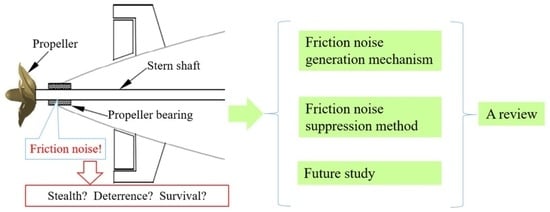

Research on the Friction Noise Generation Mechanism and Suppression Method of Submarine Rubber-Based Propeller Bearings—A Review

Abstract

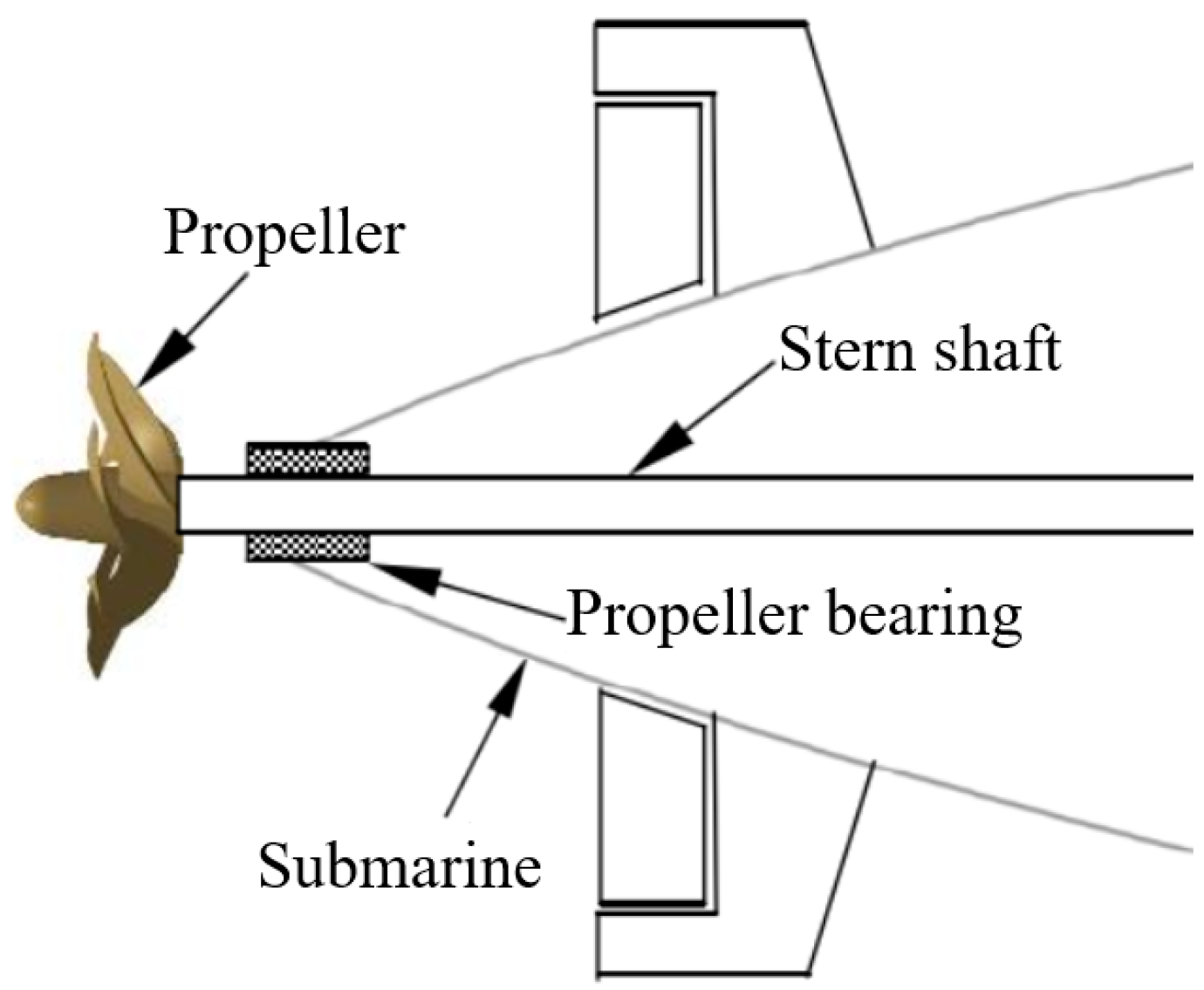

:1. Introduction

2. Friction Noise Generation Mechanism of Submarine Rubber-Based Propeller Bearings

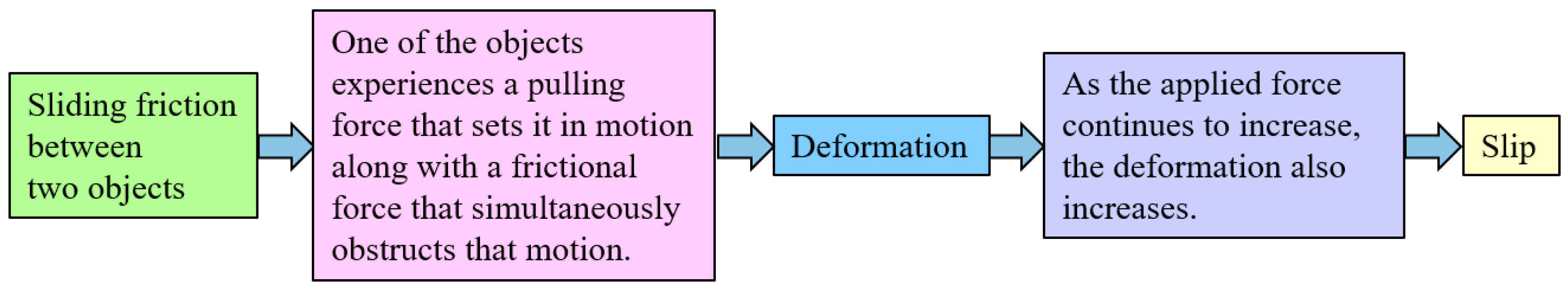

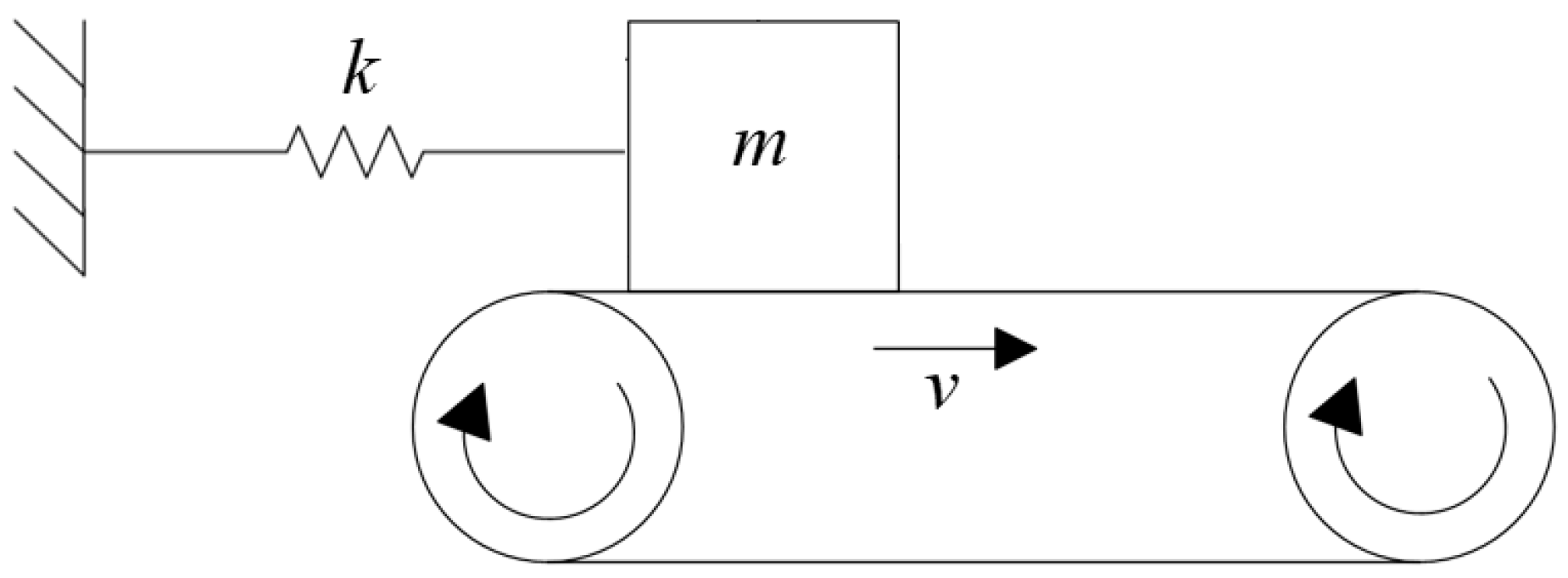

2.1. Stick-Slip Mechanism

2.2. Sprag-Slip Mechanism

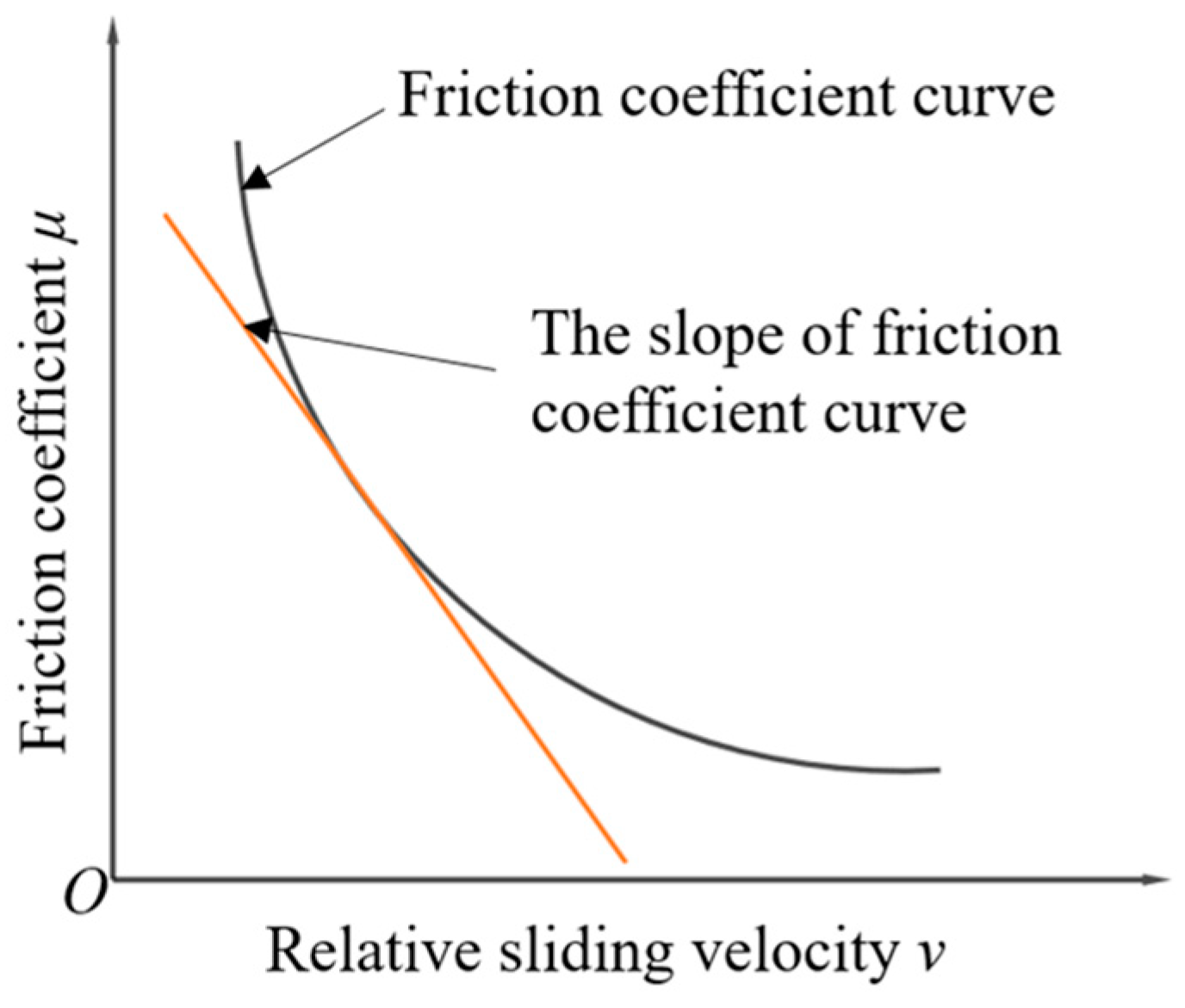

2.3. The Negative Friction–Velocity Slope Mechanism

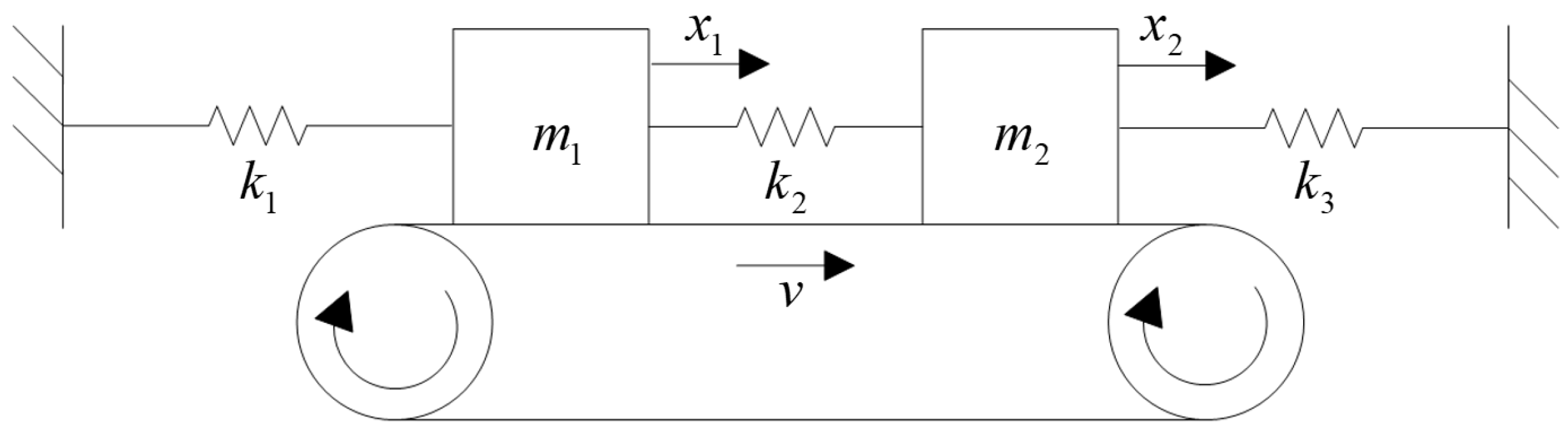

2.4. Modal Coupling Mechanism

3. Friction Noise Suppression Method of Submarine Rubber-Based Propeller Bearings

3.1. Structural Optimization

3.2. Material Modification

4. Conclusions

- Connect the research on the friction noise mechanism of propeller bearings with the molecular structure of materials to explore the relationship between composite material properties and friction noise at the molecular level;

- Study the relationships among contact interface micro-asperities, impurities in lubricating water, and friction noise;

- Study the mechanism of abnormal friction noise of propeller bearings under fluid–solid–heat multi-field coupling and multi-boundary conditions;

- Research real-time monitoring technology for propeller bearing load distribution, wear status, and friction noise as well as design composite intelligent bearings and develop real-time monitoring and warning diagnostics for the state of propeller bearing;

- Carry out research on the structural design and control technology of permanent magnet–electromagnetic bearings.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ROMOR I Bearing Brochure. Available online: www.duramaxmarine.com/pdf/Romor.pdf (accessed on 14 June 2023).

- Esmaeili, M.; Rezaei, N. In situ impact testing of a light-rail ballasted track with tyre-derived aggregate subballast layer. Int. J. Pavement Eng. 2015, 17, 176–188. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; Thom, N.H.; Moreno-Navarro, F.; Rubio-Gámez, C.; Airey, G.D. A study into the use of crumb rubber in railway ballast. Constr. Build. Mater. 2015, 75, 19–24. [Google Scholar] [CrossRef]

- Fathali, M.; Esmaeili, M.; Moghadas, N.F. Influence of tire-derived aggregates mixed with ballast on ground-borne vibrations. J. Mod. Transp. 2019, 27, 355–363. [Google Scholar] [CrossRef]

- Kraśkiewicz, C.; Chmielewska, B.; Zbiciak, A.; Al Sabouni-Zawadzka, A. Study on possible application of rubber granulate from the recycled tires as an elastic cover of prototype rail dampers, with a focus on their operational durability. Materials 2021, 14, 5711. [Google Scholar] [CrossRef]

- Kraśkiewicz, C.; Zbiciak, A.; Al Sabouni-Zawadzka, A.; Piotrowski, A. Resistance to severe environmental conditions of prototypical recycling-based under ballast mats (UBMs) used as vibration isolators in the ballasted track systems. Constr. Build. Mater. 2022, 319, 126075. [Google Scholar] [CrossRef]

- Kraśkiewicz, C.; Zbiciak, A.; Pełczyński, J.; Al Sabouni-Zawadzka, A. Experimental and numerical testing of prototypical under ballast mats (UBMs) produced from deconstructed tires-The effect of mat thickness. Constr. Build. Mater. 2023, 369, 130559. [Google Scholar] [CrossRef]

- Sinclair, D. Frictional vibrations. J. Appl. Mech. 1955, 22, 207–214. [Google Scholar] [CrossRef]

- Kinkaid, N.M.; O’Reilly, O.M.; Papadopoulos, P. Automotive disc brake squeal: A review. J. Sound Vib. 2003, 267, 105–166. [Google Scholar] [CrossRef]

- Bhushan, B. Stick-slip induced noise generation in water-lubricated compliant rubber bearings. J. Lubr. Technol. 1980, 2, 201–212. [Google Scholar] [CrossRef]

- Yao, S.; Yang, J.; Zhang, X.; Wang, J.; Rao, Z. Vibration and noise mechanism analysis and tests for water-lubrication rubber bearings. J. Vib. Shock 2011, 30, 214–216. [Google Scholar]

- Qin, H.; Zhou, C.; Yan, Z.; Liu, Z. Review of research advances of water-lubricated stern bearing noise. Noise Vib. Control 2013, 1, 123–126. [Google Scholar]

- Qin, H.; Yang, C.; Zhu, H.; Li, X.; Li, Z.; Xu, X. Experimental analysis on friction-induced vibration of water-lubricated bearings in a submarine propulsion system. Ocean Eng. 2020, 203, 107239. [Google Scholar]

- Meziane, A.; Baillet, L.; Laulagnet, B. Experimental and numerical investigation of friction-induced vibration of a beam-on-beam in contact with friction. Appl. Acoust. 2010, 71, 843–853. [Google Scholar] [CrossRef]

- Viswanathan, K.; Sundaram, N.K. Distinct stick-slip modes in adhesive polymer interfaces. Wear 2017, 376–377, 1271–1278. [Google Scholar] [CrossRef]

- Schallamach, A. How does rubber slide? Wear 1971, 17, 301–312. [Google Scholar] [CrossRef]

- Fukahori, Y.; Gabriel, P.; Busfield, J.J.C. How does rubber truly slide between schallamach waves and stick-slip motion? Wear 2010, 269, 854–866. [Google Scholar] [CrossRef]

- Spurr, R.T. A theory of brake squeal. Proc. Inst. Mech. Eng. Automob. Div. 1961, 15, 33–52. [Google Scholar] [CrossRef]

- Krauter, A.I. Generation of squeal/chatter in water-lubricated elastomeric bearings. J. Lubr. Technol. 1981, 103, 406. [Google Scholar] [CrossRef]

- Simpson, T.A.; Ibrahim, R.A. Nonlinear friction-induced vibration in water-lubricated bearings. J. Vib. Control 1996, 2, 87–113. [Google Scholar] [CrossRef]

- Peng, E.; Liu, Z.; Zhang, S.; Zhou, X.; Zhao, M.; Lan, F. Analysis on vibration and noise mechanism of marine rubber stern tube bearings. Int. J. Adv. Comput. Technol. 2012, 4, 395–403. [Google Scholar]

- Peng, E.; Liu, Z.; Zhou, X.; Tian, Y.; Zhao, M. Study on nonlinear friction-induced vibration in water-lubricated rubber stern tube bearings. Open Mech. Eng. J. 2012, 6, 140–147. [Google Scholar] [CrossRef]

- Chen, G.; Zhou, Z. Study on the dependence of the squeal generation on friction coefficient. China Mech. Eng. 2003, 4, 766–769. [Google Scholar]

- Aronov, V.; D’souza, A.F.; Kalpakjian, S.; Shareef, I. Interactions among friction, wear, and system stiffness-Part 2: Vibrations induced by dry friction. J. Tribol. 1984, 106, 59–64. [Google Scholar] [CrossRef]

- Sinou, J.J.; Jezequel, L. Mode coupling instability in friction-induced vibrations and its dependency on system parameters including damping. Eur. J. Mech. A/Solids 2007, 26, 106–122. [Google Scholar] [CrossRef]

- Mihajlovic, N.; Wouw, N.V.D.; Rosielle, P.C.J.N.; Nijmeijer, H. Interaction between torsional and lateral vibrations in flexible rotor systems with discontinuous friction. Nonlinear Dynam. 2007, 50, 679–699. [Google Scholar] [CrossRef]

- Hua, C.; Ta, N.; Rao, Z. Influence of damping ratio on coupled bending and torsion vibrations of rotor system under rub-impact. J. Vib. Shock 2014, 33, 19–25. [Google Scholar]

- Li, M. Non-linear dynamic behaviour of rotor-bearing system trained by bevel gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2008, 222, 617–627. [Google Scholar] [CrossRef]

- Kuang, F.; Zhou, X.; Liu, Z.; Huang, J.; Liu, X.; Qian, K.; Gryllias, K. Computer-Vision-Based research on friction vibration and coupling of frictional and torsional vibrations in water-lubricated bearing-shaft system. Tribol. Int. 2020, 150, 106336. [Google Scholar] [CrossRef]

- Lin, C.; Zou, M.; Sima, C.; Liu, S.; Jiang, L. Friction-induced vibration and noise of marine stern tube bearings considering perturbations of the stochastic rough surface. Tribol. Int. 2019, 131, 661–671. [Google Scholar] [CrossRef]

- Daugherty, T.; Sides, N. Friction characteristics of water-lubricated stave bearings. Friction 1980, 24, 293–301. [Google Scholar]

- Roy, L.; Orndorff, J.R. Water-lubruciated rubber bearings, history and new developments. Nav. Eng. J. 1985, 97, 39–52. [Google Scholar]

- Zhou, G. Mixed Lubrication Analysis and Dynamic Performance Optimization of Water Lubricated Rubber Alloy Bearings. Ph.D. Thesis, Chongqing University, Chongqing, China, 2013. [Google Scholar]

- Cheng, Q.; Jin, Y.; Ouyang, W.; Liu, Z.; Wang, H. Influence of groove layout on friction performance of water-lubricated bearing. Ship Eng. 2017, 39, 38–42. [Google Scholar]

- Zhou, C.; Liu, S.; Zheng, H. Numerical analysis of the inner fluid field of ship stern tube bearing. Ship Eng. 2006, 28, 26–29. [Google Scholar]

- Gao, G.; Yin, Z.; Jiang, D.; Zhang, X. CFD analysis of load-carrying capacity of hydrodynamic lubrication on a water-lubricated journal bearing. Ind. Lubr. Tribol. 2015, 67, 30–37. [Google Scholar]

- Smith, W.V.; Schneider, L. Lubrication in a sea-water environment. Nav. Eng. J. 1963, 75, 841–854. [Google Scholar] [CrossRef]

- MIL-B-17901A(SH); Bearing Components, Bonded Synthetic Rubber, Water Lubricated. Department of Defense: Washington, DC, USA, 1963.

- MIL-B-17901B(SH); Bearing Components, Bonded Synthetic Rubber, Water Lubricated. Department of Defense: Washington, DC, USA, 1983.

- MIL-DTL-17901C(SH); Bearing Components, Bonded Synthetic Rubber, Water Lubricated. Department of Defense: Washington, DC, USA, 2005.

- Etsion, I. State of the art in laser surface texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Marchetto, D.; Rota, A.; Calabri, L.; Gazzadi, G.C.; Menozzi, C.; Valeri, S. AFM investigation of tribological properties of nano-patterned silicon surface. Wear 2007, 265, 577–582. [Google Scholar] [CrossRef]

- Gualtieri, E.; Borghi, A.; Calabri, L.; Pugno, N.; Valeri, S. Increasing nanohardness and reducing friction of nitride steel by laser surface texturing. Tribol. Int. 2009, 42, 699–705. [Google Scholar] [CrossRef]

- Wang, X.; Kato, K.; Adachi, K. The lubrication effect of micro-pits on parallel sliding faces of sic in water. Tribol. Trans. 2002, 45, 294–301. [Google Scholar] [CrossRef]

- Shinkarenko, A.; Kligerman, Y.; Etsion, I. The effect of surface texturing in soft elasto-hydrodynamic lubrication. Tribol. Int. 2009, 42, 284–292. [Google Scholar] [CrossRef]

- Singh, N.; Sharma, S.C.; Jain, S.C.; Reddy, S.S. Performance of membrane compensated multirecess hydrostatic/hybrid flexible journal bearing system considering various recess shapes. Tribol. Int. 2004, 37, 11–24. [Google Scholar] [CrossRef]

- Lin, Q.; Wei, Z.; Wang, N.; Zhang, Y. Effect of recess configuration on the performances of high-speed hybrid journal bearing. Ind. Lubr. Tribol. 2016, 68, 301–307. [Google Scholar] [CrossRef]

- Liu, Z.; Qin, B.; Zhang, S.; Huang, J. Hydrostatic Stern Bearings for Marine Lubrication. China Patent CN203567922U, 30 April 2014. [Google Scholar]

- Wu, C.; Liu, Y. The Utility Model Relates to a Ship Bearing Lubricated by Water with a Short-Time Pressure Retaining Device. China Patent CN205278109U, 1 June 2016. [Google Scholar]

- Liu, Z.; Shuai, C.; Yang, X. Effect of geometric cavity shape and diameter on mechanical properties of water lubricated hydrostatic stern bearing. J. Phys. Conf. Ser. 2021, 1939, 012032. [Google Scholar]

- Li, S.; Yang, X. Research on static performance of ship magnetic composite water-lubricated rubber stern bearing. Ship Sci. Technol. 2022, 44, 33–39. [Google Scholar]

- He, L.; Yang, X.; Shuai, C. Study on hardness and friction properties of new type of low-noise water-lubricated material for ship propeller bearing. Noise Vib. Control 2012, 32, 181–184. [Google Scholar]

- Jiang, X.; Yarmolenko, M.A.; Rogachev, A.V.; Yang, X.; Lu, L. Tribological property and structure of rubber surfaces modified with composite polymeric films. Tribology 2007, 118, 106–111. [Google Scholar]

- Liu, G.; Wen, Z.; Chen, K.; Dong, L.; Wang, Z.; Zhang, B.; Qiang, L. Optimizing the microstructure, mechanical, and tribological properties of Si-DLC coatings on NBR rubber for its potential applications. Coatings 2020, 10, 671. [Google Scholar] [CrossRef]

- Han, H.; Wang, Z.; Chen, X. Study on surface fluorination and tribological properties of nitrile butadiene rubber. J. Shenyang Ligong Univ. 2020, 39, 69–72. [Google Scholar]

- Han, H.; Wang, Z.; Wang, W. Surface sulfonation of nitrile rubber and its tribological behavior under dry friction condition. J. Shenyang Univ. Chem. Technol. 2022, 26, 128–133. [Google Scholar]

- Karzov, I.; Nashchokin, A.; Tikhonov, N.; Kalugin, D.; Malakho, A. Data on compressibility of NBR samples with various cross-linking degree and zinc oxide content immersed in gasoline and oil. Data Brief 2020, 30, 105470. [Google Scholar] [CrossRef]

- Hiep, N.Q.; Huy, T.H.; Nguyen, P.C.; Sy, D.T.; Khang, D.Q. Preparation and properties of rubber nanocomposites based on NR/NBR blend reinforced with nanosilica and carbon black. Vietnam J. Chem. 2019, 57, 213–217. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, Z.; Shi, X.; Zhang, Z.; Weng, G.; Xu, Y. Study on properties of NBR filled with silica. Chem. Ind. Times 2022, 36, 26–28. [Google Scholar]

- He, E.; Wang, S.; Tang, L.; Chen, J. A study on the enhancement of the tribological properties of nitrile-butadiene rubber reinforced by nano-ZnO particles from an atomic view. Mater. Res. Express 2021, 8, 095009–095018. [Google Scholar] [CrossRef]

- Li, H.; Luo, Y. Effect of temperature on tribological properties of phenol formaldehyde resin/nitrile rubber composites. China Synth. Rubber Ind. 2022, 45, 223–230. [Google Scholar]

- Huang, X.; Wang, T.; Tian, N.; Wang, K.; Xue, Q. Tribological properties of acrylonitrile-butadiene rubber reinforced with Kevlar aramid fiber. China Synth. Rubber Ind. 2006, 29, 451–453. [Google Scholar]

- Wang, T.; Li, Y.; Wang, Q. The Utility Model Relates to a Long Life Water Lubricated Bearing Composite Material Resistant to Sediment Environment. China Patent CN105646964A, 8 June 2016. [Google Scholar]

- Liu, X.; Huang, J.; Yang, C.; Wang, P.; Xing, S.; Zhong, D.; Zhou, X. Effects of graphene and CNTs reinforcement on the friction mechanism of nitrile butadiene rubber under water lubrication conditions. Wear 2022, 500–501, 204334. [Google Scholar] [CrossRef]

- Xin, B. Environmentally Friendly Water Lubrication Rubber Bearing Research and Performance Study. Master’s Thesis, Dalian Maritime University, Dalian, China, 2013. [Google Scholar]

- Yang, J.; Liu, Z.; Liang, X.; Wang, J.; Cheng, Q. Research on friction vibration of marine water lubricated rubber bearing. Tribol. Online 2018, 13, 108–118. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, X.; Kuang, F.; Huang, J.; Wang, H. Effect of carbon nanomaterials with different dimensions on friction and wear properties of water-lubricated rubber bearings. Lubr. Eng. 2020, 45, 35–39. [Google Scholar]

- Jia, C.; Zhou, X.; Wang, C.; Kuang, F. Study on friction and wear properties of NBR/CNT composite bearing material. China Ship Repair 2019, 32, 37–41. [Google Scholar]

- Zhang, Z.; Yang, X.; Wang, X. Preparation and properties of graphene/three-component solid lubricant/NBR composites. Polym. Mater. Sci. Eng. 2021, 37, 94–100. [Google Scholar]

- Cheng, X.; Wang, Y.; Wang, X.; Liu, Y.; Yang, X. Mechanical and tribological properties of graphene/nitrile composites. Polym. Mater. Sci. Eng. 2023, in press.

- He, L.; Shuai, C.; Yang, X. Research development of noise attenuation for submarine propeller bearing. Ship Sci. Technol. 2011, 33, 3–8. [Google Scholar]

- Jiao, Y.; Ye, J.; Liu, X.; Liu, K. Influence of surface wettability on the sliding frictional property of NBR rubber. J. Mech. Eng. 2019, 55, 106–111. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, Y.; Wang, X.; Liu, Z.; Yang, X. Progress of hydrophilic modification on surface of polymer materials. China Elastomerics 2022, 32, 83–87. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, C.; Cheng, Y.; Shuai, C. Research on the Friction Noise Generation Mechanism and Suppression Method of Submarine Rubber-Based Propeller Bearings—A Review. Polymers 2023, 15, 3352. https://doi.org/10.3390/polym15163352

Cai C, Cheng Y, Shuai C. Research on the Friction Noise Generation Mechanism and Suppression Method of Submarine Rubber-Based Propeller Bearings—A Review. Polymers. 2023; 15(16):3352. https://doi.org/10.3390/polym15163352

Chicago/Turabian StyleCai, Cunguang, Yuqiang Cheng, and Changgeng Shuai. 2023. "Research on the Friction Noise Generation Mechanism and Suppression Method of Submarine Rubber-Based Propeller Bearings—A Review" Polymers 15, no. 16: 3352. https://doi.org/10.3390/polym15163352

APA StyleCai, C., Cheng, Y., & Shuai, C. (2023). Research on the Friction Noise Generation Mechanism and Suppression Method of Submarine Rubber-Based Propeller Bearings—A Review. Polymers, 15(16), 3352. https://doi.org/10.3390/polym15163352