Failure Study of BFRP Joints with Two Epoxy Adhesives under Hygrothermal Coupling

Abstract

:1. Introduction

2. Experimental Programme

2.1. Materials

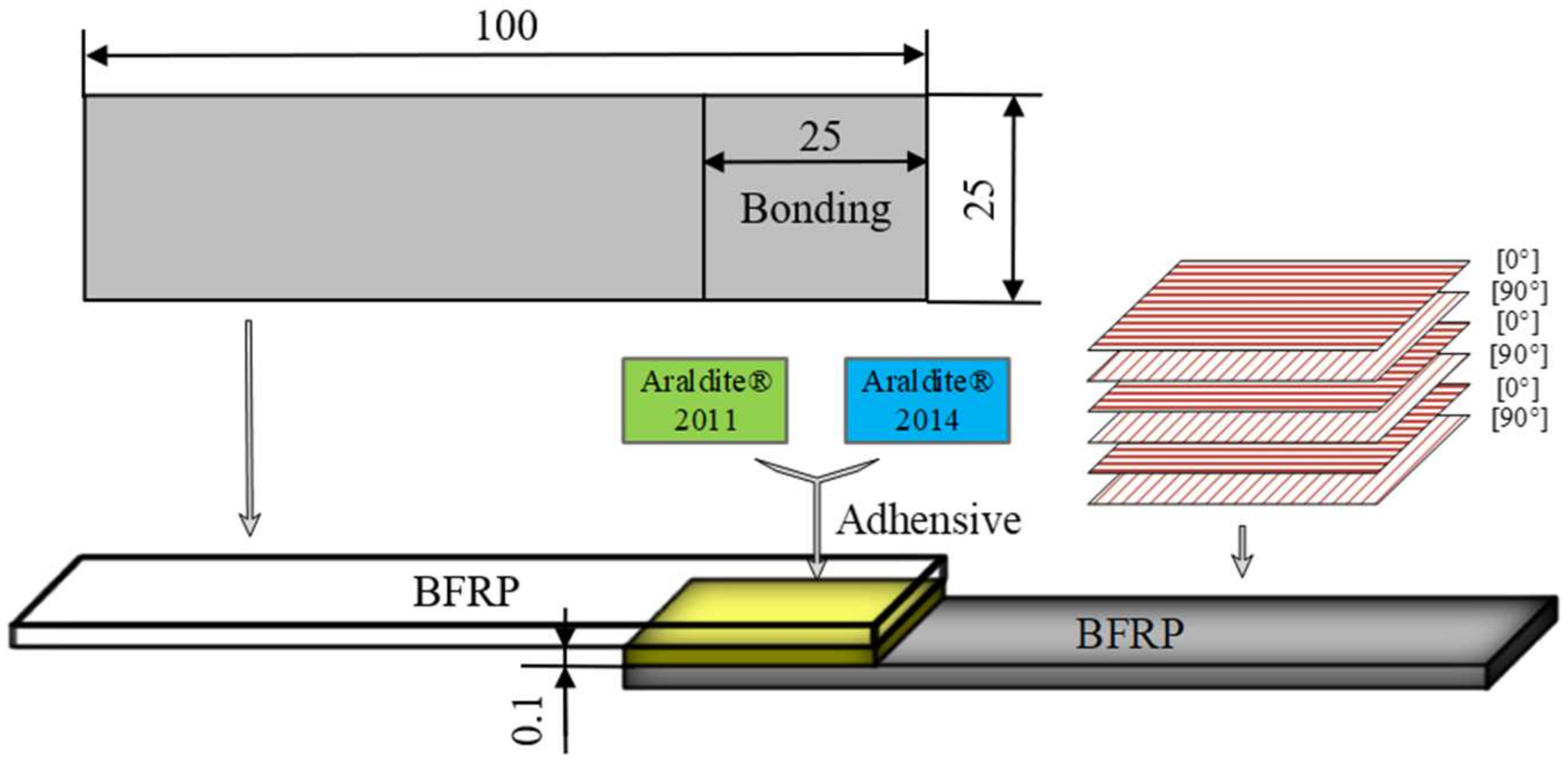

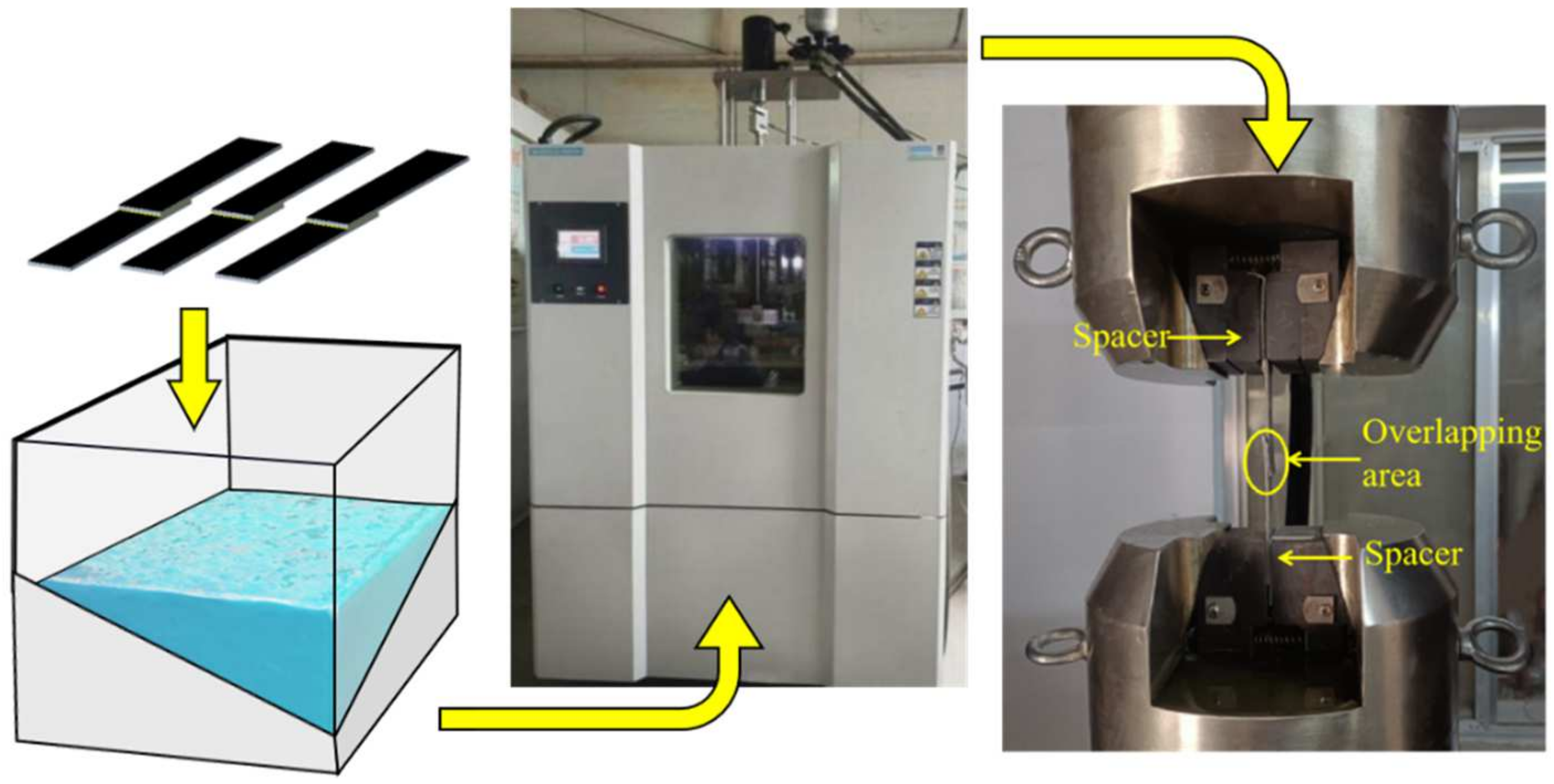

2.2. Specimen Preparation

2.3. Experimental Design

3. Results and Discussion

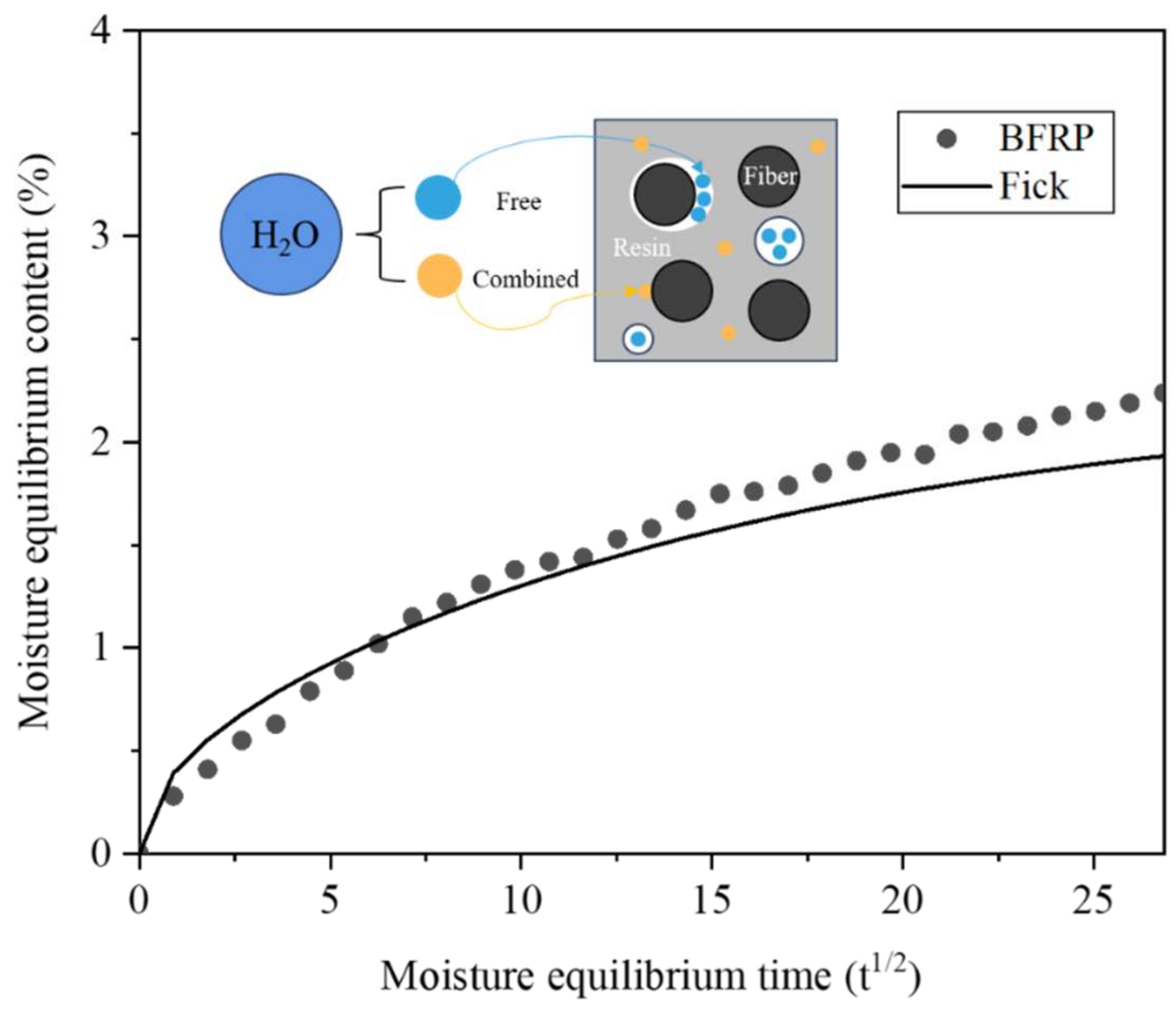

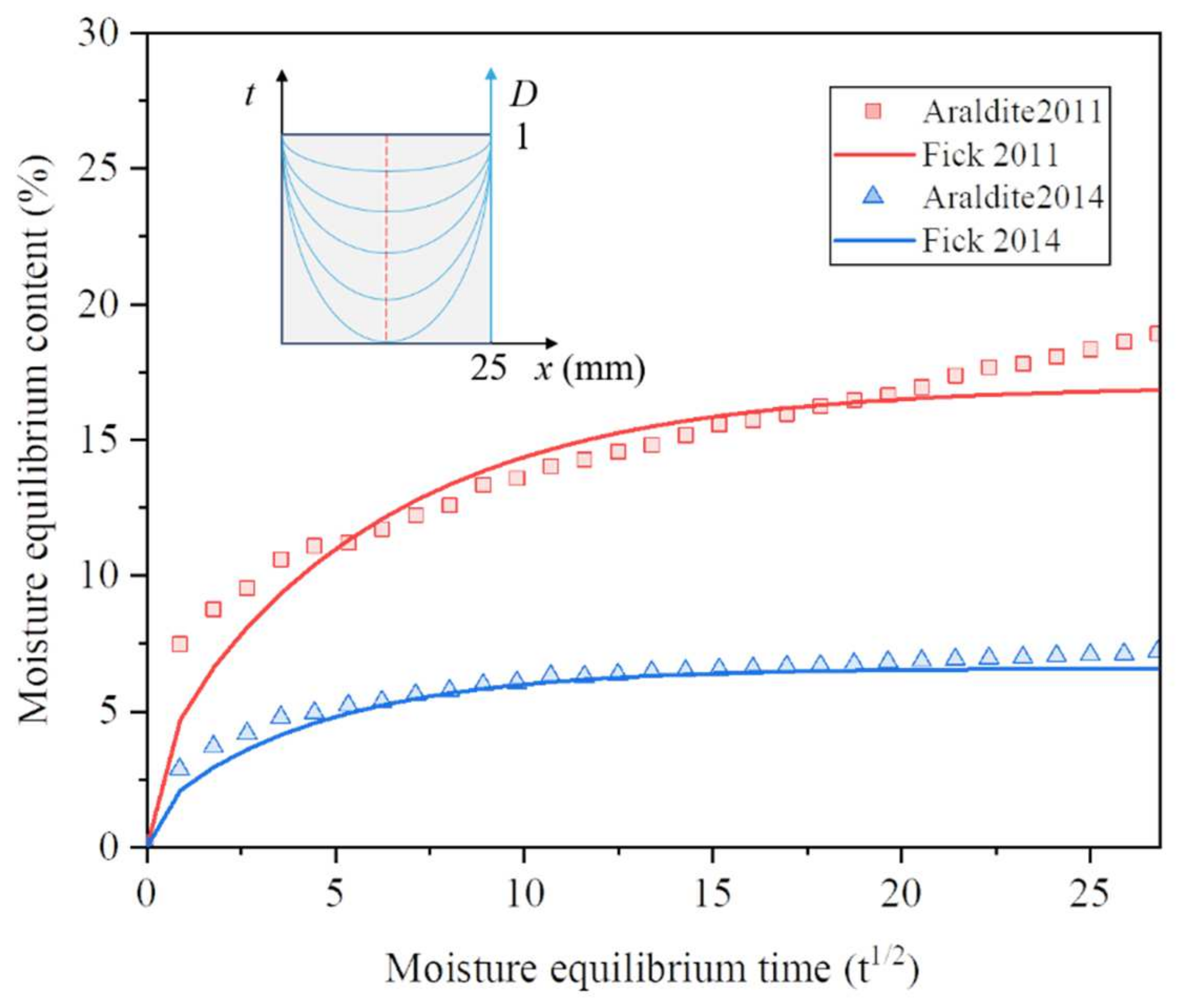

3.1. Moisture Absorption Characteristics

3.2. TGA-DTG Test

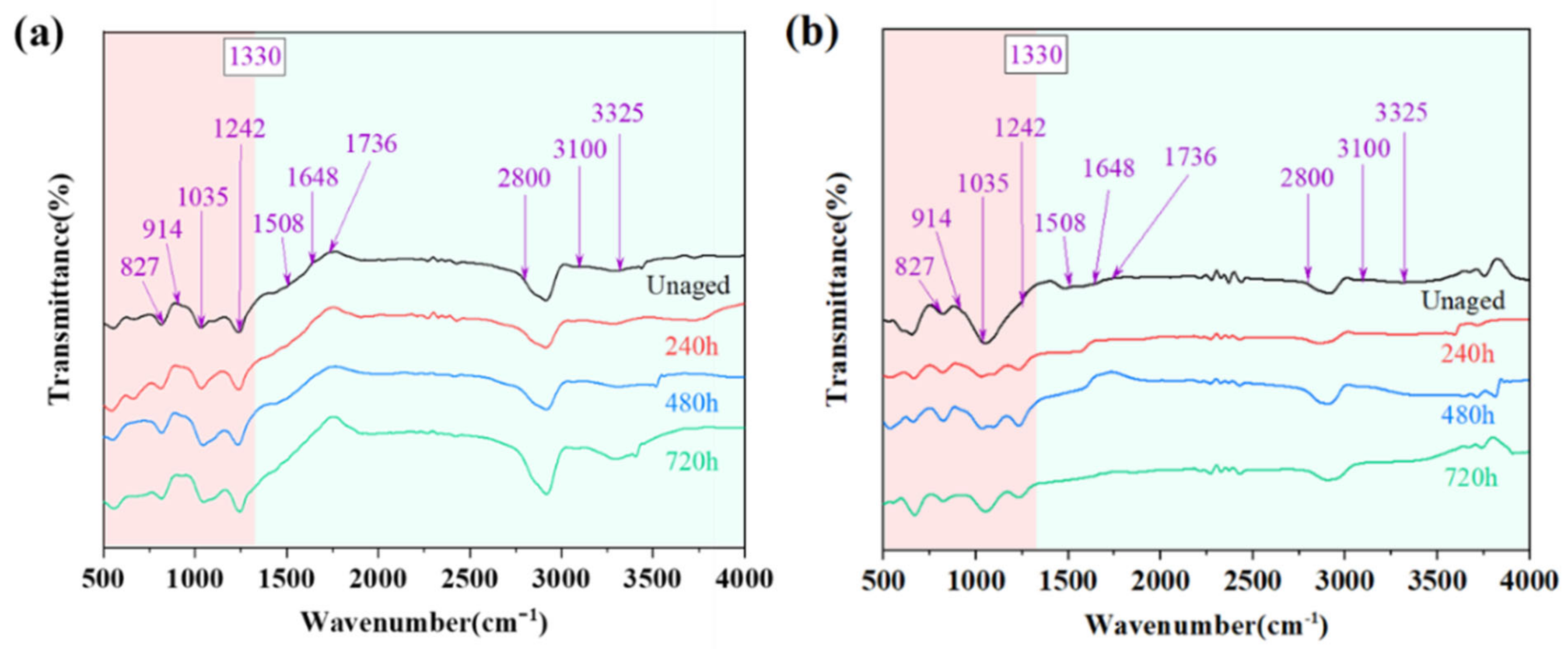

3.3. FTIR Test

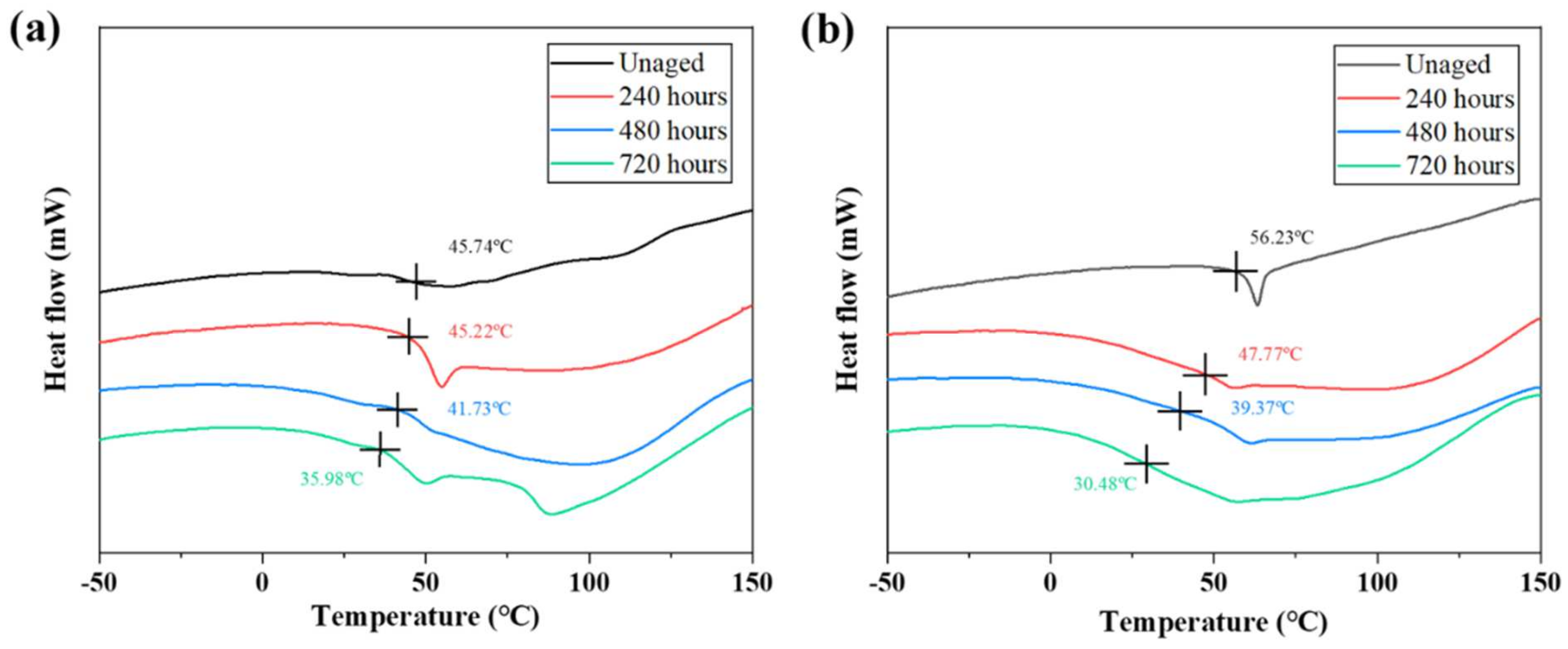

3.4. DSC Test

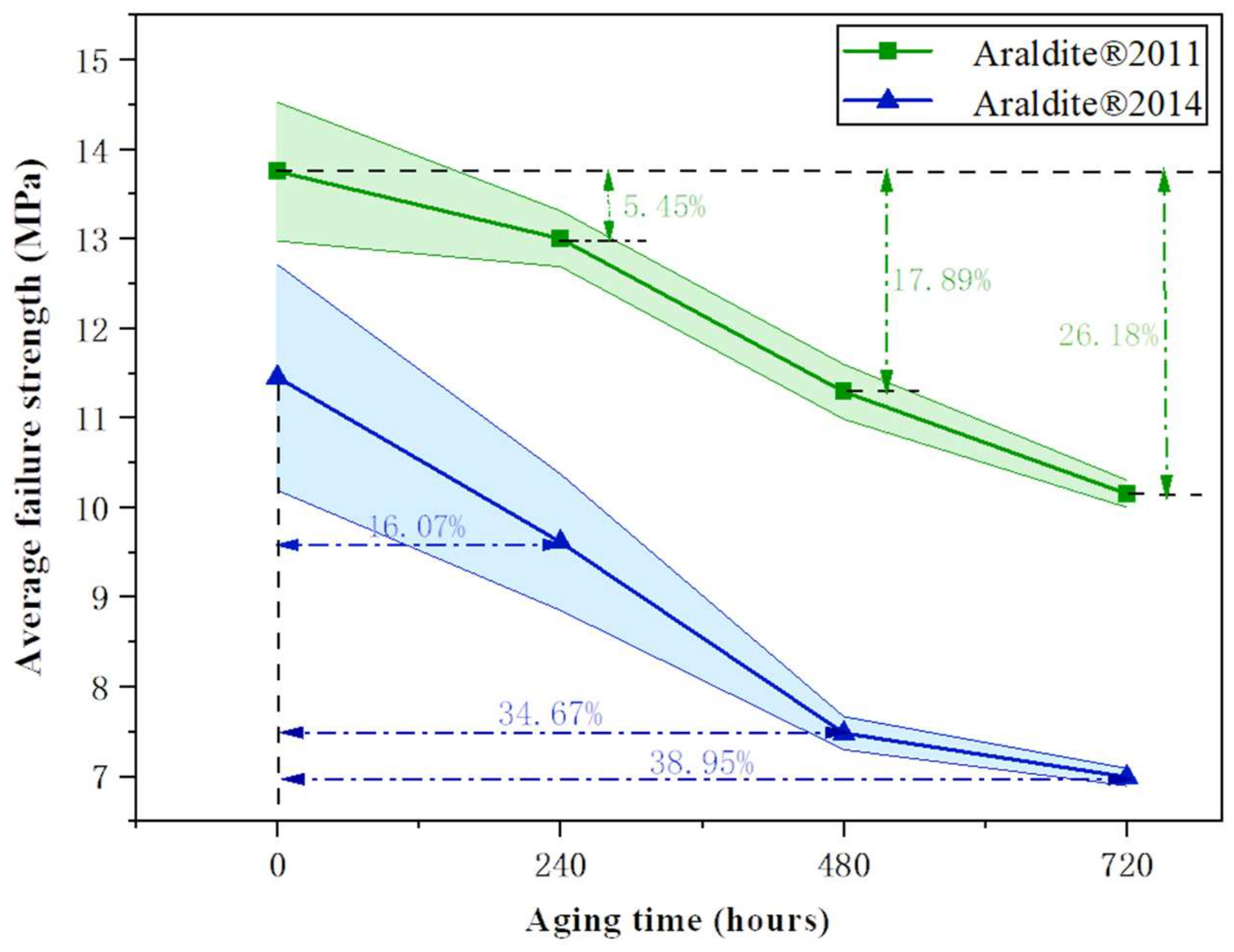

3.5. Mechanical Properties

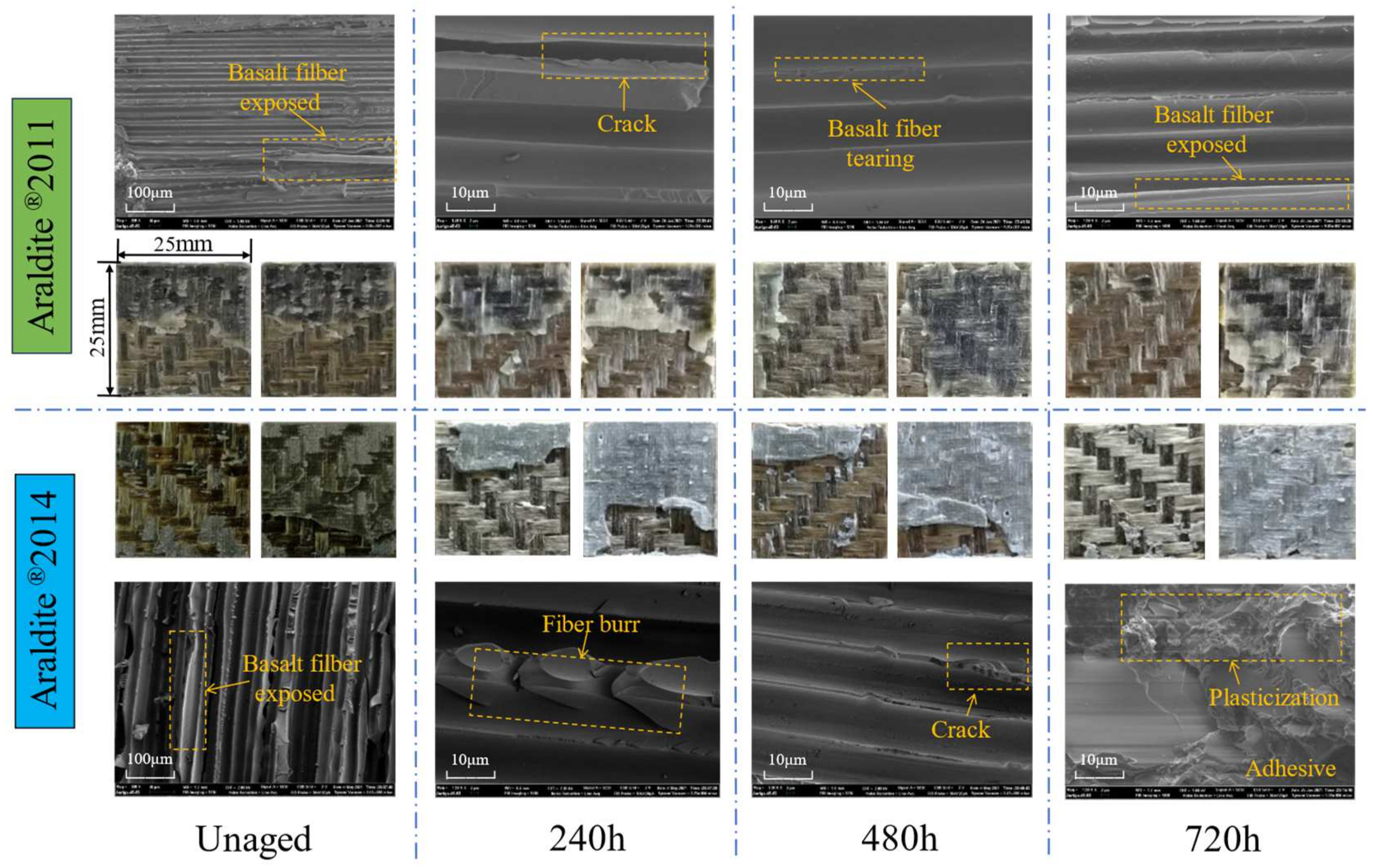

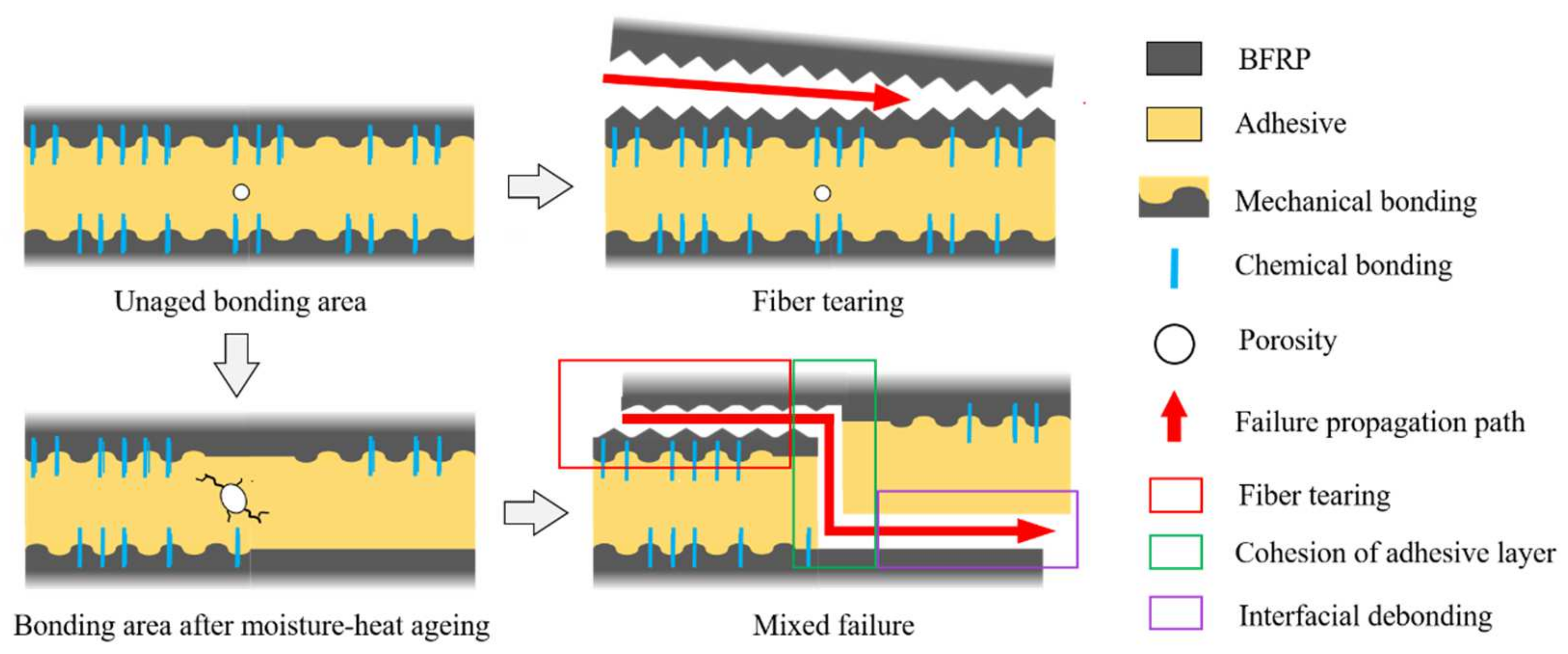

3.6. Failure Mode

3.7. EDX Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lima, R.A.A.; Tao, R.; Bernasconi, A.; Carboni, M.; Carrere, N.; de Freitas, S.T. Uncovering the toughening mechanisms of bonded joints through tailored CFRP layup. Compos. Part B Eng. 2023, 263, 110853. [Google Scholar] [CrossRef]

- Banea, M.D.; Silva, L.F.D.; Carbas, R.J.; Barros, S.D. Debonding on command of multi-material adhesive joints. J. Adhes. 2017, 93, 756–770. [Google Scholar] [CrossRef]

- Mouritz, A.; Gellert, E.; Burchill, P.; Challis, K. Review of advanced composite structures for naval ships and submarines. Compos. Struct. 2001, 53, 21–42. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Geier, N.; Xu, J.; Pereszlai, C.; Poór, D.I.; Davim, J.P. Drilling of carbon fibre reinforced polymer (CFRP) composites: Difficulties, challenges and expectations. Procedia Manuf. 2021, 54, 284–289. [Google Scholar] [CrossRef]

- Ahmad, F.; Abbassi, F.; Hong, J.-W.; Chang, S.-H.; Park, M.K. Hygroscopic effects on the penetration-resistance behavior of a specially-orthotropic CFRP composite plates. Compos. Struct. 2017, 176, 1073–1080. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Xiang, Y.; Pan, Q.; Hu, X. Effect of hygrothermal-mechanical exposure on the residual strength of adhesively bonded joints. Int. J. Adhes. Adhes. 2020, 100, 102616. [Google Scholar] [CrossRef]

- Jingxin, N.; Wenlong, M.; Guofeng, Q.; Wei, T.; Leixin, P. Effect of Temperature on the Mechanical Properties of Adhesively Bonded Basalt frp-aluminum Alloy Joints in the Automotive Industry. Int. J. Adhes. Adhes. 2018, 85, 138–148. [Google Scholar]

- Keller, T.; Theodorou, N.A.; Vassilopoulos, A.P.; De Castro, J. Effect of natural weathering on durability of pultruded glass fiber–reinforced bridge and building structures. J. Compos. Constr. 2015, 20, 1–9. [Google Scholar] [CrossRef]

- Tserpes, K.; Barroso-Caro, A.; Carraro, P.A.; Beber, V.C.; Floros, I.; Gamon, W.; Kozłowski, M.; Santandrea, F.; Shahverdi, M.; Skejic, D.; et al. A review on failure theories and simulation models for adhesive joints. J. Adhes. 2021, 98, 1855–1915. [Google Scholar] [CrossRef]

- Liu, T.Q.; Liu, X.; Feng, P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects. Compos. Part B Eng. 2020, 191, 107958. [Google Scholar] [CrossRef]

- Tsotsist, K. Thermo-oxidative aging of composite materials. J. Compos. Mater. 1995, 29, 410–422. [Google Scholar] [CrossRef]

- Stazi, F.; Giampaoli, M.; Rossi, M.; Munaf, P. Environmental ageing on GFRP pultruded joints: Comparison between different adhesives. Compos. Struct. 2015, 133, 404–414. [Google Scholar] [CrossRef]

- Sousa, J.; Correia, J.; Gonilha, J.; Cabral-Fonseca, S.; Firmo, J.; Keller, T. Durability of adhesively bonded joints between pultruded GFRP adherends under hygrothermal and natural ageing. Compos. B Eng. 2019, 158, 475–488. [Google Scholar] [CrossRef]

- Nguyen, T.-C.; Bai, Y.; Al-Mahaidi, R.; Zhao, X.-L. Time-dependent behaviour of steel/CFRP double strap joints subjected to combined thermal and mechanical loading. Compos. Struct. 2012, 94, 1826–1833. [Google Scholar] [CrossRef]

- Akderya, T.; Kemiklioglu, U.; Sayman, O. Effects of thermal ageing and impact loading on tensile properties of adhesively bonded fibre/epoxy composite joints. Compos. B Eng. 2016, 95, 117–122. [Google Scholar] [CrossRef]

- Cabral-Fonseca, S.; Correia, J.R.; Rodrigues, M.P.; Branco, F.A. Artificial accelerated ageing of GFRP pultruded profiles made of polyester and vinylester resins: Characterisation of physical-chemical and mechanical damage. Strain 2012, 48, 162–173. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, J.; Wu, C.; Han, X.; Zhang, W. Effects of moisture ingress on the mesoscale mechanical properties of epoxy adhesives under elevated temperature. Polym. Test. 2021, 94, 107049. [Google Scholar] [CrossRef]

- Heshmati, M.; Haghani, R.; Al-Emrani, M. Durability of bonded FRP-to-steel joints:effects of moisture, de-icing salt solution, temperature and FRP type. Compos. Part B Eng. 2017, 119, 153–167. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; He, J.; Gao, Y.; Hu, Z. Effect of functionalized nano-SiO2 addition on bond behavior of adhesively bonded CFRP-steel double-lap joint. Constr. Build. Mater. 2020, 244, 118400. [Google Scholar] [CrossRef]

- Qin, G.; Zheng, L.; Mi, P.; Zhu, Y.; Li, M.; Na, J.; Wang, Y. Influence of single or multi-factor coupling of temperature, humidity and load on the aging failure of adhesively bonded CFRP/aluminum alloy composite joints for automobile applications. Int. J. Adhes. Adhes. 2023, 123, 103345. [Google Scholar] [CrossRef]

- Ceylan, R.; Ozun, E.; Çoban, O.; Bora, M.Ö.; Kutluk, T. The effect of hygrothermal aging on the adhesion performance of nanomaterial reinforced aluminium adhesive joints. Int. J. Adhes. Adhes. 2023, 121, 103304. [Google Scholar] [CrossRef]

- Nian, X.I. Damage characterization and failure analysis in fifiber reinforced composites. J. Aeronaut. Mater. 2000, 20, 62–63. [Google Scholar]

- Li, J.; Yan, Y.; Zhang, T.; Liang, Z. Experimental study of adhesively bonded CFRP joints subjected to tensile loads. Int. J. Adhes. Adhes. 2015, 57, 95–104. [Google Scholar] [CrossRef]

- Arif, A.F.M.; Malik, M.H.; Al-Omari, A.S. Impact Resistance of Filament Wound Composite Pipes: A Parametric Study. In Proceedings of the American Society of Mechanical Engineers, Pressure Vessels and Piping Division (Publication) PVP, Anaheim, CA, USA, 20 July 2014. [Google Scholar] [CrossRef]

- Altalmas, A.; Refai, A.E.; Abed, F. Bond degradation of basalt fiber-reinforced polymer (BFRP) bars exposed to accelerated aging conditions. Constr. Build. Mater. 2015, 81, 162–171. [Google Scholar] [CrossRef]

- Mohabeddine, A.; Malik, G.; Correia, J.; Silva, F.; De Jesus, A.; Fantuzzi, N.; Castro, J.M. Experimental parametric investigation on the behavior of adhesively bonded CFRP/steel joints. Compos. Struct. 2023, 307, 116598. [Google Scholar] [CrossRef]

- Wu, C.; Yu, Y.Z.; Tam, L.H.; He, L. Effects of bondline defects on the bond behaviour of CFRP-steel double strap joints. Compos. Struct. 2023, 308, 116682. [Google Scholar] [CrossRef]

- Behera, R.K.; Panda, S.K.; Das, R.R. Effect of using fibre reinforced epoxy adhesive on the strength of the adhesively bonded Single Lap Joints. Compos. Part B Eng. 2023, 248, 110358. [Google Scholar] [CrossRef]

- Zamani, P.; Jaamialahmadi, A.; da Silva, L.F. Fatigue life evaluation of Al-GFRP bonded lap joints under four-point bending using strain-life criteria. Int. J. Adhes. Adhes. 2023, 122, 103338. [Google Scholar] [CrossRef]

- ASTM D5868-01; Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- Aghamohammadi, H.; Hosseini Abbandanak, S.N.; Eslami-Farsani, R.; Siadati, S.M.H. Effects of various aluminum surface treatments on the basalt fiber metal laminates interlaminar adhesion. Int. J. Adhes. Adhes. 2018, 84, 184–193. [Google Scholar] [CrossRef]

- ASTM-D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014; Volume 8, pp. 1–15.

- Mu, W.; Qin, G.; Na, J.; Tan, W.; Liu, H.; Luan, J. Effect of alternating load on the residual strength of environmentally aged adhesively bonded CFRP-aluminum alloy joints. Compos. Part B Eng. 2019, 168, 87–97. [Google Scholar] [CrossRef]

- Zheng, G.; He, Z.; Wang, K.; Liu, X.; Luo, Q.; Li, Q.; Sun, G. On failure mechanisms in CFRP/Al adhesive joints after hygrothermal aging degradation following by mechanical tests. Thin-Walled Struct. 2021, 158, 107184. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, X.; Zhang, H.; Wang, Z. Effects of hygrothermal aging on epoxy-based anisotropic conductive film. Mater Lett. 2006, 60, 2958–2963. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, X.-L.; Xian, G.; Wu, G.; Raman, R.S.; Al-Saadi, S. Durability study on interlaminar shear behaviour of basalt-, glass- and carbon-fibre reinforced polymer (B/G/CFRP) bars in seawater sea sand concrete environment. Constr. Build. Mater. 2017, 156, 985. [Google Scholar] [CrossRef]

- Mu, W.; Na, J.; Wang, G.; Tan, W.; Xu, Q.; Feng, Y. Rapid prediction method of failure load for hygrothermally aged CFRP—Aluminum alloy single lap joints. Compos. Struct. 2020, 252, 112603. [Google Scholar] [CrossRef]

- Zhou, J.; Lucas, J.P. Hygrothermal effects of epoxy resin. Part I: The nature of water in epoxy. Polymer 1999, 40, 5505–5512. [Google Scholar] [CrossRef]

- Ameli, A.; Datla, N.V.; Papini, M.; Spelt, J.K. Hygrothermal properties of highly toughened epoxy adhesives. J. Adhesion. 2010, 86, 698–725. [Google Scholar] [CrossRef]

- Jadhav, N.; Gaikwad, V.; Nair, K.; Kadam, H. Glass transition temperature: Basics and application in pharmaceutical sector. Asian J. Pharm. 2009, 3, 82–89. [Google Scholar] [CrossRef]

| ML-5417A/ML-5417B Epoxy Resin | Basalt Fibre Unidirectional Fabric | ||

|---|---|---|---|

| Cure condition | 25 °C × 24 h + 100 °C × 3 h | Surface density/(g·cm−2) | 300 |

| Tensile strength/(MPa) | 2100 | ||

| Epoxy value/(g/ep) | 165–175 | Young’s modulus/(GPa) | 105 |

| 25 °C density/(g·cm−3) | 1.10–1.20 | Elongation/(%) | 2.6 |

| Tensile modulus/(MPa) | 2800–3200 | Nominal thickness/(mm) | 0.115 |

| Tg (°C) | 110–125 | Single fibre size/(μm) | 13 |

| Araldite®2011 | Araldite®2014 | |

|---|---|---|

| Young’s modulus (GPa) | 1.65 | 4 |

| Shear modulus (GPa) | 0.2 | 1.2 |

| Density/(kg·m3) | 1.15 | 1.6 |

| Poisson’s ratio | 0.43 | 0.33 |

| Wavenumber | Assignment |

|---|---|

| cm−1 | |

| 3325 | –OH, –NH stretching |

| 3100–2800 | Alkyl groups (–OH, –CH2) stretching |

| 1736 | Ester link (–(C=O)–O) |

| 1648 | Carbonyl group (C=O) |

| 1606, 1581 | Quadrant stretching of the benzene ring |

| 1508 | Semicircle stretching of p-disubstituted benzene |

| 1452 | C-H bending of aliphatic groups |

| 1296 | Twisting mode of –CH2– groups |

| 1242 | Stretching mode for aromatic ether |

| 1180 | C–C stretching of the bridge carbon atom between two p-phenylene groups |

| 1082, 1035 | Stretching of the trans forms of the ether linkage |

| 914 | Epoxy functional group |

| 827 | p-phenylene groups |

| t | p | Cohen’s d | |

|---|---|---|---|

| A and B | −7.418 | 0.018 | 4.283 |

| C and D | −6.366 | 0.024 | 3.676 |

| A and C | 4.011 | 0.057 | |

| B and D | −0.111 | 0.922 |

| Element | a | b | c | d | ||||

|---|---|---|---|---|---|---|---|---|

| Apparent Concentration | wt% | Apparent Concentration | wt% | Apparent Concentration | wt% | Apparent Concentration | wt% | |

| C | 121.40 | 74.79 | 53.56 | 57.35 | 137.73 | 75.28 | 113.39 | 75.57 |

| O | 24.35 | 20.97 | 40.23 | 29.18 | 24.41 | 21.60 | 21.26 | 20.36 |

| Si | 3.03 | 0.91 | 16.76 | 5.42 | 1.20 | 0.43 | 2.86 | 0.95 |

| Fe | 0.63 | 0.23 | 4.26 | 1.58 | 0.28 | 0.12 | 0.84 | 0.34 |

| O/C | 0.20 | 0.75 | 0.18 | 0.19 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, R.; Yang, Y.; Lin, Y.; Liu, Z.; Fan, Y. Failure Study of BFRP Joints with Two Epoxy Adhesives under Hygrothermal Coupling. Polymers 2023, 15, 3949. https://doi.org/10.3390/polym15193949

Niu R, Yang Y, Lin Y, Liu Z, Fan Y. Failure Study of BFRP Joints with Two Epoxy Adhesives under Hygrothermal Coupling. Polymers. 2023; 15(19):3949. https://doi.org/10.3390/polym15193949

Chicago/Turabian StyleNiu, Ruitao, Yang Yang, Yinghao Lin, Zhen Liu, and Yisa Fan. 2023. "Failure Study of BFRP Joints with Two Epoxy Adhesives under Hygrothermal Coupling" Polymers 15, no. 19: 3949. https://doi.org/10.3390/polym15193949

APA StyleNiu, R., Yang, Y., Lin, Y., Liu, Z., & Fan, Y. (2023). Failure Study of BFRP Joints with Two Epoxy Adhesives under Hygrothermal Coupling. Polymers, 15(19), 3949. https://doi.org/10.3390/polym15193949