PVDF/Clay Spheres Obtained through Phase Inversion for Cu Ion Removal

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PVDF/Clay Mixtures

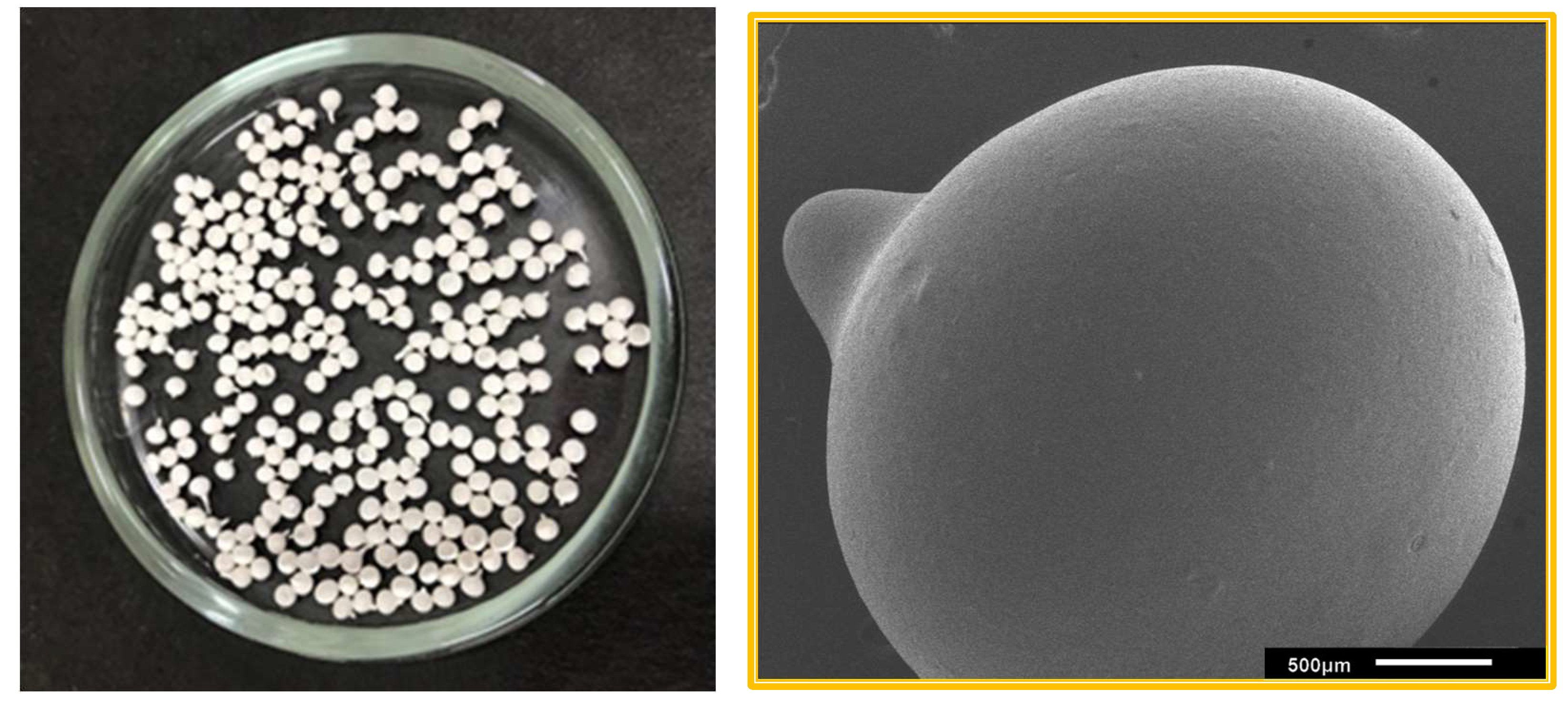

2.3. Preparation of Spheres

2.4. Characterizations

2.5. Adsorption Tests

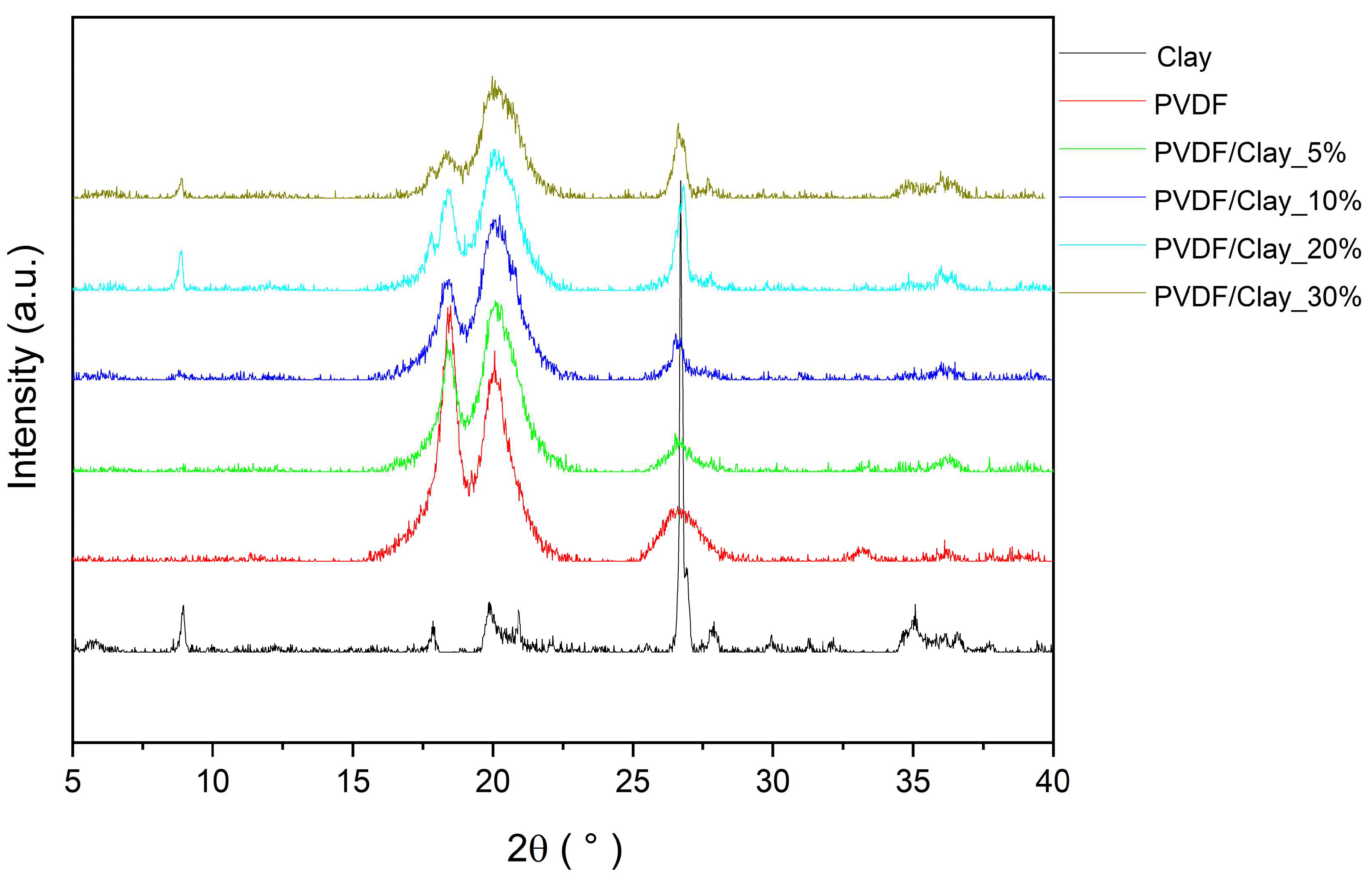

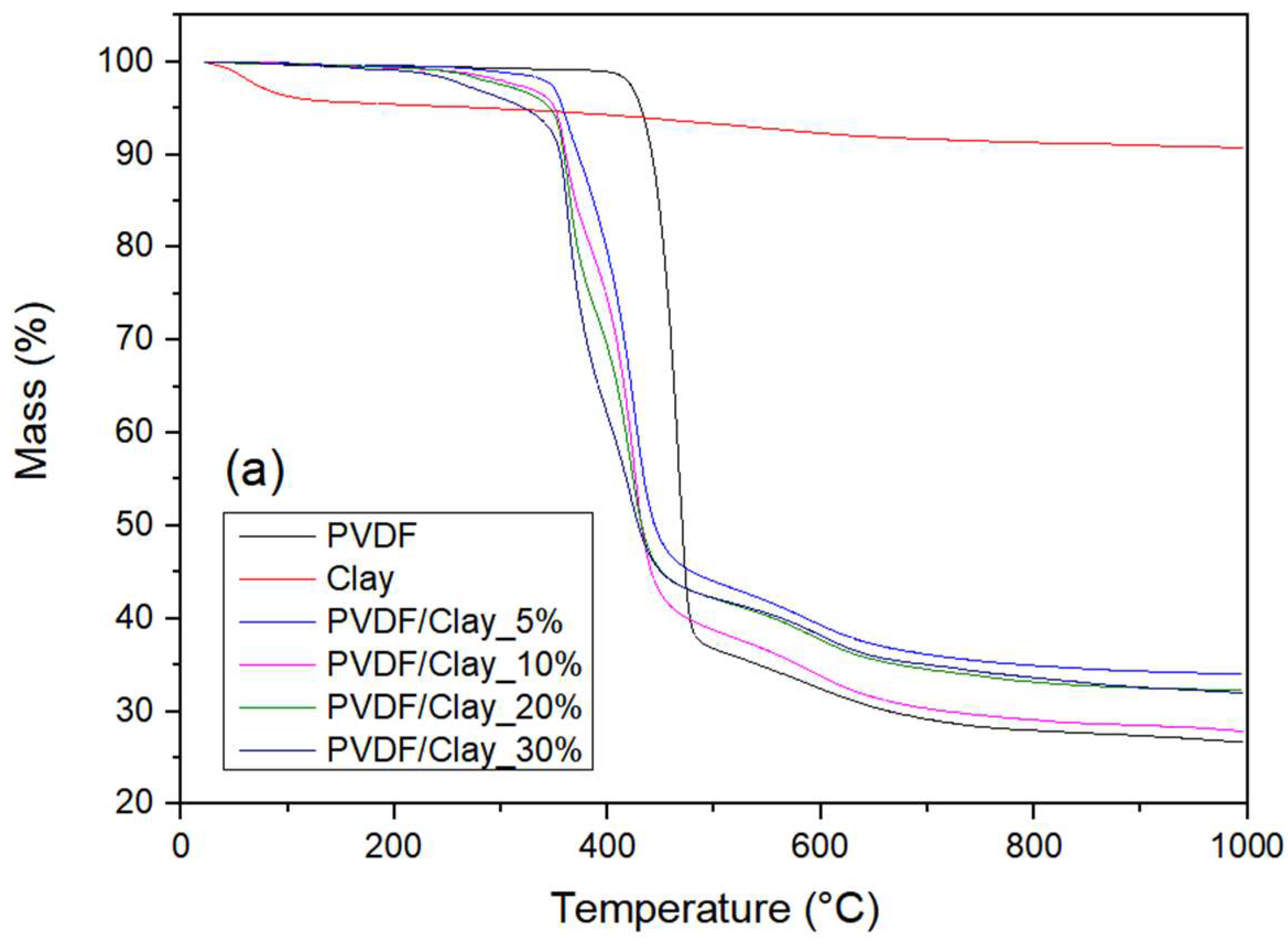

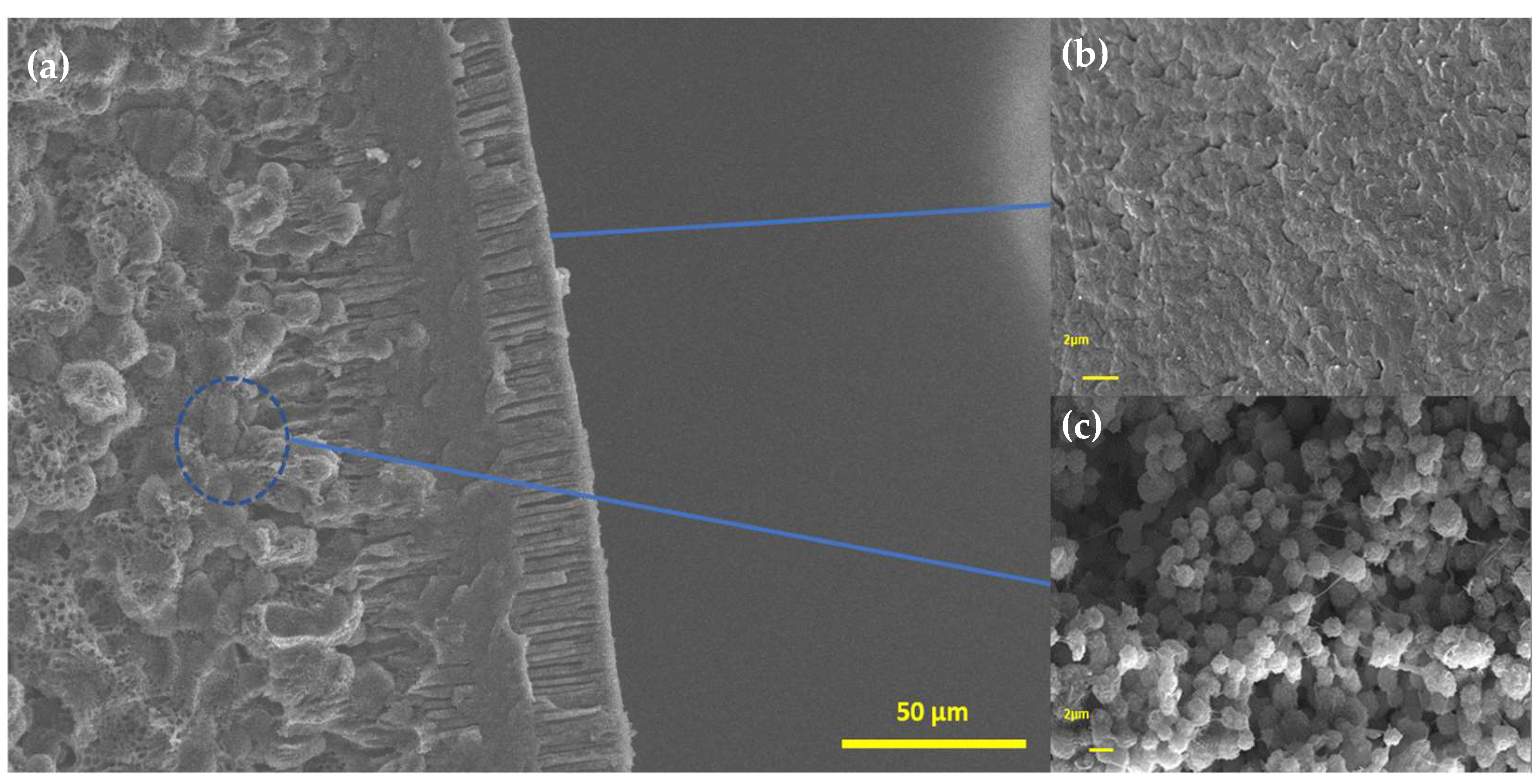

3. Results

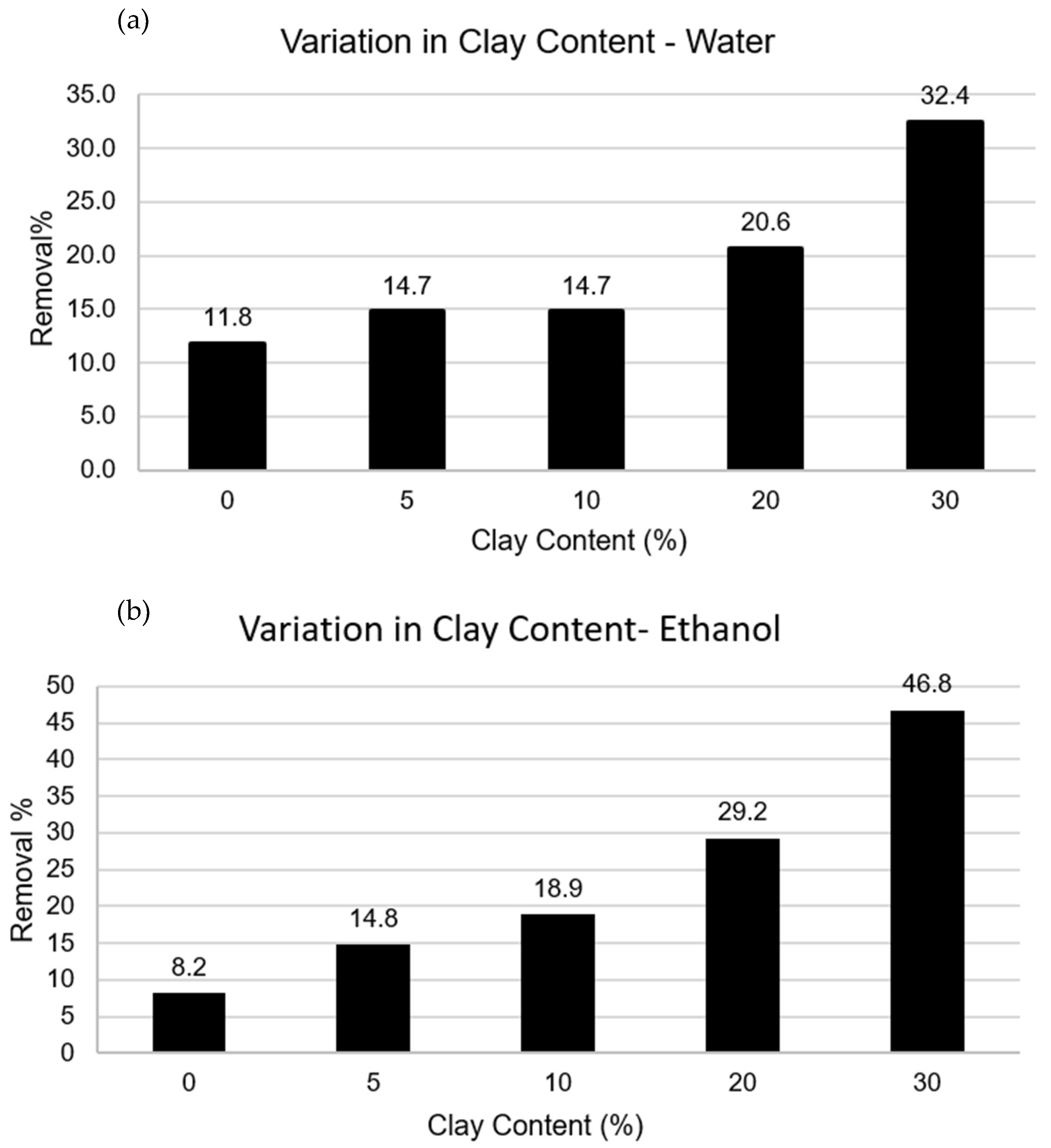

3.1. Effect of Adsorbent

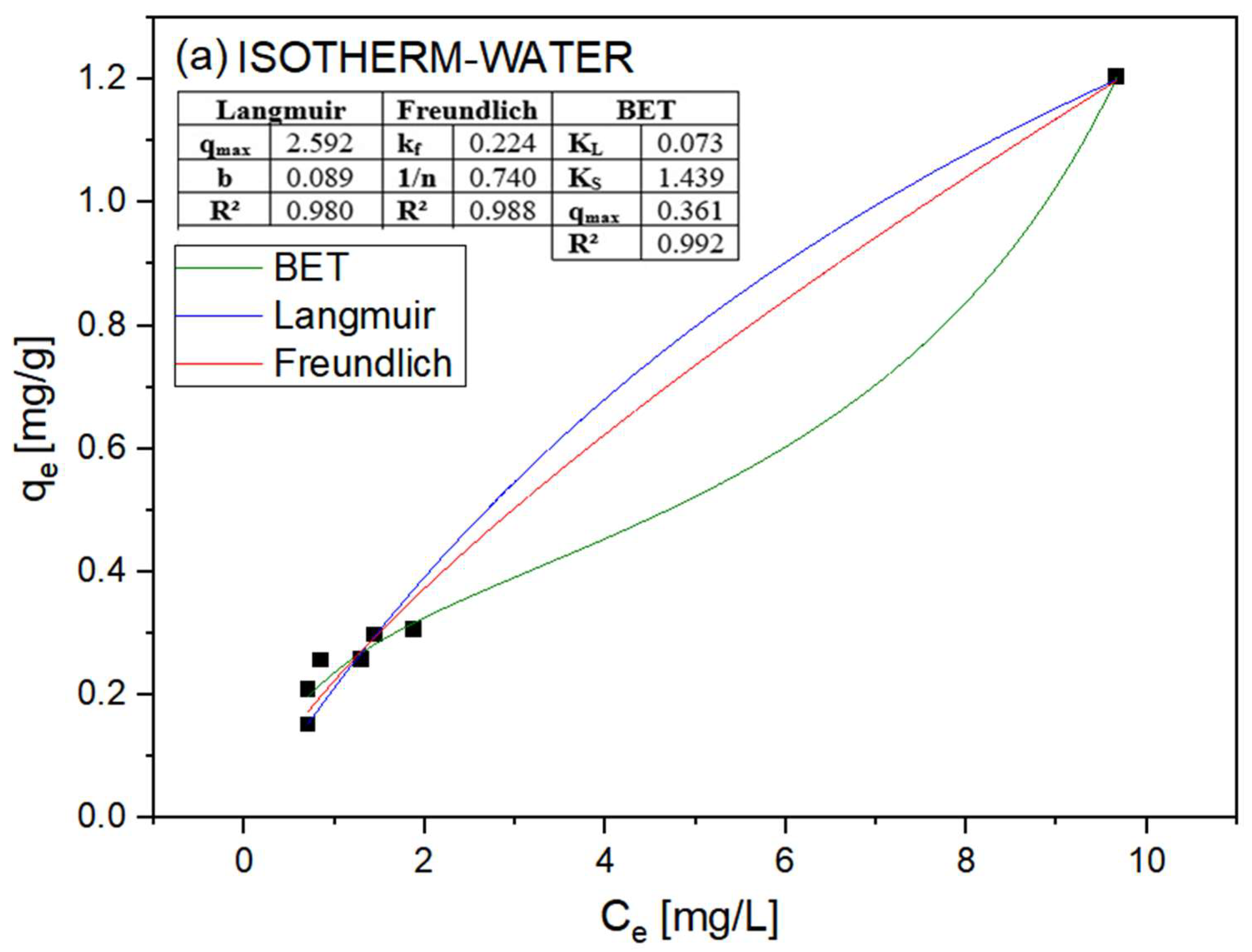

3.2. Adsorption Isotherms

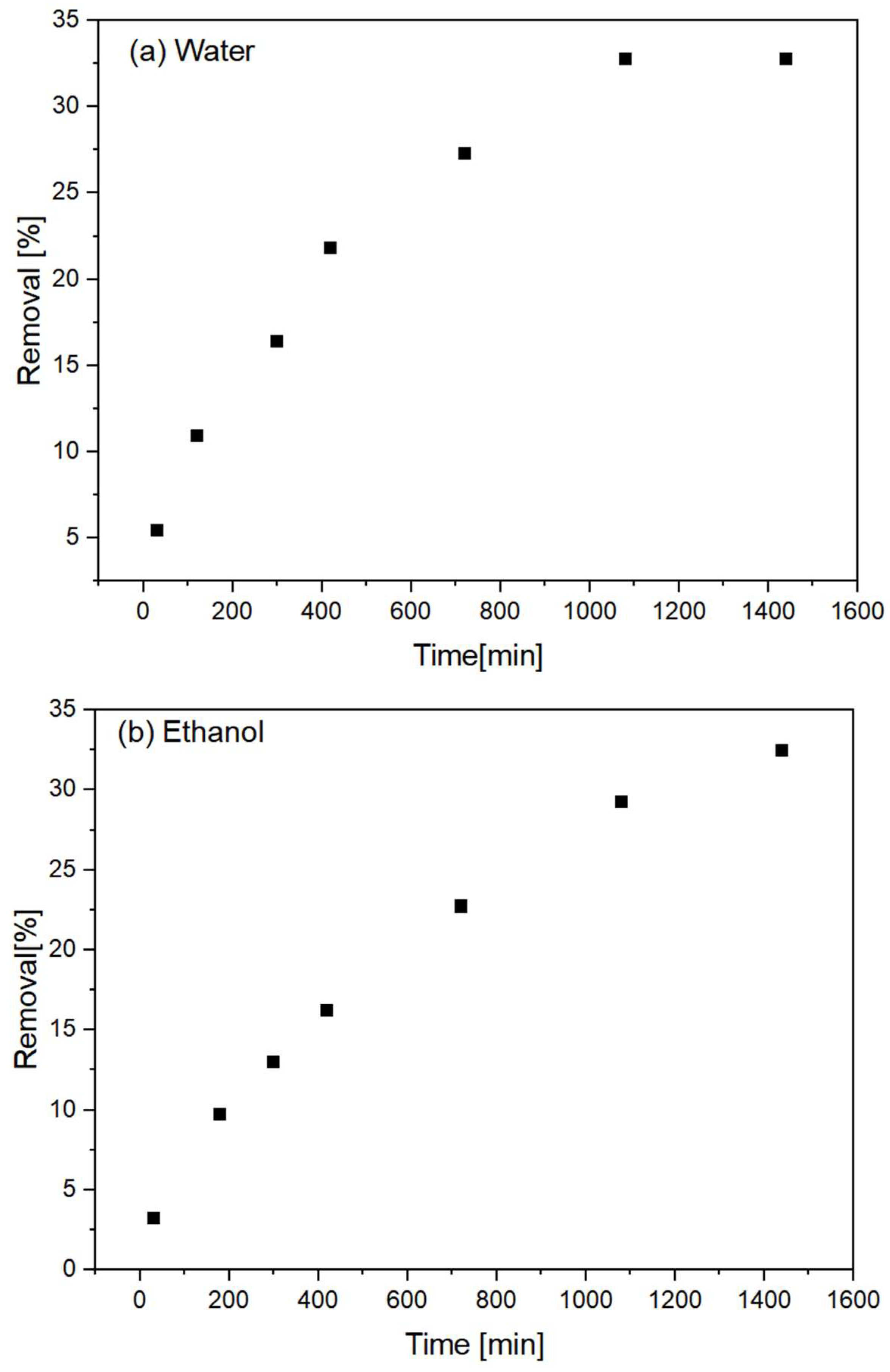

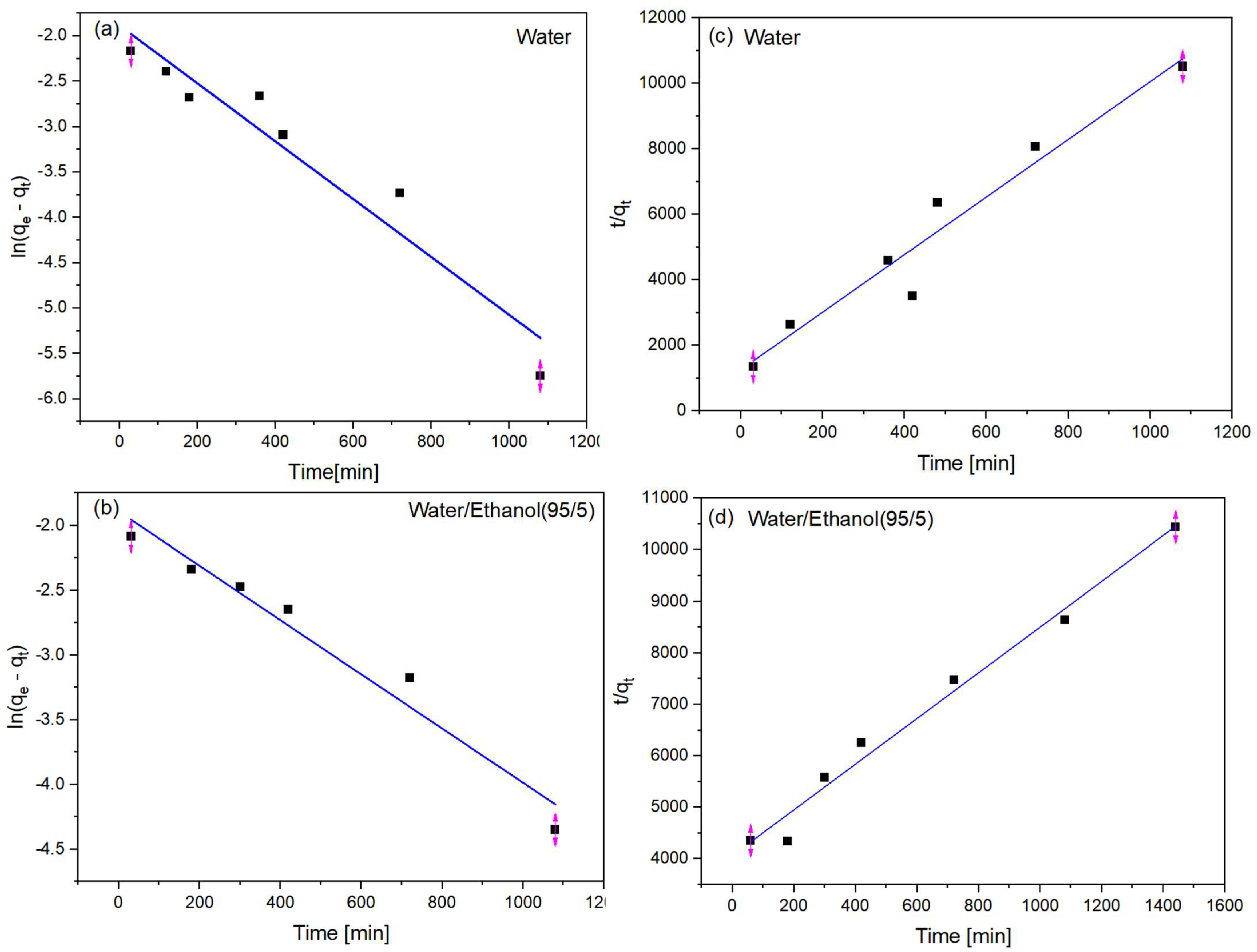

3.3. Adsorption Kinetics

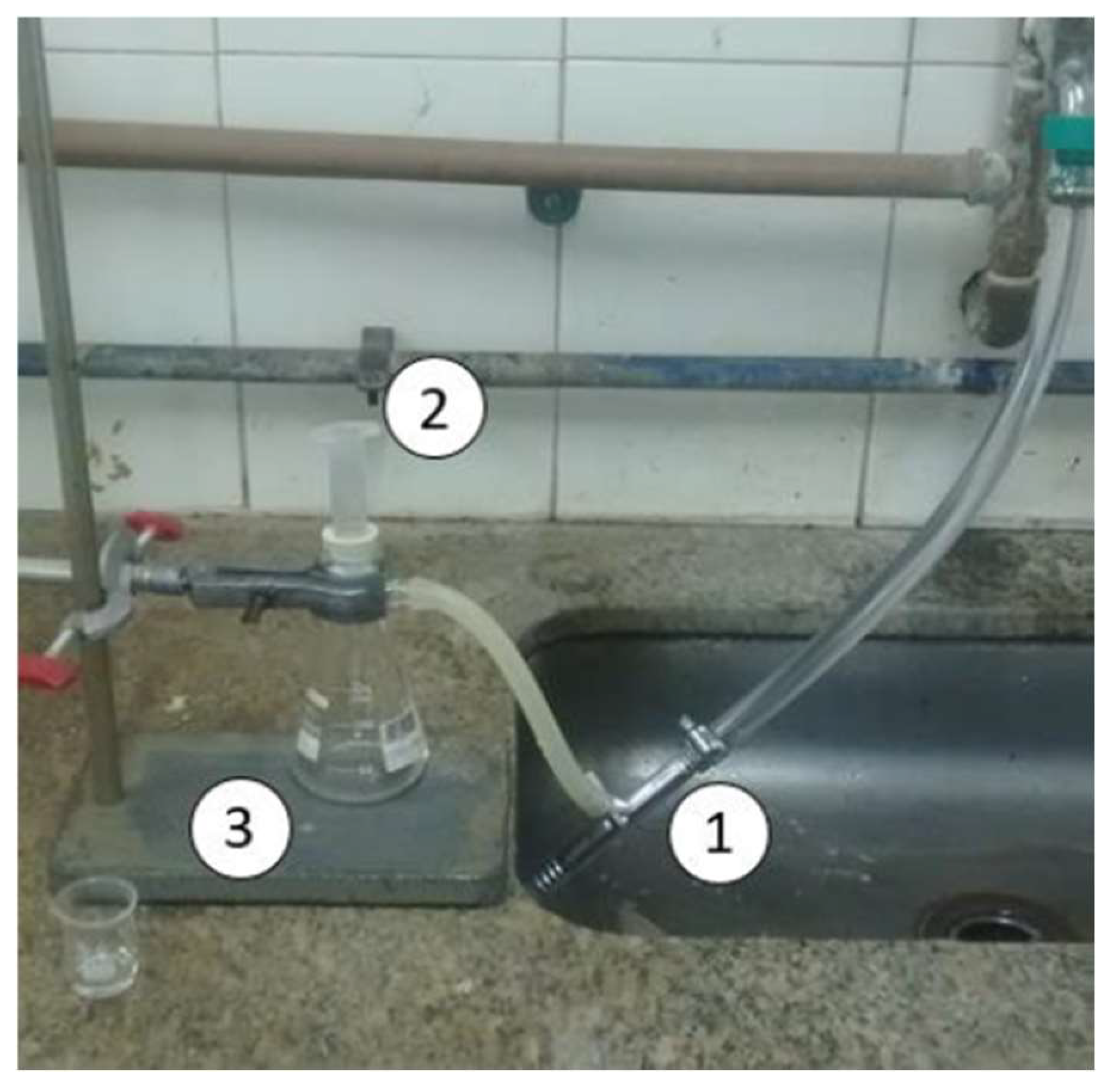

3.4. Application and Column Tests

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, Z.L.; Yang, X.E.; Stoffella, P.J. Trace elements in agroecosystems and impacts on the environment. J. Trace Elem. Med. Biol. 2005, 19, 125–140. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, K.F.S.; Deus Junior, J.O.; Nascimento, T.L.S.; Anjos, R.B.; Melo, D.M.A.; Braga, R.M.; Melo, M.A.F. Cashew nut shell (Anarcadium accidentale L.) charcoal as bioadsorbent to remove Cu2+ and Cr3+. Res. Soc. Dev. 2021, 10, e0510212238. [Google Scholar] [CrossRef]

- Gaetke, L.M.; Chow-Johnson, H.S.; Chow, C.K. Copper: Toxicological relevance and mechanisms. Arch. Toxicol. 2014, 88, 1929–1938. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garbin, R.; Bogusz, S.; Montano, M. Níveis de cobre em amostras de cachaça produzidas na região noroeste do Rio Grande do Sul, Brasil. Ciência Rural 2005, 35, 1436–1440. [Google Scholar] [CrossRef] [Green Version]

- Gunatilake, S.K. Methods of Removing Heavy Metals from Industrial Wastewater. J. Multidiscip. Eng. Sci. Stud. 2015, 1, 12–18. [Google Scholar]

- Vasconcellos, M.C.; Pagliuso, D.; Sotomaior, V.S. Phytoremediation: A proposal of soil decontamination. Estud. Biol. 2012, 34, 1–10. [Google Scholar]

- Tchounwou, P.B.; Yedjou, C.G.; Patlolla, A.K.; Sutton, D.J. Heavy metal toxicity and the environment. Mol. Clin. Environ. Toxicol. 2012, 101, 133–164. [Google Scholar] [CrossRef] [Green Version]

- Ijagbemi, C.O.; Baek, M.; Kim, D. Montmorillonite surface properties and sorption characteristics for heavy metal removal from aqueous solutions. J. Hazard. Mater. 2009, 166, 538–546. [Google Scholar] [CrossRef] [PubMed]

- Peng, B.; Li, Y.; Zhao, Z.; Chen, Y.; Han, C.C. Facile surface modification of PVDF microfiltration membrane by strong physical adsorption of amphiphilic copolymers. J. Appl. Polym. Sci. 2013, 130, 3112–3121. [Google Scholar] [CrossRef]

- Kang, G.; Cao, Y. Application and modification of poly (vinylidene fluoride)(PVDF) membranes—A review. J. Membr. Sci. 2014, 463, 145–165. [Google Scholar] [CrossRef]

- Liu, F.; Hashim, N.A.; Liu, Y.; Moghareh Abed, M.R.; Li, K. Progress in the production and modification of PVDF membranes. J. Membr. Sci. 2011, 375, 1–27. [Google Scholar] [CrossRef]

- Tiwari, V.; Srivastava, G. Structural, dielectric and piezoelectric properties of 0–3 PZT/PVDF composites. Ceram. Int. 2015, 41, 8008–8013. [Google Scholar] [CrossRef]

- Araujo, A.L.P.; Nogueira, I.L.; Silva, M.G.C.; Gimenes, M.L.; Barros, M.A.S.D. Adsorção de Ni2 e Zn2 em argila calcinada: Estudo de equilíbrio em coluna de leito fixo. Cerâmica 2013, 59, 382–388. [Google Scholar] [CrossRef] [Green Version]

- Dillon, D.R.; Tenneti, K.K.; Li, C.Y.; Ko, F.K.; Sics, I.; Hsiao, B.S. On the structure and morphology of polyvinylidene fluoride–nanoclay nanocomposites. Polymer 2006, 47, 1678–1688. [Google Scholar] [CrossRef]

- Zulfiqar, S.; Zulfiqar, M.; Rizvi, M.; Munir, A.; Mcneill, C. Study of the thermal degradation of polychlorotrifluoroethylene, poly (vinylidene fluoride) and copolymers of chlorotrifluoroethylene and vinylidene fluoride. Polym. Degrad. Stab. 1994, 43, 423–430. [Google Scholar] [CrossRef]

- Gu, A.; Liang, G. Thermal degradation behaviour and kinetic analysis of epoxy/montmorillonite nanocomposites. Polym. Degrad. Stab. 2003, 80, 383–391. [Google Scholar] [CrossRef]

- Silvano, J.; Rodrigues, S.A.; Marini, J.; Bretas, R.E.S.; Canevarolo, S.V.; Carvalho, B.M.; Pinheiro, L.A. Effect of reprocessing and clay concentration on the degradation of polypropylene/montmorillonite nanocomposites during twin screw extrusion. Polym. Degrad. Stab. 2012, 98, 801–808. [Google Scholar] [CrossRef]

- Munari, S.; Bottino, A.; Capannelli, G. Casting and performance of polyvinylidene fluoride based membranes. J. Membr. Sci. 1983, 16, 181–193. [Google Scholar] [CrossRef]

- Yeow, M.L.; Liu, Y.T. Morphological study of poly(vinylidene fluoride) asymmetric membranes: Effects of the solvent, additive, and dope temperature. Appl. Polym. Sci. 2004, 92, 1782–1789. [Google Scholar] [CrossRef]

- Zhang, L.; Zha, D.; Du, T.; Shi, Z.; Mei, S.; Jin, Z. Formation of superhydrophobic microspheres of poly (vinylidene fluoride–hexafluoropropylene)/graphene composite via gelation. Langmuir 2011, 27, 8943–8949. [Google Scholar] [CrossRef]

- Wang, B.; Jackson, E.A.; Hoff, W.J.; Dutta, P.K. Fabrication of zeolite/polymer composite membranes in a roller assembly. Microporous Mesoporous Mater. 2015, 223, 247–253. [Google Scholar] [CrossRef]

- Ebadi, A.; Mohammadzadeh, J.; Khudiev, A. What is the correct form of BET isotherm for modeling liquid phase adsorption? Adsorption 2009, 15, 65–73. [Google Scholar] [CrossRef]

- Mathlouthi, M.; Roge, B. Water vapour sorption isotherms and the caking of food powders. Food Chem. 2003, 82, 61–71. [Google Scholar] [CrossRef]

- Anovitz, L.M.; Cole, D.R. Characterization and Analysis of Porosity and Pore Structures. Rev. Miner. Geochem. 2015, 80, 61–164. [Google Scholar] [CrossRef] [Green Version]

- Veli, S.; Alyüz, B. Adsorption of copper and zinc from aqueous solutions by using natural clay. J. Hazard. Mater. 2007, 149, 226–233. [Google Scholar] [CrossRef]

- Bhattacharyya, K.G.; Gupta, S.S. Kaolinite, montmorillonite, and their modified derivatives as adsorbents for removal of Cu(II) from aqueous solution. Sep. Purif. Technol. 2006, 50, 388–397. [Google Scholar] [CrossRef]

- Jiang, M.; Jin, X.Y.; Lu, X.Q.; Chen, Z.L. Adsorption of Pb (II), Cd (II), Ni (II) and Cu (II) onto natural kaolinite clay. Desalination 2010, 252, 33–39. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Krstić, V.; Uroševoć, T.; Pešovski, B. A review on adsorbents for treatment of water and wastewaters containing copper ions. Chem. Eng. Sci. 2018, 192, 273–287. [Google Scholar] [CrossRef]

- Largitte, L.; Pasquieur, R. A review of the kinetics adsorption models and their application to the adsorption of lead by an activated carbon. Chem. Eng. Res. Des. 2016, 109, 495–504. [Google Scholar] [CrossRef]

- Lima, A.J.B.; Cardoso, M.G.; Guimarães, L.G.L.; Lima, J.M.; Nelson, D.L. Efeito de substâncias empregadas para remoção de cobre sobre o teor de compostos secundários da cachaça. Quím. Nova 2009, 32, 845–848. [Google Scholar] [CrossRef]

- Azevedo, S.M.; Cardoso, M.G.; Pereira, N.E.; Ribeiro, C.F.S.; Silva, V.F.; Aguiar, A.C. Levantamento da contaminação por cobre nas aguardentes de cana-de-açúcar produzidas em Minas Gerais. Ciência Agrotecnologia 2003, 27, 618–624. [Google Scholar] [CrossRef] [Green Version]

- Vivek, K.; Subbarao, K.V.; Routray, W.; Kamini, N.R.; Dash, K.K. Application of Fuzzy Logic in Sensory Evaluation of Food Products: A Comprehensive Study. J. Agric. Technol. 2020, 8, 1243–1254. [Google Scholar] [CrossRef]

| Clay Content [m/m] | Clay Dispersion | PVDF Solution | ||

|---|---|---|---|---|

| PVDF [g] | DMF [mL] | PVDF [g] | DMF [mL] | |

| 0 | - | - | 3.0 | 10.0 |

| 5 | 0.15 | 2.0 | 3.0 | 8.0 |

| 10 | 0.30 | 2.0 | 3.0 | 8.0 |

| 20 | 0.60 | 2.5 | 3.0 | 7.5 |

| 30 | 0.90 | 2.5 | 3.0 | 7.5 |

| Initial Concentration [mg/L] | |

|---|---|

| Sample A | 1.80 (±0.34) |

| Sample B | 6.96 (±0.79) |

| Sample C | 6.56 (±0.72) |

| Samples | Whole Spheres | |

|---|---|---|

| Final Concentration [mg/L] | Removal [%] | |

| Sample A | 1.44 (±0.26) | 20.00 |

| Sample B | 5.16 (±0.65) | 25.86 |

| Sample C | 4.96 (±0.56) | 24.39 |

| Samples | Cut Spheres * | |

| Final Concentration [mg/L] | Removal [%] | |

| Sample A | 0.80 (±0.14) | 55.56 |

| Sample B | 3.20 (±0.51) | 54.02 |

| Sample C | 3.04 (±0.34) | 53.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dias, G.C.; Cardoso, M.F.; Sanches, A.O.; Santos, M.C.; Malmonge, L.F. PVDF/Clay Spheres Obtained through Phase Inversion for Cu Ion Removal. Polymers 2023, 15, 2643. https://doi.org/10.3390/polym15122643

Dias GC, Cardoso MF, Sanches AO, Santos MC, Malmonge LF. PVDF/Clay Spheres Obtained through Phase Inversion for Cu Ion Removal. Polymers. 2023; 15(12):2643. https://doi.org/10.3390/polym15122643

Chicago/Turabian StyleDias, Gabriel C., Mayk F. Cardoso, Alex O. Sanches, Mirian C. Santos, and Luiz F. Malmonge. 2023. "PVDF/Clay Spheres Obtained through Phase Inversion for Cu Ion Removal" Polymers 15, no. 12: 2643. https://doi.org/10.3390/polym15122643