The Interconnection of Carbon Active Addition on Mechanical Properties of Hybrid Agel/Glass Fiber-Reinforced Green Composite

Abstract

:1. Introduction

2. Materials and Methods

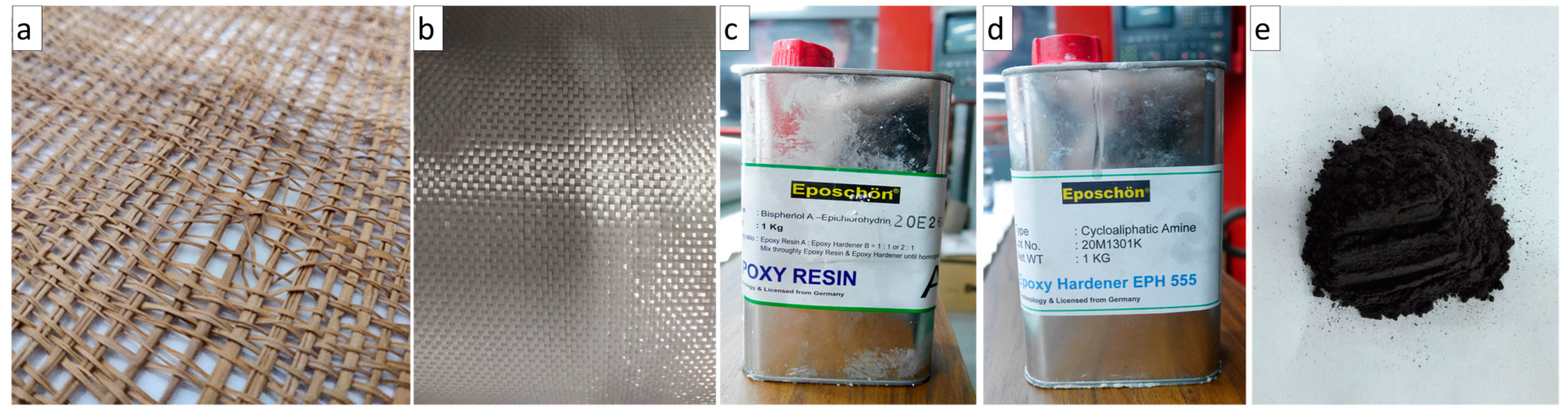

2.1. Materials

2.2. Methods

2.2.1. Mixing Epoxy Resin and Filler

2.2.2. Manufacturing Composite

3. Results and Discussion

3.1. Volume Fraction

3.2. Dispersion Analysis

3.3. Tensile Test

3.4. Flexural Test

3.5. Micrograph Analysis

4. Conclusions

- The effect of adding filler on tensile strength shows that composites obtain the highest tensile strength by adding 1% filler, which is 112.90 MPa. Composites receive the lowest tensile strength by adding 4% filler, 87.14 MPa. Composites obtained the highest tensile modulus by adding 1% filler was 1.80 GPa, while the lowest was 1.30 GPa in composites with 4% filler;

- The flexural test has revealed that the composite with 1% filler has the highest strength of 85.26 MPa, while the composite with 4% filler shows the lowest bending strength of 74.31 MPa;

- The poor dispersion of 4% filler leads to inducing agglomeration phenomenon. The agglomeration phenomenon reduces the mechanical performance of the hybrid composite. The better dispersion has obtained by 1% filler. The optimum value of filler can enhance the mechanical performance of the composite. The filler’s shape and size allow suitable interaction with the epoxy resin, thereby inhibiting the mobility of the epoxy chain. Suitable interaction confirms that the increase in strength and modulus is related to the optimum value of filler addition;

- Micrograph observations have proven several failures in each test specimen, including debonding, fiber pull-out, and cracks in the fiber and matrix.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muflikhun, M.A.; Yokozeki, T.; Aoki, T. The Strain Performance of Thin CFRP-SPCC Hybrid Laminates for Automobile Structures. Compos. Struct. 2019, 220, 11–18. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Syahril, M.; Muflikhun, M.A. Excellent Performance of Hybrid Model Manufactured via Additive Manufacturing Process Reinforced with GFRP for Sport Climbing Equipment. Heliyon 2023, 9, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Tran, T.Q.; Lee, J.K.Y.; Chinnappan, A.; Loc, N.H.; Tran, L.T.; Ji, D.; Jayathilaka, W.A.D.M.; Kumar, V.V.; Ramakrishna, S. High-Performance Carbon Fiber/Gold/Copper Composite Wires for Lightweight Electrical Cables. J. Mater. Sci. Technol. 2020, 42, 46–53. [Google Scholar] [CrossRef]

- Kumar, V.V.; Balaganesan, G.; Lee, J.K.Y.; Neisiany, R.E.; Surendran, S.; Ramakrishna, S. A Review of Recent Advances in Nanoengineered Polymer Composites. Polymers 2019, 11, 644. [Google Scholar] [CrossRef] [PubMed]

- Saba, N.; Jawaid, M.; Sultan, M.T.H.; Alothman, O. Hybrid Multifunctional Composites-Recent Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081007860. [Google Scholar]

- Panthapulakkal, S.; Raghunanan, L.; Sain, M.; Kc, B.; Tjong, J. Natural Fiber and Hybrid Fiber Thermoplastic Composites: Advancements in Lightweighting Applications; Woodhead Publishing: Sawston, UK, 2017; ISBN 9780081008003. [Google Scholar]

- Andrei, G.; Dima, D.; Andrei, L. Lightweight Magnetic Composites for Aircraft Applications. J. Optoelectron. Adv. Mater. 2006, 8, 726–730. [Google Scholar]

- Ganesarajan, D.; Simon, L.; Tamrakar, S.; Kiziltas, A.; Mielewski, D.; Behabtu, N.; Lenges, C. Hybrid Composites with Engineered Polysaccharides for Automotive Lightweight. Compos. Part C Open Access 2022, 7, 100222. [Google Scholar] [CrossRef]

- Manimaran, P.; Senthamaraikannan, P.; Sanjay, M.R.; Marichelvam, M.K.; Jawaid, M. Study on Characterization of Furcraea Foetida New Natural Fiber as Composite Reinforcement for Lightweight Applications. Carbohydr. Polym. 2018, 181, 650–658. [Google Scholar] [CrossRef]

- Hao, M.; Hu, Y.; Wang, B.; Liu, S. Mechanical Behavior of Natural Fiber-Based Isogrid Lattice Cylinder. Compos. Struct. 2017, 176, 117–123. [Google Scholar] [CrossRef]

- Karthi, N.; Kumaresan, K.; Sathish, S.; Gokulkumar, S.; Prabhu, L.; Vigneshkumar, N. An Overview: Natural Fiber Reinforced Hybrid Composites, Chemical Treatments and Application Areas. Mater. Today Proc. 2019, 27, 2828–2834. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayanti, R.; Subiyanto, B.; Fatriasari, W.; Fudholi, A. A Review on Natural Fibers for Development of Eco-Friendly Bio-Composite: Characteristics, and Utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of Natural Fiber Composites: Challenges and Opportunities. Resour. Conserv. Recycl. 2022, 177, 105962. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Benthien, J.T.; Thoemen, H.; White, R.H. Properties of Flat-Pressed Wood Plastic Composites Containing Fire Retardants. J. Appl. Polym. Sci. 2011, 122, 3201–3210. [Google Scholar] [CrossRef]

- Andre, N.G.; Ariawan, D.; Mohd Ishak, Z.A. Mechanical Properties and Micromechanical Analysis of Nonwoven Kenaf Fibre/Epoxy Composites Produced by Resin Transfer Moulding. J. Compos. Mater. 2017, 51, 1875–1885. [Google Scholar] [CrossRef]

- Johnson, W.S.; Li, E.; Miller, J.L. High Temperature Hybrid Titanium Composite Laminates: An Early Analytical Assessment. Appl. Compos. Mater. 1996, 3, 379–390. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Czél, G.; Swolfs, Y.; Jalalvand, M.; Gorbatikh, L.; Verpoest, I. Hybrid Effects in Thin Ply Carbon/Glass Unidirectional Laminates: Accurate Experimental Determination and Prediction. Compos. Part A Appl. Sci. Manuf. 2016, 88, 131–139. [Google Scholar] [CrossRef]

- Deniz, M.E.; Aydin, F. Determination of Fatigue Life of the Unidirectional GFRP/Al Hybrid Composite Laminates. Compos. B Eng. 2019, 166, 580–587. [Google Scholar] [CrossRef]

- Machado, J.J.M.; Nunes, P.D.P.; Marques, E.A.S.; da Silva, L.F.M. Adhesive Joints Using Aluminium and CFRP Substrates Tested at Low and High Temperatures under Quasi-Static and Impact Conditions for the Automotive Industry. Compos. B Eng. 2019, 158, 102–116. [Google Scholar] [CrossRef]

- Zinn, C.; Schaper, M.; Gonzalez, J.S.; Meiners, D.; Wang, Z.; Troester, T.; Pottmeyer, F.; Weidenmann, K.A. Shear Edge Tests: A Benchmark in Investigating the Influence of Different Surface Pretreatment Methods on the Shear Stress of Intrinsically Manufactured Metal-CFRP Hybrids. Int. J. Automot. Compos. 2016, 2, 244–271. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Yokozeki, T. Experimental and Numerical Analysis of CFRP-SPCC Hybrid Laminates for Automotive and Structural Applications with Cost Analysis Assessment. Compos. Struct. 2021, 263, 113707. [Google Scholar] [CrossRef]

- Wang, Z.; Lauter, C.; Sanitther, B.; Camberg, A.; Troester, T. Manufacturing and Investigation of Steel-CFRP Hybrid Pillar Structures for Automotive Applications by Intrinsic Resin Transfer Moulding Technology. Int. J. Automot. Compos. 2016, 2, 229–243. [Google Scholar] [CrossRef]

- Santhanakrishnan Balakrishnan, V.; Seidlitz, H. Potential Repair Techniques for Automotive Composites: A Review. Compos. B Eng. 2018, 145, 28–38. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Yokozeki, T. Systematic Analysis of Fractured Specimens of Composite Laminates: Different Perspectives between Tensile, Flexural, Mode I, and Mode II Test. Int. J. Lightweight Mater. Manuf. 2023, 6, 329–343. [Google Scholar] [CrossRef]

- Coutinho, F.M.B.; Costa, T.H.S.; Carvalho, D.L. Polypropylene-Wood Fiber Composites: Effect of Treatment and Mixing Conditions on Mechanical Properties. J. Appl. Polym. Sci. 1997, 65, 1227–1235. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Fiedler, B. Failure Prediction and Surface Characterization of GFRP Laminates: A Study of Stepwise Loading. Polymers 2022, 14, 4322. [Google Scholar] [CrossRef] [PubMed]

- Chapman, M.; Dhakal, H.N. Effects of Hybridisation on the Low Velocity Falling Weight Impact and Flexural Properties of Flax-Carbon/Epoxy Hybrid Composites. Fibers 2019, 7, 95. [Google Scholar] [CrossRef]

- Gargano, A.; Pingkarawat, K.; Blacklock, M.; Pickerd, V.; Mouritz, A.P. Comparative Assessment of the Explosive Blast Performance of Carbon and Glass Fibre-Polymer Composites Used in Naval Ship Structures. Compos. Struct. 2017, 171, 306–316. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Nuryanta, M.I.; Sean, L.; Budiman, K.; Kusni, M.; Muflikhun, M.A. Recent Progress on Natural Fibers Mixed with CFRP and GFRP: Properties, Characteristics, and Failure Behaviour. Polymers 2022, 14, 5138. [Google Scholar] [CrossRef]

- Uppal, N.; Pappu, A.; Gowri, V.K.S.; Thakur, V.K. Cellulosic Fibres-Based Epoxy Composites: From Bioresources to a Circular Economy. Ind. Crops Prod. 2022, 182, 114895. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent Advancements of Plant-Based Natural Fiber–Reinforced Composites and Their Applications. Compos. B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Nuryanta, M.I. Pengaruh Penambahan Filler Karbon Aktif Terhadap Sifat Mekanis Komposit Hibrid Yang Diperkuat Serat Agel Dan Serat Gelas. Ph.D. Thesis, Universitas Gadjah Mada, Yogyakarta, Indonesia, 2022. [Google Scholar]

- Ahmad, J.; Zhou, Z. Mechanical Properties of Natural as Well as Synthetic Fiber Reinforced Concrete: A Review. Constr. Build. Mater. 2022, 333, 127353. [Google Scholar] [CrossRef]

- Pramanik, S.K.; Suja, F.B.; Zain, S.; Pramanik, B.K. Surface Treatment to Improve Water Repellence and Compatibility of Natural Fiber with Polymer Matrix: Recent Advancement. Bioresour. Technol. Rep. 2019, 115, 107707. [Google Scholar]

- Muneer Ahmed, M.; Dhakal, H.N.; Zhang, Z.Y.; Barouni, A.; Zahari, R. Enhancement of Impact Toughness and Damage Behaviour of Natural Fibre Reinforced Composites and Their Hybrids through Novel Improvement Techniques: A Critical Review. Compos. Struct. 2021, 259, 113496. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, M.; Chen, L. Interface and Bonding Mechanisms of Plant Fibre Composites: An Overview. Compos. B Eng. 2016, 101, 31–45. [Google Scholar] [CrossRef]

- Negawo, T.A.; Polat, Y.; Buyuknalcaci, F.N.; Kilic, A.; Saba, N.; Jawaid, M. Mechanical, Morphological, Structural and Dynamic Mechanical Properties of Alkali Treated Ensete Stem Fibers Reinforced Unsaturated Polyester Composites. Compos. Struct. 2019, 207, 589–597. [Google Scholar] [CrossRef]

- Xu, F.; Sun, J.X.; Liu, C.F.; Sun, R.C. Comparative Study of Alkali- and Acidic Organic Solvent-Soluble Hemicellulosic Polysaccharides from Sugarcane Bagasse. Carbohydr. Res. 2006, 341, 253–261. [Google Scholar] [CrossRef]

- Poletanovic, B.; Janotka, I.; Janek, M.; Bacuvcik, M.; Merta, I. Influence of the NaOH-Treated Hemp Fibres on the Properties of Fly-Ash Based Alkali-Activated Mortars Prior and after Wet/Dry Cycles. Constr. Build. Mater. 2021, 309, 125072. [Google Scholar] [CrossRef]

- Jain, D.; Kamboj, I.; Bera, T.K.; Kang, A.S.; Singla, R.K. Experimental and Numerical Investigations on the Effect of Alkaline Hornification on the Hydrothermal Ageing of Agave Natural Fiber Composites. Int. J. Heat Mass Transf. 2019, 130, 431–439. [Google Scholar] [CrossRef]

- De Souza, R.; Maria, L.; De Souza, S.; Souto, F.; Liebscher, M. Effect of Alkali Treatment on Physical—Chemical Properties of Sisal Fibers and Adhesion towards Cement-Based Matrices. Constr. Build. Mater. 2022, 345, 128363. [Google Scholar]

- Chung, D.D.L. Processing-Structure-Property Relationships of Continuous Carbon Fiber Polymer-Matrix Composites. Mater. Sci. Eng. R Rep. 2017, 113, 1–29. [Google Scholar] [CrossRef]

- Gackowski, B.M.; Phua, H.; Sharma, M.; Idapalapati, S. Hybrid Additive Manufacturing of Polymer Composites Reinforced with Buckypapers and Short Carbon Fibres. Compos. Part A Appl. Sci. Manuf. 2022, 154, 106794. [Google Scholar] [CrossRef]

- Messiry, M. El Theoretical Analysis of Natural Fiber Volume Fraction of Reinforced Composites. Alex. Eng. J. 2013, 52, 301–306. [Google Scholar] [CrossRef]

- Vo, H.N.; Pucci, M.F.; Drapier, S.; Liotier, P.J. Capillary Pressure Contribution in Fabrics as a Function of Fibre Volume Fraction for Liquid Composite Moulding Processes. Colloids Surf. A Physicochem. Eng. Asp. 2022, 635, 128120. [Google Scholar] [CrossRef]

- Ali, M.I.; Anjaneyulu, J. Effect of Fiber-Matrix Volume Fraction and Fiber Orientation on the Design of Composite Suspension System. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012104. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Sathish, S.; Gokulkumar, S.; Karthi, N.; Rajeshkumar, L.; Balaji, D.; Vigneshkumar, N.; Elango, K.S. A Review on Natural Fiber Reinforced Hybrid Composites: Chemical Treatments, Manufacturing Methods and Potential Applications. Mater. Today Proc. 2021, 45, 8080–8085. [Google Scholar] [CrossRef]

- Amiri, A.; Ulven, C.A.; Huo, S. Effect of Chemical Treatment of Flax Fiber and Resin Manipulation on Service Life of Their Composites Using Time-Temperature Superposition. Polymers 2015, 7, 1965–1978. [Google Scholar] [CrossRef]

- Morkavuk, S.; Köklü, U.; Bağcı, M.; Gemi, L. Cryogenic Machining of Carbon Fiber Reinforced Plastic (CFRP) Composites and the Effects of Cryogenic Treatment on Tensile Properties: A Comparative Study. Compos. B Eng. 2018, 147, 1–11. [Google Scholar] [CrossRef]

- Heide-Jørgensen, S.; Budzik, M.K.; Ibsen, C.H. Three-Dimensional, Multiscale Homogenization for Hybrid Woven Composites with Fiber-Matrix Debonding. Compos. Sci. Technol. 2022, 218, 109204. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Yokozeki, T. Steel Plate Cold Commercial-Carbon Fiber Reinforce Plastics Hybrid Laminates for Automotive Applications: Curing Perspective with Thermal Residual Effect. J. Mater. Res. Technol. 2021, 14, 2700–2714. [Google Scholar] [CrossRef]

- Jiang, H.; Li, C.; Mao, X.; Chen, L.; Zhao, W.; Si, X.; Qi, J.; Dong, Z.; Cao, J. Vacuum Brazing of AlON and Ti2AlNb with LiAlSiO4 Enhanced Ag–Cu–Ti Composite Fillers: Microstructure, Mechanical Properties and Measurement of Residual Stress. Mater. Sci. Eng. A 2022, 846, 143277. [Google Scholar] [CrossRef]

- Muzammil, M.; Ejaz, M.; Shah, R.; Afaq, S.K.; Song, J. A Bio-Based Approach to Simultaneously Improve Flame Retardancy, Thermal Stability and Mechanical Properties of Nano-Silica Filled Jute/Thermoplastic Starch Composite. Mater. Chem. Phys. 2022, 289, 126485. [Google Scholar]

- Ahmed, M.B.; Hasan Johir, M.A.; Zhou, J.L.; Ngo, H.H.; Nghiem, L.D.; Richardson, C.; Moni, M.A.; Bryant, M.R. Activated Carbon Preparation from Biomass Feedstock: Clean Production and Carbon Dioxide Adsorption. J. Clean. Prod. 2019, 225, 405–413. [Google Scholar] [CrossRef]

- Saleem, J.; Bin Shahid, U.; Hijab, M.; Mackey, H.; McKay, G. Production and Applications of Activated Carbons as Adsorbents from Olive Stones. Biomass Convers. Biorefinery 2019, 9, 775–802. [Google Scholar] [CrossRef]

- Mishra, S.; Yadav, S.S.; Rawat, S.; Singh, J.; Koduru, J.R. Corn Husk Derived Magnetized Activated Carbon for the Removal of Phenol and Para-Nitrophenol from Aqueous Solution: Interaction Mechanism, Insights on Adsorbent Characteristics, and Isothermal, Kinetic and Thermodynamic Properties. J. Environ. Manag. 2019, 246, 362–373. [Google Scholar] [CrossRef]

- Mostafa, N.H.; Hunain, M.B.; Jassim, A. Mechanical Properties of the Jute Fibers-Activated Carbon Filled Reinforced Polyester Composites. Mater Res. Express 2019, 6, 125104. [Google Scholar] [CrossRef]

- Sravanthi, K.; Mahesh, V.; Rao, B.N. Influence of Micro and Nano Carbon Fillers on Impact Behavior of GFRP Composite Materials. Mater. Today Proc. 2020, 37, 1075–1078. [Google Scholar] [CrossRef]

- Li, Y.T.; Liu, W.J.; Shen, F.X.; Zhang, G.D.; Gong, L.X.; Zhao, L.; Song, P.; Gao, J.F.; Tang, L.C. Processing, Thermal Conductivity and Flame Retardant Properties of Silicone Rubber Filled with Different Geometries of Thermally Conductive Fillers: A Comparative Study. Compos. B Eng. 2022, 238, 109907. [Google Scholar] [CrossRef]

- Singh, H.; Batra, N.K.; Dikshit, I. Materials Today: Proceedings Development of New Hybrid Jute/Carbon/Fishbone Reinforced Polymer Composite. Mater. Today Proc. 2021, 38, 29–33. [Google Scholar] [CrossRef]

- Sari, N.H.; Suteja, S.; Fudholi, A.; Zamzuriadi, A.; Sulistyowati, E.D.; Pandiatmi, P.; Sinarep, S.; Zainuri, A. Morphology and Mechanical Properties of Coconut Shell Powder-Filled Untreated Cornhusk Fibre-Unsaturated Polyester Composites. Polymer 2021, 222, 123657. [Google Scholar] [CrossRef]

- Chandramohan, N.K. Variation in Compressive and Flexural Strength of the Carbon Epoxy Composites with the Addition of Various Fillers to the Epoxy Resin. Mater. Today Proc. 2020, 21, 643–647. [Google Scholar] [CrossRef]

- Barczewski, M.; Hejna, A.; Aniśko, J.; Andrzejewski, J.; Piasecki, A.; Mysiukiewicz, O.; Bąk, M.; Gapiński, B.; Ortega, Z. Rotational Molding of Polylactide (PLA) Composites Filled with Copper Slag as a Waste Filler from Metallurgical Industry. Polym. Test. 2022, 106, 107449. [Google Scholar] [CrossRef]

- Ramesh, A.; Ramu, K.; Ali Baig, M.A.; Guptha, E.D. Influence of Fly Ash Nano Filler on the Tensile and Flexural Properties of Novel Hybrid Epoxy Nano-Composites. Mater. Today Proc. 2020, 27, 1252–1257. [Google Scholar] [CrossRef]

- Bekhta, A.; Hsissou, R.; Berradi, M.; El Bouchti, M.; Elharfi, A. Viscosimetric and Rheological Properties of Epoxy Resin TGEUBA and Their Composite (TGEUBA/MDA/TGEMDA+TSP). Results Eng. 2019, 4, 100058. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nuryanta, M.I.; Aryaswara, L.G.; Korsmik, R.; Klimova-Korsmik, O.; Nugraha, A.D.; Darmanto, S.; Kusni, M.; Muflikhun, M.A. The Interconnection of Carbon Active Addition on Mechanical Properties of Hybrid Agel/Glass Fiber-Reinforced Green Composite. Polymers 2023, 15, 2411. https://doi.org/10.3390/polym15112411

Nuryanta MI, Aryaswara LG, Korsmik R, Klimova-Korsmik O, Nugraha AD, Darmanto S, Kusni M, Muflikhun MA. The Interconnection of Carbon Active Addition on Mechanical Properties of Hybrid Agel/Glass Fiber-Reinforced Green Composite. Polymers. 2023; 15(11):2411. https://doi.org/10.3390/polym15112411

Chicago/Turabian StyleNuryanta, Muhammad Irfan, Lugas Gada Aryaswara, Rudolf Korsmik, Olga Klimova-Korsmik, Ariyana Dwiputra Nugraha, Seno Darmanto, Muhammad Kusni, and Muhammad Akhsin Muflikhun. 2023. "The Interconnection of Carbon Active Addition on Mechanical Properties of Hybrid Agel/Glass Fiber-Reinforced Green Composite" Polymers 15, no. 11: 2411. https://doi.org/10.3390/polym15112411

APA StyleNuryanta, M. I., Aryaswara, L. G., Korsmik, R., Klimova-Korsmik, O., Nugraha, A. D., Darmanto, S., Kusni, M., & Muflikhun, M. A. (2023). The Interconnection of Carbon Active Addition on Mechanical Properties of Hybrid Agel/Glass Fiber-Reinforced Green Composite. Polymers, 15(11), 2411. https://doi.org/10.3390/polym15112411