A Review of Developments in Polymer Stabilized Liquid Crystals

Abstract

:1. Introduction

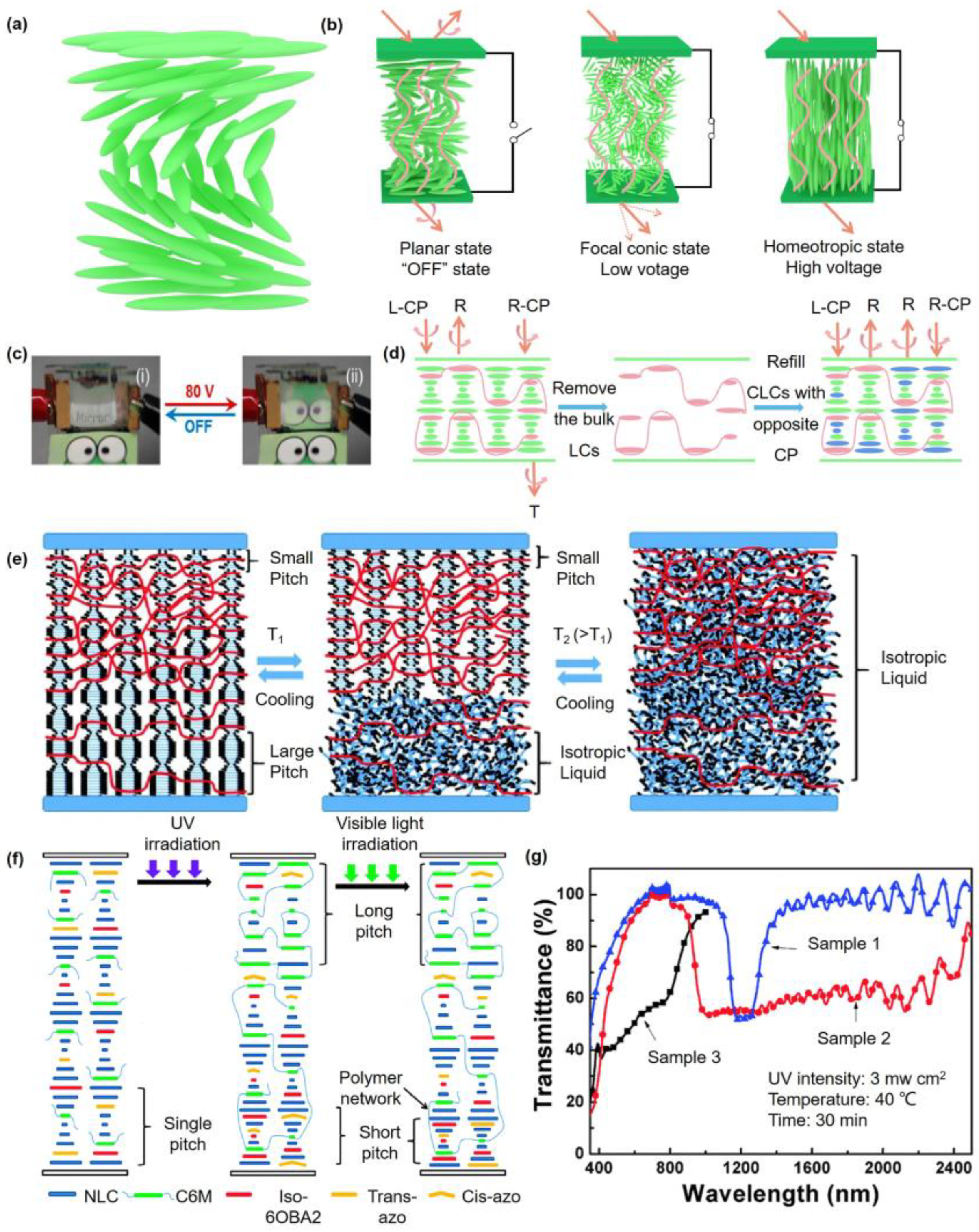

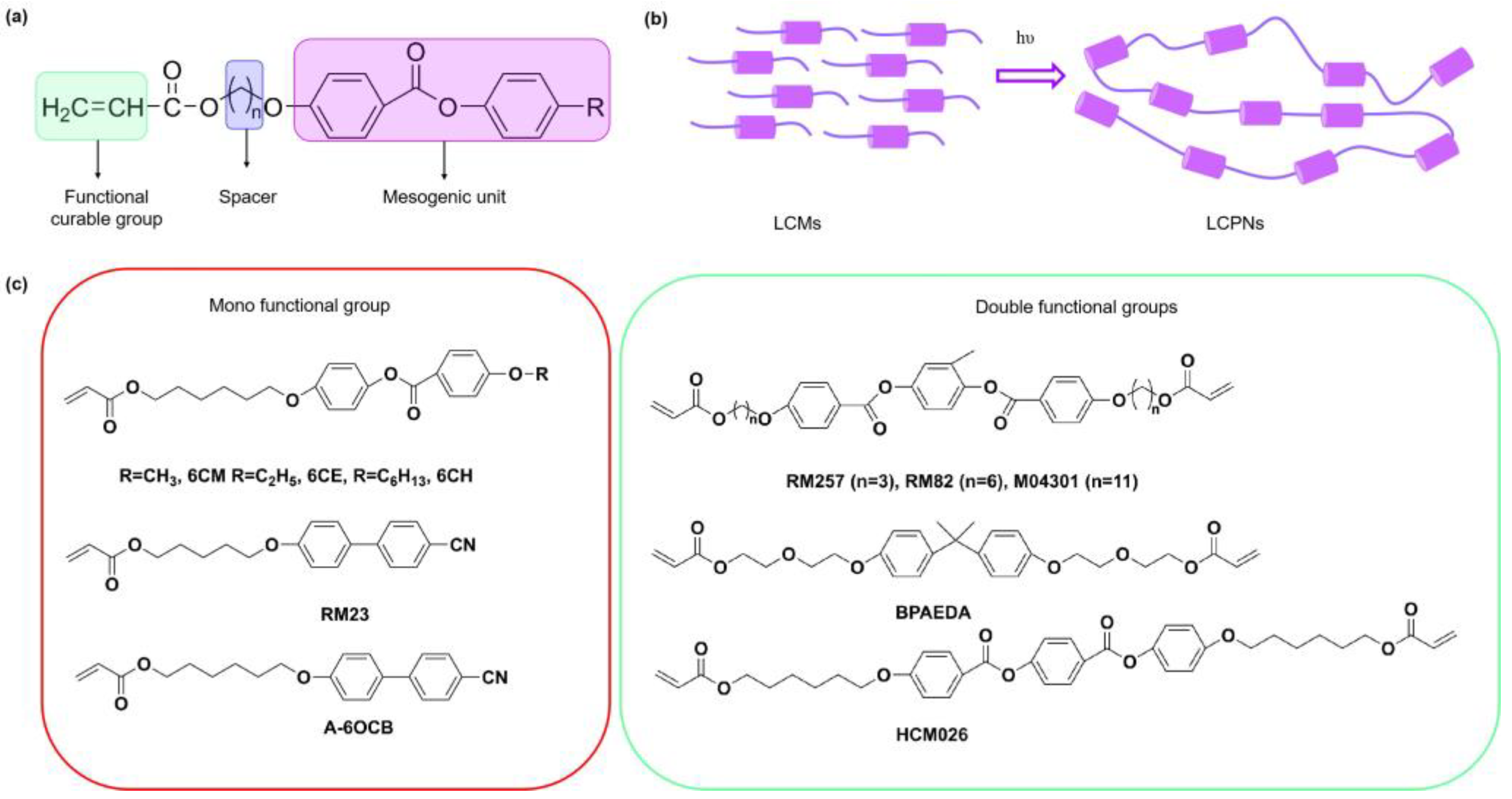

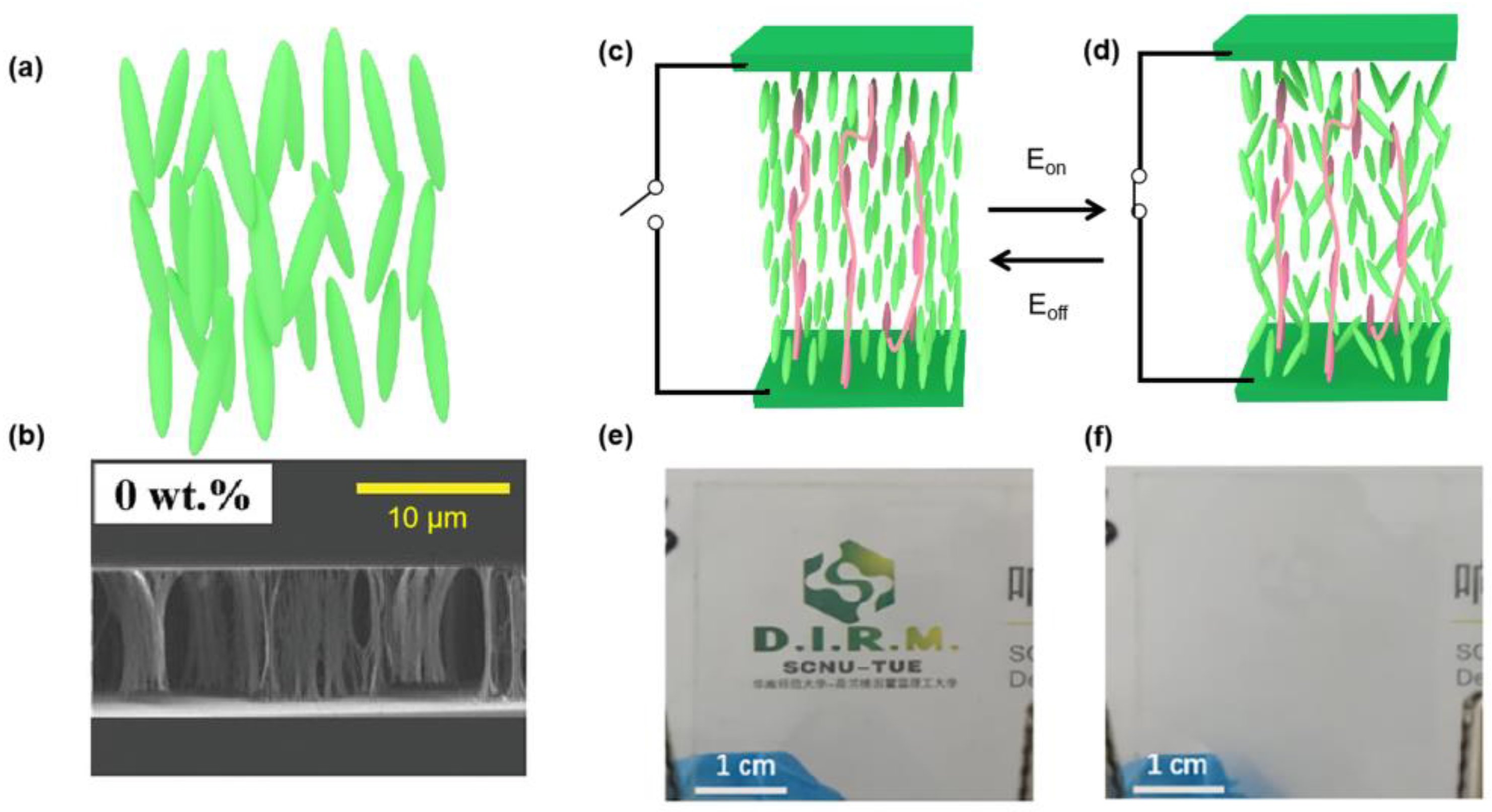

2. PSNLCs

3. PSCLCs

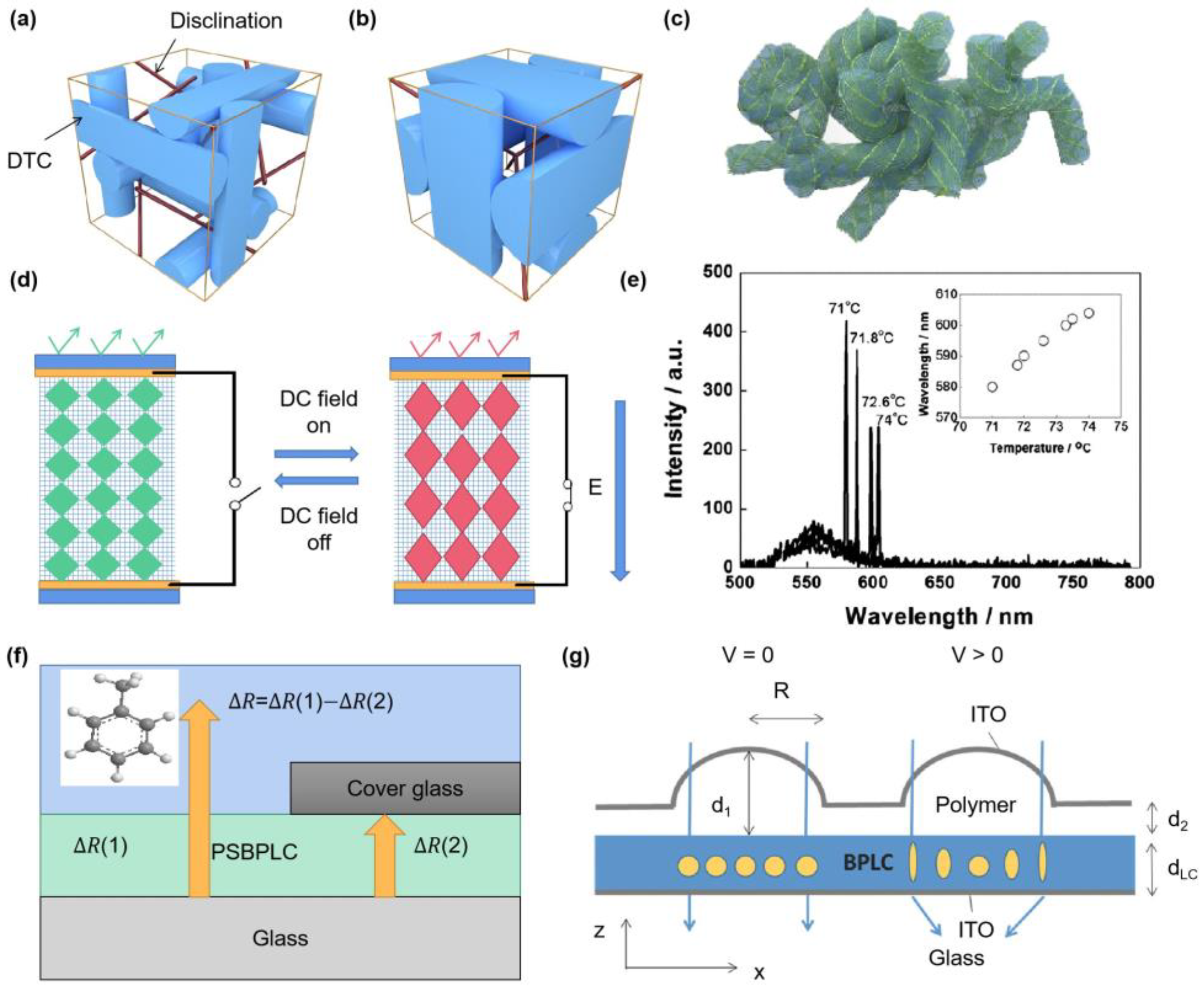

4. PSBPLCs

5. PSSLCs

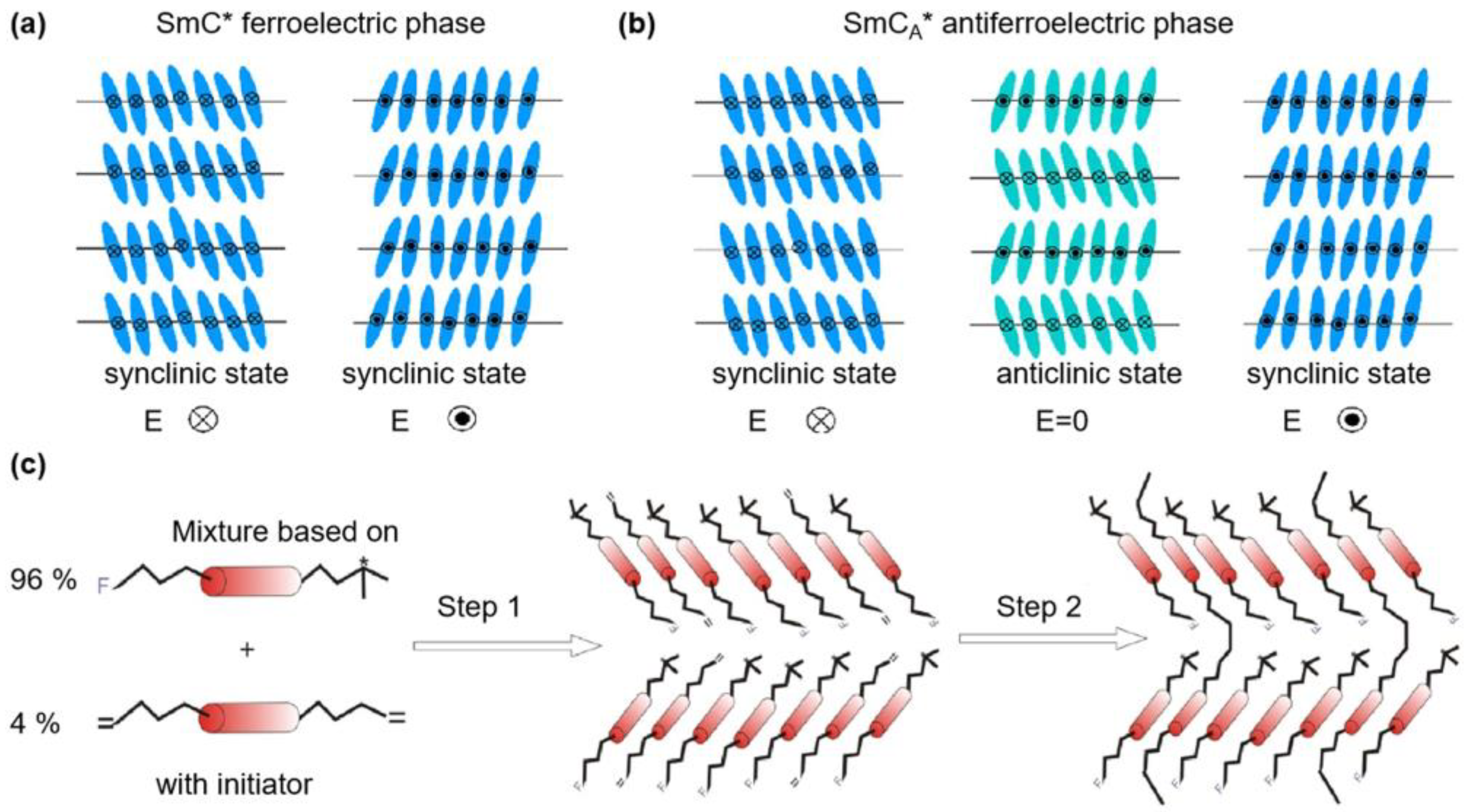

6. PSFLCs and PSAFLCs

7. Conclusions

8. Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mucha, M. Polymer as an important component of blends and composites with liquid crystals. Prog. Polym. Sci. 2003, 28, 837–873. [Google Scholar] [CrossRef]

- Lee, K.M.; Ware, T.H.; Tondiglia, V.P.; McBride, M.K.; Zhang, X.P.; Bowman, C.N.; White, T.J. Initiatorless photopolymerization of liquid crystal monomers. ACS Appl. Mater. Interfaces 2016, 8, 28040–28046. [Google Scholar] [CrossRef] [PubMed]

- Radka, B.P.; Lee, K.M.; Godman, N.P.; White, T.J. Electro-optic characteristics of stabilized cholesteric liquid crystals with non-liquid crystalline polymer networks. Soft Matter 2022, 18, 3013–3018. [Google Scholar] [CrossRef]

- Kasch, N.; Dierking, I.; Turner, M. Stabilization of the liquid crystalline blue phase by the addition of short-chain polystyrene. Soft Matter 2013, 9, 4789–4793. [Google Scholar] [CrossRef]

- Dierking, I. Fractal and non-fractal structure-property relationships of polymer-stabilized liquid crystals. Adv. Funct. Mater. 2004, 14, 883–890. [Google Scholar] [CrossRef]

- Li, X.S.; Guo, Y.Q.; Zhang, M.S.; Zhang, C.; Niu, R.; Ma, H.M.; Sun, Y.B. Colorable light-scattering device based on polymer-stabilized ion-doped cholesteric liquid crystal and an electrochromatic layer. ACS Appl. Mater. Interfaces 2023, 15, 7184–7195. [Google Scholar] [CrossRef]

- Lee, K.M.; Tondiglia, V.P.; White, T.J. Photosensitivity of reflection notch tuning and broadening in polymer stabilized cholesteric liquid crystals. Soft Matter 2016, 12, 1256–1261. [Google Scholar] [CrossRef]

- Xu, C.T.; Zhang, D.W.; Yuan, R.; Chen, Q.M.; Liang, X.; Hu, W. Optical orbital angular momentum processors with electrically tailored working bands. Laser Photonics Rev. 2023, 2201013. [Google Scholar] [CrossRef]

- Wang, L.; He, W.L.; Wang, Q.; Yu, M.N.; Xiao, X.; Zhang, Y.; Ellahi, M.; Zhao, D.Y.; Yang, H.; Guo, L. Polymer-stabilized nanoparticle-enriched blue phase liquid crystals. J. Mater. Chem. C 2013, 1, 6526–6531. [Google Scholar] [CrossRef]

- Chen, C.W.; Li, C.C.; Jau, H.C.; Yu, L.C.; Hong, C.L.; Guo, D.Y.; Wang, C.T.; Lin, T.H. Electric field-driven shifting and expansion of photonic band gaps in 3D liquid photonic crystals. ACS Photonics 2015, 2, 1524–1531. [Google Scholar] [CrossRef]

- Lahiri, T.; Majumder, T.P. The effect of cross-linked chains of polymer network on the memory states of polymer stabilized ferroelectric molecules. Polymer 2012, 53, 2121–2127. [Google Scholar] [CrossRef]

- Singh, U.; Spink, M.; Davis, F.; Mitchell, G. Morphology of polymer networks formed in the chiral and non-chiral phases of an antiferroelectric liquid crystal. Chem. Phys. Lett. 2015, 641, 80–83. [Google Scholar] [CrossRef]

- Wiederrecht, G.P.; Wasielewski, M.R. Photorefractivity in polymer-stabilized nematic liquid crystals. J. Am. Chem. Soc. 1998, 120, 3231–3236. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; You, Y.X.; Xiao, X.L.; Liu, W.; Zhou, L.; Zhang, B.B.; Zhao, W.; Hu, X.W.; Zhang, L.Y.; Yang, H.; et al. Effect of polymer network topology on the electro-optical performance of polymer stabilized liquid crystal (PSLC) devices. Macromol. Chem. Phys. 2020, 221, 18. [Google Scholar] [CrossRef]

- Hu, X.W.; Zhang, X.M.; Yang, W.M.; Jiang, X.F.; Jiang, X.S.; Haan, L.T.; Yuan, D.; Zhao, W.; Zheng, N.; Jin, M.L.; et al. Stable and scalable smart window based on polymer stabilized liquid crystals. J. Appl. Polym. Sci. 2020, 137, 48917. [Google Scholar] [CrossRef]

- Shin, Y.H.; Jiang, J.H.; Qin, G.K.; Wang, Q.; Zhou, Z.Y.; Yang, D.K. Patterned waveguide liquid crystal displays. RSC Adv. 2020, 10, 41693–41702. [Google Scholar] [CrossRef]

- Li, H.; Xu, J.J.; Ren, Y.X.; Han, R.; Song, H.; Huang, R.; Wang, X.; Zhang, L.Y.; Cao, H.; Zou, C.; et al. Preparation of highly durable reverse-mode polymer-stabilized liquid crystal films with polymer walls. ACS Appl. Mater. Interfaces 2023, 15, 2228–2236. [Google Scholar] [CrossRef]

- Zhang, Z.B.; Zhang, R.C.; Xu, L.G.; Li, J.J.; Yang, L.; Yang, Y.N.; Bolshakov, A.; Zhu, J.Q. Visible and infrared optical modulation of PSLC smart films doped with ATO nanoparticles. Dalton Trans. 2021, 50, 10033–10040. [Google Scholar] [CrossRef]

- Liu, Z.D.; Luo, D.; Yang, K.L. Monitoring the two-dimensional concentration profile of toluene vapors by using polymer-stabilized nematic liquid crystal in microchannels. Lab Chip 2020, 20, 1687–1693. [Google Scholar] [CrossRef]

- Hicks, S.E.; Hurley, S.P.; Yang, Y.C.; Yang, D.K. Electric polarization frozen by a polymer network in nematic liquid crystals. Soft Matter 2013, 9, 3834–3839. [Google Scholar] [CrossRef]

- Prasad, S.K.; Baral, M.; Murali, A.; Jaisankar, S.N. Carbon nanotube reinforced polymer-stabilized liquid crystal device: Lowered and thermally invariant threshold with accelerated dynamics. ACS Appl. Mater. Interfaces 2017, 9, 26622–26629. [Google Scholar] [CrossRef] [PubMed]

- Moheghi, A.; Nemati, H.; Yang, D.K. Polarizing light waveguide plate from polymer stabilized liquid crystals. Opt. Mater. Express 2015, 5, 1217–1223. [Google Scholar] [CrossRef]

- Nemati, H.; Liu, S.Y.; Zola, R.S.; Tondiglia, V.P.; Lee, K.M.; White, T.; Bunning, T.; Yang, D.K. Mechanism of electrically induced photonic band gap broadening in polymer stabilized cholesteric liquid crystals with negative dielectric anisotropies. Soft Matter 2015, 11, 1208–1213. [Google Scholar] [CrossRef] [PubMed]

- Mulder, D.J.; Schenning, A.P.H.J.; Bastiaansen, C.W.M. Chiral-nematic liquid crystals as one dimensional photonic materials in optical sensors. J. Mater. Chem. C 2014, 2, 6695–6705. [Google Scholar] [CrossRef] [Green Version]

- Radka, B.P.; Pande, G.K.; White, T.J. The contribution of network elasticity to electro-optic response in polymer stabilized cholesteric liquid crystals. Soft Matter, 2023; Advance Article. [Google Scholar] [CrossRef]

- Bao, R.; Liu, C.M.; Yang, D.K. Smart bistable polymer stabilized cholesteric texture light shutter. Appl. Phys. Express 2009, 2, 112401. [Google Scholar] [CrossRef]

- Gruzdenko, A.; Dierking, I. Electro-optic properties of polystyrene particle-laden polymer-stabilized liquid crystals. J. Mater. Chem. C 2023, 11, 5438–5449. [Google Scholar] [CrossRef]

- Lee, K.M.; Tondiglia, V.P.; Godman, N.P.; Middleton, C.M.; White, T.J. Blue-shifting tuning of the selective reflection of polymer stabilized cholesteric liquid crystals. Soft Matter 2017, 13, 5842–5848. [Google Scholar]

- Lee, K.M.; Tondiglia, V.P.; McConney, M.E.; Natarajan, L.V.; Bunning, T.J.; White, T.J. Color-tunable mirrors based on electrically regulated bandwidth broadening in polymer-stabilized cholesteric liquid crystals. ACS Photonics 2014, 1, 1033–1041. [Google Scholar] [CrossRef]

- Guo, J.B.; Yang, H.; Li, R.; Ji, N.; Dong, X.M.; Wu, H.; Wei, J. Effect of network concentration on the performance of polymer-stabilized cholesteric liquid crystals with a double-handed circularly polarized light reflection band. J. Phys. Chem. C 2009, 113, 16538–16543. [Google Scholar] [CrossRef]

- Rumi, M.; Bunning, T.J.; White, T.J. Polymer stabilization of cholesteric liquid crystals in the oblique helicoidal state. Soft Matter 2018, 14, 8883–8894. [Google Scholar] [CrossRef]

- Khandelwal, H.; Timmermans, G.H.; Debije, M.G.; Schenning, A.P.H.J. Dual electrically and thermally responsive broadband reflectors based on polymer network stabilized chiral nematic liquid crystals: The role of crosslink density. Chem. Commun. 2016, 52, 10109–10112. [Google Scholar] [CrossRef]

- Agez, G.; Mitov, M. Cholesteric liquid crystalline materials with a dual circularly polarized light reflection band fixed at room temperature. J. Phys. Chem. B 2011, 115, 6421–6426. [Google Scholar] [CrossRef]

- Chen, X.W.; Wang, L.; Chen, Y.J.; Li, C.Y.; Hou, G.Y.; Liu, X.; Zhang, X.G.; He, W.L.; Yang, H. Broadband reflection of polymer-stabilized chiral nematic liquid crystals induced by a chiral azobenzene compound. Chem. Commun. 2014, 50, 691–694. [Google Scholar] [CrossRef]

- White, T.J.; Bricker, R.L.; Natarajan, L.V.; Tabiryan, N.V.; Green, L.; Li, Q.; Bunning, T.J. Phototunable azobenzene cholesteric liquid crystals with 2000 nm range. Adv. Funct. Mater. 2009, 19, 3484–3488. [Google Scholar] [CrossRef]

- White, T.J.; Bricker, R.L.; Natarajan, L.V.; Serak, S.V.; Tabiryan, N.V.; Bunning, T.J. Polymer stabilization of phototunable cholesteric liquid crystals. Soft Matter 2009, 5, 3623–3628. [Google Scholar] [CrossRef]

- Li, Z.Z.; Lan, R.C.; Bao, J.Y.; Hu, W.; Wang, M.; Zhang, L.Y.; Yang, H. Tunable circularly polarized luminescence with a high dissymmetry factor emitted from luminogen-bonded and electrically controlled polymer-stabilized cholesteric liquid crystals. ACS Appl. Mater. Interfaces 2022, 14, 8490–8498. [Google Scholar] [CrossRef]

- Perera, K.; Padmini, H.N.; Mann, E.; Jάkli, A. Polymer stabilized paraboloid liquid crystal microlenses with integrated pancharatnam-berry phase. Adv. Opt. Mater. 2021, 10, 2101510. [Google Scholar] [CrossRef]

- Yang, C.J.; Wu, B.H.; Ruan, J.; Zhao, P.; Chen, L.; Chen, D.; Ye, F.F. 3D-printed biomimetic systems with synergetic color and shape responses based on oblate cholesteric liquid crystal droplets. Adv. Mater. 2021, 33, 2006361. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.J.; Wu, B.H.; Ruan, J.; Zhao, P.; Shan, J.Z.; Zhang, R.; Yoon, D.K.; Chen, D.; Liu, K. Mechanochromic responses of cholesteric liquid crystal droplets with nanoscale periodic helical structures showing reversible and tunable structural color. ACS Appl. Polym. Mater. 2022, 4, 463–468. [Google Scholar] [CrossRef]

- Yang, C.J.; Chen, D. Researches and applications of cholesteric liquid crystal droplets. Chin. J. Liq. Cryst. Disp. 2022, 37, 1070–1078. [Google Scholar] [CrossRef]

- Choi, H.J.; Bae, J.H.; Bae, S.W.; Lee, J.J.; Nishikawa, H.; Araoka, F.; Choi, S.W. Development of a liquid crystal laser using a simple cubic liquid crystalline blue phase platform. RSC Adv. 2019, 9, 32922–32927. [Google Scholar] [CrossRef] [PubMed]

- Higashiguchi, K.; Yasui, K.; Kikuchi, H. Direct observation of polymer-stabilized blue phase I structure with confocal laser scanning microscope. J. Am. Chem. Soc. 2008, 130, 6326–6327. [Google Scholar] [CrossRef] [PubMed]

- Lan, Y.F.; Tsai, C.Y.; Lu, J.K.; Sugiura, N. Mechanism of hysteresis in polymer-network stabilized blue phase liquid crystal. Polymer 2013, 54, 1876–1879. [Google Scholar] [CrossRef]

- Gandhi, S.S.; Li, Y.; Luo, D.; Chien, L.C. Laser emission in a 3D nanoporous polymer replica of amorphous blue phase III. J Polym. Sci. Pol. Phys. 2018, 56, 551–557. [Google Scholar] [CrossRef] [Green Version]

- Kikuchi, H.; Yokota, M.; Hisakado, Y.; Yang, H.; Kajiyama, T. Polymer-stabilized liquid crystal blue phases. Nat. Mater. 2002, 1, 64–68. [Google Scholar] [CrossRef] [PubMed]

- Jo, S.Y.; Jeon, S.W.; Kim, B.C.; Bae, J.H.; Araoka, F.; Choi, S.W. Polymer stabilization of liquid-crystal blue phase II toward photonic crystals. ACS Appl. Mater. Interfaces 2017, 9, 8941–8947. [Google Scholar] [CrossRef]

- Iwata, T.; Suzuki, K.; Amaya, N.; Higuchi, H.; Masunaga, H.; Sasaki, S.; Kikuchi, H. Control of cross-linking polymerization kinetics and polymer aggregated structure in polymer-stabilized liquid crystalline blue phases. Macromolecules 2009, 42, 2002–2008. [Google Scholar] [CrossRef]

- Kim, K.; Hur, S.T.; Kim, S.; Jo, S.Y.; Lee, B.R.; Song, M.H.; Choi, S.W. A well-aligned simple cubic blue phase for a liquid crystal laser. J. Mater. Chem. C 2015, 3, 5383–5388. [Google Scholar] [CrossRef] [Green Version]

- Manda, R.; Pagidi, S.; Heo, Y.J.; Lim, Y.J.; Kim, M.S.; Lee, S.H. Polymer-stabilized monodomain blue phase diffraction grating. Adv. Mater. Interfaces 2020, 7, 1901923. [Google Scholar] [CrossRef]

- Yang, Y.; Kim, Y.K.; Wang, X.; Tsuei, M.; Abbott, N.L. Structural and optical response of polymer-stabilized blue phase liquid crystal films to volatile organic compounds. ACS Appl. Mater. Interfaces 2020, 12, 42099–42108. [Google Scholar] [CrossRef]

- Wu, P.C.; Chen, H.L.; Rudakova, N.V.; Timofeev, I.V.; Zyryanov, V.Y.; Lee, W. Electro-optical and dielectric properties of polymer-stabilized blue phase liquid crystal impregnated with a fluorine-containing compound. J. Mol. Liq. 2018, 267, 138–143. [Google Scholar] [CrossRef]

- Li, Y.; Huang, S.J.; Zhou, P.C.; Liu, S.X.; Lu, J.G.; Li, X.; Su, Y.K. Polymer-stabilized blue phase liquid crystals for photonic applications. Adv. Mater. Technol. 2016, 1, 1600102. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.T. Polarization independent adaptive microlens with a blue-phase liquid crystal. Opt. Express 2011, 19, 8045–8050. [Google Scholar] [CrossRef] [PubMed]

- Dierking, I.; Mitov, M.; Osipov, M.A. Smectic layer instabilities in liquid crystals. Soft Matter 2015, 11, 819–837. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pan, G.H.; Yu, L.L.; Zhang, H.B.; Guo, J.B.; Guo, R.W.; Cao, H.; Yang, Z.; Yang, H.; Zhu, S.Q. Effects on thermo-optical properties of the composition of a polymer-stabilised liquid crystal with a smectic A-chiral nematic phase transition. Liq. Cryst. 2008, 35, 1151–1160. [Google Scholar] [CrossRef]

- Pan, G.H.; Cao, H.; Guo, R.W.; Li, W.B.; Guo, J.B.; Yang, Z.; Huang, W.; He, W.L.; Liang, X.K.; Zhang, D.W.; et al. A polymer stabilized liquid crystal film with switching characteristics between light transmission and adjustable light scattering. Opt. Mater. 2009, 31, 1163–1166. [Google Scholar] [CrossRef]

- Pan, G.H.; Cao, Y.B.; Guo, R.W.; Cheng, H.C.; Yang, Z.; Guo, J.B.; Liang, X.K.; Zhang, D.W.; Cao, H.; Yang, H. Effects of the preparing condition of a polymer-stabilised liquid crystal with a smectic-A-chiral nematic phase transition on its properties. Liq. Cryst. 2009, 36, 165–172. [Google Scholar] [CrossRef]

- Wu, J.B.; Wu, S.B.; Cao, H.M.; Chen, Q.M.; Lu, Y.Q.; Hu, W. Electrically tunable microlens array enabled by polymer-stabilized smectic hierarchical architectures. Adv. Opt. Mater. 2022, 10, 2201015. [Google Scholar] [CrossRef]

- Dmochowska, E.; Herman, J.; Czerwiński, M.; Stulov, S.; Bubnov, A.; Kula, P. Self-assembling behaviour of chiral calamitic monoacrylates targeted for polymer stabilization of polar smectic phases in chiral liquid crystals. J. Mol. Liq. 2021, 331, 115723. [Google Scholar] [CrossRef]

- Czerwiński, M.; Urbańska, M.; Bennis, N.; Rudquist, P. Influence of the type of phase sequence and polymer-stabilization on the physicochemical and electro-optical properties of novel high-tilt antiferroelectric liquid crystalline materials. J. Mol. Liq. 2019, 288, 111057. [Google Scholar] [CrossRef]

- Dierking, I. Polymer network-stabilized liquid crystals. Adv. Mater. 2000, 12, 167–181. [Google Scholar] [CrossRef]

- Dierking, I. Recent developments in polymer stabilised liquid crystals. Polym. Chem. 2010, 1, 1153–1159. [Google Scholar] [CrossRef]

- Hemine, J.; Kaaouachi, A.E.; Ismaili, M.; Douali, R.; Legrand, C.; Daoudi, A. Electro-optic and dielectric properties of polymer networks stabilised short pitch chiral smectic C* liquid crystal. Liq. Cryst. 2021, 48, 1231–1246. [Google Scholar] [CrossRef]

- Dierking, I. A review of polymer-stabilized ferroelectric liquid crystals. Materials 2014, 7, 3568–3587. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ma, Y.; Srivastava, A.K.; Guo, Q.; Chigrinov, V.G.; Kwok, H.S. 29.4: Polymer Stabilized Electrically Suppressed Helix Ferroelectric Liquid Crystal. Dig. Tech. Papers 2014, 45, 393–395. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Y.; Guo, L.; Zhong, T. A Review of Developments in Polymer Stabilized Liquid Crystals. Polymers 2023, 15, 2962. https://doi.org/10.3390/polym15132962

Ye Y, Guo L, Zhong T. A Review of Developments in Polymer Stabilized Liquid Crystals. Polymers. 2023; 15(13):2962. https://doi.org/10.3390/polym15132962

Chicago/Turabian StyleYe, Yong, Li Guo, and Tingjun Zhong. 2023. "A Review of Developments in Polymer Stabilized Liquid Crystals" Polymers 15, no. 13: 2962. https://doi.org/10.3390/polym15132962

APA StyleYe, Y., Guo, L., & Zhong, T. (2023). A Review of Developments in Polymer Stabilized Liquid Crystals. Polymers, 15(13), 2962. https://doi.org/10.3390/polym15132962