Fused Filament Fabricated Poly(lactic acid) Parts Reinforced with Short Carbon Fiber and Graphene Nanoparticles with Improved Tribological Properties

Abstract

:1. Introduction

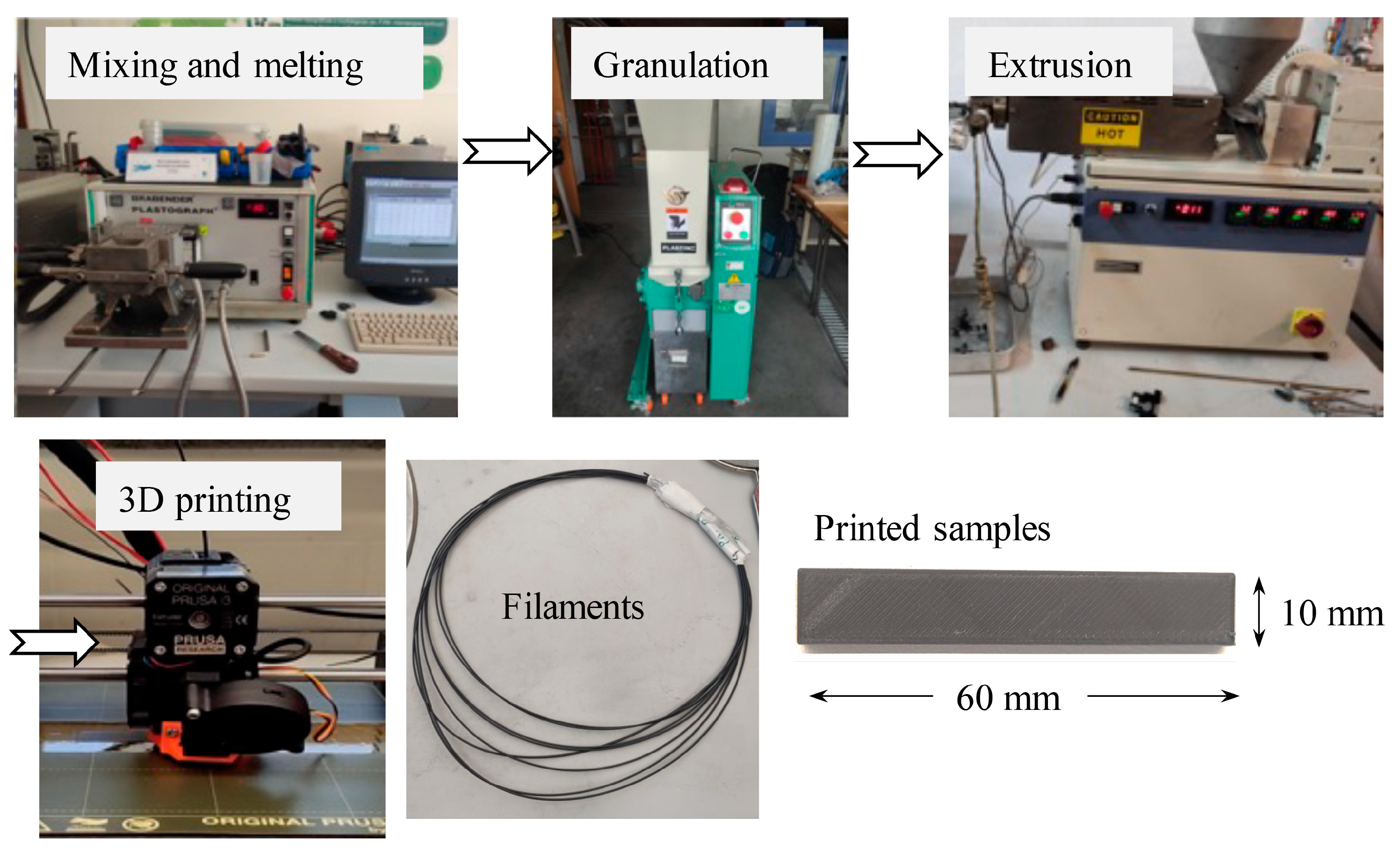

2. Materials and Methods

3. Results and Discussions

3.1. Raw Materials

3.2. Mixture of PLA with the Reinforcements

3.3. Production of the Filaments

D-Printed Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef] [PubMed]

- Ivey, M.; Melenka, G.W.; Carey, J.P.; Ayranci, C. Characterizing Short-Fiber-Reinforced Composites Produced Using Additive Manufacturing. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 81–91. [Google Scholar] [CrossRef]

- Wang, Z.Z.; Gu, P.; Zhang, Z. Indentation and Scratch Behavior of Nano-SiO2/Polycarbonate Composite Coating at the Micro/Nano-Scale. Wear 2010, 269, 21–25. [Google Scholar] [CrossRef]

- Bayer, I. Thermomechanical Properties of Polylactic Acid-Graphene Composites: A State-of-The-Art Review for Biomedical Applications. Materials 2017, 10, 748. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, C.; Pinto, A.; Machado, A.V.; Moreira, J.; Gonçalves, I.C.; Magalhães, F. Biocompatible Reinforcement of Poly(Lactic Acid) with Graphene Nanoplatelets. Polym. Compos. 2016, 39, E308–E320. [Google Scholar] [CrossRef]

- Prashantha, K.; Roger, F. Multifunctional Properties of 3D Printed Poly(Lactic Acid)/Graphene Nanocomposites by Fused Deposition Modeling. J. Macromol. Sci. A 2016, 54, 24–29. [Google Scholar] [CrossRef]

- Lin, A.-D.; Kuang, J.-H. Dynamic Interaction between Contact Loads and Tooth Wear of Engaged Plastic Gear Pairs. Int. J. Mol. Sci. 2008, 50, 205–213. [Google Scholar] [CrossRef]

- Rabinowicz, E. Friction and Wear of Materials; John Wiley & Sons: New York, NY, USA; Toronto, ON, USA, 1995; ISBN 9780471830849. [Google Scholar]

- Friedrich, K.; Zhang, Z.; Schlarb, A. Effects of Various Fillers on the Sliding Wear of Polymer Composites. Compos. Sci. Technol. 2005, 65, 2329–2343. [Google Scholar] [CrossRef]

- Khun, N.W.; Liu, E. Thermal, Mechanical and Tribological Properties of Polycarbonate/Acrylonitrile-Butadiene-Styrene Blends. J. Polym. Eng. 2013, 33, 535–543. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ren, Z.; Chou, T.-W. Advances in the Science and Technology of Carbon Nanotubes and Their Composites: A Review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef]

- Novoselov, K.S. Electric Field Effect in Atomically Thin Carbon Films. Science. 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Quan, H.; Zhang, B.; Zhao, Q.; Yuen, R.K.K.; Li, R.K.Y. Facile Preparation and Thermal Degradation Studies of Graphite Nanoplatelets (GNPs) Filled Thermoplastic Polyurethane (TPU) Nanocomposites. Compos. A Appl. Sci. Manuf. 2009, 40, 1506–1513. [Google Scholar] [CrossRef]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Bürger, D. Experimental Characterization and Micrography of 3D Printed PLA and PLA Reinforced with Short Carbon Fibers. Compos. B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Heidari-Rarani, M.; Rafiee-Afarani, M.; Zahedi, A.M. Mechanical Characterization of FDM 3D Printing of Continuous Carbon Fiber Reinforced PLA Composites. Compos. B Eng. 2019, 175, 107147. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Savvakis, K.; Maniadi, A.; Koudoumas, E. A Comprehensive Investigation of the Mechanical Behavior and the Dielectrics of Pure Polylactic Acid (PLA) and PLA with Graphene (GnP) in Fused Deposition Modeling (FDM). Int. J. Plast. Technol. 2019, 23, 195–206. [Google Scholar] [CrossRef]

- Cicero, S.; Martínez-Mata, V.; Castanon-Jano, L.; Alonso-Estebanez, A.; Arroyo, B. Analysis of Notch Effect in the Fracture Behaviour of Additively Manufactured PLA and Graphene Reinforced PLA. Theor. Appl. Fract. Mech. 2021, 114, 103032. [Google Scholar] [CrossRef]

- Gao, Y.; Picot, O.T.; Bilotti, E.; Peijs, T. Influence of Filler Size on the Properties of Poly(Lactic Acid) (PLA)/Graphene Nanoplatelet (GNP) Nanocomposites. Eur. Polym. J. 2017, 86, 117–131. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kourinou, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.; Tzounis, L. Additive Manufacturing of Multifunctional Polylactic Acid (PLA)—Multiwalled Carbon Nanotubes (MWCNTs) Nanocomposites. Nanocomposites 2021, 7, 184–199. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.; Yuan, Q.; Zhang, W. Effects of Carbon Nanotube on the Thermal, Mechanical, and Electrical Properties of PLA/CNT Printed Parts in the FDM Process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Batakliev, T.; Georgiev, V.; Angelov, V.; Ivanov, E.; Kalupgian, C.; Muñoz, P.A.R.; Fechine, G.J.M.; Andrade, R.J.E.; Kotsilkova, R. Synergistic Effect of Graphene Nanoplatelets and Multiwall Carbon Nanotubes Incorporated in PLA Matrix: Nanoindentation of Composites with Improved Mechanical Properties. J. Mater. Eng. Perform. 2021, 30, 3822–3830. [Google Scholar] [CrossRef]

- Mohammed Basheer, E.P.; Marimuthu, K. Carbon Fibre-Graphene Composite Polylactic Acid (PLA) Material for COVID Shield Frame. Mater. Werkst. 2022, 53, 119–127. [Google Scholar] [CrossRef]

- Batakliev, T. Tribological Investigation of PLA-Based Nanocomposites by Scratch and Wear Experiments. J. Theor. Appl. Mech. 2020, 50, 105–113. [Google Scholar] [CrossRef]

- Bustillos, J.; Montero, D.; Nautiyal, P.; Loganathan, A.; Boesl, B.; Agarwal, A. Integration of Graphene in Poly(Lactic) Acid by 3D Printing to Develop Creep and Wear-Resistant Hierarchical Nanocomposites. Polym. Compos. 2017, 39, 3877–3888. [Google Scholar] [CrossRef]

- Suresha, B.; Hanamasagar, V.; Anand, A. Processing and Tribological Behaviour of Carbon Fiber Reinforced Polylactic Acid Composites. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Nagpur, India, 26–28 May 2022. [Google Scholar] [CrossRef]

- Abir, A.A.; Trindade, B. A Comparative Study of Different Poly (Lactic Acid) Bio-Composites Produced by Mechanical Alloying and Casting for Tribological Applications. Materials 2023, 16, 1608. [Google Scholar] [CrossRef] [PubMed]

- Marques, A.T.; Esteves, S.; Pereira, J.P.T.; Oliveira, L.M. Additive Manufacturing Hybrid Processes for Composites Systems; Springer International Publishing: Cham, Switzerland, 2020. [Google Scholar]

- Kraghelsky, I.V. Calculation of Wear Rate. J. Basic Eng. 1965, 87, 785–790. [Google Scholar] [CrossRef]

- Ruz-Cruz, M.A.; Herrera-Franco, P.J.; Flores-Johnson, E.A.; Moreno-Chulim, M.V.; Galera-Manzano, L.M.; Valadez-González, A. Thermal and mechanical properties of PLA-based multiscale cellulosic biocomposites. J. Mater. Res. Technol. 2022, 18, 485–495. [Google Scholar] [CrossRef]

- Vinyas, M.; Athul, S.J.; Harursampath, D.; Nguyen Thoi, T. Experimental evaluation of the mechanical and thermal properties of 3D printed PLA and its composites. Mater. Res. Express 2019, 6, 115301. [Google Scholar] [CrossRef]

- Sorrentino, A.; De Santis, F.; Titomanlio, G. Polymer Crystallization under High Cooling Rate and Pressure: A Step towards Polymer Processing Conditions. In Progress in Understanding of Polymer Crystallization; Springer: Berlin/Heidelberg, Germany, 2007; pp. 329–344. [Google Scholar]

- Tronvoll, S.A.; Vedvik, N.P.; Elverum, C.W.; Welo, T. A new method for assessing anisotropy in fused deposition modeled parts using computed tomography data. Int. J. Adv. Manuf. Technol. 2019, 105, 47–65. [Google Scholar] [CrossRef]

- Chen, Y.; Qi, Y.; Tai, Z.; Yan, X.; Zhu, F.; Xue, Q. Preparation, Mechanical Properties and Biocompatibility of Graphene Oxide/Ultrahigh Molecular Weight Polyethylene Composites. Eur. Polym. J. 2012, 48, 1026–1033. [Google Scholar] [CrossRef]

- Khun, N.W.; Troconis, B.C.R.; Frankel, G.S. Effects of Carbon Nanotube Content on Adhesion Strength and Wear and Corrosion Resistance of Epoxy Composite Coatings on AA2024-T3. Prog. Org. Coat. 2014, 77, 72–80. [Google Scholar] [CrossRef]

- Terrones, M. Science and Technology of the Twenty-First Century: Synthesis, Properties, and Applications of Carbon Nanotubes. Annu. Rev. Mater. Res. 2003, 33, 419–501. [Google Scholar] [CrossRef]

- Leite, M.; Fernandes, J.; Deus, A.M.; Reis, L.; Vaz, M.F. Study of the Influence of 3D Printing Parameters on the Mechanical Properties of PLA. Available online: https://dr.ntu.edu.sg/handle/10220/45960 (accessed on 12 May 2021).

- Kang, J.; Zheng, J.; Hui, Y.; Li, D. Mechanical Properties of 3D-Printed PEEK/HA Composite Filaments. Polymers 2022, 14, 4293. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.-H.; Zhang, Y.-F.; Bai, S.-L.; Yuan, X.-W. Carbon Fibre/Graphene Foam/Polymer Composites with Enhanced Mechanical and Thermal Properties. Compos. B. Eng. 2016, 94, 102–108. [Google Scholar] [CrossRef]

- Abderrafai, Y.; Hadi Mahdavi, M.; Sosa-Rey, F.; Hérard, C.; Otero Navas, I.; Piccirelli, N.; Lévesque, M.; Therriault, D. Additive Manufacturing of Short Carbon Fiber-Reinforced Polyamide Composites by Fused Filament Fabrication: Formulation, Manufacturing and Characterization. Mater. Des. 2022, 214, 110358. [Google Scholar] [CrossRef]

- El Magri, A.; El Mabrouk, K.; Vaudreuil, S.; Ebn Touhami, M. Mechanical Properties of CF-Reinforced PLA Parts Manufactured by Fused Deposition Modeling. J. Thermoplast. Compos. Mater. 2019, 34, 089270571984724. [Google Scholar] [CrossRef]

- Ozkan, C.; Gamze Karsli, N.; Aytac, A.; Deniz, V. Short Carbon Fiber Reinforced Polycarbonate Composites: Effects of Different Sizing Materials. Compos. B Eng. 2014, 62, 230–235. [Google Scholar] [CrossRef]

- Hanon, M.M.; Ghaly, A.; Zsidai, L.; Klébert, S. Tribological Characteristics of Digital Light Processing (DLP) 3D Printed Graphene/Resin Composite: Influence of Graphene Presence and Process Settings. Mater. Des. 2022, 218, 110718. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A New Emerging Lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.-J.; Lee, W.R. A Review on Carbon Nanotubes and Graphene as Fillers in Reinforced Polymer Nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer Composites for Tribological Applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Khun, N.W.; Zhang, H.; Lim, L.H.; Yue, C.Y.; Hu, X.; Yang, J. Tribological Properties of Short Carbon Fibers Reinforced Epoxy Composites. Friction 2014, 2, 226–239. [Google Scholar] [CrossRef]

- Rodriguez, V.; Sukumaran, J.; Schlarb, A.K.; De Baets, P. Reciprocating Sliding Wear Behaviour of PEEK-Based Hybrid Composites. Wear 2016, 362–363, 161–169. [Google Scholar] [CrossRef]

- Lancaster, J.K. Abrasive Wear of Polymers. Wear 1969, 14, 223–239. [Google Scholar] [CrossRef]

| Sample Name | PLA (wt.%) | SCF (wt.%) | GNP (wt.%) |

|---|---|---|---|

| PSG-0.5 | 99 | 0.5 | 0.5 |

| PSG-1 | 98 | 1 | 1 |

| PSG-2 | 96 | 2 | 2 |

| PSG-5 | 90 | 5 | 5 |

| Parameter Name | Value |

|---|---|

| Printed sample dimensions (mm) | 60 × 10 × 3 |

| Extruder Temperature (°C) | 215 |

| Bed | Painter’s tape |

| Bed Temperature (°C) | 60 |

| Cooling (Fan speed) | 100% |

| Layer Thickness (mm) | 0.2 |

| Raster Angle (°) | −45/+45 |

| Infill Density (%) | 100% |

| Nozzle diameter (mm) | 0.8 |

| Sample | H (Shore D) | E (GPa) | H/E |

|---|---|---|---|

| PLA | 63.4 ± 0.8 | 1.86 ± 0.01 | 33.9 |

| PSG-0.5 | 77.8 ± 1.0 | 2.35 ± 0.01 | 33.2 |

| PSG-1 | 79.4 ± 0.5 | 3.14 ± 0.01 | 25.2 |

| PSG-2 | 79.2 ± 0.7 | 3.28 ± 0.02 | 24.1 |

| PSG-5 | 81.1 ± 1.0 | 4.11 ± 0.04 | 19.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Abir, A.; Chakrabarti, D.; Trindade, B. Fused Filament Fabricated Poly(lactic acid) Parts Reinforced with Short Carbon Fiber and Graphene Nanoparticles with Improved Tribological Properties. Polymers 2023, 15, 2451. https://doi.org/10.3390/polym15112451

Al Abir A, Chakrabarti D, Trindade B. Fused Filament Fabricated Poly(lactic acid) Parts Reinforced with Short Carbon Fiber and Graphene Nanoparticles with Improved Tribological Properties. Polymers. 2023; 15(11):2451. https://doi.org/10.3390/polym15112451

Chicago/Turabian StyleAl Abir, Anzum, Dipto Chakrabarti, and Bruno Trindade. 2023. "Fused Filament Fabricated Poly(lactic acid) Parts Reinforced with Short Carbon Fiber and Graphene Nanoparticles with Improved Tribological Properties" Polymers 15, no. 11: 2451. https://doi.org/10.3390/polym15112451

APA StyleAl Abir, A., Chakrabarti, D., & Trindade, B. (2023). Fused Filament Fabricated Poly(lactic acid) Parts Reinforced with Short Carbon Fiber and Graphene Nanoparticles with Improved Tribological Properties. Polymers, 15(11), 2451. https://doi.org/10.3390/polym15112451