Biomass 3D Printing: Principles, Materials, Post-Processing and Applications

Abstract

:1. Introduction

2. Three-Dimensional Printing Technology Principles Using Common Biomass Materials

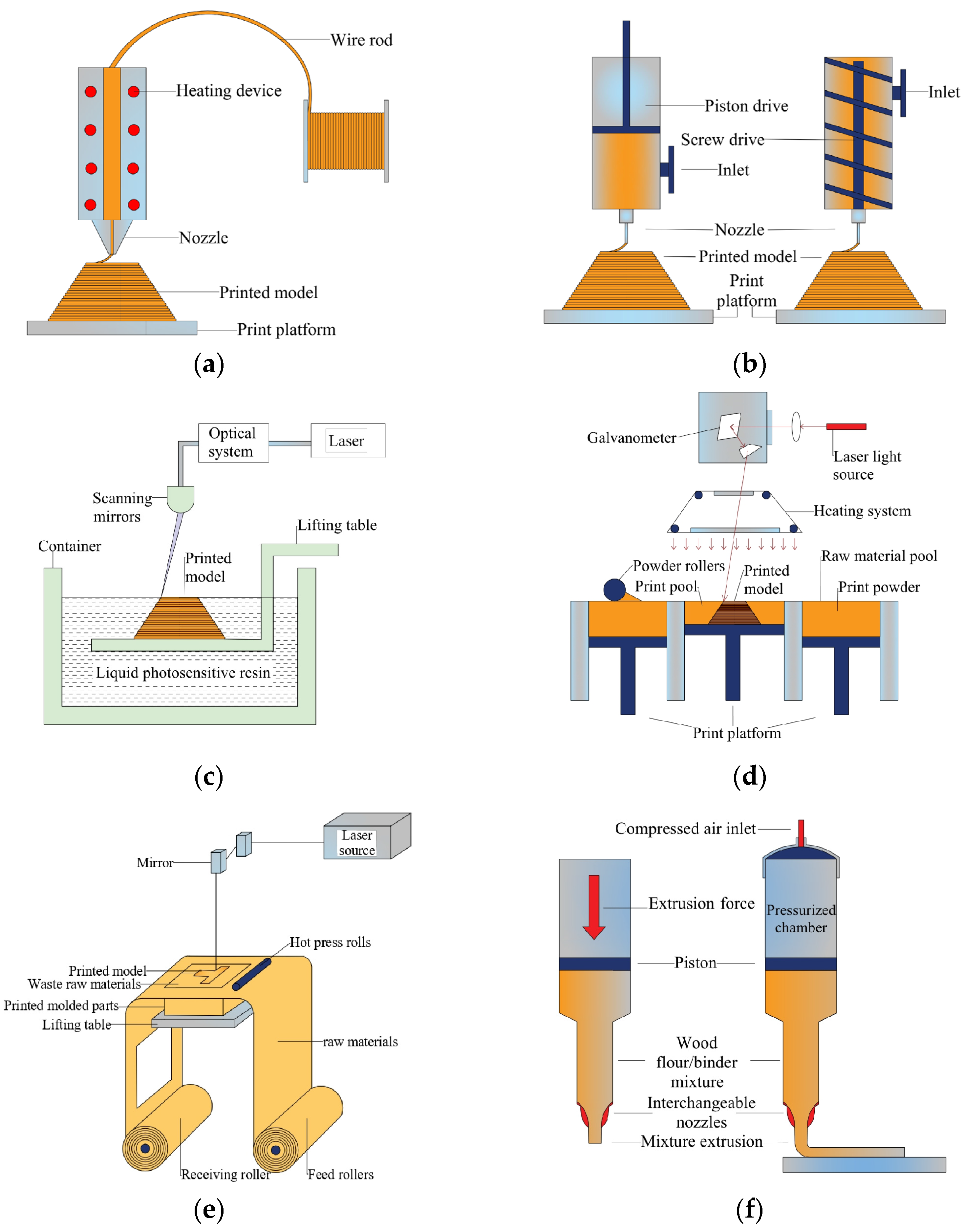

2.1. Principle of 3D Printing Technology

2.2. Biomass Materials for 3D Printing

3. Research Progress of 3D Printing Technology for Typical Biomass Materials

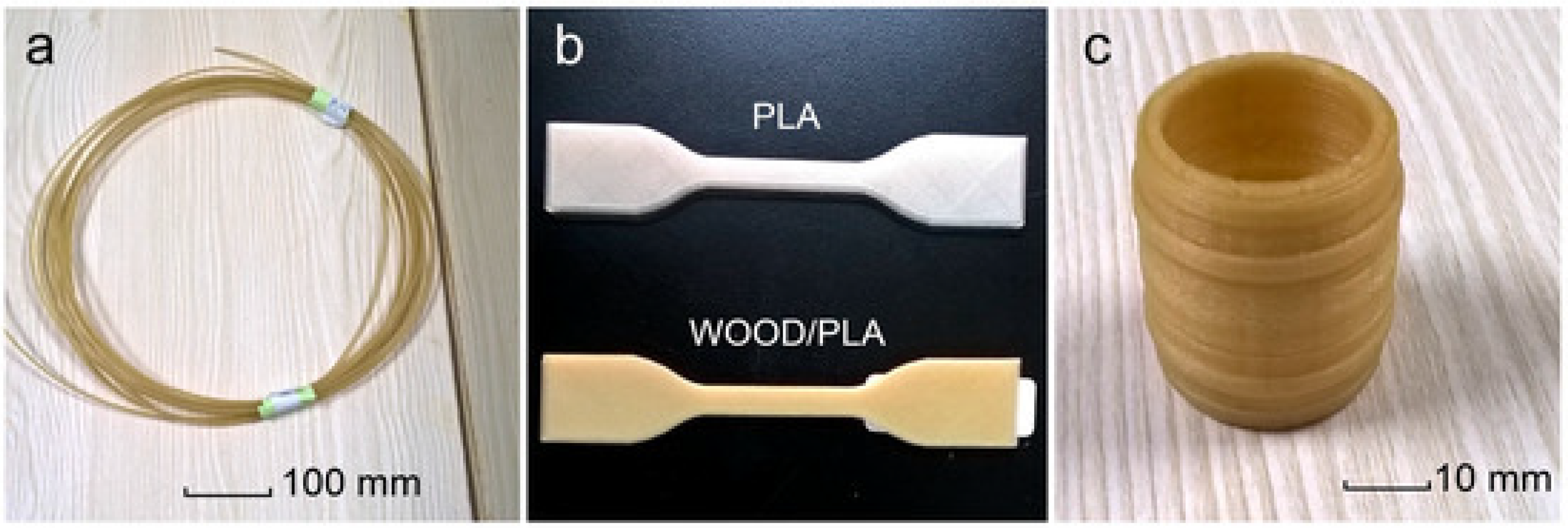

3.1. Fused Filament Fabrication (FFF) with Wood Plastic Filaments

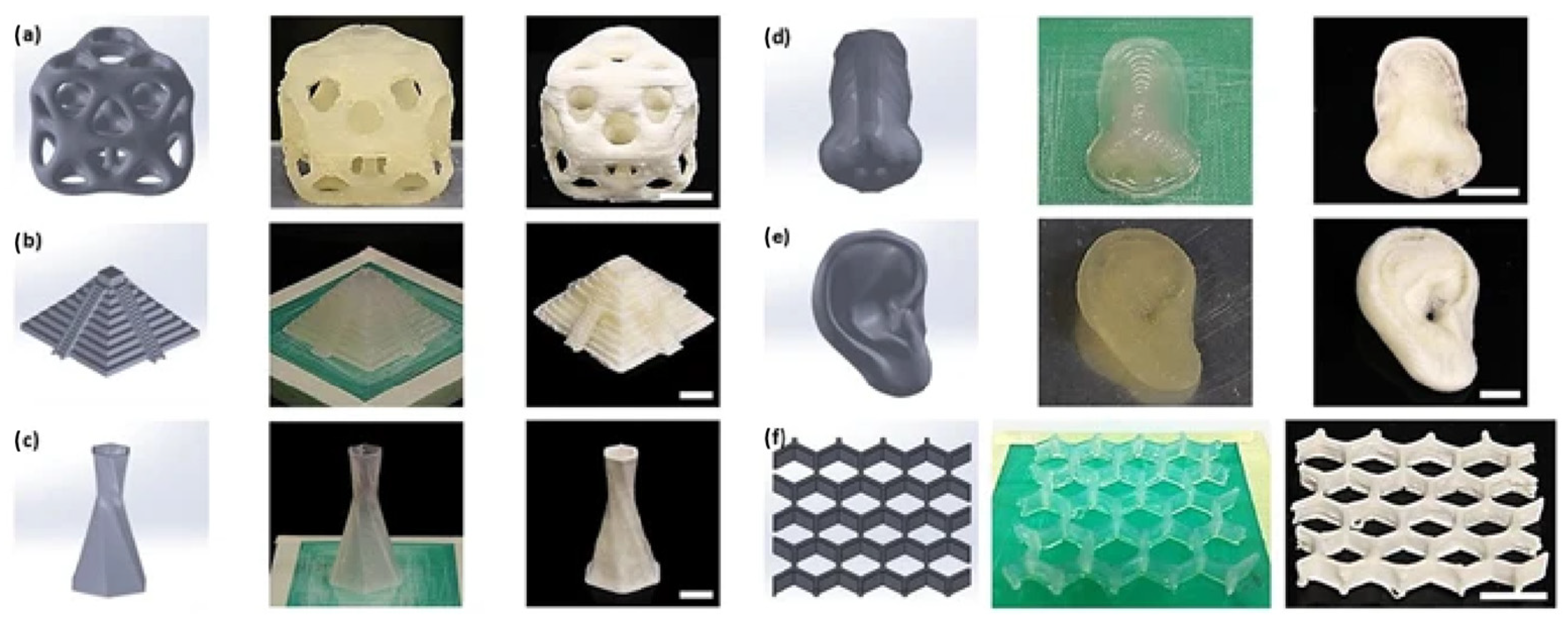

3.2. Direct Ink Writing (DIW) with Biomass Gel Material

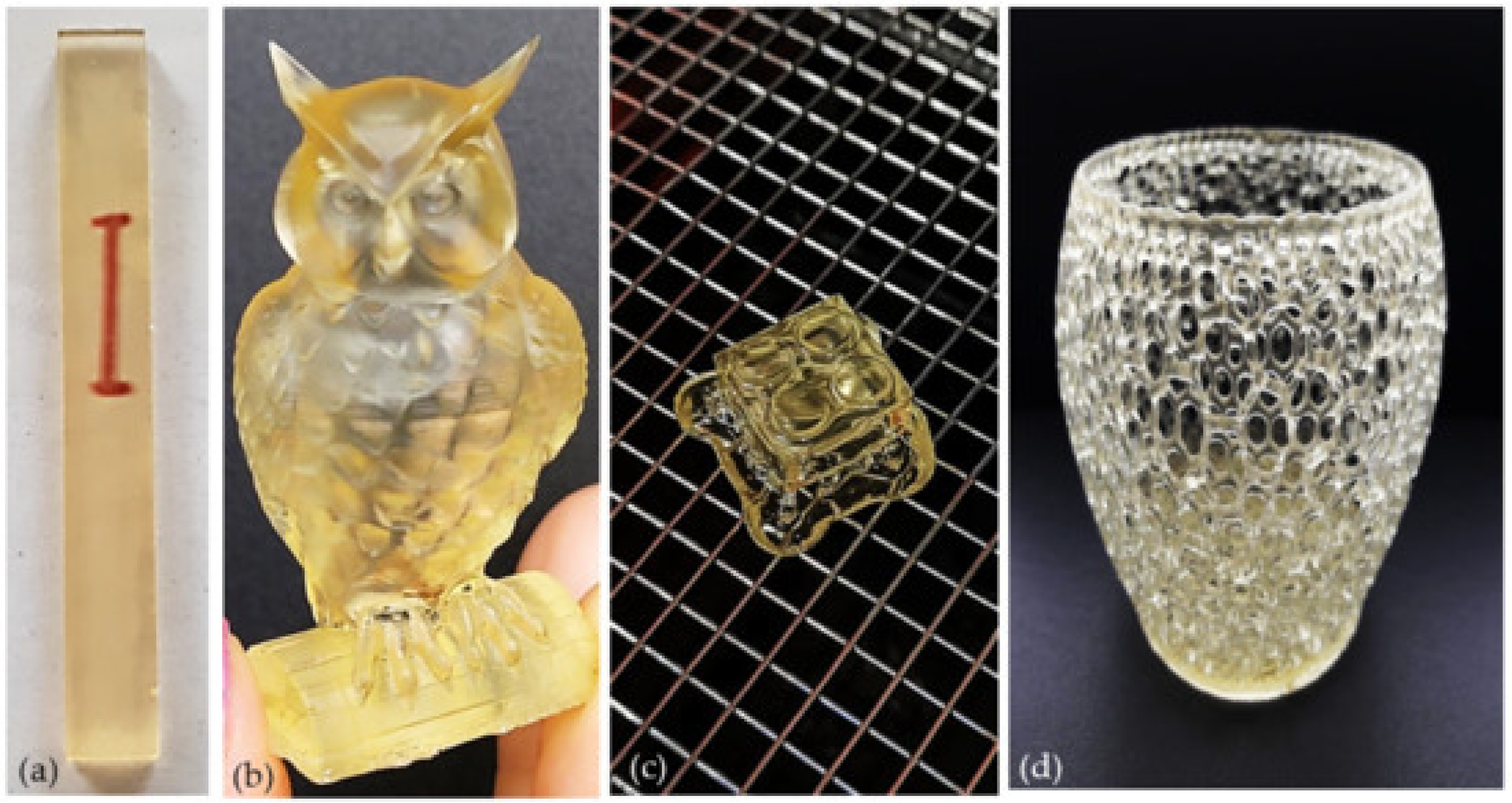

3.3. Stereo Lithography Appearance (SLA) with Biomass Resin Material

3.4. Selective Laser Sintering (SLS) with Wood Plastic Powder

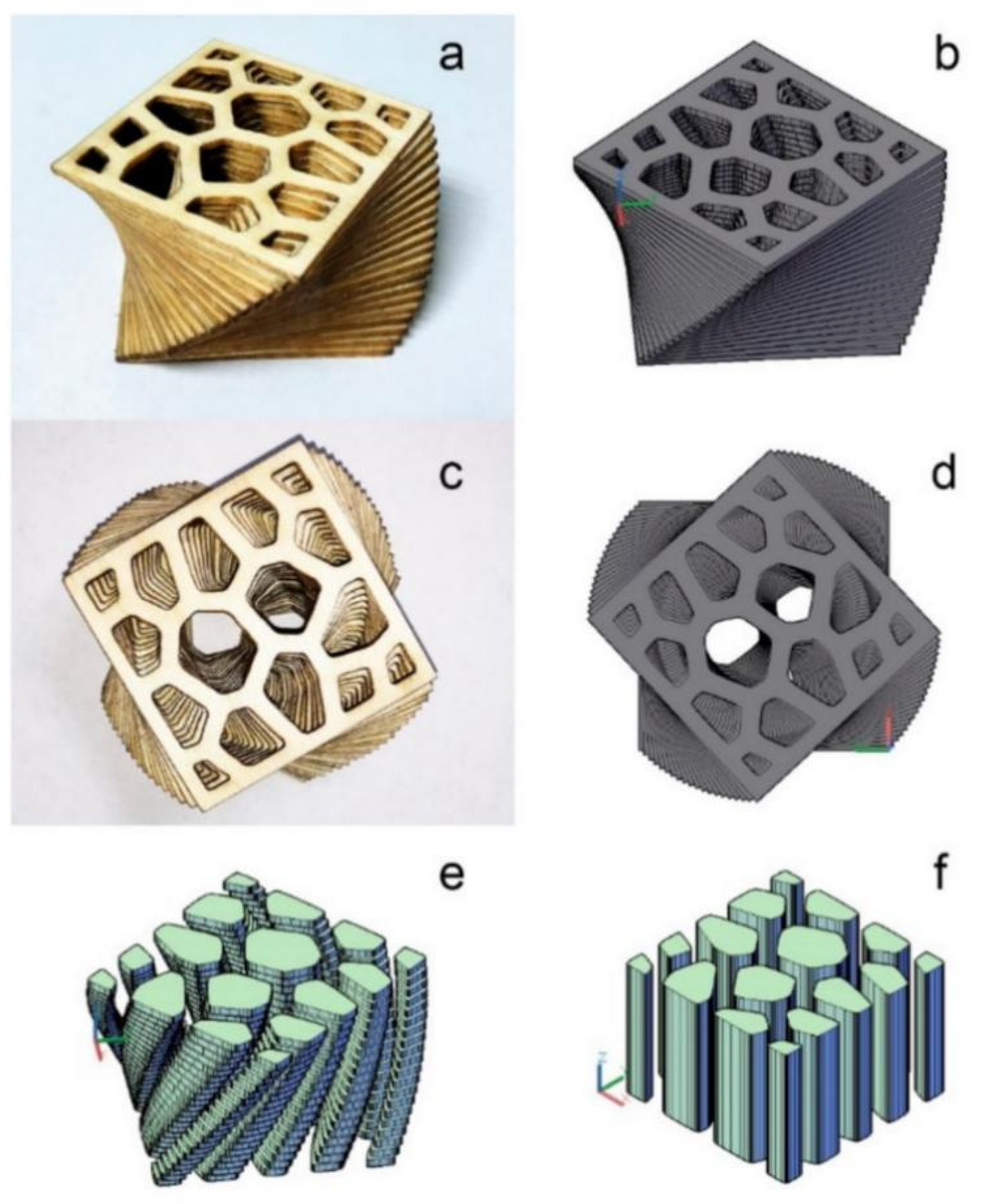

3.5. Sheet-Based Laminated Object Manufacturing (LOM)

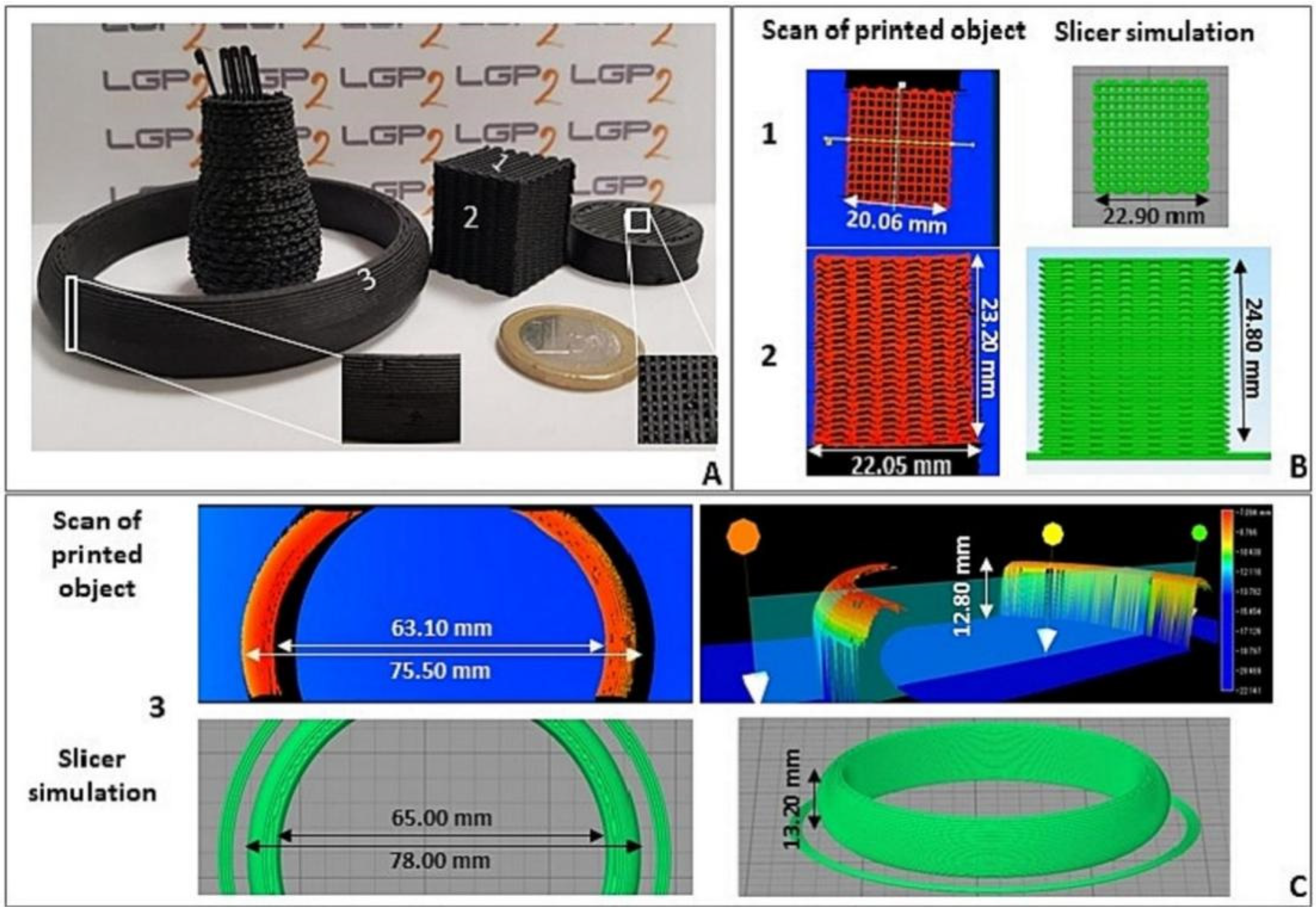

3.6. Liquid Deposition Molding (LDM) with Biomass Paste Material

4. Post-Processing

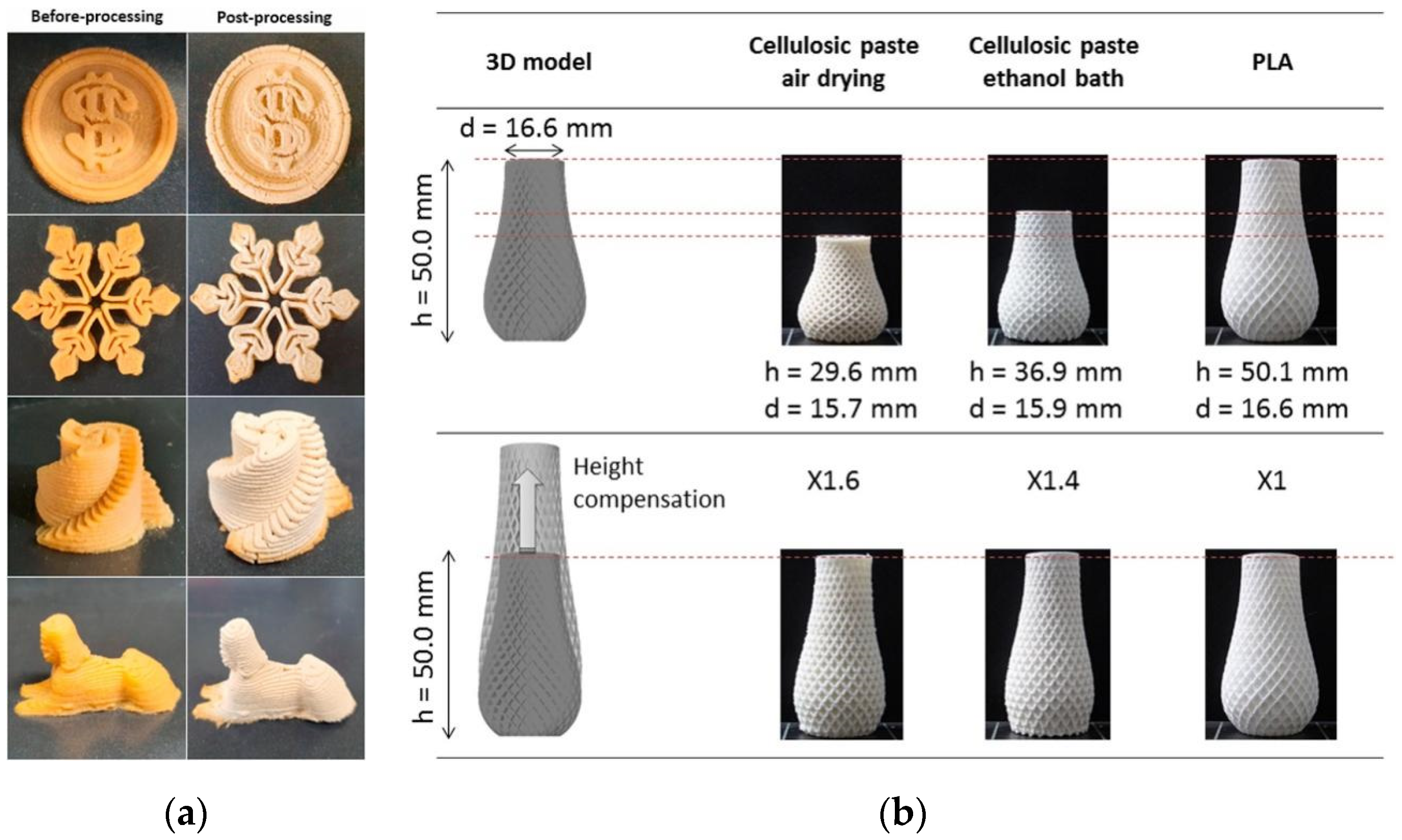

4.1. Drying Treatment

4.2. Curing Treatment

4.3. Heat Treatment

4.4. Surface Modification Treatment

4.5. Other Post-Processing Methods

5. Application

5.1. Biomedical

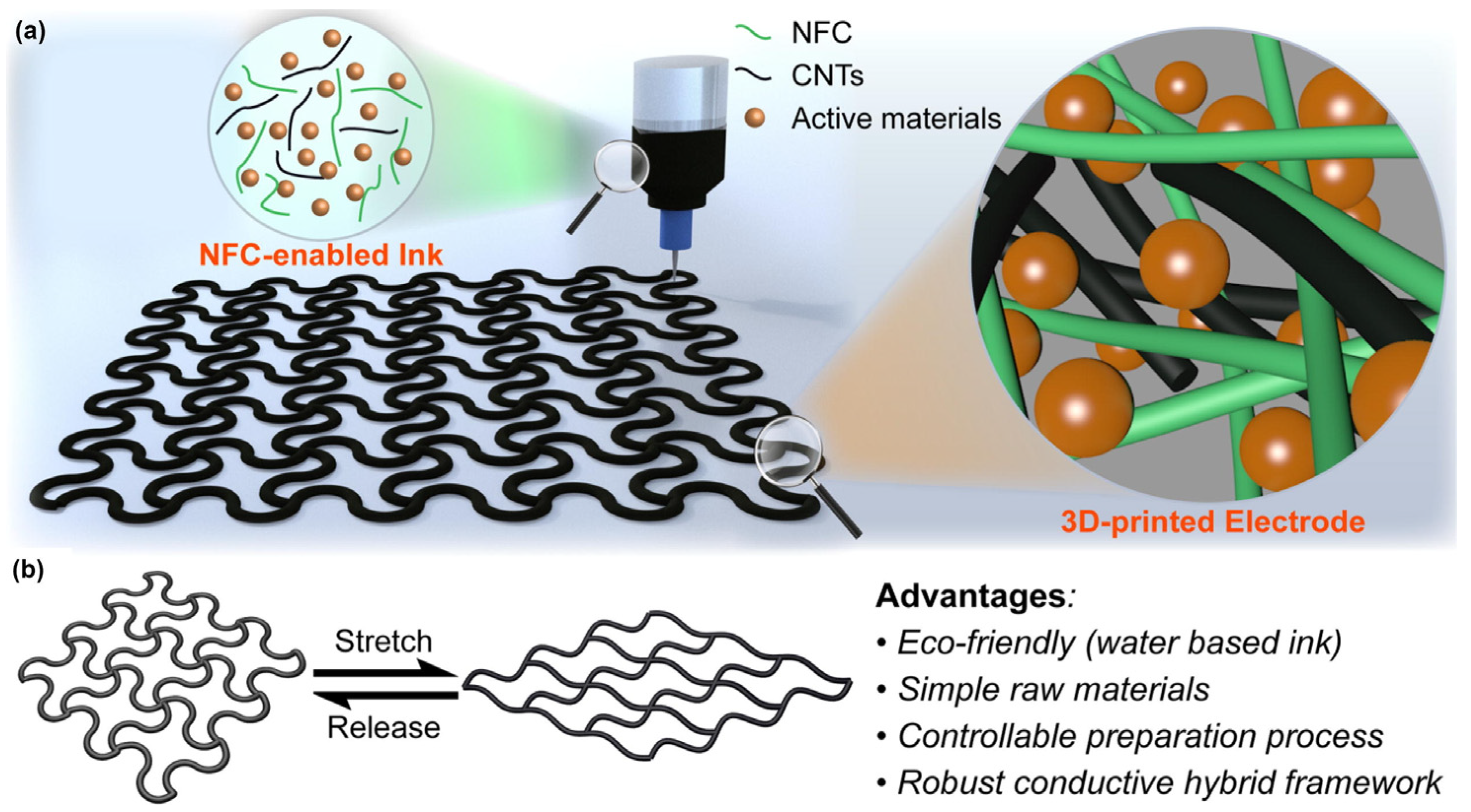

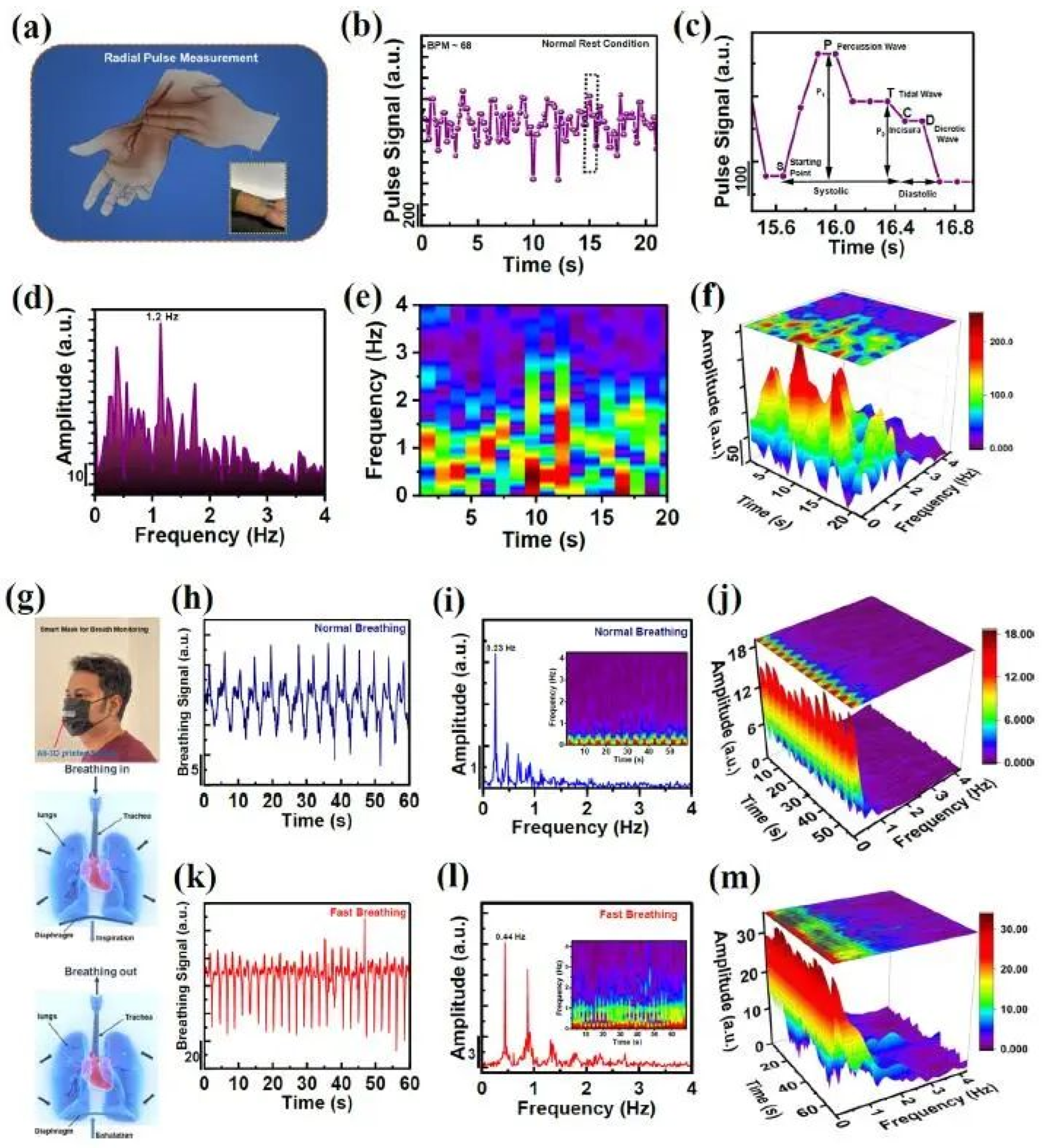

5.2. Electronics

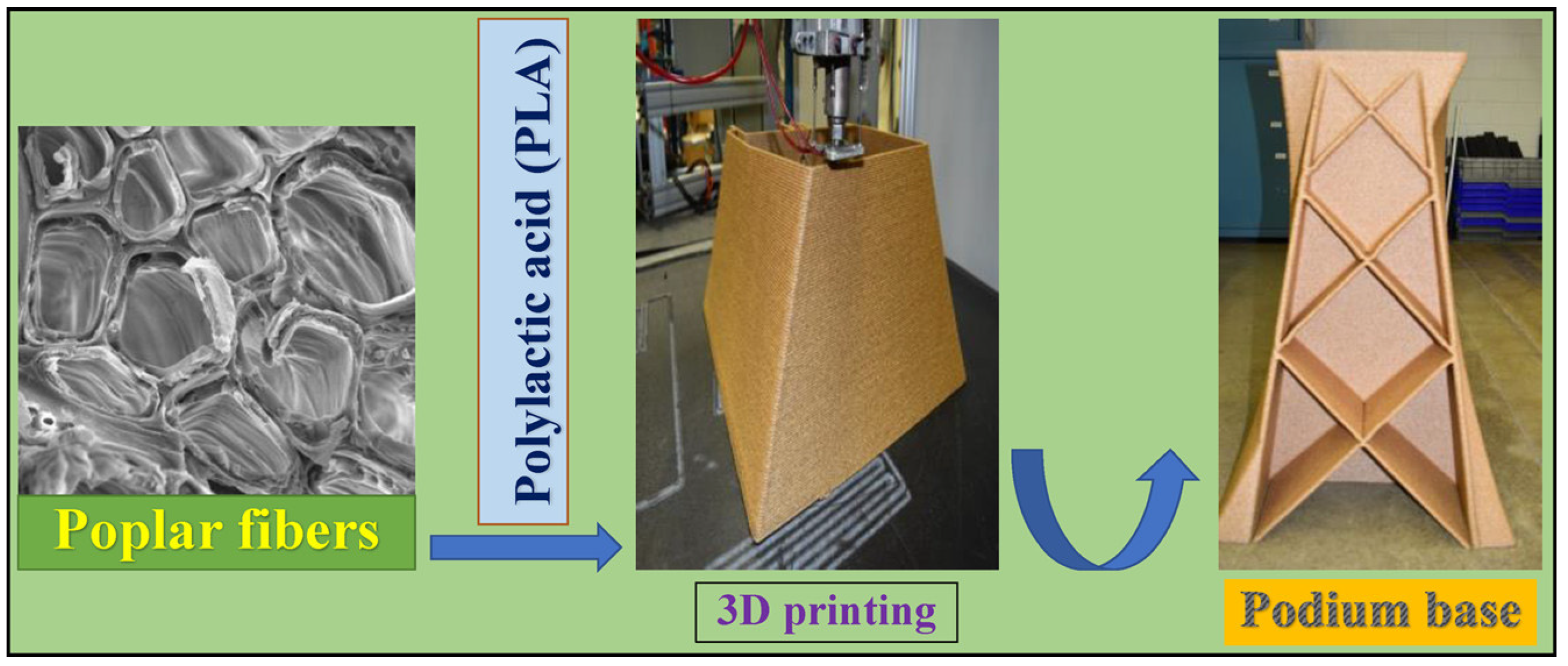

5.3. Construction Field

5.4. Furniture Field

5.5. Other Fields

6. Prospects

7. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 43, 172–196. [Google Scholar] [CrossRef]

- Tumer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Dasgupta, A.; Dutta, P. A Comprehensive Review on 3D Printing Technology: Current Applications and Challenges. Jordan J. Mech. Ind. Eng. 2022, 16, 529–542. [Google Scholar]

- Dip, T.M.; Emu, A.S.; Nafiz, M.N.H.; Kundu, P.; Rakhi, H.R.; Sayam, A.; Akhtarujjman, M.; Shoaib, M.; Ahmed, M.S.; Ushno, S.T.; et al. 3D printing technology for textiles and fashion. Text. Prog. 2020, 52, 167–260. [Google Scholar] [CrossRef]

- Rong, L.Y.; Chen, X.X.; Shen, M.Y.; Yang, J.; Qi, X.; Li, Y.L.; Xie, J.H. The application of 3D printing technology on starch-based product: A review. Trends Food Sci. Technol. 2023, 134, 149–161. [Google Scholar] [CrossRef]

- Mazurchevici, A.D.; Nedelcu, D.; Popa, R. Additive manufacturing of composite materials by FDM technology: A review. Indian J. Eng. Mat. Sci. 2020, 27, 179–192. [Google Scholar]

- Jimenez, M.; Romero, L.; Dominguez, I.A.; Espinosa, M.D.; Dominguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef] [Green Version]

- Rahmatabadi, D.; Soltanmohammadi, K.; Pahlavani, M.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Shape memory performance assessment of FDM 3D printed PLA-TPU composites by Box-Behnken response surface methodology. Int. J. Adv. Manuf. Technol. 2023, 127, 935–950. [Google Scholar] [CrossRef]

- Alghamdi, S.S.; John, S.; Choudhury, N.R.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

- Maines, E.M.; Porwal, M.K.; Ellison, C.J.; Reineke, T.M. Sustainable advances in SLA/DLP 3D printing materials and processes. Green Chem. 2021, 23, 6863–6897. [Google Scholar] [CrossRef]

- Bardot, M.; Schulz, M.D. Biodegradable Poly (Lactic Acid) Nanocomposites for Fused Deposition Modeling 3D Printing. Nanomaterials 2020, 10, 2567. [Google Scholar] [CrossRef] [PubMed]

- Azad, M.A.; Olawuni, D.; Kimbell, G.; Badruddoza, A.M.; Hossain, M.S.; Sultana, T. Polymers for Extrusion-Based 3D Printing of Pharmaceuticals: A Holistic Materials-Process Perspective. Pharmaceutics 2020, 12, 124. [Google Scholar] [CrossRef] [Green Version]

- Dai, L.; Cheng, T.; Duan, C.; Zhao, W.; Zhang, W.P.; Zou, X.J.; Aspler, J.; Ni, Y.H. 3D printing using plant-derived cellulose and its derivatives: A review. Carbohydr. Polym. 2019, 203, 71–86. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.Q.; Sun, J.Z.; Yao, Q.; Ji, C.C.; Liu, J.; Zhu, Q.Q. 3D printing with cellulose materials. Cellulose 2018, 25, 4275–4301. [Google Scholar] [CrossRef]

- Gauss, C.; Pickering, K.L.; Muthe, L.P. The use of cellulose in bio-derived formulations for 3D/4D printing: A review. Composites Part C Open Access 2021, 4, 100113. [Google Scholar] [CrossRef]

- Lin, L.; Jiang, S.L.; Yang, J.; Qiu, J.D.; Jiao, X.Y.; Yue, X.S.; Ke, X.R.; Yang, G.J.; Zhang, L. Application of 3D-bioprinted nanocellulose and cellulose derivative-based bio-inks in bone and cartilage tissue engineering. Int. J. Bioprint. 2023, 9, 212–229. [Google Scholar] [CrossRef]

- Chinga-Carrasco, G. Potential and Limitations of Nanocelluloses as Components in Biocomposite Inks for Three- Dimensional Bioprinting and for Biomedical Devices. Biomacromolecules 2018, 19, 701–711. [Google Scholar] [CrossRef]

- Li, G.S.; Hu, L.P.; Liu, J.L.; Huang, J.Y.; Yuan, C.H.; Takaki, K.; Hu, Y.Q. A review on 3D printable food materials: Types and development trends. Int. J. Food Sci. Technol. 2022, 57, 164–172. [Google Scholar] [CrossRef]

- Tomec, D.K.; Kariz, M. Use of Wood in Additive Manufacturing: Review and Future Prospects. Polymers 2022, 14, 1174. [Google Scholar] [CrossRef]

- Lamm, M.E.; Wang, L.; Kishore, V.; Tekinalp, H.; Kunc, V.; Wang, J.W.; Gardner, D.J.; Ozcan, S. Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites. Polymers 2020, 12, 2115. [Google Scholar] [CrossRef]

- Yang, J.; An, X.Y.; Liu, L.Q.; Tang, S.Y.; Cao, H.B.; Xu, Q.L.; Liu, H.B. Cellulose, hemicellulose, lignin, and their derivatives as multi-components of bio-based feedstocks for 3D printing. Carbohydr. Polym. 2020, 250, 116881. [Google Scholar] [CrossRef]

- Bi, X.; Huang, R. 3D printing of natural fiber and composites: A state-of-the-art review. Mater. Des. 2022, 222, 111065. [Google Scholar] [CrossRef]

- Ahmed, W.; Alnajjar, F.; Zaneldin, E.; Al-Marzouqi, A.H.; Gochoo, M.; Khalid, S. Implementing FDM 3D Printing Strategies Using Natural Fibers to Produce Biomass Composite. Materials 2020, 13, 4065. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.; Nagi, G.K.; Corcoran, A.A.; Agrawal, R.; Dubey, M.; Hunt, R.W. Algal polysaccharides for 3D printing: A review. Carbohydr. Polym. 2023, 300, 120267. [Google Scholar] [CrossRef] [PubMed]

- Abouzeid, R.E.; Khiari, R.; Salama, A.; Diab, M.; Beneventi, D.; Dufresne, A. In situ mineralization of nano-hydroxyapatite on bifunctional cellulose nanofiber/polyvinyl alcohol/sodium alginate hydrogel using 3D printing. Int. J. Biol. Macromol. 2020, 160, 539–547. [Google Scholar] [CrossRef] [PubMed]

- Fan, R.; Piou, M.; Darling, E.; Cormier, D.; Sun, J.; Wan, J.D. Bio-printing cell-laden Matrigel-agarose constructs. J. Biomater. Appl. 2016, 31, 684–692. [Google Scholar] [CrossRef] [PubMed]

- Tsai, M.T.; Wang, P.C. Application of lignocellulosic composite (Taiwan incense-cedar) for digital light processing (DLP) in 3D printing. Wood Mater. Sci. Eng. 2023, 2199018. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Bhagia, S.; Li, M.; Meng, X.Z.; Ragauskas, A.J. Wood-reinforced composites by stereolithography with the stress whitening behavior. Mater. Des. 2021, 206, 109773. [Google Scholar] [CrossRef]

- Muller, M.; Jirku, P.; Sleger, V.; Mishra, R.K.; Hromasova, M.; Novotny, J. Effect of Infill Density in FDM 3D Printing on Low-Cycle Stress of Bamboo-Filled PLA-Based Material. Polymers 2022, 14, 4930. [Google Scholar] [CrossRef]

- Yu, W.W.; Dong, L.L.; Lei, W.; Shi, J.N. Rice straw powder/polylactic acid biocomposites for three-dimensional printing. Adv. Compos. Lett. 2020, 29, 2633366X20967360. [Google Scholar] [CrossRef]

- Zheng, L.Y.; Liu, J.B.; Liu, R.; Xing, Y.A.; Jiang, H. 3D printing performance of gels from wheat starch, flour and whole meal. Food Chem. 2021, 356, 129546. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.T.; Tang, T.T.; Duan, S.Q.; Qin, Z.Z.; Li, C.; Zhang, Z.Q.; Liu, A.P.; Wu, D.T.; Chen, H.; Han, G.Q.; et al. Effects of sodium alginate and rice variety on the physicochemical characteristics and 3D printing feasibility of rice paste. LWT Food Sci. Technol. 2020, 127, 109360. [Google Scholar] [CrossRef]

- Paggi, R.A.; Salmoria, G.V.; Ghizoni, G.B.; Back, H.D.; Gindri, I.D. Structure and mechanical properties of 3D-printed cellulose tablets by fused deposition modeling. Int. J. Adv. Manuf. Technol. 2019, 100, 2767–2774. [Google Scholar] [CrossRef]

- Nida, S.; Moses, J.A.; Anandharamakrishnan, C. 3D printed food package casings from sugarcane bagasse: A waste valorization study. Biomass Convers. Biorefin. 2021. [Google Scholar] [CrossRef]

- Latif, M.; Jiang, Y.X.; Kumar, B.; Song, J.M.; Cho, H.C.; Kim, J. High Content Nanocellulose 3D-Printed and Esterified Structures with Strong Interfacial Adhesion, High Mechanical Properties, and Shape Fidelity. Adv. Mater. Interfaces 2022, 9, 2200280. [Google Scholar] [CrossRef]

- Shin, S.; Hyun, J. Rheological properties of cellulose nanofiber hydrogel for high-fidelity 3D printing. Carbohydr. Polym. 2021, 263, 117976. [Google Scholar] [CrossRef]

- Vorobiov, V.K.; Sokolova, M.P.; Bobrova, N.V.; Elokhovsky, V.Y.; Smirnov, M.A. Rheological properties and 3D-printability of cellulose nanocrystals/deep eutectic solvent electroactive ion gels. Carbohydr. Polym. 2022, 290, 119475. [Google Scholar] [CrossRef]

- Huang, H.X.; Dean, D. 3-D printed porous cellulose acetate tissue scaffolds for additive manufacturing. Addit. Manuf. 2020, 31, 100927. [Google Scholar] [CrossRef]

- Tuladhar, S.; Clark, S.; Habib, A. Tuning Shear Thinning Factors of 3D Bio-Printable Hydrogels Using Short Fiber. Materials 2023, 16, 572. [Google Scholar] [CrossRef]

- Murphy, C.A.; Collins, M.N. Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym. Compos. 2018, 39, 1311–1320. [Google Scholar] [CrossRef]

- Bahcegul, E.G.; Bahcegul, E.; Ozkan, N. 3D Printing of Hemicellulosic Biopolymers Extracted from Lignocellulosic Agricultural Wastes. ACS Appl. Polym. Mater. 2020, 2, 2622–2632. [Google Scholar] [CrossRef]

- Xu, W.Y.; Pranovich, A.; Uppstu, P.; Wang, X.J.; Kronlund, D.; Hemming, J.; Oblom, H.; Moritz, N.; Preis, M.; Sandler, N.; et al. Novel biorenewable composite of wood polysaccharide and polylactic acid for three dimensional printing. Carbohydr. Polym. 2018, 187, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Shi, G.; Peng, X.W.; Zeng, J.M.; Zhong, L.X.; Sun, Y.; Yang, W.; Zhong, Y.L.; Zhu, Y.X.; Zou, R.; Admassie, S.; et al. A Liquid Metal Microdroplets Initialized Hemicellulose Composite for 3D Printing Anode Host in Zn-Ion Battery. Adv. Mater. 2023. [Google Scholar] [CrossRef] [PubMed]

- Dominguez-Robles, J.; Martin, N.K.; Fong, M.L.; Stewart, S.A.; Irwin, N.J.; Rial-Hermida, M.I.; Donnelly, R.F.; Larraneta, E. Antioxidant PLA Composites Containing Lignin for 3D Printing Applications: A Potential Material for Healthcare Applications. Pharmaceutics 2019, 11, 165. [Google Scholar] [CrossRef] [Green Version]

- Ajdary, R.; Kretzschmar, N.; Baniasadi, H.; Trifol, J.; Seppala, J.V.; Partanen, J.; Rojas, O.J. Selective Laser Sintering of Lignin-Based Composites. ACS Sustain. Chem. Eng. 2021, 9, 2727–2735. [Google Scholar] [CrossRef]

- Mimini, V.; Sykacek, E.; Syed Hashim, S.N.A.; Holzweber, J.; Hettegger, H.; Fackler, K.; Potthast, A.; Mundigler, N.; Rosenau, T. Compatibility of Kraft Lignin, Organosolv Lignin and Lignosulfonate with PLA in 3D Printing. J. Wood Chem. Technol. 2019, 39, 14–30. [Google Scholar] [CrossRef]

- Bonifacio, M.A.; Cometa, S.; Cochis, A.; Scalzone, A.; Gentile, P.; Scalia, A.C.; Rimondini, L.; Mastrorilli, P.; De Giglio, E. A bioprintable gellan gum/lignin hydrogel: A smart and sustainable route for cartilage regeneration. Int. J. Biol. Macromol. 2022, 216, 336–346. [Google Scholar] [CrossRef]

- Sahai, N.; Gogoi, M.; Tewari, R.P. 3D Printed Chitosan Composite Scaffold for Chondrocytes Differentiation. Curr. Med. Imaging. 2021, 17, 832–842. [Google Scholar] [CrossRef]

- Pan, H.S.; Pei, F.; Ma, G.X.; Ma, N.; Zhong, L.; Zhao, L.Y.; Hu, Q.H. 3D printing properties of Flammulina velutipes polysaccharide-soy protein complex hydrogels. J. Food Eng. 2022, 334, 111170. [Google Scholar] [CrossRef]

- Feng, C.X.; Wang, Q.; Li, H.; Zhou, Q.C.; Meng, W. Effects of Pea Protein on the Properties of Potato Starch-Based 3D Printing Materials. Int. J. Food Eng. 2018, 14, 20170297. [Google Scholar]

- Kariz, M.; Sernek, M.; Obucina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar]

- Long, H.B.; Wu, Z.Q.; Dong, Q.Q.; Shen, Y.T.; Zhou, W.Y.; Luo, Y.; Zhang, C.Q.; Dong, X.M. Mechanical and thermal properties of bamboo fiber reinforced polypropylene/polylactic acid composites for 3D printing. Polym. Eng. Sci. 2019, 59, E247–E260. [Google Scholar] [CrossRef]

- Yu, W.W.; Dong, L.L.; Lei, W.; Zhou, Y.H.; Pu, Y.Z.; Zhang, X. Effects of Rice Straw Powder (RSP) Size and Pretreatment on Properties of FDM 3D-Printed RSP/Poly (lactic acid) Biocomposites. Molecules 2021, 26, 3234. [Google Scholar] [CrossRef] [PubMed]

- Ambone, T.; Torris, A.; Shanmuganathan, K. Enhancing the mechanical properties of 3D printed polylactic acid using nanocellulose. Polym. Eng. Sci. 2020, 60, 1842–1855. [Google Scholar] [CrossRef]

- Ryu, J.A.; Lee, J.M.; Eom, T.J. Comparison of 3D Printer Application and Strength Property Using Polylactic Acid Filaments with Lignin-free and -rich MFC. Palpu Chongi Gisul J. Korea Tech. Assoc. Pulp Pap. Ind. 2019, 51, 68–76. [Google Scholar] [CrossRef]

- Yang, T.C.; Yeh, C.H. Morphology and Mechanical Properties of 3D Printed Wood Fiber/Polylactic Acid Composite Parts Using Fused Deposition Modeling (FDM): The Effects of Printing Speed. Polymers 2020, 12, 1334. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Fang, J.; Li, J.; Guo, Y.L.; Wang, Q.W. The Effect of Carbon Nanotubes on the Mechanical Properties of Wood Plastic Composites by Selective Laser Sintering. Polymers 2017, 9, 728. [Google Scholar] [CrossRef] [Green Version]

- Ajdary, R.; Huan, S.Q.; Ezazi, N.Z.; Xiang, W.C.; Grande, R.; Santos, H.A.; Rojas, O.J. Acetylated Nanocellulose for Single-Component Bioinks and Cell Proliferation on 3D-Printed Scaffolds. Biomacromolecules 2019, 20, 2770–2778. [Google Scholar] [CrossRef] [Green Version]

- Espinosa, E.; Filgueira, D.; Rodriguez, A.; Chinga-Carrasco, G. Nanocellulose-Based Inks-Effect of Alginate Content on the Water Absorption of 3D Printed Constructs. Bioengineering 2019, 6, 65. [Google Scholar] [CrossRef] [Green Version]

- Rosa, R.P.; Rosace, G.; Arrigo, R.; Malucelli, G. Preparation and characterization of a fully biobased resin system for 3d-printing, suitable for replacing fossil-based acrylates. J. Polym. Res. 2023, 30, 139. [Google Scholar] [CrossRef]

- Travitzky, N.; Windsheimer, H.; Fey, T.; Greil, P. Preceramic Paper-Derived Ceramics. J. Am. Ceram. Soc. 2008, 91, 3477–3492. [Google Scholar] [CrossRef]

- Liu, Q.W.; Yang, C.M.; Miao, Q.; Liu, Y.F.; Liu, J.Q.; Yu, W.J. Experimental Study on Inert Gas-assisted Laser Cut Veneer Based on LOM. J. Renew. Mater. 2020, 8, 1681–1689. [Google Scholar] [CrossRef]

- Bouzidi, K.; Chaussy, D.; Gandini, A.; Bongiovanni, R.; Beneventi, D. 3D printable fully biomass-based composite using poly (furfuryl alcohol) as binder and cellulose as a filler. Carbohyd. Polym. 2022, 293, 119716. [Google Scholar] [CrossRef] [PubMed]

- Rosenthal, M.; Henneberger, C.; Gutkes, A.; Bues, C.T. Liquid Deposition Modeling: A promising approach for 3D printing of wood. Eur. J. Wood Prod. 2017, 76, 797–799. [Google Scholar] [CrossRef]

- Liu, L.X.; Lin, M.H.; Xu, Z.; Lin, M.Q. Polylactic Acid-based Wood-plastic 3D Printing Composite and its Properties. BioResources 2019, 14, 8484–8498. [Google Scholar] [CrossRef]

- Rahim, T.N.A.T.; Abdullah, A.M.; Akil, H.M. Recent Developments in Fused Deposition Modeling-Based 3D Printing of Polymers and Their Composites. Polym. Rev. 2019, 59, 589–624. [Google Scholar] [CrossRef]

- Tascioglu, E.; Kitay, O.; Keskin, A.O.; Kaynak, Y. Effect of printing parameters and post-process on surface roughness and dimensional deviation of PLA parts fabricated by extrusion-based 3D printing. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 139. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Corcione, C.E. A Review of Polymer-Based Materials for Fused Filament Fabrication (FFF): Focus on Sustainability and Recycled Materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef]

- Cano-Vicent, A.; Tambuwala, M.M.; Hassan, S.S.; Barh, D.; Aljabali, A.A.A.; Birkett, M.; Arjunan, A.; Serrano-Aroca, A. Fused deposition modelling: Current status, methodology, applications and future prospects. Addit. Manuf. 2021, 47, 102378. [Google Scholar] [CrossRef]

- Baechle-Clayton, M.; Loos, E.; Taheri, M.; Taheri, H. Failures and Flaws in Fused Deposition Modeling (FDM) Additively Manufactured Polymers and Composites. J. Compos. Sci. 2022, 6, 202. [Google Scholar] [CrossRef]

- Markstedt, K.; Sundberg, J.; Gatenholm, P. 3D Bioprinting of Cellulose Structures from an Ionic Liquid. 3D Print. Addit. Manuf. 2014, 1, 115–121. [Google Scholar]

- Hu, X.Z.; Yang, Z.J.; Kang, S.X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D.; He, J. Cellulose hydrogel skeleton by extrusion 3D printing of solution. Nanotechnol. Rev. 2020, 9, 345–353. [Google Scholar] [CrossRef]

- Wang, J.P.; Chiappone, A.; Roppolo, I.; Shao, F.; Fantino, E.; Lorusso, M.; Rentsch, D.; Dietliker, K.; Pirri, C.F.; Grutzmacher, H. All-in-One Cellulose Nanocrystals for 3D Printing of Nanocomposite Hydrogels. Angew. Chem. Int. Edit. 2018, 57, 2353–2356. [Google Scholar] [CrossRef] [PubMed]

- Hossain, S.S.; Lu, K.T.Y. Recent progress of alumina ceramics by direct ink writing: Ink design, printing and post-processing. Ceram. Int. 2023, 49, 10199–10212. [Google Scholar] [CrossRef]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef] [PubMed]

- Hou, Z.Z.; Lu, H.; Yang, L.X.; Gao, Y. Direct Ink Writing of Materials for Electronics-Related Applications: A Mini Review. Front. Mater. 2021, 8, 647229. [Google Scholar] [CrossRef]

- Sutton, J.T.; Rajan, K.; Harper, D.P.; Chmelu, S.C. Lignin-Containing Photoactive Resins for 3D Printing by Stereolithography. ACS Appl. Mater. Interfaces 2018, 10, 36456–36463. [Google Scholar] [CrossRef]

- Quan, H.Y.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X.Q. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef]

- Rosa, R.P.; Rosace, G. Nanomaterials for 3D Printing of Polymers via Stereolithography: Concept, Technologies, and Applications. Macromol. Mater. Eng. 2021, 306, 2100345. [Google Scholar] [CrossRef]

- Han, W.; Kong, L.B.; Xu, M. Advances in selective laser sintering of polymers. Int. J. Extreme Manuf. 2022, 4, 042002. [Google Scholar] [CrossRef]

- Chin, S.Y.; Dikshit, V.; Priyadarshini, B.M.; Zhang, Y. Powder-Based 3D Printing for the Fabrication of Device with Micro and Mesoscale Features. Micromachines 2020, 11, 658. [Google Scholar] [CrossRef] [PubMed]

- Awad, A.; Fina, F.; Goyanes, A.; Gaisford, S.; Basit, A.W. 3D printing: Principles and pharmaceutical applications of selective laser sintering. Int. J. Pharm. 2020, 586, 119594. [Google Scholar] [CrossRef] [PubMed]

- Lupone, F.; Padovano, E.; Casamento, F.; Badini, C. Process Phenomena and Material Properties in Selective Laser Sintering of Polymers: A Review. Materials 2022, 15, 183. [Google Scholar] [CrossRef] [PubMed]

- Pilipovic, A.; Raos, P.; Sercer, M. Experimental testing of quality of polymer parts produced by laminated object manufacturing—LOM. Teh. Vjesn. 2011, 18, 253–260. [Google Scholar]

- Wang, M.R.; Jin, G.R.; He, W.D.; Nan, F.Q. 3D printing of gun propellants based on laminated object manufacturing. Mater. Manuf. Process. 2022, 37, 1246–1256. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Gache, C.C.L.; Cascolan, H.M.S.; Cancino, L.T.; Advincula, R.C. Post-Processing of 3D-Printed Polymers. Technologies 2021, 9, 61. [Google Scholar] [CrossRef]

- Postiglione, G.; Natale, G.; Griffini, G.; Levi, M.; Turri, S. Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling. Compos. Part A Appl. Sci. Manuf. 2015, 76, 110–114. [Google Scholar] [CrossRef]

- Bi, H.J.; Jia, X.; Ye, G.Y.; Ren, Z.C.; Yang, H.Y.; Guo, R.; Xu, M.; Cai, L.P.; Huang, Z.H. Three-Dimensional-Printed Shape Memory Biomass Composites for Thermal-Responsive Devices. 3D Print Addit. Manuf. 2020, 7, 170–180. [Google Scholar] [CrossRef]

- Tanase-Opedal, M.; Espinosa, E.; Rodriguez, A.; Chinga-Carrasco, G.; Rodríguez, A. Lignin: A Biopolymer from Forestry Biomass for Biocomposites and 3D Printing. Materials 2019, 12, 3006. [Google Scholar] [CrossRef] [Green Version]

- Le Guen, M.J.; Hill, S.; Smith, D.; Theobald, B.; Gaugler, E.; Barakat, A.; Mayer-Laigle, C. Influence of Rice Husk and Wood Biomass Properties on the Manufacture of Filaments for Fused Deposition Modeling. Front. Chem. 2019, 7, 735. [Google Scholar] [CrossRef] [Green Version]

- Mohan, D.; Bakir, A.N.; Sajab, M.S.; Bakarudin, S.B.; Mansor, N.N.; Roslan, R.; Kaco, H. Homogeneous distribution of lignin/graphene fillers with enhanced interlayer adhesion for 3D printing filament. Polym. Compos. 2021, 42, 2408–2421. [Google Scholar] [CrossRef]

- Tao, Y.B.; Wang, H.L.; Li, Z.L.; Li, P.; Shi, S.Q. Development and Application of Wood Flour-Filled Polylactic Acid Composite Filament for 3D Printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef] [Green Version]

- Bhagia, S.; Lowden, R.R.; Erdman, D.; Rodriguez, M.; Haga, B.A.; Solano, I.R.M.; Gallego, N.C.; Pu, Y.Q.; Muchero, W. Tensile properties of 3D-printed wood-filled PLA materials using poplar trees. Appl. Mater. Today 2020, 21, 100832. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Aberoumand, M.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Toughening PVC with Biocompatible PCL Softeners for Supreme Mechanical Properties, Morphology, Shape Memory Effects, and FFF Printability. Macromol. Mater. Eng. 2023, 202300114. [Google Scholar] [CrossRef]

- Yu, W.W.; Shi, J.N.; Sun, L.W.; Lei, W. Effects of Printing Parameters on Properties of FDM 3D Printed Residue of Astragalus/Polylactic Acid Biomass Composites. Molecules 2022, 27, 7373. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.Q.; Ji, C.C.; Sun, L.S.; Liu, J. Cellulose nanofibrils filled poly (Lactic Acid) biocomposite filament for FDM 3D printing. Molecules 2020, 25, 2319. [Google Scholar] [CrossRef] [PubMed]

- Dezaki, M.L.; Ariffin, M.K.A.M.; Serjouei, A.; Zolfagharian, A.; Hatami, S.; Bodaghi, M. Influence of Infill Patterns Generated by CAD and FDM 3D Printer on Surface Roughness and Tensile Strength Properties. Appl. Sci. 2021, 11, 7272. [Google Scholar] [CrossRef]

- Thibaut, C.; Denneulin, A.; du Roscoat, S.R.; Beneventi, D.; Orgeas, L.; Chaussy, D. A fibrous cellulose paste formulation to manufacture structural parts using 3D printing by extrusion. Carbohydr. Polym. 2019, 212, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Håkansson, K.M.O.; Henriksson, I.C.; Vazquez, C.D.; Kuzmenko, V.; Markstedt, K.; Enoksson, P.; Gatenholm, P. Solidification of 3D Printed Nanofibril Hydrogels into Functional 3D Cellulose Structures. Adv. Mater. Technol. 2016, 1, 1600096. [Google Scholar] [CrossRef]

- Li, V.C.F.; Dunn, C.K.; Zhang, Z.; Deng, Y.L.; Qi, H.J. Direct Ink Write (DIW) 3D Printed Cellulose Nanocrystal Aerogel Structures. Sci. Rep. 2017, 7, 8018. [Google Scholar] [CrossRef] [Green Version]

- Lai, C.W.; Yu, S.S. 3D Printable Strain Sensors from Deep Eutectic Solvents and Cellulose Nanocrystals. ACS Appl. Mater. Interfaces 2020, 12, 34235–34244. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Yao, Y.G.; Liang, Z.Q.; Gao, J.L.; Chen, G.C.; Xia, Q.Q.; Mi, R.Y.; Jiao, M.L.; Wang, X.Z.; Hu, L.B. Lignin-Based Direct Ink Printed Structural Scaffolds. Small 2020, 16, 1907212. [Google Scholar] [CrossRef] [PubMed]

- Lebedevaite, M.; Ostrauskaite, J.; Skliutas, E.; Malinauskas, M. Photoinitiator Free Resins Composed of Plant-Derived Monomers for the Optical µ-3D Printing of Thermosets. Polymers 2019, 11, 116. [Google Scholar] [CrossRef] [Green Version]

- Barkane, A.; Platnieks, O.; Jurinovs, M.; Kasetaite, S.; Ostrauskaite, J.; Gaidukovs, S.; Habibi, Y. UV-Light Curing of 3D Printing Inks from Vegetable Oils for Stereolithography. Polymers 2021, 13, 1195. [Google Scholar] [CrossRef]

- Wu, Y.C.; Advincula, P.A.; Giraldo-Londono, O.; Yu, Y.K.; Xie, Y.C.; Chen, Z.R.; Huang, G.l.; Tour, J.M.; Lin, J. Sustainable 3D Printing of Recyclable Biocomposite Empowered by Flash Graphene. ACS Nano 2022, 16, 17326–17335. [Google Scholar] [CrossRef] [PubMed]

- Romero-Ocana, I.; Molina, S.I. Cork photocurable resin composite for Stereolithography (SLA): Influence of cork particle size on mechanical and thermal properties. Addit. Manuf. 2022, 51, 102586. [Google Scholar] [CrossRef]

- Rosace, G.; Rosa, R.P.; Arrigo, R.; Malucelli, G. Photosensitive acrylates containing bio-based epoxy-acrylate soybean oil for 3D printing application. J. Appl. Polym. Sci. 2021, 138, e51292. [Google Scholar] [CrossRef]

- Guit, J.; Tavares, M.B.L.; Hul, J.; Ye, C.N.; Loos, K.; Jager, J.; Folkersma, R.; Voet, V.S.D. Photopolymer Resins with Biobased Methacrylates Based on Soybean Oil for Stereolithography. ACS Appl. Polym. Mater. 2020, 2, 949–957. [Google Scholar] [CrossRef]

- Sutton, J.T.; Rajan, k.; Harper, D.P.; Chmely, S.C. Improving UV Curing in Organosolv Lignin-Containing Photopolymers for Stereolithography by Reduction and Acylation. Polymers 2021, 13, 3473. [Google Scholar] [CrossRef]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Kadri, N.A.; Osman, N.A.A. A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef]

- Zeng, W.L.; Guo, Y.L.; Liu, Y.; Gong, Y.P.; Zhao, P.F.; Li, C.L.; Zhao, J.W. A New Rice Husk-Plastic Composite Powder Preparation Process for Selective Laser Sintering Fabrication. Adv. Mater. Res. 2013, 750–752, 1577–1581. [Google Scholar] [CrossRef]

- Guo, S.; Li, J.; Zhang, L.; Li, Y.C. Preparation of high-porosity biomass-based carbon electrodes by selective laser sintering. Mater. Lett. 2023, 330, 133300. [Google Scholar] [CrossRef]

- Zeng, W.L.; Guo, Y.L.; Jiang, K.Y.; Yu, Z.X.; Liu, Y.; Shen, Y.D.; Deng, J.R.; Wang, P.X. Laser intensity effect on mechanical properties of wood-plastic composite parts fabricated by selective laser sintering. J. Thermoplast. Compos. Mater. 2013, 26, 125–136. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Cui, Y.H.; Wang, S.; Zhao, X.W.; Wang, F.M.; Wu, G.H. Effect of microwave treatment on bending properties of carbon nanotube/wood plastic composites by selective laser sintering. Mater. Lett. 2020, 267, 127547. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Wang, F.M.; Zhang, Y.F.; Li, J.; Guo, Y.L. Effect of Al powder on mechanical properties and microstructure of wood-plastic composites by selective laser sintering. Mater. Today Commun. 2021, 27, 102235. [Google Scholar] [CrossRef]

- Sonmez, F.O.; Hahn, H.T. Thermomechanical analysis of the laminated object manufacturing (LOM) process. Rapid Prototyp. J. 1998, 4, 26–36. [Google Scholar] [CrossRef] [Green Version]

- Tao, Y.B.; Yin, Q.; Li, P. An Additive Manufacturing Method Using Large-Scale Wood Inspired by Laminated Object Manufacturing and Plywood Technology. Polymers 2020, 13, 144. [Google Scholar] [CrossRef] [PubMed]

- Kariz, M.; Sernek, M.; Kuzman, M.K. Use of wood powder and adhesive as a mixture for 3D printing. Eur. J. Wood Wood Prod. 2016, 74, 123–126. [Google Scholar] [CrossRef]

- Pitt, K.; Lopez-Botello, O.; Lafferty, A.D.; Todd, I.; Mumtaz, K. Investigation into the material properties of wooden composite structures with in-situ fibre reinforcement using additive manufacturing. Compos. Sci. Technol. 2017, 138, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Arif, Z.U.; Khalid, M.Y.; Zolfagharian, A.; Bodaghi, M. 4D bioprinting of smart polymers for biomedical applications: Recent progress, challenges, and future perspectives. React. Funct. Polym. 2022, 179, 105374. [Google Scholar] [CrossRef]

- Jo, G.H.; Lim, W.S.; Kim, H.W.; Park, H.J. Post-processing and printability evaluation of red ginseng snacks for three-dimensional (3D) printing. Food Biosci. 2021, 42, 101094. [Google Scholar] [CrossRef]

- Tetik, H.; Zhao, K.R.; Shah, N.A.; Lin, D. 3D freeze-printed cellulose-based aerogels: Obtaining truly 3D shapes, and functionalization with cross-linking and conductive additives. J. Manuf. Process. 2021, 68, 445–453. [Google Scholar] [CrossRef]

- Garcia, E.A.; Ayranci, C.; Qureshi, A.J. Material Property-Manufacturing Process Optimization for Form 2 Vat-Photo Polymerization 3D printers. J. Manuf. Mater. Process. 2020, 4, 12. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.S.; Knetzer, D.A.; Wang, J.F.; Chu, F.X.; Lu, C.W.; Calvert, P.D. 3D printing acrylated epoxidized soybean oil reinforced with functionalized cellulose by UV curing. J. Appl. Polym. Sci. 2021, 139, e51561. [Google Scholar] [CrossRef]

- Zhao, Z.C.; Wu, H.; Liu, X.D.; Kang, D.S.; Xiao, Z.H.; Lin, Q.Q.; Zhang, A.H. Synthesis and characterization of tung oil-based UV curable for three-dimensional printing resins. RSC Adv. 2022, 12, 22119–22130. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.J.; Kuang, X.; Li, V.; Kang, G.Z.; Qi, H.J. Fabrication of tough epoxy with shape memory effects by UV-assisted direct-ink write printing. Soft Matter 2018, 14, 1879–1886. [Google Scholar] [CrossRef] [PubMed]

- Pascual-Gonzalez, C.; San Martin, P.; Lizarralde, I.; Fernandez, A.; Leon, A.; Lopes, C.S.; Fernandez-Biazquez, J.P. Post-processing effect on microstructure, interlaminar and thermal properties of 3D printed continuous carbon fiber composites. Compos. Part B Eng. 2021, 210, 108652. [Google Scholar] [CrossRef]

- Yang, Z.Z.; Wu, G.M.; Wang, S.Q.; Xu, M.; Feng, X.H. Dynamic Postpolymerization of 3D-Printed Photopolymer Nanocomposites: Effect of Cellulose Nanocrystal and Postcure Temperature. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 935–946. [Google Scholar] [CrossRef]

- Ge, Y.; Zhang, T.; Zhou, B.; Wang, H.Q.; Zhang, Z.H.; Shen, J.; Du, A. Nanostructured resorcinol-formaldehyde ink for 3D direct writing. J. Mater. Res. 2018, 33, 2052–2061. [Google Scholar] [CrossRef]

- Armstrong, C. Post Processing for FDM Printed Parts. Available online: https://www.hubs.com/knowledge-base/post-processing-FFF-printed-parts/#weld (accessed on 6 August 2021).

- Sun, Z.; Lu, Y.H.; Zhao, Q.; Wu, J.J. A new stereolithographic 3D printing strategy for hydrogels with a large mechanical tunability and self-weldability. Addit. Manuf. 2022, 50, 102563. [Google Scholar] [CrossRef]

- Yang, E.; Miao, S.D.; Zhong, J.; Zhang, J.Y.; Mills, D.K.; Zhang, L.G. Bio-Based Polymers for 3D Printing of Bioscaffolds. Polym. Rev. 2018, 58, 668–687. [Google Scholar] [CrossRef] [PubMed]

- Athukoralalage, S.S.; Balu, R.; Dutta, N.K.; Choudhury, N.R. 3D Bioprinted Nanocellulose-Based Hydrogels for Tissue Engineering Applications: A Brief Review. Polymers 2019, 11, 898. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kanikireddy, V.; Varaprasad, K.; Jayaramudu, T.; Karthikeyan, C.; Sadiku, R. Carboxymethyl cellulose-based materials for infection control and wound healing: A review. Int. J. Biol. Macromol. 2020, 164, 963–975. [Google Scholar] [CrossRef] [PubMed]

- Surini, S.; Bimawanti, Y.; Kurniawan, A. The Application of Polymers in Fabricating 3D Printing Tablets by Fused Deposition Modeling (FDM) and The Impact on Drug Release Profile. Pharm. Sci. 2022, 29, 156–164. [Google Scholar] [CrossRef]

- Zamboulis, A.; Michailidou, G.; Koumentakou, I.; Bikiaris, D.N. Polysaccharide 3D Printing for Drug Delivery Applications. Pharmaceutics 2022, 14, 145. [Google Scholar] [CrossRef]

- Miao, S.D.; Zhu, W.; Castro, N.J.; Nowicki, M.; Zhou, X.; Cui, H.T.; Fisher, J.P.; Zhang, L.G. 4D printing smart biomedical scaffolds with novel soybean oil epoxidized acrylate. Sci. Rep. 2016, 6, 27226. [Google Scholar] [CrossRef] [Green Version]

- Calì, M.; Pascoletti, G.; Gaeta, M.; Milazzo, G.; Ambu, R. New filaments with natural fillers for FDM 3D printing and their applications in biomedical field. Procedia Manuf. 2020, 51, 698–703. [Google Scholar] [CrossRef]

- Khaled, S.A.; Burley, J.C.; Alexander, M.R.; Yang, J.; Roberts, C.J. 3D printing of five-in-one dose combination polypill with defined immediate and sustained release profiles. J. Control. Release 2015, 217, 308–314. [Google Scholar] [CrossRef]

- Rees, A.; Powell, L.C.; Chinga-Carrasco, G.; Gethin, D.T.; Syverud, K.; Hill, K.E.; Thomas, D.W. 3D Bioprinting of Carboxymethylated-Periodate Oxidized Nanocellulose Constructs for Wound Dressing Applications. Biomed Res. Int. 2015, 2015, 925757. [Google Scholar] [CrossRef] [Green Version]

- Leppiniemi, J.; Lahtinen, P.; Paajanen, A.; Mahlberg, R.; Metsa-Kortelainen, S.; Pinornaa, T.; Pajari, H.; Vikholm-Lundin, I.; Pursula, P.; Hytonen, V.P. 3D-printable bioactivated nanocellulose-alginate hydrogels. Acs Appl. Mater. Interfaces 2017, 9, 21959–21970. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.Y.; Zhang, X.; Yang, P.R.; Langvik, O.; Wang, X.J.; Zhang, Y.C.; Cheng, F.; Osterberg, M.; Willfor, S.; Xu, C.L. Surface Engineered Biomimetic Inks Based on UV Cross-Linkable Wood Biopolymers for 3D Printing. ACS Appl. Mater. Interfaces 2019, 11, 12389–12400. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Schwarz, S.; Avila, H.M.; Rotter, N.; Gatenholm, P. 3D Bioprinting of Human Chondrocyte-laden Nanocellulose Hydrogels for Patient-specific Auricular Cartilage Regeneration. Tissue Eng. Part A 2016, 21, s373. [Google Scholar]

- Jessop, Z.M.; Al-Sabah, A.; Gao, N.; Kyle, S.; Thomas, B.; Badiei, N.; Hawkins, K.; Whitaker, I.S. Printability of pulp derived crystal, fibril and blend nanocellulose-alginate bioinks for extrusion 3D bioprinting. Biofabrication 2019, 11, 045006. [Google Scholar] [CrossRef]

- Zhang, T.Y.; Li, X.; Asher, E.; Deng, S.X.; Sun, X.L.; Yang, J. Paper with Power: Engraving 2D Materials on 3D Structures for Printed, High-Performance, Binder-Free, and All-Solid-State Supercapacitors. Adv. Funct. Mater. 2018, 28, 1803600. [Google Scholar] [CrossRef]

- Zhu, Y.X.; Qin, J.D.; Shi, G.; Sun, C.; Ingram, M.; Qian, S.S.; Lu, J.; Zhang, S.Q.; Zhong, Y.L. A focus review on 3D printing of wearable energy storage devices. Carbon Energy 2022, 4, 1242–1261. [Google Scholar] [CrossRef]

- Hamad, W.Y. Photonic and Semiconductor Materials Based on Cellulose Nanocrystals. Adv. Polym. Sci. 2016, 271, 287–328. [Google Scholar]

- Ee, L.Y.; Li, S.F.Y. Recent advances in 3D printing nanocellulose: Structure, preparation and application prospects. Nanoscale Adv. 2021, 3, 1167–1208. [Google Scholar] [CrossRef]

- Cao, D.X.; Xing, Y.J.; Tantratian, K.; Wang, X.; Ma, Y.; Mukhopadhyay, A.; Cheng, Z.; Zhang, Q.; Jiao, Y.C.; Chen, L.; et al. 3D Printed High-Performance Lithium Metal Microbatteries Enabled by Nanocellulose. Adv. Mater. 2019, 31, 1807313. [Google Scholar] [CrossRef]

- Wang, C.S.; Wu, S.Q.; Li, Z.Q.; Chen, S.; Chen, A.N.; Yan, C.Z.; Shi, Y.S.; Zhang, H.B.; Fan, P.Y. 3D printed porous biomassderived SiCnw/SiC composite for structurefunction integrated electromagnetic absorption. Virtual Phys. Prototyp. 2022, 17, 718–733. [Google Scholar] [CrossRef]

- Hsieh, M.C.; Kim, C.; Nogi, M.; Suganuma, K. Electrically conductive lines on cellulose nanopaper for flexible electrical devices. Nanoscale 2013, 5, 9289–9295. [Google Scholar] [CrossRef]

- Huang, S.Q.; Su, S.Y.; Gan, H.B.; Wu, L.J.; Lin, C.H.; Xu, D.Y.; Zhou, H.F.; Lin, X.L.; Qin, Y.L. Facile fabrication and characterization of highly stretchable lignin-based hydroxyethyl cellulose self-healing hydrogel. Carbohydr. Polym. 2019, 223, 115080. [Google Scholar] [CrossRef] [PubMed]

- Qian, J.; Chen, Q.Y.; Hong, M.; Xie, W.Q.; Jing, S.S.; Bao, Y.H.; Chen, G.; Pang, Z.Q.; Hu, L.B.; Li, T. Toward stretchable batteries: 3D-printed deformable electrodes and separator enabled by nanocellulose. Mater. Today 2022, 54, 18–26. [Google Scholar] [CrossRef]

- Saha, M.C.; Maity, K.; Mondal, A. Cellulose Nanocrystal-Based All-3D-Printed Pyro-Piezoelectric Nanogenerator for Hybrid Energy Harvesting and Self-Powered Cardiorespiratory Monitoring toward the Human-Machine Interface. Acs Appl. Mater. Interfaces 2023, 15, 13956–13970. [Google Scholar]

- Henke, K.; Treml, S. Wood based bulk material in 3D printing processes for applications in construction. Eur. J. Wood Wood Prod. 2013, 71, 139–141. [Google Scholar] [CrossRef]

- Yoshida, H.; Igarashi, T.; Obuchi, Y.; Takami, Y.; Sato, J.; Araki, M.; Miki, M.; Nagata, K.; Sakai, K.; Igarashi, S. Architecture-Scale Human-Assisted Additive Manufacturing. ACM Trans. Grap. 2015, 34, 88. [Google Scholar] [CrossRef]

- Zhao, X.H.; Tekinalp, H.; Meng, X.Z.; Ker, D.; Benson, B.; Pu, Y.Q.; Ragauskas, A.J.; Wang, Y.; Li, K.; Webb, E.; et al. Poplar as Biofiber Reinforcement in Composites for Large-Scale 3D Printing. ACS Appl. Bio Mater. 2019, 2, 4557–4570. [Google Scholar] [CrossRef] [PubMed]

- Alqenaee, A.; Memari, A. Experimental study of 3D printable cob mixtures. Constr. Build. Mater. 2022, 324, 126574. [Google Scholar] [CrossRef]

- Yang, S.G.; Du, P. The application of 3D printing technology in furniture design. Sci. Program. 2022, 2022, 1960038. [Google Scholar] [CrossRef]

- Bhagia, S.; Bornani, K.; Agrawal, R.; Satlewal, A.; Durkovic, J.; Lagana, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.H.; Kunc, V.; et al. Critical review of FDM 3D printing of PLA biocomposites filled with biomass resources, characterization, biodegradability, upcycling and opportunities for biorefineries. Appl. Mater. Today 2021, 24, 101078. [Google Scholar] [CrossRef]

- Feng, X.H.; Wu, Z.H.; Sang, R.J.; Wang, F.; Zhu, Y.Y.; Wu, M.J. Surface design of wood-based board to imitate wood texture using 3D printing technology. BioResources 2019, 14, 8196–8211. [Google Scholar] [CrossRef]

- Sang, R.J.; Manley, A.J.; Wu, Z.H.; Feng, X.H. Digital 3D Wood Texture: UV-Curable Inkjet Printing on Board Surface. Coatings 2020, 10, 1144. [Google Scholar] [CrossRef]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsa-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Shahbazi, M.; Jager, H.; Ettelaie, R. A Promising Therapeutic Soy-Based Pickering Emulsion Gel Stabilized by a Multifunctional Microcrystalline Cellulose: Application in 3D Food Printing. J. Agric. Food Chem. 2022, 70, 2374–2388. [Google Scholar] [CrossRef]

- Letras, P.; Oliveira, S.; Varela, J.; Nunes, M.C.; Raymundo, A. 3D printed gluten-free cereal snack with incorporation of Spirulina (Arthrospira platensis) and/or Chlorella vulgaris. Algal Res. 2022, 68, 102863. [Google Scholar] [CrossRef]

| Classification Basis | Category | Biomass Materials | Printing Method | |

|---|---|---|---|---|

| Resource species | Marine Biomass | Sodium alginate [25], Agarose [26] | DIW | |

| Forestry Biomass | Coniferous wood [27], Broadleaf wood [28], Bamboo wood [29] | FFF, DIW, SLS, SLA, LOM, LDM | ||

| Agricultural biomass | Straw [30], Wheat [31], Rice [32], Corn [33], Sugar cane [34] | FFF, DIW, SLS, SLA, LOM, LDM | ||

| Chemical component | Mono-component biomass materials | Cellulose | Nanocellulose [35], Cellulose nanofiber [36], Cellulose nanocrystals [37], Cellulose acetate [38], Nano-fibrillated cellulose [39], Microcrystalline cellulose [40] | FFF, DIW, SLS, SLA, LOM, LDM |

| Hemicellulose | Hemicellulose paste [41] Galactoglucomannan [42], Hemicellulose hydrogel [43] | DIW, FFF | ||

| Lignin | Lignin powder | FFF [44], SLS [45] | ||

| Sulfonate lignin [46] | FFF | |||

| Lignin hydrogel [47] | DIW | |||

| Other | Chitosan [48], Soy protein [49], Starch [50] | DIW | ||

| Composite biomass materials | Compound of wood with plastic [51] Bamboo compounded with plastic [52] Compound of straw with plastic [53] Compound of cellulose [54]/lignin [55] with plastic | FFF, SLS | ||

| Form and morphology | Wires | Wood plastic wire [56] | FFF | |

| Particles | Wood plastic pellets [57] | SLS | ||

| Gel | Nanocellulose hydrogel [58] Cellulose ionic liquid [59] | DIW | ||

| Resin | Epoxy acrylate soybean oil (AESO) [60], | SLA | ||

| Sheet | Paper [61], Wood veneer [62] | LOM | ||

| Chips and powder | cellulose powder [63], Wood chips [64] | LDM | ||

| Technology | Applicable Biomass Materials | Advantages | Disadvantages |

|---|---|---|---|

| FFF | Bamboo plastic composite [52] Wood plastic composite [65] | Easy operation of the equipment [66], Simple post-processing [67], Wide range of molding materials [68] | Low accuracy of molded parts [69], Support structure required, Slow molding speed, Nozzle easily clogged [70] |

| DIW | Hemicellulose hydrogel [43] Lignin hydrogel [47] Cellulose ionic liquid [71] Cellulose hydrogel [72] Cellulose derivative hydrogels [73] | No support required [74], Wide range of raw material sources [75], Higher accuracy [76] | Complex post-processing [76] |

| SLA | Vegetable oil-based photosensitive resin [60] Lignin-based photosensitive resins [77] | Fast molding speed, Highest printing accuracy [78] | Poor environmental protection of raw materials [10] Restricted material types [79], |

| SLS | Wood Plastic Composite [57] | Simple process, No support structure required [80], High raw material utilization [81] | Complex post-processing [82], Rough and porous forming surface, Requires preheating and cooling [83] |

| LOM | Paper [61] Wood veneer [62] | Low price of raw materials [84], Fast molding speed, High printing accuracy, No support structure required [85] | Complex post-treatment process [86] |

| LDM | Cellulose powder [63] Wood chips [64], | Easy operation of the equipment, Lower cost [87] | Restricted material types [63] Post-processing required [86] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Ren, X.; Zhu, L.; Li, C. Biomass 3D Printing: Principles, Materials, Post-Processing and Applications. Polymers 2023, 15, 2692. https://doi.org/10.3390/polym15122692

Li Y, Ren X, Zhu L, Li C. Biomass 3D Printing: Principles, Materials, Post-Processing and Applications. Polymers. 2023; 15(12):2692. https://doi.org/10.3390/polym15122692

Chicago/Turabian StyleLi, Yongxia, Xueyong Ren, Lin Zhu, and Chunmiao Li. 2023. "Biomass 3D Printing: Principles, Materials, Post-Processing and Applications" Polymers 15, no. 12: 2692. https://doi.org/10.3390/polym15122692

APA StyleLi, Y., Ren, X., Zhu, L., & Li, C. (2023). Biomass 3D Printing: Principles, Materials, Post-Processing and Applications. Polymers, 15(12), 2692. https://doi.org/10.3390/polym15122692