Flow Disturbance Characterization of Highly Filled Thermoset Injection Molding Compounds behind an Obstacle and in a Spiral Flow Part

Abstract

1. Introduction

2. Materials and Methods

2.1. Injection Molding Process

2.1.1. Highly Filled Thermoset Injection Molding Compounds

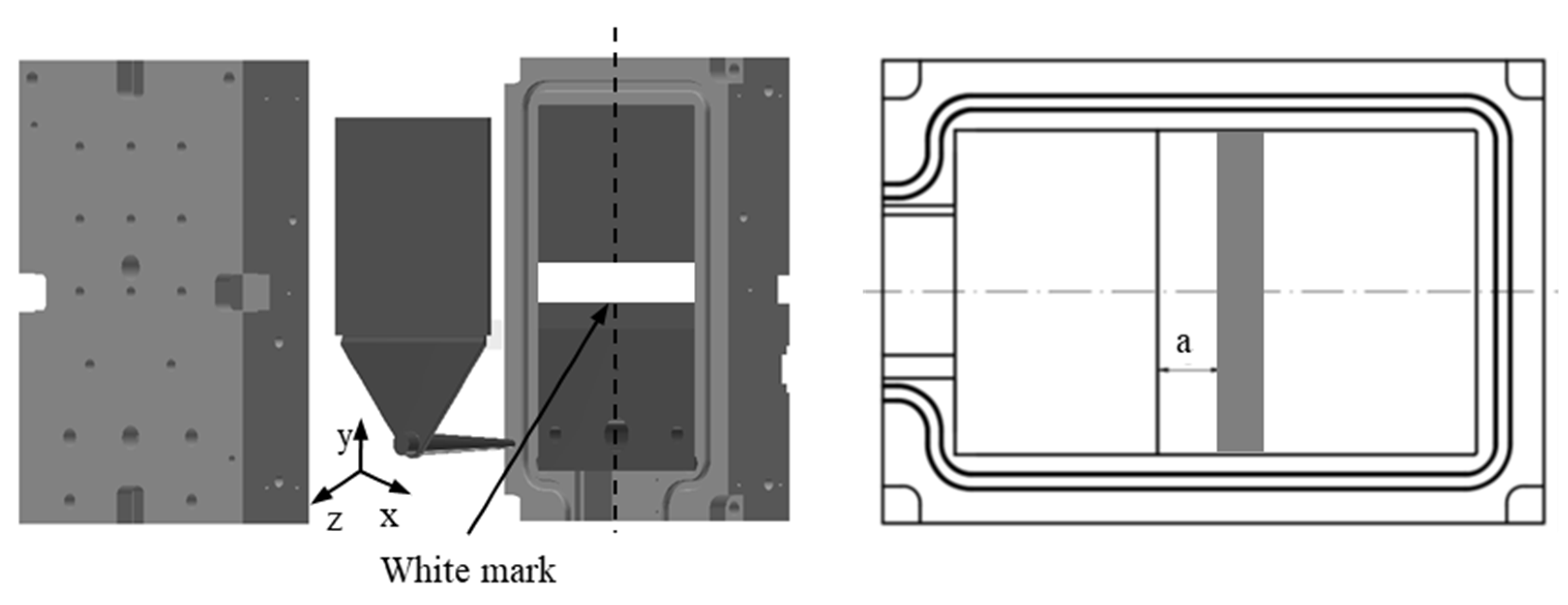

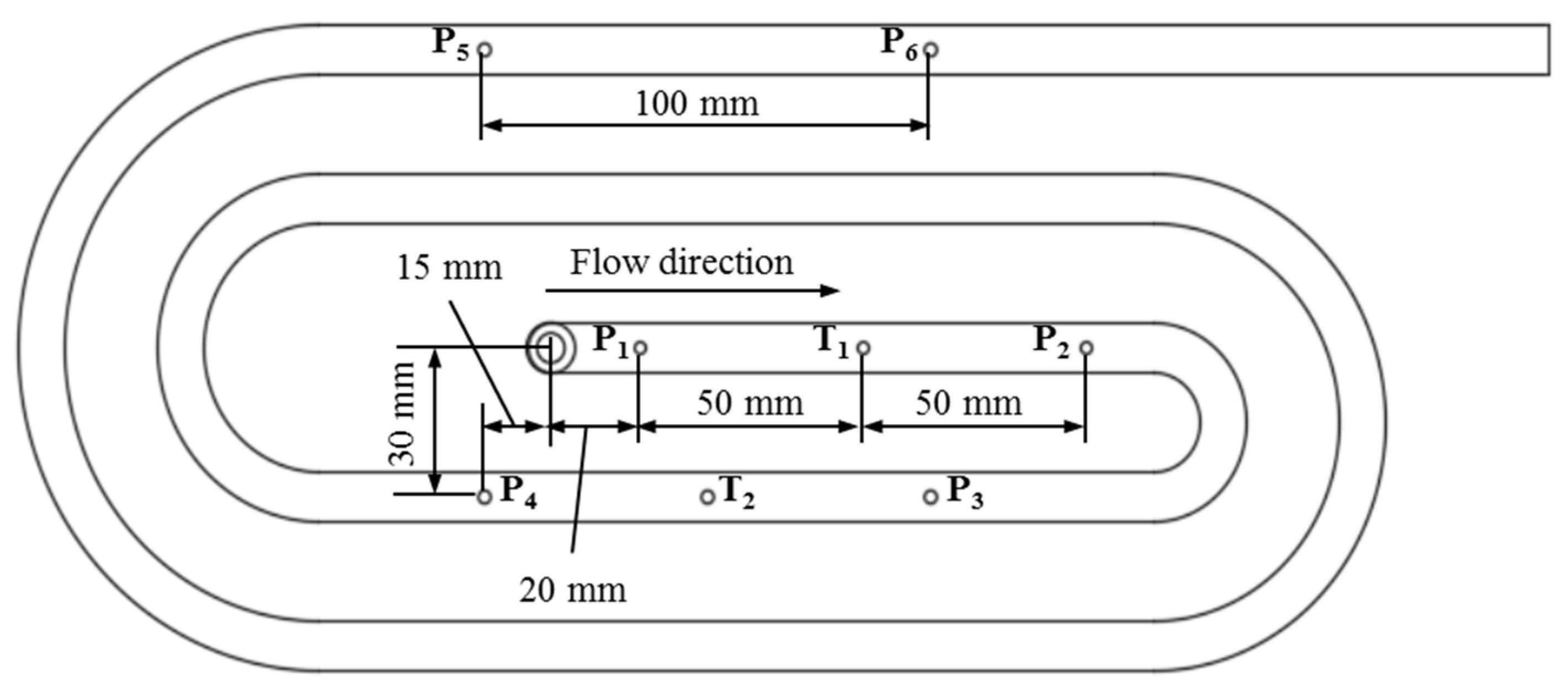

2.1.2. Studying Objects

2.1.3. Experimental Procedure

2.2. Simulation Process

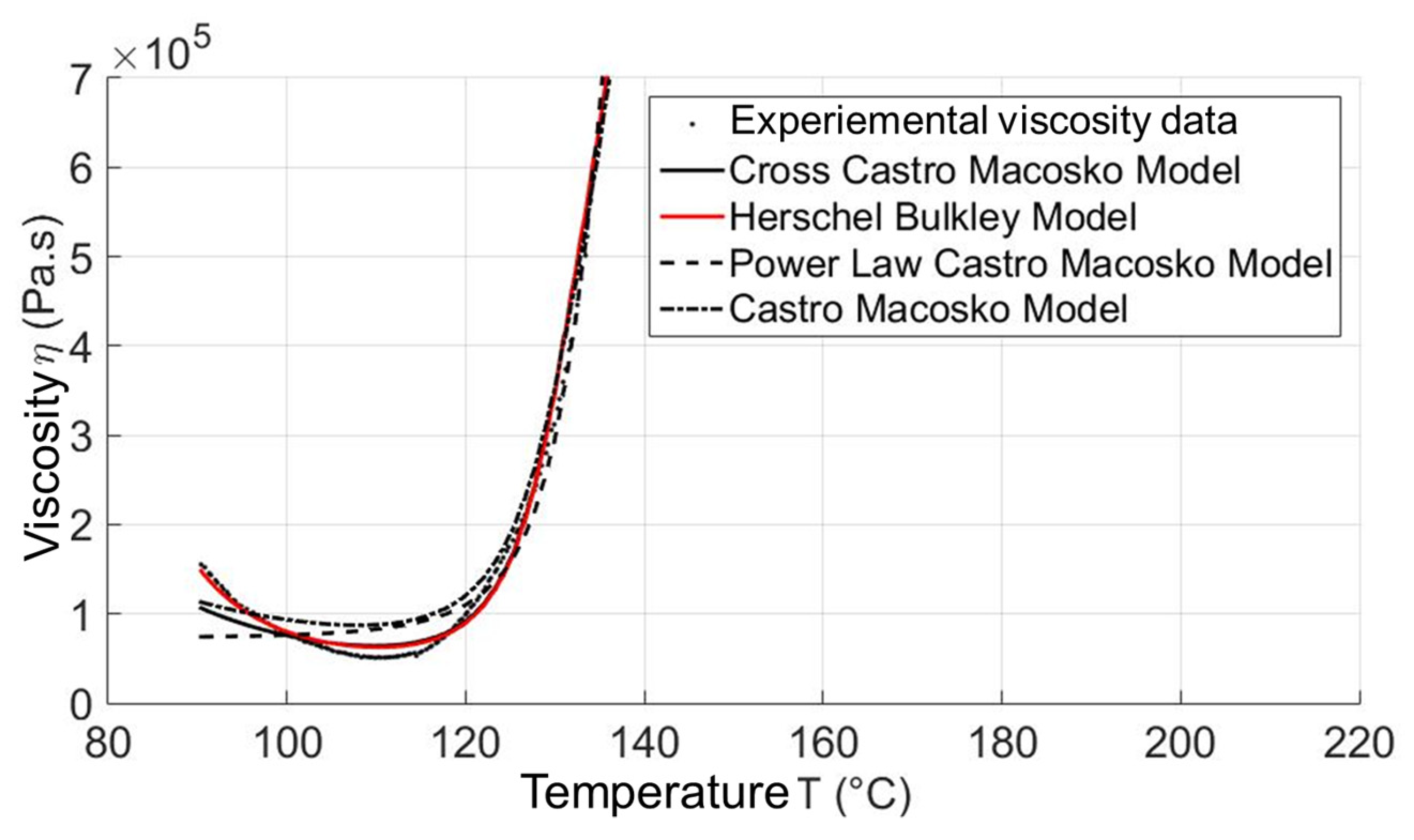

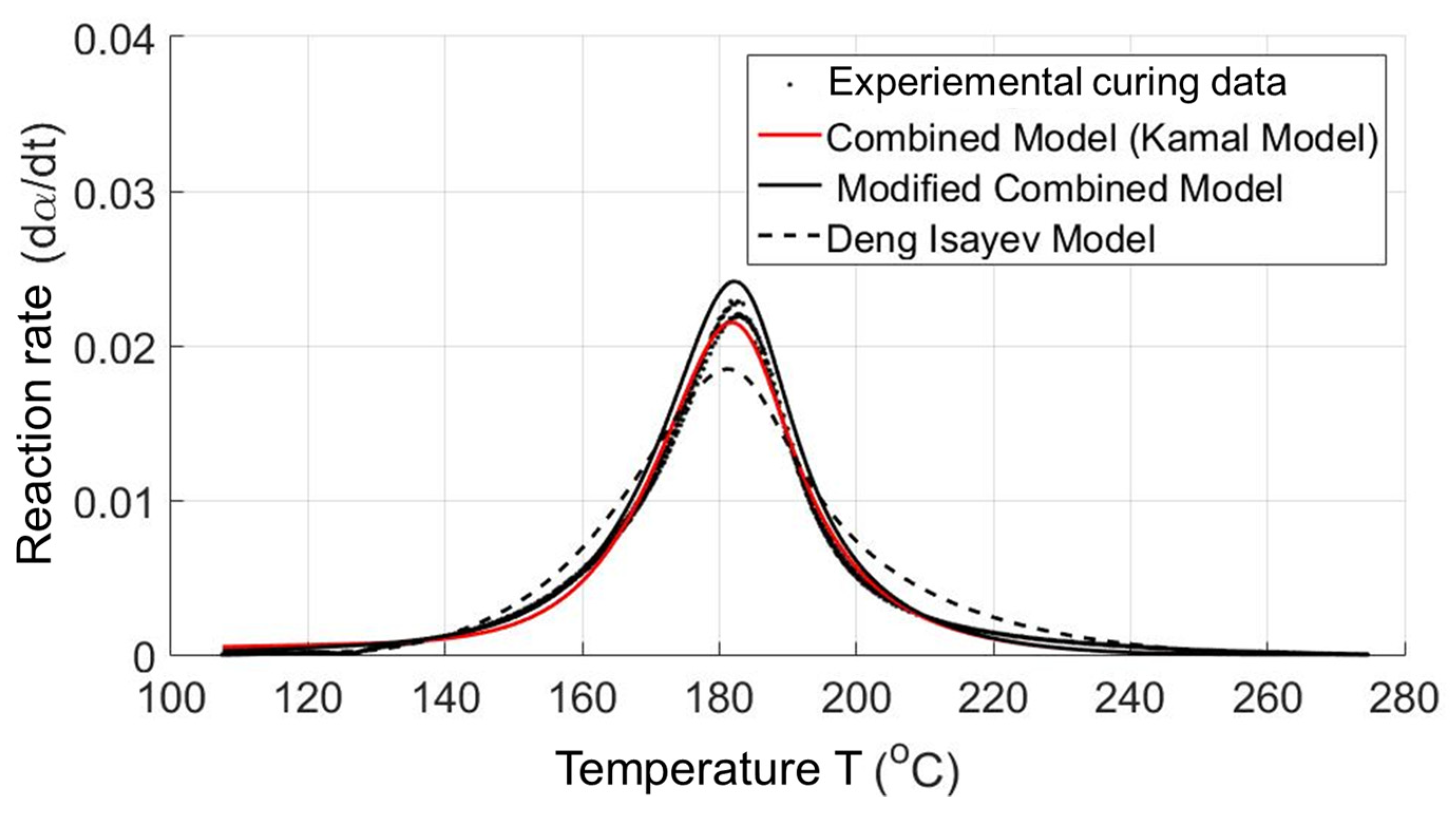

2.2.1. Generating Material Data Sheet for the Injection Molding Simulation Process

2.2.2. Simulation of the Mold-Filling Behavior

3. Results and Discussion

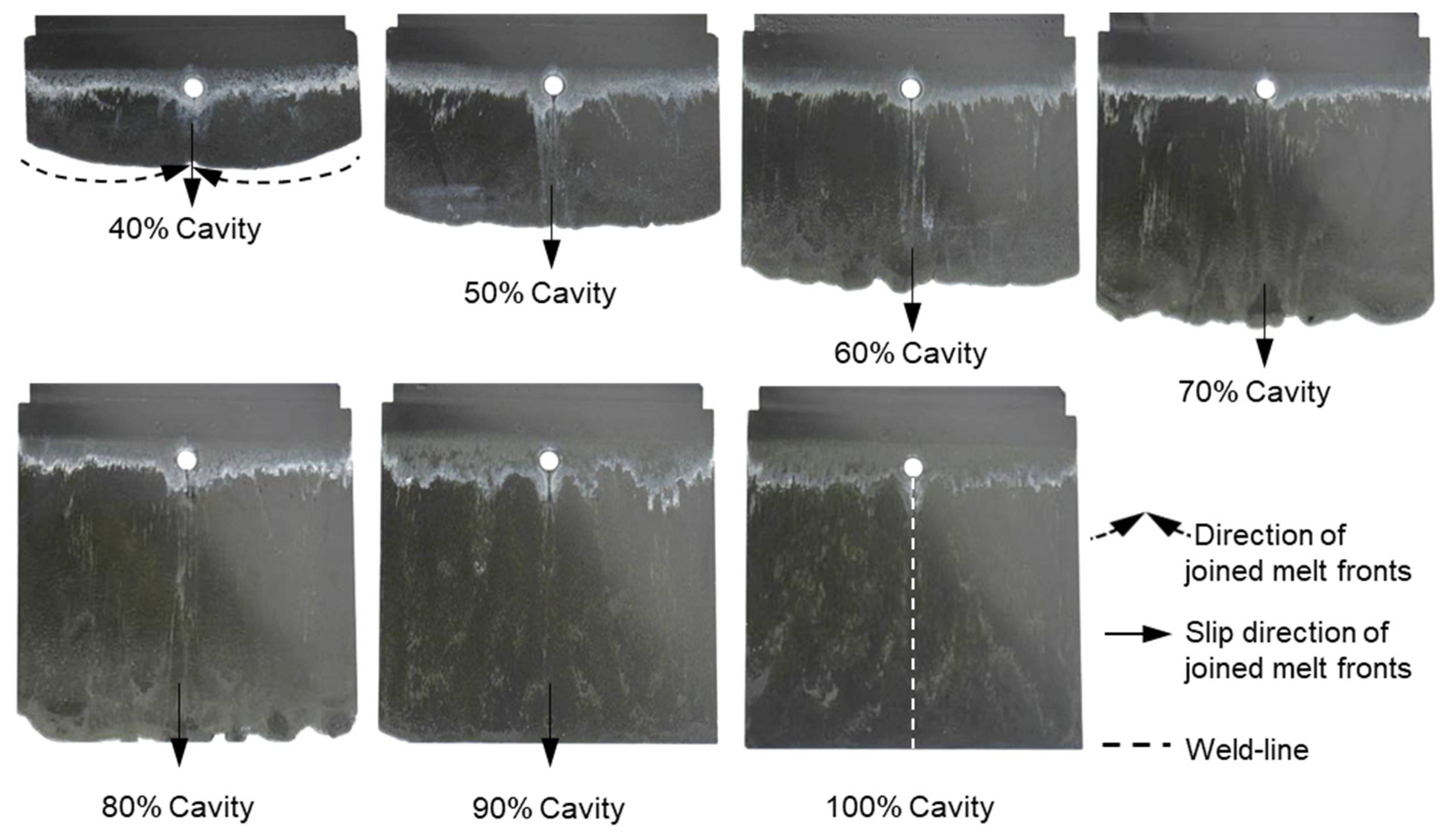

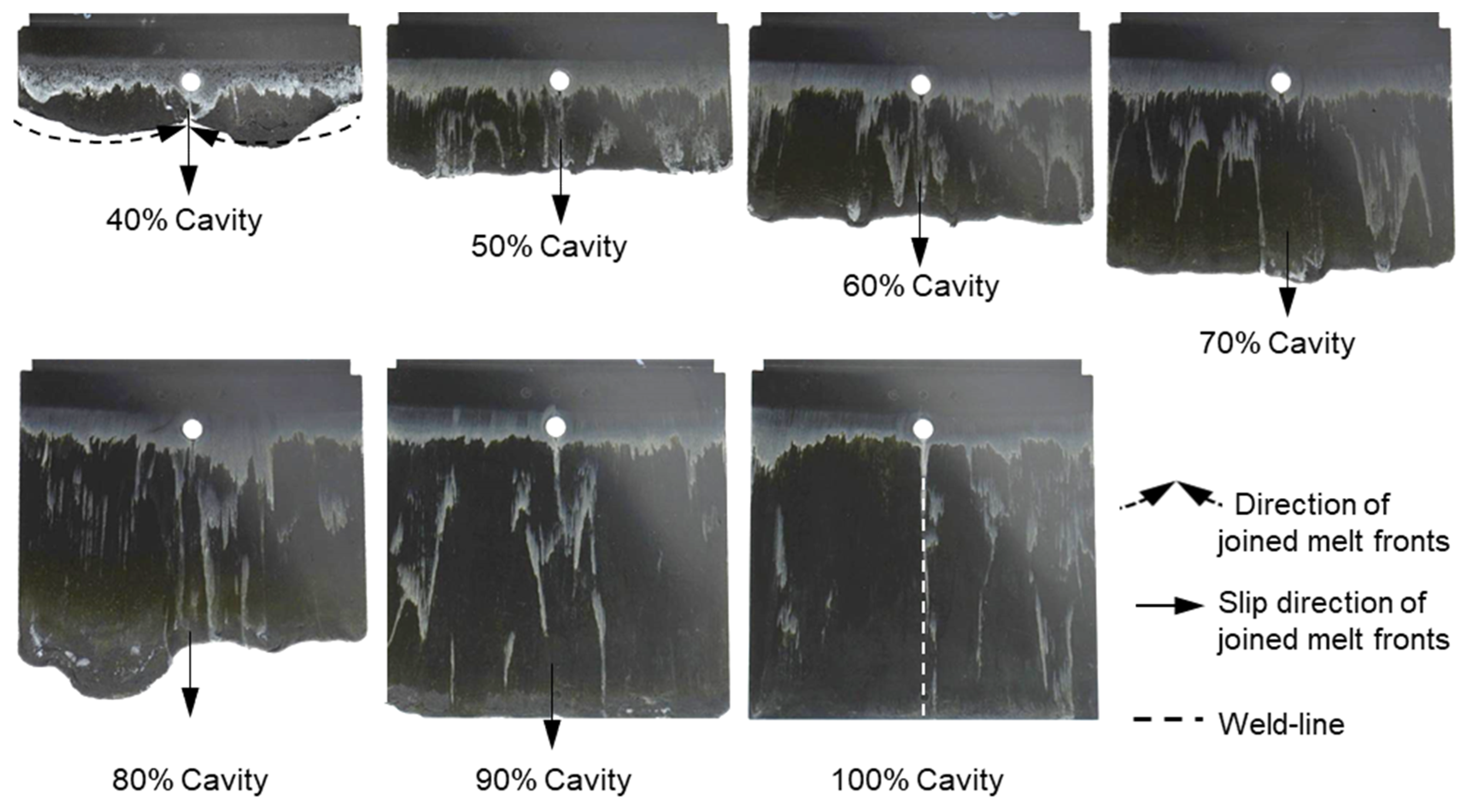

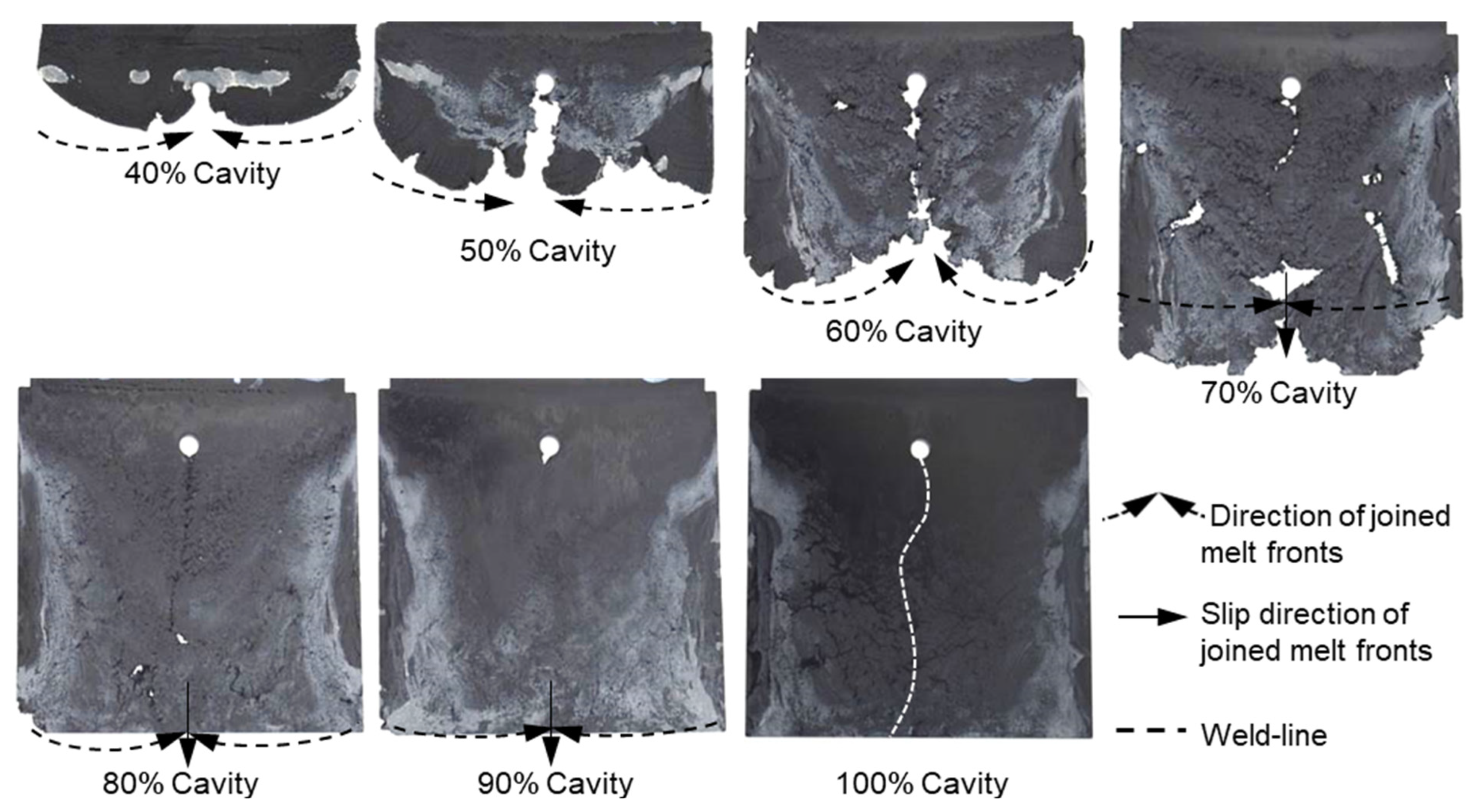

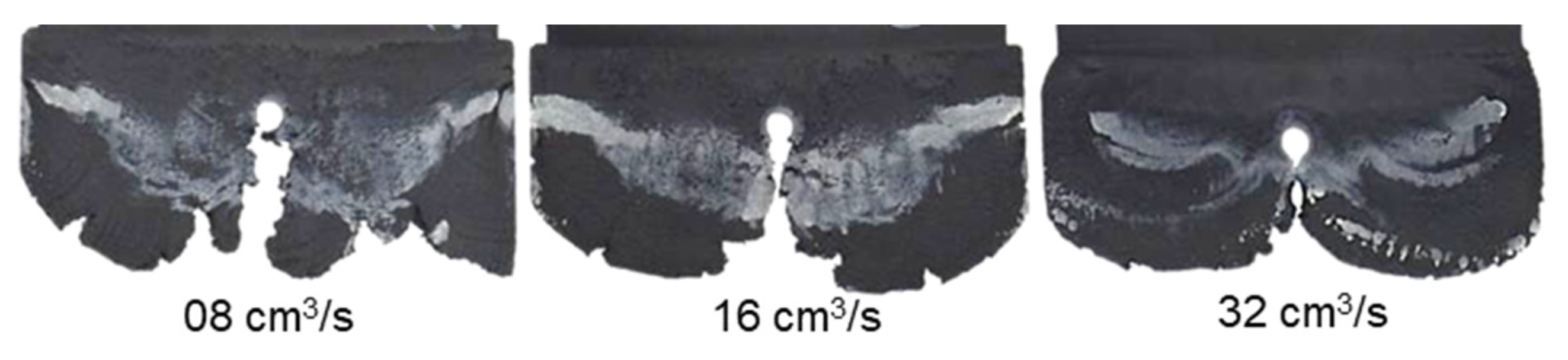

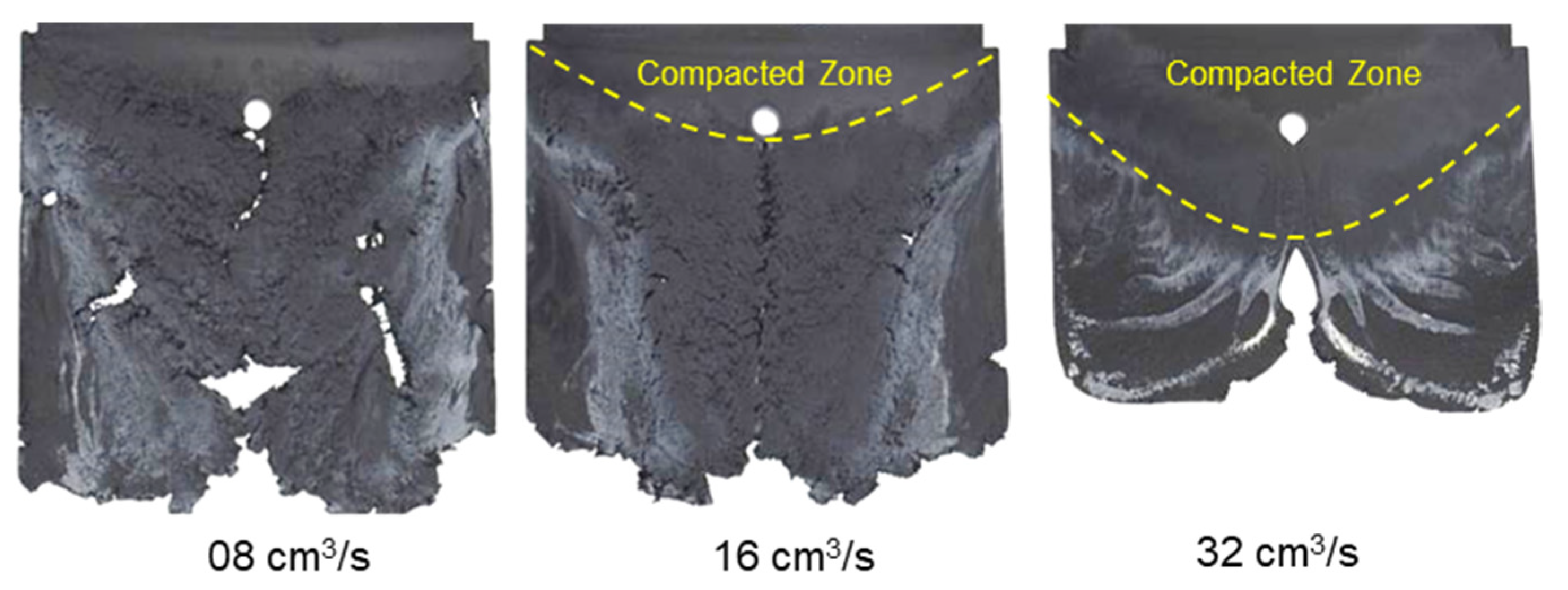

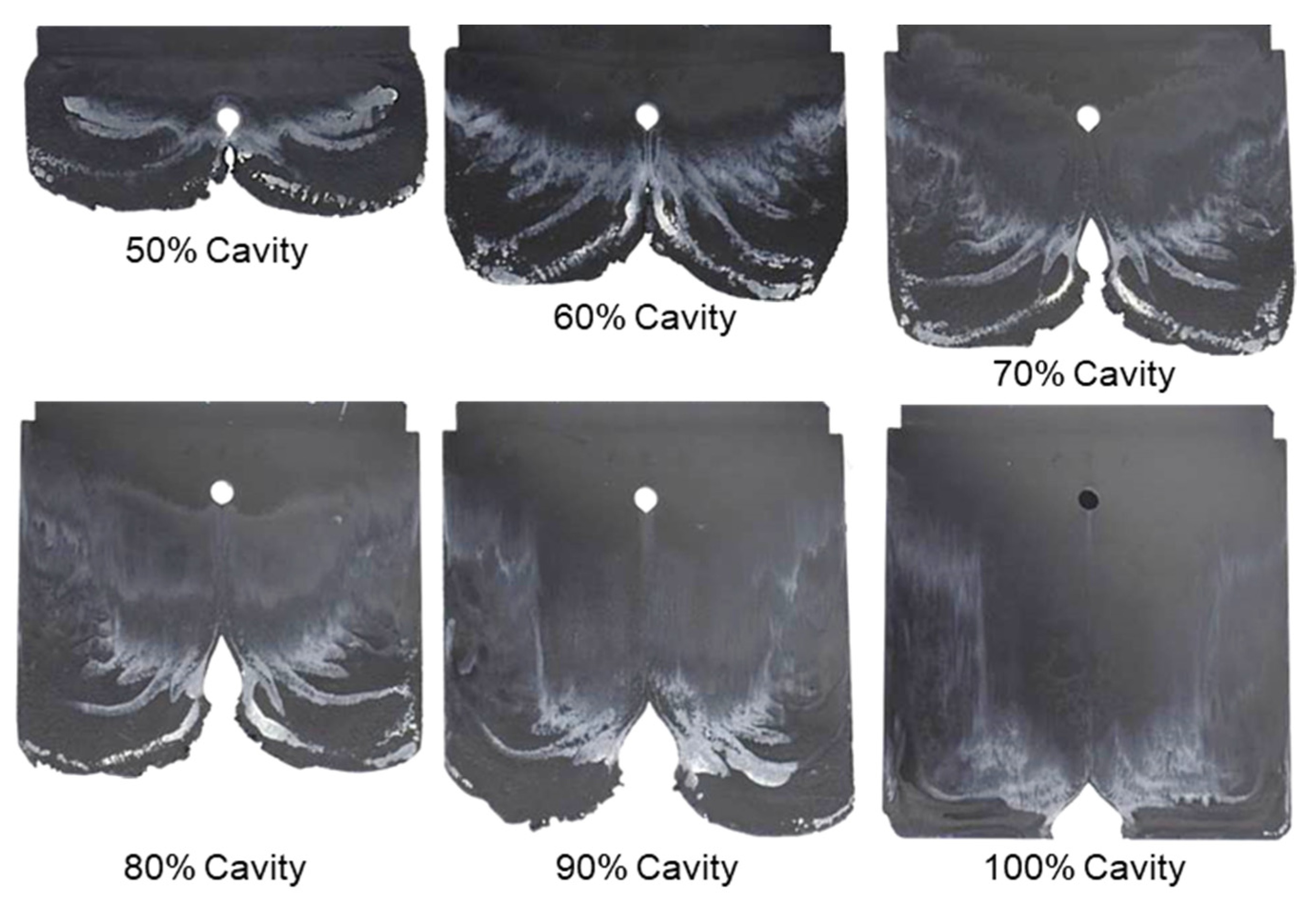

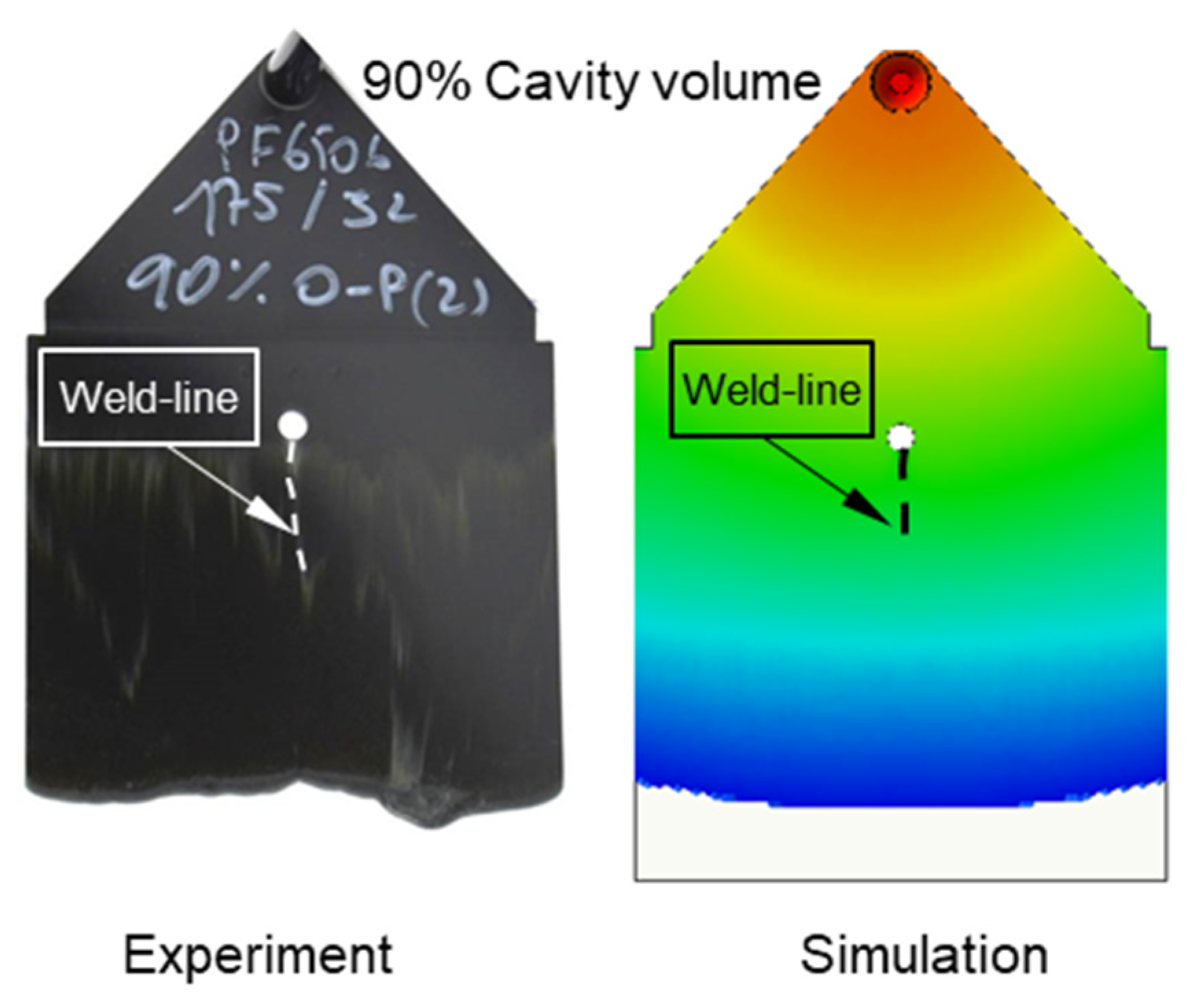

3.1. Mechanism of Weld Line Formation and Development behind an Obstacle

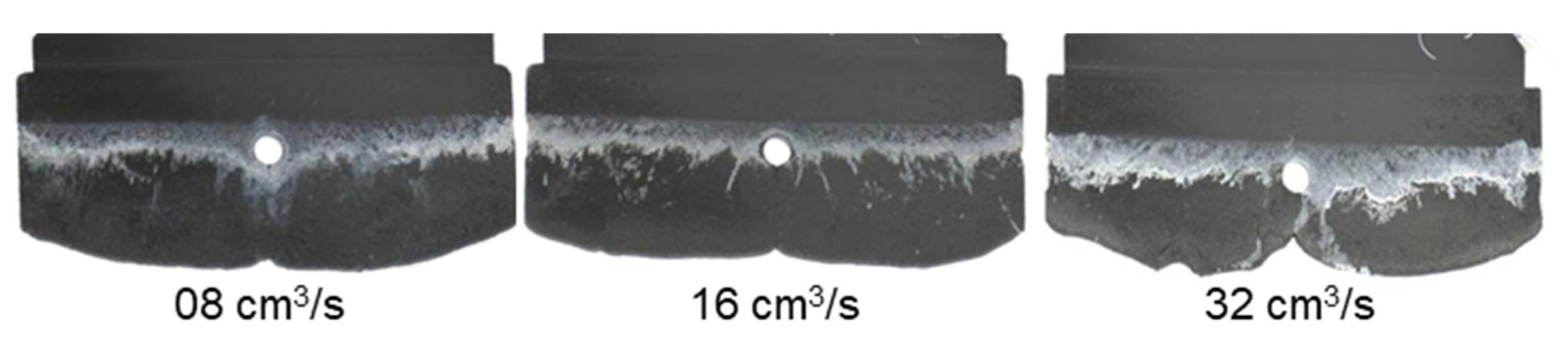

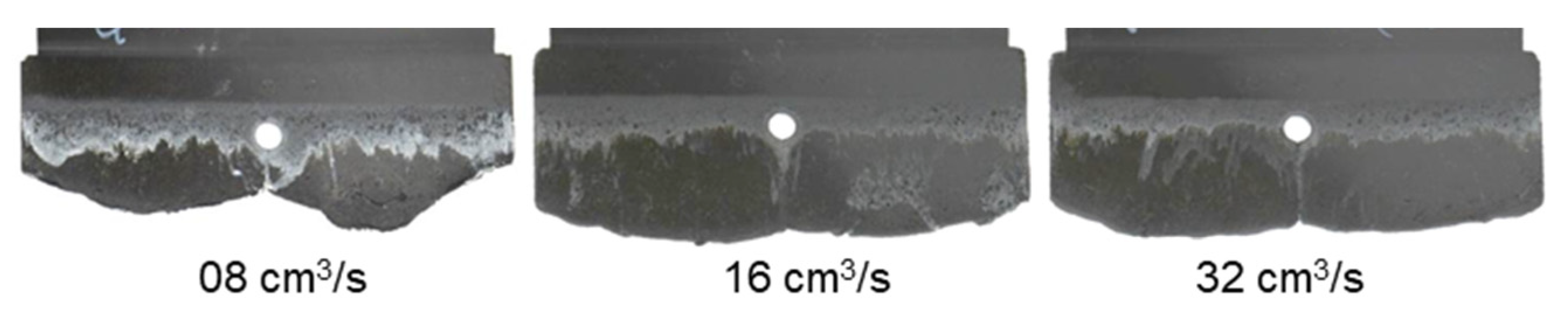

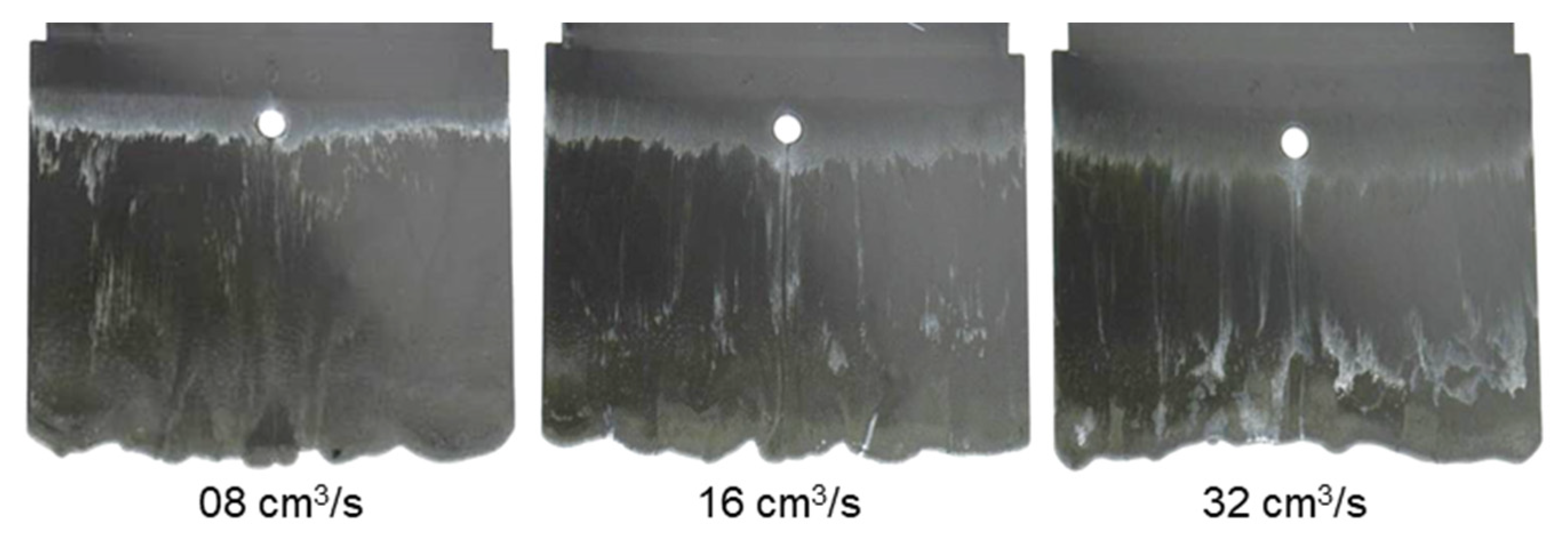

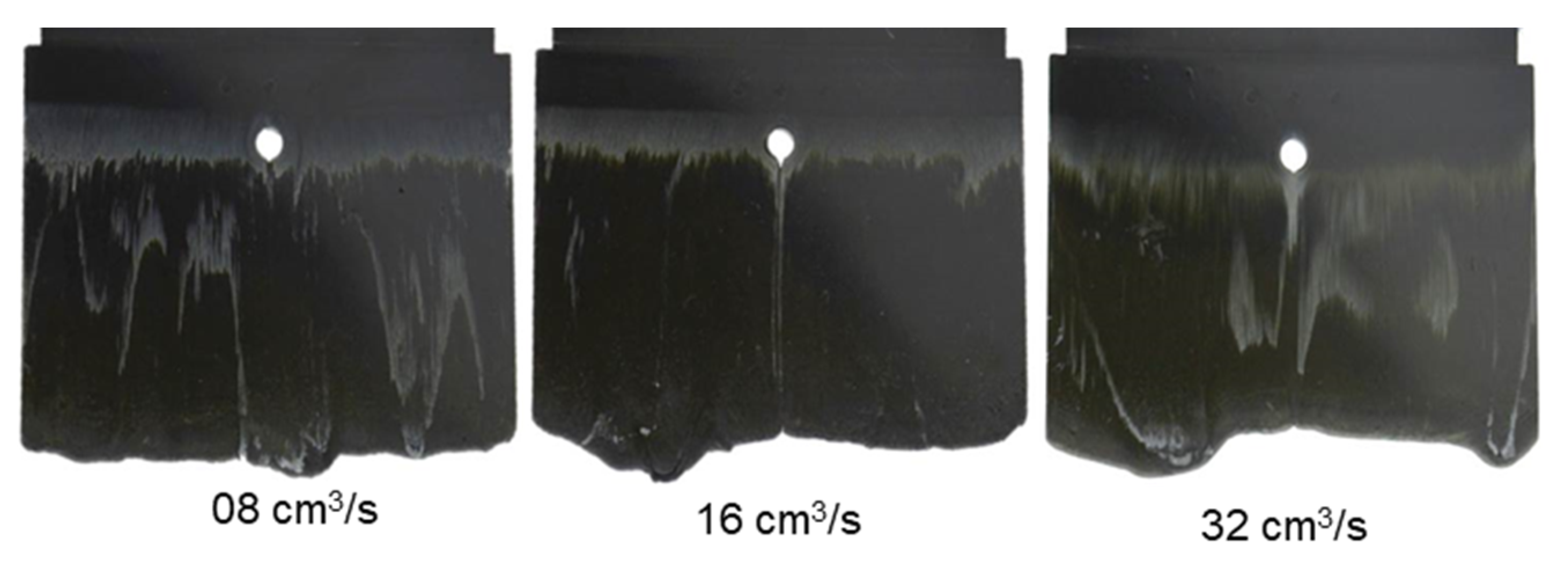

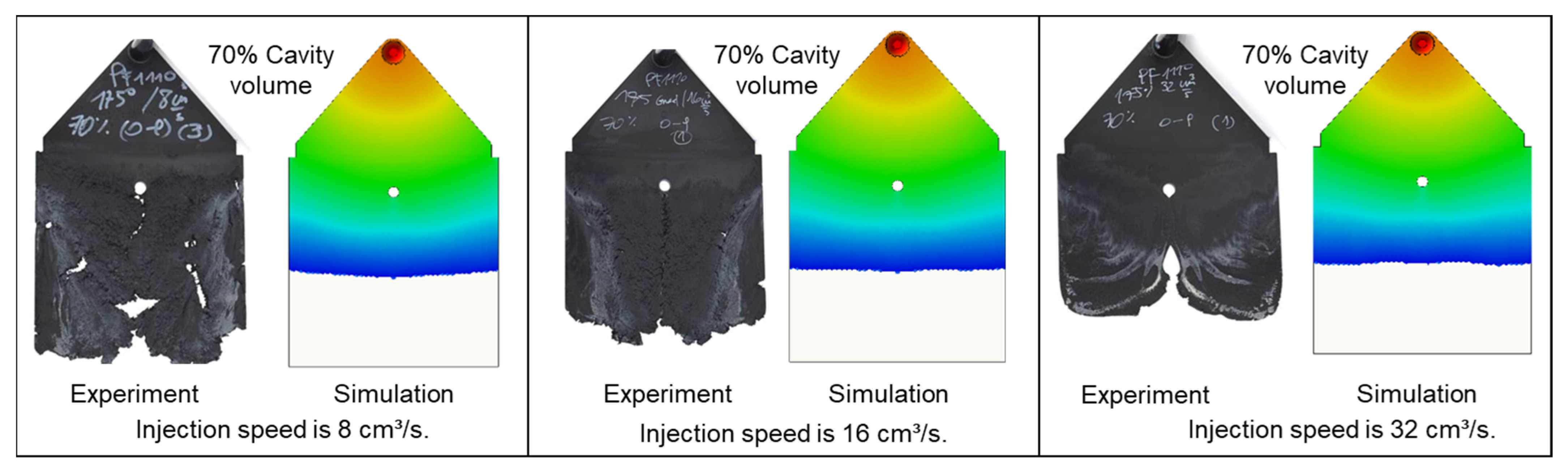

3.2. Influence of Injection Speeds on the Mechanisim of Weld Line Formation and Development

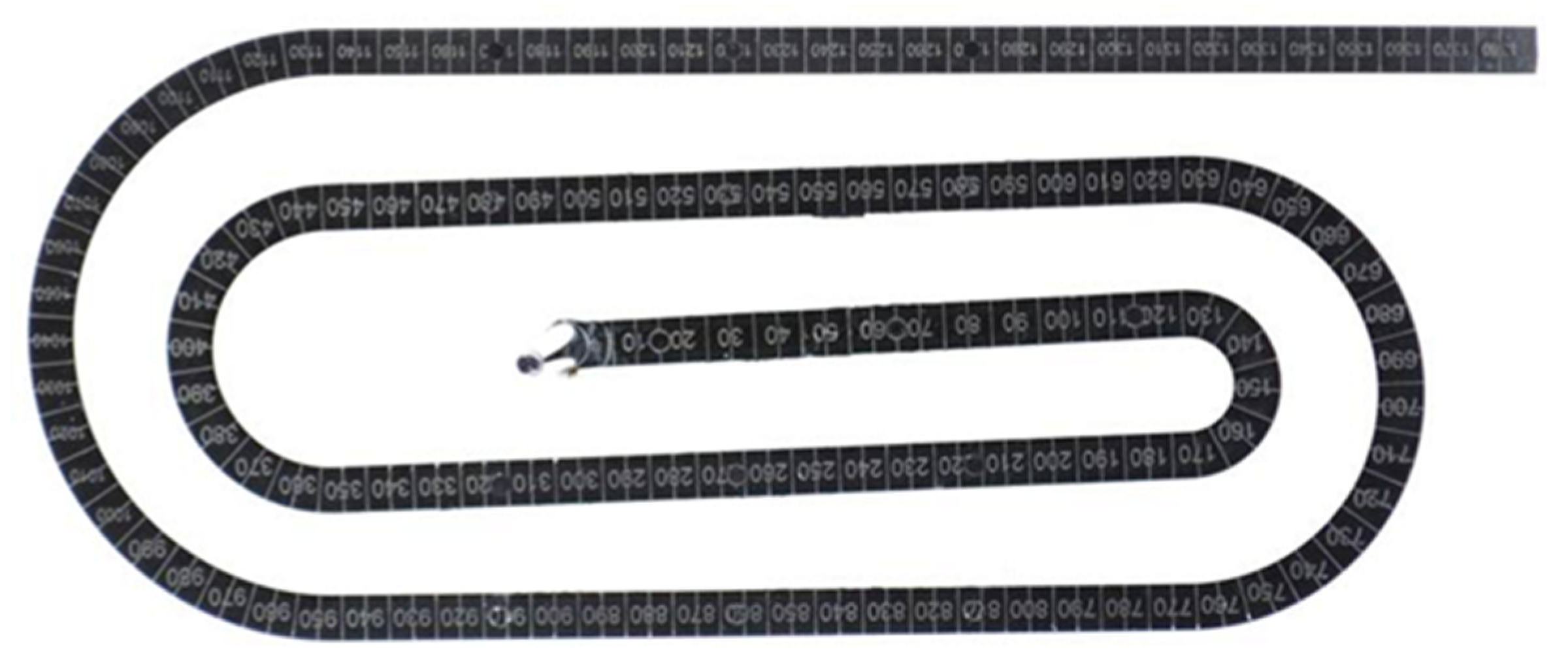

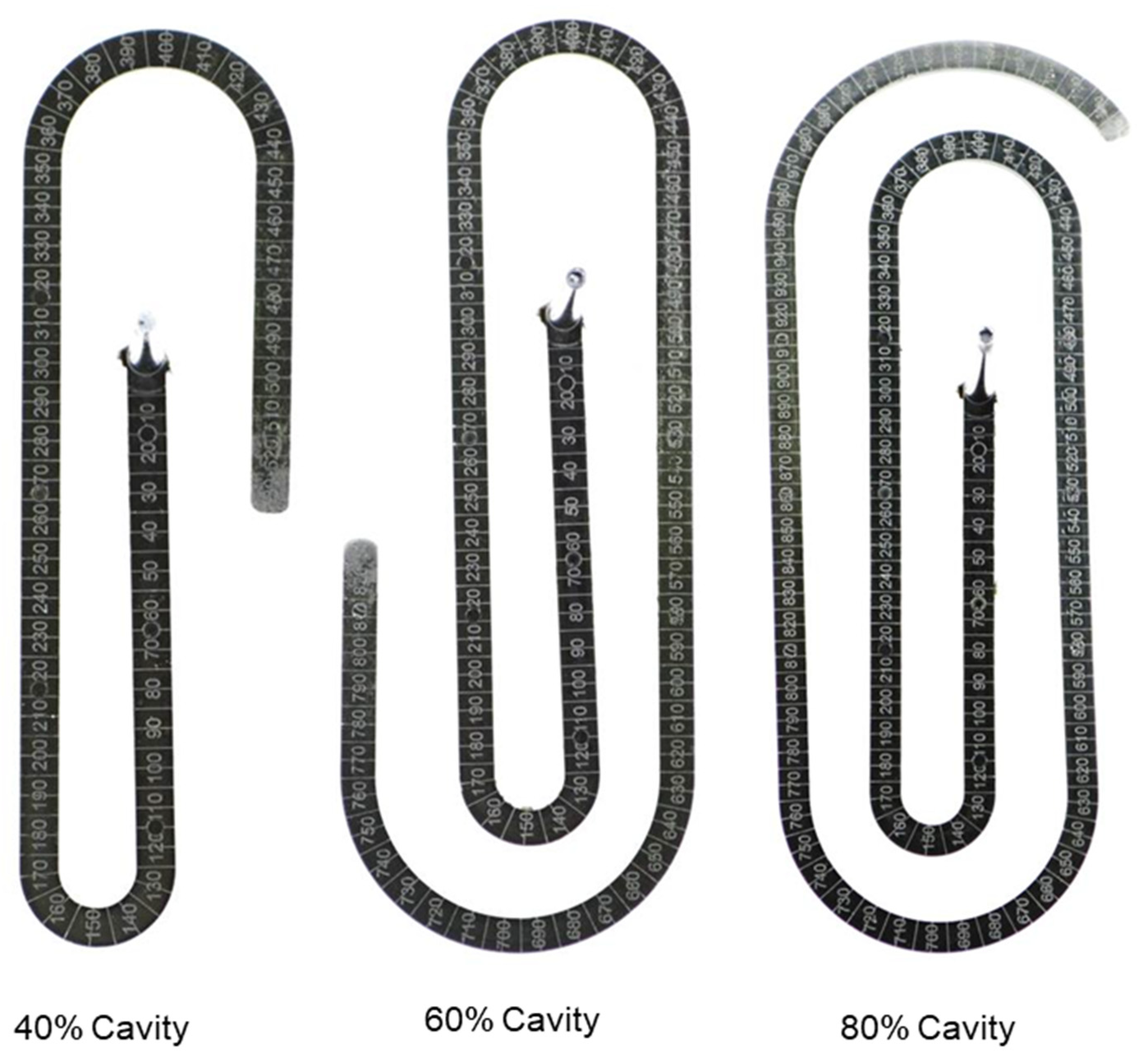

3.3. Mold-Filling Behavior in the Spiral Flow Part

3.3.1. Flow Length

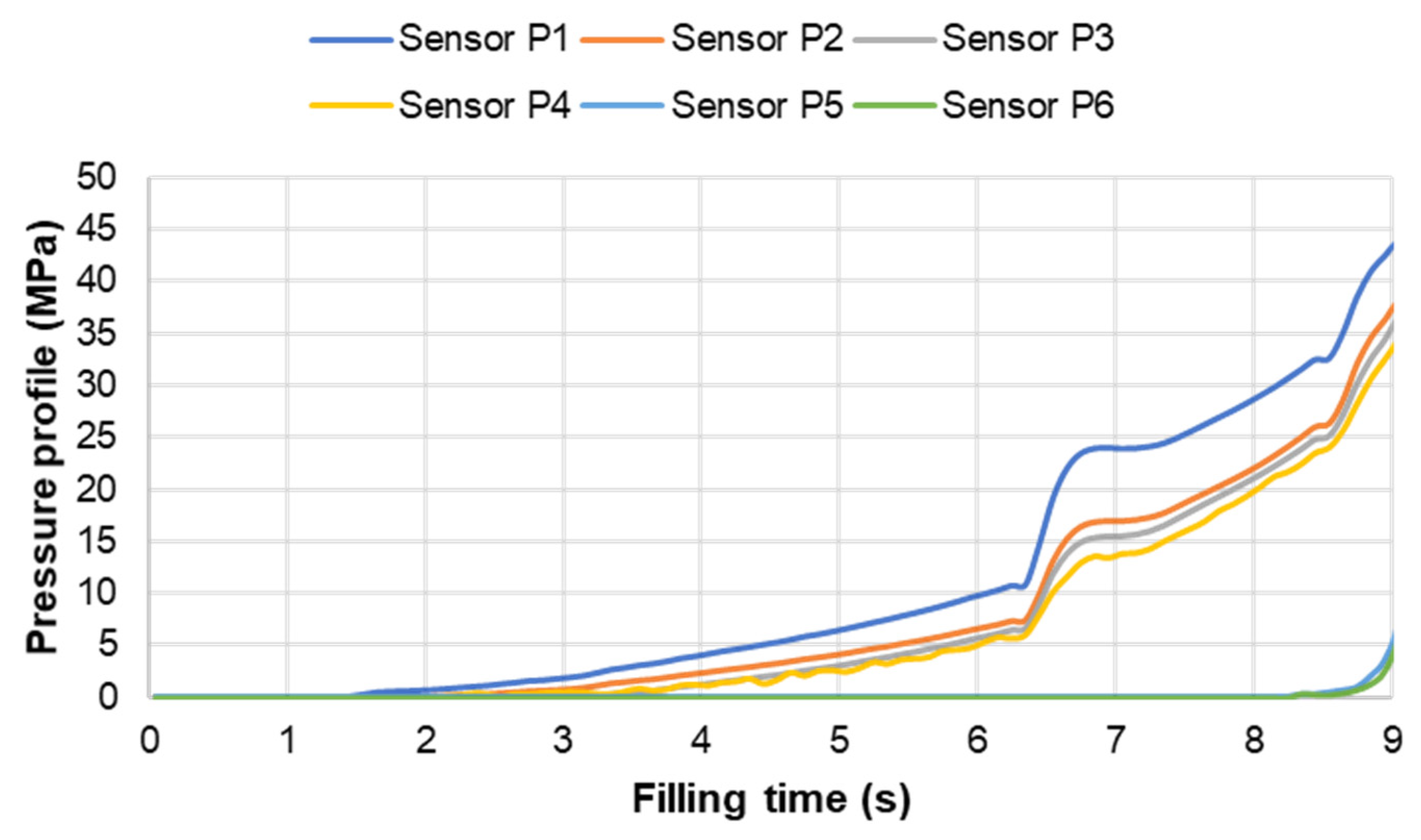

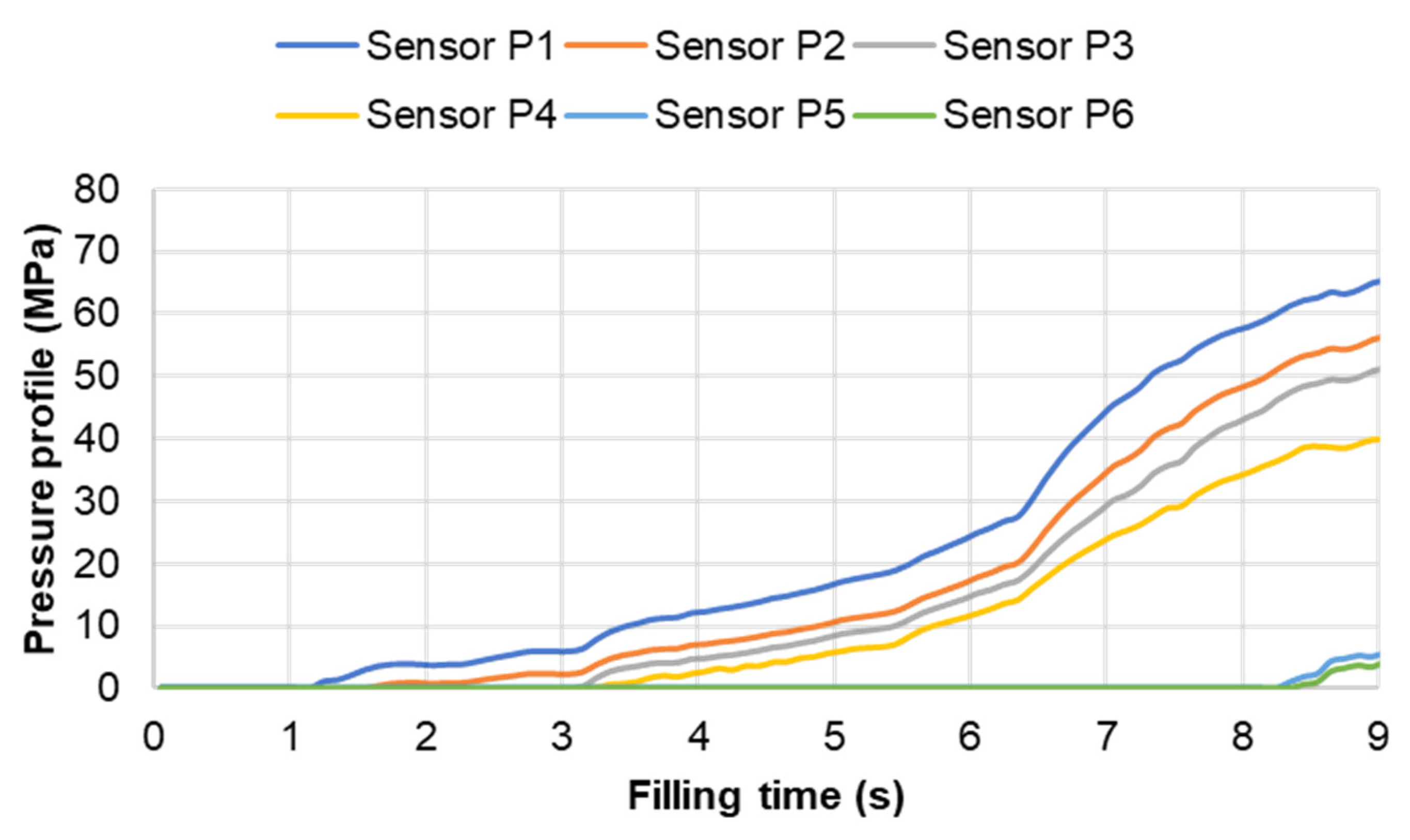

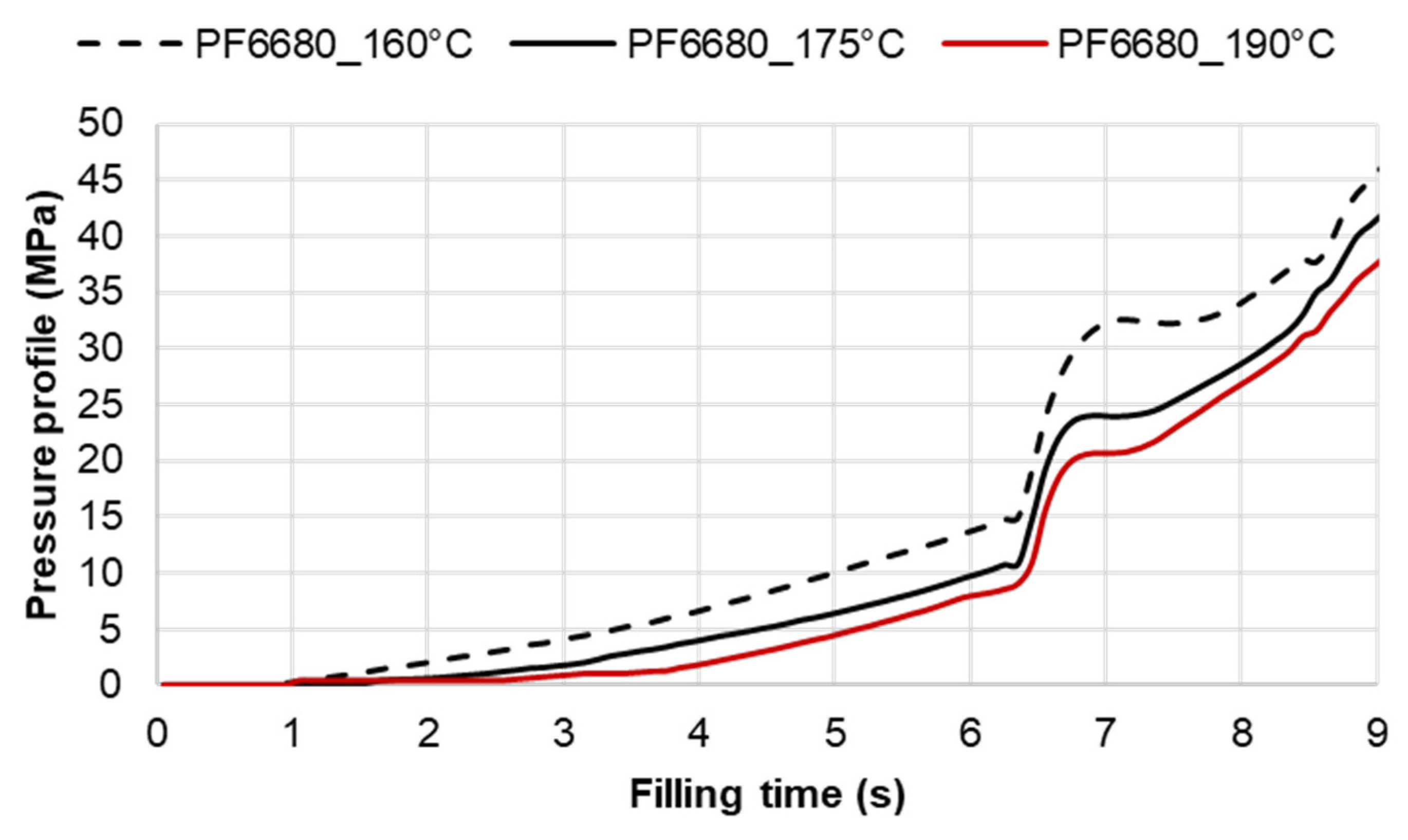

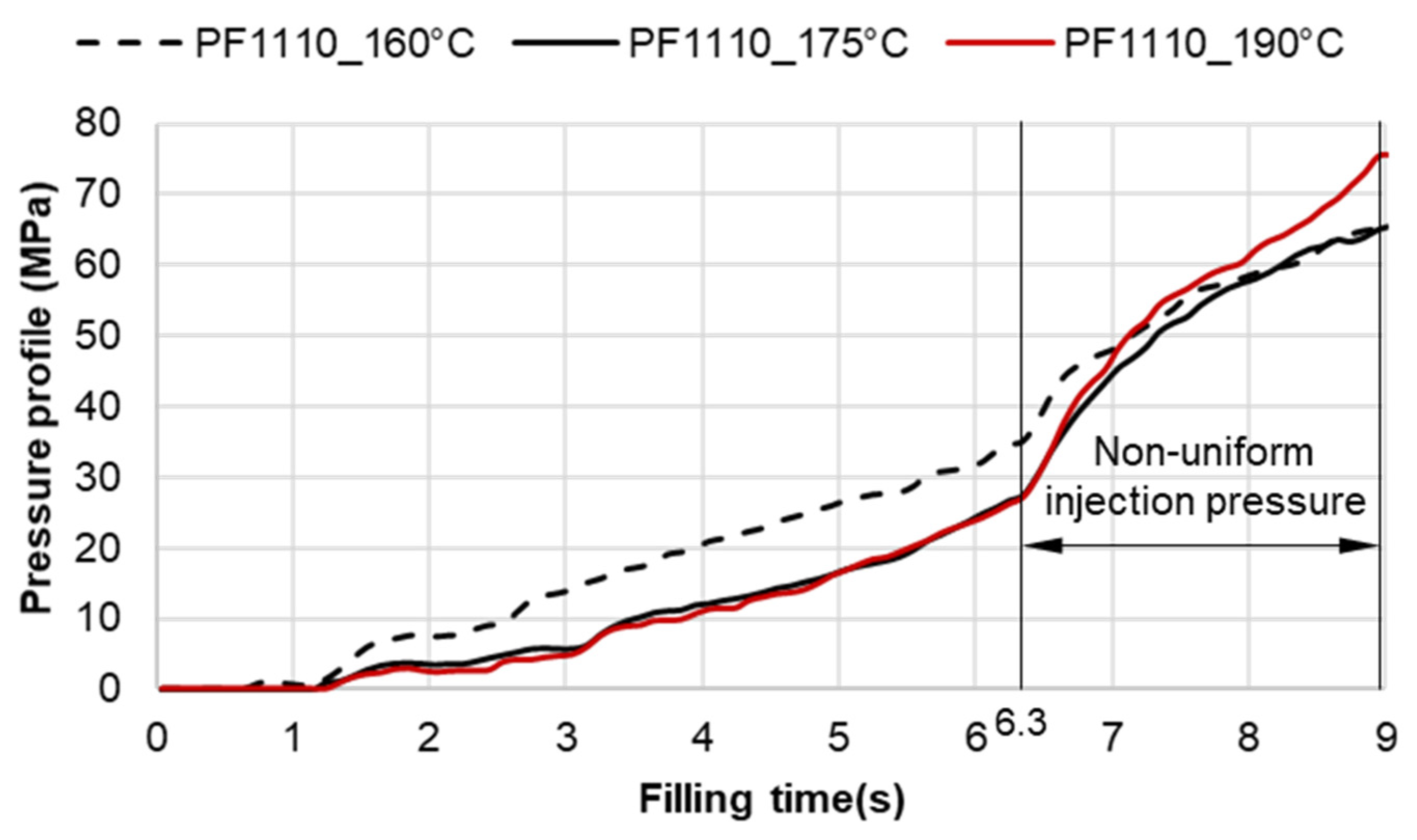

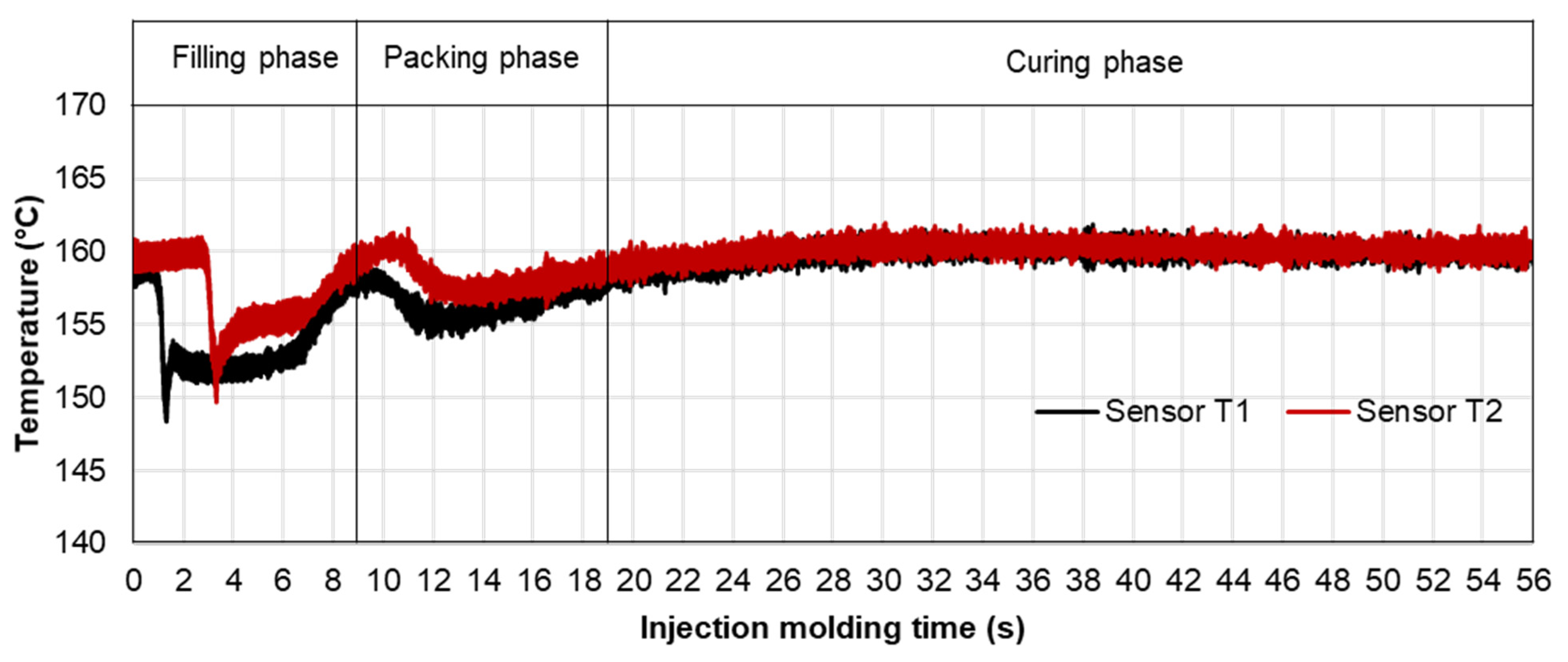

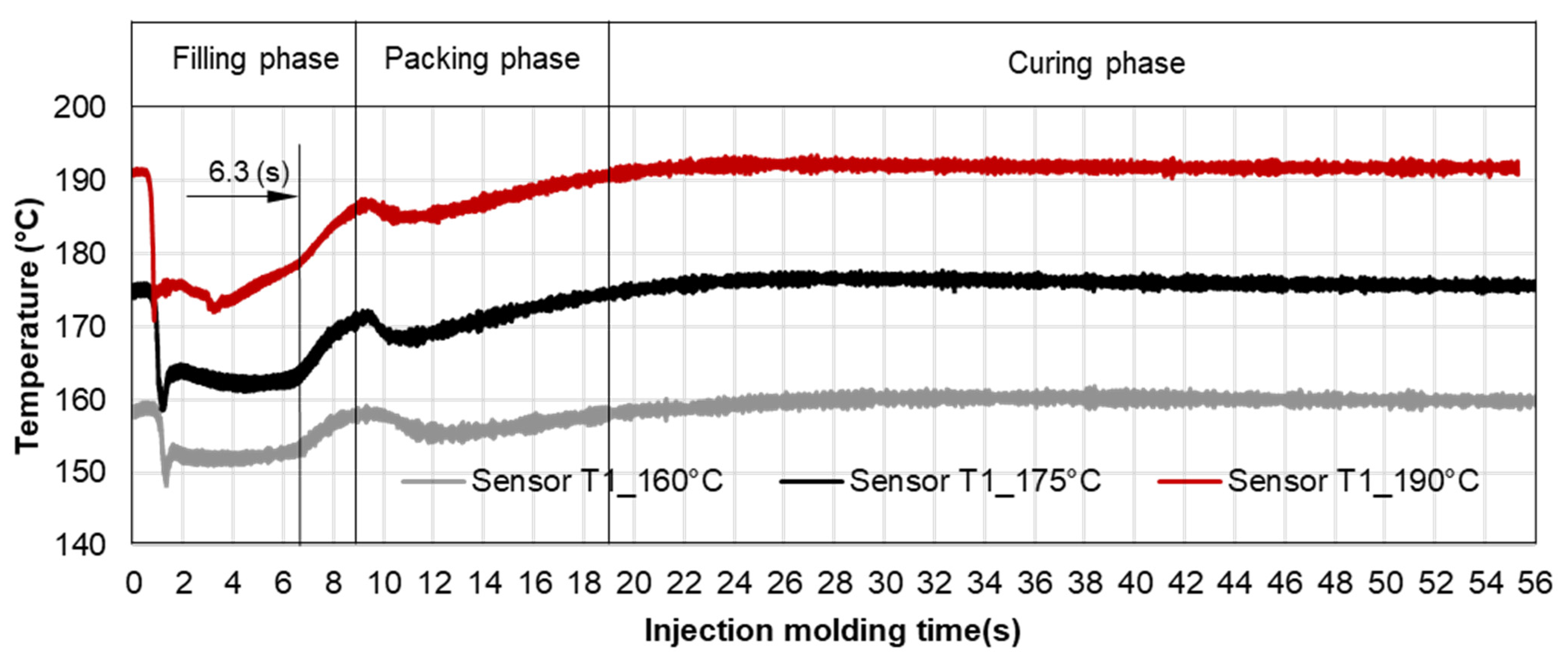

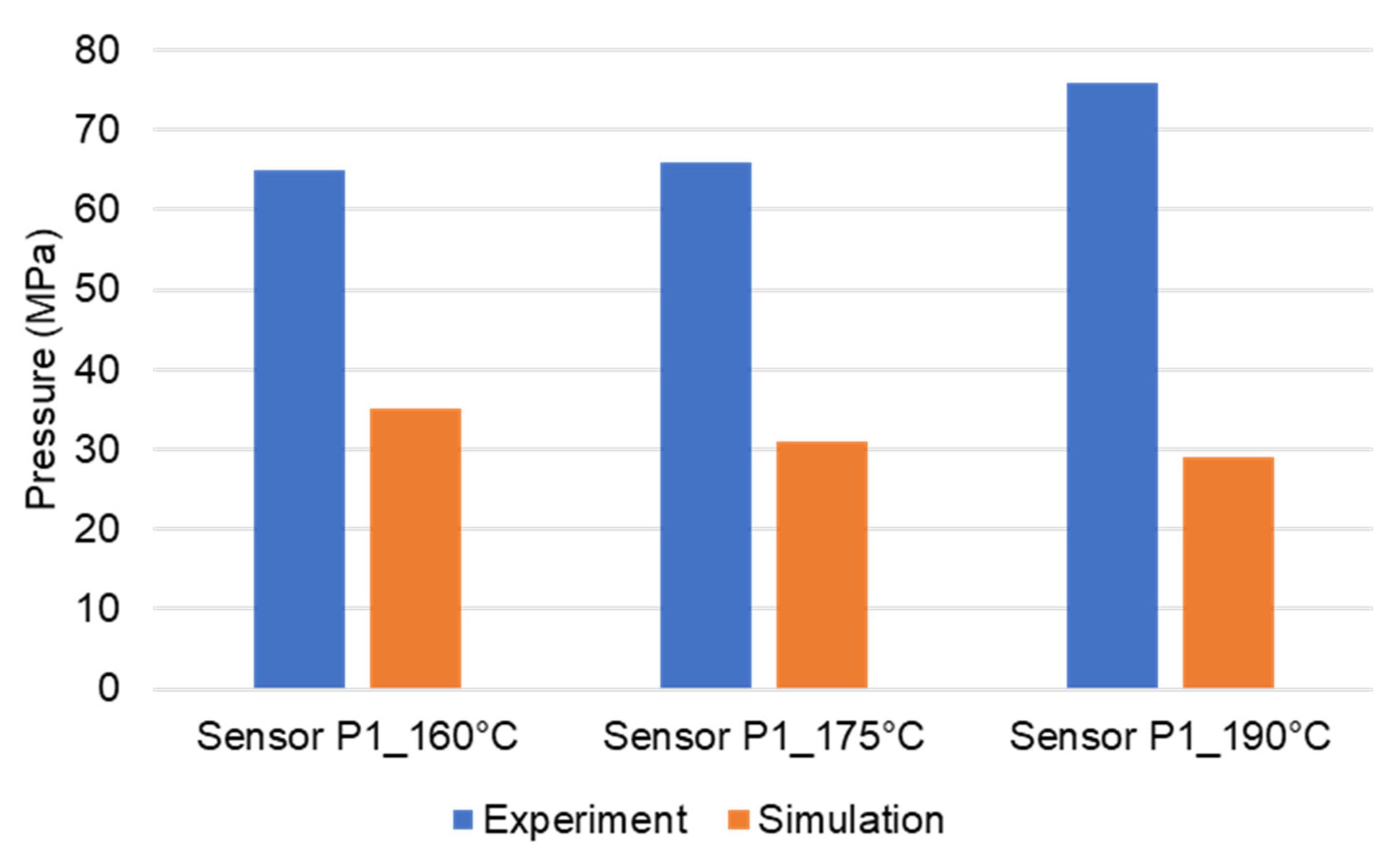

3.3.2. Cavity Pressure Profile and Melt Temperature Distribution

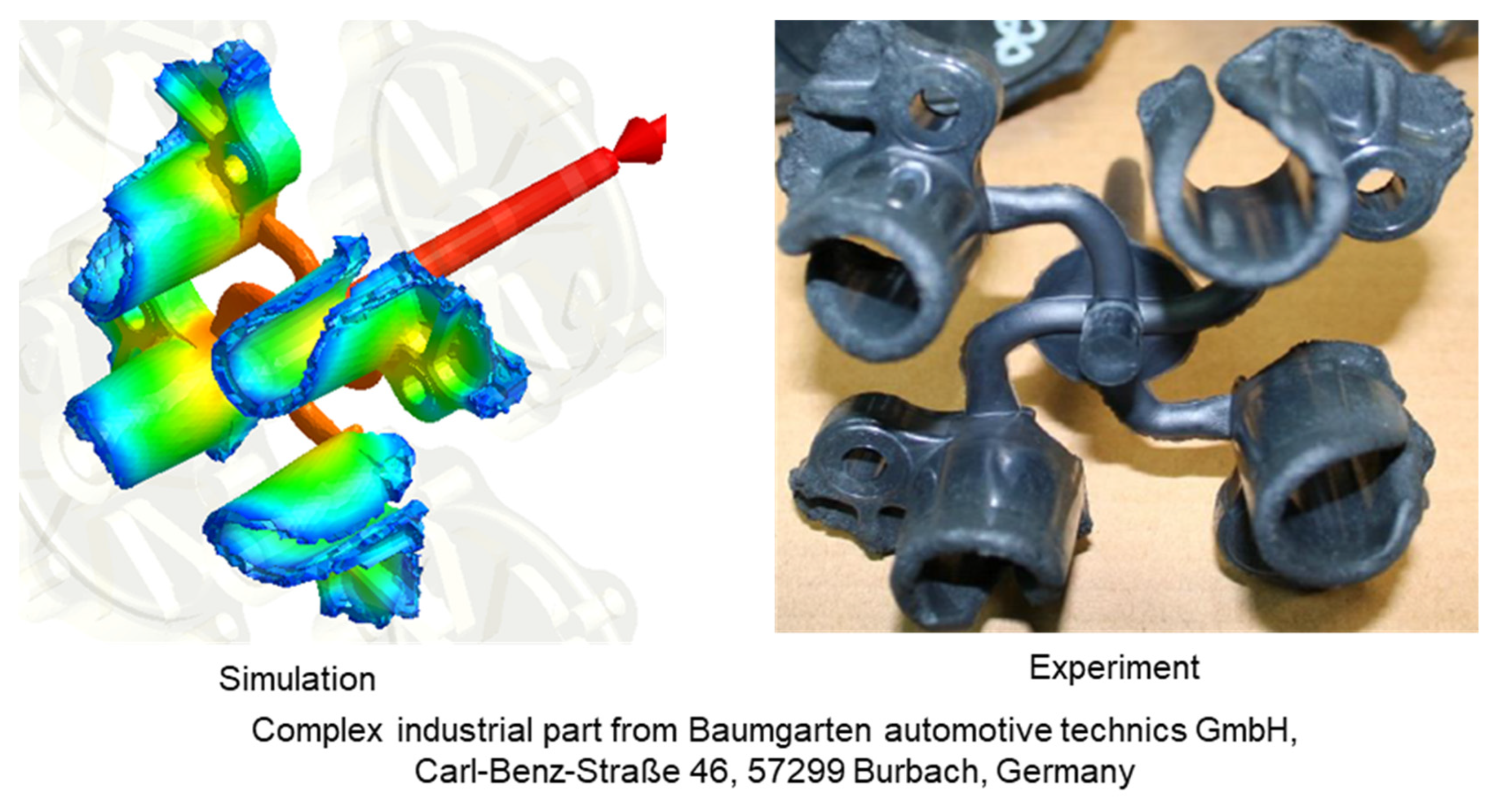

3.4. Validating Simulation Results and Adapting Simulation Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wieland, C.; Topic, N.; Hirz, J. More precision for sensitive fast curing compounds. Kunststoffe 2018, 8, 20–23. [Google Scholar]

- Osswald, T.A.; Menges, G. Materials Science of Polymers for Engineering; Carl Hanser: Munich, Germany, 2003. [Google Scholar]

- Haagh, G.A.A.V.; Peters, G.W.M.; Meijer, H.E.H. Reaction injection molding: Analyzing the filling stage of a complex product with highly viscous thermoset. Polym. Eng. Sci. 1996, 36, 2579–2588. [Google Scholar] [CrossRef]

- Pilato, L. Phenolic Resins: A Century of Progress; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Kazmer, D. Injection Molding Design Engineering; Carl Hanser: Munich, Germany, 2007. [Google Scholar]

- Malloy, R. Plastic Part Design for Injection Molding: An Introduction; Carl Hanser: Munich, Germany, 2011. [Google Scholar]

- Zheng, R.; Tanner, R.; Fan, X.J. Injection Molding: Integration of Theory and Modeling Methods; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Yao, L. Heat Transfer Process between Polymer and Cavity Wall during Injection Molding. Ph.D. Thesis, Universitätsverlag der Technischen Universität Chemnitz, TU Chemnitz, Chemnitz, Germany, 2015. [Google Scholar]

- Michaeli, W. Plastics Processing: An Introduction; Carl Hanser: Munich, Germany, 1995. [Google Scholar]

- Han, R.; Shi, L.; Gupta, M. Three-dimensional simulation of microchip encapsulation process. Polym. Eng. Sci. 2000, 40, 776–785. [Google Scholar] [CrossRef]

- Malguarnera, S.C.; Manisali, A.I.; Riggs, D.C. Weld line structures and properties in injection molded polypropylene. Polym. Eng. Sci. 1981, 21, 1149–1155. [Google Scholar] [CrossRef]

- Wu, C.Y.; Ku, C.C.; Pai, H.Y. Injection molding optimization with weld line design constraint using distributed multi-population genetic algorithm. Int. J. Adv. Manuf. Technol. 2011, 52, 131–141. [Google Scholar] [CrossRef]

- Ozcelik, B. Optimization of injection parameters for mechanical properties of specimens with weld line of polypropylene using Taguchi method. Int. Commun. Heat Mass Transfer. 2011, 38, 1067–1072. [Google Scholar] [CrossRef]

- Kitayama, S.; Tamada, K.; Takano, M.; Aiba, S. Numerical and experimental investigation on process parameters optimization in plastic injection molding for weld lines reduction and clamping force minimization. Int. J. Adv. Manuf. Technol. 2018, 97, 2087–2098. [Google Scholar] [CrossRef]

- Xie, L.; Ziegmann, G. Mechanical properties of the weld line defect in micro injection molding for various nano filled polypropylene composites. J. Alloys Compd. 2011, 509, 226–233. [Google Scholar] [CrossRef]

- Xie, L.; Ziegmann, G. A visual mold with variotherm system for weld line study in micro injection molding. Microsyst. Technol. 2008, 14, 809–814. [Google Scholar] [CrossRef]

- Kagitci, Y.C.; Tarakcioglu, N. The effect of weld line on tensile strength in a polymer composite part. Int. J. Adv. Manuf. Technol. 2016, 85, 1125–1135. [Google Scholar] [CrossRef]

- Tosello, G.; Gava, A.; Hansen, H.N.; Lucchetta, G. Study of process parameters effect on the filling phase of micro-injection moulding using weld lines as flow markers. Int J Adv Manuf Technol. 2010, 47, 81–97. [Google Scholar] [CrossRef]

- Nguyen-Chung, T.; Plichta, C.; Mennig, G. Flow disturbance in polymer melt behind an obstacle. Rheologica Acta. 1998, 37, 299–305. [Google Scholar] [CrossRef]

- Nguyen-Chung, T. Strömungsanalyse der Bindenahtformation Beim Spritzgießen von Thermoplastischen Kunststoffen. Ph.D. Thesis, Universitätsverlag der Technischen Universität Chemnitz, TU Chemnitz, Chemnitz, Germany, 2002. [Google Scholar]

- Nguyen-Chung, T. Flow analysis of the weld line formation during injection moulding of thermoplastics. Rheol. Acta 2004, 43, 240–245. [Google Scholar] [CrossRef]

- Malguarnera, S.; Manisali, A. The effects of processing parameters on the tensile properties of weld lines in injection molded thermoplastics. Polym. Eng. Sci. 1981, 21, 586–593. [Google Scholar] [CrossRef]

- Malguarnera, S.C. Weld lines in polymer processing. Polym. Plast. Technol. Eng. 1982, 18, 1–45. [Google Scholar] [CrossRef]

- Onken, J.; Hopmann, C. Prediction of weld line strength in injection-moulded parts made of unreinforced amorphous thermoplastics. Int. Polym. Sci. Technol. 2016, 43, T1. [Google Scholar] [CrossRef]

- Tomari, K.; Tonogai, S.; Harada, T.; Hamada, H.; Lee, K.; Morii, T.; Maekawa, Z. The V-notch at weld lines in polystyrene injection moldings. Polym. Eng. Sci. 1990, 30, 931–936. [Google Scholar] [CrossRef]

- Zhao, Y.; Mattner, T.; Drummer, D. Investigation of the effects of pre-cross-linked thermoset molding compounds on weld line strength in injection molding. Int. J. Adv. Manuf. Technol. 2019, 105, 1723–1733. [Google Scholar] [CrossRef]

- Tran, N.T.; Gehde, M. Visualization of wall slip during thermoset phenolic resin injection molding. Int. J. Adv. Manuf. Technol. 2018, 95, 4023–4029. [Google Scholar] [CrossRef]

- Tran, N.T.; Gehde, M. Creating material data for thermoset injection molding simulation process. Polym. Test. 2019, 73, 284–292. [Google Scholar] [CrossRef]

- Tran, N.T. Creating Material Properties for Thermoset Injection Molding Simulation Process. Ph.D. Thesis, Universitätsverlag der Technischen Universität Chemnitz, TU Chemnitz, Chemnitz, Germany, 2020. [Google Scholar]

- Tran, N.T.; Gehde, M. Bewertung der aktuellen eingesetzten reaktiven Viskositätsmodelle zur rheologischen Simulation im Spritzgießprozess. In Technomer Fachtagung über Verarbeitung und Anwendung von Polymeren; Technischen Universität Chemnitz: Chemnitz, Germany, 2021. [Google Scholar]

- Tran, N.T.; Gehde, M. Modelling of rheological and thermal properties for thermoset injection molding simulation process (the full article has been accepted for publication). In Proceedings of the AIP Publisher Conference Proceedings, 37th International Conference of the Polymer Processing Society, Fukuoka, Japan, 11–15 April 2022. [Google Scholar]

- Tran, N.T.; Seefried, A.; Gehde, M. Investigation of the Influence of Fiber Content, Processing Conditions and Surface Roughness on the Polymer Filling Behavior in Thermoset Injection Molding. Polymers 2023, 15, 1244. [Google Scholar] [CrossRef] [PubMed]

- Koszkul, J.; Nabialek, J. Viscosity models in simulation of the filling stage of the injection molding process. J. Mater. Process. Technol. 2004, 157, 183–187. [Google Scholar] [CrossRef]

- Englich, S. Strukturbildung bei der Verarbeitung von glasfasergefüllten Phenolformaldehydharzformmassen. Ph.D. Thesis, Universitätsverlag der Technischen Universität Chemnitz, TU Chemnitz, Chemnitz, Germany, 2015. [Google Scholar]

- Scheffler, T. Werkstoffeinflüsse auf den Spritzgussprozess von hochgefüllten Phenol-Formaldehydharz-Formmassen. Ph.D. Thesis, Technische Universität Chemnitz, Germany, 2018. [Google Scholar]

- Marquardt, D.W. An algorithm for least–sqaures eatimation of nonlinear parameters. J. Soc. Indust. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Raffaele, D.; Gilles, D. Cure kinetics of a polysilazane system: Experimental characterization and numerical modelling. Eur. Polym. J. 2016, 76, 40–52. [Google Scholar]

- Kennedy, P.K.; Zheng, R. Flow Analysis of Injection Molds; Carl Hanser: Munich, Germany, 2013. [Google Scholar]

| Abbreviation | Commercial Name | Manufacturer |

|---|---|---|

| PF-GF25 + GB30 | Bakelite PF6680 | Bakelite |

| PF-GF30 + GB30 | Bakelite PF6506 | Bakelite |

| PF-GF35 + GB45 | Bakelite PF1110 | Bakelite |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, N.T.; Seefried, A.; Gehde, M.; Hirz, J.; Klaas, D. Flow Disturbance Characterization of Highly Filled Thermoset Injection Molding Compounds behind an Obstacle and in a Spiral Flow Part. Polymers 2023, 15, 2984. https://doi.org/10.3390/polym15142984

Tran NT, Seefried A, Gehde M, Hirz J, Klaas D. Flow Disturbance Characterization of Highly Filled Thermoset Injection Molding Compounds behind an Obstacle and in a Spiral Flow Part. Polymers. 2023; 15(14):2984. https://doi.org/10.3390/polym15142984

Chicago/Turabian StyleTran, Ngoc Tu, Andreas Seefried, Michael Gehde, Jan Hirz, and Dietmar Klaas. 2023. "Flow Disturbance Characterization of Highly Filled Thermoset Injection Molding Compounds behind an Obstacle and in a Spiral Flow Part" Polymers 15, no. 14: 2984. https://doi.org/10.3390/polym15142984

APA StyleTran, N. T., Seefried, A., Gehde, M., Hirz, J., & Klaas, D. (2023). Flow Disturbance Characterization of Highly Filled Thermoset Injection Molding Compounds behind an Obstacle and in a Spiral Flow Part. Polymers, 15(14), 2984. https://doi.org/10.3390/polym15142984