Methodologies to Evaluate the Micromechanics Flexural Strength Properties of Natural-Fiber-Reinforced Composites: The Case of Abaca-Fiber-Reinforced Bio Polyethylene Composites

Abstract

1. Introduction

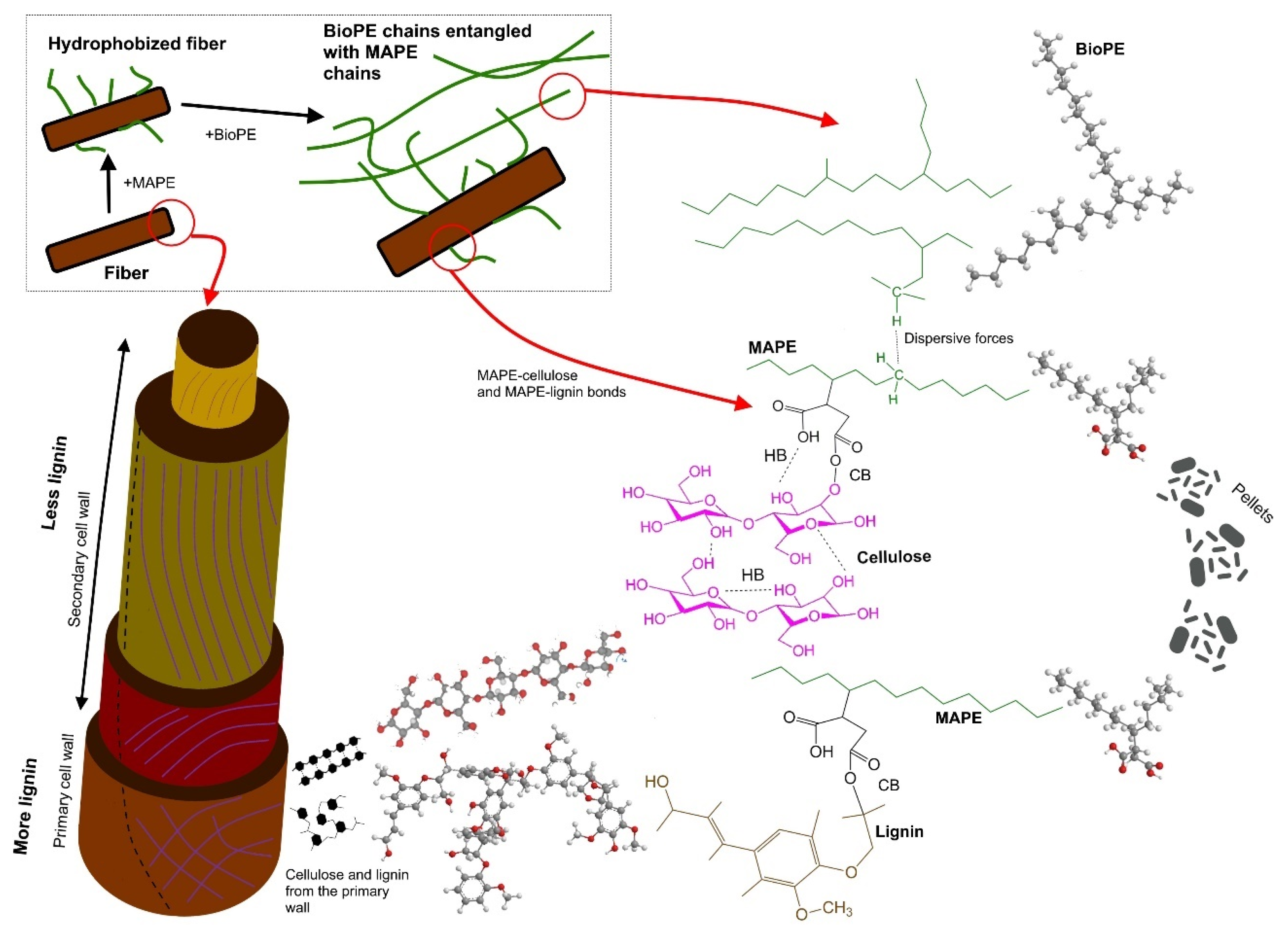

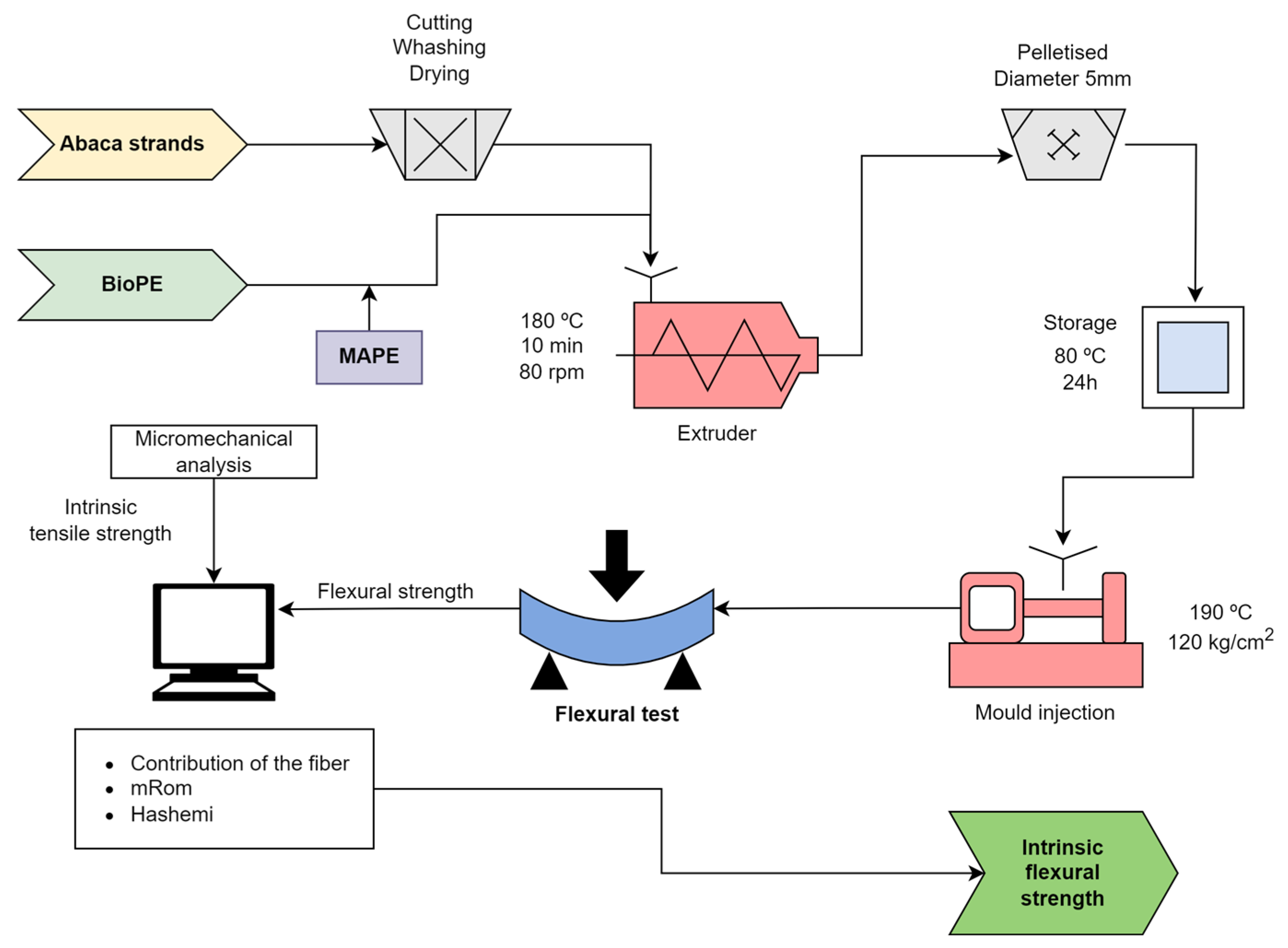

2. Materials and Methods

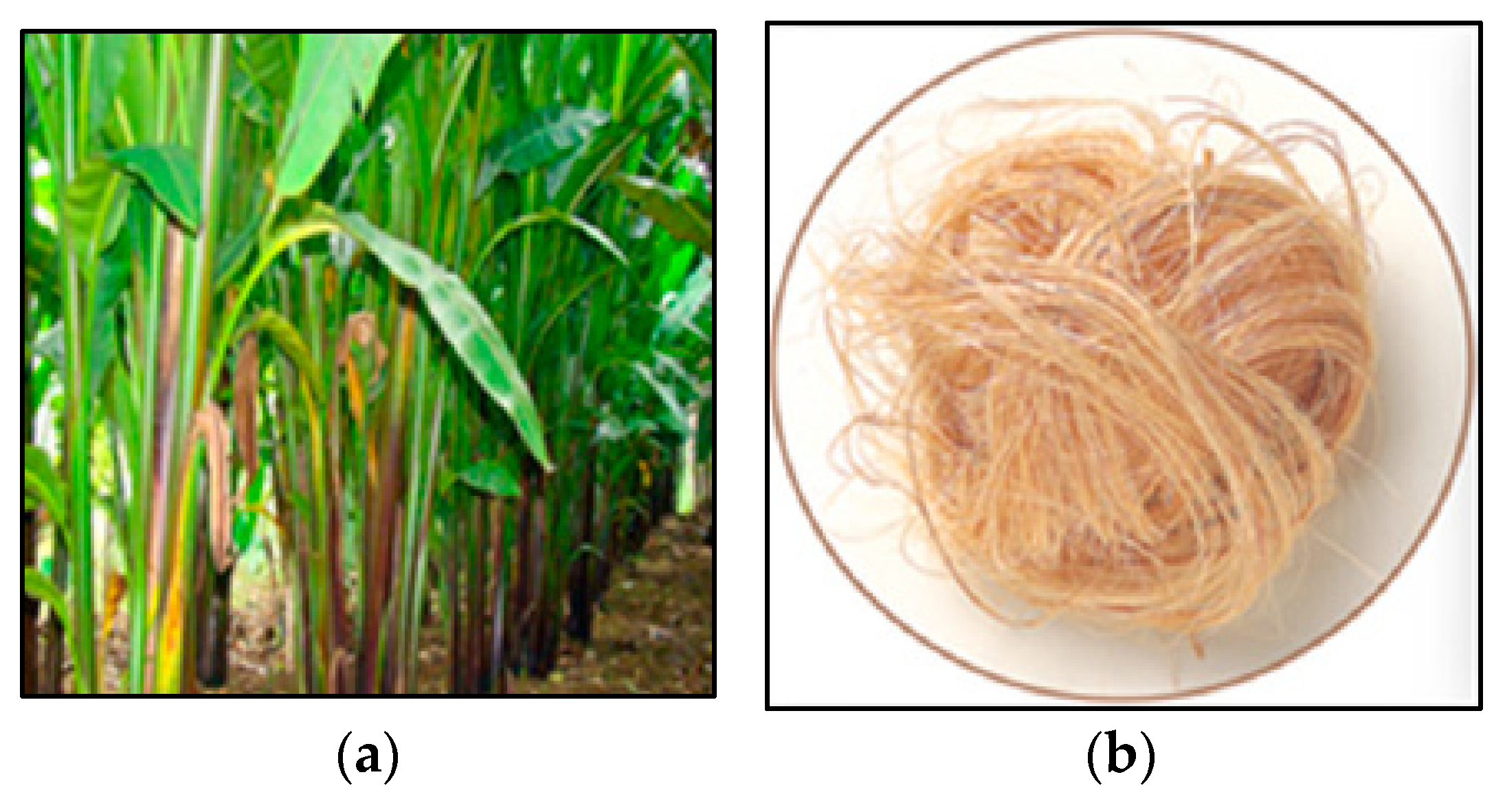

2.1. Materials

2.2. Composite Fabrication

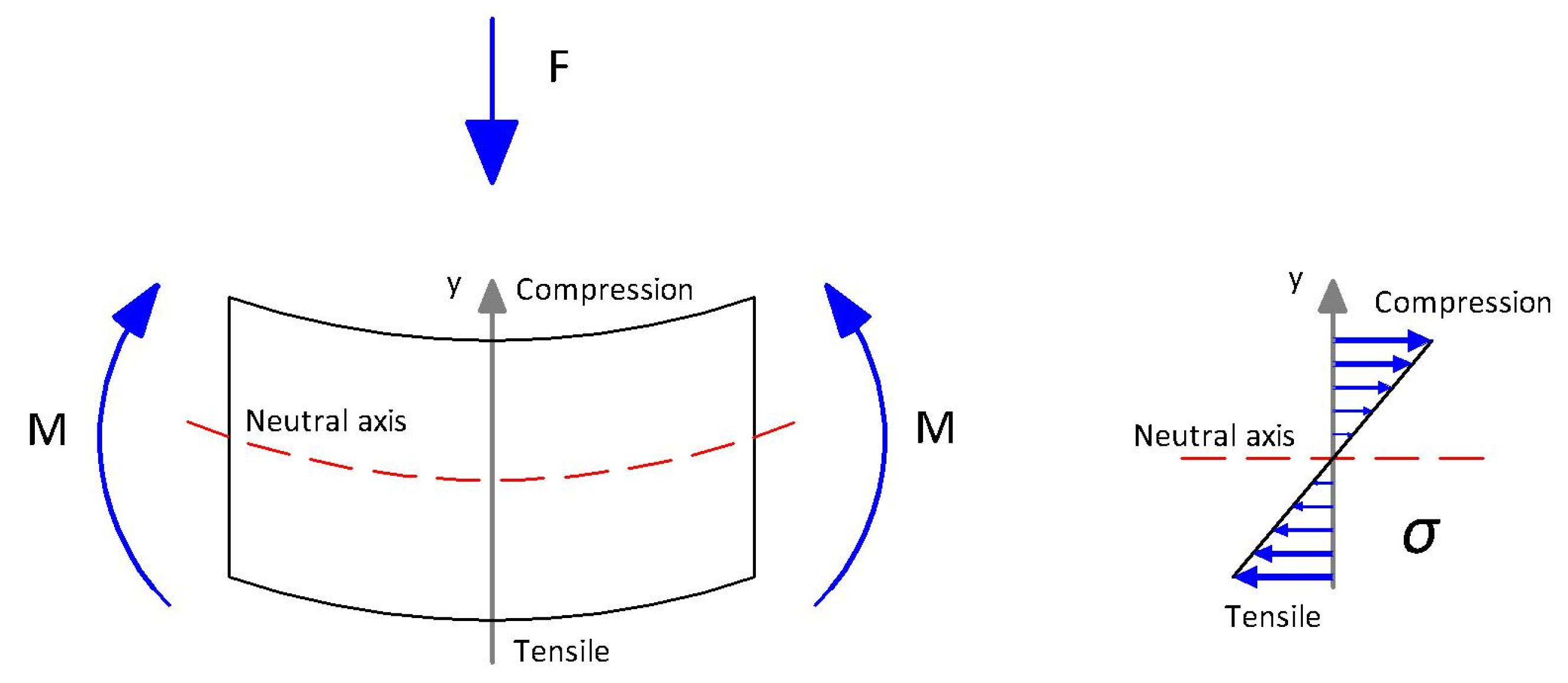

2.3. Flexural Testing of the Composites

3. Flexural Strength Micromechanics Models

4. Results and Discussion

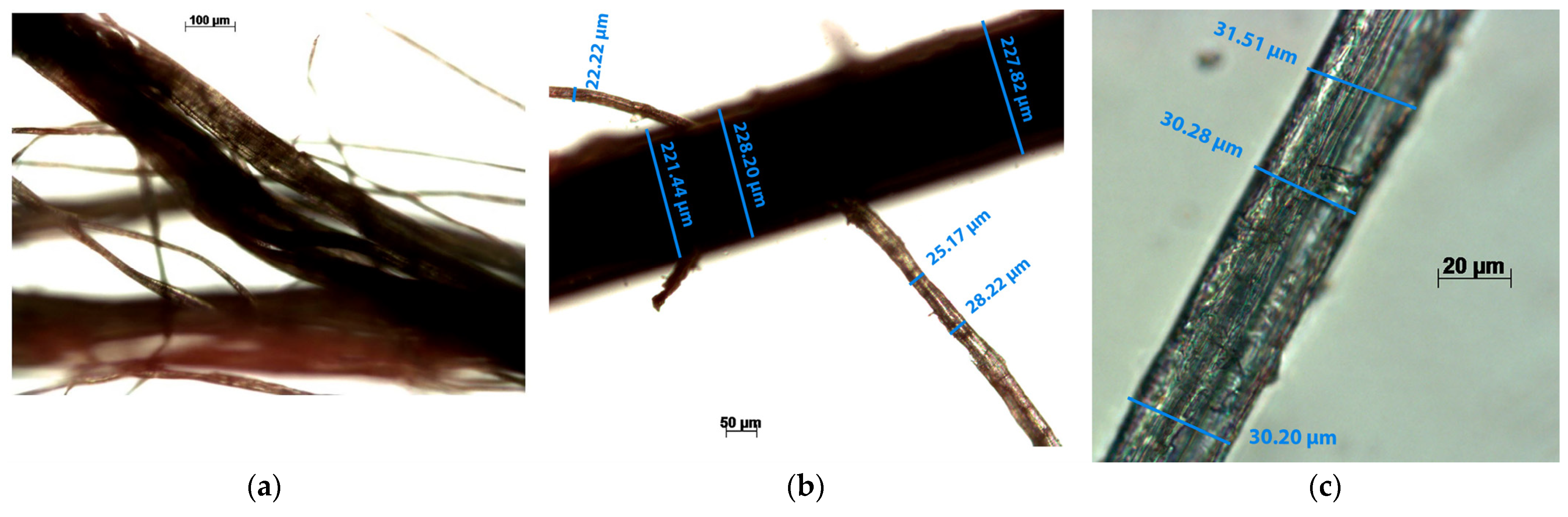

4.1. Characterization of the Reinforcing Fibers

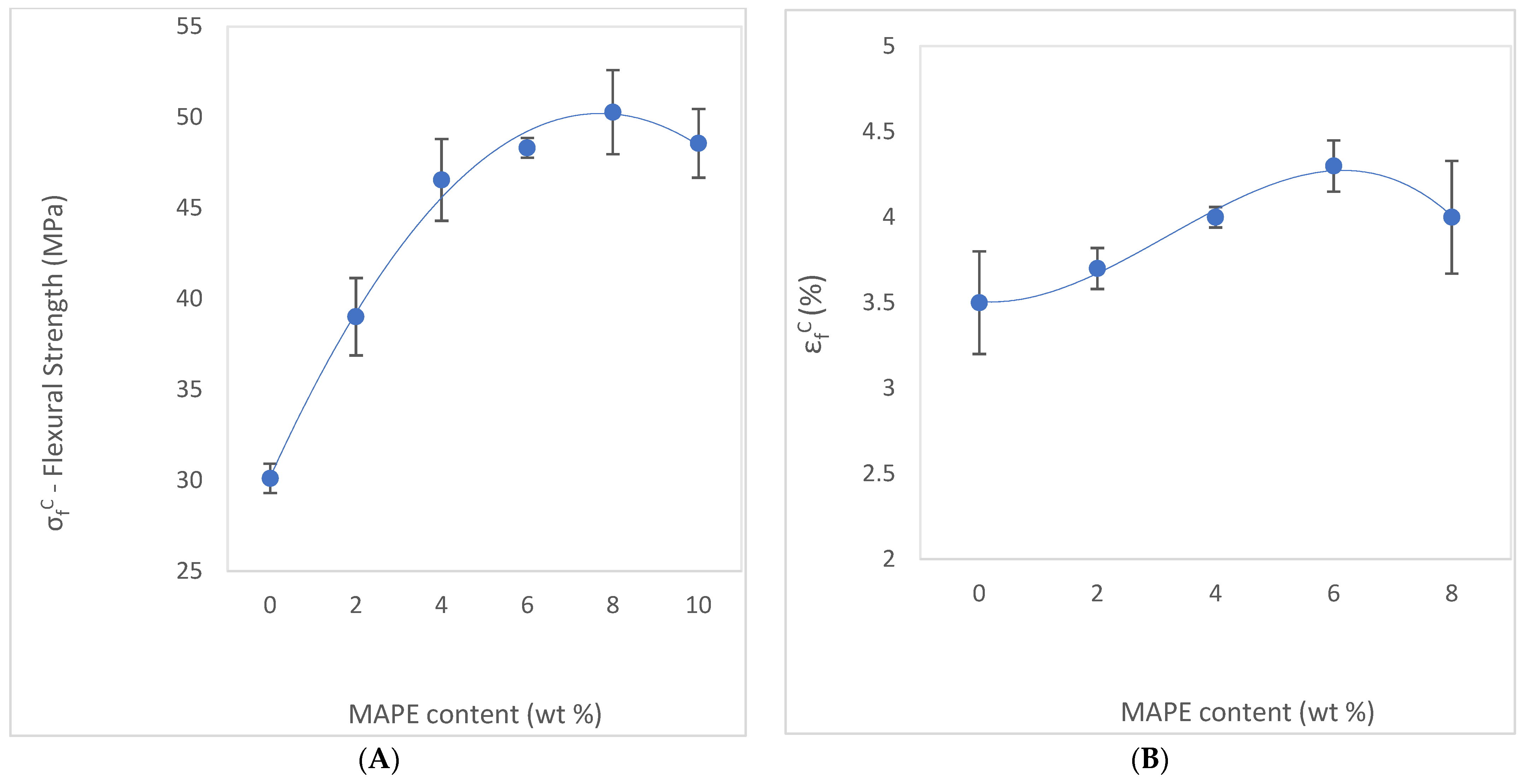

4.2. Effect of MAPE Coupling Agent on Flexural Properties

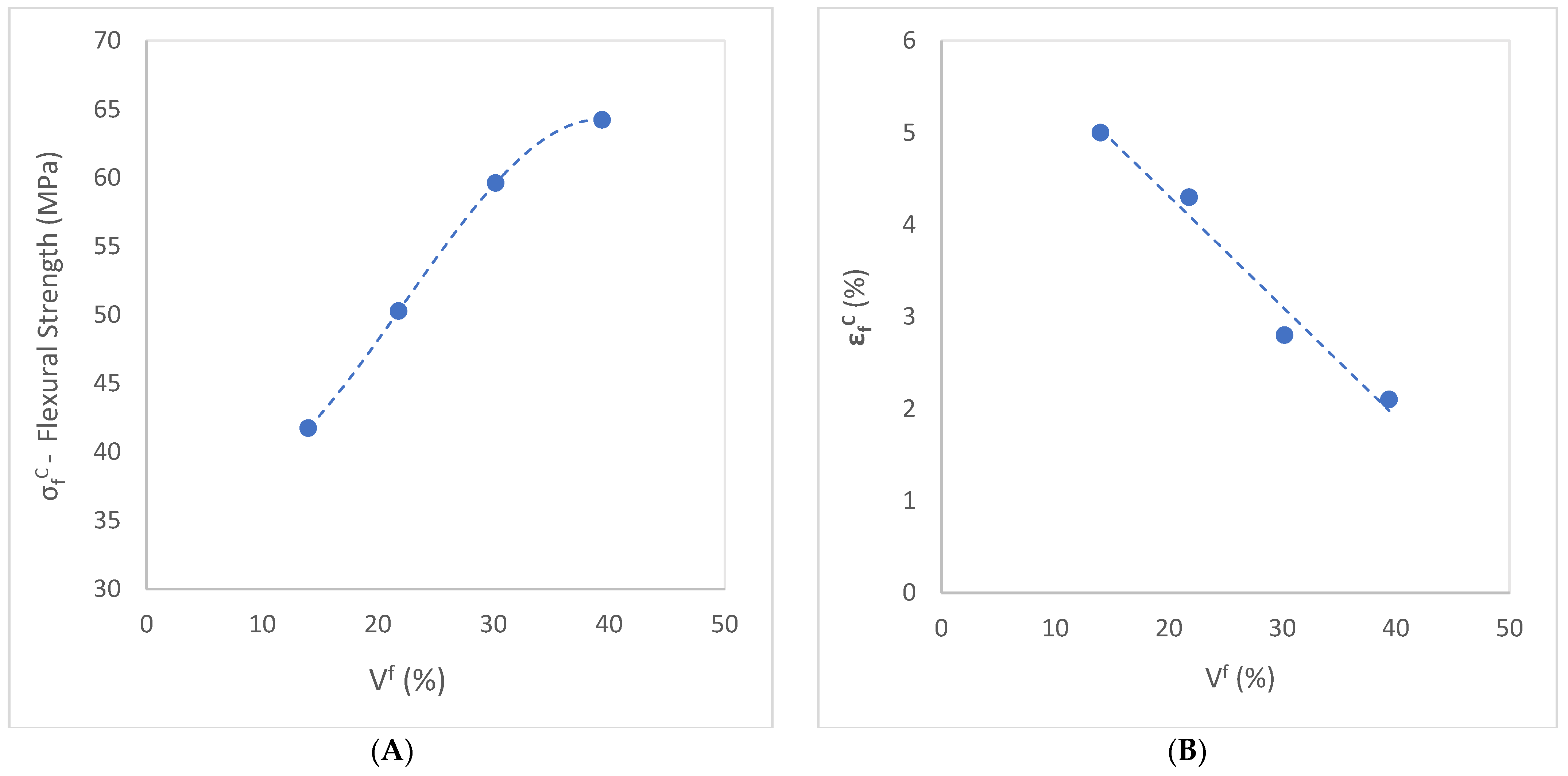

4.3. Effect of Fiber Content on Flexural Properties

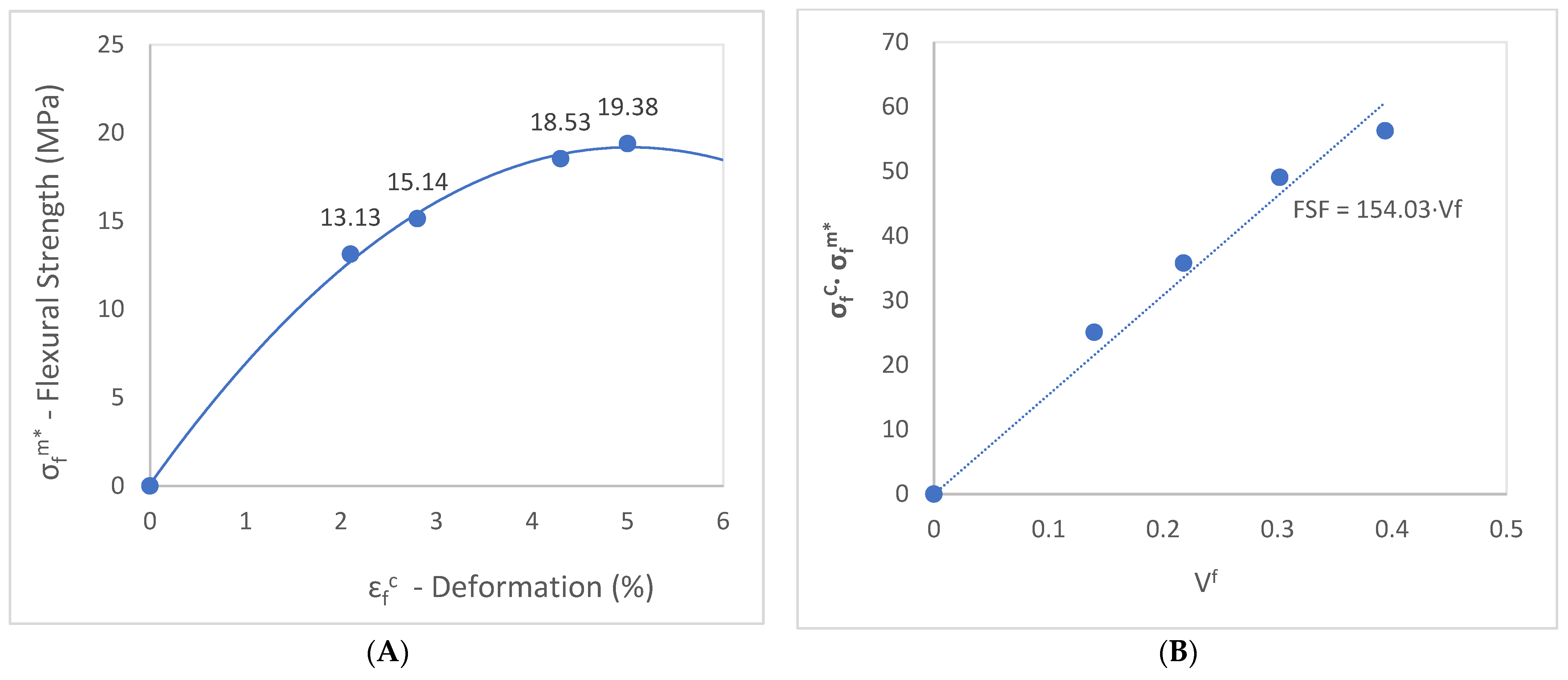

4.4. Modeling of the Flexural Strength of the Composites

4.4.1. Modeling of the Composite regarding MAPE Content

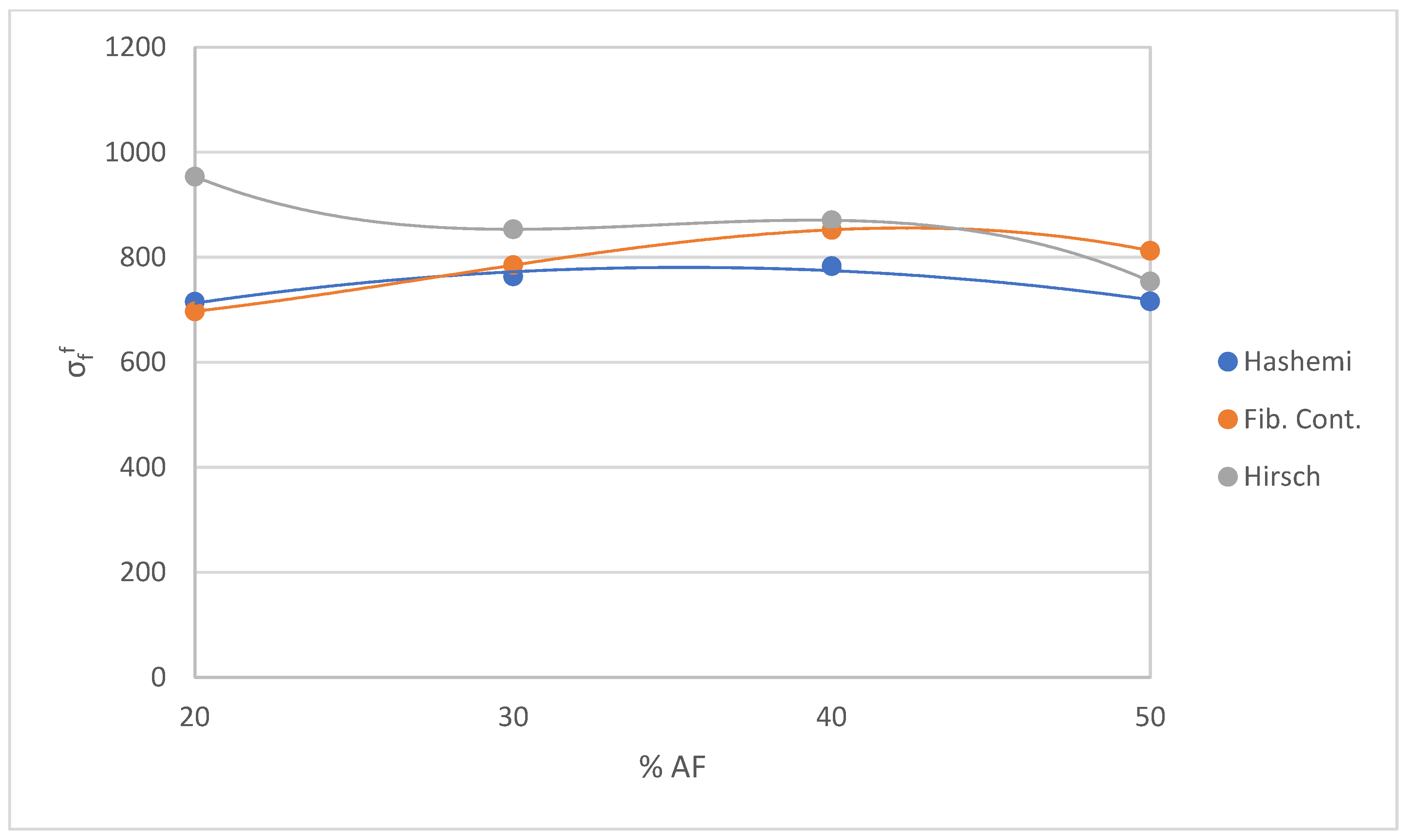

4.4.2. Modeling of the Composite regarding AF Content

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gironès, J.; Lopez, J.P.; Vilaseca, F.; Bayer, R.; Herrera-Franco, P.J.; Mutjé, P. Biocomposites from Musa textilis and polypropylene: Evaluation of flexural properties and impact strength. Compos. Sci. Technol. 2011, 71, 122–128. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Franciszczak, P.; Osman, Z.; Elbadawi, M. Polypropylene biocomposites reinforced with softwood, abaca, jute, and kenaf fibers. Ind. Crops Prod. 2015, 70, 91–99. [Google Scholar] [CrossRef]

- Moreno, L.O.; Parac, A.A.; Ocon, F.L.; Gapasin Leyte, R.M. Fiber characteristics of promising abaca (Musa textilis Nee) accessions in NARC [National Abaca Research Center] germplasm suited for specific industry end uses. Philipp. J. Crop Sci. 2010, 35, 113. [Google Scholar]

- Lalusin, A.G.; Villavicencio, M.L.H. Abaca (Musa textilis Nee) Breeding in the Philippines BT—Industrial Crops: Breeding for BioEnergy and Bioproducts; Cruz, V.M.V., Dierig, D.A., Eds.; Springer: New York, NY, USA, 2015; pp. 265–289. ISBN 978-1-4939-1447-0. [Google Scholar]

- Mwaikambo, L.Y. Review of the history, properties and application of plant fibres. African J. Sci. Technol. 2006, 7, 120–133. [Google Scholar]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Storz, H.; Vorlop, K.D. Bio-based plastics: Status, challenges and trends. Landbauforsch. Volkenrode 2013, 63, 321–332. [Google Scholar] [CrossRef]

- Nishino, T.; Hirao, K.; Kotera, M.; Nakamae, K.; Inagaki, H. Kenaf reinforced biodegradable composite. Compos. Sci. Technol. 2003, 63, 1281–1286. [Google Scholar] [CrossRef]

- Job, S. Recycling glass fibre reinforced composites—History and progress. Reinf. Plast. 2013, 57, 19–23. [Google Scholar] [CrossRef]

- Carpenter, R.L.; Wilson, C.L. The Inhalation Toxicity of Glass Fibers—A Review of the Scientific Literature; Naval Health Research Center Detachment: Dayton, OH, USA, 1999. [Google Scholar]

- Donaldson, K.; Tran, C.L. An introduction to the short-term toxicology of respirable industrial fibres. Mutat. Res.–Fundam. Mol. Mech. Mutagen. 2004, 553, 5–9. [Google Scholar] [CrossRef]

- Niranjan, R.R.; Junaid Kokan, S.; Sathya Narayanan, R.; Rajesh, S.; Manickavasagam, V.M.; Ramnath, B.V. Fabrication and testing of abaca fibre reinforced epoxy composites for automotive applications. Adv. Mater. Res. 2013, 718–720, 63–68. [Google Scholar] [CrossRef]

- Puglia, D.; Biagiotti, J.; Kenny, J.M. A review on natural fibre-based composites—Part II: Application of natural reinforcements in composite materials for automotive industry. J. Nat. Fibers 2004, 1, 23–65. [Google Scholar] [CrossRef]

- Hirondo, M.; Hirondo, L.L.; Mataya, K.J.; Francisco, E.; Mazon, A.; Natal, P.; Senoro, D.; Catajay-Mani, M. Abaca fiber (Musa textilis nee) and plastic post-consumer wastes (A/PCW) as potential building material. J. Environ. Sci. Manag. 2020, 23, 8–17. [Google Scholar] [CrossRef]

- Pranoto, Y.; Suryono, J.; Rahman, L.H. Study of Utilizations Abaca Fibre with Kalimantan Local Material on the Concrete Compressive and Flexural Strength. IOP Conf. Ser. Earth Environ. Sci. 2021, 832, 012028. [Google Scholar] [CrossRef]

- Delicano, J.A. A review on abaca fiber reinforced composites. Compos. Interfaces 2018, 25, 1039–1066. [Google Scholar] [CrossRef]

- Snijder, M.H.B.; Bos, H.L. Reinforcement of polypropylene by annual plant fibers: Optimisation of the coupling agent efficiency. Compos. Interfaces 2000, 7, 69–75. [Google Scholar] [CrossRef]

- Beckermann, G.W.; Pickering, K.L. Engineering and evaluation of hemp fibre reinforced polypropylene composites: Micro-mechanics and strength prediction modelling. Compos. Part A Appl. Sci. Manuf. 2009, 40, 210–217. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Letcher, T.M. Plastic Waste and Recycling: Environmental Impact, Societal Issues, Prevention, and Solutions; Academic Press: Cambridge, MA, USA, 2020; ISBN 0128178817. [Google Scholar]

- Barbalho, G.H.A.; Nascimento, J.J.S.; da Silva, L.B.; Gomez, R.S.; de Farias, D.O.; Diniz, D.D.S.; Santos, R.S.; de Figueiredo, M.J.; de Lima, A.G.B. Bio-Polyethylene Composites Based on Sugar Cane and Curauá Fiber: An Experimental Study. Polymers 2023, 15, 1369. [Google Scholar] [CrossRef]

- Mendieta, C.M.; Cardozo, R.E.; Felissia, F.E.; Clauser, N.M.; Vallejos, M.E.; Area, M.C. Bioconversion of wood waste to bio-ethylene: A review. BioResources 2021, 16, 4411–4437. [Google Scholar] [CrossRef]

- Siracusa, V.; Blanco, I. Bio-polyethylene (Bio-PE), Bio-polypropylene (Bio-PP) and Bio-poly(ethylene terephthalate) (Bio-PET): Recent developments in bio-based polymers analogous to petroleum-derived ones for packaging and engineering applications. Polymers 2020, 12, 1641. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Seculi, F.; Espinach, F.X.; Julián, F.; Delgado-Aguilar, M.; Mutjé, P.; Tarrés, Q. Comparative Evaluation of the Stiffness of Abaca-Fiber-Reinforced Bio-Polyethylene and High Density Polyethylene Composites. Polymers 2023, 15, 1096. [Google Scholar] [CrossRef] [PubMed]

- Seculi, F.; Espinach, F.X.; Julián, F.; Delgado-Aguilar, M.; Mutjé, P.; Tarrés, Q. Evaluation of the Strength of the Interface for Abaca Fiber Reinforced Hdpe and Biope Composite Materials, and Its Influence over Tensile Properties. Polymers 2022, 14, 5412. [Google Scholar] [CrossRef]

- Preet Singh, J.I.; Dhawan, V.; Singh, S.; Jangid, K. Study of Effect of Surface Treatment on Mechanical Properties of Natural Fiber Reinforced Composites. Mater. Today Proc. 2017, 4, 2793–2799. [Google Scholar] [CrossRef]

- Bajpai, P.K.; Singh, I.; Madaan, J. Comparative studies of mechanical and morphological properties of polylactic acid and polypropylene based natural fiber composites. J. Reinf. Plast. Compos. 2012, 31, 1712–1724. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Samuel, B.O.; Sumaila, M.; Dan-Asabe, B. Manufacturing of a natural fiber/glass fiber hybrid reinforced polymer composite (PxGyEz) for high flexural strength: An optimization approach. Int. J. Adv. Manuf. Technol. 2022, 119, 2077–2088. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Press forming of short natural fiber-reinforced biodegradable resin: Effects of fiber volume and length on flexural properties. Polym. Test. 2005, 24, 1005–1011. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Julián, F.; Espinosa, E.; Rodríguez, A.; Espinach, F.X.; Vilaseca, F. Feasibility of barley straw fibers as reinforcement in fully biobased polyethylene composites: Macro and micro mechanics of the flexural strength. Molecules 2020, 25, 2242. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Nayak, S.K.; Mohanty, S. Sisal glass fiber reinforced PP hybrid composites: Effect of MAPP on the dynamic mechanical and thermal properties. J. Reinf. Plast. Compos. 2010, 29, 1551–1568. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G. Natural Fiber Composites; CRC Press: Boca Raton, FL, USA, 2015; ISBN 1482239019. [Google Scholar]

- Lakshmi Narayana, V.; Bhaskara Rao, L. A brief review on the effect of alkali treatment on mechanical properties of various natural fiber reinforced polymer composites. Mater. Today Proc. 2021, 44, 1988–1994. [Google Scholar] [CrossRef]

- Kidalova, L.; Stevulova, N.; Terpakova, E.; Sicakova, A. Utilization of alternative materials in lightweight composites. J. Clean. Prod. 2012, 34, 116–119. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Mamun, A.A.; Jaszkiewicz, A.; Erdmann, K. Polypropylene composites with enzyme modified abaca fibre. Compos. Sci. Technol. 2010, 70, 854–860. [Google Scholar] [CrossRef]

- Siregar, J.P.; Jaafar, J.; Cionita, T.; Jie, C.C.; Bachtiar, D.; Rejab, M.R.M.; Asmara, Y.P. The Effect of Maleic Anhydride Polyethylene on Mechanical Properties of Pineapple Leaf Fibre Reinforced Polylactic Acid Composites. Int. J. Precis. Eng. Manuf.–Green Technol. 2019, 6, 101–112. [Google Scholar] [CrossRef]

- Punyamurthy, R.; Sampathkumar, D.; Bennehalli, B.; Rangana Gouda, R.P.G.; Srinivasa, C.V. Influence of fiber content and effect of chemical pre-treatments on mechanical characterization of natural abaca epoxy composites. Indian J. Sci. Technol. 2015, 8, 53236. [Google Scholar] [CrossRef]

- Amir, N.; Abidin, K.A.Z.; Shiri, F.B.M. Effects of Fibre Configuration on Mechanical Properties of Banana Fibre/PP/MAPP Natural Fibre Reinforced Polymer Composite. Procedia Eng. 2017, 184, 573–580. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated coupling agents for natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Birnin-yauri, A.U.; Ibrahim, N.A.; Zainuddin, N.; Abdan, K.; Then, Y.Y.; Chieng, B.W. Effect of maleic anhydride-modified poly(lactic acid) on the properties of its hybrid fiber biocomposites. Polymers 2017, 9, 165. [Google Scholar] [CrossRef] [PubMed]

- Ramadevi, P.; Sampathkumar, D.; Srinivasa, C.V.; Bennehalli, B. Effect of alkali treatment on water absorption of single cellulosic abaca fiber. BioResources 2012, 7, 3515–3524. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Aguado, R.J.; Morcillo-Martín, R.; Méndez, J.A.; Vilaseca, F.; Tarrés, Q.; Mutjé, P. Behavior of the Flexural Strength of Hemp/Polypropylene Composites: Evaluation of the Intrinsic Flexural Strength of Untreated Hemp Strands. Polymers 2023, 15, 371. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Chamorro-Trenado, M.À.; Soler, J.; Mutjé, P.; Vilaseca, F.; Espinach, F.X. Macro and micromechanical preliminary assessment of the tensile strength of particulate rapeseed sawdust reinforced polypropylene copolymer biocomposites for its use as building material. Constr. Build. Mater. 2018, 168, 422–430. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Julian, F.; Del Rey, R.; Mendez, J.A.; Mutje, P. Estimation of the interfacial shears strength, orientation factor and mean equivalent intrinsic tensile strength in old newspaper fiber/polypropylene composites. Compos. Part B Eng. 2013, 50, 232–238. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Scherzer, D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos. Part A Appl. Sci. Manuf. 2009, 40, 404–412. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D760; Specification for Enclosures and Servicing Units for Tests Above and Below Room Temperatures. ASTM: West Conshohocken, PA, USA, 2000.

- Seculi, F.; Espinach, F.X.; Juli, F.; Delgado-aguilar, M. Evaluation of the Interface Strength in the Abaca-Fiber-Reinforced Bio-Polyethylene Composites. Polymers 2023, 15, 2686. [Google Scholar] [CrossRef]

- Kalaprasad, G.; Joseph, K.; Thomas, S.; Pavithran, C. Theoretical modelling of tensile properties of short sisal fibre-reinforced low-density polyethylene composites. J. Mater. Sci. 1997, 32, 4261–4267. [Google Scholar] [CrossRef]

- Singh, V.K.; Bansal, G.; Negi, P.; Bisht, A. Characterization of Flexural and Impact Strength of Jute/Almond Hybrid Biocomposite. J. Test. Eval. 2017, 45, 20140414. [Google Scholar] [CrossRef]

- Shah, D.U.; Nag, R.K.; Clifford, M.J. Why do we observe significant differences between measured and ‘back-calculated’ properties of natural fibres? Cellulose 2016, 23, 1481–1490. [Google Scholar] [CrossRef]

- Reixach, R.; Espinach, F.X.; Franco-Marquès, E.; Ramirez De Cartagena, F.; Pellicer, N.; Tresserras, J.; Mutjé, P. Modeling of the tensile moduli of mechanical, thermomechanical, and chemi-thermomechanical pulps from orange tree pruning. Polym. Compos. 2013, 34, 1840–1846. [Google Scholar] [CrossRef]

- Tarrés, Q.; Oliver-Ortega, H.; Espinach, F.X.; Mutjé, P.; Delgado-Aguilar, M.; Méndez, J.A. Determination of mean intrinsic flexural strength and coupling factor of natural fiber reinforcement in polylactic acid biocomposites. Polymers 2019, 11, 1736. [Google Scholar] [CrossRef]

- Espinach, F.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.; Vilaseca, F.; Mutje, P. Analysis of tensile and flexural modulus in hemp strands/polypropylene composites. Compos. Part B Eng. 2013, 47, 339–343. [Google Scholar] [CrossRef]

- López, J.P.; Mutjé, P.; Angels Pèlach, M.; El Mansouri, N.E.; Boufi, S.; Vilaseca, F. Analysis of the tensile modulus of polypropylene composites reinforced with stone groundwood fibers. BioResources 2012, 7, 1310–1323. [Google Scholar] [CrossRef]

- Munde, Y.S.; Ingle, R.B. Theoretical Modeling and Experimental Verification of Mechanical Properties of Natural Fiber Reinforced Thermoplastics. Procedia Technol. 2015, 19, 320–326. [Google Scholar] [CrossRef]

- Hashemi, S. Hybridisation effect on flexural properties of single- and double- gated injection moulded acrylonitrile butadiene styrene (ABS) filled with short glass fibres and glass beads particles. J. Mater. Sci. 2008, 43, 4811–4819. [Google Scholar] [CrossRef]

- Mutjé, P.; Vallejos, M.E.; Gironès, J.; Vilaseca, F.; López, A.; López, J.P.; Méndez, J.A. Effect of maleated polypropylene as coupling agent for polypropylene composites reinforced with hemp strands. J. Appl. Polym. Sci. 2006, 102, 833–840. [Google Scholar] [CrossRef]

- Saragih, S.W.; Lubis, R.; Wirjosentono, B.; Eddyanto, E. Characteristic of abaca (Musa textilis) fiber from Aceh Timur as bioplastic. AIP Conf. Proc. 2020, 2049, 020058. [Google Scholar]

- de Souza, N.C.R.; d’Almeida, J.R.M. Tensile, Thermal, Morphological and Structural Characteristics of Abaca (Musa Textiles) Fibers. Polym. Renew. Resour. 2014, 5, 47–60. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Vilaseca, F.; Espinach, F.X.; Mutjé, P.; Delgado-Aguilar, M.; Tarrés, Q. Stiffening potential of lignocellulosic fibers in fully biobased composites: The case of abaca strands, spruce tmp fibers, recycled fibers from onp and barley tmp fibers. Polymers 2021, 13, 619. [Google Scholar] [CrossRef]

- Yan, J.; Demirci, E.; Gleadall, A. Are classical fibre composite models appropriate for material extrusion additive manufacturing? A thorough evaluation of analytical models. Addit. Manuf. 2023, 62, 103371. [Google Scholar] [CrossRef]

| Samples | (MPa) | (mm) | (%) | (MPa) | |

|---|---|---|---|---|---|

| HDPE | 0 | 22.28 ± 0.39 | 10.51 ± 0.17 | 7.1 | 22.28 |

| BioPE | 0 | 21.25 ± 0.27 a | 9.8 ± 0.04 e | 6.6 | 21.25 |

| BioPE + 30% Abaca + 0% MAPE | 0.218 | 30.11 ± 0.71 b | 5.04 ± 0.10 a | 3.4 | 16.73 |

| BioPE + 30% Abaca + 2% MAPE | 0.218 | 39.01 ± 0.75 c | 5.19 ± 0.04 a | 3.5 | 16.95 |

| BioPE + 30% Abaca + 4% MAPE | 0.218 | 46.55 ± 0.18 d | 5.48 ± 0.02 b | 3.7 | 17.37 |

| BioPE + 30% Abaca + 6% MAPE | 0.218 | 48.31 ± 0.77 e | 5.94 ± 0.05 c | 4.0 | 18.00 |

| BioPE + 30% Abaca + 8% MAPE | 0.218 | 50.28 ± 0.63 f | 6.34 ± 0.11 d | 4.3 | 18.53 |

| BioPE + 30% Abaca + 10% MAPE | 0.218 | 48.56 ± 0.41 e | 5.99 ± 0.10 c | 4.0 | 18.00 |

| Samples | (MPa) | (mm) | (MPa) | (%) | |

|---|---|---|---|---|---|

| HDPE | 0 | 22.28 ± 0.39 | 10.51 ± 0.17 | 22.82 | 7.1 |

| BioPE | 0 | 21.25 ± 0.33 | 9.8 ± 0.05 | 21.25 | 6.6 |

| BioPE + 20% Abaca + 8% MAPE | 0.140 | 41.74 ± 0.64 | 7.45 ± 0.08 | 19.38 | 5.0 |

| BioPE + 30% Abaca + 8% MAPE | 0.218 | 50.28 ± 0.45 | 6.34 ± 0.10 | 18.53 | 4.3 |

| BioPE + 40% Abaca + 8% MAPE | 0.302 | 59.62 ± 0.32 | 4.12 ± 0.23 | 15.14 | 2.8 |

| BioPE + 50% Abaca + 8% MAPE | 0.394 | 64.23 ± 0.81 | 3.12 ± 0.06 | 13.13 | 2.1 |

| Hashemi | Contrib. of Fiber | Hirsch | ||||

|---|---|---|---|---|---|---|

| Samples | (MPa) | (MPa) | (MPa) | |||

| BioPE + 30% Abaca + 0% MAPE | 689.4 | 0.113 | 785.1 | 0.100 | 312.8 | 0.25 |

| BioPE + 30% Abaca + 2% MAPE | 803.4 | 0.147 | 785.1 | 0.150 | 573.3 | 0.206 |

| BioPE + 30% Abaca + 4% MAPE | 838.2 | 0.180 | 785.1 | 0.193 | 787.3 | 0.192 |

| BioPE + 30% Abaca + 6% MAPE | 788.2 | 0.199 | 785.1 | 0.200 | 818.1 | 0.192 |

| BioPE + 30% Abaca + 8% MAPE | 763.9 | 0.215 | 785.1 | 0.209 | 858.9 | 0.191 |

| BioPE + 30% Abaca + 10% MAPE | 767.0 | 0.206 | 785.1 | 0.202 | 825.7 | 0.192 |

| Hirsch | ||

|---|---|---|

| Samples | (MPa) | |

| BioPE + 30% Abaca + 0% MAPE | 858.9 | 0.091 |

| BioPE + 30% Abaca + 2% MAPE | 858.9 | 0.138 |

| BioPE + 30% Abaca + 4% MAPE | 858.9 | 0.176 |

| BioPE + 30% Abaca + 6% MAPE | 858.9 | 0.183 |

| BioPE + 30% Abaca + 8% MAPE | 858.9 | 0.191 |

| BioPE + 30% Abaca + 10% MAPE | 858.9 | 0.184 |

| Hashemi | Contrib. of Fiber | Hirsch | ||||

|---|---|---|---|---|---|---|

| Samples | (MPa) | (MPa) | (MPa) | |||

| BioPE + 20% Abaca + 8% MAPE | 715.5 | 0.250 | 697.2 | 0.257 | 959.4 | 0.187 |

| BioPE + 30% Abaca + 8% MAPE | 763.9 | 0.215 | 785.1 | 0.209 | 858.9 | 0.191 |

| BioPE + 40% Abaca + 8% MAPE | 783.0 | 0.207 | 852.4 | 0.191 | 877.1 | 0.185 |

| BioPE + 50% Abaca + 8% MAPE | 716.2 | 0.199 | 812.5 | 0.176 | 758.5 | 0.188 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seculi, F.; Julián, F.; Llorens, J.; Espinach, F.X.; Mutjé, P.; Tarrés, Q. Methodologies to Evaluate the Micromechanics Flexural Strength Properties of Natural-Fiber-Reinforced Composites: The Case of Abaca-Fiber-Reinforced Bio Polyethylene Composites. Polymers 2023, 15, 3137. https://doi.org/10.3390/polym15143137

Seculi F, Julián F, Llorens J, Espinach FX, Mutjé P, Tarrés Q. Methodologies to Evaluate the Micromechanics Flexural Strength Properties of Natural-Fiber-Reinforced Composites: The Case of Abaca-Fiber-Reinforced Bio Polyethylene Composites. Polymers. 2023; 15(14):3137. https://doi.org/10.3390/polym15143137

Chicago/Turabian StyleSeculi, Faust, Fernando Julián, Joan Llorens, Francisco X. Espinach, Pere Mutjé, and Quim Tarrés. 2023. "Methodologies to Evaluate the Micromechanics Flexural Strength Properties of Natural-Fiber-Reinforced Composites: The Case of Abaca-Fiber-Reinforced Bio Polyethylene Composites" Polymers 15, no. 14: 3137. https://doi.org/10.3390/polym15143137

APA StyleSeculi, F., Julián, F., Llorens, J., Espinach, F. X., Mutjé, P., & Tarrés, Q. (2023). Methodologies to Evaluate the Micromechanics Flexural Strength Properties of Natural-Fiber-Reinforced Composites: The Case of Abaca-Fiber-Reinforced Bio Polyethylene Composites. Polymers, 15(14), 3137. https://doi.org/10.3390/polym15143137