Design and Study of Fractal-Inspired Metamaterials with Equal Density Made from a Strong and Tough Thermoplastic

Abstract

:1. Introduction

2. Materials and Methods

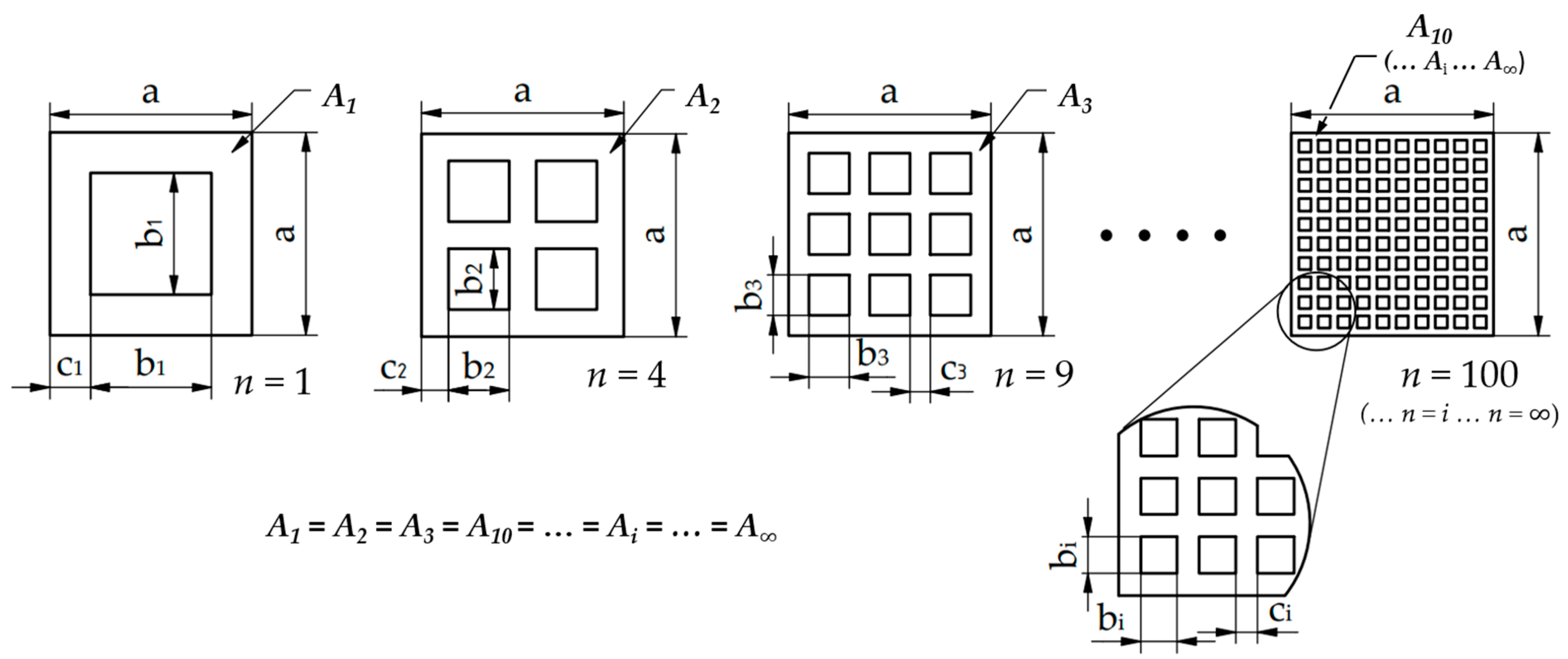

2.1. Mathematical Description of the Geometry of Metamaterials

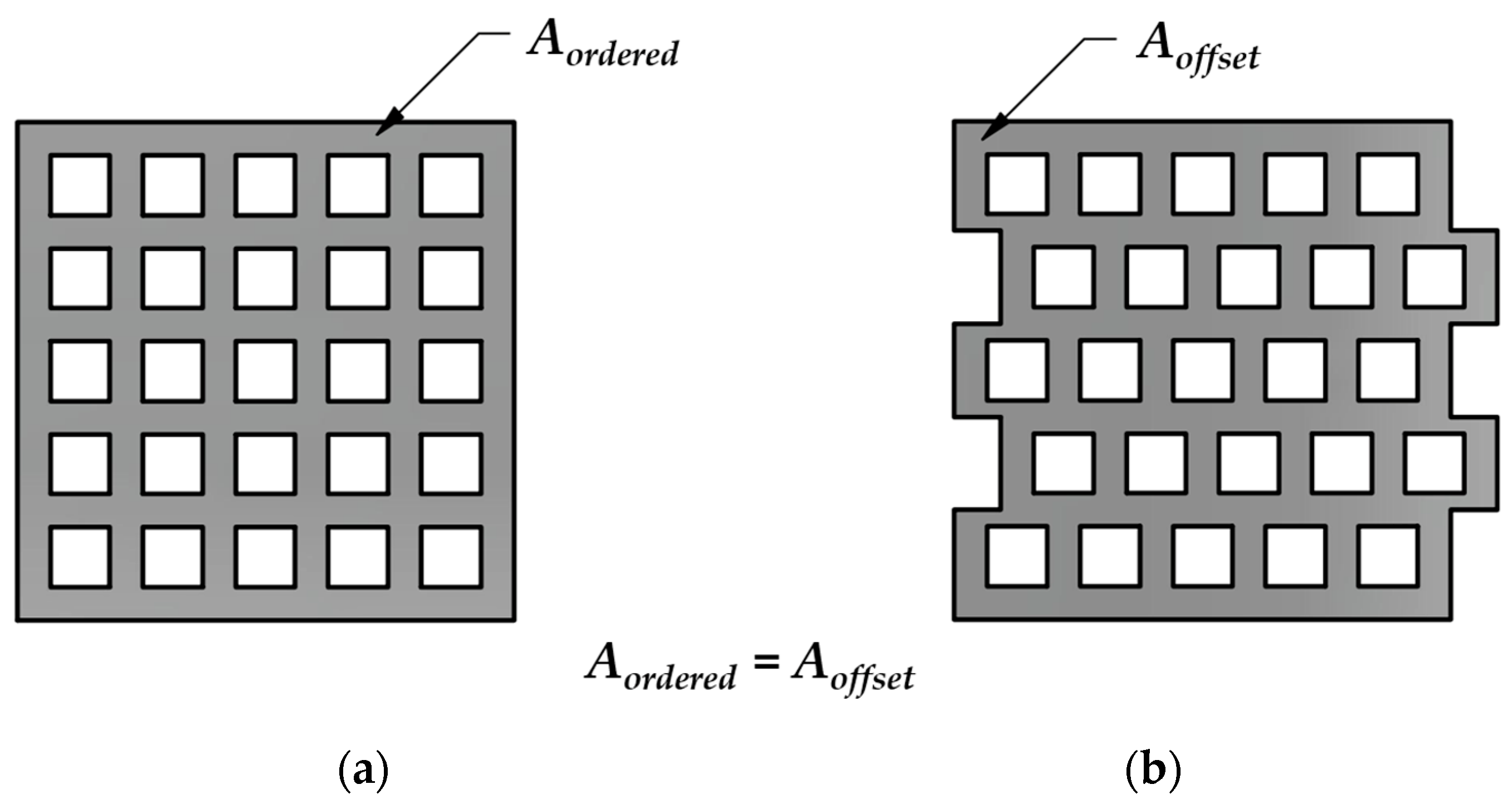

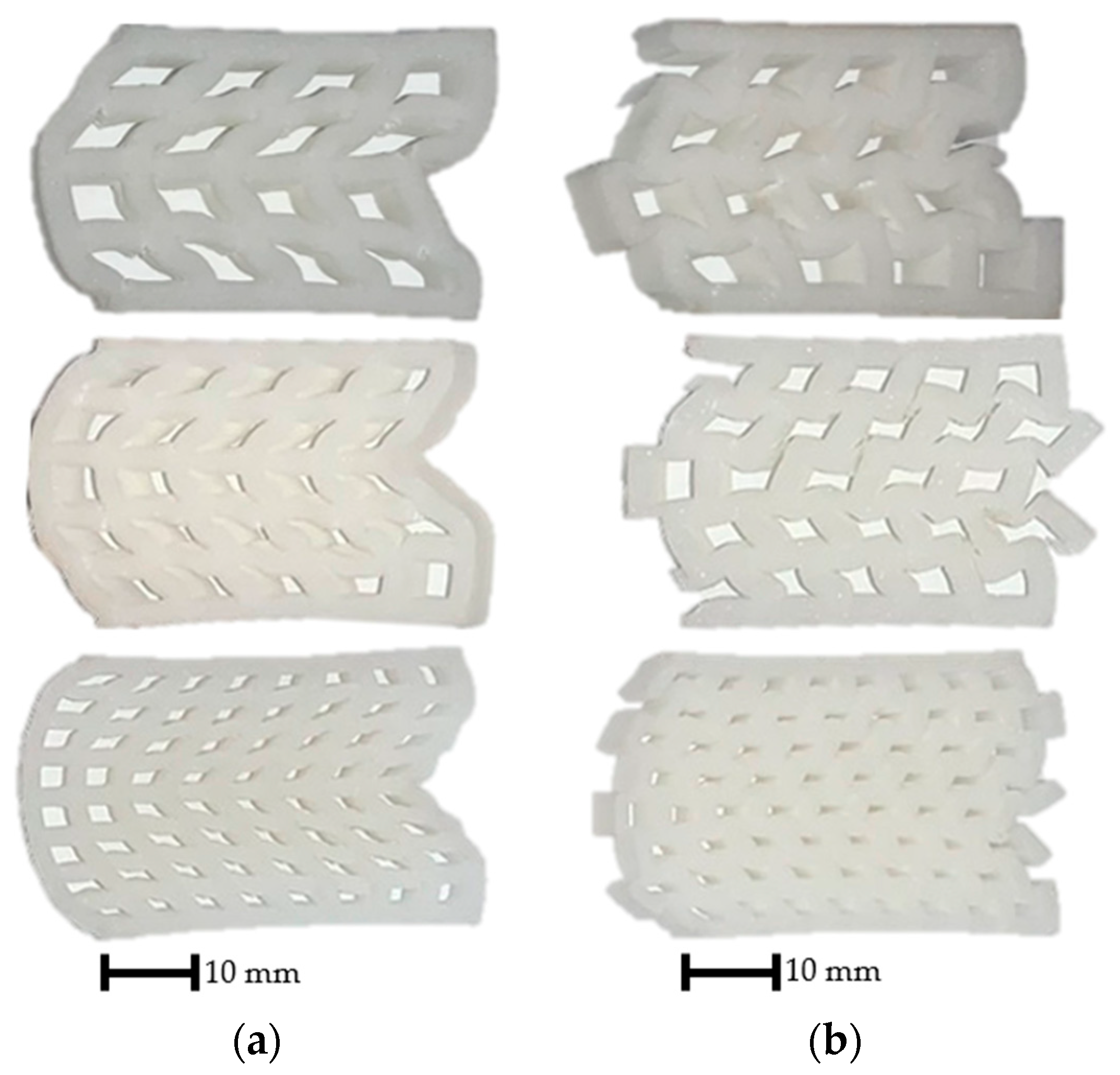

2.2. Introduction of the Two Studied Metamaterial Structures

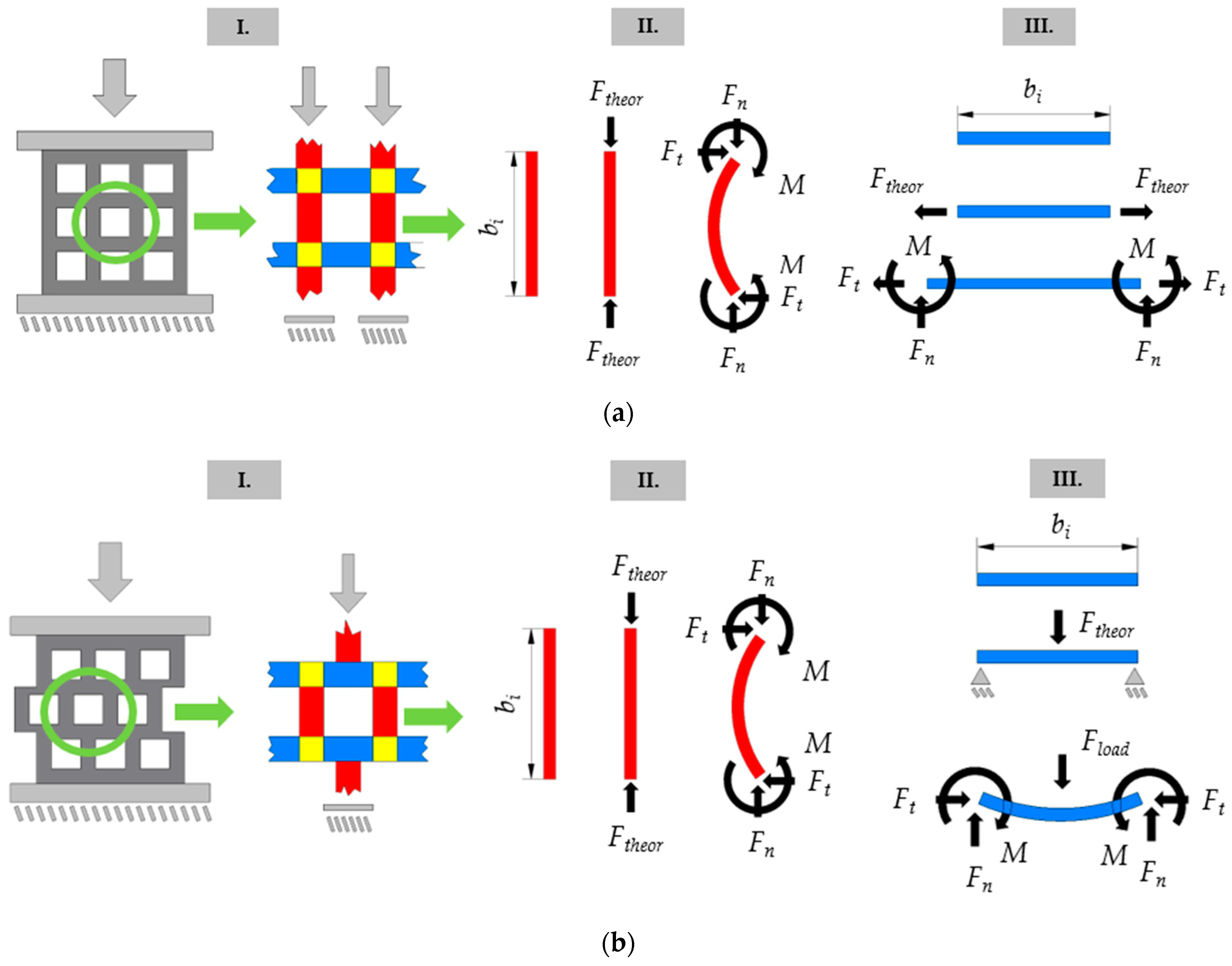

2.3. Estimation of Macrostructural Behavior Based on Microstructural Constituents

2.4. Manufacturing Metamaterials with Additive Technologies

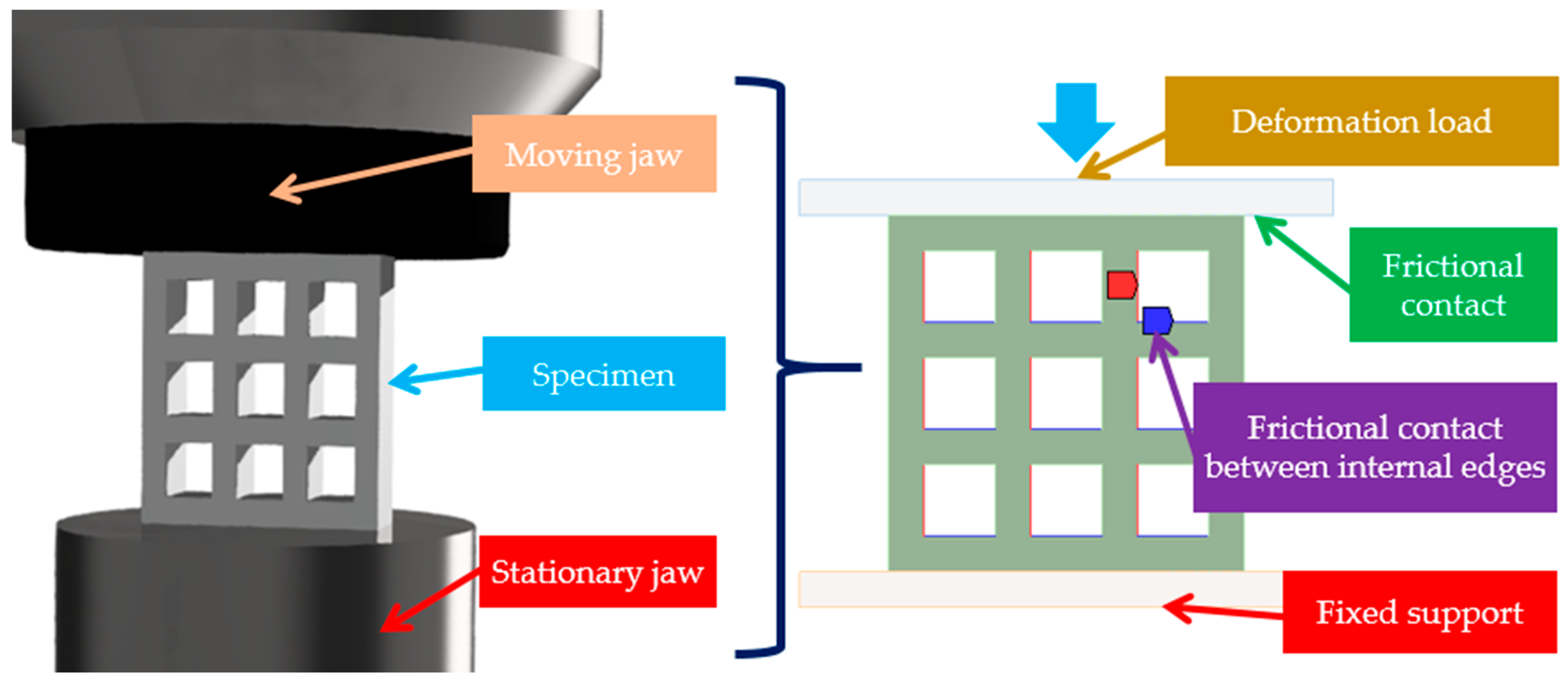

2.5. FEM Test Environment

2.6. Boundary Conditions and Loads in the Finite Element Environment

2.7. Material Model

3. Results

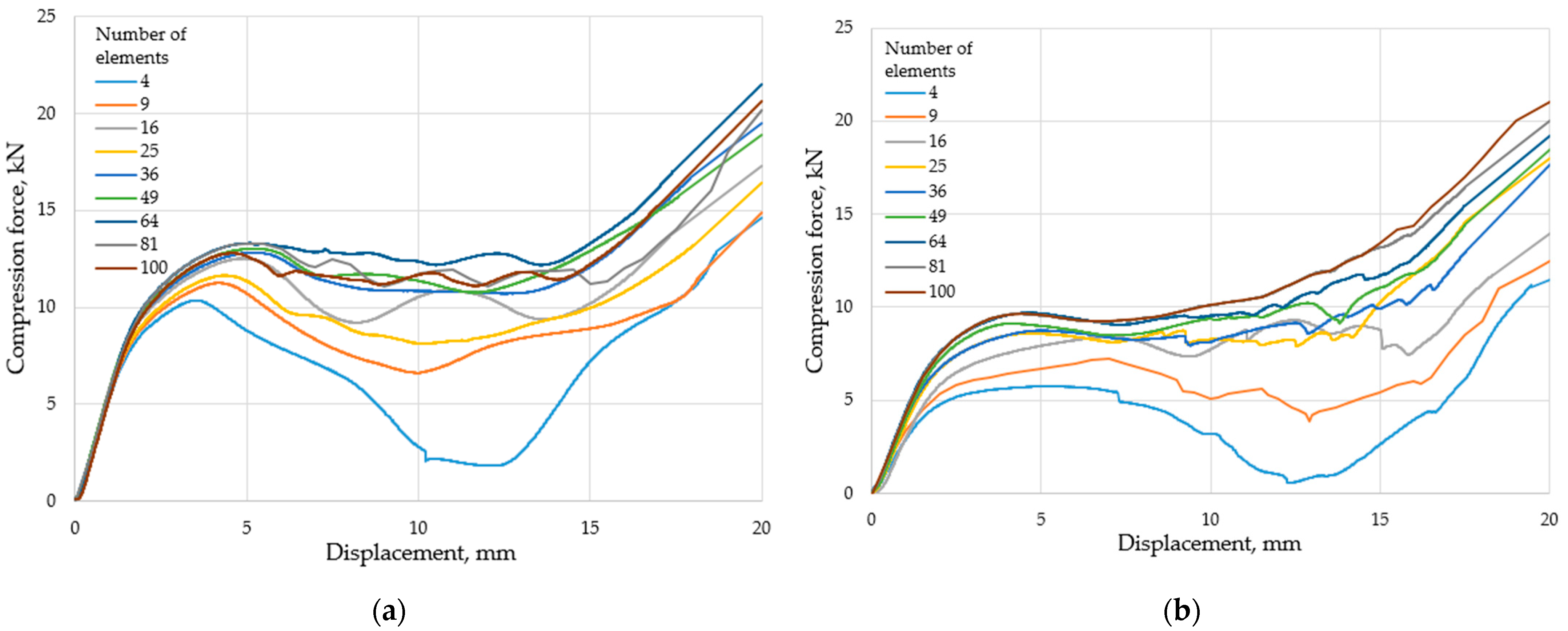

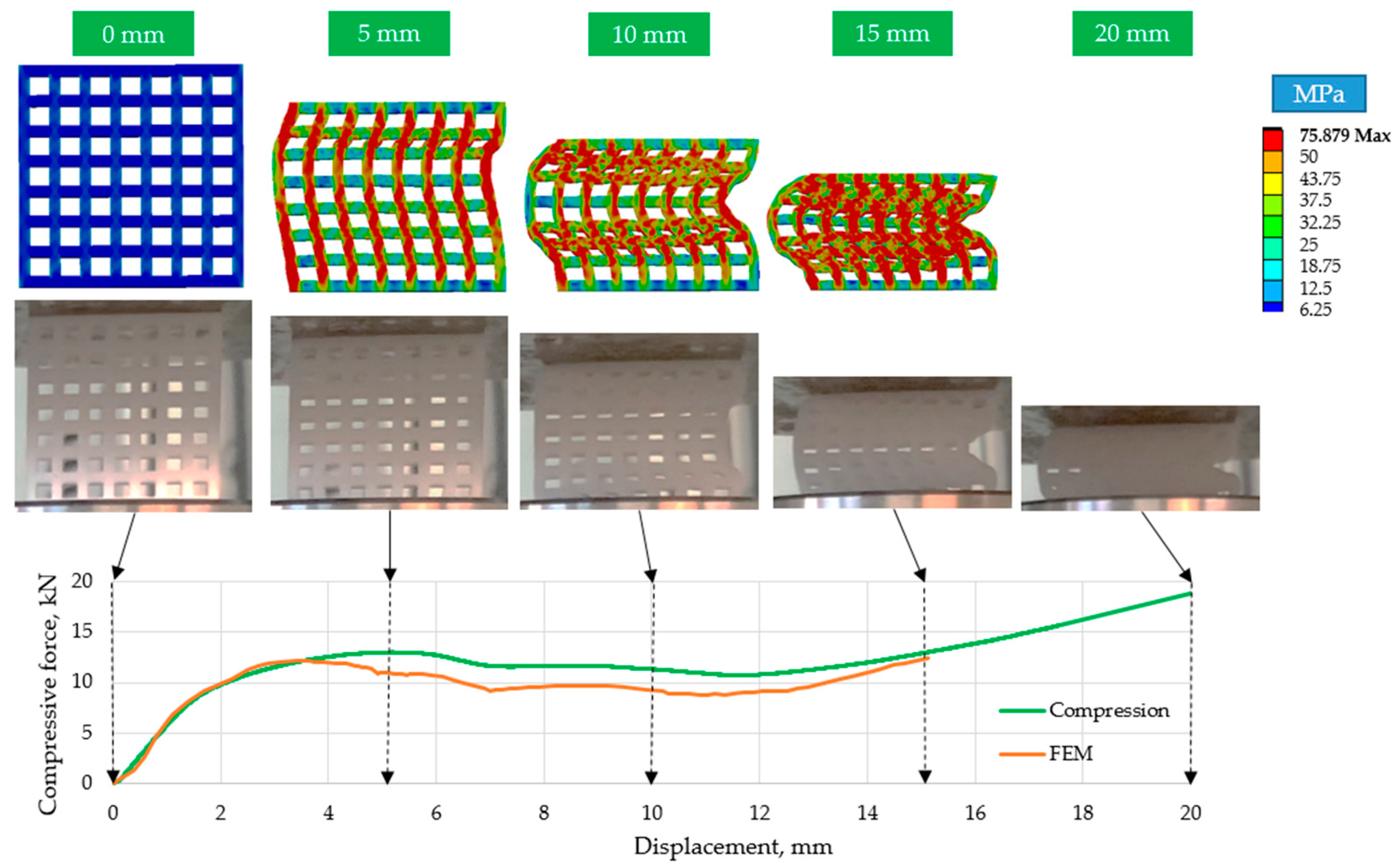

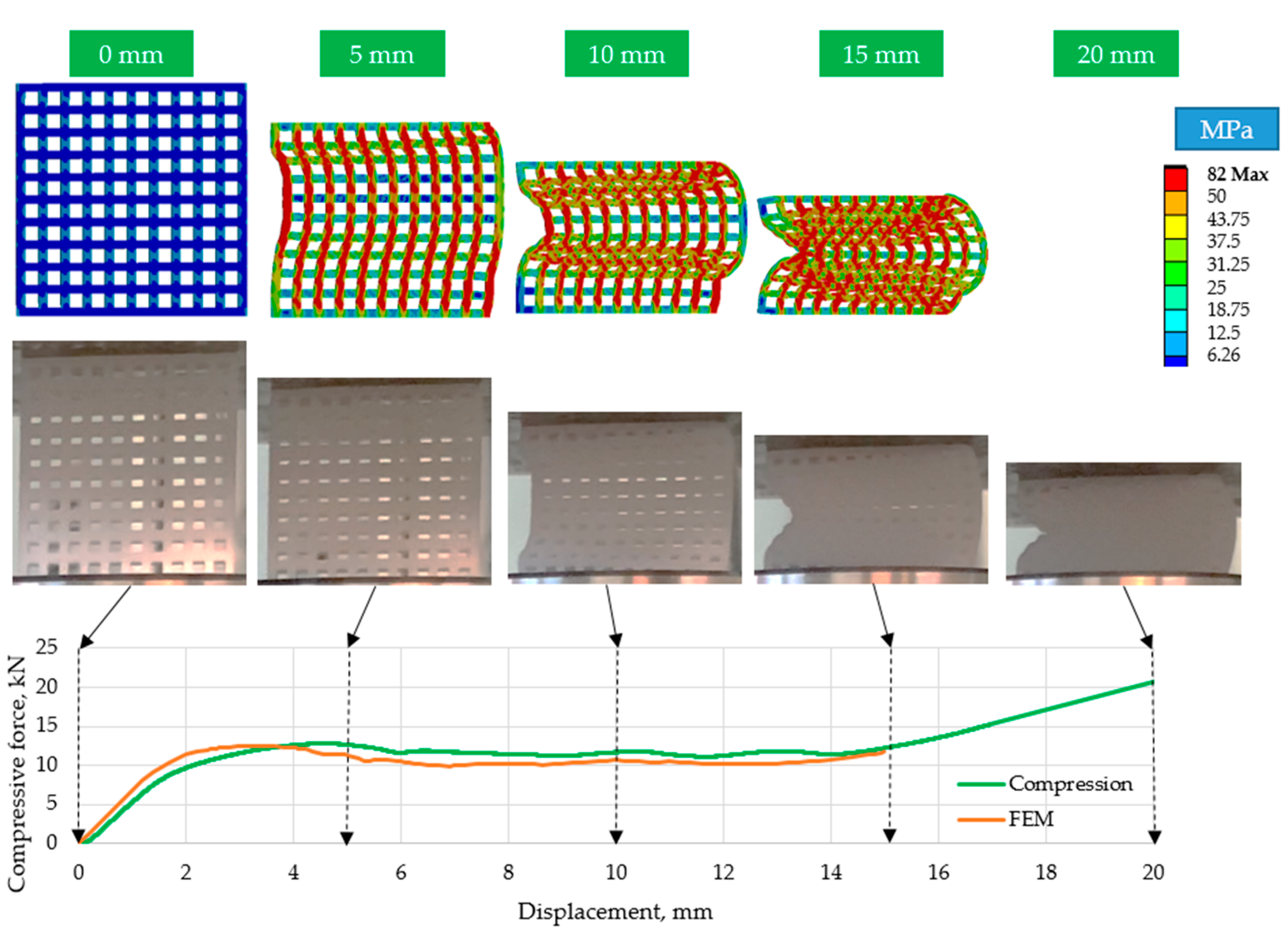

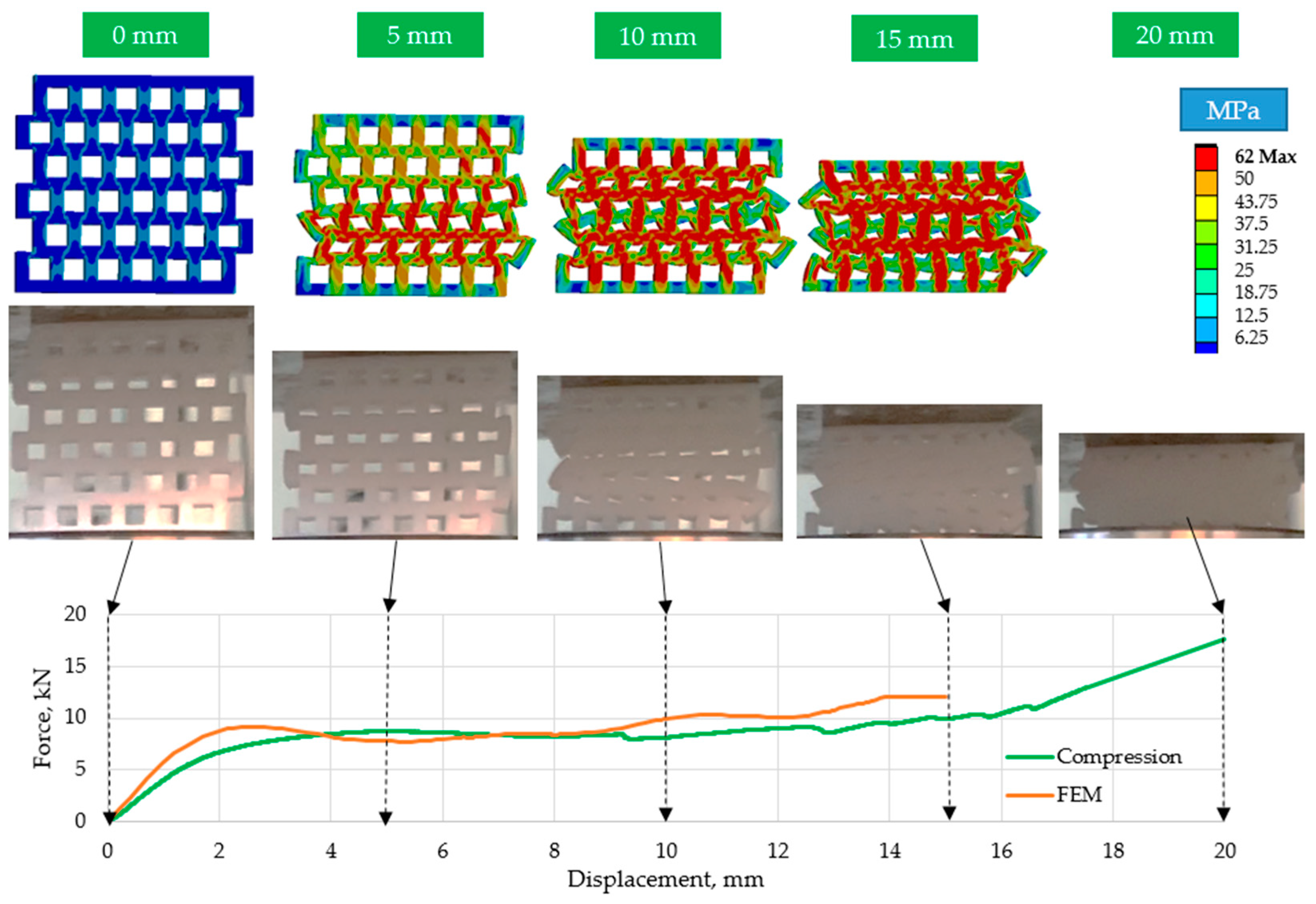

3.1. Compression Test Results

3.2. Assessment of the Absorbed Energy and Comparative Analysis of Offset and Ordered Structures

4. Conclusions

- Increasing the element number results in a more stable behavior, i.e., the load-bearing capacity increases throughout the entire deformation load. The behavior of the specimens can be considered stable for 36 or more elements.

- As the number of elements increases, the absorbed energy also increases for both structures studied; increasing the element number from 4 to 36 almost doubles the amount of energy absorbed. Increasing the element number above the stable threshold (36) does not significantly increase the energy absorption capability.

- Since the ordered structure is composed purely of compressed components, its load-bearing capacity and absorbed energy rate are also higher. At the same time, the results of the tests show that the deformation behavior of the offset structure is predictable and designable in comparison with the ordered structure.

- Offset structures are softer; on average, 27% less force is required to compress them.

- The finite element simulations also suggest that the stress distribution of the offset specimens is more uniform.

- The finite element method showed accurate and reliable results above 36 elements and can therefore be applied under the presented conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Riva, L.; Ginestra, P.S.; Pandini, S.; Pasini, C. Production and characterization of the Poisson’s ratio of cellular structured metamaterials by additive manufacturing. Procedia CIRP 2022, 110, 378–382. [Google Scholar] [CrossRef]

- Zhu, Y.; Jiang, S.; Zhang, Q.; Li, J.; Yu, C.; Zhang, C. A novel monoclinic auxetic metamaterial with tunable mechanical properties. Int. J. Mech. Sci. 2022, 236, 107750. [Google Scholar] [CrossRef]

- Guo, S.; Gao, R.; Tian, X.; Liu, S. A 3D metamaterial with negative stiffness for six-directional energy absorption and cushioning. Thin-Walled Struct. 2022, 180, 109963. [Google Scholar] [CrossRef]

- Sharma, D.; Hiremath, S.S.; Kenchappa, N.B. Bio-inspired Ti-6Al-4V mechanical metamaterials fabricated using selective laser melting process. Mater. Today Commun. 2022, 33, 104631. [Google Scholar] [CrossRef]

- Zhang, X.; He, X.; Wu, L. Experimental investigation of thermal architected metamaterials for regulating transient heat transfer. Int. J. Heat Mass Transf. 2022, 193, 122960. [Google Scholar] [CrossRef]

- Sha, W.; Xiao, M.; Huang, M.; Gao, L. Topology-optimized freeform thermal metamaterials for omnidirectionally cloaking sensors. Mater. Today Phys. 2022, 28, 100880. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, Z.; Chen, Y. Dual-functional hierarchical mechanical metamaterial for vibration insulation and energy absorption. Eng. Struct. 2022, 271, 114916. [Google Scholar] [CrossRef]

- Jiang, W.; Yin, G.; Xie, L.; Yin, M. Multifunctional 3D lattice metamaterials for vibration mitigation and energy absorption. Int. J. Mech. Sci. 2022, 233, 107678. [Google Scholar] [CrossRef]

- Zhao, P.; Zheng, B.B.; Zhong, R.C.; Chen, X.; Fu, M.H.; Hu, L.L. A novel metamaterial with tension-torsion coupling effect. Mater. Des. 2019, 171, 107700. [Google Scholar] [CrossRef]

- Zhang, K.; Qi, L.; Deng, Z. 3D chiral mechanical metamaterial for tailored band gap and manipulation of vibration isolation. Mech. Syst. Signal Process. 2022, 180, 109430. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Bodaghi, M.; Hamzehei, R.; Parr, L.; Fard, M.; Rolfe, B.F. 3D-Printed Programmable Mechanical Metamaterials for Vibration Isolation and Buckling Control. Sustainability 2022, 14, 6831. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Chen, E.; Luan, S.; Gaitanaros, S. On the compressive strength of brittle lattice metamaterials. Int. J. Solids Struct. 2022, 257, 111871. [Google Scholar] [CrossRef]

- de Jonge, C.P.; Kolken, H.M.; Zadpoor, A.A. Non-auxetic mechanical metamaterials. Materials 2019, 12, 635. [Google Scholar] [CrossRef] [Green Version]

- Wagner, M.A.; Lumpe, T.S.; Chen, T.; Shea, K. Programmable, active lattice structures: Unifying stretch-dominated and bending-dominated topologies. Extrem. Mech. Lett. 2019, 29, 100461. [Google Scholar] [CrossRef]

- Yin, S.; Wu, L.; Nutt, S. Stretch–bend-hybrid hierarchical composite pyramidal lattice cores. Compos. Struct. 2013, 98, 153–159. [Google Scholar] [CrossRef]

- Al Nashar, M.; Sutradhar, A. Design of Hierarchical Architected Lattices for Enhanced Energy Absorption. Materials 2021, 14, 5384. [Google Scholar] [CrossRef]

- Zhong, R.; Fu, M.; Chen, X.; Zheng, B.; Hu, L. A novel three-dimensional mechanical metamaterial with compression-torsion properties. Compos. Struct. 2019, 226, 111232. [Google Scholar] [CrossRef]

- Wang, L.; Liu, H.T. 3D compression–torsion cubic mechanical metamaterial with double inclined rods. Extrem. Mech. Lett. 2020, 37, 100706. [Google Scholar] [CrossRef]

- Ren, C.; Yang, D.; Qin, H. Mechanical performance of multidirectional buckling-based negative stiffness metamaterials: An analytical and numerical study. Materials 2018, 11, 1078. [Google Scholar] [CrossRef] [Green Version]

- Shruti, M.; Hemanth, N.S.; Badgayan, N.D.; Sahu, S.K. Compressive behavior of auxetic structural metamaterial for lightweight construction using ANSYS static structural analysis. Mater. Today Proc. 2021, 38, 12–17. [Google Scholar] [CrossRef]

- Wu, W.; Liu, P.; Kang, Z. A novel mechanical metamaterial with simultaneous stretching-and compression-expanding property. Mater. Des. 2021, 208, 109930. [Google Scholar] [CrossRef]

- Li, X.; Yang, Z.; Lu, Z. Design 3D metamaterials with compression-induced-twisting characteristics using shear–compression coupling effects. Extrem. Mech. Lett. 2019, 29, 100471. [Google Scholar] [CrossRef]

- Wang, Y.B.; Liu, H.T.; Zhang, D.Q. Compression-torsion conversion behavior of a cylindrical mechanical metamaterial based on askew re-entrant cells. Mater. Lett. 2021, 303, 130572. [Google Scholar] [CrossRef]

- Carneiro, V.H.; Peixinho, N.; Meireles, J. Significance of cell number on the bulk elastic properties of auxetic reentrant lattices. Sci. Technol. Mater. 2018, 30, 8–12. [Google Scholar] [CrossRef]

- AlQaydi, H.A.; Krishnan, K.; Oyebanji, J.; Lee, D.W.; Alneyadi, S.A.; Ghisi, N.; Kindleyside, L.; Aboulkhair, N.T. Hybridisation of AlSi10Mg lattice structures for engineered mechanical performance. Addit. Manuf. 2022, 57, 102935. [Google Scholar] [CrossRef]

- Yang, X.; Yang, Q.; Shi, Y.; Yang, L.; Wu, S.; Yan, C.; Shi, Y. Effect of volume fraction and unit cell size on manufacturability and compressive behaviors of Ni-Ti triply periodic minimal surface lattices. Addit. Manuf. 2022, 54, 102737. [Google Scholar] [CrossRef]

- Xiao, Z.; Yang, Y.; Xiao, R.; Bai, Y.; Song, C.; Wang, D. Evaluation of topology-optimized lattice structures manufactured via selective laser melting. Mater. Des. 2018, 143, 27–37. [Google Scholar] [CrossRef]

- Bolan, M.; Dean, M.; Bardelcik, A. The Energy Absorption Behavior of 3D-Printed Polymeric Octet-Truss Lattice Structures of Varying Strut Length and Radius. Polymers 2023, 15, 713. [Google Scholar] [CrossRef]

- Osman, M.M.; Shazly, M.; El-Danaf, E.A.; Jamshidi, P.; Attallah, M.M. Compressive behavior of stretched and composite microlattice metamaterial for energy absorption applications. Compos. Part B Eng. 2020, 184, 107715. [Google Scholar] [CrossRef]

- Olivas-Alanis, L.H.; Fraga-Martínez, A.A.; García-López, E.; Lopez-Botello, O.; Vazquez-Lepe, E.; Cuan-Urquizo, E.; Rodriguez, C.A. Mechanical Properties of AISI 316L Lattice Structures via Laser Powder Bed Fusion as a Function of Unit Cell Features. Materials 2023, 16, 1025. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Chen, S.; Zhu, S.; Wang, B.; Xu, P.; Yao, K.; Sun, Y. Reusable metamaterial via inelastic instability for energy absorption. Int. J. Mech. Sci. 2019, 155, 509–517. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, P.; Zhang, Z.; Lin, G.; Sun, W. Structural response and energy absorption assessment of corrugated wall mechanical metamaterials under static and dynamic compressive loading. Int. J. Impact Eng. 2022, 172, 104427. [Google Scholar] [CrossRef]

- Dwyer, C.M.; Carrillo, J.G.; De la Peña, J.A.D.; Santiago, C.C.; MacDonald, E.; Rhinehart, J.; Williams, R.M.; Burhop, M.; Yelamanchi, B.; Cortes, P. Impact Performance of 3D Printed Spatially Varying Elastomeric Lattices. Polymers 2023, 15, 1178. [Google Scholar] [CrossRef] [PubMed]

- Park, K.M.; Min, K.S.; Roh, Y.S. Design optimization of lattice structures under compression: Study of unit cell types and cell arrangements. Materials 2022, 15, 97. [Google Scholar] [CrossRef]

- Truszkiewicz, E.; Thalhamer, A.; Rossegger, M.; Vetter, M.; Meier, G.; Rossegger, E.; Fuchs, P.; Schlögl, S.; Berer, M. Mechanical behavior of 3D-printed polymeric metamaterials for lightweight applications. J. Appl. Polym. Sci. 2021, 139, 51618. [Google Scholar] [CrossRef]

- Pickover, C.A. The Math Book: From Pythagoras to the 57th Dimension, 250 Milestones in the History of Mathematics; Sterling Publishing Company, Inc.: New York, NY, USA, 2009; ISBN 978-1-4027-5796-9. [Google Scholar]

- Mandelbrot, B.B.; Mandelbrot, B.B. The Fractal Geometry of Nature; WH Freeman: New York, NY, USA, 1982; Volume 1. [Google Scholar]

- Schaefer, S.; Levin, D.; Goldman, R. Subdivision Schemes and Attractors. In Symposium on Geometry Processing; The Eurographics Association: Reims, France, 2015; pp. 171–180. [Google Scholar]

- Majewski, M. A tutorial on the realistic visualization of 3D Sierpinski fractals. Comput. Graph. 1998, 22, 129–142. [Google Scholar] [CrossRef]

- Bunde, A.; Havlin, S. (Eds.) Fractals in Science; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Ghanbarian-Alavijeh, B.; Millán, H.; Huang, G. A review of fractal, prefractal and pore-solid-fractal models for parameterizing the soil water retention curve. Can. J. Soil Sci. 2011, 91, 1–14. [Google Scholar] [CrossRef]

- Li, J.; Qin, Q.; Zhang, J. Internal blast resistance of sandwich cylinder with lattice cores. Int. J. Mech. Sci. 2021, 191, 106107. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Zhao, W.; Zou, S.; Zhou, G.; Wang, Y. Structure design and multi-objective optimization of a novel crash box based on biomimetic structure. Int. J. Mech. Sci. 2018, 138, 489–501. [Google Scholar] [CrossRef]

- Simpson, J.; Kazancı, Z. Crushing investigation of crash boxes filled with honeycomb and re-entrant (auxetic) lattices. Thin-Walled Struct. 2020, 150, 106676. [Google Scholar] [CrossRef]

- Nasim, M.; Hasan, M.J.; Galvanetto, U. Impact behavior of energy absorbing helmet liners with PA12 lattice structures: A computational study. Int. J. Mech. Sci. 2022, 233, 107673. [Google Scholar] [CrossRef]

- Yin, S.; Chen, H.; Wu, Y.; Li, Y.; Xu, J. Introducing composite lattice core sandwich structure as an alternative proposal for engine hood. Compos. Struct. 2018, 201, 131–140. [Google Scholar] [CrossRef]

- Shidid, D.; Leary, M.; Choong, P.; Brandt, M. Just-in-time design and additive manufacture of patient-specific medical implants. Phys. Procedia 2016, 83, 4–14. [Google Scholar] [CrossRef] [Green Version]

- Boschetto, A.; Bottini, L.; Macera, L.; Vatanparast, S. Additive Manufacturing for Lightweighting Satellite Platform. Appl. Sci. 2023, 13, 2809. [Google Scholar] [CrossRef]

- Van De Velde, F.; De Baets, P. The friction and wear behaviour of polyamide 6 sliding against steel at low velocity under very high contact pressures. Wear 1997, 209, 106–114. [Google Scholar] [CrossRef]

- Lindberg, A.; Alfthan, J.; Pettersson, H.; Flodberg, G.; Yang, L. Mechanical performance of polymer powder bed fused objects–FEM simulation and verification. Addit. Manuf. 2018, 24, 577–586. [Google Scholar] [CrossRef]

| Number of Elements, n | Absorbed Energy (Ordered Geometry), J | Absorbed Energy (Offset Geometry), J |

|---|---|---|

| 4 | 131.5 | 81.6 |

| 9 | 169.7 | 119.0 |

| 16 | 206.9 | 155.5 |

| 25 | 189.1 | 174.1 |

| 36 | 226.4 | 172.2 |

| 49 | 230.5 | 188.2 |

| 64 | 250.0 | 201.3 |

| 81 | 236.0 | 209.8 |

| 100 | 234.1 | 215.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Széles, L.; Horváth, R.; Rádics, J.P. Design and Study of Fractal-Inspired Metamaterials with Equal Density Made from a Strong and Tough Thermoplastic. Polymers 2023, 15, 2650. https://doi.org/10.3390/polym15122650

Széles L, Horváth R, Rádics JP. Design and Study of Fractal-Inspired Metamaterials with Equal Density Made from a Strong and Tough Thermoplastic. Polymers. 2023; 15(12):2650. https://doi.org/10.3390/polym15122650

Chicago/Turabian StyleSzéles, Levente, Richárd Horváth, and János Péter Rádics. 2023. "Design and Study of Fractal-Inspired Metamaterials with Equal Density Made from a Strong and Tough Thermoplastic" Polymers 15, no. 12: 2650. https://doi.org/10.3390/polym15122650

APA StyleSzéles, L., Horváth, R., & Rádics, J. P. (2023). Design and Study of Fractal-Inspired Metamaterials with Equal Density Made from a Strong and Tough Thermoplastic. Polymers, 15(12), 2650. https://doi.org/10.3390/polym15122650