Transformation from Electromagnetic Inflection to Absorption of Silicone Rubber and Accordion-Shaped Ti3C2MXene Composites by Highly Electric Conductive Multi-Walled Carbon Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Mixed Silicone Rubber/Multi-Walled Carbon Nanotube/MXene Composites

2.3. Test Instruments and Methods

3. Results and Discussion

3.1. Vulcanization Parameters

3.2. Dynamic Mechanical Properties

3.3. Thermal Behavior

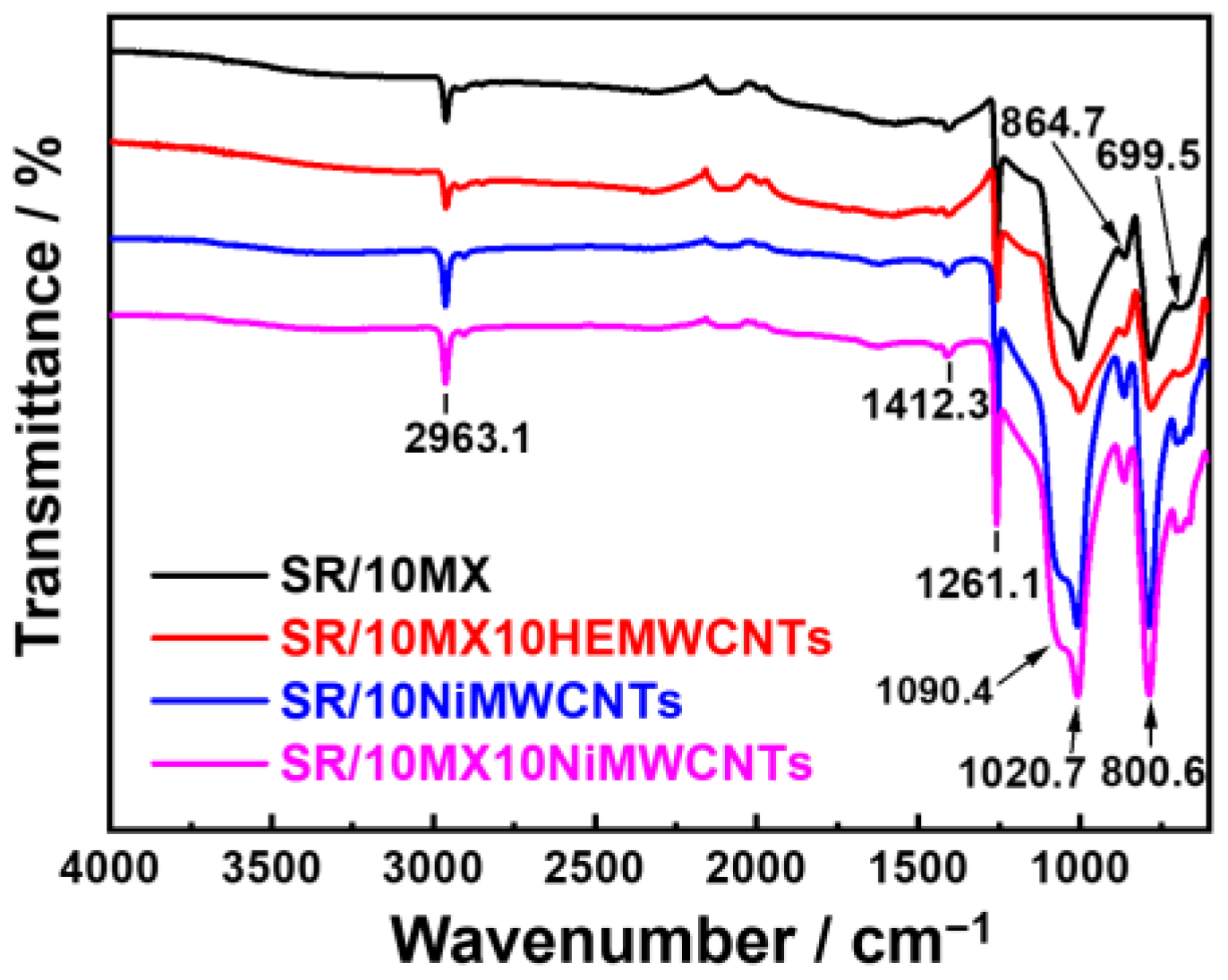

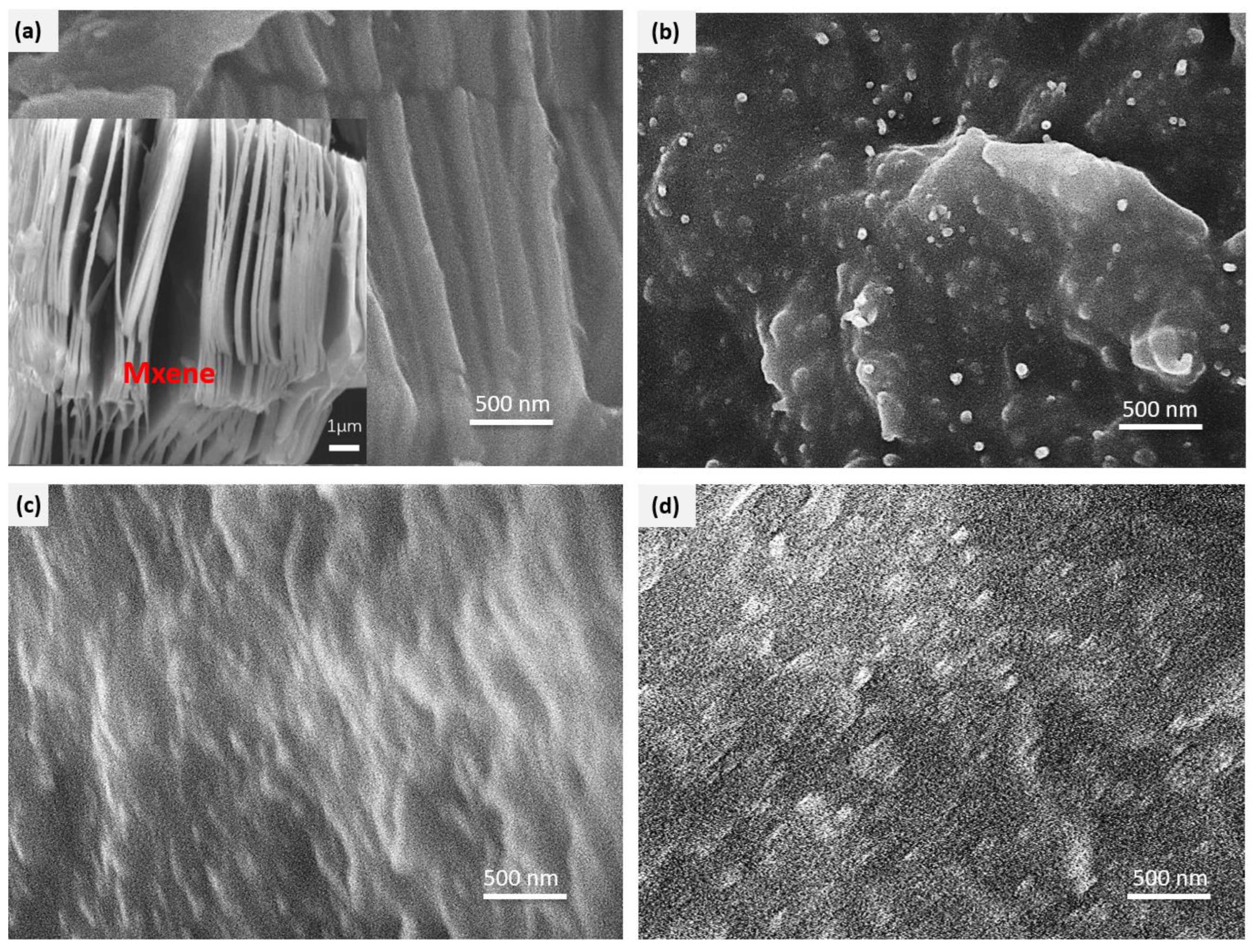

3.4. Morphological Structure

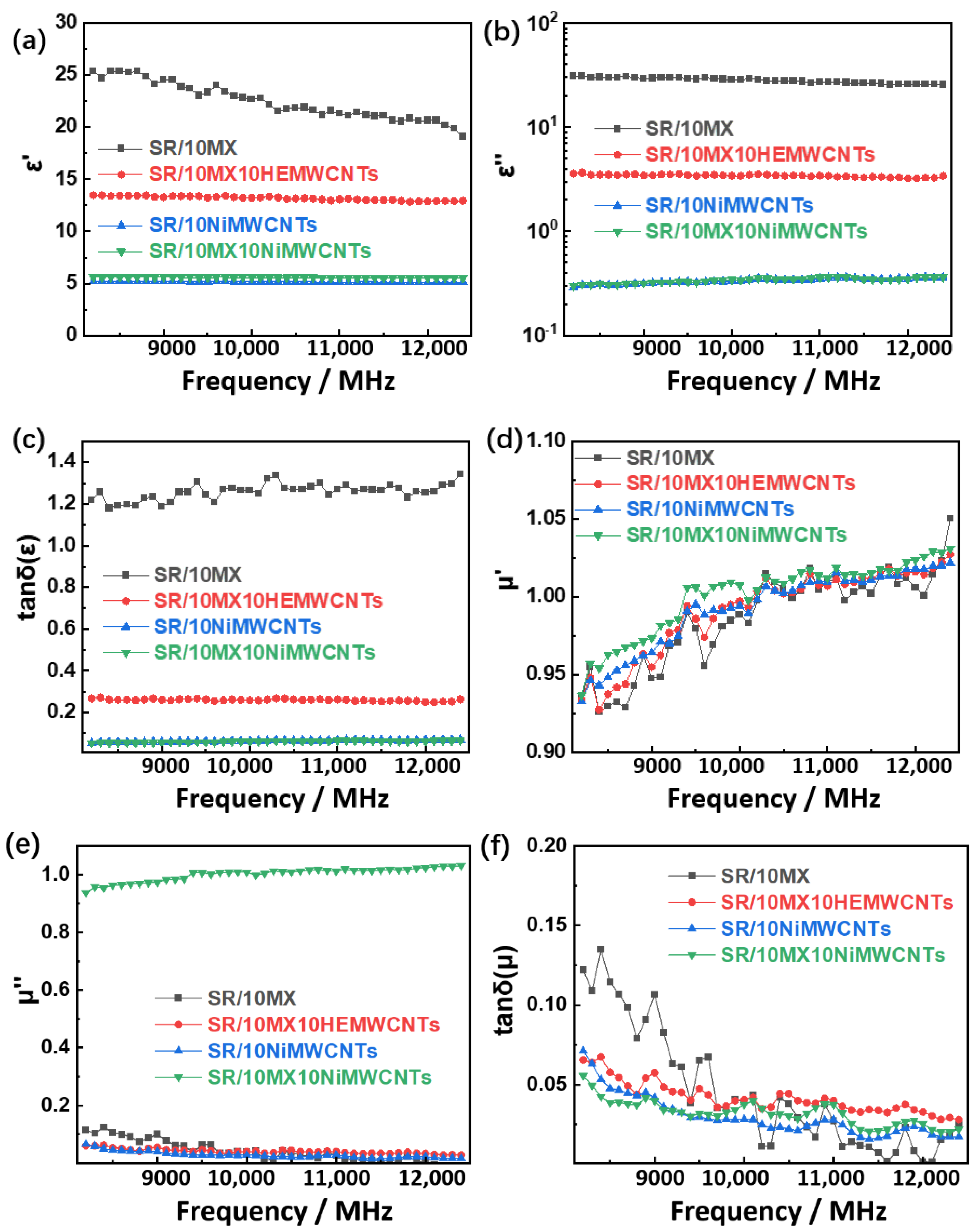

3.5. Dielectric and Magnetic Properties

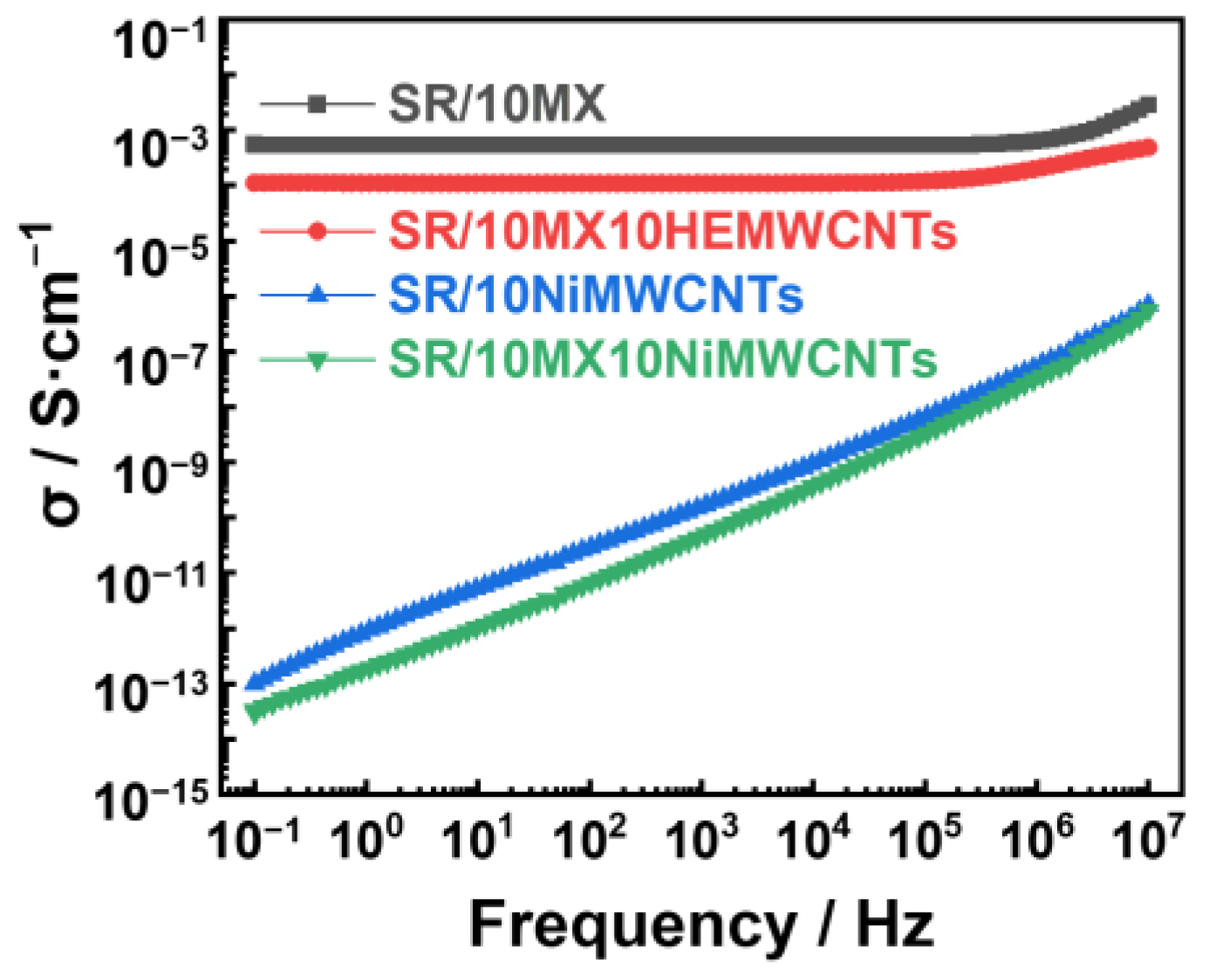

3.6. Electrical Conductivity

3.7. EMI Shielding Effectiveness

3.8. Electromagnetic Wave Absorbing Properties

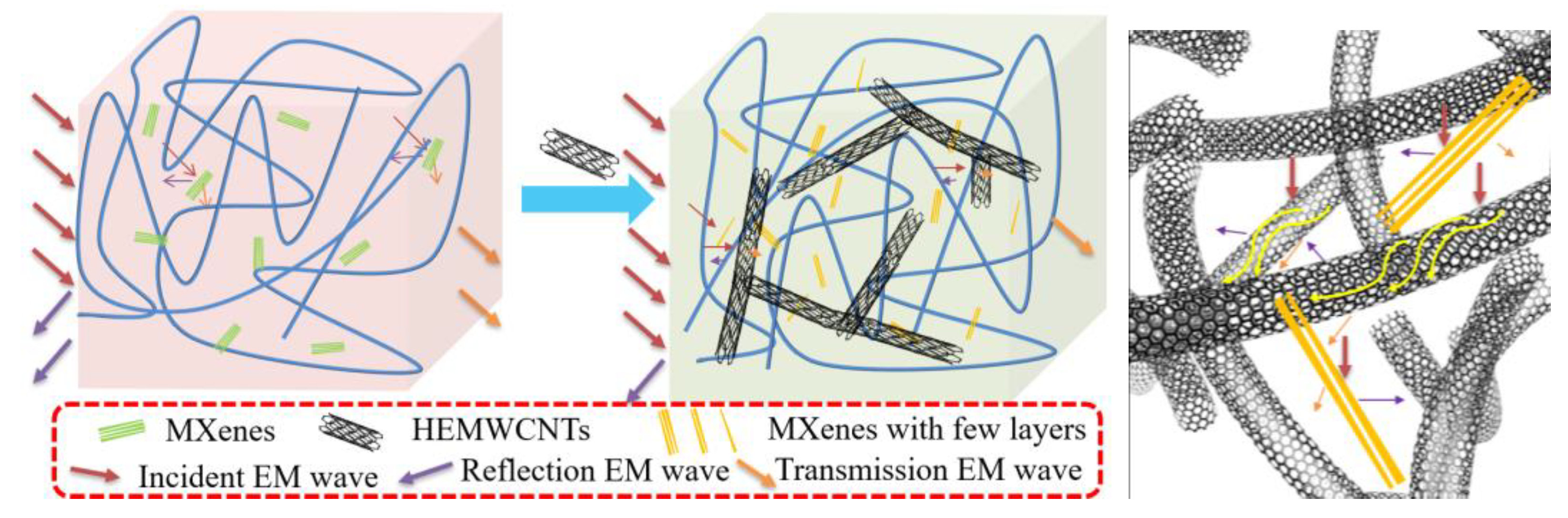

3.9. Dispersion Structure Schematic

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jian, X.; Wu, B.; Wei, Y.; Dou, S.X.; Wang, X.; He, W.; Mahmood, N. Facile Synthesis of Fe3O4/GCs Composites and Their Enhanced Microwave Absorption Properties. ACS Appl. Mater. Interfaces 2016, 8, 6101–6109. [Google Scholar] [CrossRef]

- Jiao, Z.; Huyan, W.; Yang, F.; Yao, J.; Tan, R.; Chen, P.; Tao, X.; Yao, Z.; Zhou, J.; Liu, P. Achieving Ultra-Wideband and Elevated Temperature Electromagnetic Wave Absorption via Constructing Lightweight Porous Rigid Structure. Nano-Micro Lett. 2022, 14, 173. [Google Scholar] [CrossRef] [PubMed]

- Zoughi, R.; Arias-Monje, P.J.; Gallion, J.; Sarkar, S.; Wang, P.-H.; Gulgunje, P.; Verghese, N.; Kumar, S. Microwave dielectric properties and Targeted heating of polypropylene nano-composites containing carbon nanotubes and carbon black. Polymer 2019, 179, 121658. [Google Scholar] [CrossRef]

- Wang, L.; Wang, W.; Fu, Y.; Wang, J.; Lvov, Y.; Liu, J.; Lu, Y.; Zhang, L. Enhanced electrical and mechanical properties of rubber/graphene film through layer-by-layer electrostatic assembly. Compos. Part B Eng. 2016, 90, 457–464. [Google Scholar] [CrossRef]

- Wu, H.-Y.; Zhang, Y.-P.; Jia, L.-C.; Yan, D.-X.; Gao, J.-F.; Li, Z.-M. Injection Molded Segregated Carbon Nanotube/Polypropylene Composite for Efficient Electromagnetic Interference Shielding. Ind. Eng. Chem. Res. 2018, 57, 12378–12385. [Google Scholar] [CrossRef]

- Jia, L.-C.; Yan, D.-X.; Jiang, X.; Pang, H.; Gao, J.-F.; Ren, P.-G.; Li, Z.-M. Synergistic Effect of Graphite and Carbon Nanotubes on Improved Electromagnetic Interference Shielding Performance in Segregated Composites. Ind. Eng. Chem. Res. 2018, 57, 11929–11938. [Google Scholar] [CrossRef]

- Joseph, N.; Janardhanan, C.; Sebastian, M.T. Electromagnetic interference shielding properties of butyl rubber-single walled carbon nanotube composites. Compos. Sci. Technol. 2014, 101, 139–144. [Google Scholar] [CrossRef]

- Jia, L.-C.; Yan, D.-X.; Yang, Y.; Zhou, D.; Cui, C.-H.; Bianco, E.; Lou, J.; Vajtai, R.; Li, B.; Ajayan, P.M.; et al. High Strain Tolerant EMI Shielding Using Carbon Nanotube Network Stabilized Rubber Composite. Adv. Mater. Technol. 2017, 2, 1700078. [Google Scholar] [CrossRef]

- Pawar, S.P.; Rzeczkowski, P.; Pötschke, P.; Krause, B.; Bose, S. Does the Processing Method Resulting in Different States of an Interconnected Network of Multiwalled Carbon Nanotubes in Polymeric Blend Nanocomposites Affect EMI Shielding Properties? ACS Omega 2018, 3, 5771–5782. [Google Scholar] [CrossRef]

- Nallabothula, H.; Bhattacharjee, Y.; Samantara, L.; Bose, S. Processing-Mediated Different States of Dispersion of Multiwalled Carbon Nanotubes in PDMS Nanocomposites Influence EMI Shielding Performance. ACS Omega 2019, 4, 1781–1790. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Y.; Hua, W.; Zhang, A.; Bao, J. Light-Weight Silver Plating Foam and Carbon Nanotube Hybridized Epoxy Composite Foams with Exceptional Conductivity and Electromagnetic Shielding Property. ACS Appl. Mater. Interfaces 2016, 8, 24131–24142. [Google Scholar] [CrossRef] [PubMed]

- Sambyal, P.; Iqbal, A.; Hong, J.; Kim, H.; Kim, M.-K.; Hong, S.M.; Han, M.; Gogotsi, Y.; Koo, C.M. Ultralight and Mechanically Robust Ti3C2Tx Hybrid Aerogel Reinforced by Carbon Nanotubes for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2019, 11, 38046–38054. [Google Scholar] [CrossRef] [PubMed]

- Anasori, B.; Naguib, M.; Editors, G. Two-dimensional MXenes. MRS Bull. 2023, 48, 238–244. [Google Scholar] [CrossRef]

- Mathur, P.; Raman, S. Electromagnetic Interference (EMI): Measurement and Reduction Techniques. J. Electron. Mater. 2020, 49, 2975–2998. [Google Scholar] [CrossRef]

- Riazi, H.; Taghizadeh, G.; Soroush, M. MXene-Based Nanocomposite Sensors. ACS Omega 2021, 6, 11103–11112. [Google Scholar] [CrossRef]

- Xia, Q.; Fan, Y.; Li, S.; Zhou, A.; Shinde, N.; Mane, R.S. MXene-based chemical gas sensors: Recent developments and challenges. Diam. Relat. Mater. 2023, 131, 109557. [Google Scholar] [CrossRef]

- Li, D.-D.; Pu, X.; Hu, P.; Han, M.; Xin, W.; Ma, M.-G. Multifunctional Ti3C2Tx MXene/montmorillonite/cellulose nanofibril films for electromagnetic interference shielding, photothermal conversion, and thermal insulation. Cellulose 2023, 30, 3793–3805. [Google Scholar] [CrossRef]

- Cheng, H.; Xing, L.; Zuo, Y.; Pan, Y.; Huang, M.; Alhadhrami, A.; Ibrahim, M.M.; El-Bahy, Z.M.; Liu, C.; Shen, C.; et al. Constructing nickel chain/MXene networks in melamine foam towards phase change materials for thermal energy management and absorption-dominated electromagnetic interference shielding. Adv. Compos. Hybrid Mater. 2022, 5, 755–765. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, Z.; Zhang, Y.; Peng, Y.; Wang, Z.; Xia, L.; Ma, S.; Yin, Z.; Wang, R.; Cao, Y.; et al. The recent progress of MXene-Based microwave absorption materials. Carbon 2020, 174, 484–499. [Google Scholar] [CrossRef]

- Han, M.; Liu, Y.; Rakhmanov, R.; Israel, C.; Tajin, A.S.; Friedman, G.; Volman, V.; Hoorfar, A.; Dandekar, K.R.; Gogotsi, Y. Solution-Processed Ti3C2Tx MXene Antennas for Radio-Frequency Communication. Adv. Mater. 2021, 33, 2003225. [Google Scholar] [CrossRef]

- Zhou, A.; Liu, Y.; Li, S.; Wang, X.; Ying, G.; Xia, Q.; Zhang, P. From structural ceramics to 2D materials with multi-applications: A review on the development from MAX phases to MXenes. J. Adv. Ceram. 2021, 10, 1194–1242. [Google Scholar] [CrossRef]

- Xu, W.; Chen, L.; Han, S.; Cao, P.J.; Fang, M.; Liu, W.J.; Zhu, D.L.; Lu, Y.M. Aqueous Solution-Processed Boron-Doped Gallium Oxide Dielectrics for High-Performance Thin-Film Transistors. J. Phys. Chem. C 2020, 124, 8015–8023. [Google Scholar] [CrossRef]

- Lu, S.; Li, B.; Ma, K.; Wang, S.; Liu, X.; Ma, Z.; Lin, L.; Zhou, G.; Zhang, D. Flexible MXene/EPDM rubber with excellent thermal conductivity and electromagnetic interference performance. Appl. Phys. A 2020, 126, 513. [Google Scholar] [CrossRef]

- Luo, J.-Q.; Zhao, S.; Zhang, H.-B.; Deng, Z.; Li, L.; Yu, Z.-Z. Flexible, stretchable and electrically conductive MXene/natural rubber nanocomposite films for efficient electromagnetic interference shielding. Compos. Sci. Technol. 2019, 182, 107754. [Google Scholar] [CrossRef]

- Dee, N.T.; Bedewy, M.; Rao, A.; Beroz, J.; Lee, B.; Meshot, E.R.; Chazot, C.A.C.; Kidambi, P.R.; Zhao, H.; Serbowicz, T.; et al. In Situ Mechanochemical Modulation of Carbon Nanotube Forest Growth. Chem. Mater. 2019, 31, 407–418. [Google Scholar] [CrossRef]

| Items | MH dNm | ML dNm | MH-ML dNm | t10 min | t90 min |

|---|---|---|---|---|---|

| SR/10MX | 19.53 | 10.41 | 9.12 | 0.65 | 4.02 |

| SR/10MX10HEMWCNTs | 13.31 | 6.92 | 6.39 | 0.36 | 2.48 |

| SR/10NiMWCNTs | 25.60 | 3.63 | 21.97 | 0.36 | 2.21 |

| SR/10MX10NiMWCNTs | 19.08 | 4.11 | 14.98 | 0.31 | 1.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, X.; Liu, L.; Ding, N.; Liu, G. Transformation from Electromagnetic Inflection to Absorption of Silicone Rubber and Accordion-Shaped Ti3C2MXene Composites by Highly Electric Conductive Multi-Walled Carbon Nanotubes. Polymers 2023, 15, 2332. https://doi.org/10.3390/polym15102332

Guo X, Liu L, Ding N, Liu G. Transformation from Electromagnetic Inflection to Absorption of Silicone Rubber and Accordion-Shaped Ti3C2MXene Composites by Highly Electric Conductive Multi-Walled Carbon Nanotubes. Polymers. 2023; 15(10):2332. https://doi.org/10.3390/polym15102332

Chicago/Turabian StyleGuo, Xin, Li Liu, Naixiu Ding, and Guangye Liu. 2023. "Transformation from Electromagnetic Inflection to Absorption of Silicone Rubber and Accordion-Shaped Ti3C2MXene Composites by Highly Electric Conductive Multi-Walled Carbon Nanotubes" Polymers 15, no. 10: 2332. https://doi.org/10.3390/polym15102332