Review of Plasma Processing for Polymers and Bio-Materials Using a Commercial Frequency (50/60 Hz)-Generated Discharge

Abstract

:1. Introduction

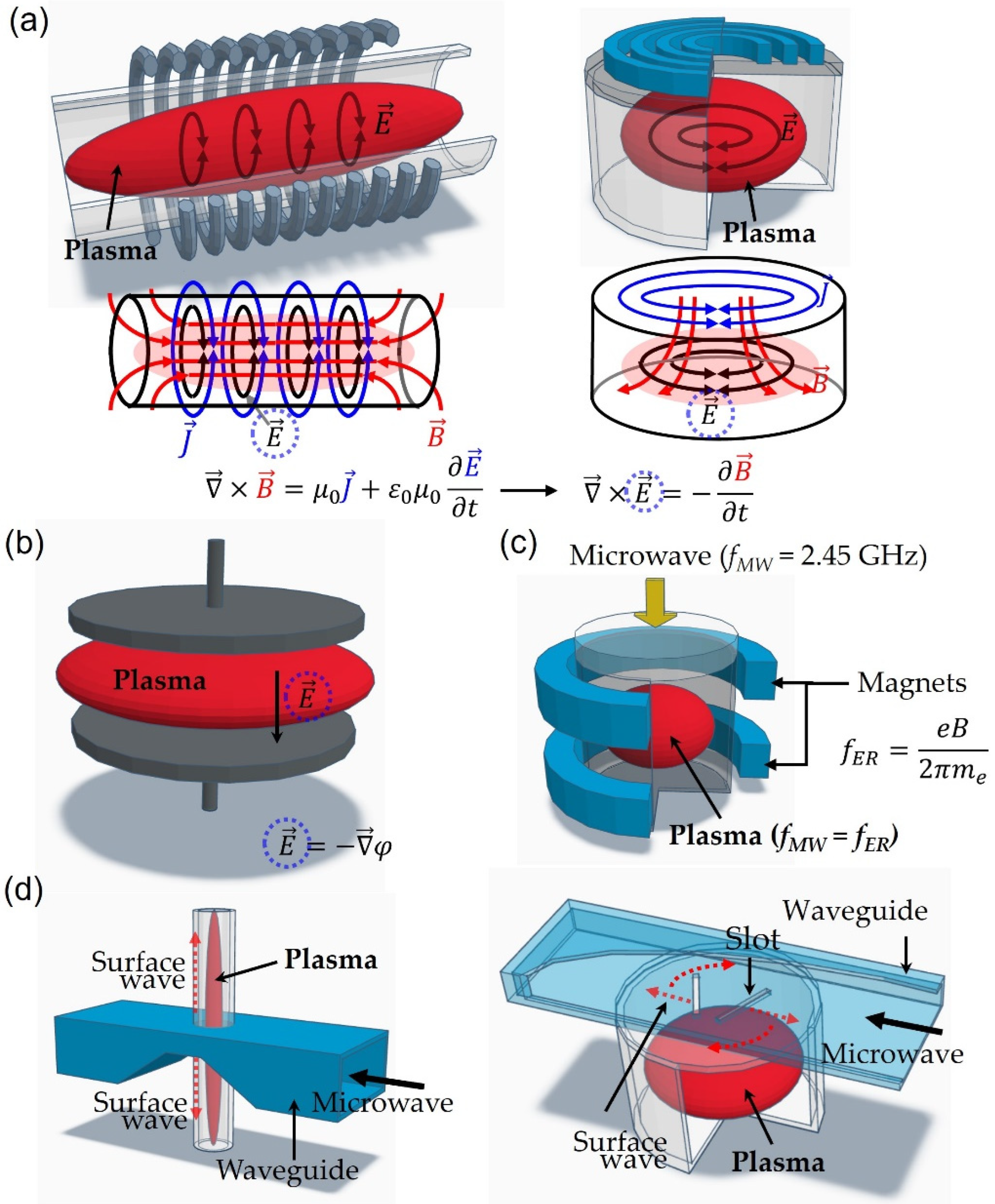

2. Plasma Properties Generated Using a Commercial-Frequency (50/60 Hz) Power Source

2.1. Nonthermal Plasma

2.2. Design and Construction of CF power Source

2.3. Plasma Characterizations and Properties Generated Using CF power

3. Plasma Processes Using CF-Derived Discharge

3.1. Film Depositions on Polymer and Polymeric Materials Using CF-Derived Discharge

3.2. Surface Modifications of Polymer and Polymer-like Materials Using CF-Derived Discharge

3.3. In-Package Cold Plasma Treatment on Organic Materials Using CF-Derived Plasma

3.4. Comparison of CF-Derived Plasma and Cold Atmospheric Pressure Plasma Jet

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sahoo, A.; Tripathy, S. Development in plasma arc welding process: A review. Mater. Today Proc. 2021, 41, 363–368. [Google Scholar] [CrossRef]

- Lieberman, M.A.; Lichtenberg, A.J. Principles of Plasma Discharges and Materials Processing, 2nd ed.; Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Fridman, A. Plasma Chemistry; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Hitchon, W.N.G. Plasma Processes for Semiconductor Fabrication; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Kabongo, G.L.; Mothudi, B.M.; Dhlamini, M.S. Advanced Development of Sustainable PECVD semitransparent Photovoltaics: A Review. Front. Mater. 2021, 8, 762030. [Google Scholar] [CrossRef]

- Yi, K.; Liu, D.; Chen, X.; Yang, J.; Wei, D.; Liu, Y.; Wei, D. Plasma-Enhanced Chemical Vapor Deposition of Two-Dimensional Materials for Applications. Acc. Chem. Res. 2021, 54, 1011–1022. [Google Scholar] [CrossRef] [PubMed]

- Gudmundsson, J.T. Physics of technology of magnetron sputtering discharge. Plasma Sources Sci. Technol. 2020, 29, 113001. [Google Scholar] [CrossRef]

- Liang, J.; Liu, Q.; Li, T.; Luo, Y.; Lu, S.; Shi, X.; Zhang, F.; Asiri, A.M.; Sun, X. Magnetron sputtering enabled sustainable synthesis of nanomaterials for energy electrocatalyst. Green Chem. 2021, 23, 2834–2867. [Google Scholar] [CrossRef]

- Larhlimi, H.; Ghailane, A.; Makha, M.; Alami, J. Magnetron sputtered titanium carbide-based coatings: A review of science and technology. Vacuum 2022, 197, 110853. [Google Scholar] [CrossRef]

- Deng, Y.; Chen, W.; Li, B.; Wang, C.; Kuang, T.; Li, Y. Physical vapor deposition technology for coated cutting tools: A review. Ceram. Int. 2020, 46 Pt B, 18373–18390. [Google Scholar] [CrossRef]

- Huff, M. Recent Advances in Reactive Ion Etching and Applications of High-Aspect Ratio Microfabrication. Micromachines 2021, 12, 991. [Google Scholar] [CrossRef]

- He, T.; Wang, Z.; Zhong, F.; Fang, H.; Wang, P.; Hu, W. Etching Techniques in 2D Materials. Adv. Mater. Technol. 2019, 4, 1900064. [Google Scholar] [CrossRef]

- Vajpayee, M.; Singh, M.; Ledwani, L. Non-thermal plasma treatment of cellulosic biopolymer to enhance its surface property for various applications: A review. Mater. Today Proc. 2021, 43, 3250–3255. [Google Scholar] [CrossRef]

- Laroussi, M. Cold Plasma in Medicine and Healthcare: The New Frontier in Low Temperature Plasma Applications. Front. Phys. 2020, 8, 74. [Google Scholar] [CrossRef]

- Ma, C.; Nikiforov, A.; Hegemann, D.; Geyter, N.D.; Morent, R.; Ostrikov, K. Plasma-controlled surface wettability: Recent advances and future applications. Int. Mater. Rev. 2023, 68, 82–119. [Google Scholar] [CrossRef]

- Sanito, R.C.; You, S.-J.; Wang, Y.-F. Degradation of contaminants in plasma technology: An overview. J. Hazard. Mater. 2022, 424, 127390. [Google Scholar] [CrossRef] [PubMed]

- Friedrich, J. The Plasma Chemistry of Polymer Surfaces: Advanced Techniques for Surface Design; Wiley-VCH: Weinheim, Germany, 2012. [Google Scholar]

- Laroque, D.A.; Seó, S.T.; Valencia, G.A.; Laurindo, J.B.; Carciofi, B.A.M. Cold plasma in food processing: Design, mechanisms, and application. J. Food Eng. 2022, 312, 110748. [Google Scholar] [CrossRef]

- Yang, D.-K.; Wang, D.; Huang, Q.-S.; Song, Y.; Wu, J.; Li, W.-X.; Wang, Z.-S.; Tang, X.-H.; Xu, H.-X.; Liu, S.; et al. The development of laser-produced plasma EUV light source. Chip 2022, 1, 100019. [Google Scholar] [CrossRef]

- Jaritz, M.; Behm, H.; Hopmann, C.; Kirchheim, D.; Mitschker, F.; Awakowicz, P.; Dahlmann, R. The effect of UV radiation from oxygen and argon plasma on the adhesion of organosilicon coatings on polypropylene. J. Phys. D-Appl. Phys. 2017, 50, 015201. [Google Scholar] [CrossRef]

- Jiang, Y.; Peng, S.; Wu, W.; Ma, T.; Zhang, J.; Ren, H.; Li, K.; Zhang, T.; Wen, J.; Xu, Y.; et al. A miniaturized ECR plasma flood gun for wafer charge neutralization. Rev. Sci. Instrum. 2020, 91, 033319. [Google Scholar] [CrossRef]

- Zamri, A.A.; Ong, M.Y.; Nomanbhay, S.; Show, P.L. Microwave plasma technology for sustainable energy production and the electromagnetic interaction within the plasma system: A review. Environ. Res. 2021, 197, 111204. [Google Scholar] [CrossRef]

- Deng, P.; Xiao, W.; Wang, F.; Zhang, Z. Design of a Novel Microwave Plasma Source Based on Ridged Waveguide. Prog. Electromagn. Res. Lett. 2021, 101, 19–27. [Google Scholar] [CrossRef]

- Zalieckas, J.; Pobedinskas, P.; Greve, M.M.; Eikehaug, K.; Haenen, K.; Holst, B. Large area microwave plasma CVD of diamond using composite right/left-handed materials. Diam. Relat. Mat. 2021, 116, 108394. [Google Scholar] [CrossRef]

- Fujiwara, T.; Sato, T.; Sekikawa, J.; Yamada, H. Transient glow discharge in nitrogen after the breakdown. J. Phys. D-Appl. Phys. 1994, 27, 826–829. [Google Scholar] [CrossRef]

- Okazaki, S.; Kogoma, M.; Uehara, M.; Kimura, Y. Appearance of stable glow discharge in air, argon, oxygen and nitrogen at atmospheric pressure using a 50 Hz source. J. Phys. D-Appl. Phys. 1993, 26, 889–892. [Google Scholar] [CrossRef]

- Kim, H.T.; Kim, C.-D.; Pyo, M.S.; Park, C. Electrical and optical characteristics of Ar plasma generated by low-frequency (60 Hz) power source. Korean J. Chem. Eng. 2014, 31, 1892–1897. [Google Scholar] [CrossRef]

- Shimozuma, M.; Tochitani, G.; Tagashira, H. Optical emission diagnostics of H2+CH4 50 Hz–13.56 MHz plasmas for chemical vapor deposition. J. Appl. Phys. 1991, 70, 645–648. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.T.; Park, D.K.; Choi, W.S. Measurements of plasma parameters in low-frequency (60 Hz) hydrogen discharge. J. Korean Phys. Soc. 2003, 42, S916–S919. [Google Scholar]

- Kim, H.T. Diagnostics and Some Applications of Low-Frequency (60 Hz) Plasma. Ph.D. Thesis, Kyungpook National University, Daegu, Republic of Korea, 2002. [Google Scholar]

- Shimozuma, M.; Kitamori, K.; Ohno, H.; Hasegawa, H.; Tagashira, H. Room temperature Deposition of Silicon Nitride Films Using Very Low Frequency (50 Hz) Plasma CVD. J. Electron. Mater. 1985, 14, 573–586. [Google Scholar] [CrossRef]

- Tochitani, G.; Shimozuma, M.; Tagashira, H. Deposition of silicon oxide films from TEOS by low-frequency plasma chemical vapor deposition. J. Vac. Sci. Technol. A 1993, 11, 400–405. [Google Scholar] [CrossRef]

- Hashizume, T.; Hasegawa, H.; Tochitani, G.; Shimozuma, M. Annealing behavior of HF-treated GaAs capped with SiO2 films prepared by 50-Hz plasma-assisted chemical vapor deposition. Jpn. J. Appl. Phys. 1992, 31, 3794–3800. [Google Scholar] [CrossRef]

- Tochitani, G.; Shimozuma, M.; Tagashira, H. Properties of hydrogenated amorphous silicon films prepared by low-frequency (50 Hz) plasma-enhanced chemical-vapor deposition. J. Appl. Phys. 1992, 72, 234–238. [Google Scholar] [CrossRef]

- Kim, H.T.; Sohn, S.H. Effects of applied power on hydrogenated amorphous carbon (a-C:H) film deposition by low frequency (60 Hz) plasma-enhanced chemical vapor deposition. Vacuum 2012, 86, 2148–2151. [Google Scholar] [CrossRef]

- Shimozuma, M.; Date, H.; Iwasaki, T.; Tagashira, H.; Yoshino, M.; Yoshida, K. Three-dimensional deposition of TiN film using low frequency (50 Hz) plasma chemical vapor deposition. J. Vac. Sci. Technol. A 1997, 15, 1897–1901. [Google Scholar] [CrossRef] [Green Version]

- Yoshino, M.; Shimozuma, M.; Date, H.; Rodrigo, A.; Tagashira, H. Properties of TiN Films on Heated Substrate Below 550 ºC by 50 Hz Plasma-Enhanced Chemical Vapor Deposition. Jpn. J. Appl. Phys. 2000, 39, 1299–1302. [Google Scholar] [CrossRef]

- Kim, H.T.; Kim, M.J.; Sohn, S.H. Characterization of TiN thin films grown by low-frequency (60 Hz) plasma enhanced chemical vapor deposition. J. Phys. Chem. Solids 2012, 73, 931–935. [Google Scholar] [CrossRef]

- Kim, H.T.; Chae, C.S.; Han, D.H.; Park, D.K. Effect of substrate temperature and input power on TiN film deposition by low-frequency (60 Hz) PECVD. J. Korean Phys. Soc. 2000, 37, 319–323. [Google Scholar]

- Kim, H.T.; Lee, S.-Y.; Lee, H.R.; Park, C. Effects of growth temperature on titanium carbide (TiC) film formation using low-frequency (60 Hz) plasma-enhanced chemical vapor deposition. Korean J. Chem. Eng. 2018, 35, 246–250. [Google Scholar] [CrossRef]

- Roth, J.R. Industrial Plasma Engineering Vol. 2: Applications to Nonthermal Plasma Processing; Institute of Physics Publishing: Bristol, UK, 2001. [Google Scholar]

- Meichester, J.; Schmidt, M.; Schneider, R.; Wagner, H.-E. Nonthermal Plasma Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Hong, Y.; Niu, J.; Pan, J.; Bi, Z.; Ni, W.; Liu, D.; Li, J.; Wu, Y. Electron temperature and density measurement of a dielectric barrier discharge argon plasma generated with tube-to-plate electrodes in water. Vacuum 2016, 130, 130–136. [Google Scholar] [CrossRef] [Green Version]

- Park, S.; Choe, W.; Moon, S.Y.; Yoo, S.J. Spatio-temporally resolved electron temperature in argon radio-frequency capacitive discharge at atmospheric pressure. Plasma Sources Sci. Technol. 2015, 24, 032006. [Google Scholar] [CrossRef]

- Wong, C.S.; Mongkolnavin, R. Elements of Plasma Technology; Springer: Singapore, 2016. [Google Scholar]

- Brieda, L. Plasma Simulation by Example; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Kushner, M.J. Hybrid modelling of low temperature plasma for fundamental investigations and equipment design. J. Phys. D Appl. Phys. 2009, 42, 194013. [Google Scholar] [CrossRef] [Green Version]

- Cohen, B.I. Perspectives on research in computational plasma physics with applications to experiments. IEEE Trans. Plasma Sci. 2020, 48, 757–767. [Google Scholar] [CrossRef]

- Tendero, C.; Tixier, C.; Tristant, P.; Desmaison, J.; Leprince, P. Atmospheric pressure plasmas: A review. Spectroc. Acta Part B-Atom. Spectr. 2006, 61, 2–30. [Google Scholar] [CrossRef]

- Mumtaz, S.; Khan, R.; Rana, J.N.; Javed, R.; Iqbal, M.; Choi, E.H.; Han, I. Review on the Biomedical and Environmental Applications of Nonthermal Plasma. Catalysis 2023, 13, 685. [Google Scholar] [CrossRef]

- Kekez, M.M.; Barrault, M.R.; Craggs, J.D. Spark channel formation. J. Phys. D-Appl. Phys. 1970, 3, 1886–1896. [Google Scholar] [CrossRef]

- Baeva, M.; Lofhagen, D.; Becker, M.M.; Uhrlandt, D. Fluid modelling of DC argon micro-plasmas: Efects of the electron transport description. Plasma Chem. Plasma Process. 2019, 39, 949–968. [Google Scholar] [CrossRef]

- Saifutdinov, A.I. Numerical study of various scenarios for the formation of atmospheric pressure DC discharge characteristics in argon: From glow to arc discharge. Plasma Sources Sci. Technol. 2022, 31, 094008. [Google Scholar] [CrossRef]

- Lau, Y.T.; Chiu, W.S.; Lee, H.C.; Woo, H.J.; Chin, O.H.; Tou, T.Y. A low power 50 Hz argon plasma for surface modification of polytetrafluoroethylene. Plasma Sci. Technol. 2022, 24, 114001. [Google Scholar] [CrossRef]

- Griem, H.R. Principle of Plasma Spectroscopy; Cambridge University Press: Cambridge, UK, 1992. [Google Scholar]

- Eletskiĭ, A.V.; Smirnov, B.M. Nonuniform gas discharge plasma. Phys. Usp. 1996, 39, 1137. [Google Scholar] [CrossRef]

- Baranov, V.Y.; Ul’yanov, K.N. Contraction of a positive column. I, II(Positive column contraction in Ar and Ar-Cs mixtures, developing theory for nonisothermal local collision arc). Sov. Phys. Tech. Phys. 1969, 14, 176. [Google Scholar]

- Zhao, Z.; Li, J. Repetitively pulsed gas discharges: Memory effect and discharge mode transition. High Volt. 2020, 5, 569–582. [Google Scholar] [CrossRef]

- Huang, B.-D.; Takashima, K.; Zhu, X.-M.; Pu, Y.-K. The influence of the repetition rate on the nanosecond pulsed pin-to-pin microdischarges. J. Phys. D App. Phys. 2014, 47, 422003. [Google Scholar] [CrossRef]

- Huang, B.-D.; Carbone, E.; Takashima, K.; Zhu, X.-M.; Czarnetzki, U.; Pu, Y.-K. The effect of the pulse repetition rate on the fast ionization wave discharge. J. Phys. D App. Phys. 2018, 51, 225202. [Google Scholar] [CrossRef]

- Xu, Y.; Yan, X.-T. Chemical Vapour Deposition: An Integrated Engineering Design of Advanced Materials; Springer: London, UK, 2010. [Google Scholar]

- Jung, S.K.; Kim, M.C.; Sohn, S.H.; Park, D.K.; Lee, S.H.; Park, L.S. Properties of indium tin oxide on polymer films deposited by low-frequency magnetron sputtering method. Mol. Cryst. Liquid Cryst. 2006, 459, 167–177. [Google Scholar] [CrossRef]

- Kim, E.Y.; Jung, S.K.; Sohn, S.H.; Park, D.K.; Lee, S.M.; Park, L.S.; Lee, S.H.; Song, K.D. Properties of indium zinc oxide films on various polymer substrates deposited by low-frequency 60 Hz magnetron sputtering. Mol. Cryst. Liquid Cryst. 2007, 470, 241–250. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, D.K.; Seo, S.H.; Oh, J.H.; Jung, S.K.; Sohn, S.H.; Park, D.K. Influence of oxygen flow rate on the properties of ITO films prepared by low-frequency (60 Hz) magnetron sputtering. Mol. Cryst. Liquid Cryst. 2006, 459, 221–229. [Google Scholar] [CrossRef]

- Kim, H.T.; Jung, S.K.; Lee, S.-Y. Properties of ITO films deposited on paper sheets using a low-frequency (60 Hz) DC-pulsed magnetron sputtering. Vacuum 2021, 187, 110056. [Google Scholar] [CrossRef]

- Kim, H.T.; Jung, S.K.; Kim, D.-E.; Park, C.Y.; Lee, S.-Y. Wettability control of paper through substitution between the hydroxyl group and carbon elements using argon-carbon plasma treatment. Vacuum 2022, 205, 111398. [Google Scholar] [CrossRef]

- Wolf, R.A. Atmospheric Pressure Plasma for Surface Modification; Scrivener Publishing LLC: Salem, MA, USA, 2013. [Google Scholar]

- Kusano, Y.; Norrman, K.; Singh, S.V.; Leipold, F.; Morgen, P.; Bardenshtein, A.; Krebs, N. Ultrasound enhanced 50 Hz plasma treatment of glass-fiber-reinforced polyester at atmospheric pressure. J. Adhes. Sci. Technol. 2013, 27, 825–833. [Google Scholar] [CrossRef]

- Mei, D.; Tu, X. Atmospheric pressure non-thermal plasma activation of CO2 in a packed-bed dielectric barrier discharge reactor. ChemPhysChem 2017, 18, 3253–3259. [Google Scholar] [CrossRef] [Green Version]

- Bhak, J.-G.; Kim, H.T.; Kim, C.; Rhee, I. Damage-free surface treatment of polyethersulfone films using magnetized plasma generated by low-frequency (60 Hz) power. Mol. Cryst. Liquid Cryst. 2017, 645, 239–245. [Google Scholar] [CrossRef]

- Prasertsung, I.; Kanokpanont, S.; Mongkolnavin, R.; Wong, C.S.; Panpranot, J.; Damrongsakkul, S. Plasma enhancement of in vitro attachment of rat bone-marrow-derived stem cells on cross-linked gelatin films. J. Biomater. Sci.-Polym. Ed. 2012, 23, 1485–1504. [Google Scholar] [CrossRef] [Green Version]

- Takahashi, Y.; Yamamoto, M.; Tabata, Y. Osteogenic differentiation of mesenchymal stem cells in biodegradable sponges composed of gelatin and beta-tricalcium phosphate. Biomaterials 2005, 26, 3587–3596. [Google Scholar] [CrossRef]

- Prasertsung, I.; Mongkolnavin, R.; Damrongsakkul, S.; Wong, C.S. Surface modification of dehydrothermal cross-linked gelatin film using a 50 Hz oxygen glow discharge. Surf. Coat. Technol. 2010, 205, S133–S138. [Google Scholar] [CrossRef]

- Prasertsung, I.; Kanokpanont, S.; Mongkolnavin, R.; Wong, C.S.; Panpranot, J.; Damrongsakkul, S. Comparison of the behavior of fibroblast and bone marrow-derived mesenchymal stem cell on nitrogen plasma-treated gelatin films. Mater. Sci. Eng. C-Mater. Biol. Appl. 2013, 33, 4475–4479. [Google Scholar] [CrossRef]

- Morent, R.; De Geyter, N.; Leys, C. Effects of operating parameters on plasma-induced PET surface treatment. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. Atoms 2008, 266, 3081–3085. [Google Scholar] [CrossRef]

- Jang, H.J.; Jung, E.Y.; Parsons, T.; Tae, H.-S.; Park, C.-S. A review of plasma synthesis methods for polymer films and nanoparticles under atmospheric pressure conditions. Polymers 2021, 13, 2267. [Google Scholar] [CrossRef] [PubMed]

- Zabidi, N.Z.A.; Zaaba, S.K.; Sut, K.D.E.; Mohamed, C.W.S.R.; Masiman, R.I. A brief review on atmospheric air plasma. J. Phys. Conf. Ser. 2021, 2071, 012004. [Google Scholar] [CrossRef]

- Reema; Khanikar, R.R.; Bailung, H.; Sankaranarayanan, K. Review of the cold atmospheric plasma technology application in food, disinfection, and textiles: A way forward for achieving circular economy. Front. Physics 2022, 10, 942952. [Google Scholar] [CrossRef]

- Kumar, A.; Škoro, N.; Gernjak, W.; Pauč, N. Cold atmospheric plasma technology for removal of organic micropollutants from wastewater-a review. Eur. Phys. J. D 2021, 75, 283. [Google Scholar] [CrossRef]

- Choi, Y.-H.; Kim, J.-H.; Paek, W.-T.; Ju, W.-T.; Hwang, Y.S. Characteristics of atmospheric pressure N2 cold plasma torch using 60-Hz AC power and its application to polymer surface modification. Surf. Coat. Technol. 2005, 193, 319–324. [Google Scholar] [CrossRef]

- Joshi, U.M.; Subedi, D.P. Surface treatment of polypropylene (PP) film by 50 Hz dielectric barrier discharge produced in air and argon/air mixture at atmospheric pressure. AIP Conf. Proc. 2015, 1670, 020003. [Google Scholar]

- Rana, S.; Mehta, D.; Bansal, V.; Shivhare, U.S.; Yadav, S.K. Atmospheric cold plasma (ACP) treatment improved in-package shelf-life of strawberry fruit. J. Food Sci. Technol. 2020, 57, 102–112. [Google Scholar] [CrossRef]

- María, C.; Pérez-Pizá, M.C.; Prevosto, L.; Grijalba, P.E.; Zilli, C.G.; Cejas, E.; Mancinelli, B.; Balestrasse, K.B. Improvement of growth and yield of soybean plants through the application of non-thermal plasma to seeds with different health status. Heliyon 2019, 5, e01495. [Google Scholar]

- Mahnot, N.K.; Siyu, L.-P.; Wan, Z.; Keener, K.M.; Misra, N.N. In-package cold plasma decontamination of fresh-cut carrots: Microbial and quality aspects. J. Phys. D App. Phys. 2020, 53, 154002. [Google Scholar] [CrossRef]

- Ganesan, A.R.; Tiwari, U.; Ezhilarasi, P.N.; Rajauria, G. Application of cold plasma on food matrices: A review on current and future prospects. J. Food Process. Preserv. 2021, 45, e15070. [Google Scholar] [CrossRef]

- Zhou, R.; Rezaeimotlagh, A.; Zhou, R.; Zhang, T.; Wang, P.; Hong, J.; Soltani, B.; Mai-Prochnow, A.; Liao, X.; Ding, T.; et al. In-package plasma: From reactive chemistry to innovative food preservation technologies. Trends Food Sci. Technol. 2022, 120, 59–74. [Google Scholar] [CrossRef]

- Perera, K.Y.; Prendeville, J.; Jaiswal, A.K.; Jai-wal, S. Cold Plasma Technology in Food Packaging. Coatings 2022, 12, 1986. [Google Scholar] [CrossRef]

- Misra, N.N.; Yepez, X.; Xu, L.; Keener, K. In-package cold plasma technologies. J. Food Eng. 2019, 244, 21–31. [Google Scholar] [CrossRef]

- Li, S.; Dang, X.; Yu, X.; Abbas, G.; Zhang, Q.; Cao, L. The application of dielectric barrier dis-charge non-thermal plasma in VOCs abatement: A review. Chem. Eng. J. 2020, 388, 124275. [Google Scholar] [CrossRef]

- He, J.; Wen, X.; Wu, L.; Chen, H.; Hu, J.; Hou, X. Dielectric barrier discharge plasma for nanomaterials: Fabrication, modification and analytical applications. Trac-Trends Anal. Chem. 2022, 156, 116715. [Google Scholar] [CrossRef]

- Niu, G.; Knodel, A.; Burhenn, S.; Brandt, S.; Franzke, J. Review: Miniature dielectric barrier discharge (DBD) in analytical atomic spectrometry. Anal. Chim. Acta 2021, 1147, 211–239. [Google Scholar] [CrossRef]

- Ibra-him, J.; Al-Bataineh, S.A.; Michelmore, A.; Whittle, J.D. Atmospheric Pressure Dielectric Barrier Discharges for the Deposition of Organic Plasma Polymer Coatings for Biomedical Application. Plasma Chem. Plasma Process. 2021, 41, 47–83. [Google Scholar] [CrossRef]

- Rosocha, L.A.; Anderson, G.K.; Bechtold, L.A.; Coogan, J.J.; Heck, H.G.; Kang, M.; McCulla, W.H.; Tennant, R.A.; Wantuck, P.J. Nonthermal Plasma Techniques for Pollution Control: Part B—Electron Beam and Electrical Discharge Processing; Penetrante, B.M., Schultheis, S.E., Eds.; Springer: Berlin, Germany, 1993. [Google Scholar]

- Osawa, N.; Yoshioka, Y. Generation of low-frequency homogeneous dielectric barrier discharge at atmospheric pressure. IEEE Trans. Plasma Sci. 2012, 40, 2–8. [Google Scholar] [CrossRef]

- Tay, W.H.; Kausik, S.S.; Yap, S.L.; Wong, C.S. Role of secondary emission on discharge dynamics in an atmospheric pressure dielectric barrier discharge. Phys. Plasmas 2014, 21, 044502. [Google Scholar] [CrossRef] [Green Version]

- El-Zein, A.; Talaat, M.; El-Aragi, G.; El-Amawy, A. The characteristics of dielectric barrier discharge plasma under the effect of parallel magnetic field. IEEE Trans. Plasma Sci. 2020, 48, 1022–1029. [Google Scholar] [CrossRef]

- Los, A.; Ziuzina, D.; Akkermans, S.; Boehm, D.; Cullen, P.J.; Van Impe, J.; Bourke, P. Improving microbiological safety and quality characteristics of wheat and barley by high voltage atmospheric cold plasma closed processing. Food Res. Int. 2018, 106, 509–521. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ziuzina, D.; van Cleynenbreugel, R.; Tersaruolo, C.; Bourke, P. Cold plasma for insect pest control: Tribolium castaneum mortality and defense mechanisms in response to treatment. Plasma Process. Polym. 2021, 18, e200017. [Google Scholar] [CrossRef]

- Lu, X.P.; Liu, D.W.; Xian, Y.B.; Nie, L.L.; Cao, Y.G.; He, G.Y. Cold atmospheric-pressure air plasma jet: Physics and opportunities. Phys. Plasmas 2021, 28, 100501. [Google Scholar] [CrossRef]

- Braný, D.; Dvorská, D.; Halašová, E.; Škovierová, H. Cold Atmospheric Plasma: A Powerful Tool for Modern Medicine. Int. J. Mol. Sci. 2020, 21, 2932. [Google Scholar] [CrossRef] [Green Version]

- Bae, G.T.; Jang, H.J.; Jung, E.Y.; Lee, Y.R.; Park, C.-S.; Kim, J.Y.; Tae, H.-S. Development of an Atmospheric Pressure Plasma Jet Device Using Four-Bore Tubing and Its Applications of In-Liquid Material Decomposition and Solution Plasma Polymerization. Polymers 2022, 14, 4917. [Google Scholar] [CrossRef]

- Winter, J.; Brandenburg, R.; Weltmann, K.-D. Atmospheric pressure plasma jets: An overview of devices and new directions. Plasma Sources Sci. Technol. 2015, 24, 064001. [Google Scholar] [CrossRef]

- Adamovich, I.; Agarwal, S.; Ahedo, E.; Alves, L.L.; Baalrud, S.; Babaeva, N.; Bogaerts, A.; Bourdon, A.; Bruggeman, P.J.; Canal, C.; et al. The 2022 Plasma Roadmap: Low temperature plasma science and technology. J. Phys. D-Appl. Phys. 2022, 55, 373001. [Google Scholar] [CrossRef]

- Reuter, S.; Von Woedtke, T.; Weltmann, K.-D. The kINPen-a review on physics and chemistry of the atmospheric pressure plasma jet and its applications. J. Phys. D-Appl. Phys. 2018, 51, 233001. [Google Scholar] [CrossRef] [Green Version]

- Weltmann, K.-D.; Kindel, E.; Brandenburg, R.; Meyer, C.; Bussiahn, R.; Wilke, C.; von Woedtke, T. Atmospheric Pressure Plasma Jet for Medical Therapy: Plasma Parameters and Risk Estimation. Contrib. Plasma Phys. 2009, 49, 631–640. [Google Scholar] [CrossRef]

- Korzec, D.; Hoppenthaler, F.; Nettesheim, S. Piezoelectric Direct Discharge: Devices and Applications. Plasma 2021, 4, 1–41. [Google Scholar] [CrossRef]

- Carazo, A.V. Piezoelectrsic Transformers: An Historical Review. Actuators 2016, 5, 12. [Google Scholar] [CrossRef] [Green Version]

| Type | Frequency | Pressure (Torr) | Te (eV) | ne (cm−3) | Ref. |

|---|---|---|---|---|---|

| Positive Column | DC | 10−2–10 | 1–3 | ~109–1011 | [2,3,4] |

| CCP | DC, CF 13.56 MHz | 10−2–1 | 1–5 | ~108–1010 | [2,3,27,28,29,41] |

| ICP | 13.56 MHz | 10−4–10−1 | 1–10 | 1011–1012 | [2,3,4,41] |

| Magnetron Sputtering | 13.56 MHz | 10−3–1 | 1–5 | 1010–1012 | [2,3,4,7,41] |

| ECR | 2.45 GHz | 10−4–10−2 | 2–7 | 1010–1012 | [2,3,4,41] |

| Microwave plasma (Surfatron) | 2.45 GHz | 760 | 5 | 1012–1015 | [42] |

| Microwave plasma (SLAN) | 2.45 GHz | 760 | 5 | 1011 | [42] |

| DBD | 8 kHz 13.56 MHz | 760 | 1–3 | 1014 | [43,44] |

| Thermal Arc | 30 A-30 kA | 76–76,000 | 1–10 | 1015–1019 | [1,2,3] |

| Non-complete Thermal Arc | 1-30 A | 10−3–100 | 0.2–2 | 1014–1015 | [1,2,3] |

| Properties | Thermal Plasma | Non-Thermal Plasma |

|---|---|---|

| Temperature | ||

| Electron density (cm−3) | 1015–1020 | <1013 |

| Heating | Joule heating Thermal heating | Electron impact process |

| Characteristics | High gas temperature Low excitation selectivity | Low gas temperature High excitation selectivity |

| Examples | Arc discharge | Glow discharge |

| Properties | DC | CF | RF |

|---|---|---|---|

| Power frequency | 0 | 50/60 Hz | 13.56 MHz |

| Discharge type | Continuous | Discrete | Continuous |

| Main heating mechanism | Ohmic | Ohmic | Ohmic, Stochastic |

| Deposition/treatment material | Metal | Metal, dielectric | Metal, dielectric |

| Deposition/treatment rate | Lower in DC and RF discharge | ||

| Plasma parameters | Similar in DC and RF discharge (Te: 1–5 eV, ne: ~108–1010) | ||

| Type | Frequency | Pressure (Torr) | Characteristics | Ref. |

|---|---|---|---|---|

| kINPen | Typically, 1 MHz | ~760 | Low gas temperature: ~40 °C Te = 4 eV, ne = ~1014 cm−3 Wired portable Affordable cost | [95] |

| PCPG | 40-90 kHz | ~760 | Low gas temperature: ~40 °C Low input power: typically, 10 W Wireless portable Affordable cost | [97] |

| CF-derived Plasma | 50/60 Hz | ~1 | Te = 1.4–3.2 eV, ne = ~108 cm−3 Inexpensive power source | [27,28,29,30,49] |

| ~760 | Inexpensive power source High voltage: 50–80 kV | [89,90] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.T.; Jung, C.M.; Kim, S.H.; Lee, S.-Y. Review of Plasma Processing for Polymers and Bio-Materials Using a Commercial Frequency (50/60 Hz)-Generated Discharge. Polymers 2023, 15, 2850. https://doi.org/10.3390/polym15132850

Kim HT, Jung CM, Kim SH, Lee S-Y. Review of Plasma Processing for Polymers and Bio-Materials Using a Commercial Frequency (50/60 Hz)-Generated Discharge. Polymers. 2023; 15(13):2850. https://doi.org/10.3390/polym15132850

Chicago/Turabian StyleKim, Hong Tak, Cheol Min Jung, Se Hyun Kim, and Sung-Youp Lee. 2023. "Review of Plasma Processing for Polymers and Bio-Materials Using a Commercial Frequency (50/60 Hz)-Generated Discharge" Polymers 15, no. 13: 2850. https://doi.org/10.3390/polym15132850