lee, B.; Kim, S.; Jae, J.; Jung, S.; Kim, T.; Park, Y. Catalytic copyrolysis of torrefied cork oak and high density polyethylene over a mesoporous HY catalyst. Catal. Today 2018, 307, 301–307. [Google Scholar] [CrossRef]

- Diaz Silvarrey, L.S.; Phan, A.N. Kinetic study of municipal plastic waste. Int. J. Hydrogen Energy 2016, 41, 16352–16364. [Google Scholar] [CrossRef] [Green Version]

- Xiang, Z.; Liang, J.; Morgan, H.M.J.; Liu, Y.; Mao, H.; Bu, Q. Thermal behavior and kinetic study for co-pyrolysis of lignocellulosic biomass with polyethylene over Cobalt modified ZSM-5 catalyst by thermogravimetric analysis. Bioresour. Technol. 2018, 247, 804–811. [Google Scholar] [CrossRef]

- Osman, A.I.; Farrell, C.; Al-Muhtaseb, A.H.; Al-Fatesh, A.S.; Harrison, J.; Rooney, D.W. Pyrolysis kinetic modelling of abundant plastic waste (PET) and in-situ emission monitoring. Environ. Sci. Eur. 2020, 32, 112. [Google Scholar] [CrossRef]

- Ali, G.; Nisar, J.; MIqbal, M.; Shah, A.; Abbas, M.; Shah, M.R.; Rashid, U.; Bhatti, I.A.; Khan, R.A.; Shah, F. Thermo-catalytic decomposition of polystyrene waste: Comparative analysis using different kinetic models. Waste Manag. Res. 2020, 38, 202–212. [Google Scholar] [CrossRef]

- Lai, J.; Meng, Y.; Yan, Y.; Lester, E.; Wu, T.; Pang, C.H. Catalytic pyrolysis of linear low-density polyethylene using recycled coal ash: Kinetic study and environmental evaluation. Korean J. Chem. Eng. 2021, 38, 2235–2246. [Google Scholar] [CrossRef]

- Yap, T.L.; Loy, A.C.M.; Chin, B.L.F.; Lim, J.Y.; Alhamzi, H.; Chai, Y.H.; Yiin, C.L.; Cheah, K.W.; Wee, M.X.J.; Lam, M.K.; et al. Synergistic effects of catalytic co-pyrolysis Chlorella vulgaris and polyethylene mixtures using artificial neuron network: Thermodynamic and empirical kinetic analyses. J. Environ. Chem. Eng. 2022, 10, 107391. [Google Scholar] [CrossRef]

- Kokuryo, S.; Miyake, K.; Uchida, Y.; Mizusawa, A.; Kubo, T.; Nishiyama, N. Defect engineering to boost catalytic activity of Beta zeolite on low density polyethylene cracking. Mater. Today Sustain. 2022, 17, 100098. [Google Scholar] [CrossRef]

- Dourari, M.; Tarchoun, A.F.; Trache, D.; Abdelaziz, A.; Bekhouche, S.; Harrat, A.; Boukeciat, H.; Matmat, N. Unraveling the Effect of MgAl/CuO Nanothermite on the Characteristics and Thermo-Catalytic Decomposition of Nanoenergetic Formulation Based on Nanostructured Nitrocellulose and Hydrazinium Nitro-Triazolone. Catalysts 2022, 12, 1573. [Google Scholar] [CrossRef]

- Tarchoun, A.F.; Trache, D.; Abdelaziz, A.; Harrat, A.; Boukecha, W.O.; Hamouche, M.A.; Boukeciat, H.; Dourari, M. Elaboration, Characterization and Thermal Decomposition Kinetics of New Nanoenergetic Composite Based on Hydrazine 3-Nitro-1,2,4-triazol-5-one and Nanostructured Cellulose Nitrate. Molecules 2022, 27, 6945. [Google Scholar] [CrossRef] [PubMed]

- Dubdub, I.; Al-Yaari, M. Thermal Behavior of Mixed Plastics at Different Heating Rates: I. Pyrolysis Kinetics. Polymers 2021, 13, 3413. [Google Scholar] [CrossRef] [PubMed]

- Chan, J.H.; Balke, S.T. The thermal degradation kinetics of polypropylene: Part III. thermogravimetric analyses. Polym. Degrad. Stabil. 1997, 57, 135–149. [Google Scholar] [CrossRef]

- Xu, F.; Wang, B.; Yang, D.; Hao, J.; Qiao, Y.; Tian, Y. Thermal degradation of typical plastics under high heating rate conditions by TG-FTIR: Pyrolysis behaviors and kinetic analysis. Energy Convers. Manag. 2018, 171, 1106–1115. [Google Scholar] [CrossRef]

- Dubdub, I.; Al-Yaari, M. Pyrolysis of Mixed Waste Polymers: I: Kinetics Study. Materials 2020, 13, 4912. [Google Scholar] [CrossRef]

- Muravyev, N.V.; Luciano, G.; Ornaghi, H.L.J.; Svoboda, R.; Vyazovkin, S. Artificial Neural Networks for Pyrolysis, Thermal Analysis, and Thermokinetic Studies: The Status Quo. Molecules 2021, 26, 3727. [Google Scholar] [CrossRef]

- Quantrille, T.E.; Liu, Y.A. Artificial Intelligence in Chemical Engineering; Elsevier Science: Amsterdam, The Netherlands, 1992. [Google Scholar]

- Al-Yaari, M.; Dubdub, I. Application of Artificial Neural Networks to Predict the Catalytic Pyrolysis of HDPE Using Non-Isothermal TGA Data. Polymers 2020, 12, 1813. [Google Scholar] [CrossRef]

- Dubdub, I.; Al-Yaari, M. Pyrolysis of High Density Polyethylene: II. Artificial Neural Networks Modeling. In Proceedings of the 9th Jordan International Chemical Engineering Conference (JICHEC9), Amman, Jordan, 12–14 October 2021. [Google Scholar]

- Dubdub, I.; Al-Yaari, M. Pyrolysis of Mixed Plastic Waste: II. Artificial Neural Networks Prediction and Sensitivity Analysis. Appl. Sci. 2021, 11, 8456. [Google Scholar] [CrossRef]

- Bar, N.; Bandyopadhyay, T.K.; Biswas, M.N.; Das, S.K. Prediction of pressure drop using artificial neural network for non-Newtonian liquid flow through piping components. J. Pet. Sci. Eng. 2010, 71, 187. [Google Scholar] [CrossRef]

- Osman, A.I.; Fawzy, S.; Farrell, C.; Al-Muhtaseb, A.H.; Harrison, J.; Al-Mawali, S.; Rooney, D.W. Comprehensive thermokinetic modelling and predictions of cellulose decomposition in isothermal, non-isothermal, and stepwise heating modes. J. Anal. Appl. Pyrolysis 2022, 161, 105427. [Google Scholar] [CrossRef]

- Farrell, C.; Osman, A.I.; Harrison, J.; Vennard, A.; Murphy, A.; Doherty, R.; Russell, M.; Kumaravel, V.; Al-Muhtaseb, A.H.; Zhang, X.; et al. Pyrolysis Kinetic Modeling of a Poly(ethylene-co-vinyl acetate) Encapsulant Found in Waste Photovoltaic Modules. Ind. Eng. Chem. Res. 2021, 60, 13492–13504. [Google Scholar] [CrossRef]

- Muravyev, N.V.; Vyazovkin, S. The Status of Pyrolysis Kinetics Studies by Thermal Analysis: Quality Is Not as Good as It Should and Can Readily Be. Thermo 2022, 2, 435–452. [Google Scholar] [CrossRef]

- Koga, N.; Vyazovkin, S.; Burnham, A.K.; Favergeon, L.; Muravyev, N.V.; Pérez-Maqueda, L.A.; Saggese, C.; Sánchez-Jiménez, P.E. ICTAC Kinetics Committee recommendations for analysis of thermal decomposition kinetics. Thermochim. Acta 2023, 719, 179384. [Google Scholar] [CrossRef]

- Osman, A.I.; Young, T.J.; Farrell, C.; Harrison, J.; Al-Muhtaseb, A.H.; Rooney, D.W. Physicochemical Characterization and Kinetic Modeling Concerning Combustion of Waste Berry Pomace. ACS Sustain. Chem. Eng. 2020, 8, 17573–17586. [Google Scholar] [CrossRef]

- Osman, A.I.; Abdelkader, A.; Johnston, C.R.; Morgan, K.; Rooney, D.W. Thermal Investigation and Kinetic Modeling of Lignocellulosic Biomass Combustion for Energy Production and Other Applications. Ind. Eng. Chem. Res. 2017, 56, 12119–12130. [Google Scholar] [CrossRef] [Green Version]

- Vyazovkin, S.; Wight, C.A. Model-free and model-fitting approaches to kinetic analysis of isothermal and nonisothermal data. Thermochim. Acta 1999, 340–341, 53–68. [Google Scholar] [CrossRef]

- Özsin, G.; Pütün, A.E. TGA/MS/FT-IR study for kinetic evaluation and evolved gas analysis of a biomass/PVC co-pyrolysis process. Energy Convers. Manag. 2019, 182, 143–153. [Google Scholar] [CrossRef]

- Al-Yaari, M.; Dubdub, I. Pyrolysis of High Density Polyethylene: I. Kinetic Study. In Proceedings of the 9th Jordan International Chemical Engineering Conference (JICHEC9), Amman, Jordan, 12–14 October 2021. [Google Scholar]

- Al-Yaari, M.; Dubdub, I. Pyrolytic Behavior of Polyvinyl Chloride: Kinetics, Mechanisms, Thermodynamics, and Artificial Neural Network Application. Polymers 2021, 13, 4359. [Google Scholar] [CrossRef]

- Al-Wahaibi, T.; Mjalli, F.S. Prediction of Horizontal Oil-Water Flow Pressure Gradient Using Artificial Intelligence Techniques. Chem. Eng. Commun. 2014, 201, 209. [Google Scholar] [CrossRef]

- Osman, E.A.; Aggour, M.A. Artificial Neural Network Model for Accurate Prediction of Pressure Drop in Horizontal and Near-Horizontal-Multiphase Flow. Pet. Sci. Technol. 2002, 20, 1–15. [Google Scholar] [CrossRef]

- Qinghua, W.; Honglan, Z.; Wei, L.; Junzheng, Y.; Xiaohong, W.; Yan, W. Experimental Study of Horizontal Gas-liquid Two-phase Flow in Two Medium-diameter Pipes and Prediction of Pressure Drop through BP Neural Networks. Int. J. Fluid Mach. Syst. 2018, 11, 255–264. [Google Scholar] [CrossRef]

- Beale, M.; Hagan, T.; Demuth, H.B. Neural Network Toolbox TM User’s Guide; MathWorks: Natick, MA, USA, 2018. [Google Scholar]

| Plastic | Proximate Analysis, wt% | Ultimate Analysis, wt% | |||||

|---|---|---|---|---|---|---|---|

| Moisture | Volatile | Ash | C | H | N | O | |

| PET | 0.523 | 88.231 | 11.246 | 64.256 | 4.367 | 0 | 31.377 |

| S.A. m2/g | SiO2:Al2O3 | Pore Volume 1.7–300 nm, m2/g |

|---|---|---|

| 680 | 25:1 | 0.127 |

| Heating Rate K/min | Main Reaction (Catalytic Cracking) | Pyrolysis of Pure PET | References | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Onset (K) | Peak (K) | Final (K) | Mass Loss (%) | Onset (K) | Peak (K) | Final (K) | Mass Loss (%) | ||

| 2 | 575 | 675 | 700 | 70 | 623 | 667 | 694 | 100 | Osman et al. (2020) [16] |

| 5 | 600 | 685 | 710 | 75 | 658 | 700 | 723 | 80 | Das and Tiwari (2019) [5] |

| 10 | 625 | 710 | 740 | 78 | 671 (643) | 711 (714) | 748 (775) | 80 | Das and Tiwari (2019) [5], Yang et al. (2001) [6] |

| 20 | 650 | 720 | 750 | 85 | 681 | 721 | 759 | 80 | Das and Tiwari (2019) [5] |

| Conversion | Friedman | FWO | KAS | Starnik | ||||

|---|---|---|---|---|---|---|---|---|

| E (kJ/mol) | R2 | E (kJ/mol) | R2 | E (kJ/mol) | R2 | E (kJ/mol) | R2 | |

| 0.1 | 130 | 0.9621 | 97 | 0.9286 | 91 | 0.9116 | 92 | 0.9124 |

| 0.2 | 158 | 0.9271 | 119 | 0.9278 | 115 | 0.9142 | 115 | 0.9148 |

| 0.3 | 178 | 0.9065 | 137 | 0.9184 | 132 | 0.9052 | 133 | 0.9058 |

| 0.4 | 185 | 0.8493 | 149 | 0.898 | 145 | 0.8833 | 145 | 0.844 |

| 0.5 | 186 | 0.8041 | 156 | 0.8741 | 153 | 0.8573 | 153 | 0.8581 |

| 0.6 | 188 | 0.8034 | 162 | 0.8532 | 158 | 0.8347 | 159 | 0.8355 |

| 0.7 | 179 | 0.7574 | 164 | 0.8298 | 161 | 0.8092 | 161 | 0.8101 |

| 0.8 | 136 | 0.5434 | 158 | 0.7905 | 155 | 0.7654 | 155 | 0.7664 |

| Average | 167.5 | 0.8192 | 142.75 | 0.8775 | 138.75 | 0.8601 | 139.13 | 0.8559 |

| Heating Rate (K/min) | E (kJ/mol) | Mechanism |

|---|---|---|

| 2 | 146 | F1 (first-order chemical reaction) |

| 104 | R2 (two-dimensional phase interfacial reaction) | |

| 5 | 179 | F1 (first-order chemical reaction) |

| 141 | R2 (two-dimensional phase interfacial reaction) | |

| 10 | 139 | F1 (first-order chemical reaction) |

| 123 | R2 (two-dimensional phase interfacial reaction) | |

| 20 | 242 | F1 (first-order chemical reaction) |

| 115 | A2 (two-dimensional nucleation and growth reaction) | |

| 224 | R2 (two-dimensional phase interfacial reaction) |

| Heating Rate (K/min) | Training Set No. | Simulation set No. | ||

|---|---|---|---|---|

| Training | Validation | Test | ||

| 2 | 248 | 3 | ||

| 5 | 248 | 3 | ||

| 10 | 246 | 3 | ||

| 20 | 241 | 3 | ||

| Total | 983 | 12 | ||

| No. | Input Data | Output Data | |

|---|---|---|---|

| Heating Rate (K/min) | Temperature (K) | Remaining Weight (Fraction) | |

| 1 | 2 | 702.1 | 0.30153 |

| 2 | 2 | 682.2 | 0.46976 |

| 3 | 2 | 618.9 | 0.90445 |

| 4 | 5 | 704.8 | 0.25160 |

| 5 | 5 | 670.4 | 0.62158 |

| 6 | 5 | 641.3 | 0.85232 |

| 7 | 10 | 968.5 | 0.15028 |

| 8 | 10 | 687.2 | 0.69914 |

| 9 | 10 | 700.4 | 0.55610 |

| 10 | 20 | 718.6 | 0.43629 |

| 11 | 20 | 697.8 | 0.79087 |

| 12 | 20 | 732.4 | 0.20794 |

| Set | Statistical Parameters | |||

|---|---|---|---|---|

| R2 | RMSE | MAE | MBE | |

| Training | 1.000 | 1.820 × 10−4 | 9.800 × 10−5 | −4.505079 × 10−7 |

| Validation | 1.000 | 3.680 × 10−4 | 1.680 × 10−4 | −0.0000295 |

| Test | 1.000 | 2.580 × 10−4 | 1.390 × 10−4 | 8.015 × 10−6 |

| All | 1.000 | 2.310 × 10−4 | 1.140 × 10−4 | −0.00000353 |

| Set | Statistical Parameters | |||

|---|---|---|---|---|

| R2 | RMSE | MAE | MBE | |

| simulated | 1.000 | 3.903 × 10−4 | 2.843 × 10−4 | 6.360 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dubdub, I.; Alhulaybi, Z. Catalytic Pyrolysis of PET Polymer Using Nonisothermal Thermogravimetric Analysis Data: Kinetics and Artificial Neural Networks Studies. Polymers 2023, 15, 70. https://doi.org/10.3390/polym15010070

Dubdub I, Alhulaybi Z. Catalytic Pyrolysis of PET Polymer Using Nonisothermal Thermogravimetric Analysis Data: Kinetics and Artificial Neural Networks Studies. Polymers. 2023; 15(1):70. https://doi.org/10.3390/polym15010070

Chicago/Turabian StyleDubdub, Ibrahim, and Zaid Alhulaybi. 2023. "Catalytic Pyrolysis of PET Polymer Using Nonisothermal Thermogravimetric Analysis Data: Kinetics and Artificial Neural Networks Studies" Polymers 15, no. 1: 70. https://doi.org/10.3390/polym15010070

APA StyleDubdub, I., & Alhulaybi, Z. (2023). Catalytic Pyrolysis of PET Polymer Using Nonisothermal Thermogravimetric Analysis Data: Kinetics and Artificial Neural Networks Studies. Polymers, 15(1), 70. https://doi.org/10.3390/polym15010070