Design of Superhydrophobic Shape Memory Composites with Kirigami Structures and Uniform Wetting Property

Abstract

:1. Introduction

2. Experiment

2.1. Materials

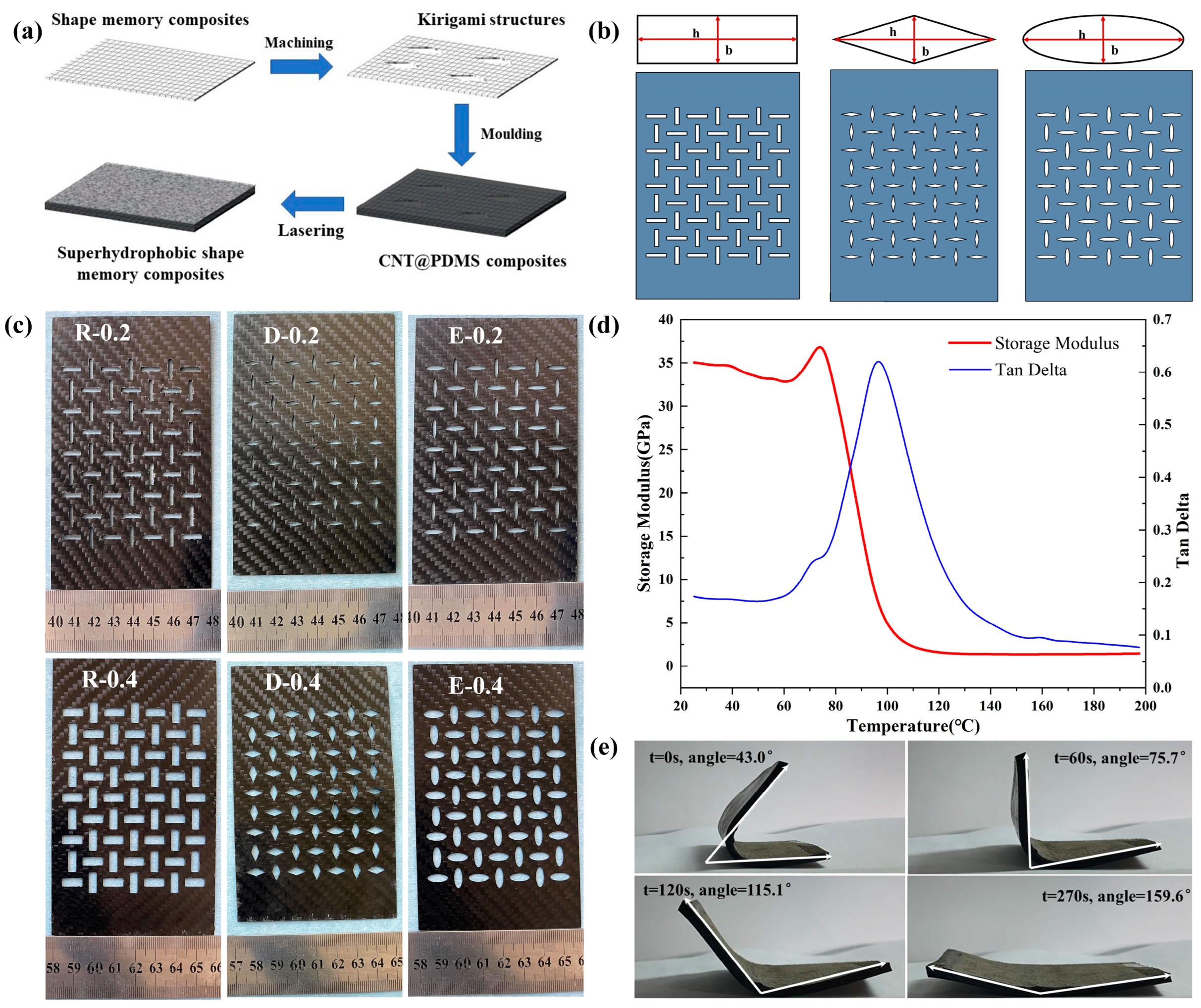

2.2. Preparation of Superhydrophobic Shape Memory Composites

2.2.1. Design of Composite Structure

2.2.2. Preparation of Superhydrophobic CNT@PDMS Mixture

2.2.3. Preparation of Superhydrophobic Shape Memory Composites

2.3. Characterization

2.3.1. Surface Characterization

2.3.2. Shape Memory Test

2.3.3. Water Dynamics Evaluation

3. Results and Discussion

3.1. Shape Memory Characteristic Testing

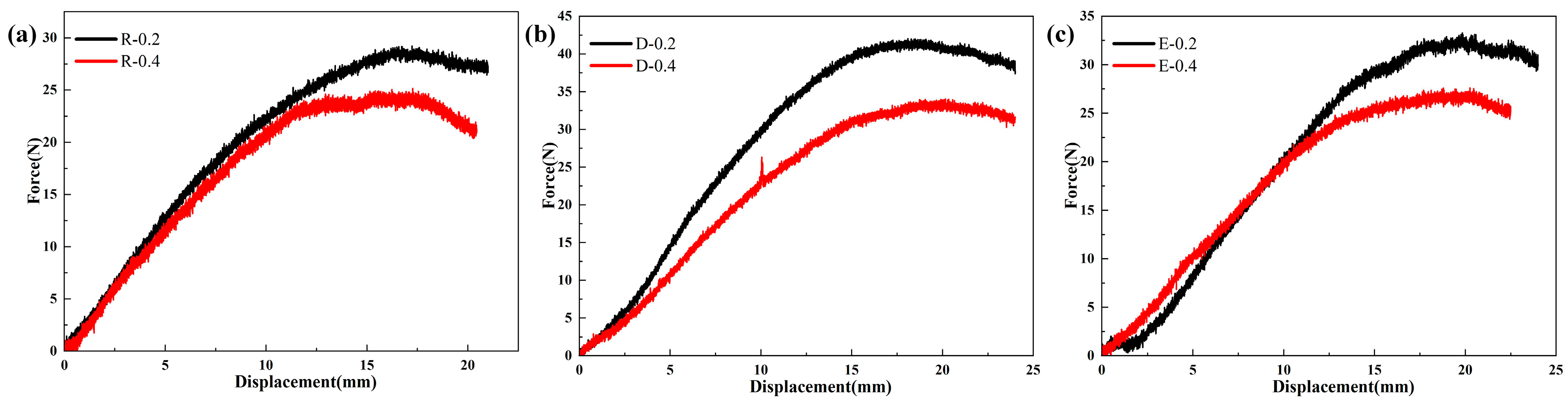

3.2. Bending Performance of SSMC

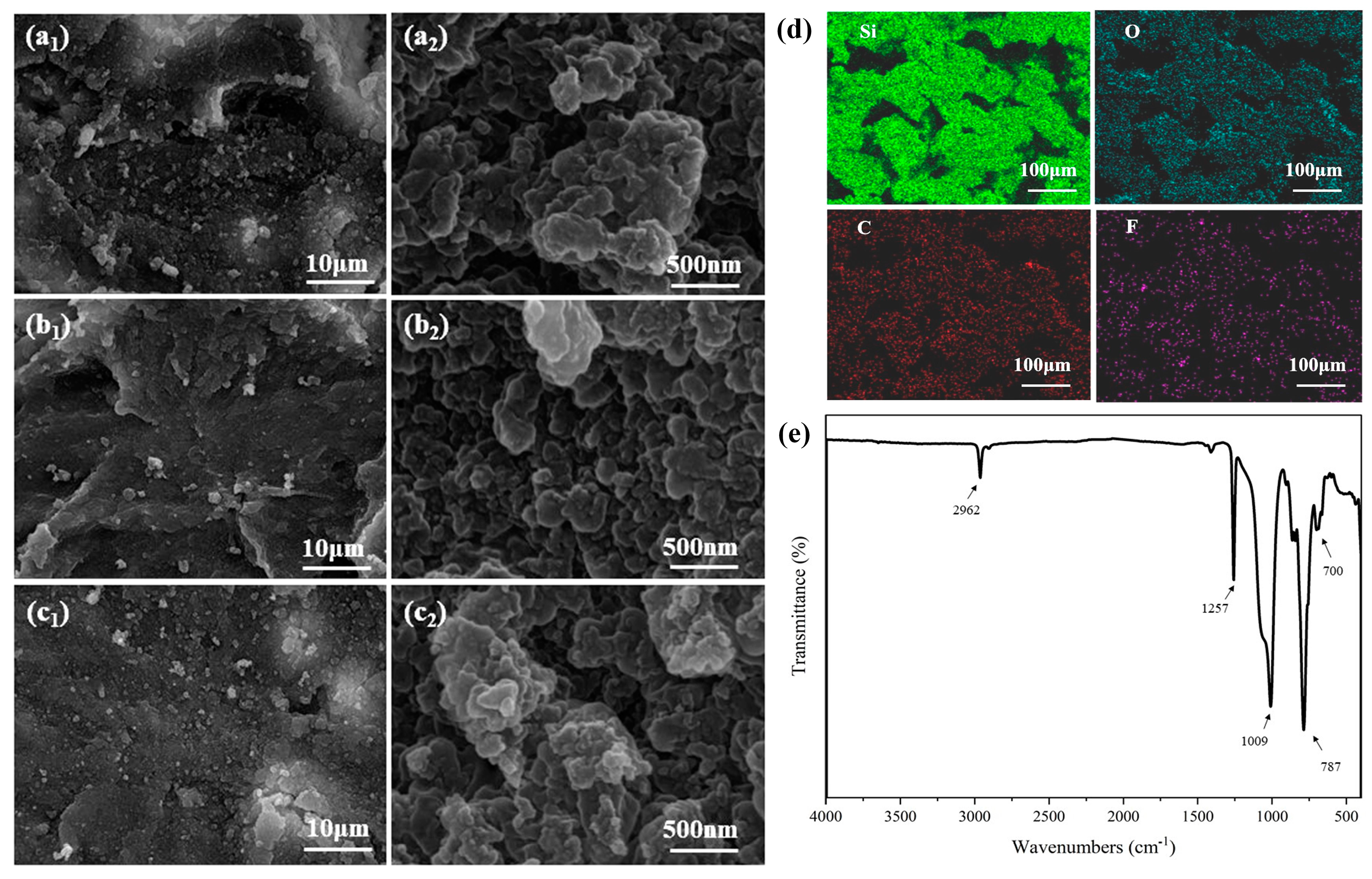

3.3. Surface Morphology Observation

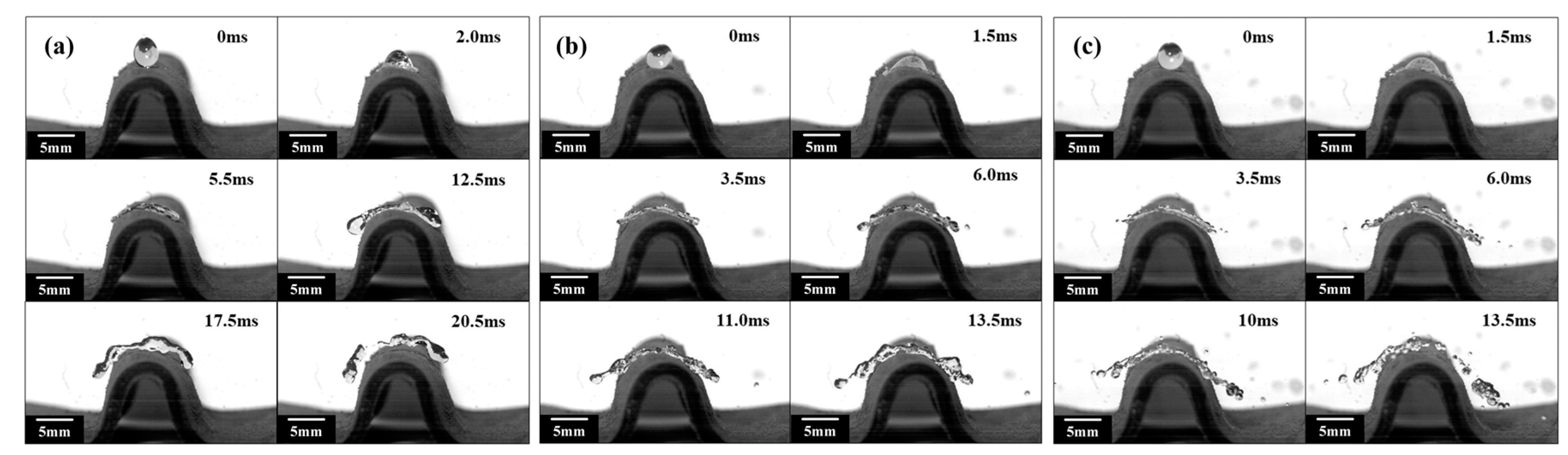

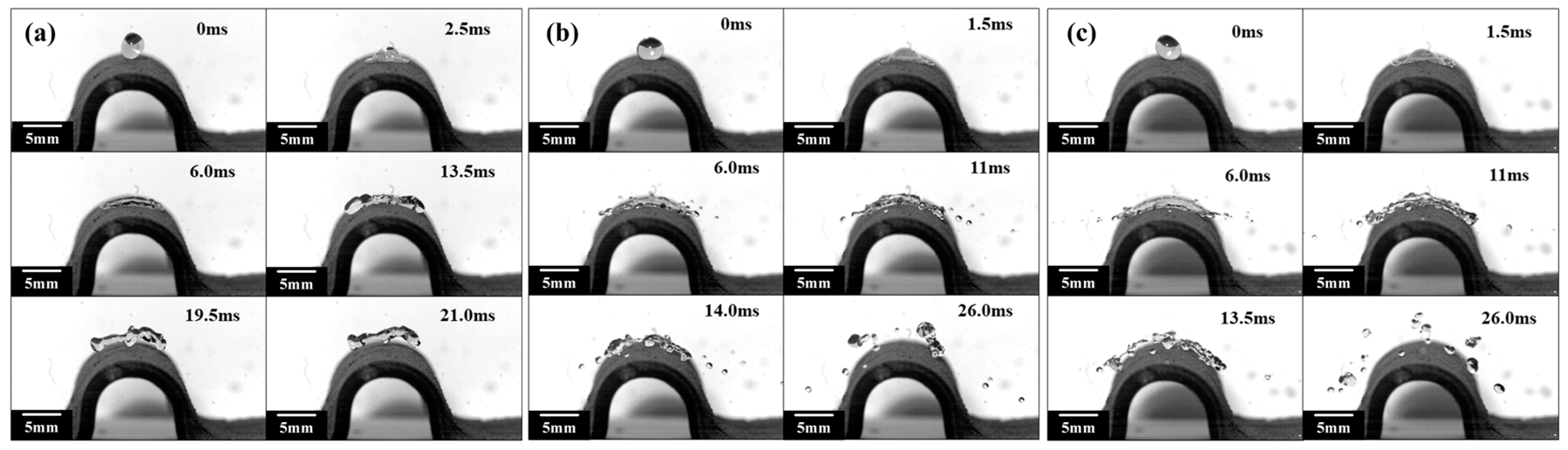

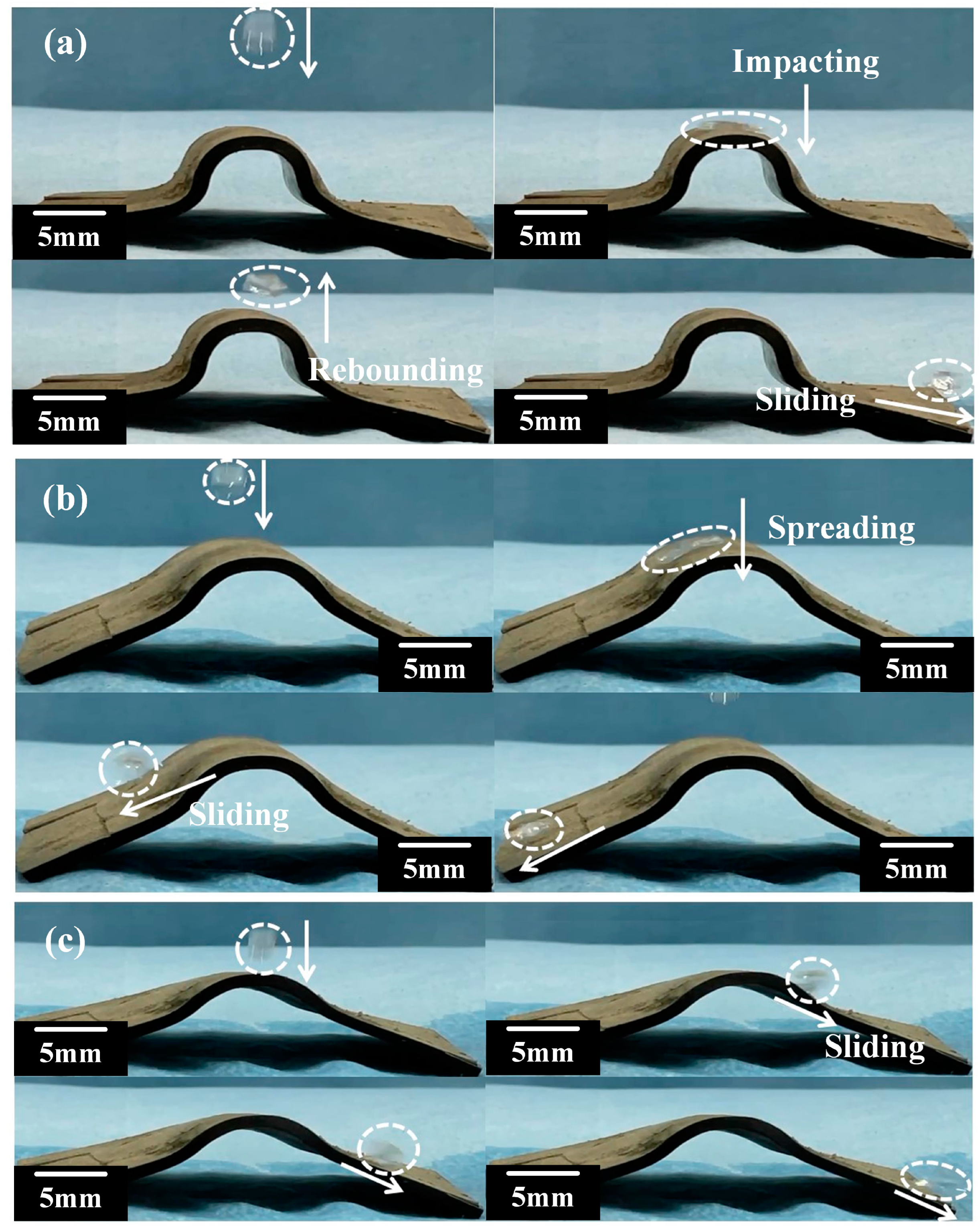

3.4. Investigation of Droplet Impacting Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, W.; Li, Y.; Lv, M.; Pei, B. Modeling and switching adaptive control for nonlinear morphing aircraft considering actuator dynamics. Aerosp. Sci. Technol. 2022, 122, 107349. [Google Scholar] [CrossRef]

- Xu, W.; Li, Y.; Pei, B.; Yu, Z. A Nonlinear Programming-Based Morphing Strategy for a Variable-Sweep Morphing Aircraft Aiming at Optimizing the Cruising Efficiency. Aerospace 2023, 10, 49. [Google Scholar] [CrossRef]

- Ajaj, R.; Parancheerivilakkathil, M.; Amoozgar, M.; Friswell, M.; Cantwell, W. Recent developments in the aeroelasticity of morphing aircraft. Prog. Aeosp. Sci. 2021, 120, 100682. [Google Scholar] [CrossRef]

- Woods, B.K.; Heeb, R.M. Design principles for geometrically anisotropic thermoplastic rubber morphing aircraft skins. J. Intell. Mater. Syst. Struct. 2023, 34, 29–46. [Google Scholar] [CrossRef]

- Alsaidi, B.; Joe, W.; Akbar, M. Computational analysis of 3d lattice structures for skin in real-scale camber morphing aircraft. Aerospace 2019, 6, 79. [Google Scholar] [CrossRef]

- Olivett, A.; Corrao, P.; Karami, M. Flow control and separation delay in morphing wing aircraft using traveling wave actuation. Smart Mater. Struct. 2021, 30, 25028. [Google Scholar] [CrossRef]

- Moreno, J.C.; Mora, R.B.; Sevillano, A.R.; González, C. Performance enhancement of a bioinspired micro air vehicle by integrating a smart composite in its morphing wing. Compos. Struct. 2023, 311, 116794. [Google Scholar] [CrossRef]

- Inman, D.; Haughn, K.; Harvey, C. Nature, smart structures, and morphing UAVs. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2023, Long Beach, CA, USA, 18 April 2023; p. 1248602. [Google Scholar]

- Chillara, V.S.C.; Dapino, M.J. Review of Morphing Laminated Composites. Appl. Mech. Rev. 2020, 72, 10801. [Google Scholar] [CrossRef]

- Gu, J.; Zhang, X.; Duan, H.; Wan, M.; Sun, H. A hygro-thermo-mechanical constitutive model for shape memory polymers filled with nano-carbon powder. Int. J. Smart Nano Mater. 2021, 12, 286–306. [Google Scholar] [CrossRef]

- Curtis, S.; Sielenkämper, M.; Arivanandhan, G.; Dengiz, D.; Li, Z.; Jetter, J.; Hanke, L.; Bumke, L.; Quandt, E.; Wulfinghoff, S. Tinihf/sio2/si shape memory film composites for bi-directional micro actuation. Int. J. Smart Nano Mater. 2022, 13, 293–314. [Google Scholar] [CrossRef]

- Yang, S.; He, Y.; Leng, J. Shape memory poly (ether ether ketone) s with tunable chain stiffness, mechanical strength and high transition temperatures. Int. J. Smart Nano Mater. 2022, 13, 1–16. [Google Scholar] [CrossRef]

- Li, T.; Sun, J.; Leng, J.; Liu, Y. An electrical heating shape memory polymer composite incorporated with conductive elastic fabric. J. Compos. Mater. 2022, 56, 1725–1736. [Google Scholar] [CrossRef]

- Gong, X.; Liu, L.; Liu, Y.; Leng, J. An electrical-heating and self-sensing shape memory polymer composite incorporated with carbon fiber felt. Smart Mater. Struct. 2016, 25, 35036. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Yang, J.; Yue, Y.; Zhang, H. A review of recent advances in superhydrophobic surfaces and their applications in drag reduction and heat transfer. Nanomaterials 2021, 12, 44. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Wang, Q.; Xu, S. A Review on Applications of Superhydrophobic Materials in Civil Engineering. Adv. Eng. Mater. 2022, 24, 2101238. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, H.; Zhu, Y.; Liu, X.; Wang, Z.; Chen, J. A robust superhydrophobic anti-icing/de-icing composite coating with electrothermal and auxiliary photothermal performances. Compos. Sci. Technol. 2022, 227, 109578. [Google Scholar] [CrossRef]

- Li, D.; Ma, L.; Zhang, B.; Chen, S. Large-scale fabrication of a durable and self-healing super-hydrophobic coating with high thermal stability and long-term corrosion resistance. Nanoscale 2021, 13, 7810–7821. [Google Scholar] [CrossRef] [PubMed]

- Sarma, B.; Dalal, A.; Basu, D.N. Interfacial dynamics of viscous droplets impacting a superhydrophobic candle soot surface: Overview and comparison. Phys. Fluids 2022, 34, 012121. [Google Scholar] [CrossRef]

- Antonov, D.; Kuznetsov, G.; Strizhak, P.; Fedorenko, R. Micro-explosion of droplets containing liquids with different viscosity, interfacial and surface tension. Chem. Eng. Res. Des. 2020, 158, 129–147. [Google Scholar] [CrossRef]

- Prakash, C.G.J.; Prasanth, R. Approaches to design a surface with tunable wettability: A review on surface properties. J. Mater. Sci. 2021, 56, 108–135. [Google Scholar] [CrossRef]

- Khojasteh, D.; Kazerooni, M.; Salarian, S.; Kamali, R. Droplet impact on superhydrophobic surfaces: A review of recent developments. J. Ind. Eng. Chem. 2016, 42, 1–14. [Google Scholar] [CrossRef]

- Liu, Y.; Whyman, G.; Bormashenko, E.; Hao, C.; Wang, Z. Controlling drop bouncing using surfaces with gradient features. Appl. Phys. Lett. 2015, 107, 051604. [Google Scholar] [CrossRef]

- Aria, A.I.; Gharib, M. Physicochemical Characteristics and Droplet Impact Dynamics of Superhydrophobic Carbon Nanotube Arrays. Langmuir 2014, 30, 6780–6790. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, N.; Khurana, G.; Harikrishnan, A.; Samanta, D.; Dhar, P. Post impact droplet hydrodynamics on inclined planes of variant wettabilities. Eur. J. Mech. B/Fluids 2020, 79, 27–37. [Google Scholar] [CrossRef]

- Guan, Y.; Fu, J.; Wu, S.; Chen, X.; Zhou, C. The post-impact dynamics of drop rebound on inclined hydrophobic surfaces of various wettabilities. Phys. Fluids 2021, 33, 072108. [Google Scholar] [CrossRef]

- Debnath, D.; Verma, D.; Kumar, P.; Balakrishnan, V. Understanding the impact dynamics of droplets on superhydrophobic surface. Int. J. Multiph. Flow 2023, 159, 104344. [Google Scholar] [CrossRef]

- Tian, Y.; Yuan, Z.; Huang, X.; Liu, C.; Li, S.; Lu, D. High-efficiency enhancement of the surface weatherability and electrical and mechanical properties of a cycloaliphatic epoxy-based hybrid nanocomposite via reaction-induced organic functional groups. Prog. Org. Coat. 2020, 148, 105830. [Google Scholar] [CrossRef]

- Jeong, S.Y.; Lee, J.U.; Hong, S.M.; Lee, C.W.; Hwang, S.H.; Cho, S.C.; Shin, B.S. Highly Skin-Conformal Laser-Induced Graphene-Based Human Motion Monitoring Sensor. Nanomaterials 2021, 11, 951. [Google Scholar] [CrossRef]

- Choi, C.; Kwak, Y.; Kim, M.; Kim, D. Effective harmful organism management i: Fabrication of facile and robust superhydrophobic coating on fabric. Sustainability 2020, 12, 5876. [Google Scholar] [CrossRef]

- Geng, Y.; Guo, J.; Wang, H.; Ling, S.; Chen, Z.; Chen, S.; Xu, J. Large-scale production of ligand-engineered robust lead halide perovskite nanocrystals by a droplet-based microreactor system. Small 2022, 18, 2200740. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Li, X.; Wei, D.; Sun, J.; Leng, J. Design of Superhydrophobic Shape Memory Composites with Kirigami Structures and Uniform Wetting Property. Polymers 2023, 15, 3738. https://doi.org/10.3390/polym15183738

Zhao Z, Li X, Wei D, Sun J, Leng J. Design of Superhydrophobic Shape Memory Composites with Kirigami Structures and Uniform Wetting Property. Polymers. 2023; 15(18):3738. https://doi.org/10.3390/polym15183738

Chicago/Turabian StyleZhao, Zhe, Xinlin Li, Dongsong Wei, Jian Sun, and Jinsong Leng. 2023. "Design of Superhydrophobic Shape Memory Composites with Kirigami Structures and Uniform Wetting Property" Polymers 15, no. 18: 3738. https://doi.org/10.3390/polym15183738

APA StyleZhao, Z., Li, X., Wei, D., Sun, J., & Leng, J. (2023). Design of Superhydrophobic Shape Memory Composites with Kirigami Structures and Uniform Wetting Property. Polymers, 15(18), 3738. https://doi.org/10.3390/polym15183738