Prospects for Recyclable Multilayer Packaging: A Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Test Specimen

2.2. Test Specimen

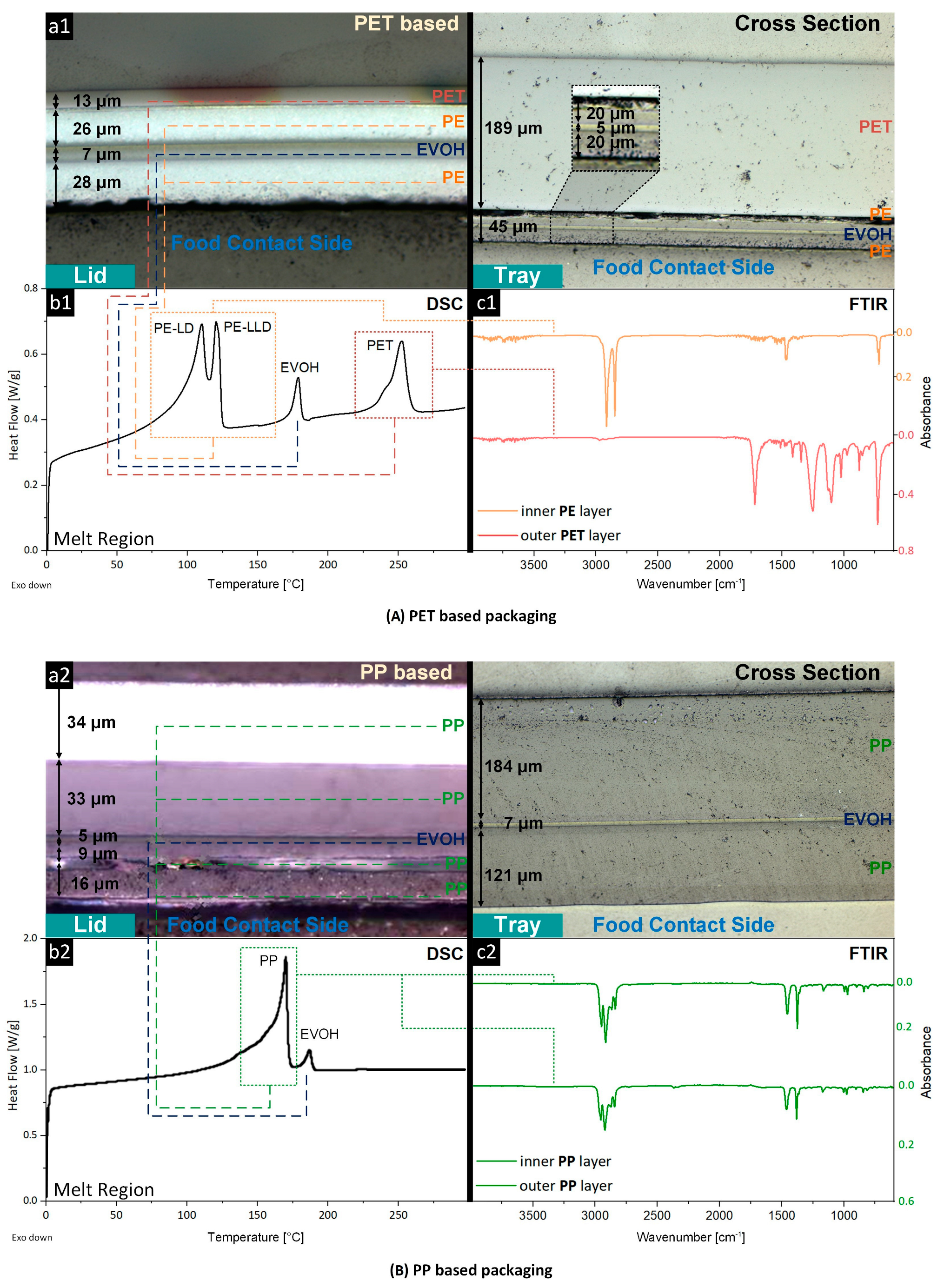

2.3. Multilayer Structure Analysis of Post-consumer MAP

2.4. Mechanical Properties of Recyclate Blends and Films

2.5. Rheological Properties of Recyclate Blends

2.6. Morphological Characterization of the Recyclate Blends

3. Results and Discussion

3.1. Multilayer Structure Analysis of Post-consumer PET- and PP-Based MAP Lids and Trays

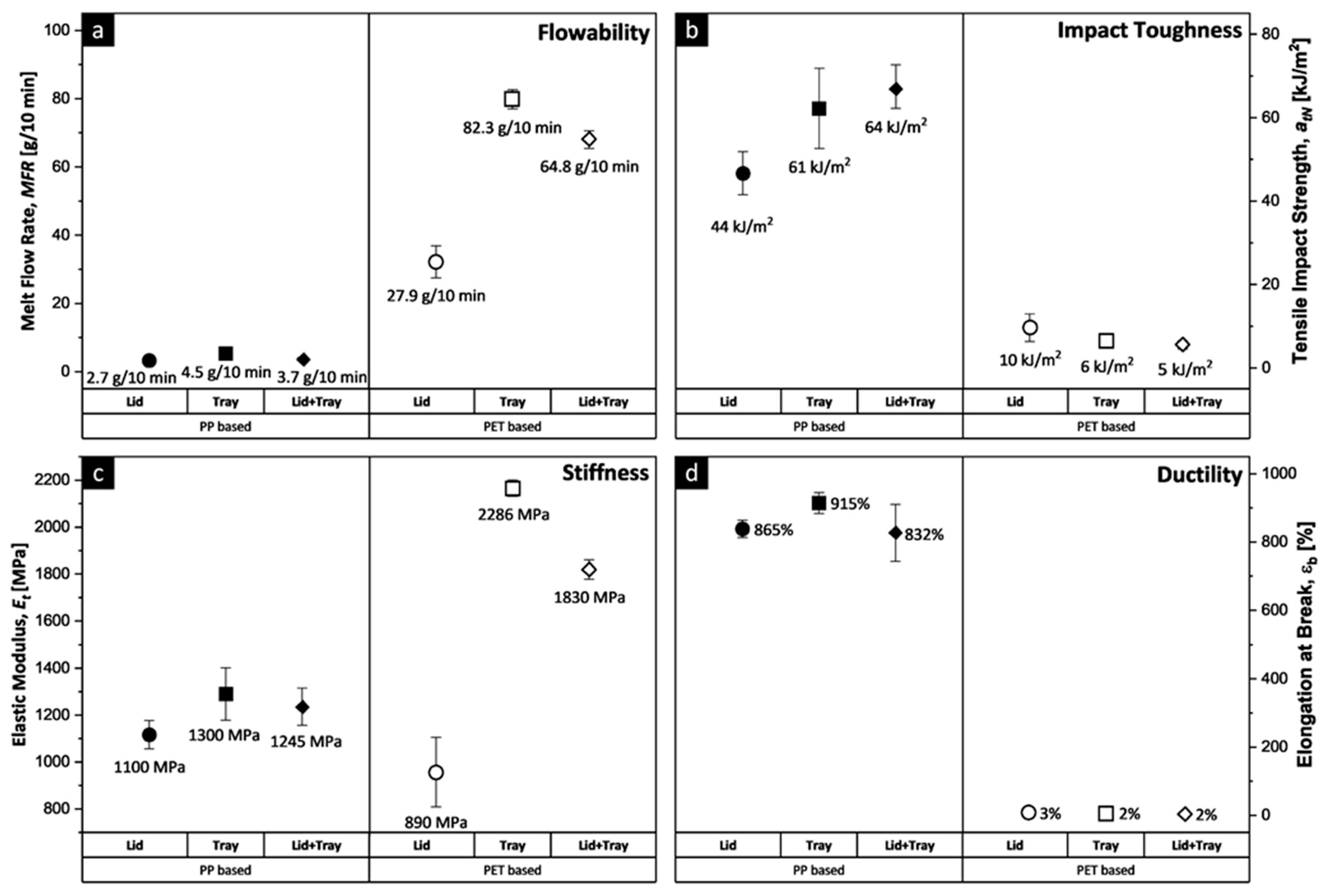

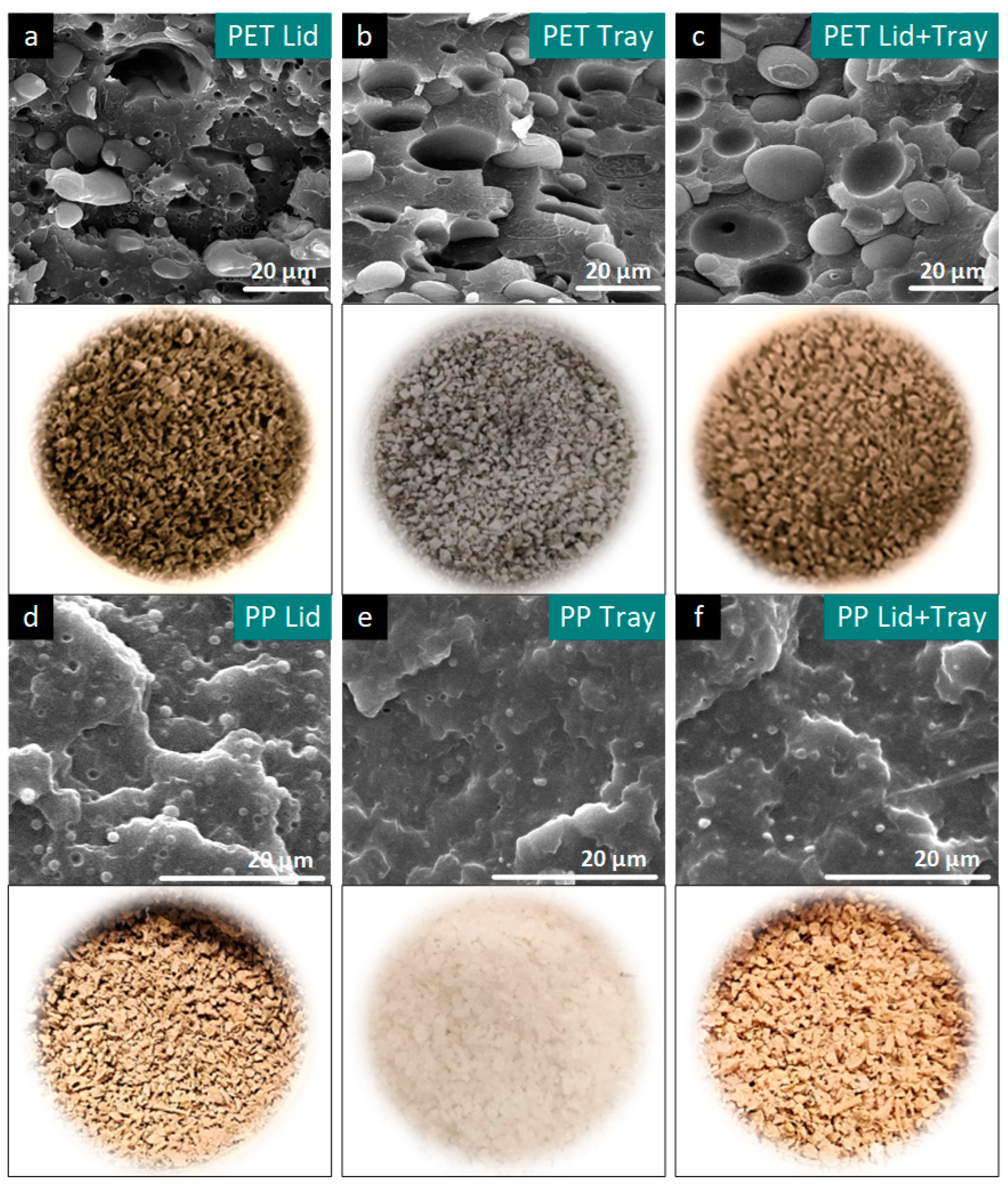

3.2. Comparison of the Property Profile of Reprocessed PET- and PP-Based MAP

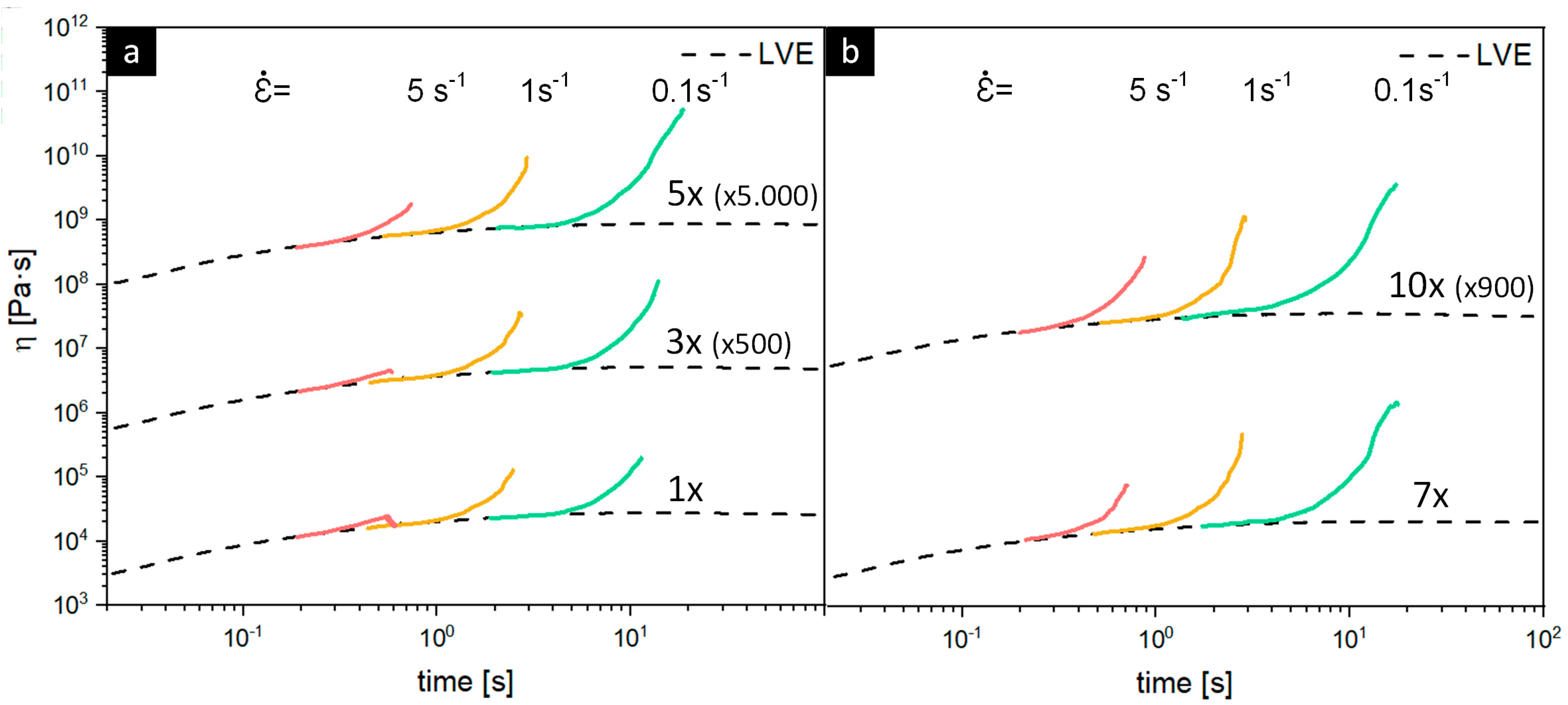

3.3. Multiple Processing of the PP-Based MAP

3.3.1. Mechanical Properties

3.3.2. Rheology

3.4. Film Blowing of Reprocessed PP-Based MAP

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Plastics Europe. Plastics the Facts. 2022. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2022/ (accessed on 9 February 2023).

- Schmidt, J.; Grau, L.; Auer, M.; Maletz, R.; Woidasky, J. Multilayer Packaging in a Circular Economy. Polymers 2022, 14, 1825. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.S. Modified Atmosphere Packaging of Foods: Principles and Applications; Wiley Blackwell: Hoboken, NJ, USA, 2021. [Google Scholar]

- Saha, N.C.; Ghosh, A.K.; Garg, M.; Sadhu, S.D. Food Packaging: Materials, Techniques and Environmental Issues, 1st ed.; Springer Nature Singapore; Imprint:; Springer: Singapore, 2022. [Google Scholar]

- Klemens, K.; Michael, B. Harald Rust. Plastics Compounding and Polymer Processing: Fundamentals, Machines, Equipment, Application Technology; Carl Hanser Verlag: Munich, Germany, 2022. [Google Scholar]

- Robertson, G.L. Food Packaging; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Selke, S.E.M.; Culter, J.D.; Auras, R.A.; Rabnawaz, M. Plastics Packaging: Properties, Processing, Applications, and Regulations, 4th ed.; Hanser: München, Germany, 2021. [Google Scholar]

- Quicker, P.; Seitz, M.; Vogel, J. Chemical recycling: A critical assessment of potential process approaches. Waste Manag. Res. 2022, 40, 1494–1504. [Google Scholar] [CrossRef]

- Kawecki, D.; Wu, Q.; Gonçalves, J.S.; Nowack, B. Polymer-specific dynamic probabilistic material flow analysis of seven polymers in Europe from 1950 to 2016. Resour. Conserv. Recycl. 2021, 173, 105733. [Google Scholar] [CrossRef]

- Roosen, M.; Mys, N.; Kleinhans, K.; Lase, I.S.; Huysveld, S.; Brouwer, M.; van Thoden Velzen, E.U.; van Geem, K.M.; Dewulf, J.; Ragaert, K.; et al. Expanding the collection portfolio of plastic packaging: Impact on quantity and quality of sorted plastic waste fractions. Resour. Conserv. Recycl. 2022, 178, 106025. [Google Scholar] [CrossRef]

- Van Belle, A.; Demets, R.; Mys, N.; van Kets, K.; Dewulf, J.; van Geem, K.; de Meester, S.; Ragaert, K. Microstructural Contributions of Different Polyolefins to the Deformation Mechanisms of Their Binary Blends. Polymers 2020, 12, 1171. [Google Scholar] [CrossRef]

- Tsironi, T.N.; Chatzidakis, S.M.; Stoforos, N.G. The future of polyethylene terephthalate bottles: Challenges and sustainability. Packag. Technol. Sci. 2022, 35, 317–325. [Google Scholar] [CrossRef]

- European Commission. A New Circulat Economy Action Plan; COM(2020) 98 final; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. The European Green Deal; COM(2019) 640 final; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Directive (EU) 2018/852 of the European Parliament and the Council of 30 May 2018 Amending Directive 94/62/EC on Packaging and Packaging Waste; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Mulakkal, M.C.; Castillo, A.C.; Taylor, A.C.; Blackman, B.R.; Balint, D.S.; Pimenta, S.; Charalambides, M.N. Advancing mechanical recycling of multilayer plastics through finite element modelling and environmental policy. Resour. Conserv. Recycl. 2021, 166, 105371. [Google Scholar] [CrossRef]

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Siracusa, V.; Rosa, M.D. Sustainable Packaging. Sustainable Food Systems from Agriculture to Industry; Elsevier: Amsterdam, The Netherlands, 2018; pp. 275–307. [Google Scholar]

- De Feo, G.; Ferrara, C.; Minichini, F. Comparison between the perceived and actual environmental sustainability of beverage packagings in glass, plastic, and aluminium. J. Clean. Prod. 2022, 333, 130158. [Google Scholar] [CrossRef]

- Pragati, P.; Yasunobu, M. Life cycle environmental impacts of consumer packaging products in Japan. Risk Anal. 2022, 1–12. [Google Scholar] [CrossRef]

- Frojan, J.; Bisquert, P.; Buche, P.; Gontard, N.; Boone, L.; Nhu Thuy, T.N.; Vermeulen, A.; Ragaert, P.; Dewulf, J.; Guillard, V. Scoring methodology for comparing the environmental performance of food packaging. Packag Technol Sci 2023, 36, 439–463. [Google Scholar] [CrossRef]

- Korte, I.; Albrecht, A.; Mittler, M.; Waldhans, C.; Kreyenschmidt, J. Influence of different bio-based and conventional packaging trays on the quality loss of fresh cherry tomatoes during distribution and storage. Packag. Technol. Sci. 2023, 36, 569–583. [Google Scholar] [CrossRef]

- Chen, J.; Mu, X.; Tu, C.; Hu, G. Evaluation index system for the implementation of extended producer responsibility system: Chinese beverage paper-based composite packaging manufacturers. Packag. Technol. Sci. 2023, 36, 195–210. [Google Scholar] [CrossRef]

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-sourced polymers as alternatives to conventional food packaging materials: A review. Trends Food Sci. Technol. 2021, 115, 87–104. [Google Scholar] [CrossRef]

- Pålsson, H.; Olsson, J. Current state and research directions for disposable versus reusable packaging: A systematic literature review of comparative studies. Packag. Technol. Sci. 2023, 36, 391–409. [Google Scholar] [CrossRef]

- Barlow, C.Y.; Morgan, D.C. Polymer film packaging for food: An environmental assessment. Resour. Conserv. Recycl. 2013, 78, 74–80. [Google Scholar] [CrossRef]

- Stefanini, R.; Borghesi, G.; Ronzano, A.; Vignali, G. Plastic or glass: A new environmental assessment with a marine litter indicator for the comparison of pasteurized milk bottles. Int. J. Life Cycle Assess 2021, 26, 767–784. [Google Scholar] [CrossRef]

- Gómez, I.D.L.; Escobar, A.S. The dilemma of plastic bags and their substitutes: A review on LCA studies. Sustain. Prod. Consum. 2022, 30, 107–116. [Google Scholar] [CrossRef]

- Huang, T.; Yamaguchi, M. Effect of cooling conditions on the mechanical properties of crystalline poly(lactic acid). J. Appl. Polym. Sci. 2017, 134, 44960. [Google Scholar] [CrossRef]

- Tee, Y.B.; Talib, R.A.; Abdan, K.; Chin, N.L.; Basha, R.K.; Yunos, K.F.M. Comparative Study of Chemical, Mechanical, Thermal, and Barrier Properties of Poly(Lactic Acid) Plasticized with Epoxidized Soybean Oil and Epoxidized Palm Oil. BioResources 2015, 11, 1518–1540. [Google Scholar] [CrossRef]

- Ortega-Toro, R.; Bonilla, J.; Talens, P.; Chiralt, A. Future of Starch-Based Materials in Food Packaging. Starch-Based Materials in Food Packaging; Elsevier: Amsterdam, The Netherlands, 2017; pp. 257–312. ISBN 9780128094396. [Google Scholar]

- Borealis Polyolefine GmbH. Mechanically Recyclable Modified Atmosphere Packaging System based on PP: Unpublished Internal Data of Borealis; Borealis Innovation Headquarters: Linz, Austria, 2022. [Google Scholar]

- Roosen, M.; Mys, N.; Kusenberg, M.; Billen, P.; Dumoulin, A.; Dewulf, J.; van Geem, K.M.; Ragaert, K.; de Meester, S. Detailed Analysis of the Composition of Selected Plastic Packaging Waste Products and Its Implications for Mechanical and Thermochemical Recycling. Environ. Sci. Technol. 2020, 54, 13282–13293. [Google Scholar] [CrossRef]

- Boz, Z.; Korhonen, V.; Sand, C.K. Consumer Considerations for the Implementation of Sustainable Packaging: A Review. Sustainability 2020, 12, 2192. [Google Scholar] [CrossRef]

- Pauer, E.; Wohner, B.; Heinrich, V.; Tacker, M. Assessing the Environmental Sustainability of Food Packaging: An Extended Life Cycle Assessment including Packaging-Related Food Losses and Waste and Circularity Assessment. Sustainability 2019, 11, 925. [Google Scholar] [CrossRef]

- Escursell, S.; Llorach-Massana, P.; Roncero, M.B. Sustainability in e-commerce packaging: A review. J. Clean. Prod. 2021, 280, 124314. [Google Scholar] [CrossRef]

- Coelho, P.M.; Corona, B.; ten Klooster, R.; Worrell, E. Sustainability of reusable packaging–Current situation and trends. Resour. Conserv. Recycl. X 2020, 6, 100037. [Google Scholar] [CrossRef]

- Meherishi, L.; Narayana, S.A.; Ranjani, K.S. Sustainable packaging for supply chain management in the circular economy: A review. J. Clean. Prod. 2019, 237, 117582. [Google Scholar] [CrossRef]

- Foschi, E.; Bonoli, A. The Commitment of Packaging Industry in the Framework of the European Strategy for Plastics in a Circular Economy. Adm. Sci. 2019, 9, 18. [Google Scholar] [CrossRef]

- Guerritore, M.; Olivieri, F.; Castaldo, R.; Avolio, R.; Cocca, M.; Errico, M.E.; Galdi, M.R.; Carfagna, C.; Gentile, G. Recyclable-by-design mono-material flexible packaging with high barrier properties realized through graphene hybrid coatings. Resour. Conserv. Recycl. 2022, 179, 106126. [Google Scholar] [CrossRef]

- Tartakowski, Z. Recycling of packaging multilayer films: New materials for technical products. Resour. Conserv. Recycl. 2010, 55, 167–170. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U. Novel biopolymer-based sustainable composites for food packaging applications: A narrative review. Food Packag. Shelf Life 2022, 33, 100892. [Google Scholar] [CrossRef]

- Soro, A.B.; Noore, S.; Hannon, S.; Whyte, P.; Bolton, D.J.; O’Donnell, C.; Tiwari, B.K. Current sustainable solutions for extending the shelf life of meat and marine products in the packaging process. Food Packag. Shelf Life 2021, 29, 100722. [Google Scholar] [CrossRef]

- Rigotti, D.; Soccio, M.; Dorigato, A.; Gazzano, M.; Siracusa, V.; Fredi, G.; Lotti, N. Novel Biobased Polylactic Acid/Poly(pentamethylene 2,5-furanoate) Blends for Sustainable Food Packaging. ACS Sustain. Chem. Eng. 2021, 9, 13742–13750. [Google Scholar] [CrossRef]

- Van Thoden Velzen, E.U.; Chu, S.; Molenveld, K.; Jašo, V. Effect of poly lactic acid trays on the optical and thermal properties of recycled poly (ethylene terephthalate). Packag. Technol. Sci. 2022, 35, 351–360. [Google Scholar] [CrossRef]

- Jönkkäri, I.; Poliakova, V.; Mylläri, V.; Anderson, R.; Andersson, M.; Vuorinen, J. Compounding and characterization of recycled multilayer plastic films. J. Appl. Polym. Sci. 2020, 137, 49101. [Google Scholar] [CrossRef]

- Ügdüler, S.; de Somer, T.; van Geem, K.M.; Roosen, M.; Kulawig, A.; Leineweber, R.; de Meester, S. Towards a Better Understanding of Delamination of Multilayer Flexible Packaging Films by Carboxylic Acids. ChemSusChem 2021, 14, 4198–4213. [Google Scholar] [CrossRef]

- Horodytska, O.; Valdés, F.J.; Fullana, A. Plastic flexible films waste management—A state of art review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef]

- Soares, C.T.d.M.; Ek, M.; Östmark, E.; Gällstedt, M.; Karlsson, S. Recycling of multi-material multilayer plastic packaging: Current trends and future scenarios. Resour. Conserv. Recycl. 2022, 176, 105905. [Google Scholar] [CrossRef]

- Seier, M.; Archodoulaki, V.-M.; Koch, T.; Duscher, B.; Gahleitner, M. Polyethylene terephthalate based multilayer food packaging: Deterioration effects during mechanical recycling. Food Packag. Shelf Life 2022, 33, 100890. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C Open Access 2021, 6, 100168. [Google Scholar] [CrossRef]

- Rumetshofer, T.; Fischer, J. Information-Based Plastic Material Tracking for Circular Economy-A Review. Polymers 2023, 15, 1623. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung. DIN SPEC 91446; Classification of recycled plastics by Data Quality Levels for Use and (Digital) Trading. Beuth: Berlin, Germany, 2021.

- International Organization for Standardization. ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. Beuth: Berlin, Germany, 2012.

- International Organization for Standardization. ISO 8256:2004; Plastics—Determination of Tensile-Impact Strength. Beuth: Berlin, Germany, 2004.

- Mieth, A.; Simoneau, C.; Hoekstra, E. Guidance for the Identification of Polymers in Multilayer Films Used in Food Contact Materials: User Guide of Selected Practices to Determine the Nature of Layers; Publications Office of the European Union: Brussels, Belgium, 2016. [Google Scholar]

- Grellmann, W.; Seidler, S. Polymer Testing, 2nd ed.; Hanser Publishers: Cincinnati, OH, USA, 2013. [Google Scholar]

- Baur, E.; Osswald, T.A.; Rudolph, N. Plastics Handbook—The Resource for Plastics Engineers, 5th ed.; Carl Hanser Verlag: Munich, Germany, 2018. [Google Scholar]

- International Organization for Standardization. ISO 527-3:2018; Plastics—Determination of Tensile Properties—Part 3: Tensile Properties of Films and Sheets. Beuth: Berlin, Germany, 2019.

- Europrean Institution for Standardization. EN 14477:2004; Packaging, Flexible Packaging Material—Determination of Puncture Resistance—Test Methods. Beuth: Berlin, Germany, 2004.

- International Organization for Standardization. ISO 1133-1:2022; Plastics—Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics—Part 1: Standard Method. Beuth: Berlin, Germany, 2011.

- Thakur, M.; Modi, V.K. Emerging Technologies in Food Science: Focus on the Developing World; Springer: Singapore, 2020. [Google Scholar]

- Morris, B.A. Science and Technology of Flexible Packaging: Multilayer Films from Resin and Process to End Use; William Andrew Publishing: Norwich, NY, USA, 2022; ISBN 9780323854351. [Google Scholar]

- Vukoje, M.; Mirković, I.B.; Bolanča, Z. Influence of printing technique and printing conditions on prints recycling efficiency and effluents quality. Sustainability 2022, 14, 335. [Google Scholar] [CrossRef]

- Maksimov, R.D.; Meri, R.M.; Kalnin, M.; Zicans, J. Mechanical Properties of Polyethylene and Poly(Ethylene Terephthalate) Blends. Polym. Mech. 2003, 39, 189–196. [Google Scholar] [CrossRef]

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Uehara, G.A.; França, M.P.; Canevarolo, S.V., Jr. Recycling assessment of multilayer flexible packaging films using design of experiments. Polímeros 2015, 25, 371–381. [Google Scholar] [CrossRef]

- Ragaert, K.; Huysveld, S.; Vyncke, G.; Hubo, S.; Veelaert, L.; Dewulf, J.; Du Bois, E. Design from recycling: A complex mixed plastic waste case study. Resour. Conserv. Recycl. 2020, 155, 104646. [Google Scholar] [CrossRef]

- Agassant, J.; Avenas, P.; Carreau, P.J.; Vergnes, B.; Vincent, M. Polymer Processing: Principles and Modeling, 2nd ed.; Hanser Publishers: Cincinnati, OH, USA, 2017. [Google Scholar]

- Cecon, V.S.; Da Silva, P.F.; Curtzwiler, G.W.; Vorst, K.L. The challenges in recycling post-consumer polyolefins for food contact applications: A review. Resour. Conserv. Recycl. 2021, 167, 105422. [Google Scholar] [CrossRef]

- Bashirgonbadi, A.; Lase, I.S.; Delva, L.; van Geem, K.M.; de Meester, S.; Ragaert, K. Quality evaluation and economic assessment of an improved mechanical recycling process for post-consumer flexible plastics. Waste Manag. 2022, 153, 41–51. [Google Scholar] [CrossRef]

- Inoue, T. Morphology of polymer blends. In Polymer Blends Handbook; Utracki, L.A., Ed.; Springer: Dordrecht, The Netherlands, 2003; pp. 547–576. [Google Scholar]

- Dorigato, A. Recycling of polymer blends. Adv. Ind. Eng. Polym. Res. 2021, 4, 53–69. [Google Scholar] [CrossRef]

- Gahleitner, M.; Bernreitner, K.; Neiβl, W.; Paulik, C.; Ratajski, E. Influence of molecular structure on crystallization behaviour and mechanical properties of polypropylene. Polym. Test. 1995, 14, 173–187. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Mihelčič, M.; Oseli, A.; Huskić, M.; Perše, L.S. Influence of Stabilization Additive on Rheological, Thermal and Mechanical Properties of Recycled Polypropylene. Polymers 2022, 14, 5438. [Google Scholar] [CrossRef] [PubMed]

- Gahleitner, M.; Wolfschwenger, J.; Bachner, C.; Bernreitner, K.; Neil, W. Crystallinity and mechanical properties of PP-homopolymers as influenced by molecular structure and nucleation. J. Appl. Polym. Sci. 1996, 61, 649–657. [Google Scholar] [CrossRef]

- Tocháček, J.; Jančář, J.; Kalfus, J.; Hermanová, S. Processing stability of polypropylene impact-copolymer during multiple extrusion—Effect of polymerization technology. Polym. Degrad. Stab. 2011, 96, 491–498. [Google Scholar] [CrossRef]

- Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T.H. Degradation Behavior of Polypropylene during Reprocessing and Its Biocomposites: Thermal and Oxidative Degradation Kinetics. Polymers 2020, 12, 1627. [Google Scholar] [CrossRef]

- Morshedian, J.; Karbalaei-Bagher, M.; Bayazian, H.; Jamshidi, A.; Razavi-Nouri, M. Unraveling the Bimodality of Polypropylene Film Grades Using Rheological Shear and Elongational Measurements: Inconsistent Results of Gel Permeation Chromatography. Polym. Sci. Ser. A 2018, 60, 523–529. [Google Scholar] [CrossRef]

- Tzoganakis, C. A rheological evaluation of linear and branched controlled-rheology polypropylenes. Can. J. Chem. Eng. 1994, 72, 749–754. [Google Scholar] [CrossRef]

- Friedrich, C.; Loy, R.J.; Anderssen, R.S. Relaxation time spectrum molecular weight distribution relationships. Rheol. Acta 2009, 48, 151–162. [Google Scholar] [CrossRef]

- Mezger, T. The Rheology Handbook; Vincentz Network: Hannover, Germany, 2020. [Google Scholar]

- Traxler, I.; Marschik, C.; Farthofer, M.; Laske, S.; Fischer, J. Application of Mixing Rules for Adjusting the Flowability of Virgin and Post-Consumer Polypropylene as an Approach for Design from Recycling. Polymers 2022, 14, 2699. [Google Scholar] [CrossRef]

- Wagner, M.H.; Bastian, H.; Hachmann, P.; Meissner, J.; Kurzbeck, S.; Münstedt, H.; Langouche, F. The strain-hardening behaviour of linear and long-chain-branched polyolefin melts in extensional flows. Rheol. Acta 2000, 39, 97–109. [Google Scholar] [CrossRef]

- Kim, S.Y.; Kim, M.C.; Song, H.Y.; Hyun, K.; Hong, S.C. Preparation and characteristics of polypropylene with long chain branches utilizing the C–H insertion capability of azidoformate. Polym. Test. 2022, 116, 107792. [Google Scholar] [CrossRef]

- Gabriel, C.; Münstedt, H. Strain hardening of various polyolefins in uniaxial elongational flow. J. Rheol. 2003, 47, 619–630. [Google Scholar] [CrossRef]

- Radusin, T.; Nilsen, J.; Larsen, S.; Annfinsen, S.; Waag, C.; Eikeland, M.S.; Pettersen, M.K.; Fredriksen, S.B. Use of recycled materials as mid layer in three layered structures-new possibility in design for recycling. J. Clean. Prod. 2020, 259, 120876. [Google Scholar] [CrossRef]

| Film Sample | Et [MPa] | Tg [°C] | Tm [°C] | OTR [cm³/m²·d·bar] | WVTR [g/m²·d] |

|---|---|---|---|---|---|

| PET | 3021 | 70 | 256 | 20.0 * | 4.0 * |

| PP | 1530 | 0 | 165 | 800.0 * | 0.6 * |

| PLA | 3600 | 55 | 146 | 280.0 * | 14.0 * |

| PET/PE | 2851 | 70 | 256 | 18.6 | 1.3 |

| PET/EVOH/PE | 3395 | 70 | 256 | 1.5 | 1.1 |

| PP/EVOH/PE | 2368 | 0 | 165 | 0.4 | 0.2 |

| Composition (Estimated from Analysis) | Blend Model | Extrusion | |||||

|---|---|---|---|---|---|---|---|

| EVOH | PE- LD/LLD | PET | PP | Representation | TPET | TPP | Processing Steps |

| 4 wt.% | 23 wt.% | 73 wt.% | - | ‘PET Lid + Tray’ | 275 °C | - | 1× |

| 2 wt.% | 13 wt.% | 85 wt.% | - | ‘PET Tray’ | 275 °C | - | 1× |

| 11 wt.% | 66 wt.% | 23 wt.% | - | ‘PET Lid’ | 275 °C | - | 1× |

| 4 wt.% | 4 wt.% | - | 92 wt.% | ‘PP Lid + Tray’ | - | 220 °C | 10× |

| 3 wt.% | 5 wt.% | - | 92 wt.% | ‘PP Tray’ | - | 220 °C | 1× |

| 6 wt.% | - | - | 94 wt.% | ‘PP Lid’ | - | 220 °C | 1× |

| Sample | ωc [rad/s] | Gc [Pa] | MW/MMD |

|---|---|---|---|

| PP lid + tray 1× | 45 | 31,230 | |

| PP lid + tray 3× | 59 | 31,522 | Mw ↓, MMD ↑ |

| PP lid + tray 5× | 64 | 31,610 | Mw ↓, MMD ↑ |

| PP lid + tray 7× | 73 | 31,789 | Mw ↓, MMD ↑ |

| PP lid + tray 10× | 82 | 31,816 | Mw ↓, MMD ↑ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seier, M.; Archodoulaki, V.-M.; Koch, T.; Duscher, B.; Gahleitner, M. Prospects for Recyclable Multilayer Packaging: A Case Study. Polymers 2023, 15, 2966. https://doi.org/10.3390/polym15132966

Seier M, Archodoulaki V-M, Koch T, Duscher B, Gahleitner M. Prospects for Recyclable Multilayer Packaging: A Case Study. Polymers. 2023; 15(13):2966. https://doi.org/10.3390/polym15132966

Chicago/Turabian StyleSeier, Martina, Vasiliki-Maria Archodoulaki, Thomas Koch, Bernadette Duscher, and Markus Gahleitner. 2023. "Prospects for Recyclable Multilayer Packaging: A Case Study" Polymers 15, no. 13: 2966. https://doi.org/10.3390/polym15132966

APA StyleSeier, M., Archodoulaki, V.-M., Koch, T., Duscher, B., & Gahleitner, M. (2023). Prospects for Recyclable Multilayer Packaging: A Case Study. Polymers, 15(13), 2966. https://doi.org/10.3390/polym15132966