Preparation and Product Characterization of Microwaveable Food Using Lentinus edodes Protein through 3D Printing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Determination of Amino Acid Composition in Lentinus edodes Protein

2.3. Preparation of LP/Potato Flour Mixture for 3D Printing

2.4. Three-Dimensional Printing of Microwaveable Food Products

2.5. Rheological Measurements

2.6. Pasting Behaviors

2.7. Texture Analysis

2.8. Low Field-Nuclear Magnetic Resonance (LF-NMR) Analysis

2.9. Fourier Transforms Infrared (FTIR) Spectroscopy

2.10. Sensory Evaluation

2.11. Statistical Analysis

3. Results and Discussion

3.1. Analysis of LP Amino Acid Composition

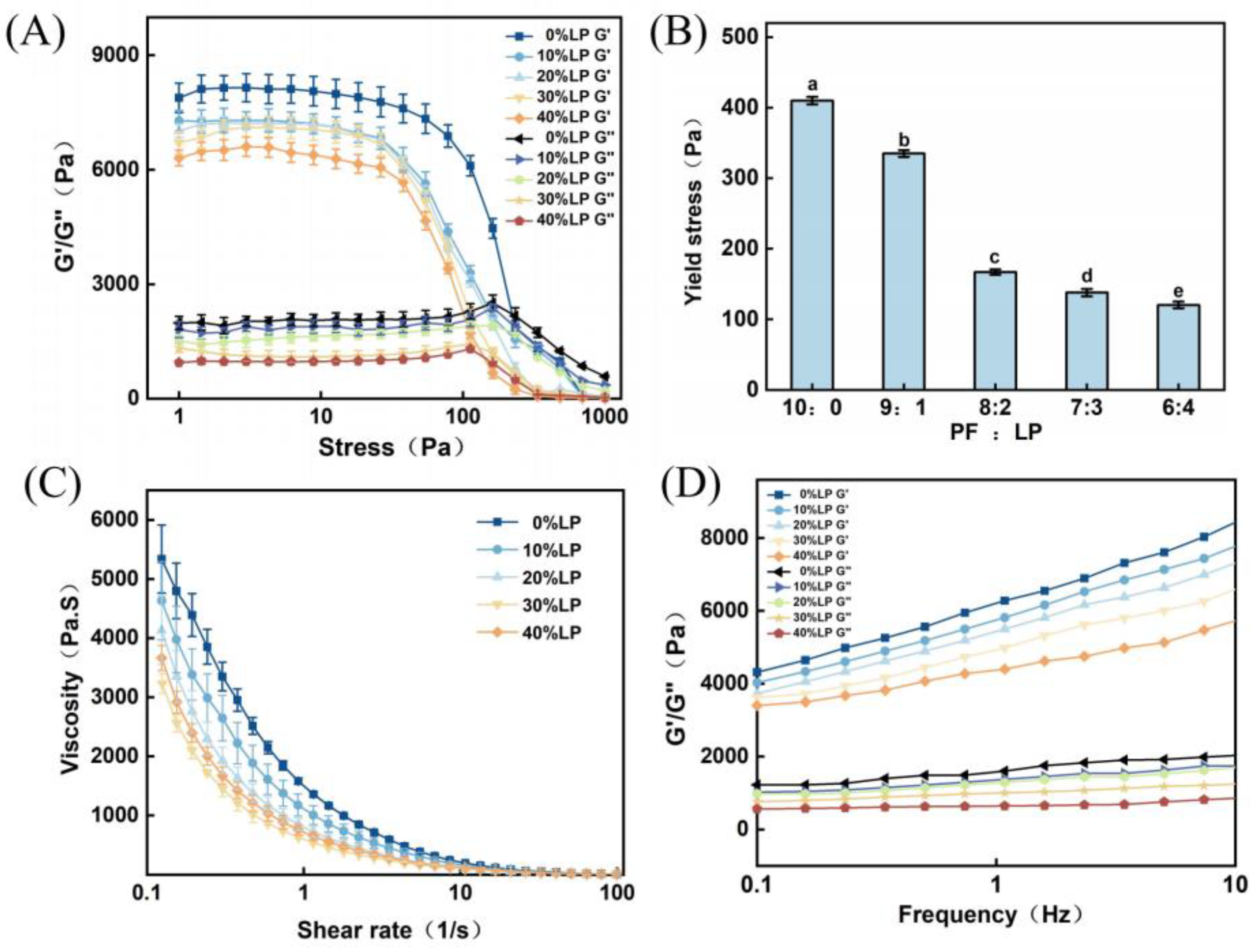

3.2. Rheological Properties and Correlation with 3D Printing Behavior

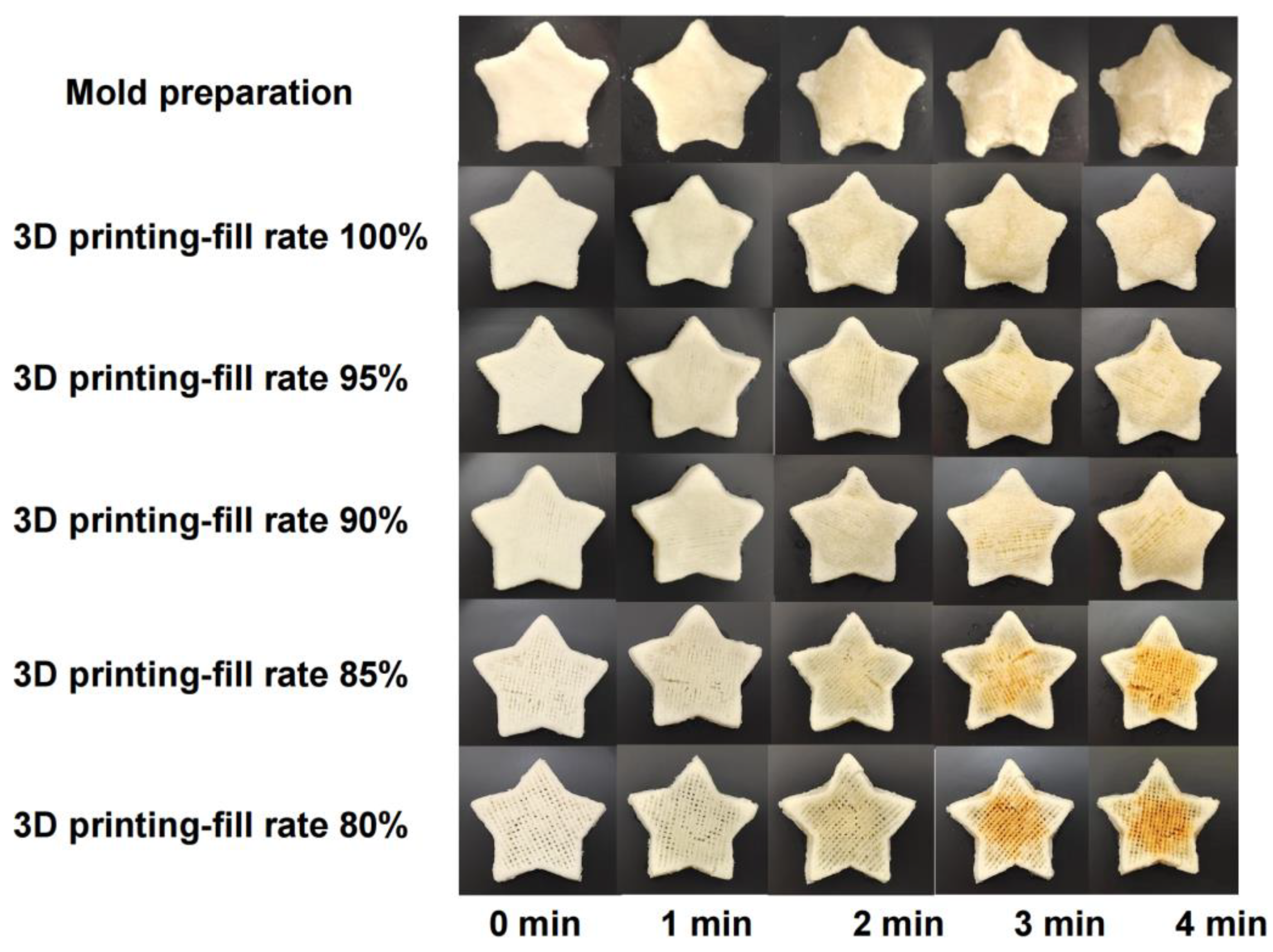

3.3. The 3D Printing Performance Analysis of 3D-Printed Ink

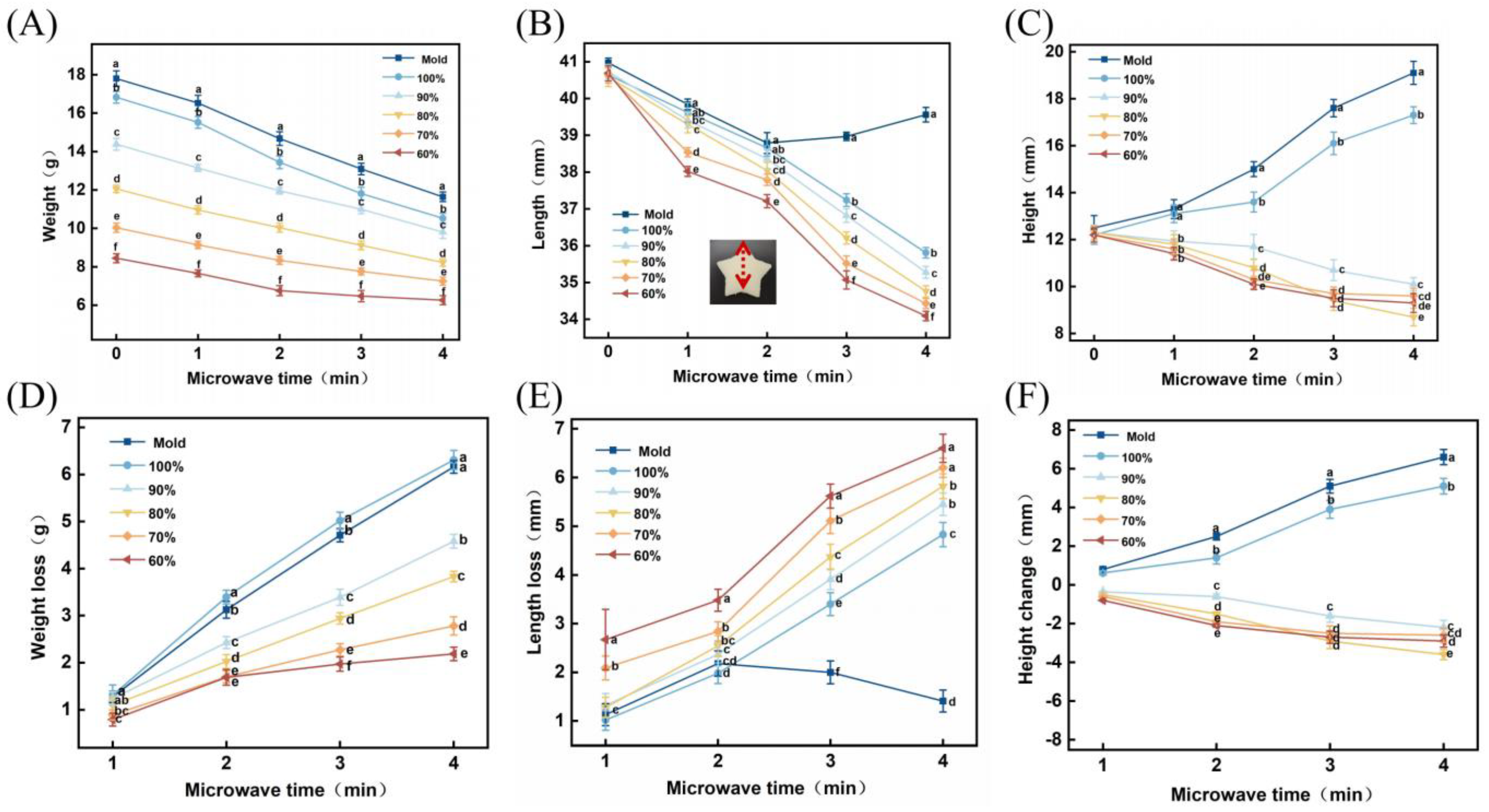

3.4. Comparative Analysis of 3D-Printed Samples and Molded Samples with Different Fill Ratios after Microwave Treatment

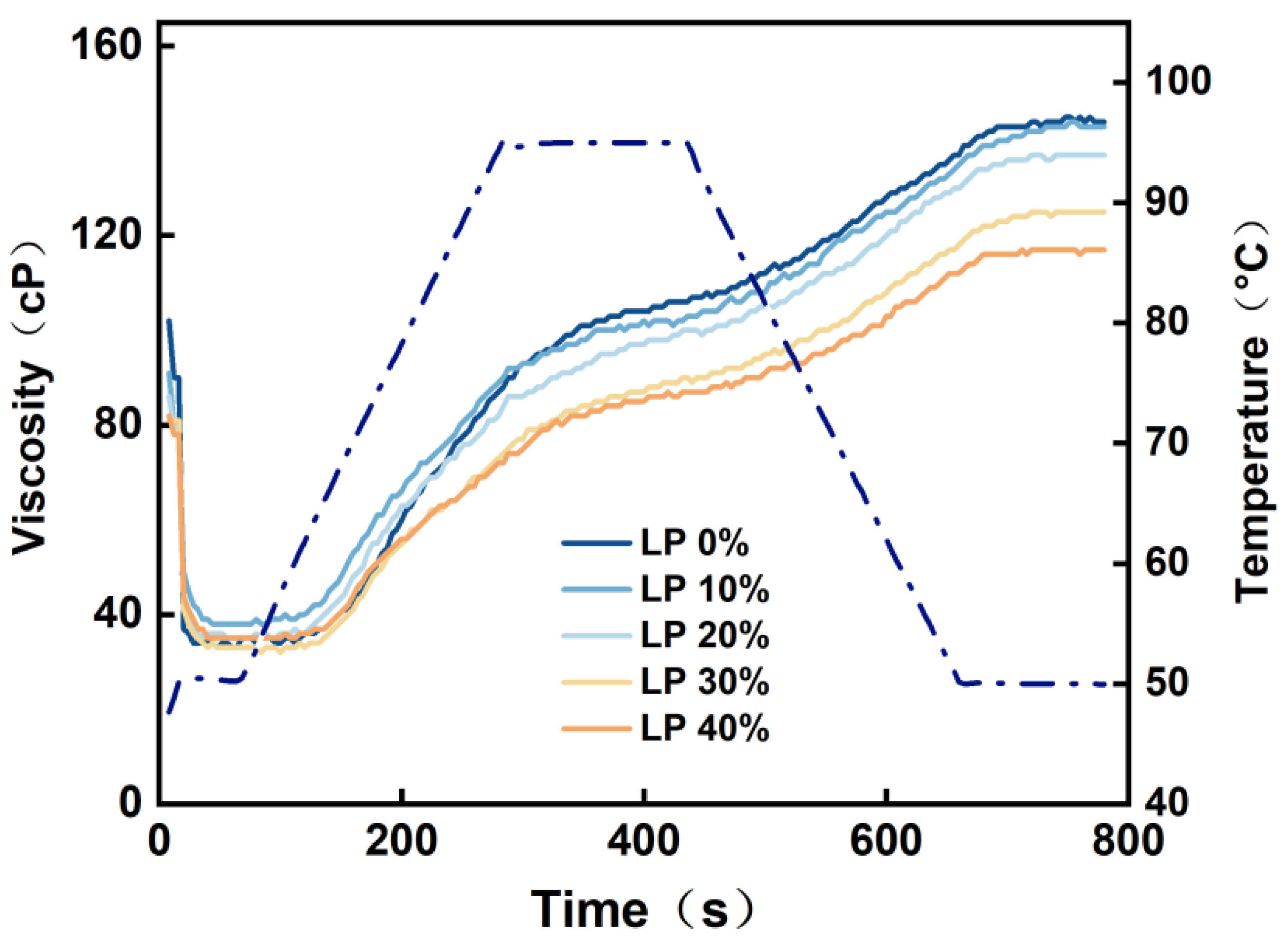

3.5. Analysis of Gelatinization Characteristics of LP–Potato Starch

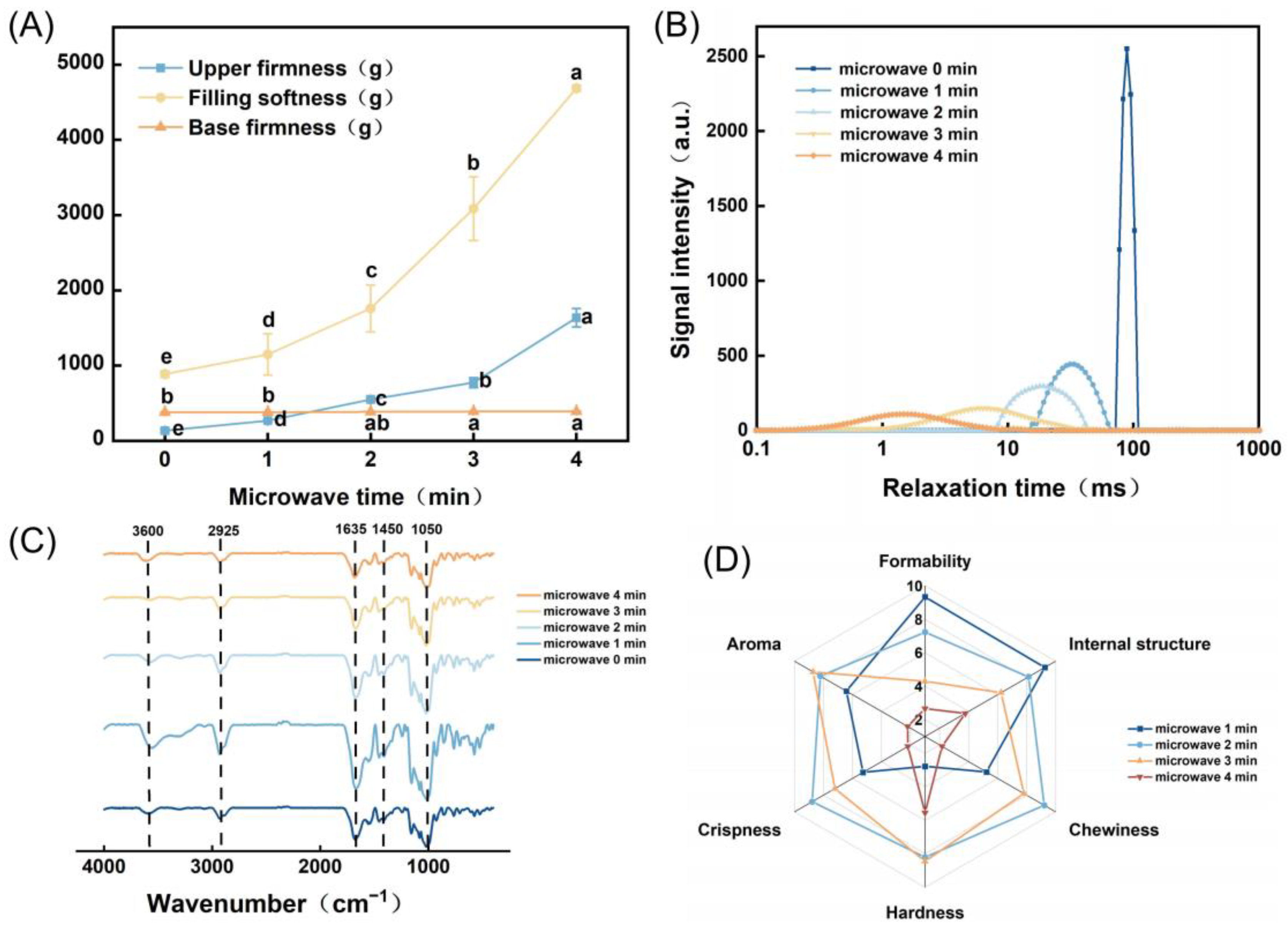

3.6. Analysis of Texture Characteristics of LP-Based 3D-Printed Microwave Food

3.7. Analysis of LF-NMR in LP-Based 3D-Printed Food

3.8. FT-IR Analysis of LP-Based 3D-Printed Food

3.9. Sensory Evaluation Analysis of LP-Based 3D-Printed Food

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Roach, D.J.; Hamel, C.M.; Dunn, C.K.; Johnson, M.V.; Qi, H.J. The m4 3d printer: A multi-material multi-method additive manufacturing platform for future 3d printed structures. Addit. Manuf. 2019, 29, 100819. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Pandya, J.K.; McClements, D.J.; Lu, J.; Kinchla, A.J. Advancements in 3D food printing: A comprehensive overview of properties and opportunities. Crit. Rev. Food Sci. Nutr. 2022, 62, 4752–4768. [Google Scholar] [CrossRef] [PubMed]

- Singhal, S.; Rasane, P.; Kaur, S.; Garba, U.; Bankar, A.; Singh, J.; Gupta, N. 3D food printing: Paving way towards novel foods. An. Acad. Bras. Ciências 2020, 92, e20180737. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of rheological properties of mashed potatoes on 3d printing. J. Food Eng. 2017, 220, 76–82. [Google Scholar] [CrossRef]

- Wen, Y.; Che, Q.T.; Kim, H.W.; Park, H.J. Potato starch altered the rheological, printing, and melting properties of 3D-printable fat analogs based on inulin emulsion-filled gels. Carbohydr. Polym. 2021, 269, 118285. [Google Scholar] [CrossRef]

- Liu, Z.; Xing, X.; Xu, D.; Chitrakar, B.; Hu, L.; Hati, S.; Mo, H.; Li, H. Correlating rheology with 3D printing performance based on thermo-responsive κ-carrageenan/Pleurotus ostreatus protein with regard to interaction mechanism. Food Hydrocoll. 2022, 131, 107813. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Liu, X.; Wang, W.; Wang, J.; Li, X.; Sun, S. Preparation and identification of peptides with α-glucosidase inhibitory activity from shiitake mushroom (Lentinus edodes) protein. Foods 2023, 12, 2534. [Google Scholar] [CrossRef]

- Spim, S.R.V.; Pistila, A.M.H.; Pickler, T.B.; Silva, M.T.; Grotto, D. Effects of shiitake culinary-medicinal mushroom, lentinus edodes (agaricomycetes), bars on lipid and antioxidant profiles in individuals with borderline high cholesterol: A double-blind randomized clinical trial. Int. J. Med. Mushrooms 2021, 23, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Zannou, O.; Oussou, K.F.; Chabi, I.B.; Odouaro, O.B.O.; Deli, M.G.E.P.; Goksen, G.; Vahid, A.M.; Kayodé, A.P.P.; Kelebek, H.; Selli, S.; et al. A comprehensive review of recent development in extraction and encapsulation techniques of betalains. Crit. Rev. Food Sci. Nutr. 2023, 21, 1–18. [Google Scholar] [CrossRef]

- Wu, Y.; Mu, R.; Li, G.; Li, M.; Lv, W. Research progress in fluid and semifluid microwave heating technology in food processing. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3436–3454. [Google Scholar] [CrossRef] [PubMed]

- Tang, T.; Zhang, M.; Mujumdar, A.S.; Teng, X. 3D printed white radish/potato gel with microcapsules: Color/flavor change induced by microwave-infrared heating. Food Res. Int. 2022, 158, 111496. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M. Texture properties of microwave post-processed 3D printed potato snack with different ingredients and infill structure. Future Foods 2021, 3, 100017. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, Z.; Zhang, X.; He, C.; Zhang, X. Microwave-triggered 4D automatic color change in 3D-printed food materials incorporating natural pigments. Foods 2023, 12, 2055. [Google Scholar] [CrossRef]

- Guo, C.; Zhang, M.; Bhandari, B.; Devahastin, S. Investigation on simultaneous change of deformation, color and aroma of 4D printed starch-based pastes from fruit and vegetable as induced by microwave. Food Res. Int. 2022, 157, 111214. [Google Scholar] [CrossRef]

- Phuhongsung, P.; Zhang, M.; Bhandari, B. 4D printing of products based on soy protein isolate via microwave heating for flavor development. Food Res. Int. 2020, 137, 109605. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Wang, P.; Yang, Z.; Xu, X. 3D printing based on meat materials: Challenges and opportunities. Curr. Res. Food Sci. 2022, 6, 100423. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Kuenzel, C.; Gundlach, C.; Spangenberg, J. Rheological characterization of 3d printable geopolymers. Cem. Concr. Res. 2021, 147, 106498. [Google Scholar] [CrossRef]

- Starzyńska-Janiszewska, A.; Stodolak, B.; Fernández-Fernández, C.; Mickowska, B.; Verardo, V.; Gómez-Caravaca, A.M. Phenolic profile, antioxidant activity and amino acid composition of moringa leaves fermented with edible fungal strains. Foods 2022, 22, 3762. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Guo, C.; Zheng, W.; Cao, S.; Lu, H.; Mo, H.; Li, H. 3D printing of shiitake mushroom incorporated with gums as dysphagia diet. Foods 2021, 10, 2189. [Google Scholar] [CrossRef]

- Pulatsu, E.T.; Su, J.W.; Lin, J.; Lin, M. Factors affecting 3d printing and post-processing capacity of cookie dough. Innov. Food Sci. Emerg. Technol. 2020, 61, 102316. [Google Scholar] [CrossRef]

- Yu, X.; Zhao, Z.; Zhang, N.; Yan, B.; Gao, W.; Huang, J.; Zhao, J.; Zhang, H.; Chen, W.; Fan, D. Effects of preheating-induced denaturation treatments on the printability and instant curing property of soy protein during microwave 3D printing. Food Chem. 2022, 397, 133682. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, L.; Wang, H.; Ai, L.; Xiong, W. Insight into protein-starch ratio on the gelatinization and retrogradation characteristics of reconstituted rice flour. Int. J. Biol. Macromol. 2020, 146, 524–529. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, M.; Bhandari, B.; Yang, P. Intelligent detection of flavor changes in ginger during microwave vacuum drying based on LF-NMR. Food Res. Int. 2019, 119, 417–425. [Google Scholar] [CrossRef]

- Dankar, I.; Haddarah, A.; Omar, F.E.L.; Pujolà, M.; Sepulcre, F. Characterization of food additive-potato starch complexes by FTIR and X-ray diffraction. Food Chem. 2018, 260, 7–12. [Google Scholar] [CrossRef]

- Santosh, O.; Bajwa, H.K.; Bisht, M.S.; Chongtham, N. Antioxidant activity and sensory evaluation of crispy salted snacks fortified with bamboo shoot rich in bioactive compounds. Appl. Food Res. 2021, 1, 100018. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.R.; Wang, Y. 3d printing: Printing precision and application in food sector. Trends Food Sci. Technol. 2017, 69, 83–94. [Google Scholar] [CrossRef]

- Chen, H.M.; Fu, X.; Luo, Z.G. Effect of gum arabic on freeze-thaw stability, pasting and rheological properties of tapioca starch and its derivatives. Food Hydrocoll. 2015, 51, 355–360. [Google Scholar] [CrossRef]

- Li, H.; Zhao, Z.; Xiouras, C.; Stefanidis, G.D.; Gao, X. Fundamentals and applications of microwave heating to chemicals separation processes. Renew. Sustain. Energy Rev. 2019, 114, 109316. [Google Scholar] [CrossRef]

- Olsson, A.M.; Salmén, L. The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr. Res. 2004, 339, 813–818. [Google Scholar] [CrossRef] [PubMed]

- Xing, X.; Chitrakar, B.; Hati, S.; Xie, S.; Li, H.; Li, C.; Liu, Z.; Mo, H. Development of black fungus-based 3d printed foods as dysphagia diet: Effect of gums incorporation. Food Hydrocoll. 2022, 123, 107173. [Google Scholar] [CrossRef]

| Score | Moldability | Internal Structure | Chewiness | Hardness | Crispiness | Aroma |

|---|---|---|---|---|---|---|

| 7–10 | Good moldability | Uniform, fine, and regular cross-section | Good chewiness | Moderate hardness | Crispy on the outside, tender on the inside | Strong aroma |

| 4–6 | Average moldability | Partially broken cross-section | Average chewiness | Hard or mushy | Average tenderness | Slight aroma |

| 0–3 | Poor moldability | Irregular cross-section | Poor chewiness | Too hard or too mushy | Poor tenderness | Burnt taste |

| Essential Amino Acids (EAA) | Non-Essential Amino Acids (NEAA) | ||

|---|---|---|---|

| Category | Amino Acid Content (mg/g) | Category | Amino Acid Content (mg/g) |

| Threonine (Thr) | 28.63 | Aspartic Acid (Asp) | 56.33 |

| Valine (Val) | 41.17 | Serine (Ser) | 30.15 |

| Methionine (Met) | 28.24 | Glutamic Acid (Glu) | 63.86 |

| Isoleucine (Ile) | 40.77 | Glycine (Gly) | 27.17 |

| Leucine (Leu) | 54.25 | Alanine (Ala) | 32.49 |

| Phenylalanine (Phe) | 28.13 | Cysteine (Cys) | 3.27 |

| Lysine (Lys) | 37.26 | Tyrosine (Tyr) | 27.01 |

| Proline (Pro) | 51.43 | ||

| Arginine (Arg) | 32.64 | ||

| Histidine (His) | 16.45 | ||

| Total | 258.45 | Total | 340.8 |

| EAA/NEAA | 75.84% | EAA/Total Amino Acids (TAA) | 43.13% |

| Sample | Peak Viscosity (cP) | Trough Viscosity (cP) | Final Viscosity (cP) | Breakdown Value (cP) | Setback Value (cP) |

|---|---|---|---|---|---|

| 0% | 106.47 ± 2.31 a | 102.63 ± 3.16 a | 148.62 ± 3.16 a | 3.84 ± 0.25 a | 45.99 ± 0.83 a |

| 10% | 102.79 ± 3.27 b | 100.71 ± 1.64 b | 143.84 ± 2.89 b | 2.08 ± 0.21 c | 43.13 ± 0.45 b |

| 20% | 98.24 ± 2.95 c | 95.62 ± 1.93 c | 137.65 ± 3.07 c | 2.62 ± 0.37 b | 42.03 ± 0.72 c |

| 30% | 90.16 ± 1.85 d | 87.99 ± 2.56 d | 125.24 ± 2.34 d | 2.17 ± 0.28 b | 37.25 ± 0.64 d |

| 40% | 87.26 ± 2.17 e | 83.37 ± 2.83 e | 117.81 ± 3.15 e | 3.89 ± 0.43 a | 34.44 ± 0.51 e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, N.; Li, H.; Liu, Z.; Lv, S.; Xie, S.; Shi, C.; Wu, Y. Preparation and Product Characterization of Microwaveable Food Using Lentinus edodes Protein through 3D Printing. Polymers 2023, 15, 3736. https://doi.org/10.3390/polym15183736

Li N, Li H, Liu Z, Lv S, Xie S, Shi C, Wu Y. Preparation and Product Characterization of Microwaveable Food Using Lentinus edodes Protein through 3D Printing. Polymers. 2023; 15(18):3736. https://doi.org/10.3390/polym15183736

Chicago/Turabian StyleLi, Na, Hongbo Li, Zhenbin Liu, Shuang Lv, Suya Xie, Chunyang Shi, and Yue Wu. 2023. "Preparation and Product Characterization of Microwaveable Food Using Lentinus edodes Protein through 3D Printing" Polymers 15, no. 18: 3736. https://doi.org/10.3390/polym15183736