Generation of Controlled Micrometric Fibers inside Printed Scaffolds Using Standard FDM 3D Printers

Abstract

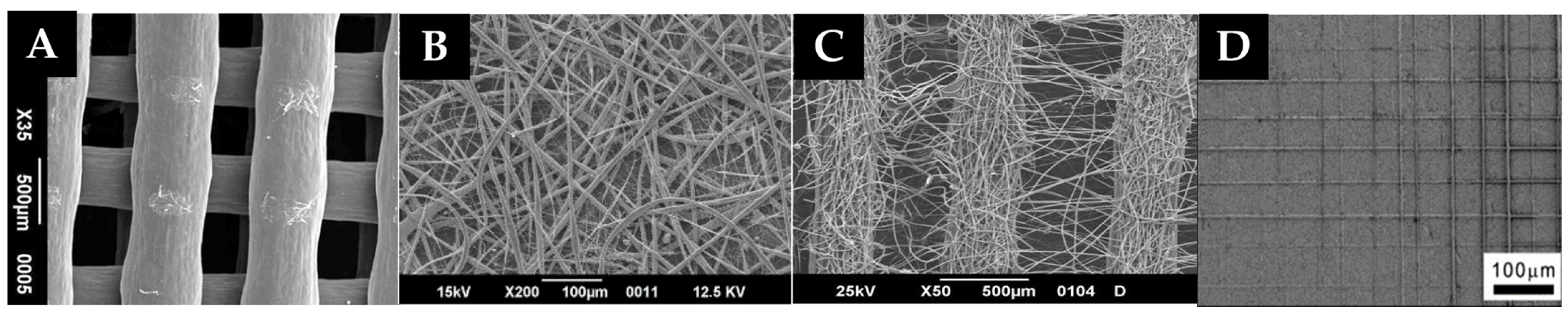

1. Introduction

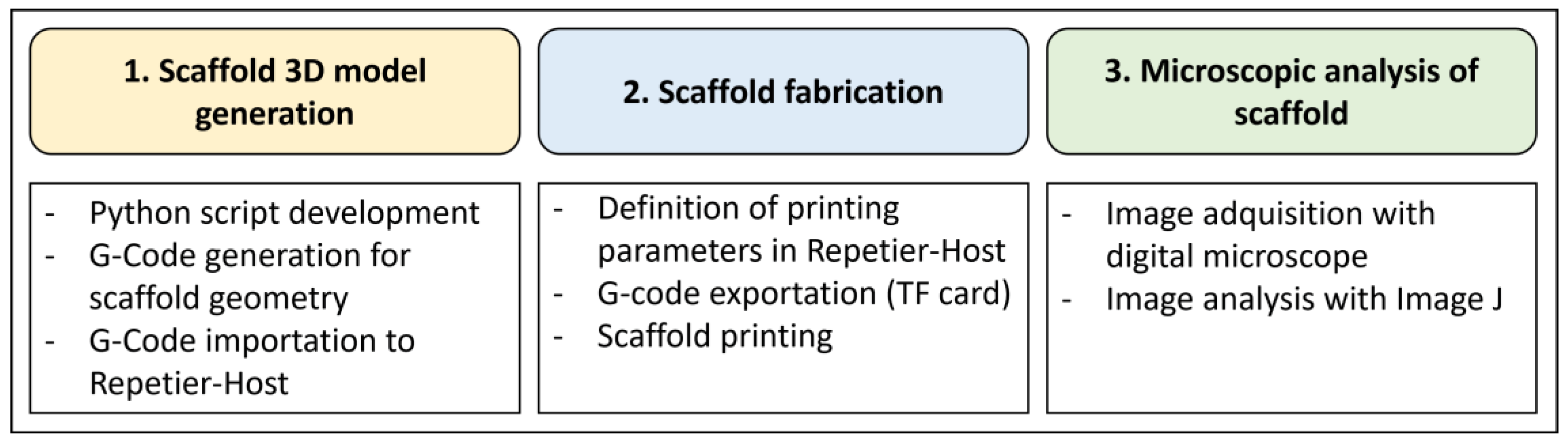

2. Materials and Methods

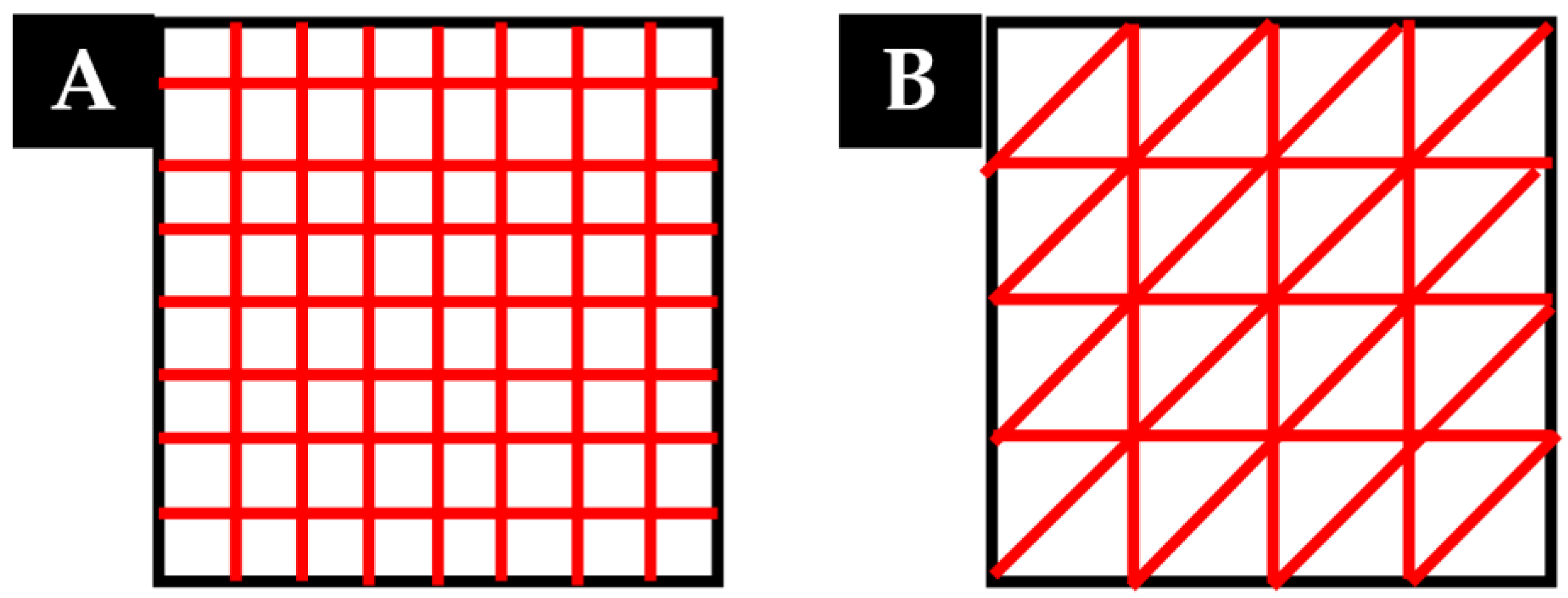

2.1. Scaffold 3D Model Generation

2.1.1. Creation of Scripts in Python Code for the Generation of the G-Code

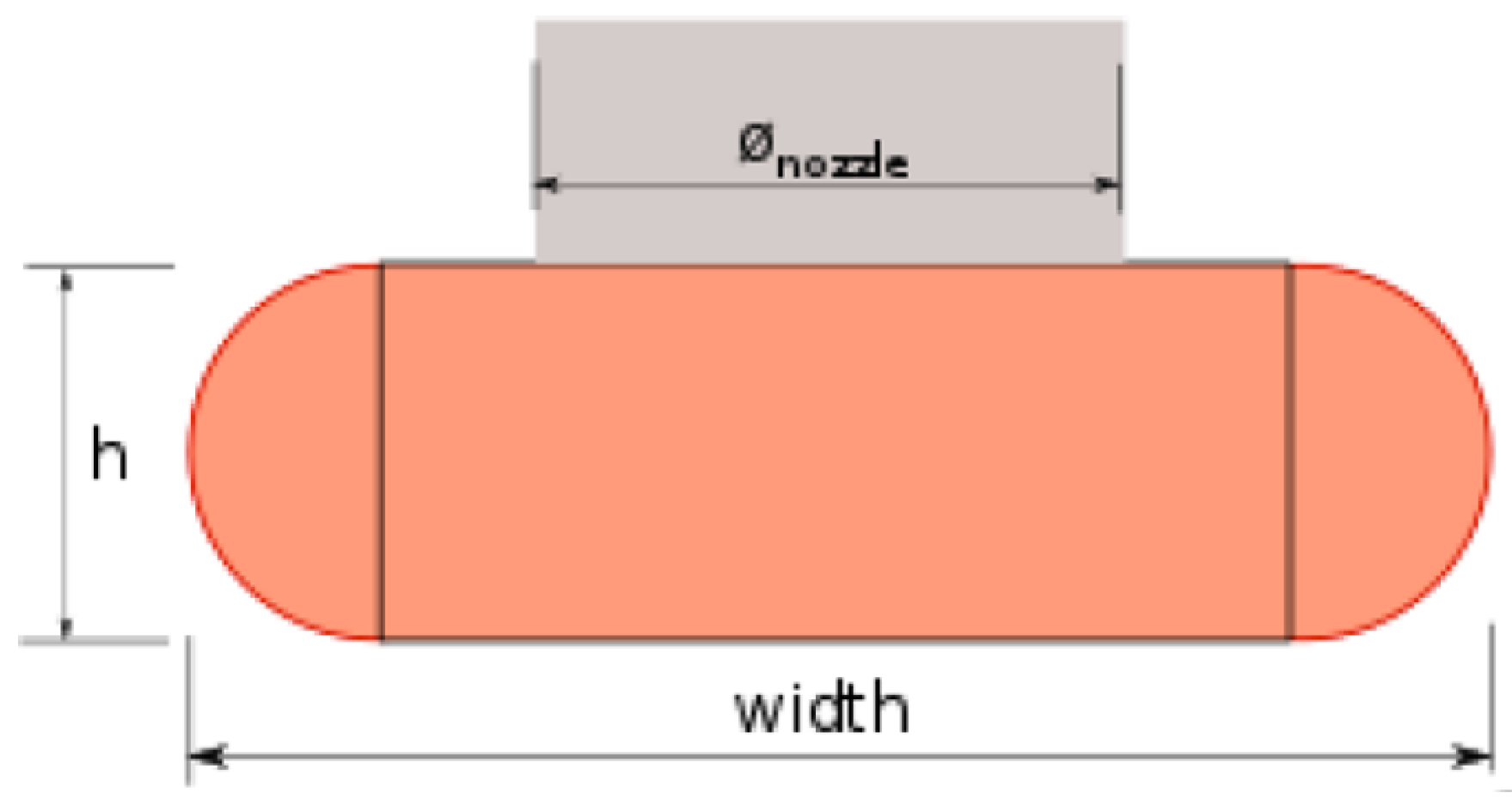

- First, the independent variables are defined, including the scaffold dimensions (length, line spacing, layer height), the number of scaffold layers on the Z-axis, the printer nozzle diameter, the filament diameter, the printing speed, and the extrusion multiplier.

- -

- A is the cross section of the extruded filament (mm2)

- -

- Ø, from now d, is the diameter of the printer nozzle (mm)

- -

- h is the layer height (mm)

- -

- w is the extrusion width (mm)

- -

- d is the diameter of the printer nozzle.

- -

- E is the amount of extruded filament in mm.

- 2.

- Finally, the code that generates the G-code is defined, including the printing speed (instruction starts with F, followed by a number in mm/min), geometric coordinates (marked as X, Y and Z, followed by a number in mm), and the amount of extruded filament (marked as E and followed by a number in mm),\. It is worth mentioning that the value of E is cumulative.

2.1.2. Generation of the 3D Model in Repetier Host

2.2. Fabrication of Scaffolds

2.2.1. Setting up the 3D Printer

- 3.

- Layer height: It is directly related to the printing Z-resolution. The higher the layer height, the shorter the printing time, but the worse the finish of the printed part. Generally, it is recommended not to use a layer height of more than 80% of the nozzle diameter of the printer [24]. That is, if the printer has a nozzle diameter of 0.40 mm, the layer height should not exceed 0.32 mm in any case.

- 4.

- Extrusion width: Thicker lines allow for better bonding between layers. However, it will worsen the accuracy of the shape. It is very important to choose the correct extrusion width, especially when printing the first layer to ensure good adhesion. Generally, values between 1.05 and 1.7 times the diameter of the printing nozzle are used [25].

- 5.

- Print speed: To obtain a good print, the optimum print speed values generally used are between 15 and 20 mm/s. The print quality will decrease at higher print speeds. Speeds above 100 mm/s may cause instability in the printer and, therefore, it is not recommended to print at higher speed values. It is also recommended not to print the first layer at speeds higher than 25 mm/s to avoid adhesion problems to the base [26].

- 6.

- Extrusion temperature: This will depend on the material used and will be defined according to the melting temperature of the material. If the extrusion temperature is determined to be above the melting temperature, too much filament will be extruded without control. Conversely, if the extrusion temperature is lower than the melting temperature of the material, no filament will be extruded. The optimum extrusion temperature value can be modified by other parameters such as printing speed [26]. The manufacturer of the materials used in this work recommends printing by setting an extrusion temperature between 130 and 170 °C for PCL [27].

- 7.

- Hot bed temperature: This is defined according to the material used and is essential to ensure correct adhesion to the printer base of the first printed layer. The value recommended by the material manufacturer is between 30 and 45 °C when working with PCL [27].

- 8.

- Extrusion multiplier: Its default value is 1 (100%). It can be modified to adjust the amount of extruded filament and the appropriate line width.

- 9.

- Cooling speed: To make the filament extruded and deposited during printing solidify faster, the layer fan can be used. This will reduce the likelihood of deformation. The layer fan, located in the printhead, will cool the filament as it exits the printer nozzle. The layer fan speed can be adjusted by assigning values between 0 and 255 for PWM (Pulse Width Modulation) control, which determine a fan motor speed from 0% to 100%, respectively.

2.2.2. Printing of Scaffolds

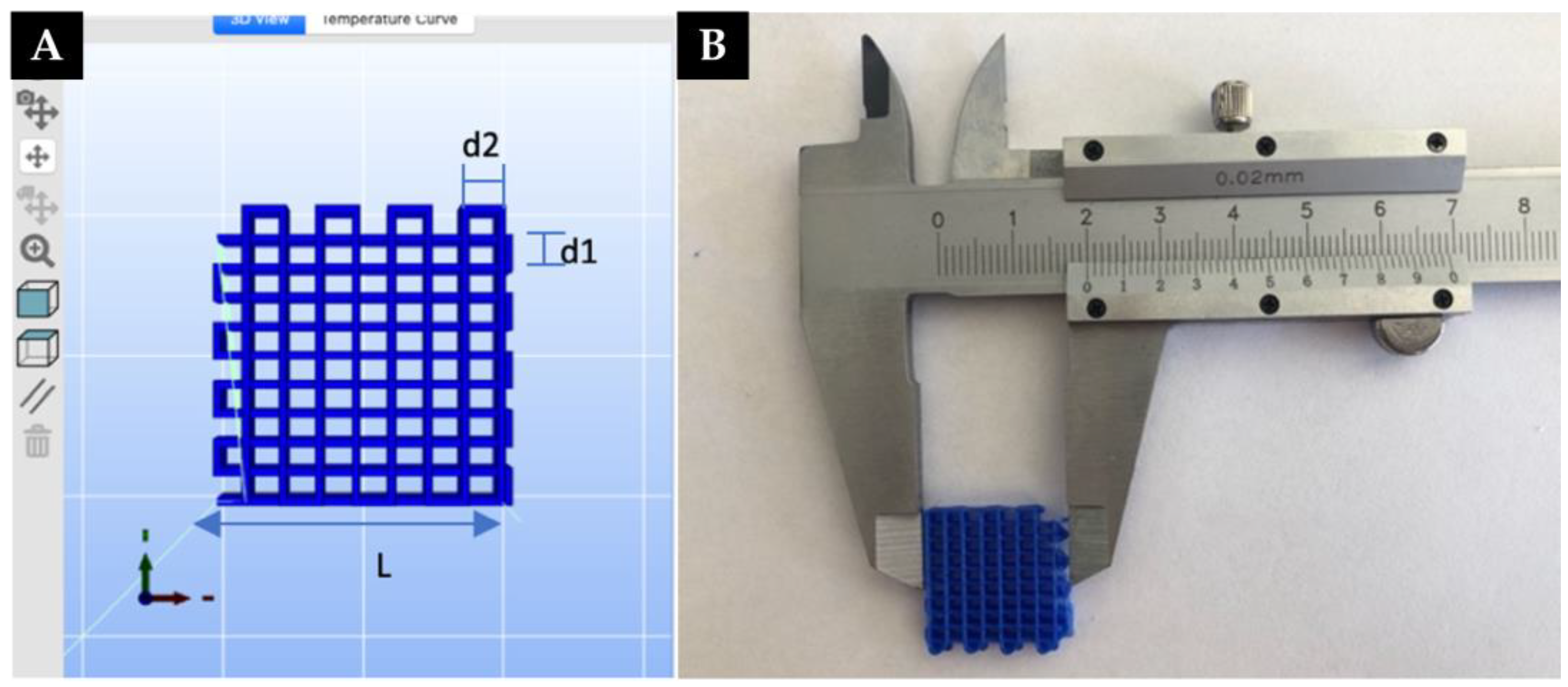

- -

- L is the length of the scaffold

- -

- d1 is the distance between printed strands in the X-axis

- -

- d2 is the distance between printed filaments in the Y-axis.

- Sensitivity analysis changing the extrusion volume through different values of the extrusion multiplier.

- Sensitivity analysis of the printing speed.

- Sensitivity analysis of the cool-down speed through the toggling of the extruder fan.

- Performing minimum extrusion volume passes of filament on the printed scaffold without raising the layer in the Z-axis.

- Reproducibility study once the printing conditions for microfiber formation have been identified.

2.3. Microscopic Analysis of the Printed Scaffolds

3. Results

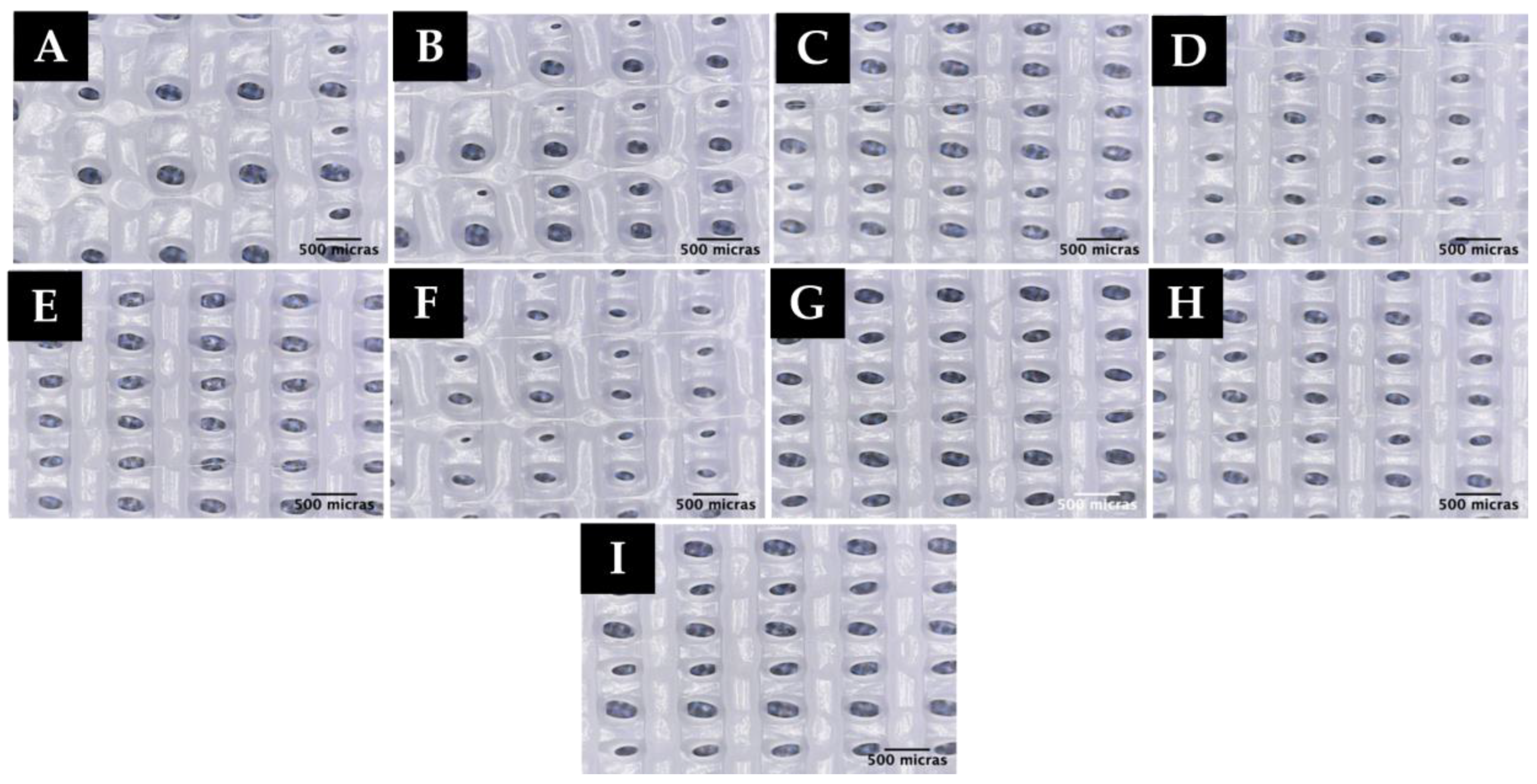

3.1. Extrusion Multiplier Sensitivity Analysis

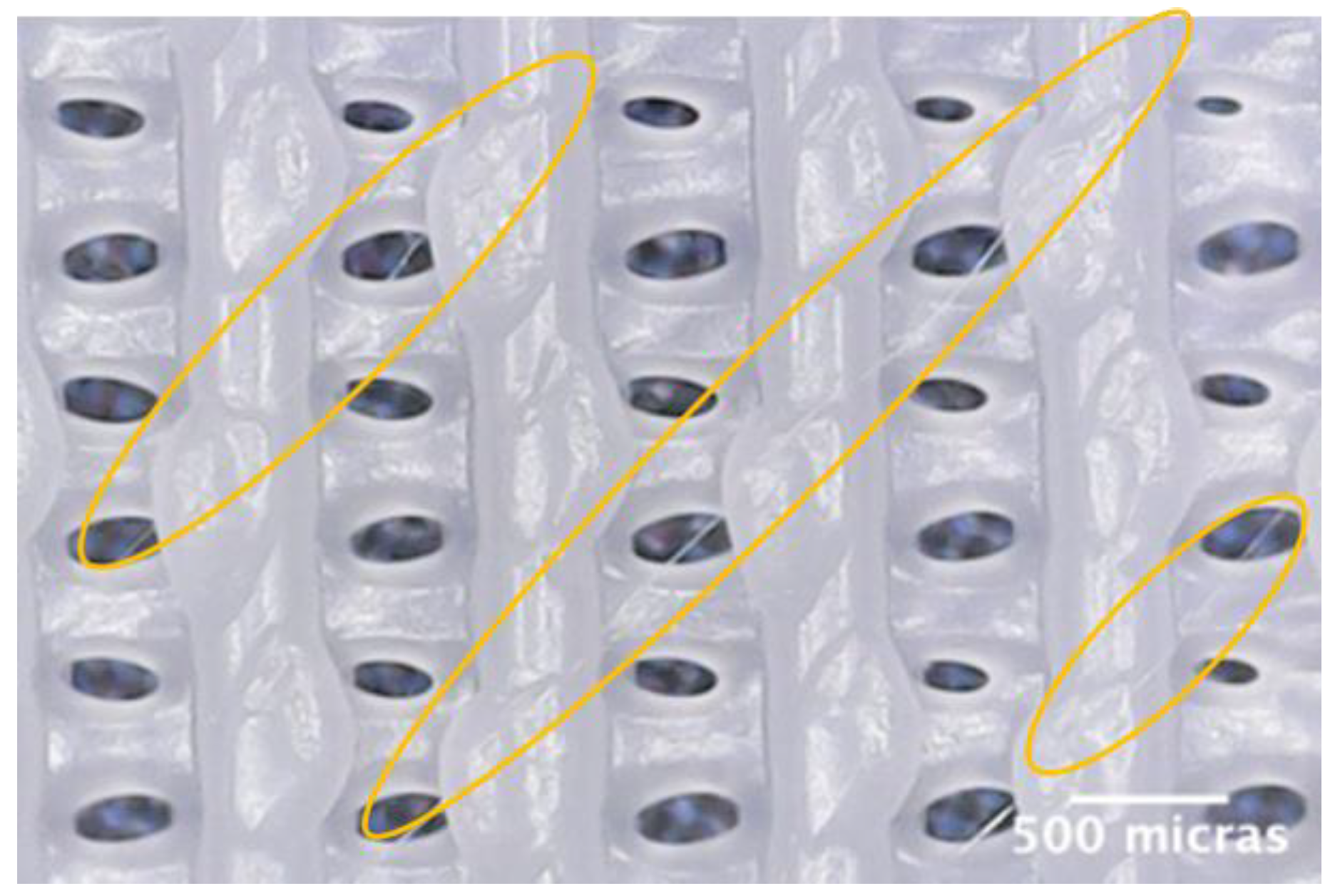

3.2. Printing Speed Sensitivity Analysis

3.3. Sensitivity Analysis of the Cooling Rate

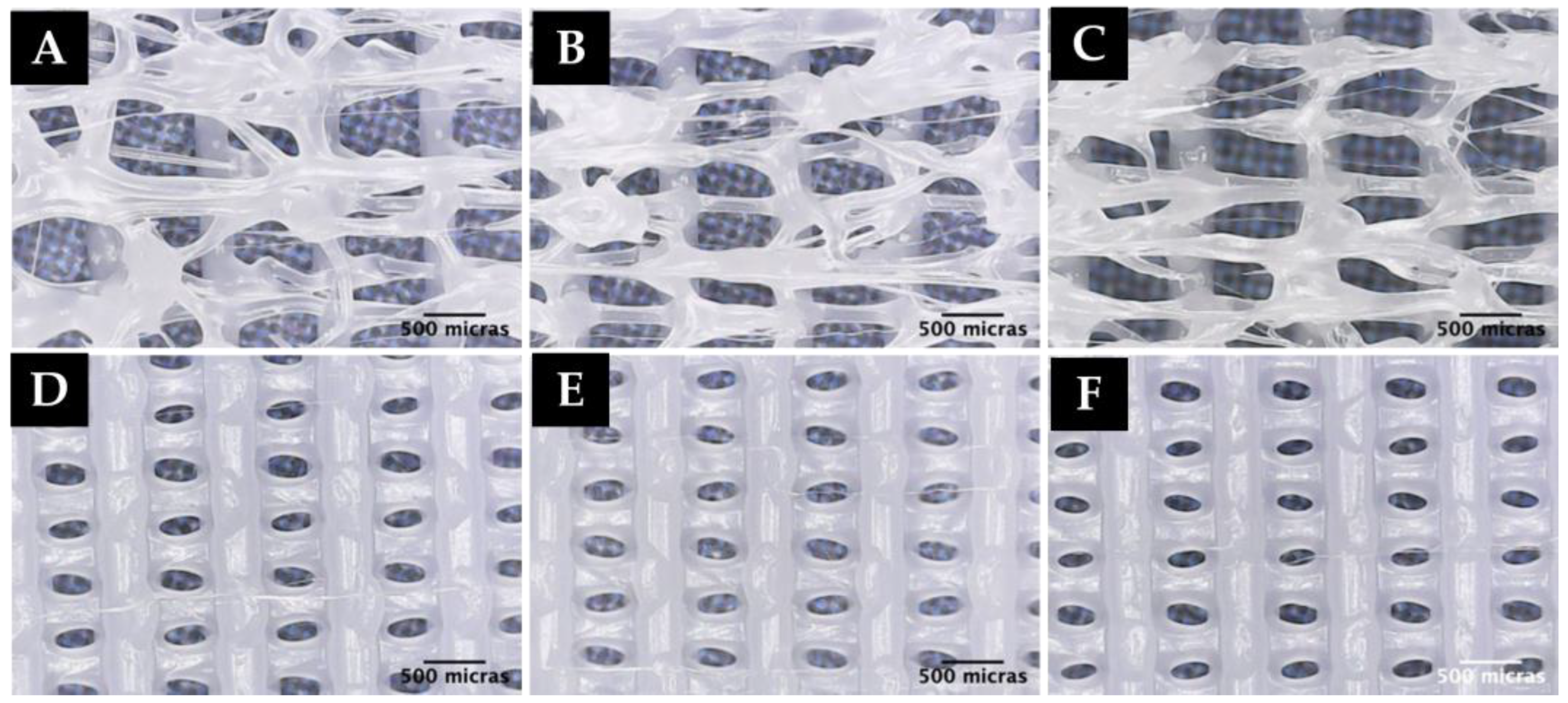

3.4. Further Study: Filament Passes without Raising the Layer in the Z-Axis

3.5. Reproducibility Study

4. Conclusions

- -

- The formation of controlled-shaped microfilaments (48 ± 12 µm, mean ± S.D.) is possible in scaffolds whose geometry has been generated through scripts based on primitive geometrical figures.

- -

- With the layer fan off and at low speeds for material deposition (600 mm/min (10.0 mm/s)), random microfiber formation begins to be observed as the extrusion volume decreases below 0.60.

- -

- When printing at high speeds with the extruder fan switched off, despite the formation of microfibers, the formation of lumps is observed. This influences the quality of the print, resulting in an inhomogeneous morphology of the formed macropores.

- -

- The use of the extruder fan provides a faster drying of the PCL, reducing the formation of lumps or agglomerations of material during manufacturing and resulting in the formation of a greater quantity of microfibers.

- -

- In general, it can be concluded that the optimal conditions for obtaining microfibers are at high speeds (4200–5000 mm/min (70–83.3 mm/s) and extrusion multiplier values between 0.60 and 0.45.

- -

- It is possible to obtain controlled microfibers with the newly developed algorithms by making extruded filament passes without raising the layer in the Z-axis with an extrusion multiplier value of 0.2 and a print speed of 5000 mm/min (83.3 mm/s).

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| „„„ x0,y0 _________________ ________________| ^ |________________ | ________________| | L |________________ | ________________|v <-----------------------> L „„„ # Import numpy library (numerical computation) and matpotlib (generate plots from data in lists and vectors) import numpy as np import matplotlib.pyplot as plt # Definition of variables # independent variables L = 30 # scaffold length (mm) D = 1.75 # filament diameter (mm) d = 0.400 # extruder nozzle diameter (mm) dist1= 1 # distance between lines of the first layer (mm) dist2 = 2 # line spacing of second layer (mm) nz = 4 # number of layers ts = 1200 # traverse speed (mm/min) fr = 800 # printing speed (mm/min) flow = 1 # extrusion multiplier E_extruded = 0 # initialization of extruded length (mm) h = 0.2 # layer height (mm) # Dependent variables n1 = int(L/dist1) # number of turns per horizontal layer n2 = int(L/dist2) # number of turns per vertical layer w = 2*h # extrusion width A= (w-h)*h + pi*((h/2)**2) # cross section of extruded filament # EXTRUSION FUNCTION # extrusion volume calculation for a given length (L) def extrusion(L): ext = L*(A*4)/(pi*(D**2)) #source: Slic3r return ext # FIRST LAYER # assign vector (x, y, z), initial position P0 = [100-L/2, 100-L/2, h] xpos1 = [] #1D array—storage of x values for g-code ypos1 = [] #1D array—storage of x values for the g-code extr_l = [] #1D array—storage of the extrusion values for the g-code # GENERATION OF XY POSITIONS ypos1.append(P0[1]) # initial position Y for j in range (0,int(n1/2)): # generate positions in X for n1 laps xpos1.append(P0[0]) xpos1.append(P0[0] + L) xpos1.append(P0[0] + L) xpos1.append(P0[0]) for k in range (1,2*n1-1): #generate Y positions for n1 turns if (k % 2) == 0: ypos1.append(ypos1[-1]) # Y position (k= even number). else: ypos1.append(ypos1[-2] + dist1) # Y position (k= odd number). # G-Code generation and text file creation # Write a .txt file with the values obtained and the G-code format for each position: file = open(“gcode.txt”, “w+”) extr_l.append(0) print(‘G0 F{:.0f} X{:.3f} Y{:.3f} Z{:.3f}’.format(ts, P0[0], P0[1], P0[2])) for o in range(1,len(xpos1)): extr_l.append(np.abs((xpos1[o]-xpos1[o-1]) + (ypos1[o]-ypos1[o-1]))) E_extruded = E_extruded + extrusion(extr_l[o])*flow print(‘G1 F{:.0f} X{:.3f} Y{:.3f} E{:.3f}’.format(fr, xpos1[o], ypos1[o], E_extruded)) file.write(‘G1 F{:.0f} X{:.3f} Y{:.3f} E{:.3f} E{:.3f}’.format(fr, xpos1[o], ypos1[o], E_extruded)) # Save and close file file.close # Generate XY positions for a scaffold with ‘nz’ layers for i in range (1,nz): # Generate XY positions for even layers. if (i % 2) = = 0: P2 = [100-L/2, 100-L/2, (i + 1)*h] xpos2 = [] ypos2 = [] ypos2.append(P2[1]) ypos2.append(P2[1]) for j in range (0,int(n1/2)): xpos2.append(P2[0]) xpos2.append(P2[0] + L) xpos2.append(P2[0] + L) xpos2.append(P2[0]) for k in range (1,2*n1-1): if (k % 2) == 0: ypos2.append(ypos2[-1]) else: ypos2.append(ypos2[-2] + dist1) file = open(„gcode.txt”,”w+”) # ‘w’ for write, the ‘ + ’ to create the file if it does not exists extr_l.append(0) print(‘G0 F{:.0f} X{:.3f} Y{:.3f} Z{:.3f}’.format(ts, P2[0], P2[1], P2[2])) for o in range(1,len(xpos2)): extr_l.append(np.abs((xpos2[o]-xpos2[o-1]) + (ypos2[o]-ypos2[o-1]))) E_extruded = E_extruded + extrusion(extr_l[o])*flow2 print(‘G1 F{:.0f} X{:.3f} Y{:.3f} E{:.3f}’.format(fr, xpos2[o], ypos2[o], E_extruded)) file.write(‘G1 F{:.0f} X{:.3f} Y{:.3f} E{:.3f}\n’.format(fr, xpos2[o], ypos2[o], E_extruded)) file.close # Generate XY positions for odd layers else: P3 = [100-L/2, 100-L/2, (i + 1)*h] #100-L/2.5 xpos3 = [] ypos3 = [] xpos3.append(P3[0]) for j in range (0,2*n2-1) if (j % 2) == 0: xpos3.append(xpos3[-1]) else: xpos3.append(xpos3[-2] + dist2) for k in range (0,int(n2/2)): ypos3.append(P3[1]) ypos3.append(P3[1] + L) ypos3.append(P3[1] + L) ypos3.append(P3[1]) file = open(„gcode.txt”,”w+”) # ‘w’ for write, the ‘+’ to create the file if it does not exists extr_l.append(0) print(‘G0 F{:.0f} X{:.3f} Y{:.3f} Z{:.3f}’.format(ts, P3[0], P3[1], P3[2]) for o in range(1,len(xpos3)): extr_l.append(np.abs((xpos3[o]-xpos3[o-1]) + (ypos3[o]-ypos3[o-1]))) E_extruded = E_extruded + extrusion(extr_l[o])*flow2 print(‘G1 F{:.0f} X{:.3f} Y{:.3f} E{:.3f}’.format(fr, xpos3[o], ypos3[o], E_extruded)) file.write(‘G1 F{:.0f} X{:.3f} Y{:.3f} E{:.3f}\n’.format(fr, xpos3[o], ypos3[o], E_extruded)) file.close # GENERATE PLOT ax = plt.figure().gca() plt.axis(‘square’) plt.ylim(80, 120) plt.xlim(80, 120) #plot the final g-code values (green, red, blue)) ax.plot(xpos3,ypos3,’g’) ax.plot(xpos1,ypos1,’b’) plt.show() |

Appendix B

| M140 S40; —ACTIVATE HOT BED AND EXTRUDER TEMPERATURE—SET THE TEMPERATURE OF THE HOT BED AND THE EXTRUDER—SET THE TEMPERATURE OF THE EXTRUDER—SET THE TEMPERATURE OF THE EXTRUDER M140 S40 ; sets the hot bed temperature to 40 °C (do not wait to reach the value) M104 S150 ; sets extruder temperature to 150 °C (do not wait for the value to be reached) M105 ; requests the extruder temperature value M190 S40 ; sets the hot bed temperature to 40 °C (wait until the value is reached) M105 ; requests extruder temperature value M109 S150 ; sets extruder temperature to 150 °C (wait until value is reached) M82 ; makes the extruder interpret the extrusion as absolute positions -- START G-CODE -- M302 S120 ; allows for printing at temperatures lower than 170 °C G21 ; sets the units in millimeters G90 ; sets the extruder position as absolute position M106 S0 ; sets the fan speed (PWM 0—off) G28 X0 Y0 ; moves the extruder to the origin (X/Y Home) M117 ; purges the extruder G92 E0 ; restarts the extruder G28 Z0 ; moves the extruder to the origin (Z Home) G1 Z15.0 F2400 ; moves the extruder to the Z 15.0 mm position G92 E0 ; does not extrude the filament on the move G1 E1 F200 ; extrudes 1mm of filament G1 E1 F200 ; —end of START G-CODE— ; PRINTING LAYER_1 (Code generated in Python) ; fast motion (traverse speed F mm/min; Position XYZ (mm)) G0 F800 X85.000 Y85.000 Z0.200 ; controlled motion (printing speed F (mm/min); XY position (mm); extruded filament E (mm)) G1 F600 X115.000 Y85.000 E0.891 G1 F600 X115.000 Y86.000 E0.920 G1 F600 X85.000 Y86.000 E1.811 G1 F600 X85.000 Y87.000 E1.841 G1 F600 X115.000 Y87.000 E2.732 G1 F600 X115.000 Y88.000 E2.761 G1 F600 X85.000 Y88.000 E3.652 G1 F600 X85.000 Y89.000 E3.682 G1 F600 X115.000 Y89.000 E4.572 G1 F600 X115.000 Y90.000 E4.602 G1 F600 X85.000 Y90.000 E5.493 G1 F600 X85.000 Y91.000 E5.523 G1 F600 X115.000 Y91.000 E6.413 G1 F600 X115.000 Y92.000 E6.443 G1 F600 X85.000 Y92.000 E7.334 G1 F600 X85.000 Y93.000 E7.363 G1 F600 X115.000 Y93.000 E8.254 G1 F600 X115.000 Y94.000 E8.284 G1 F600 X85.000 Y94.000 E9.175 G1 F600 X85.000 Y95.000 E9.204 G1 F600 X115.000 Y95.000 E10.095 G1 F600 X115.000 Y96.000 E10.125 G1 F600 X85.000 Y96.000 E11.015 G1 F600 X85.000 Y97.000 E11.045 G1 F600 X115.000 Y97.000 E11.936 G1 F600 X115.000 Y98.000 E11.966 G1 F600 X85.000 Y98.000 E12.856 G1 F600 X85.000 Y99.000 E12.886 G1 F600 X115.000 Y99.000 E13.777 G1 F600 X115.000 Y100.000 E13.806 G1 F600 X85.000 Y100.000 E14.697 G1 F600 X85.000 Y101.000 E14.727 G1 F600 X115.000 Y101.000 E15.618 G1 F600 X115.000 Y102.000 E15.647 G1 F600 X85.000 Y102.000 E16.538 G1 F600 X85.000 Y103.000 E16.568 G1 F600 X115.000 Y103.000 E17.458 G1 F600 X115.000 Y104.000 E17.488 G1 F600 X85.000 Y104.000 E18.379 G1 F600 X85.000 Y105.000 E18.409 G1 F600 X115.000 Y105.000 E19.299 G1 F600 X115.000 Y106.000 E19.329 G1 F600 X85.000 Y106.000 E20.220 G1 F600 X85.000 Y107.000 E20.249 G1 F600 X115.000 Y107.000 E21.140 G1 F600 X115.000 Y108.000 E21.170 G1 F600 X85.000 Y108.000 E22.061 G1 F600 X85.000 Y109.000 E22.090 G1 F600 X115.000 Y109.000 E22.981 G1 F600 X115.000 Y110.000 E23.011 G1 F600 X85.000 Y110.000 E23.901 G1 F600 X85.000 Y111.000 E23.931 G1 F600 X115.000 Y111.000 E24.822 G1 F600 X115.000 Y112.000 E24.852 G1 F600 X85.000 Y112.000 E25.742 G1 F600 X85.000 Y113.000 E25.772 G1 F600 X115.000 Y113.000 E26.663 G1 F600 X115.000 Y114.000 E26.692 G1 F600 X85.000 Y114.000 E27.583 ; —END G-CODE— M104 S0; sets the extruder temperature to zero (off) G91; sets the extruder position as relative position G1 E-2 F600 ; retracts the filament to release pressure G1 Z10 ; moves the extruder to position Z 10 mm G90; sets the extruder position as absolute position M84; switches off the motor ; —END G-CODE— |

Appendix C

| FAN OFF | ||||||||

|---|---|---|---|---|---|---|---|---|

| Extrusion Factor | Printing Speed (mm/min) | |||||||

| 300 | 600 | 800 | 1200 | 3000 * | 4200 * | 5000 * | 6000 * | |

| 1 | ||||||||

| 0.6 | ||||||||

| 0.45 | ||||||||

| 0.3 | ||||||||

| FAN ON | ||||||||

|---|---|---|---|---|---|---|---|---|

| Extrusion Factor | Printing Speed (mm/min) | |||||||

| 300 | 600 | 800 | 1200 | 3000 * | 4200 * | 5000 * | 6000 * | |

| 1 | ||||||||

| 0.6 | ||||||||

| 0.45 | ||||||||

| 0.3 | ||||||||

| PASSES IN THE Z-AXES (FAN ON) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Extrusion Factor | Printing Speed (mm/min) | |||||||

| 300 ** | 600 ** | 800 ** | 1200 ** | 3000 ** | 4200 ** | 5000 ** | 6000 ** | |

| 0.4 | ||||||||

| 0.2 | ||||||||

| 0.1 | ||||||||

References

- Ojansivu, M.; Rashad, A.; Ahlinder, A.; Massera, J.; Mishra, A.; Syverud, K.; Finne-Wistrand, A.; Miettinen, S.; Mustafa, K. Wood-Based Nanocellulose and Bioactive Glass Modified Gelatin-Alginate Bioinks for 3D Bioprinting of Bone Cells. Biofabrication 2019, 11, 035010. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Salazar, M.G.; Álvarez, M.M.; Trujillo-de Santiago, G. Advances in 3D Bioprinting for the Biofabrication of Tumor Models. Bioprinting 2021, 21, e00120. [Google Scholar] [CrossRef]

- Mahajan, N.; Yoo, J.J.; Atala, A.; Mahajan, N.; Yoo, J.J.; Atala, A. Bioink Materials for Translational Applications. MRS Bull. 2022, 47, 80–90. [Google Scholar] [CrossRef]

- Vagropoulou, G.; Trentsiou, M.; Georgopoulou, A.; Papachristou, E.; Prymak, O.; Kritis, A.; Epple, M.; Chatzinikolaidou, M.; Bakopoulou, A.; Koidis, P. Hybrid Chitosan/Gelatin/Nanohydroxyapatite Scaffolds Promote Odontogenic Differentiation of Dental Pulp Stem Cells and in Vitro Biomineralization. Dent. Mater. 2021, 37, e23–e36. [Google Scholar] [CrossRef] [PubMed]

- Nga, N.K.; Thanh Tam, L.T.; Ha, N.T.; Hung Viet, P.; Huy, T.Q. Enhanced Biomineralization and Protein Adsorption Capacity of 3D Chitosan/Hydroxyapatite Biomimetic Scaffolds Applied for Bone-Tissue Engineering. RSC Adv. 2020, 10, 43045–43057. [Google Scholar] [CrossRef]

- Zhang, W.; Guan, X.; Qiu, X.; Gao, T.; Yu, W.; Zhang, M.; Song, L.; Liu, D.; Dong, J.; Jiang, Z.; et al. Bioactive Composite Janus Nanofibrous Membranes Loading Ciprofloxacin and Astaxanthin for Enhanced Healing of Full-Thickness Skin Defect Wounds. Appl. Surf. Sci. 2023, 610, 155290. [Google Scholar] [CrossRef]

- Han, M.C.; Cai, S.Z.; Wang, J.; He, H.W. Single-Side Superhydrophobicity in Si3N4-Doped and SiO2-Treated Polypropylene Nonwoven Webs with Antibacterial Activity. Polymers 2022, 14, 2952. [Google Scholar] [CrossRef]

- Khan, S.B.; Irfan, S.; Lam, S.S.; Sun, X.; Chen, S. 3D Printed Nanofiltration Membrane Technology for Waste Water Distillation. J. Water Process Eng. 2022, 49, 102958. [Google Scholar] [CrossRef]

- Dinis, J.C.; Morais, T.F.; Amorim, P.H.J.; Ruben, R.B.; Almeida, H.A.; Inforçati, P.N.; Bártolo, P.J.; Silva, J.V.L. Open Source Software for the Automatic Design of Scaffold Structures for Tissue Engineering Applications. Procedia Technol. 2014, 16, 1542–1547. [Google Scholar] [CrossRef]

- Kantaros, A. 3D Printing in Regenerative Medicine: Technologies and Resources Utilized. Int. J. Mol. Sci. 2022, 23, 14621. [Google Scholar] [CrossRef]

- Sabino, M.A.; Loaiza, M.; Dernowsek, J.; Rezende, R.; da Silva, J.V.L. Techniques for Manufacturing Polymer Scaffolds with Potential Applications in Tissu. Rev. Latinoam. De Metal. Y Mater. 2017, 37, 1–27. [Google Scholar]

- Peltola, S.M.; Melchels, F.P.W.; Grijpma, D.W.; Kellomäki, M. A Review of Rapid Prototyping Techniques for Tissue Engineering Purposes. Ann. Med. 2008, 40, 268–280. [Google Scholar] [CrossRef] [PubMed]

- Ghasemi-Mobarakeh, L. Structural Properties of Scaffolds: Crucial Parameters towards Stem Cells Differentiation. World J. Stem Cells 2015, 7, 728. [Google Scholar] [CrossRef] [PubMed]

- Hochleitner, G.; Jüngst, T.; Brown, T.D.; Hahn, K.; Moseke, C.; Jakob, F.; Dalton, P.D.; Groll, J. Additive Manufacturing of Scaffolds with Sub-Micron Filaments via Melt Electrospinning Writing. Biofabrication 2015, 7, 035002. [Google Scholar] [CrossRef] [PubMed]

- Kilian, D.; von Witzleben, M.; Lanaro, M.; Wong, C.S.; Vater, C.; Lode, A.; Allenby, M.C.; Woodruff, M.A.; Gelinsky, M. 3D Plotting of Calcium Phosphate Cement and Melt Electrowriting of Polycaprolactone Microfibers in One Scaffold: A Hybrid Additive Manufacturing Process. J. Funct. Biomater. 2022, 13, 75. [Google Scholar] [CrossRef]

- Lu, Q.; Song, K.-Y.; Feng, Y.; Xie, J. Fabrication of Suspended Uniform Polymer Microfibers by FDM 3D Printing. CIRP J. Manuf. Sci. Technol. 2021, 32, 179–187. [Google Scholar] [CrossRef]

- Chung, S.; Ingle, N.P.; Montero, G.A.; Kim, S.H.; King, M.W. Bioresorbable Elastomeric Vascular Tissue Engineering Scaffolds via Melt Spinning and Electrospinning. Acta Biomater. 2010, 6, 1958–1967. [Google Scholar] [CrossRef]

- Cheng, J.; Jun, Y.; Qin, J.; Lee, S.H. Electrospinning versus Microfluidic Spinning of Functional Fibers for Biomedical Applications. Biomaterials 2017, 114, 121–143. [Google Scholar] [CrossRef]

- Visser, J.; Melchels, F.P.W.; Jeon, J.E.; van Bussel, E.M.; Kimpton, L.S.; Byrne, H.M.; Dhert, W.J.A.; Dalton, P.D.; Hutmacher, D.W.; Malda, J. Reinforcement of Hydrogels Using Three-Dimensionally Printed Microfibres. Nat. Commun. 2015, 6, 6933. [Google Scholar] [CrossRef]

- Kara, Y.; Kovács, N.K.; Nagy-György, P.; Boros, R.; Molnár, K. A Novel Method and Printhead for 3D Printing Combined Nano-/Microfiber Solid Structures. Addit. Manuf. 2023, 61, 103315. [Google Scholar] [CrossRef]

- Li, W.; Yao, K.; Tian, L.; Xue, C.; Zhang, X.; Gao, X. 3D Printing of Heterogeneous Microfibers with Multi-Hollow Structure via Microfluidic Spinning. J. Tissue Eng. Regen. Med. 2022, 16, 913–922. [Google Scholar] [CrossRef] [PubMed]

- Cubo-Mateo, N.; Rodríguez-Lorenzo, L.M. Design of Thermoplastic 3D-Printed Scaffolds for Bone Tissue Engineering: Influence of Parameters of “Hidden” Importance in the Physical Properties of Scaffolds. Polymers 2020, 12, 1546. [Google Scholar] [CrossRef] [PubMed]

- Artillery 3D. Available online: https://artillery3d.com/products/artillery-genius-3d-printer-kit-220220250mm-print-size-with-ultra-quiet-stepper-motor-tft-touch-screen (accessed on 3 December 2022).

- Filament2print. Nozzles de Impresoras 3D: Clasificación y Recomendaciones. Available online: https://filament2print.com/es/blog/56_guia-nozzles-clasificacion-recomendaciones.html (accessed on 3 December 2022).

- Slic3r 3D. Available online: https://manual.slic3r.org/advanced/flow-math (accessed on 3 December 2022).

- Filament2print. Temperatura y Velocidad de Impresión PLA. Available online: https://filament2print.com/es/blog/9_dudas-temperatura-velocidad-impresion-3d.html (accessed on 3 December 2022).

- 3D4makers. Facilan Ortho Filament. Available online: https://www.3d4makers.com/products/facilan-ortho-filament (accessed on 3 December 2022).

- Patrício, T.; Domingos, M.; Gloria, A.; Bártolo, P. Characterisation of PCL and PCL/PLA Scaffolds for Tissue Engineering. Procedia CIRP 2013, 5, 110–114. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D Printing-Encapsulated Polycaprolactone–Thermoplastic Polyurethane with High Shape Memory Performances. Adv. Eng. Mater. 2022, 2201309. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An Open-Source Platform for Biological-Image Analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

| CHARACTERISTICS | VALUES |

|---|---|

| Maximum printing speed | 150 mm/s |

| Maximum travel speed | 250 mm/s |

| X, Y, Z resolution | 0.05 mm, 0.05 mm, 0.10 mm |

| Filament diameter | 1.75 mm |

| Nozzle diameter | 0.40 mm |

| PRINTING CONDITIONS | VALUES |

|---|---|

| d1 | 1.0 mm |

| d2 | 2.5 mm |

| L | 20.0 mm |

| Layer height | 0.20 mm |

| Hot bed temperature | 40 °C |

| Extruder temperature | 150 °C |

| Extrusion multiplier | 1.00 |

| Printing speed | 600 mm/min (10.0 mm/s) |

| Fan (Switch on/off) | Off |

| EXPERIMENT | F1B | F2B | F3B | F4B |

|---|---|---|---|---|

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 1.00 | 0.60 | 0.45 | 0.30 |

| EXPERIMENT | V1B | V2B | V3B | V4B |

|---|---|---|---|---|

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.60 | 0.60 | 0.45 | 0.45 |

| Printing speed | 5000 mm/min (83.3 mm/s) | 6000 mm/min (100.0 mm/s) | 1200 mm/min (20.0 mm/s) | 3000 mm/min (50.0 mm/s) |

| EXPERIMENT | V5B | V6B | V7B | V8B |

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.45 | 0.60 | 0.45 | 0.30 |

| Printing speed | 4200 mm/min (70.0 mm/s) | 5000 mm/min (83.3 mm/s) | 6000 mm/min (100.0 mm/s) | 1200 mm/min (20.0 mm/s) |

| EXPERIMENT | T1B | T2B | T3B | T4B |

|---|---|---|---|---|

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.60 | 0.60 | 0.60 | 0.45 |

| Printing speed | 600 mm/min (10.0 mm/s) | 5000 mm/min (83.3 mm/s) | 5000 mm/min (83.3 mm/s) | 6000 mm/min (100.0 mm/s) |

| PWM | 255 (100 %) | 150 (58.8 %) | 255 (100 %) | 50 (19.6%) |

| EXPERIMENT | T5B | T6B | T7B | T8B |

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.60 | 0.60 | 0.45 | 0.45 |

| Printing speed | 6000 mm/min (100.0 mm/s) | 6000 mm/min (100.0 mm/s) | 600 mm/min (10.0 mm/s) | 3000 mm/min (50.0 mm/s) |

| PWM | 150 (58.8 %) | 255 (100 %) | 255 (100 %) | 255 (100 %) |

| EXPERIMENT | T9B | T10B | T11B | T12B |

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.45 | 0.45 | 0.45 | 0.45 |

| Printing speed | 4200 mm/min (70.0 mm/s) | 5000 mm/min (83.3 mm/s) | 6000 mm/min (100.0 mm/s) | 6000 mm/min (100.0 mm/s) |

| PWM | 255 (100 %) | 255 (19.6%) | 50 (100 %) | 255 (19.6%) |

| EXPERIMENT | T13B | |||

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.30 | |||

| Printing speed | 600 mm/min (10.0 mm/s) | |||

| PWM | 255 (100 %) | |||

| EXPERIMENT | P1B | P2B | P3B | P4B |

|---|---|---|---|---|

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.40 | 0.20 | 0.20 | 0.20 |

| Printing speed | 6000 mm/min (100.0 mm/s) | 600 mm/min (10.0 mm/s) | 4200 mm/min (70.0 mm/s) | 5000 mm/min (83.3 mm/s) |

| EXPERIMENT | P5B | P6B | P7B | P8B |

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.20 | 0.10 | 0.10 | 0.10 |

| Printing speed | 6000 mm/min (100.0 mm/s) | 600 mm/min (10.0 mm/s) | 4200 mm/min (70.0 mm/s) | 5000 mm/min (83.3 mm/s) |

| EXPERIMENT | P9B | |||

| PRINTING CONDITIONS | VALUES | |||

| Extrusion multiplier | 0.10 | |||

| Printing speed | 6000 mm/min (100.0 mm/s) | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

del Barrio Cortés, E.; Matutano Molina, C.; Rodríguez-Lorenzo, L.; Cubo-Mateo, N. Generation of Controlled Micrometric Fibers inside Printed Scaffolds Using Standard FDM 3D Printers. Polymers 2023, 15, 96. https://doi.org/10.3390/polym15010096

del Barrio Cortés E, Matutano Molina C, Rodríguez-Lorenzo L, Cubo-Mateo N. Generation of Controlled Micrometric Fibers inside Printed Scaffolds Using Standard FDM 3D Printers. Polymers. 2023; 15(1):96. https://doi.org/10.3390/polym15010096

Chicago/Turabian Styledel Barrio Cortés, Elisa, Clara Matutano Molina, Luis Rodríguez-Lorenzo, and Nieves Cubo-Mateo. 2023. "Generation of Controlled Micrometric Fibers inside Printed Scaffolds Using Standard FDM 3D Printers" Polymers 15, no. 1: 96. https://doi.org/10.3390/polym15010096

APA Styledel Barrio Cortés, E., Matutano Molina, C., Rodríguez-Lorenzo, L., & Cubo-Mateo, N. (2023). Generation of Controlled Micrometric Fibers inside Printed Scaffolds Using Standard FDM 3D Printers. Polymers, 15(1), 96. https://doi.org/10.3390/polym15010096