Enhancing Strength and Sustainability: Evaluating Glass and Basalt Fiber-Reinforced Biopolyamide as Alternatives for Petroleum-Based Polyamide Composite

Abstract

:1. Introduction

2. Materials and Methods

- (1)

- Glass fibers with a diameter of 10 μm and nominal chop length of 4.5 mm—Nippon Electric Glass ChopVantage HP 3610 (Otsu, Japan), with the following basic properties: density equal to 2.54 g/cm3, tensile strength approximately equal to 2.4 GPa, and Young’s modulus approximately equal to 76 GPa;

- (2)

- Basalt fibers with a diameter of 13 μm and nominal chop length of 3.2 mm—BASALTEX (Kamenny Vek, Moscow, Russia) BSC13-3.2-KV02M with the following basic properties: density equal to 2.67 g/cm3, tensile strength approximately equal to 2.7 GPa, and Young’s modulus approximately equal to 85 GPa.

3. Results

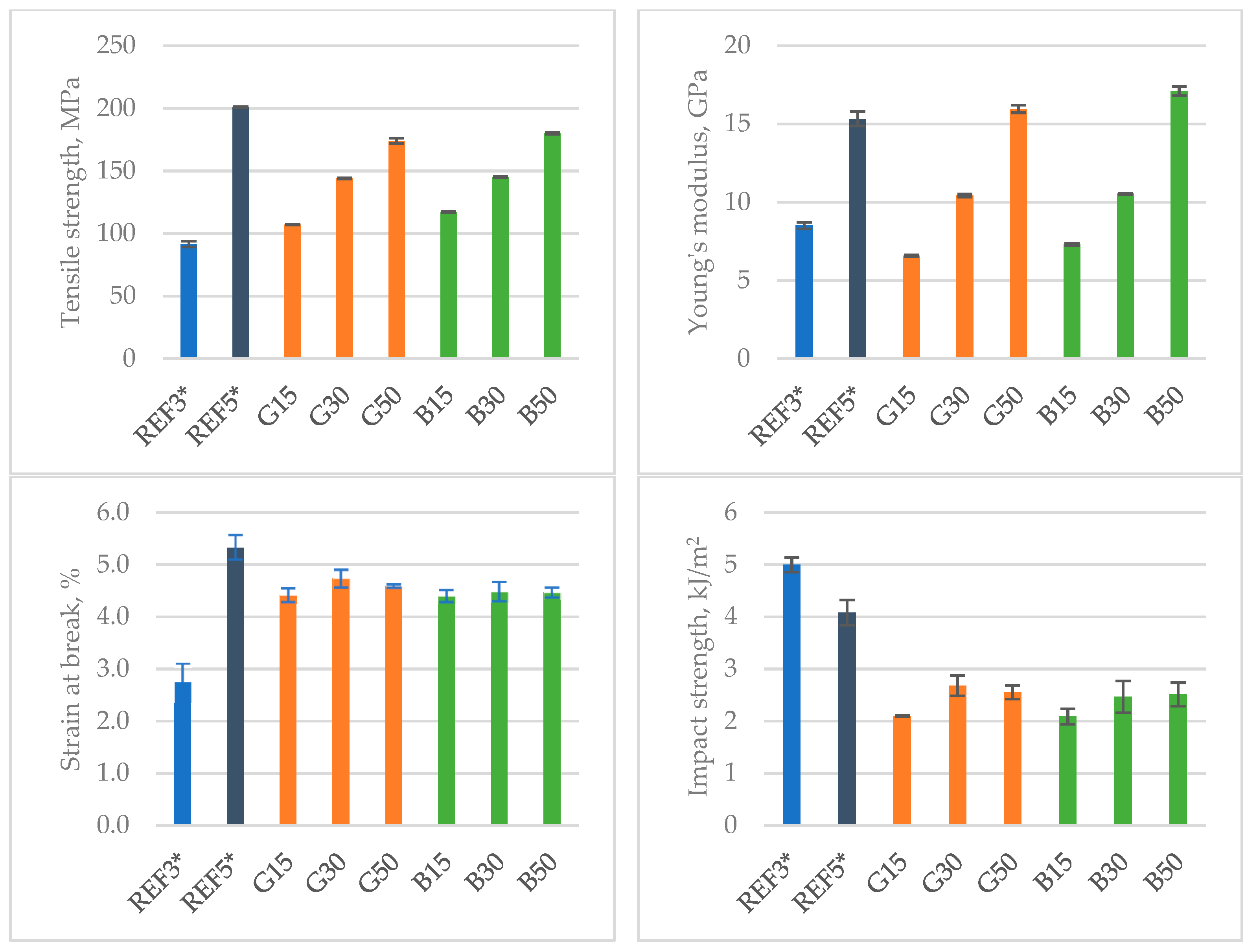

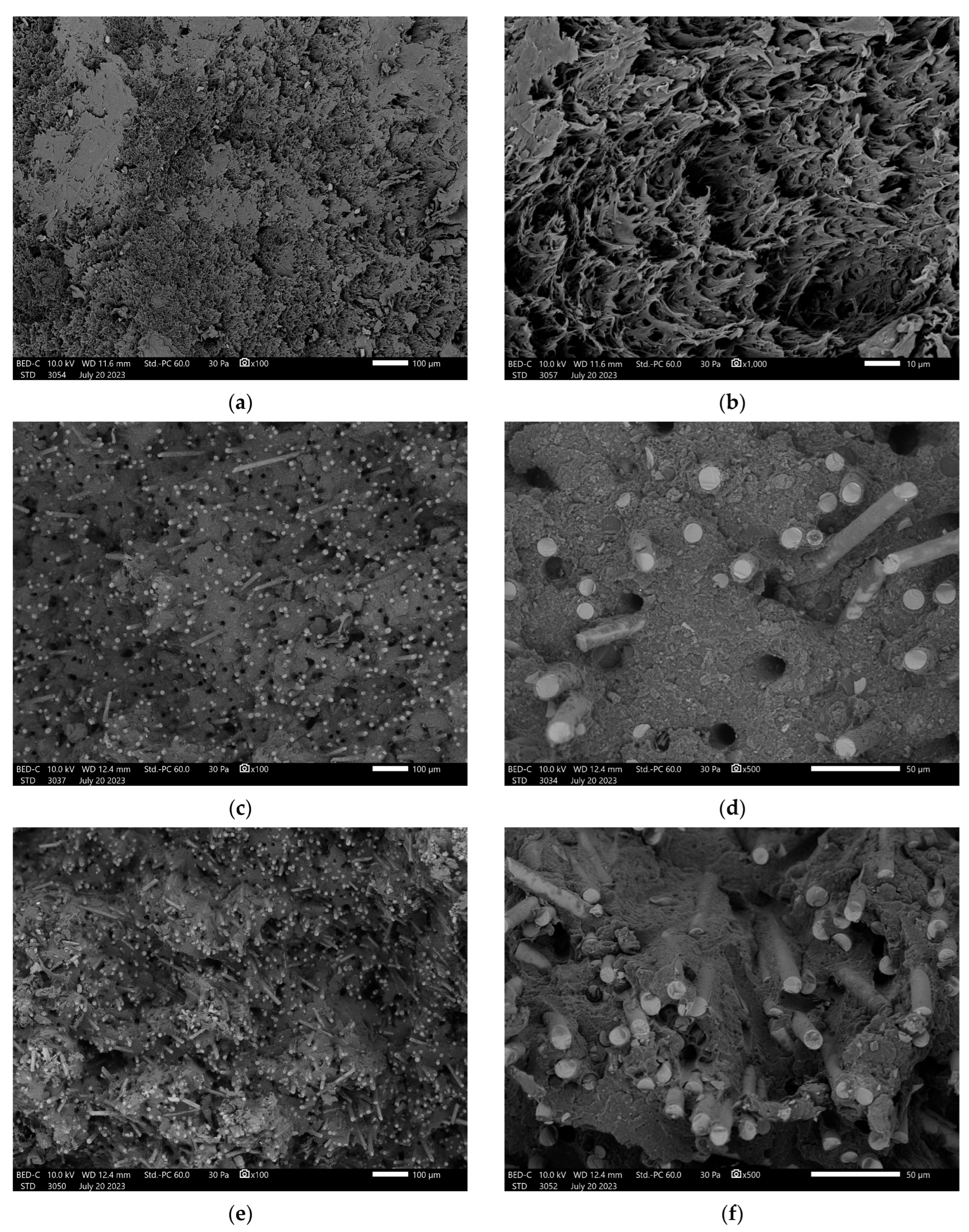

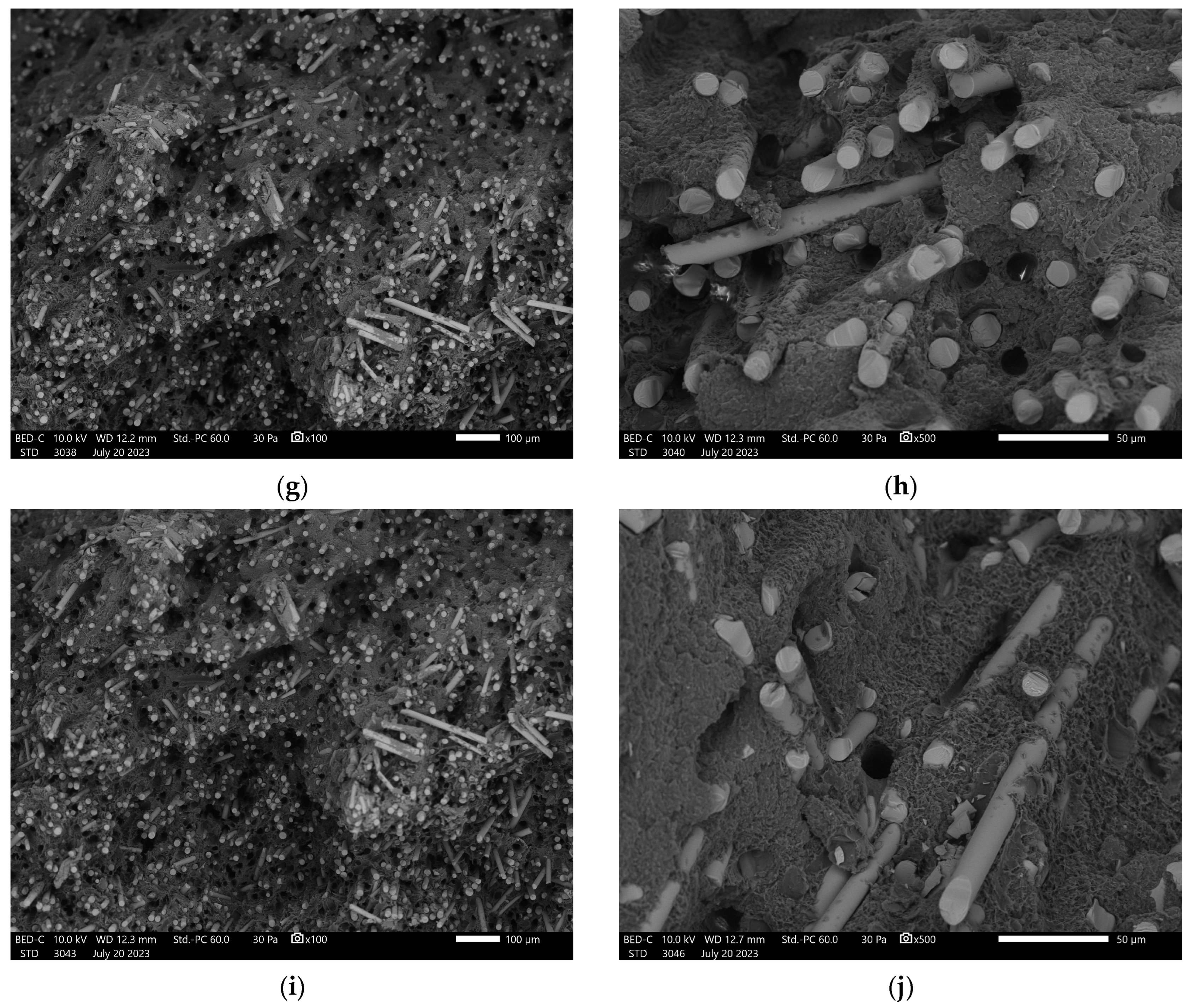

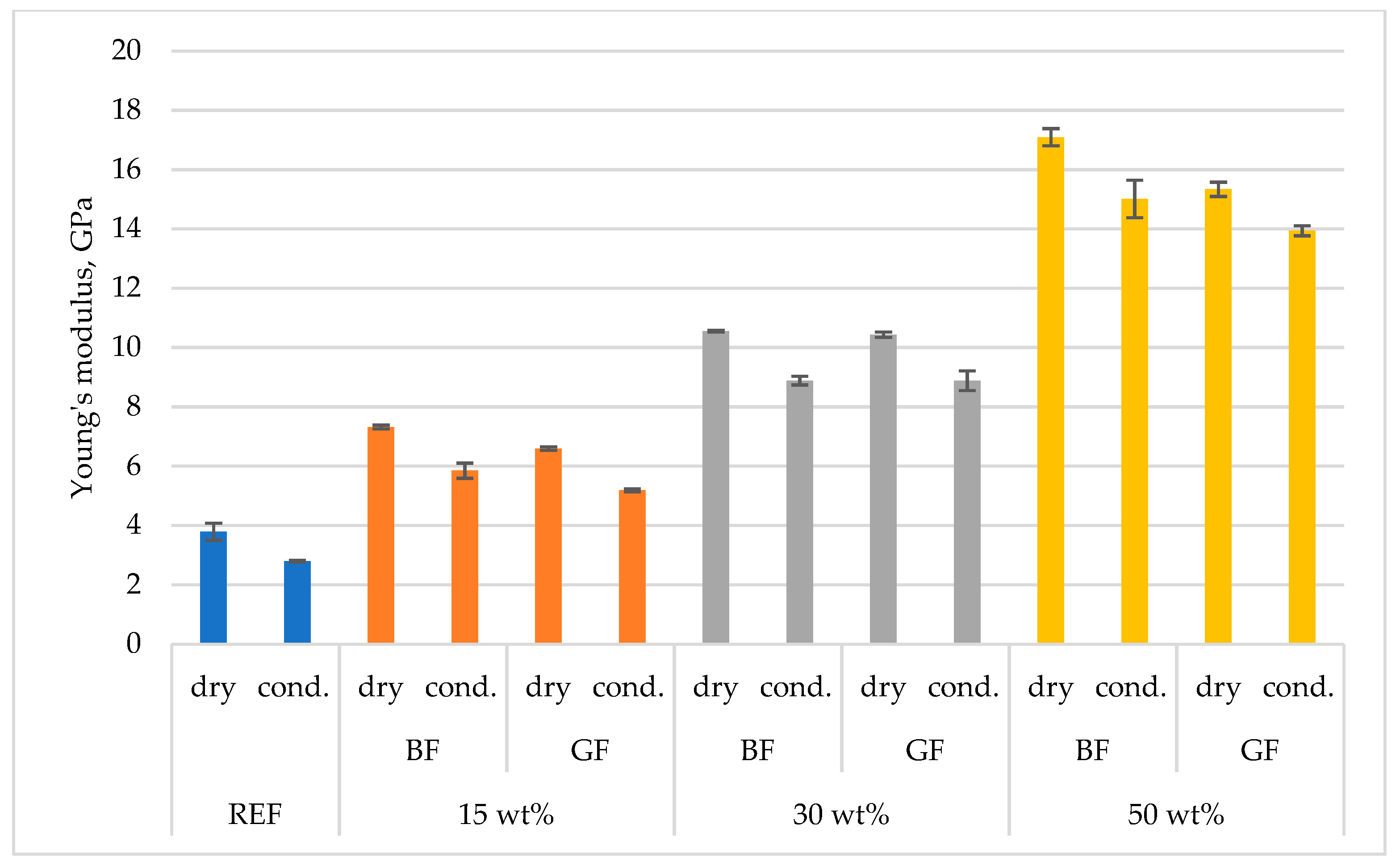

3.1. Physical and Mechanical Properties

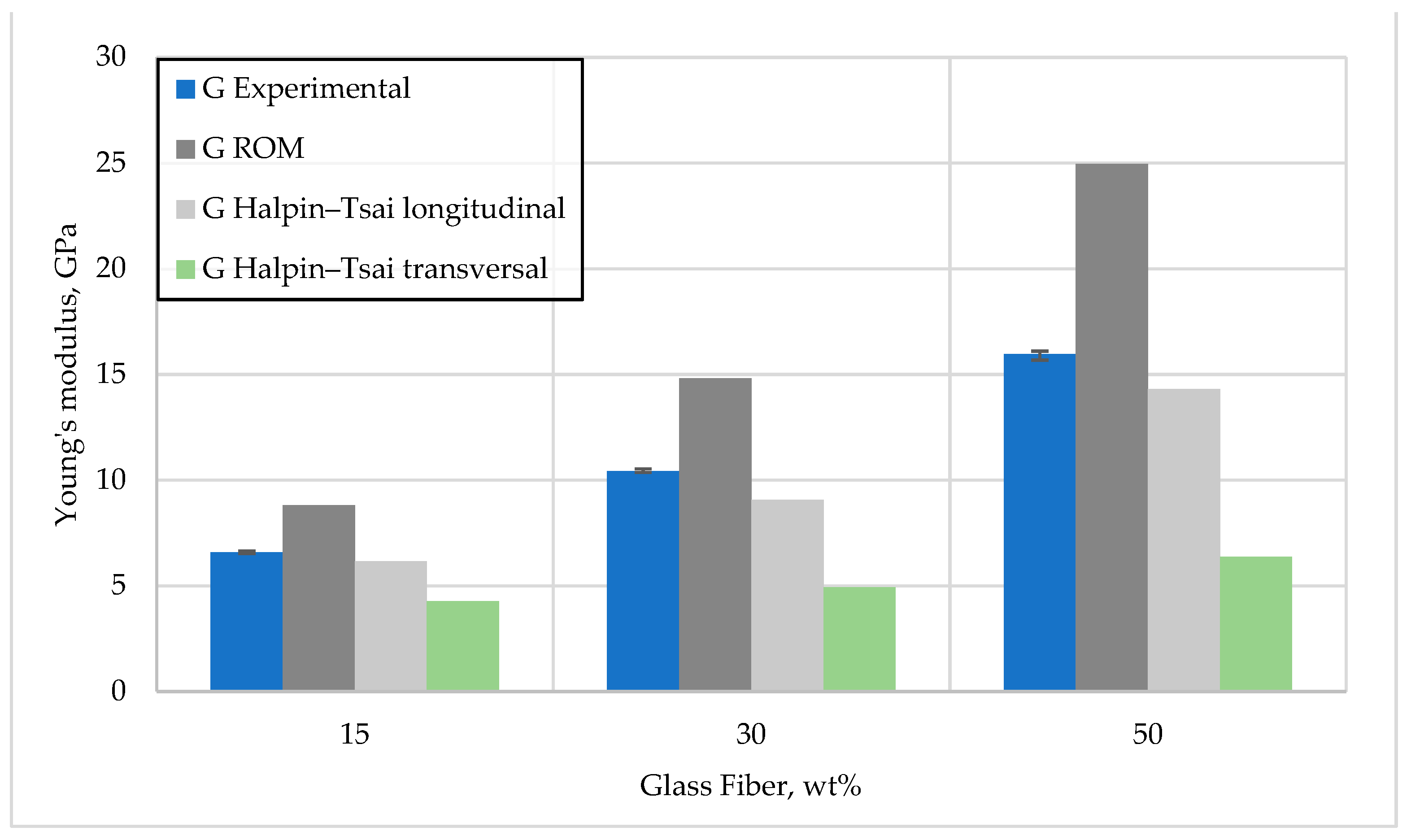

3.2. Modeling of Effective Properties

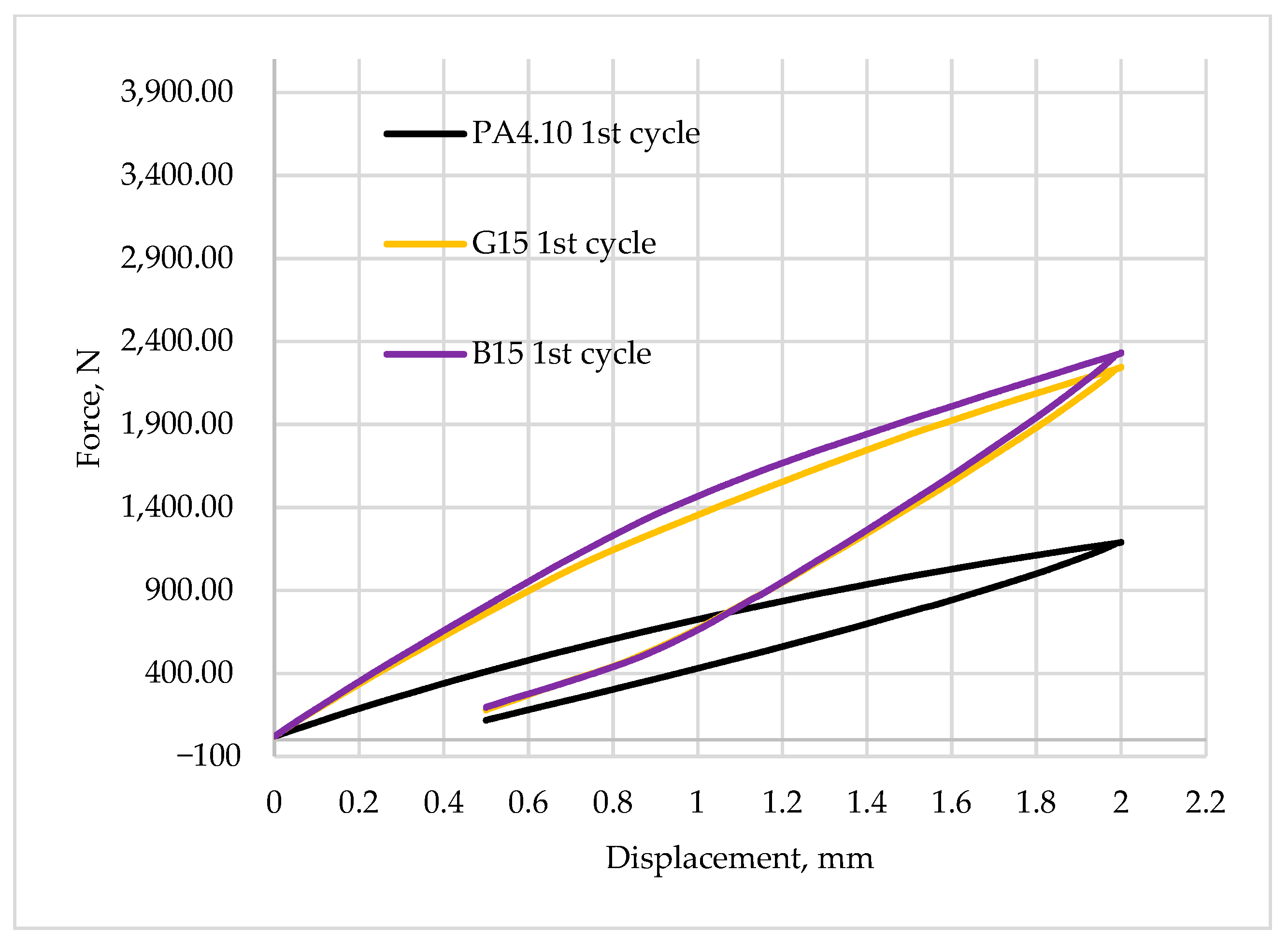

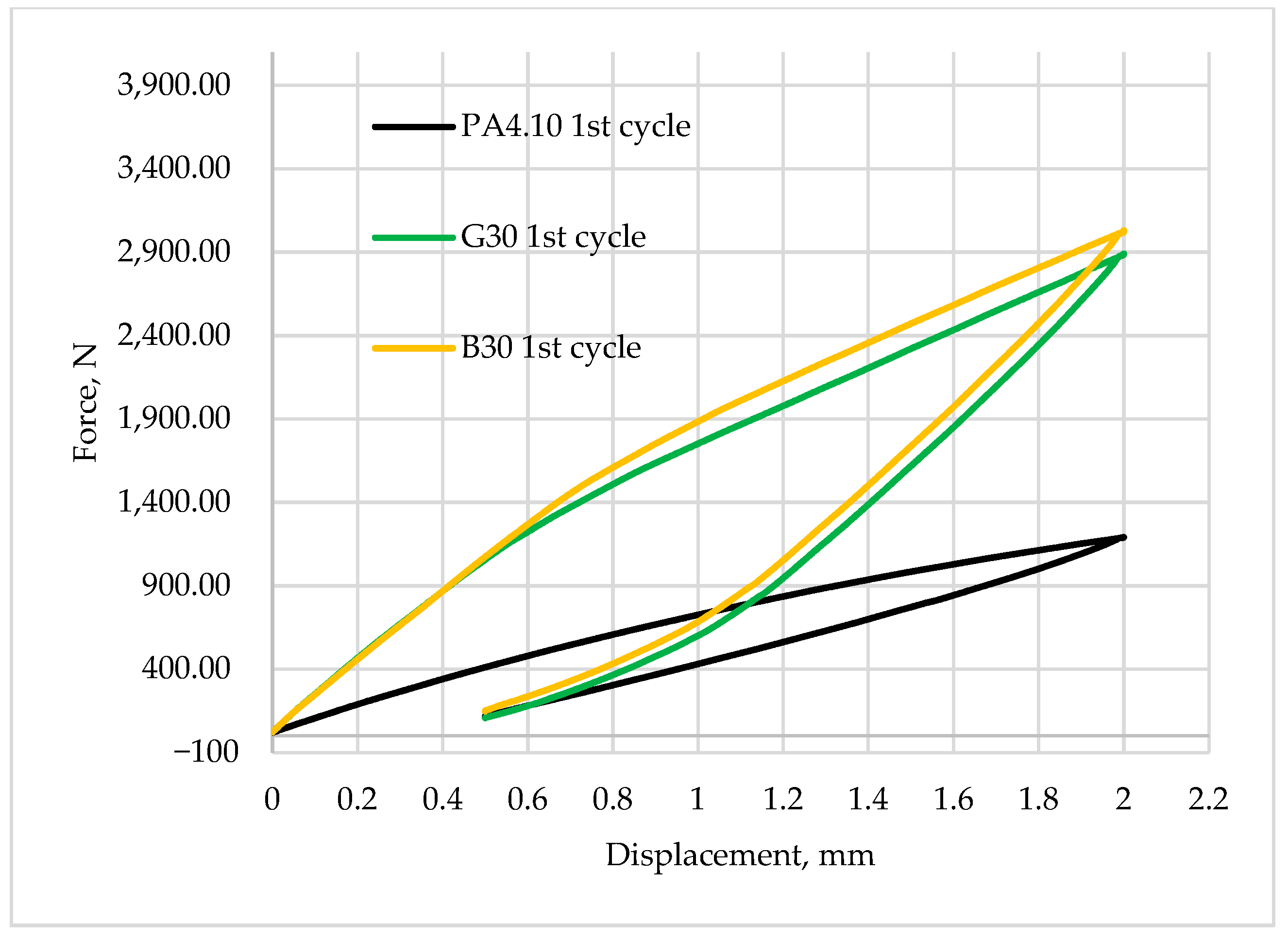

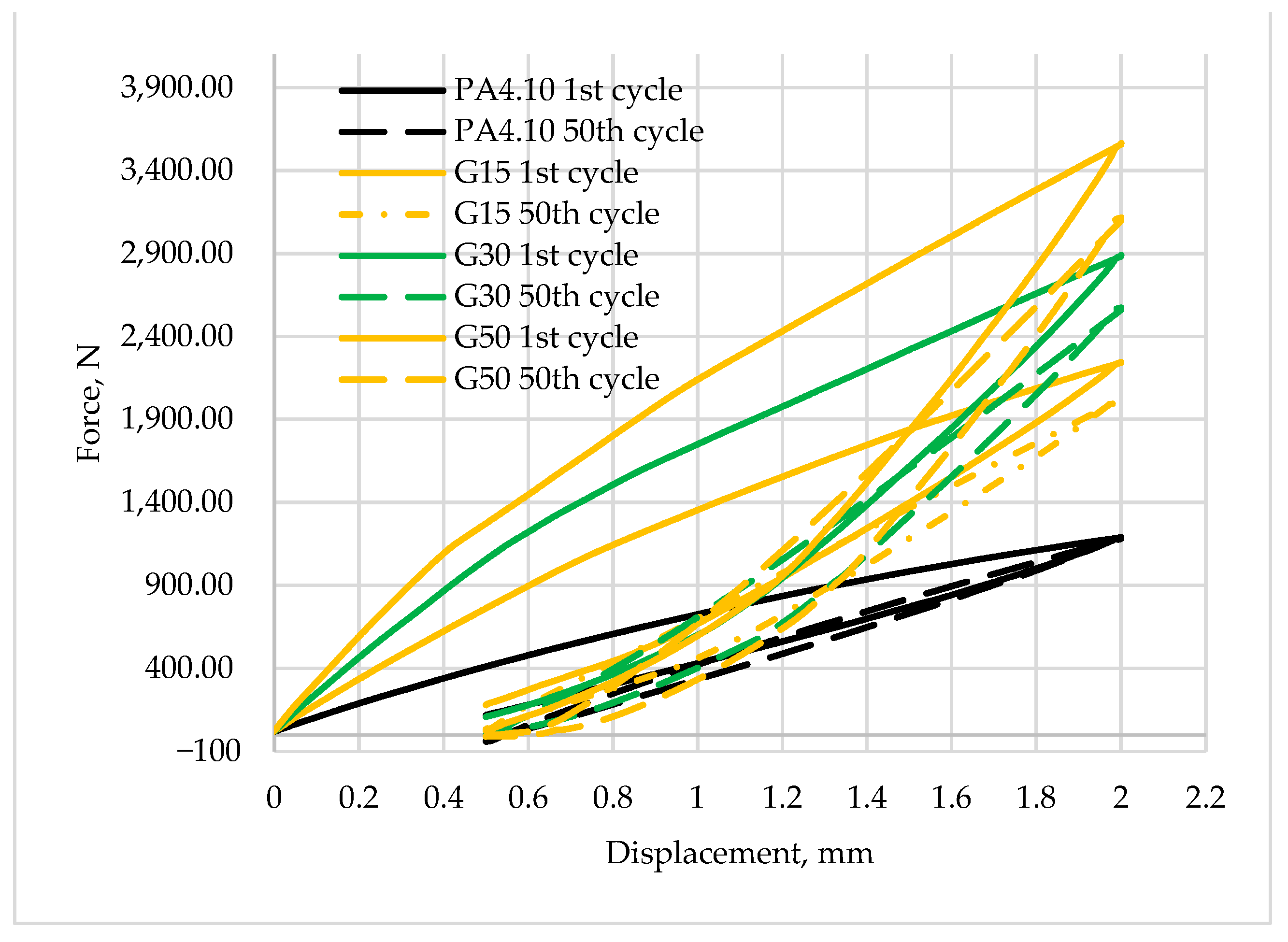

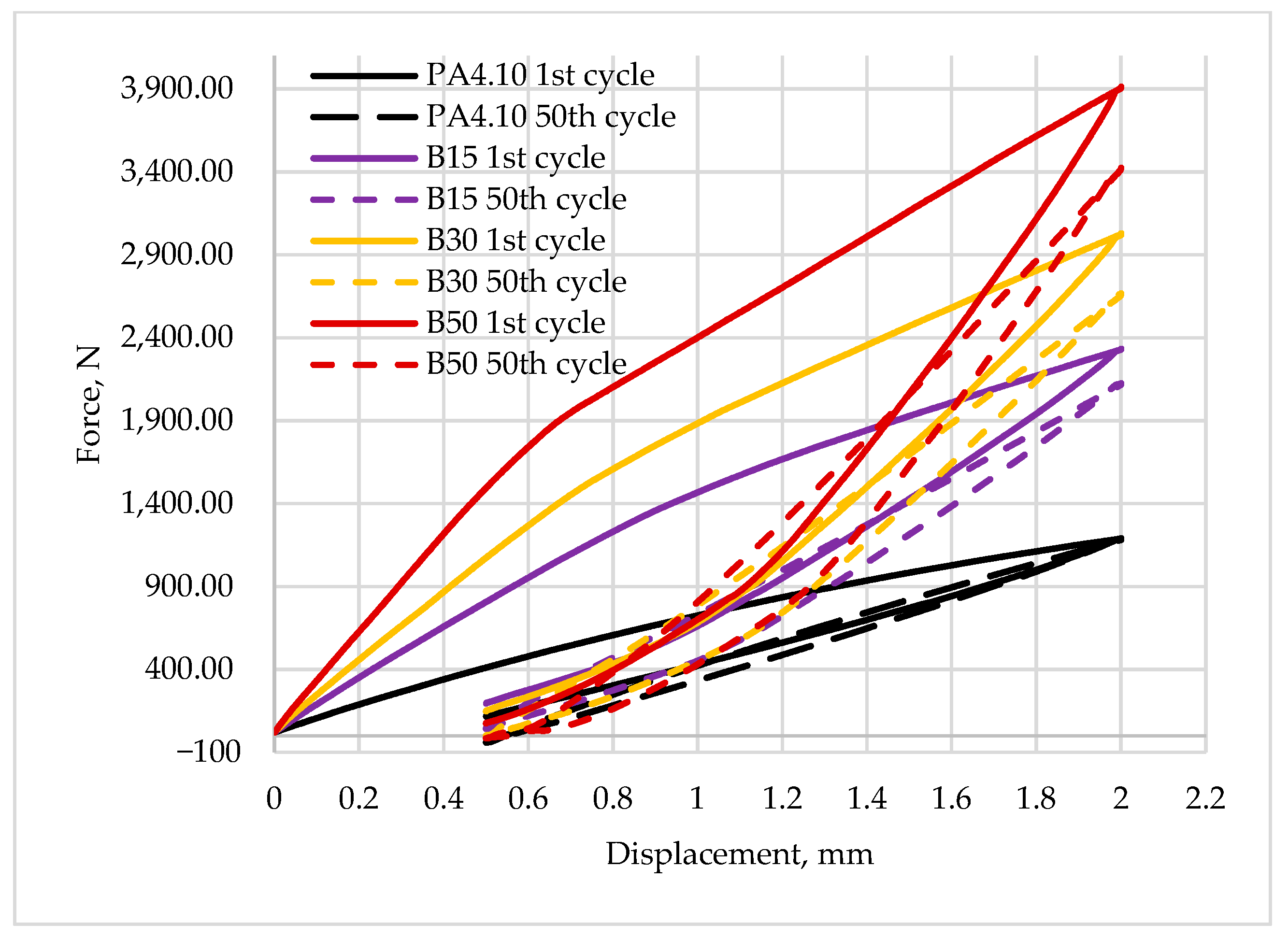

3.3. Energy Dissipation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lingesh, B.; Ravikumar, B.N.; Rudresh, B.M. Mechanical Characterization of Hybrid Thermoplastic Composites of Short Carbon Fibers and PA 66/PP. Indian J. Adv. Chem. Sci. 2016, 4, 425–434. [Google Scholar]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Al-alkawi, H.J.; Al-fattal, D.S.; Ali, A.H. Fatigue behavior of woven glass fiber reinforced polyester under variable temperature. Exil. Mech. Eng. 2012, 53, 12045–12050. [Google Scholar]

- Aramide, F.O.; Atanda, P.O.; Olorunniwo, O.E. Mechanical Properties of a Polyester Fibre Glass Composite. Int. J. Compos. Mater. 2012, 2, 147–151. [Google Scholar]

- Karakuzu, R.; Erbil, E.; Aktas, M. Impact characterization of glass/epoxy composite plates: An experimental and numerical study. Compos. Part B Eng. 2010, 41, 388–395. [Google Scholar] [CrossRef]

- Erden, S.; Sever, K.; Seki, Y.; Sarikanat, M. Enhancement of the mechanical properties of glass/polyester composites via matrix modification glass/polyester composite siloxane matrix modification. Fibers Polym. 2010, 11, 732–737. [Google Scholar] [CrossRef]

- Yuanjian, T.; Isaac, D.H. Combined impact and fatigue of glass fiber reinforced composites. Compos. Part B Eng. 2008, 39, 505–512. [Google Scholar] [CrossRef]

- Faizal, M.A.; Beng, Y.K.; Dalimin, M.N. Tensile property of hand lay-up plain-weave E-glass/polyester composite: Curing pressure and ply arrangement effect. Borneo Sci. 2008, 23, 27–34. [Google Scholar]

- Araújo, E.M.; Araújo, K.D.; Pereira, O.D.; Ribeiro, P.C.; De Melo, T.J.A. Fiberglass wastes/polyester resin composites: Mechanical properties and water sorption. Polímeros 2006, 16, 332–335. [Google Scholar] [CrossRef]

- Atas, C.; Liu, D. Impact response of woven composites with small weaving angles. Int. J. Impact Eng. 2008, 35, 80–97. [Google Scholar] [CrossRef]

- Iba, H.; Chang, T.; Kagawa, Y. Optically transparent continuous glass fibre-reinforced epoxy matrix composite: Fabriction, optical and mechanical properties. Compos. Sci. Technol. 2002, 62, 2043–2052. [Google Scholar] [CrossRef]

- Aktaş, A.; Tercan, M.; Aktaş, M.; Turan, F. Investigation of knitting architecture on the impact behavior of glass/epoxy composites. Compos. Part B Eng. 2013, 46, 81–90. [Google Scholar] [CrossRef]

- Patniak, A.; Satapathy, A.; Biswas, S. Investigations on Three-Body Abrasive Wear and Mechanical Properties of Particulate Filled Glass Epoxy Composites. Malays. Polym. J. 2010, 5, 37–48. [Google Scholar]

- Luhar, S.; Chaudhary, S.; Luhar, I. Development of rubberized geopolymer concrete: Strength and durability studies. Constr. Build. Mater. 2019, 204, 740–753. [Google Scholar] [CrossRef]

- Moura, M.D. Thermoplastic Composites and Their Promising Applications in Joining and Repair Composites Structures: A Review. Materials 2020, 13, 5832. [Google Scholar]

- Mann, G.S.; Singh, L.P.; Kumar, P.; Singh, S. Green composites: A review of processing technologies and recent applications. J. Thermoplast. Compos. Mater. 2018, 33, 1145–1171. [Google Scholar] [CrossRef]

- Bernatas, R.; Dagreou, S.; Despax-ferreres, A.; Barasinski, A. Recycling of fiber reinforced composites with a focus on thermoplastic composites. Clean. Eng. Technol. 2021, 5, 100272. [Google Scholar] [CrossRef]

- Forintos, N.; Czigány, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers—A short review. Compos. Part B 2018, 162, 331–343. [Google Scholar] [CrossRef]

- Ren, Y.; Guo, H.; Liu, Y.; Lv, R.; Zhang, Y.; Maqbool, M.; Bai, S. A trade-o ff study toward highly thermally conductive and mechanically robust thermoplastic composites by injection moulding. Compos. Sci. Technol. 2019, 183, 107787. [Google Scholar] [CrossRef]

- Bernasconi, A.; Cosmi, F.; Dreossi, D. Local anisotropy analysis of injection moulded fibre reinforced polymer composites. Compos. Sci. Technol. 2008, 68, 2574–2581. [Google Scholar] [CrossRef] [Green Version]

- Kuciel, S.; Mazur, K.; Hebda, M. The Influence of Wood and Basalt Fibres on Mechanical, Thermal and Hydrothermal Properties of PLA Composites. J. Polym. Environ. 2020, 28, 1204–1215. [Google Scholar] [CrossRef] [Green Version]

- Bazan, P.; Wierzbicka-miernik, A. A novel hybrid composites based on biopolyamide 10. 10 with basalt/aramid fibers: Mechanical and thermal investigation. Compos. Part B Eng. 2021, 223, 109125. [Google Scholar] [CrossRef]

- Park, K.; Sohn, D.; Cho, K. Eliminating weldlines of an injection-molded part with the aid of high-frequency induction heating. J. Mech. Sci. Technol. 2010, 24, 149–152. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, K. Effects of molding on property of thermally conductive and electrically insulating polyamide 6—Based composite. J. Thermoplast. Compos. Mater. 2018, 32, 1190–1203. [Google Scholar] [CrossRef]

- Winnacker, M.; Rieger, B. Biobased Polyamides: Recent Advances in Basic and Applied Research. Macromol. Rapid Commun. 2016, 37, 1391–1413. [Google Scholar] [CrossRef]

- Chaichanawong, J.; Thongchuea, C.; Areerat, S. Effect of moisture on the mechanical properties of glass fiber reinforced polyamide composites. Adv. Powder Technol. 2016, 27, 898–902. [Google Scholar] [CrossRef]

- Fredi, G.; Dorigato, A.; Pegoretti, A. Multifunctional glass fiber/polyamide composites with thermal energy storage/release capability. Express Polym. Lett. 2018, 12, 349–364. [Google Scholar] [CrossRef]

- Kausar, A.; Division, N.; Physics, F. Advances in Carbon Fiber Reinforced Polyamide-Based Composite Materials. Adv. Mater. Sci. 2019, 19, 67–82. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Pei, X.; Wang, Q. Friction and Wear Properties of Polyimide Matrix Composites Reinforced with Short Basalt Fibers Xinrui. J. Appl. Polym. Sci. 2009, 11, 2980–2985. [Google Scholar] [CrossRef]

- Hong, H.; Mingxing, Z.; Fangueiro, R.; De Araujo, M. Mechanical properties of composite materials made of 3D stitched woven-knitted preforms. J. Compos. Mater. 2010, 44, 1753–1767. [Google Scholar] [CrossRef] [Green Version]

- Park, J.M.; Shin, W.G.; Yoon, D.J. A study of interfacial aspects of epoxy-based composites reinforced with dual basalt and SiC fibres by means of the fragmentation and acoustic emission techniques. Compos. Sci. Technol. 1999, 59, 355–370. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S. Investigation of Basalt Fiber Composite Aging Behavior for Applications in Transportation. Polym. Compos. 2006, 27, 475–483. [Google Scholar] [CrossRef]

- Czigány, T.; Pölöskei, K.; Karger-Kocsis, J. Fracture and failure behavior of basalt fiber mat-reinforced vinylester/epoxy hybrid resins as a function of resin composition and fiber surface treatment. J. Mater. Sci. 2005, 40, 5609–5618. [Google Scholar] [CrossRef]

- Carmisciano, S.; Rosa, I.M.D.; Sarasini, F.; Tamburrano, A.; Valente, M. Basalt woven fiber reinforced vinylester composites: Flexural and electrical properties. Mater. Des. 2011, 32, 337–342. [Google Scholar] [CrossRef]

- Li, D.W.; Cao, H.; Chen, G.; Shi, P. Preparation and characterization of BF reinforced phenolic resin-based composites. J. Adv. Mater. 2010, 43, 67–73. [Google Scholar]

- Wang, Q.; Zhang, X.; Pei, X. Study on the friction and wear behavior of basalt fabric composites filled with graphite and nano-SiO2. Mater. Des. 2010, 31, 1403–1409. [Google Scholar] [CrossRef]

- Armioun, S.; Panthapulakkal, S.; Scheel, J.; Tjong, J.; Sain, M. Sustainable and Lightweight Biopolyamide Hybrid Composites for Greener Auto Parts. Can. J. Chem. Eng. 2016, 94, 2052–2060. [Google Scholar] [CrossRef]

- Kyulavska, M.; Toncheva-moncheva, N.; Rydz, J. Biobased Polyamide Ecomaterials and Their Susceptibility to Biodegradation. In Handbook of Ecomaterials; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Nikiforov, A.A.; Volfson, S.I.; Rinberg, R.; Okhotina, N.A.; Fayzullin, I.Z. Effect of Lubricants on Fiber Length Distribution and Properties of Glass Fiber Reinforced Composites Based on Polyamide 1010. Key Eng. Mater. 2019, 816, 202–207. [Google Scholar] [CrossRef]

- Rinberg, R.; Kroll, L. Stress-Strain Properties of Composites Based on Bio-Based Polyamide 1010 Filled with Cut Fibers. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2016. [Google Scholar] [CrossRef] [Green Version]

- Rinberg, R.; Hartmann, T.; Nikiforov, A.; Doynikov, A.; Volfson, S. Investigation of bio-based polyamide with short fibers for lightweight structures. Technol. Lightweight Struct. 2021, 1, 147–156. [Google Scholar] [CrossRef]

- Kuciel, S.; Kuÿnia, P.; Jakubowska, P. Properties of composites based on polyamide 10. 10 reinforced with carbon fibers. Polimery 2016, 61, 106–112. [Google Scholar] [CrossRef]

- Karki, S.; Gohain, M.B.; Yadav, D.; Ingole, P.G. Nanocomposite and bio-nanocomposite polymeric materials/membranes development in energy and medical sector: A review. Int. J. Biol. Macromol. 2021, 193, 2121–2139. [Google Scholar] [CrossRef] [PubMed]

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- ISO 1172; Textile-Glass-Reinforced Plastics—Prepregs, Moulding Compounds and Laminates—Determination of the Textile-glass and Mineral-Filler Content—Calcination Methods. ISO: Geneva, Switzerland, 1996.

- Boczkowska, A.; Kapuściński, J.; Lindemann, Z.; Witemberg-Perzyk, D.; Wojciechowski, S. Kompozyty; Oficyna Wydawnicza |Politechniki Warszawskiej: Warszawa, Poland, 2003. [Google Scholar]

- Liu, J.; Chen, M.; Yang, J.; Wu, Z. Study on mechanical properties of basalt fibers superior to E-glass fibers. J. Nat. Fibers 2022, 19, 882–894. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar]

- Manikandan, V.; Jappes, J.W.; Kumar, S.S.; Amuthakkannan, P.J.C.P.B.E. Investigation of the effect of surface modifications on the mechanical properties of basalt fibre reinforced polymer composites. Compos. Part B Eng. 2012, 43, 812–818. [Google Scholar]

- Wu, Z.; Wang, X.; Iwashita, K.; Sasaki, T.; Hamaguchi, Y. Tensile fatigue behaviour of FRP and hybrid FRP sheets. Compos. Part B Eng. 2010, 41, 396–402. [Google Scholar]

- Dorigato, A.; Pegoretti, A. Fatigue resistance of basalt fibers-reinforced laminates. J. Compos. Mater. 2012, 46, 1773–1785. [Google Scholar]

- Song, J.; Liu, J.; Zhang, Y.; Chen, L.; Zhong, Y.; Yang, W. Basalt fibre-reinforced PA1012 composites: Morphology, mechanical properties, crystallization behaviours, structure and water contact angle. J. Compos. Mater. 2015, 49, 415–424. [Google Scholar] [CrossRef]

- Aboudi, J.; Arnold, A.; Bednarcyk, B. Micromechanics of Composite Materials. A Generalized Multiscale Analysis Approach; Elsevier: Oxford, UK, 2013. [Google Scholar]

- Mortazavian, S.; Fatemi, A. Effects of Fiber Orientation and Anisotropy on Tensile Strength and Elastic Modulus of Short Fiber Reinforced Polymer Composites. Compos. Part B Eng. 2014, 72, 116–129. [Google Scholar] [CrossRef]

- Nabiałek, J.; Kwiatkowski, D.; Gnatowski, A. Modelowanie procesu wtryskiwania wielokomponentowego kompozytów polimerowych. Kompozyty 2010, 10, 340–343. [Google Scholar]

- Science, M.; Western, C.; Unizjersity, R. The Reinforcement Mechanism of Fiber-Glass Reinforced Plastics under Wet Conditions: A Review. Polym. Eng. Sci. 1978, 18, 128–145. [Google Scholar]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

- Halpin, J.; Tsai, S. Environmental factors in composite materials design. In Air Force Technical Report AFML-TR; Wright Aeronautical Labs: Dayton, OH, USA, 1967. [Google Scholar]

- Suarez, S.A.; Gibson, R.F.; Sun, C.T.; Chaturvedi, S.K. The influence of fiber length and fiber orientation on damping and stiffness of polymer composite materials. Exp. Mech. 1986, 26, 175–184. [Google Scholar] [CrossRef]

- Mazurkiewicz, S.; Porębska, R. Próba oceny jakości struktury kompozytów za pomocą pierwszych obciążeń cyklicznych. Czas. Tech. 2004, 101, 87–92. [Google Scholar]

- Porebska, R.; Mazurkiewicz, S. Disspated Energy in polymeric composites. Tech. Trans. 2009, 3, 1–4. [Google Scholar]

- Bazan, P.; Ewelina, K.; Rybicka, K. The influence of organic and inorganic antibacterial additives on the strength and biocidal properties of thermoplastic elastomers (TPO). Ind. Crops Prod. 2023, 198, 116682. [Google Scholar] [CrossRef]

- Bazan, P.; Kuciel, S.; Nykiel, M. Characterization of composites based on polyoxymethylene and effect of silicone addition on mechanical and tribological behavior. Polym. Eng. Sci. 2019, 59, 935–940. [Google Scholar] [CrossRef]

- Cieszyński, T.; Topoliński, T. Badania zmęczeniowe kompozytów polimerowych przy sterowaniu energią dyssypacji. Czas. Tech. Mech.-WPK. Mech. 2006, 103, 115–119. [Google Scholar]

| Description | Index | Matrix | Reinforcement | % wt. Share |

|---|---|---|---|---|

| PA410 + 15% Glass fiber | G15 | PA410 | ChopVantage HP3610 | 15 |

| PA410 + 30% Glass fiber | G30 | 30 | ||

| PA410 + 50% Glass fiber | G50 | 50 | ||

| PA410 + 15% Basalt fiber | B15 | BSC13-3.2-KV02M | 15 | |

| PA410 + 30% Basalt fiber | B30 | 30 | ||

| PA410 + 50% Basalt fiber | B50 | 50 |

| Index | RPM | Torque, % | Feeder, TS | RPM Side | Feeder GF/BF | Temperature of Cylinder, °C | RPM Reception | RPM Cutting |

|---|---|---|---|---|---|---|---|---|

| G15 | 90 | 55 | 20 | 100 | 5 | 260/250 | 40 | 30 |

| G30 | 82 | 25 | 100 | 15 | 260/250 | 45 | 30 | |

| G50 | 82 | 20 | 100 | 25 | 260/250 | 40 | 30 | |

| B15 | 69 | 25 | 100 | 20/10 | 260/250 | 40 | 30 | |

| B30 | 59 | 20 | 100 | 35/10 | 260/250 | 35 | 30 | |

| B50 | 56 | 15 | 100-150-460 | 65/10 | 260/250 | 33 | 25 |

| I Zone, °C | II Zone, °C | III Zone, °C | IV ZONE, °C | Nozzle, °C | Pressure of Injection, Bar | Pressure of Packing, Bar | Mold, °C |

|---|---|---|---|---|---|---|---|

| 260 | 265 | 265 | 275 | 290 | 1400 | 500 | 80 |

| Index | Filler Content, wt% | Arithmetic Mean Length, µm | Weighted Mean Length, µm |

|---|---|---|---|

| REF3* | 36.3 | 375 | 429 |

| REF5* | 49.3 | 312 | 351 |

| G15 | 14.7 | 226 | 264 |

| G30 | 26.7 | 252 | 284 |

| G50 | 48.0 | 220 | 261 |

| B15 | 17.7 | 348 | 399 |

| B30 | 30.6 | 389 | 453 |

| B50 | 49.3 | 328 | 365 |

| Index | Tensile Strength, MPa | Tensile Modulus, MPa | Strain at Break, % | Impact Strength, kJ/m2 |

|---|---|---|---|---|

| REF | 40.3 ± 0.3 | 2765 ± 45 | 5.53 ± 0.8 | ± |

| REF3* | 91.6 ± 2.3 | 8502 ± 210 | 2.8 ± 0.4 | 5.000 ± 0.140 |

| REF5* | 201.1 ± 0.4 | 15,333 ± 458 | 5.3 ± 0.2 | 4.082 ± 0.240 |

| G15 | 107.0 ± 0.2 | 6587 ± 57 | 4.4 ± 0.1 | 2.102 ± 0.012 |

| G30 | 144.8 ± 0.5 | 10,432 ± 94 | 4.7 ± 0.2 | 2.683 ± 0.197 |

| G50 | 174.6 ± 2.1 | 15,955 ± 241 | 4.6 ± 0.1 | 2.555 ± 0.133 |

| B15 | 117.4 ± 0.4 | 7313 ± 65 | 4.4 ± 0.1 | 2.090 ± 0.146 |

| B30 | 145.8 ± 0.5 | 10,552 ± 34 | 4.5 ± 0.2 | 2.466 ± 0.304 |

| B50 | 180.5 ± 0.6 | 17,091 ± 291 | 4.5 ± 0.1 | 2.513 ± 0.223 |

| Index | Energy Dissipation, J | ||

|---|---|---|---|

| 1st Cycle | 2nd Cycle | 50th Cycle | |

| REF | 0.454 | 0.157 | 0.099 |

| G15 | 0.943 | 0.306 | 0.229 |

| G30 | 1.499 | 0.483 | 0.327 |

| G50 | 2.026 | 0.639 | 0.397 |

| B15 | 1.057 | 0.349 | 0.259 |

| B30 | 1.537 | 0.498 | 0.346 |

| B50 | 2.245 | 0.702 | 0.438 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bednarowski, D.; Bazan, P.; Kuciel, S. Enhancing Strength and Sustainability: Evaluating Glass and Basalt Fiber-Reinforced Biopolyamide as Alternatives for Petroleum-Based Polyamide Composite. Polymers 2023, 15, 3400. https://doi.org/10.3390/polym15163400

Bednarowski D, Bazan P, Kuciel S. Enhancing Strength and Sustainability: Evaluating Glass and Basalt Fiber-Reinforced Biopolyamide as Alternatives for Petroleum-Based Polyamide Composite. Polymers. 2023; 15(16):3400. https://doi.org/10.3390/polym15163400

Chicago/Turabian StyleBednarowski, Dariusz, Patrycja Bazan, and Stanisław Kuciel. 2023. "Enhancing Strength and Sustainability: Evaluating Glass and Basalt Fiber-Reinforced Biopolyamide as Alternatives for Petroleum-Based Polyamide Composite" Polymers 15, no. 16: 3400. https://doi.org/10.3390/polym15163400