2.1. AM Method and Composite Curved Beams

A Markforged Mark Two 3D printer [

32] has the capability of manufacturing continuous fiber-reinforced thermoplastics by using two heated nozzles that are fed by plastic and fiber filament spools separately. The operating temperatures are around 275 °C and 250 °C for the thermoplastic and fiber nozzles, respectively. The printer has a build volume of 320 mm (

X; width) × 132 mm (

Y; depth) × 154 mm (

Z; height), which is sufficient for printing desired curved beams. The layer height (

Z layer resolution) is achieved as 0.1 mm by reinforcing with high strength high temperature fiberglass (HSHT FG), an aramid (Kevlar

®) and fiberglass (FG) filament as well as by using only thermoplastic substances without reinforcing. When a carbon filament is used as reinforcement, the resolution is achieved as 0.125 mm. There are some limitations to embedding fibers in the matrix. Five-roof and five-floor plastic layers are needed above and below the fiber groups in the

Z direction. While two wall layers made of plastic are recommended to have a good surface finish and be watertight in the

XY plane, it is mandatory to have a minimum of one wall layer that is 0.4 mm in thickness [

33].

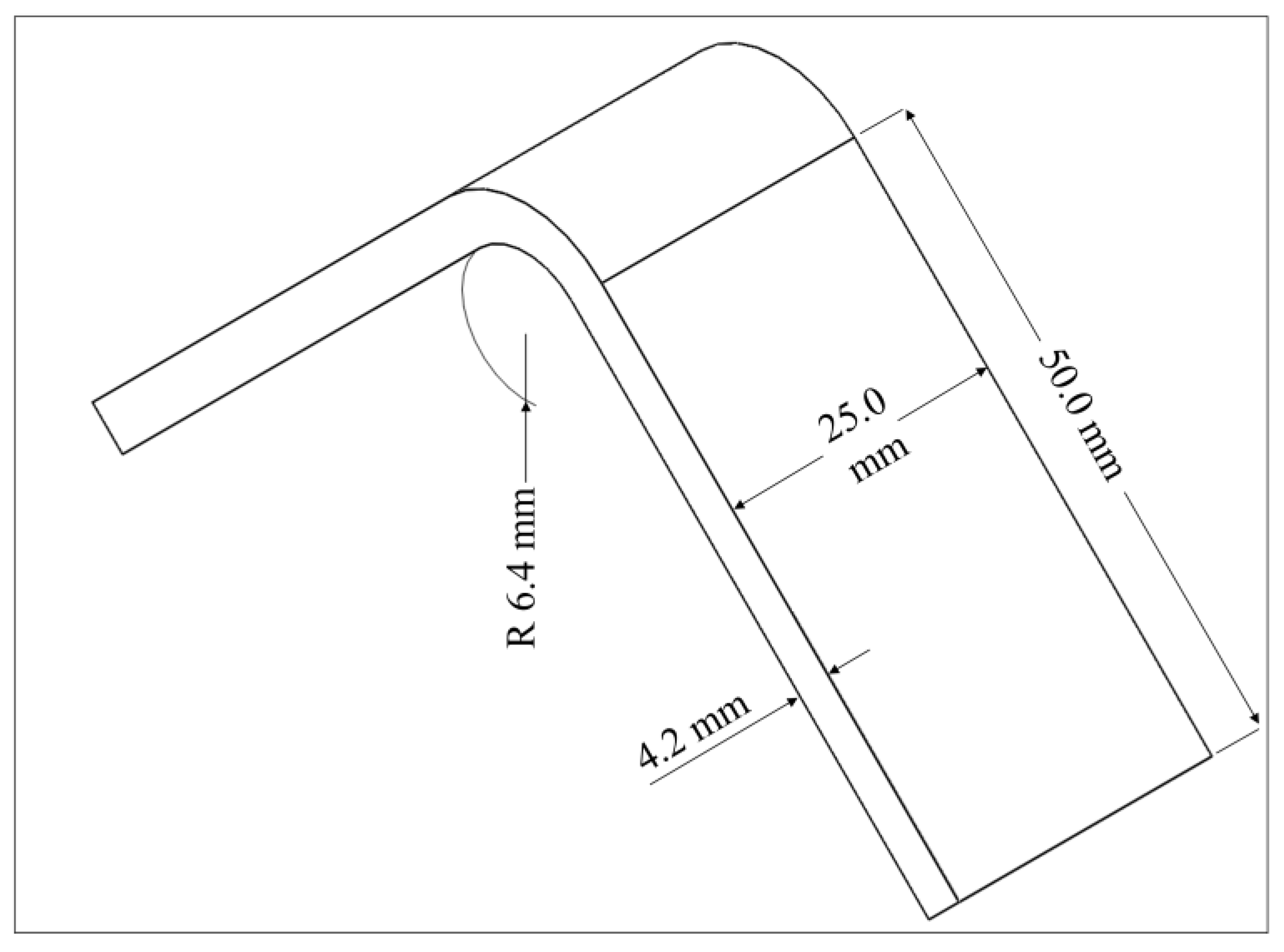

The design of the curved specimen is based on the ASTM D6415/D6415M-22 standard. The curved beam is designed as integrated two direct loading legs joined by a 90° curve part with a 6.4 mm inner radius (

ri) while the legs and the bend are 25 mm in width (

w) and 4.2 mm in thickness (

t) in this study [

4]. The outer radius (

r0) of curved region is 10.6 mm. The length of each straight leg (

L) is chosen as 50 mm, which is long enough to provide certain span lengths of four-point fixtures, and which is short enough to prevent contact with the fixture base. The dimensions are shown in

Figure 1. A polyamide (Nylon White) is used as the thermoplastic material and is reinforced with various continuous fibers such as carbon, HSHT FG, Kevlar and FG. After drawing the L-shaped curved beam with Solidworks

® [

34], the composite model is designed by using Eiger software [

35] which enables the management of all parameters about the material and printing including the placement of fiber filaments in the matrix. After the completion of the composite design, the parts are manufactured by a Mark Two 3D printer.

Firstly, the optimum build configuration needs to be specified before the selection of other process parameters, since a curved beam is a complex structure and the print orientation affects the mechanical performance of a 3D-printed part. Three basic configurations were compared for the tensile properties of 3D-printed dog bone specimens using FDM by Chacón et al. [

36] and Ma et al. [

37]. The results of the flat (

XY) and on-edge (

XZ) orientation were measured close to each other, although the flat orientation had slightly better tensile strength. The tensile strength of the upright (

ZX) orientation was measured at about half of the others.

Figure 2 shows various build orientations in Eiger software for printing a curved beam. On-edge orientation is obviously the optimum layer-by-layer printing configuration among all possible build configurations due to the capability of having both a UD stacking sequence with the fibers running circumferentially around the curved region and a few supports for raising the part. All possible flat and upright configurations are a combination of both for the whole curved beam, since different layered regions of the beam such as each beam leg need to be built via different configurations. Building the curved beam on-edge is a pure configuration for printing, unlike the others. Moreover, each flat configuration and an upright build design need a huge amount of support material due to the curved shape. Lastly, the fiber reinforcement is not desirable and effective due to the changeable small areas of printing layers, asymmetric orientation and unbalanced fiber density between regions.

A solid fill with a density of 100% is selected as the infill pattern, which describes the repeating geometric shape inside a part. A brim is used to hold each curved beam to the print bed as the part has few points of contact on the bed that leads to warping. A raft that is made of a thick grid is also added under the beam to ensure that the warping problem is completely prevented.

t is the most critical dimension for embedding as many continuous fibers into matrix as possible. There are two types of fiber fill algorithms, which are concentric fibers and isotropic fibers, to reinforce the part while each layer is printed in the

XY plane. The concentric fiber type reinforces the part along any walls while the isotropic fiber type makes the part reinforced in selected directions, which are controlled by a list of angles between 0° and 180° in the

XY plane. A concentric fiber fill that contains one fiber ring per layer (the maximum amount that is allowed by Eiger software for the selected

t) with a start rotation percent of 0 is selected after many simulations are compared under the circumstances of the thin curved region. The number of wall layers is chosen as two since the software lets the curved beam have the same number of fiber layers in selected

t by choosing one wall layer. The printer parameters, which are demonstrated above, are summarized in

Table 1.

Graphical 2D views of two adjacent carbon fiber-reinforced nylon layers along the

Z direction are shown in

Figure 3 where the nozzle pattern for the fiber-reinforced lamina is represented with a blue color line. The slight difference between

Figure 3a,b is the printing pattern assigned by the software for the plastic region between fiber-reinforced layers along the legs, which change symmetrically. The pair of layers is used for printing the total of fiber-reinforced layers along the

Z direction continuously.

The layers for HSHT FG, Kevlar and FG reinforced layers have the same printed patterns in

Figure 3. However, there are more pairs of layers than a carbon/nylon specimen because of their higher

Z layer resolution although they all have the same

w. The carbon/nylon composite curved beams are printed by using a total of 190 fiber-reinforced layers plus a total of 10 plastic layers for the roof and the surface while the rest of the reinforced composite curved beams are printed by using a total of 240 fiber-reinforced layers plus a total of 10 plastic layers according to

Z layer printer resolution. There is a pleasing fiber polymer laminate (FPL) design consisting of symmetrically bonded four plastic wall layers (~1.6 mm), two UD fiber-reinforced plastic lamina (~1.8 mm) and one plastic lamina (~0.8 mm) through the thickness. A cross-section of the top view, which contains fiber-reinforced layers, is depicted and the image of a carbon/nylon printing layer with the material composition is shown in

Figure 4a. Moreover, a front and a side view of a curved specimen is depicted in

Figure 4b. The steps of the manufacturing process, which are printing the brim and the raft, the early-stage, the late-stage and the finished products, are shown in

Figure 5. The number of manufactured curved beam specimens per build is arranged as one, two and three as shown in

Figure 5 to observe the effect of delay time between each layer of parts. The more specimens the printer manufactures, the more delay time the next layer has because of the layer-by-layer process. This can lead to a reduction in interlayer adhesion depending on the cooling time. Enough test coupons are printed for certain reinforcing types and each specimen is stored in a bag containing a silica gel moisture absorber until the test after printing.

The calculations of

Vf are made for each fiber-reinforced 3D-printed specimen by using the estimated fiber and plastic volume via Eiger software and excluding the plastic parts for the brim and raft.

Vf is defined in Equation (1) according to the rule of mixtures (ROM), where

υf is the volume of fiber and

υm is the volume of matrix, by neglecting the void content.

However, the estimated

υf can be modified since the 3D printer’s fiber filaments should be defined as a kind of prepreg consisting of a bundle of long fiber-reinforced nylon. The actual diameter of the filament in the spool is measured as 0.3 mm for all fiber materials. The nylon in filament melts while it moves through the fiber nozzle and the bundle of fibers is embedded diffusely in the printing area. That is why the thickness of carbon fiber lamina looks thicker in

Figure 4a. Justo et al. [

38] proved that the fiber mass fraction (

Wf) of a carbon fiber-reinforced filament was achieved as 0.4, while the

Wf of an FG lamina is 0.5 after the calcination process had been carried out. HSHT FG and Kevlar filaments supposedly have the same

Wf as does FG. Henceforth, the estimated

Vf obtained in Eiger software can be described as a volumetric fiber-reinforced region (

Vr). It was suggested that the modified

Vf would be 0.4x

Vr for a carbon/nylon part while it would be 0.5x

Vr for an FG/nylon part (and so on for HSHT FG/nylon and Kevlar/nylon) by Díaz-Rodríguez et al. [

39].

Longitudinal elastic modulus in the 0° direction (

E1) and transverse elastic modulus in the 90° direction (

E2), which are used in analytical functions of radial tensile stress in the unidirectional curved region, can be predicted by using the ROM and strength of materials approach in the following equations [

40]:

where

Ef and

Em are elastic modulus of the fiber and matrix, respectively. The Halphin–Tsai (HT) semi-empirical model in Equation (4) is a well-known better approach for obtaining

E2 since it is a fact in the literature that Equation (3) does not have a good agreement with the experimental data [

40]:

where

ζ is called the reinforcing factor and 2.0 is usually chosen as the default. It can be calibrated by a formula that is suggested by the HT model to be used when there are no experimental data [

41]:

In-plane material properties of a 3D-printed UD carbon and a Kevlar reinforced lamina were obtained by an experimentally validated numerical study by Galati et al. [

42]. The elastic properties of FG/nylon, which were obtained by Justo et al. [

38], are used in this study. The properties of HSHT FG/nylon are assumed to be the same as FG/nylon since the manufacturer’s data reported that the properties of FG and HSHT filaments have the same or close values except for flexural and compressive strengths [

43]. Nylon White is a stronger and stiffer material by comparison with the conventional nylon used for 3D printers. Fisher et al. [

44] obtained the elastic tension and compression properties of Nylon White at different strain rates by also considering three different infill parameters including the on-edge orientation used in this study. The material properties of the constituents used in this study are shown in

Table 2.

Table 3 shows the estimated properties of each UD fiber-reinforced curved beam design. However,

Vf is the realistic value to estimate the amount of fiber in the curved beams,

Vr and the related properties in

Table 2 are meaningfully used to calculate the

E1,

E2 and

E2HT of the printed curved beams.

2.2. Test Method

The test procedure is based on the ASTM D6415/D6415M-22 standard. The four-point bending tests on certain types of 3D-printed composite curved beam specimens are conducted to create a sufficient moment in the bend, which produces radial tensile stress through the thickness. The tests are carried out using a Lloyd LS5 testing machine [

45] and a four-point bending apparatus as shown in

Figure 6. The apparatus has an upper and a lower fixture that is also integrated with two steel struts and two cylindrical ball bearings to insure against misalignment of span lengths during the head displacement.

The cylindrical loading and supporting steel bars have diameters (

D) of 10 mm. The top span length (

lt) is assigned as 22.1 mm to create an acceptable failure mode while the head displacement (

Δ) is as small as it can be before damage in a bending situation. The acceptable failure mode is supposed to be a delamination in the radial position when the ILTS is obtained at the damage location. On the other hand, the distance for the bottom span length (

lb) is selected as 42.1 mm to create enough moments in the curved region without excessive flexure of the specimen legs.

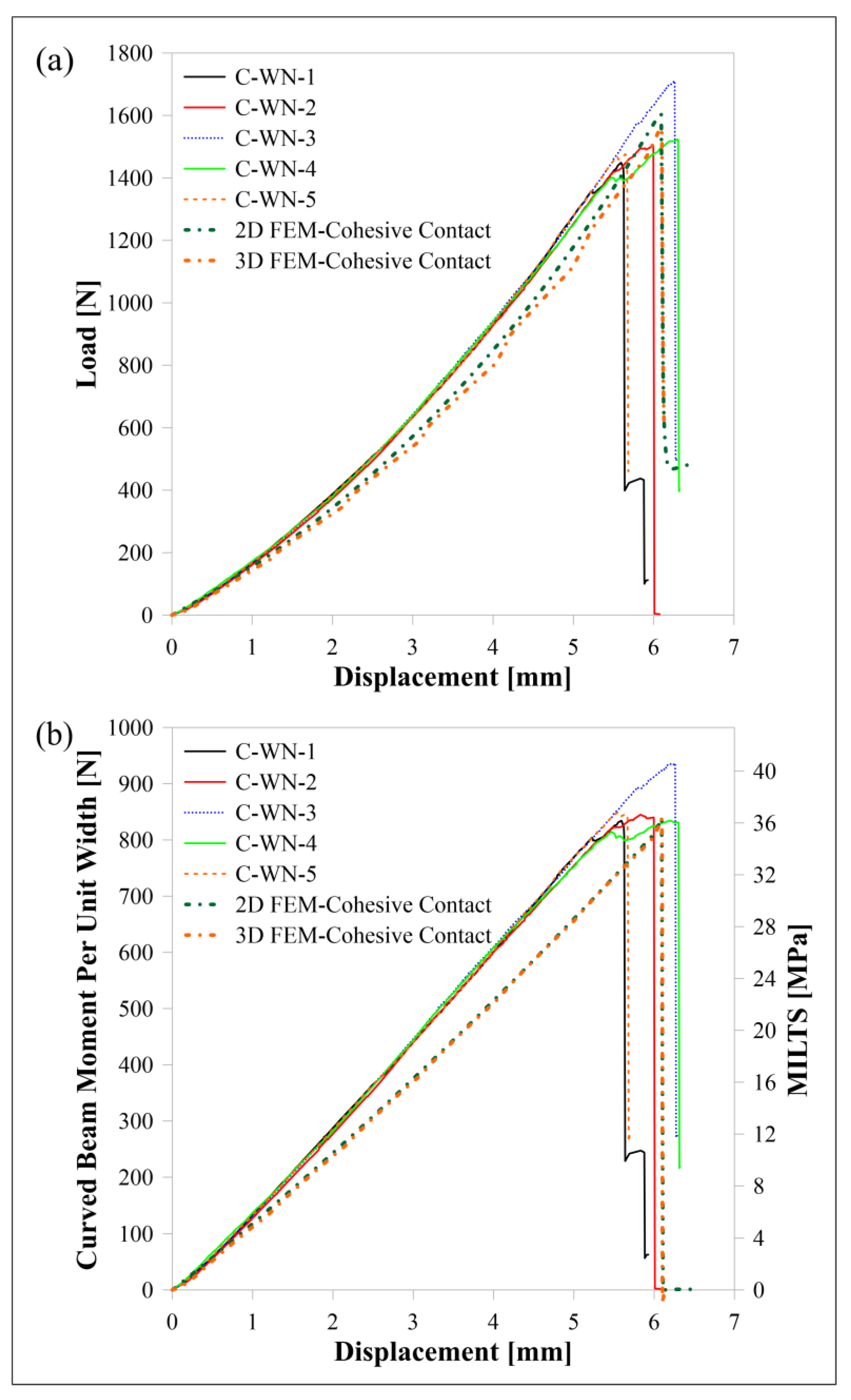

Figure 7 shows the general view of the test setup and the parameters that configure the apparatus and test procedure as well as the analytical formulations for the strength of the curved beam. The test speed is set as 3 mm/min while the sampling rate is set as 10 Hz. Experimental load and displacement data are collected, and calculations are analytically made to obtain certain properties.

The CBS of a curved specimen is described as the ultimate applied moment per unit

w in the curved region, which simultaneously occurs with the first force drop. A single sharp drop occurs for a UD specimen while there can be multiple force drops for a multidirectional specimen. It is a good way of measuring for the design and analysis of curved structures. The applied moment is calculated as the multiplication of the force applied to one of the supporting bars (

Pb) and the straight length between that supporting bar and the adjacent loading bar (

l0) [

4]:

Pb and

l0 can be expressed in terms of the measurable parameters, which are the force applied to the fixture (

P), angle between the specimen leg and horizontal axis (

φ), horizontal distance between two bars along one of the legs (

dx),

D and

t. The curved beam moment (

M) is derived as:

where

φ is defined as

φi when it is 45° at the start of the test. It is essential to calculate

φ during the test since it decreases significantly as well as

dy does although

dx is a constant position during loading:

where

dy is vertical distance between two adjacent bars:

ILTS is calculated by using the formula for the radial (interlaminar) tensile stress through the thickness developed by Lekhnitski [

13]:

where

rm is the radial position of MILTS.

Eθ and

Er are the elastic modulus in the tangential and radial directions and should be replaced with

E1 and

E2 (

E2HT) in

Table 3 but only if a UD configuration exists. ILTS can be calculated easily in Equation (14), producing an error of less than 2% if

Eθ/

Er (

E1/

E2) is less than 20 [

4]. The expressions in Equations (12) and (14) do not represent a tensile stress distribution through the thickness but can show the change in MILTS during a test until having ILTS at the radial position where potential delamination occurs.

The angle between the legs,

t and

w of each specimen are measured before testing. The 90° angle, the 4.2 mm

t and the 25 mm

w are confirmed for all samples by means of the sensitive manufacturing capability of AM technology. However, the unreinforced plastic roof and floor layers in

Figure 4b are neglected for the calculation of CBS and ILTS since their contribution to delamination strength is so limited by comparison with the reinforced section.

W is consequently selected as 23.75 mm for carbon/nylon specimens and as 24 mm for the rest of the fiber reinforced specimens.

2.3. Finite Element Modelling

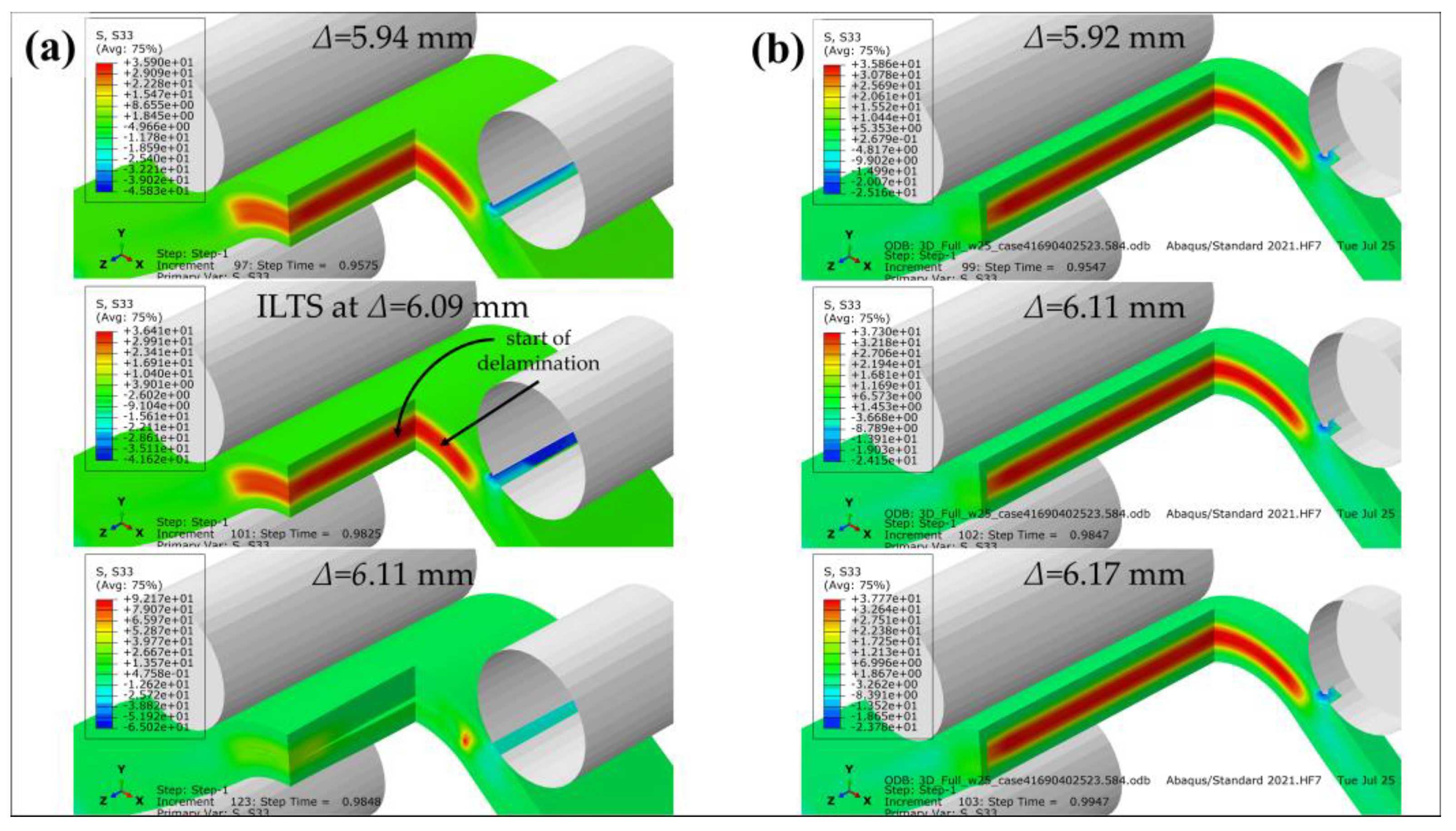

An additively manufactured curved beam subjected to four-point bending is modelled in 2D planar and 3D space using commercial Abaqus finite element software [

46]. A UD carbon fiber reinforced cross-section of the beam is included in the 2D model. The deformable cross-section is created by separately modelled five layers in

t as

Figure 4a while 2D cylindrical roller, which has the specific

D, is created as a discrete rigid wire. The laminas are first perfectly bonded in the finite element model.

Table 2 is used for elastic in-plane engineering constants for a carbon/nylon lamina and White Nylon. Materials are assigned to 2D parts as sections. Material orientations in two directions are generated to form a UD laminated structure with all fibers running continuously along the curved beam. A contact property, which has both normal hard contact and frictionless tangential behavior, is created subsequently. The contact is applied between the surfaces of a 2D curved beam and the surfaces of rollers by defining a surface-to-surface contact after the assembly of a virtual test is arranged by considering

lt and

lb. The clamped boundary condition is defined for the lower roller while the upper roller is only allowed to have a certain displacement in the

Y direction.

Deformable 3D UD carbon reinforced part and deformable 3D nylon part for the roof and floor of the whole curved beam, which has the same

t and

ri, are created by tying the beam in

w as

Figure 4b while the 3D cylindrical roller is created as a discrete rigid body and is then transformed to a shell body in 3D finite element model. UD carbon reinforced part consists of five layers in a

t likewise 2D model. Out-of-plane properties in the 3-direction are assumed to be the same as the ones, which are related to the 2-direction. Materials are assigned to 3D parts as sections and material orientations in three directions are then generated. The contacts and the boundary conditions are similarly defined in the 3D model too.

The 2D model of the beam is meshed using four-node plane strain elements with reduced integration (CPE4R) since the beam is thick in the

Z direction to define a plane stress condition. The rollers are discretized using two-node 2D linear rigid elements (R2D2). On the other hand, the 3D model of the beam is discretized using eight-node 3D solid elements with reduced integration (C3D8R) while a four-node 3D bilinear quadrilateral rigid element (R3D4) is used for meshing the rollers. A general static analysis, which contains the nonlinear effects of large displacements and dissipated energy fraction for automatic stabilization, is performed for both 2D and 3D numerical modelling. The 2D and 3D full-scale models are analyzed. A mesh sensitivity analysis is first carried as shown in

Figure 8. Certain cases, which have the properties in

Table 4, are defined and used.

The approximate global sizes for the beam and the roller model are decreased while a local mesh is applied for the critically loaded bend. The number of finite elements is increased from 10 to 350 on the curved edges of the bend and the number of elements through the beam thickness is increased from 5 to 60 by performing ten cases. The number of elements for the 2D and 3D model are also labeled for each case in

Figure 8. Sufficient convergence is obtained, and the fourth case is chosen for 3D model while the last case is used for 2D model without concerning high calculation time. The finite element models of the final cases are shown by mainly focusing on the local mesh of the bend in

Figure 9.

An effective elastic approach for 2D and 3D numerical models is lastly obtained by defining and applying surface-to-surface cohesive contact between certain laminas after evaluating the experimental results, especially the location of delamination and confirming that the delamination is the only damage mode. Each perfectly bonded contact in the previous models between a carbon/nylon lamina and an adjacent White Nylon lamina in

Figure 4a is replaced with the bilinear traction-separation cohesive behavior. Four cohesive contacts are created between layers along the legs and the bend. The unreinforced plastic roof and floor layers are not included in the 3D numerical cohesive model.

Cohesive behavior is incorporated as a component of the surface interaction properties assigned to a contact pair rather than an inherent material property in Abaqus. These properties are input data in the linear elastic traction–separation model, criteria for initiating damage, and laws governing the evolution of damage [

46].

The first segment of a typical traction–separation response represents the initial linear elastic behavior of the cohesive model, where the cohesive traction increases linearly with separation until reaching a critical peak traction strength point. An uncoupled model that uses penalties, which are normal (

knn) and shear stiffness components (

kss;

ktt) only, is used to obtain traction stresses (

Tn,

Ts,

Tt) versus separation vectors (

δn,

δs,

δt):

Damage initiation or the degradation process in the cohesive contact at a specific point commences when the traction stresses fulfill defined specific damage initiation criteria, which is defined as quadratic stress criterion in this study:

where

Tn0,

Ts0 and

Tt0 represent the normal and shear strengths of cohesive contact, respectively. After the peak traction, the second linear segment of response exists where the cohesive traction decreases linearly as the separation continues to increase. A damage variable (

d) that varies from 0 to 1 during the overall damage is used to generate the evolution model:

An energy-based mixed mode approach based on the nature of

d is useful to define damage evolution since the fracture energy is the area under the traction–separation curve. If

GnC,

GsC and

GtC, also commonly known as

GIC,

GIIC and

GIIIC, define the critical normal, first shear and second shear energy release rates, respectively, and

GsC =

GtC, Benzeggagh and Kenane (BK) fracture criterion expresses mix-mode energy dissipated due to the failure of what is defined as the function of

GS (the sum of shear fracture energies) and

GT (the sum of normal and shear fracture energies) where

m is BK cohesive parameter [

47]:

Turon et al. [

48] offered an equation to obtain the interface stiffness (

k) analytically, when α is a parameter that is much bigger than 1 and each sublaminate has the thickness,

t and out-of-plane elastic modulus,

E3:

E3 can be substituted for

E2HT for carbon/nylon curved beam in

Table 3.

t is selected as 0.85 mm, which is the average of a fiber reinforced layer and pure nylon layer. α is defined as 50 [

48]. All penalties in this study are assumed to be the same.

Santos et al. [

27] experimentally obtained

GnC and

GsC of 3D-printed continuous carbon fiber-reinforced polyamide while

Ts0 was investigated via short beam three-point bending tests by Yavas et al. [

31]. A relation between

Ts0,

GnC and

GsC can define the missing cohesive contact parameter (

Tn0) in the literature [

49]:

The predicted interfacial properties of cohesive contact between a 3D-printed carbon/nylon layer and a nylon layer are shown in

Table 5. A viscosity coefficient, which is 0.0001, is also used to regularize the convergence difficulties because of the nature of the problem in Abaqus.