1. Introduction

The progress in the development of high-performance materials and structures has been a challenge that has required the development of novel materials with superior and selective mechanical properties and physical features to overcome the standard demand for quality and reliability at different scales [

1,

2,

3]. The need to increase conventional material efficiency continues to focus materials development on the exploration of materials as composites [

4,

5]. In this regard, new polymer composites are developed to have special microstructures with unique features to replace conventional materials (e.g., steel, glass, wood) that are frequently used in the design of advanced structures. They are characterized above all by mechanical properties such as tensile, compressive, and torsional strength, lightness, long lifespan, and weather resistance. These exceptional mechanical properties make possible composite structures that can endure extreme loads and boundary conditions [

4,

6,

7]. The important role of such composites in various applications that require the development of structures with complex geometries, such as profiles with open or closed cross-section forms, curved frames with rectangle to circular geometries, and antisymmetric planer shapes [

8,

9], forced designers to innovate many fabrication methods, such as the vacuum-infusion process, pultrusion process, and robot winding, enabling the possibility of such fabrications [

10]. Examples for application of such composite structures are reinforcements for the fuselages, wings, and doors of aircraft, or the attachment part of windows to helicopter cockpits [

11], or chassis reinforcements, car cabins, and door reinforcements in the automotive industry [

12]. Composite frames (narrow curves, hollow structure) are utilized in many applications, such as orthopedic devices [

13], the manufacture of sports equipment and bicycles [

14], ship construction and fishery (hull reinforcements and masts) [

5], internal parts of aircraft bodies [

15], or to play the role of structural reinforcement [

16]. As one of the important applications, such frame structures have been used in oil and petroleum industries as complex pipe or tank structures branching off different cross-sectional configurations of circular to elliptic shapes, utilized for transporting or storing oil and other petroleum liquid materials [

17,

18]. This is also due to the high potential of composite materials to bear severe loading under harsh environmental conditions. The composite frame structures with long wound fibers are normally fabricated using the filament-winding method by robot or machine to wind continuous strands of tow [

19,

20]. This winding process is highly adapted to arrange the fiber orientation in such a way that an ideal custom creation with lightweight structures is engineered to meet the desired strength characteristics as dictated by the application [

21,

22].

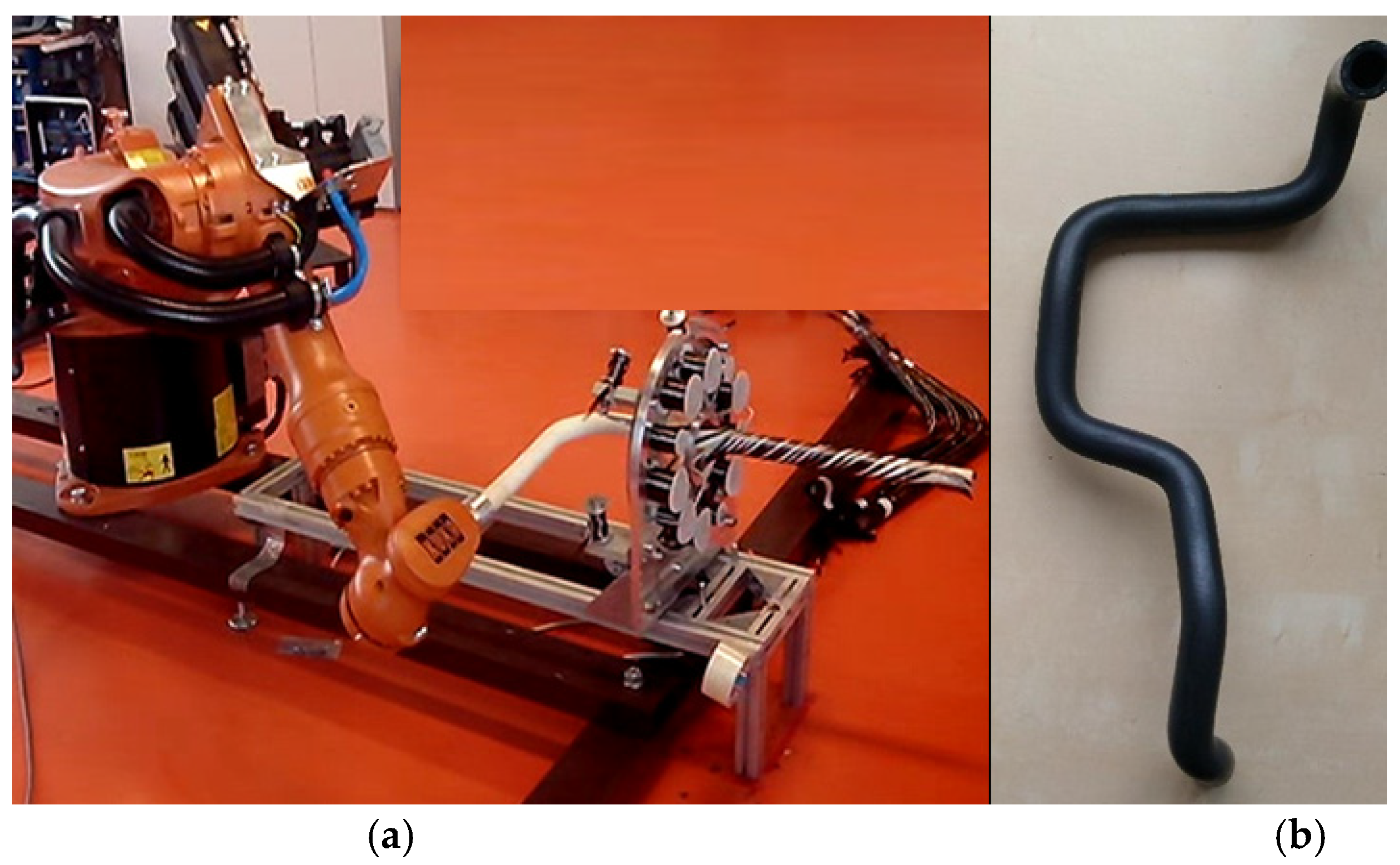

In robot filament winding, the winding of rovings on a non-load-bearing frame is performed by a winding head and an industrial robot (see

Figure 1a). The frame is generally 3D; it can also have a geometrically complicated shape (see

Figure 1b). The frame is attached to the end of the robot’s working arm (robot end effector; see

Figure 1a). The winding head contains usually three rotating rings (see

Figure 2a). Several coils with rovings are placed evenly around the circumference of each ring (see

Figure 2c).

Based on the determination of a suitable robot trajectory, the frame passes through the winding head at a constant speed. Each of the three rings performs the winding of a layer of rovings; based on the determination of the necessary angular speed of each ring (control provided by the robot’s external axis), each layer is wound at the specified angle. Three layers of windings at different angles are thus created in one pass of the frame through the winding head. A detailed description of the calculation of the optimized robot trajectory is given in [

23].

Note 1.

Roving is a fiber system that enables single filaments to be arranged in one parallel collection without twists. Fiber rovings (from carbon, glass, basalt, or aramid fibers) are used to produce 3D composite reinforcement.

Both open and closed frames can be wound using this winding procedure (see

Figure 2a,b).

The quality of the composite frame significantly depends on maintaining the required winding angles, and ensuring the homogeneity of the windings (i.e., roving windings without overlaps and gaps). This article focuses on the quality of winding of the composite frame from a geometric perspective. At the same time, the quality of the composite also depends on the material properties of the rovings (e.g., rovings from carbon, glass, aramid, and rovings from recycled materials). However, studying the properties and quality of the fibers used in rovings is not included in the article.

Ideal roving winding can be formed on a frame with a circular cross-section if it forms a straight segment. In this case, a smooth, high-quality winding of the roving onto the frame can be realized. However, winding the curved parts of the frame is more difficult when high-quality winding is required. Simultaneous testing and ensuring the collision-free passage of the frame through the winding head is essential for 3D frames [

23,

24].

A constant speed of the frame through the winding head is assumed during the winding process. The winding angle is regulated by changing the angular speed of the winding rotated ring of the head. This issue is discussed in detail in [

25]. It is also possible to calculate the distance of the roving winding on the frame from the rotating ring (this distance depends on the specified winding angle, the radius of the ring, and the radius of the wound frame; for detail see [

25]). This enables smooth and continuous change from a given winding angle to another. The optimization of the number and width of the rovings used for specific winding is discussed in [

26]. Based on this optimization, the formation of gaps and overlaps is minimized during the winding process.

As already mentioned, winding the curved parts of the frames is the most difficult process of winding technology. The curved sections of the frame often form parts of a torus (see next figures). Based on the literature review and to the best of the authors’ knowledge, such a study has not been undertaken before. Therefore, this study focuses on the procedures for the optimal winding of the curved sections of frames shaped like parts of a torus. It is highlighted that achieving acceptable winding quality depends on the torus geometry. A mathematical model of the winding procedure and a detailed analysis of the possibility of achieving an acceptable and optimized winding of the frame with toroidal parts is described in the next sections. In addition, practical examples of the application of the various torus geometries are provided.

2. Materials and Methods

Winding the roving onto a straight frame of circular cross-section using a winding head creates a helix on the surface of the frame (see

Figure 3). A standard helix wound on a straight frame is called a

straight helix.

If the wound roving forms a right-handed straight helix on the surface of the frame, it is said to have a positive winding angle (see

Figure 4a). If a left-hand straight helix is formed, this is interpreted as a negative winding angle (see

Figure 4b). One turn of the straight helix is shown in both cases

Figure 4a,b. The following sections focus only on the winding in a positive direction and the creation of a right-handed straight helix. Winding at a negative angle is completely analogous.

One turn of right-handed straight helix

(initial point A and endpoint A’) is shown in

Figure 4a. This straight helix is defined by its axis

o (longitudinal axis of the frame), radius

r (radius of the frame), and pitch

(height of one helix turn measured parallel to axis

of the helix), which is the Euclidean distance between points A and A’ in Figure 4a; for detail see [

27]. A characteristic triangle (see

Figure 4c) defines the straight helix angle α, where

Parameter

is a pitch of straight helix per 2π, and parameter

is a pitch per one radian. Angle

is defined as an angle between tangent

t to

at point

of the straight helix and its orthogonal projection

into the ground plane (see

Figure 4a). In the following, we will call the angle α defined by Relation (1); the winding angle. It is true that

. In case of

, the roving is laid parallel to the axis

and longitudinal to the frame surface.

Specialists in the field of composite materials often call the

angle; the winding angle, as defined by the relationship

In this article, the winding angle will mean the angle defined by Relation (1).

2.1. Torus-Shaped Part of the Frame

As already mentioned in the introduction of the article, winding the curved sections of frames belongs to the most difficult part of the winding technology when using a winding head and an industrial robot. These frame sections often form parts of a torus (see

Figure 5).

Instead of describing the winding of the curved part of the frame in the shape of a torus, for simplicity, we provide a description of the procedure for the case of winding rovings on the whole torus.

From a geometric point of view, a torus is a 3D body created by rotating a circle of radius

r around a line lying in the plane of this circle and not intersecting this circle (see

Figure 6a). The center of the circle of radius

r is placed on the

y-axis and its distance from origin

S of the coordinate system is

R, where

. Rotation of this circle around axis

creates a torus (see

Figure 6a). The value of

is called the

major radius and

the

minor radius of the torus.

Similar to winding a roving on a straight frame at the

angle, it is necessary that the tangent

t at point

of the intersection of frame axis

and plane

of winding of the roving on the frame is orthogonal to plane

(see

Figure 7).

However, the roving is not wound at the specified constant

angle. The winding angle of the roving changes continuously during one turn (it is described in more detail in

Section 2.3 and

Section 2.4; see also [

28]).

2.2. Level of Difficulty of Roving Winding

In this paragraph, the focus is on determining the difficulty of winding the roving onto a torus.

The

aspect ratio of the torus is defined as

The aspect ratio significantly affects the difficulty of winding the torus. The smaller the value of , the easier the torus can be wound. In the case of , the torus transforms into a straight cylinder.

A vertical cut through the circle

(see

Figure 5b) divides the surface

of the whole torus into outer part

and inner part

(see

Figure 5a and

Figure 7). The winding difficulty is caused by the different surface sizes of part

and part

of the torus. Integral calculus is used to determine

and

(see

Figure 8a). Radius

of circle

(see

Figure 6a and

Figure 7) is called the

outer radius of the torus and radius

r of circle

the

inner radius of the torus.

Surface

of the whole torus is composed of partial surfaces

and

, i.e.,

, and (see [

29], p. 26)

Surface

of the whole torus is thus equal to the contents of a rectangle with the lengths of the sides 2

πR and 2

πr (see

Figure 9).

In addition, the focus is concentrated on the calculation of values

and

. Surface

is created by rotating the curve

around the x-axis, where

(see [

30], p. 107;

Figure 8a). Therefore, the size of surface

can be calculated by the following procedure:

In the previous derivation, the relation

(see [

30], p. 150) is used. This relationship also follows from the derivative of composite function

:

The size of the surface

is therefore given by the relation

Since the following holds:

, and from the Relations (4) and (5), this implies

Thus, the value for the ratio

and the use of Relations (5) and (6) is equal to

The more the ratio

in Relation (7) approaches the value 1, the more acceptable the conditions for the winding of rovings are. It follows from Relation (7) that the larger the value of

R with respect to

r, the better the conditions for roving winding. The sizes of the areas corresponding to

,

, and

are shown graphically in

Figure 9.

Figure 9 shows that the geometrical conditions for roving winding are better the smaller the blue marked area of size

.

As stated in [

26], circumference

of the

outer circumferential circle (see

Figure 6b and

Figure 7) is equal to

and circumference

of inner circumferential circle

is equal to

, while it is valid

(see

Figure 6). This then implies

It follows from Relation (8) that winding of the torus is easier the closer the ratio is to 1, i.e., the smaller the positive value of .

Relations (7) and (8) characterize the difficulty of winding rovings on the curved part of the frame.

Thus, it follows from Relations (7) and (8) that the smaller the value of aspect ratio defined by Relation (3) , the more homogeneous the winding that can be achieved.

2.3. Mathematical Description of Roving Winding on the Torus

Our attention in this paragraph is focused on the procedure of winding rovings onto the surface of a torus. In the next mathematical model of the roving winding on the surface of the torus, only the central axis

l (see

Figure 8b) of the roving will be considered.

The torus can be parametrically defined in a 3D right-handed Euclidean space in the form (see [

31], p. 65)

Recall that major radius

R denotes the radius of the central axis

o of the torus (see

Figure 7) and the minor radius

r the radius of the tube (see

Figure 6a,

Figure 7 and

Figure 8a). Parameters

and

are the angles that make the whole torus,

Angle

represents rotation around the tube, whereas

represents rotation around the torus’s central axis

(see

Figure 7).

The parametric expression of a right-handed helix wound on a torus can be expressed in the following form [

28]

for

,

is a real positive constant; parameters

and

r have the same meaning as in Relation (9). This winding defined by Relation (10) describes the helix wrapped around the torus and is called the right-handed

toroidal helix (see

Figure 10a).

When

is a natural number, the toroidal helix creates a closed loop and

defines the number of times the toroidal helix coils around the torus (in more detail see [

28]). The circumference

of the central axis

of the torus (see

Figure 7) is equal to

. Following this, toroidal pitch

(specifies the length of repetition along the center axis

) and corresponding reduced toroidal pitch

(pitch per one radian) are defined by the relations

The central axis

of the torus passes at the same speed through the winding head as in the case of a straight frame and this and Relation (1) imply that for toroidal pitch,

Recall that indicates the winding angle on the straight part of the frame.

2.4. Determination of Winding Angle on Torus

When the roving is wound onto a straight frame, a straight helix is formed with the same winding angle at all points of the resulting helix. When winding the toroidal helix, however, the winding angle continuously changes. This paragraph focuses on a more detailed description of the winding angle in the case of the toroidal helix.

A torus with major radius

and minor radius

in

Figure 6a and

Figure 7 has its center

S placed at the origin in the 3D right-handed Euclidean coordinate system. Circles

,

, and central axis

lie in the plane defined by the

x and

y axes. The points of the wound toroidal helix defined by Relation (10) and lying on the circles

or

can be determined by the following procedure. The z-coordinate of these points is zero. Therefore, it follows from Relation (10)

The relationship is valid when

, which implies

, where

is an arbitrary integer number. From here it follows

Applying Relation (13) successively for

, it follows

, and

. Points of toroidal helix

,

lie on the outer circle

of torus and points

,

lie on the inner circle

of the torus. The components of these points can be expressed using the relationship (10):

Attention is focused on determining the winding angle on the outer circumference of the torus (circle

) and on the inner circumference of the torus (circle

). The tangent vector

at any point of the toroidal helix can be obtained by the following procedure. From Relation (10) it follows

The tangential direction vector

at the point

has the expression

where

, and

are defined by Relation (15).

Point lies on the circle and has coordinates according to Relation (14).

Tangent vector

to the circle

at point

lying in the plane of the

x and

y axes (ground plane) can then be expressed in the form

; see

Figure 10b.

Recall that in Euclidean space

, the length of the vector

is defined by the relation

. The scalar product

of vectors

and

is defined by

. The tangent vector

to the toroidal helix at point

is according to Relations (15) and (16) of the form

The angle

enclosed by the vectors

and

can be determined using the relation (see [

32], p. 113)

thus

Similarly, tangent vector

to the toroidal helix at point

is

Tangent vector

to the circle

at point

lying in the plane of the

x,

y axes (ground plane) can be expressed in the form

Thus, it is true for the angle between vectors

and

Note 2.

Let

be real numbers and

. Thus,

Proof. Assume the validity of Relation (19). After the removal of fractions, partial adjustments of the inequality are gradually made

The last inequality holds for arbitrary real numbers

for

. From Relation (19) and the fact the

function is decreasing in the interval

, it follows that

. In accordance with Relation (2), it follows that

,

and it is true

. The transition from the point

to point

on the circle

is made at one turn of the filament on the outer circumference of the torus. Analogously, transition from the point

to

on the circle

is made also in one turn filament on internal circumference of the torus. This means that on the outer circumference of the torus, the filament is wound at an angle

and in the internal circumference of the torus, the filament is wound at an angle

At the same time, and the filament winding angle varies continuously over the interval . When winding the filament on a straight frame with a circular cross-section, the filament is wound at a constant angle. However, if the filament is wound on a torus-shaped frame section, the wound angle changes and is valid . □

2.5. Determination of Torodial Helix Parameter

One of the parameters defining the expression of the toroidal helix in Relation (10) is a real

value. If

is a natural number, it indicates the number of turns of the toroidal helix on the whole torus. According to Relations (11) and (12),

holds. From here it follows

The value determined by Relation (22) and used in the toroidal helix parametric Expression (10) ensures that the central axis of the frame will pass through the winding head at the same speed when passing through both the straight and curved torus-shaped parts of the frame. In this case, the length on the -axis at one turn of the straight frame part of the frame is equal to the length on the -axis at one turn of the toroidal helix on curved part of helix.

2.6. Optimal Number of Rovings Used during Winding

When winding the frame using rovings, it is desirable to ensure the following properties of the wound layer: the winding does not contain any gaps on the outer part of the torus, overlaps of adjacent rovings on the inner part of torus are minimized, and the approximate desired winding angle is maintained. The determination of the appropriate number of rovings when winding a curved torus-shaped frame section is the subject of this paragraph.

First, attention is paid to determining the length of the arc on the circle

at one turn of the toroidal helix (i.e., the length of the arc with the starting point

and the ending point

on the circle

; see

Figure 10b). Similarly, the length of the arc on the circle

with starting point

and ending point

will be determined.

From the parametric expression of the coordinates of points

,

,

and

in Relation (14) it is clear that the vectors

and

(see

Figure 11a) are at an angle

and analogously vectors

and

are also at the same angle

. At one turn of the toroidal helix, point

corresponds to point

and point

corresponds to point

. The arc length

of circle

with origin point

and end point

is given by relation (see [

29], p. 11)

Angle

is given in Relation (23) in arc measure. Analogously the arc length

of circle

with origin point

and end point

is given by the relation

From Relations (23) and (24), it follows that the difference of the arc lengths and is equal to . As the -value increases, it becomes more difficult to ensure quality winding of the rovings on the curved part of the frame.

Let

denote the width of the roving (see

Figure 8b). The appropriate number of rovings when winding the curved part of the frame is determined by making one turn of the toroidal helix. Recall that

is the angle that the tangent vector

of the toroidal helix makes with the tangent vector

of the circle

at the point

(see

Figure 10b, Relation (17)). It is valid (see

Figure 11b) that

where

denotes the width of the wound roving on the circle

. From here it follows

Thus, the optimized number

of rovings used during torus winding is equal to

Note 3.

The ceiling of a real number, , is defined as , where Z denotes a set of integers.

Further the total sum

of overlaps of adjacent rovings on the circle

when winding a layer of rovings within one turn of the toroidal helix is equal to

The overlap

of two adjacent rovings on the circle

is then equal to

Similarly, the angle

at the point

lying on the circle

is defined. Parameter

denotes the width of the wound roving on the circle

. Thus,

and the total sum

of overlaps of adjacent rovings on the circle

within one turn of the toroidal helix is equal to

The overlap

of two adjacent rovings on the circle

is then equal to

Relations (26)–(30), (31) allow us to determine the optimized number of rovings when winding the torus. For a given roving width , the minimum number of rovings used in the winding process can be determined. This prevents the formation of gaps between the rovings and at the same time ensures minimum overlaps between adjacent rovings on the outer circumference of the torus (circle ). At the same time, overlaps of adjacent rovings on the inner circumference of the torus (circle ) are minimized.

When using

rovings (

is defined by Relation (26)) of width

when winding the curved part of the torus-shaped frame, the

n coils with wound rovings are distributed evenly around the circumference of the rotating ring of the winding head (see

Figure 3). When winding the curved part of the frame, the relationships given in

Section 2.6 apply. After the transition to the straight part of the frame, the rovings are wound at the desired

angle. The process of winding rovings onto a straight frame is discussed in detail in [

26] and [

25].

Note 4.

Relation (10) defines a toroidal helix wound on the torus. Consider hereafter only the central axes

l of

rovings (see

Figure 8b) wound on the torus. Following this, these axes form on the torus

regular toroidal n-helix ([

28]; see

Figure 12).

4. Conclusions

The article focuses on the problem of winding rovings on a non-load-bearing frame with a circular cross-section, and the problem of winding the curved part of the frame is solved. In particular, attention is paid to the case where the curved section of the frame forms part of the torus. The problem is solved from a geometric point of view. Based on the geometric parameters of the torus and the relations derived in the paper, the level of difficulty of the roving layer winding, including the real feasibility of homogeneous winding, can be determined. Based on the given torus and using the relations derived in Chapter 2, the parametric expression of the wound toroidal helix can be determined. As a result, the behavior of the roving when winding on a torus can be described analytically. The winding angle changes continuously within one turn of the roving.

In

Section 2.2. we provide three alternative quantities, specifically

,

, and

, that describe the level of difficulty of winding on given toroidal part of the frame. However, we recommend the quantity

as the most practically oriented measure of the winding difficulty.

When winding the roving layer, it is necessary to avoid gaps in the winding on the outer circumference of the torus and at the same time it is necessary to minimize overlaps of adjacent rovings on the inner circumference of the torus. Using the relations from the previous section, the optimal number of rovings used to wind the layer onto the torus can be determined for a given roving width. At the same time, the overlap size of two adjacent wound rovings can be determined.

A greater number of rovings and their shorter length are required when the frame is wound at a greater angle (for a curved section of the frame in the shape of a torus section, a smaller parameter corresponds to a greater winding angle). When winding at a smaller winding angle, fewer rovings of greater length are required. The total amount of material required is practically the same, unless we consider the issue of overlapping adjacent rovings. Of course, different frame loads (tension, torsion, etc.) correspond to different suitable winding angles. Practical tests show that it is not advisable to wind the roving on the torus at an angle greater than 45°, as this usually causes the roving to “slide” on the surface of the frame and degrade the entire winding.

Meeting the necessary geometric conditions of winding is a prerequisite for a quality winding of the roving layer. As the frame passes through the winding head, three layers of roving are wound simultaneously at different angles (the winding head contains three rotating rings with coils of wound roving). If more layers of windings are required on the frame, the frame can be passed through the winding head repeatedly.

The problems of winding straight frames with circular cross-sections (especially the smooth transition to another winding angle, the distance of winding roving from the rotating ring of the winding head, and the determination of the optimal number of rovings when winding a layer of rovings) are analyzed mainly in previous published works [

25,

26]. These articles, together with this paper, comprehensively describe the problem of winding composite frames using rovings. The fulfillment of the required geometrical conditions of winding is a prerequisite for ensuring the production of high-quality polymer composite frames. A detailed procedure for calculating the optimal trajectory of the industrial robot during the winding process even for curved frames is described in [

23,

33].