Three-Dimensional Printing of Shape Memory Liquid Crystalline Thermoplastic Elastomeric Composites Using Fused Filament Fabrication

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

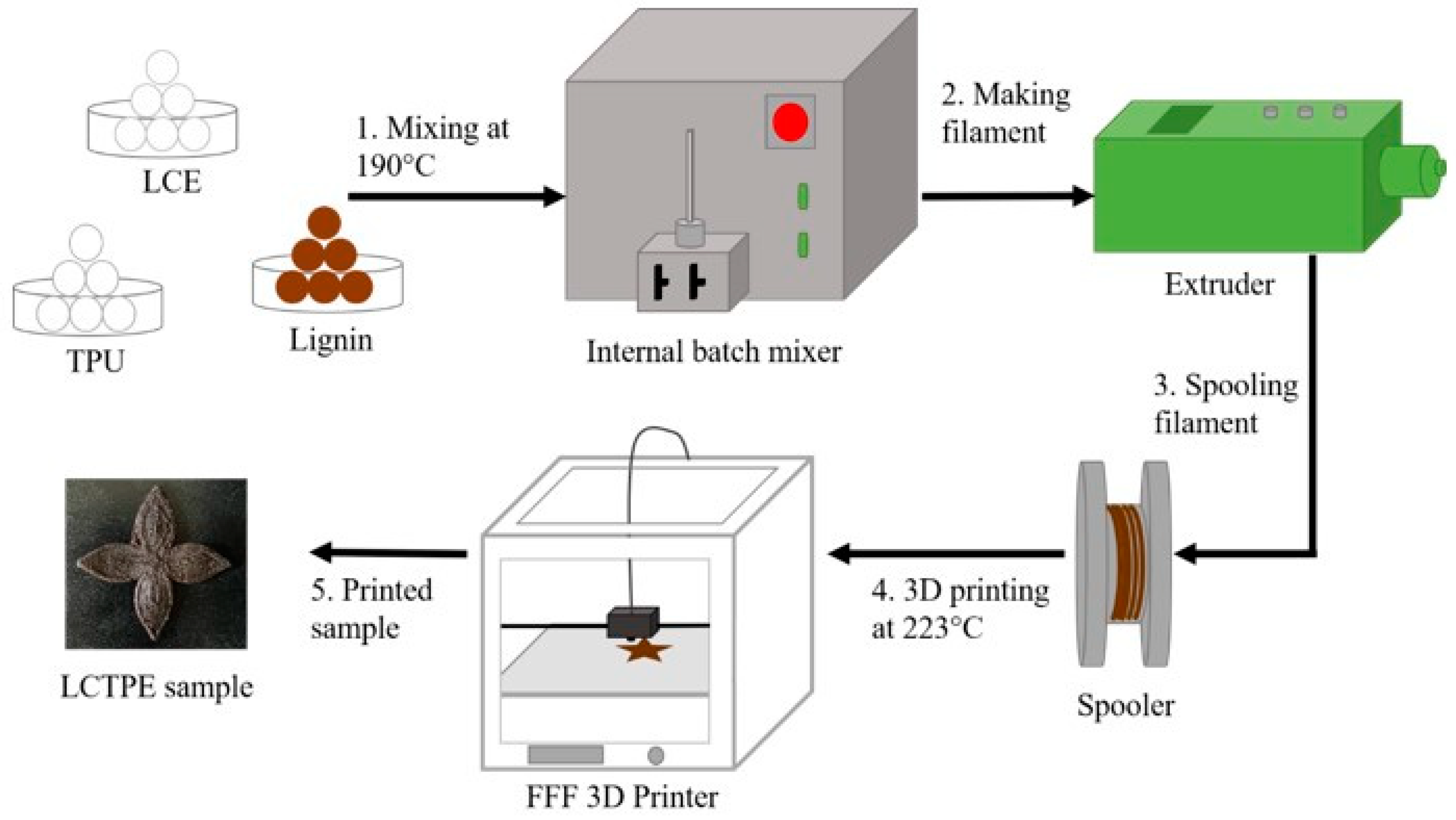

2.2. Sample Preparation

2.3. Sample Characterisation

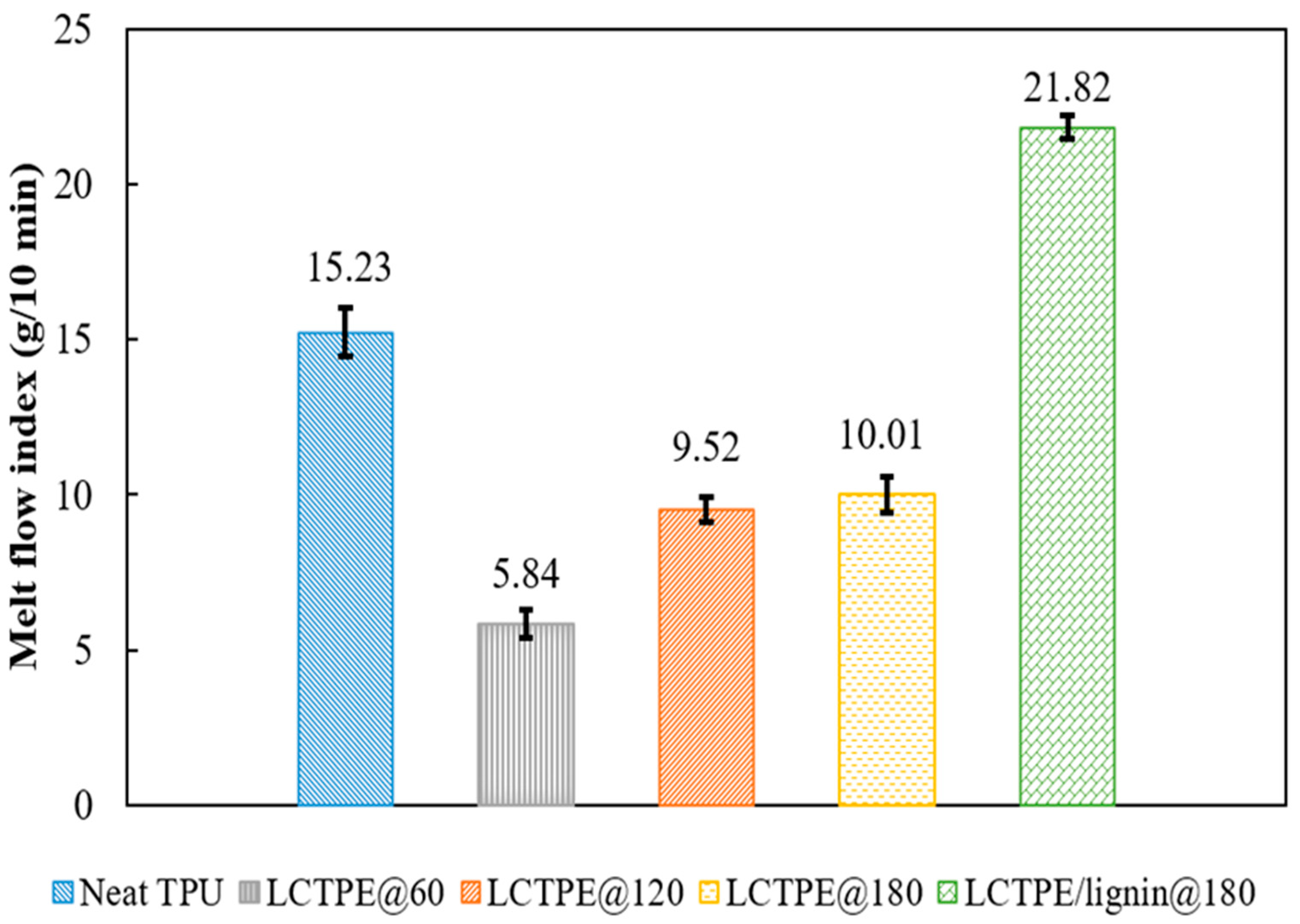

2.3.1. Melt Flow Index

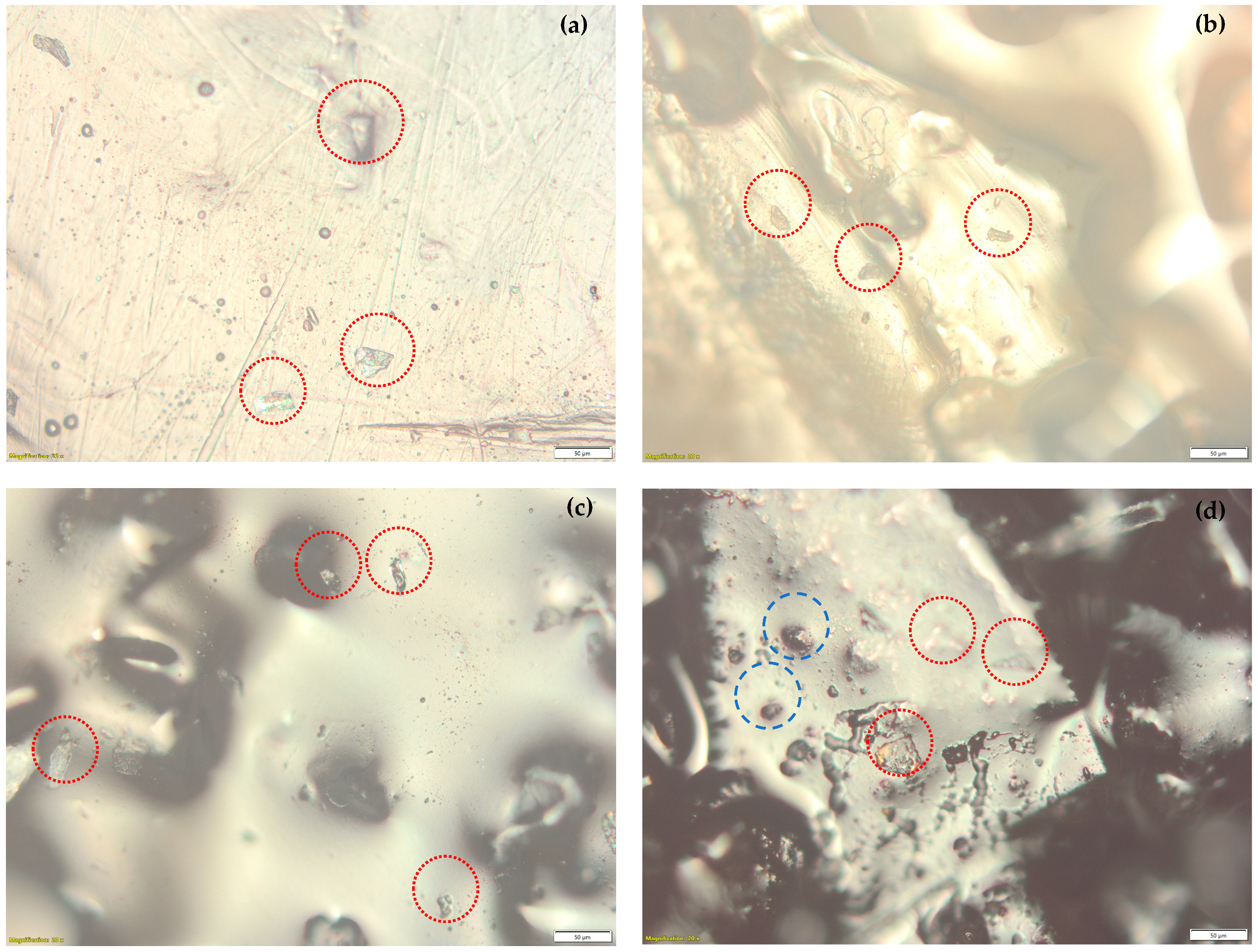

2.3.2. Optical Microscopy

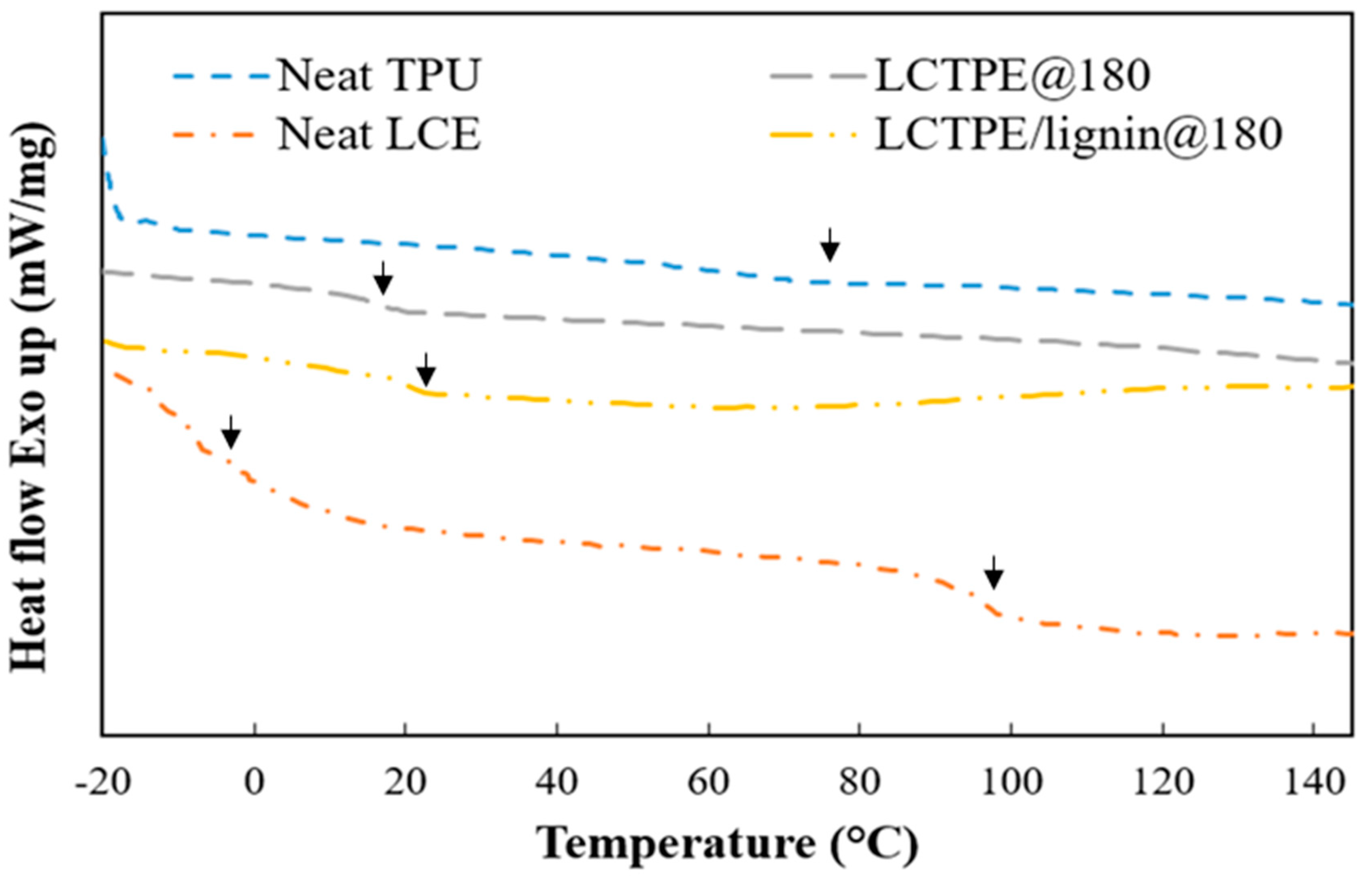

2.3.3. Thermal Properties

2.3.4. Thermal Stability

2.3.5. Fourier-Transform Infrared (FTIR) Spectroscopy

2.3.6. Shape Memory Behaviours

3. Fabrication of 3D-Printed LCTPEs and Their Composites

4. Results and Discussion

4.1. The Effect of Rotor Speed on the Melt Flow Index of LCTPE and Their Composites

4.2. Surface Morphology of LCTPE and Composite Materials

4.3. Thermal Properties of LCTPEs and Their Composites

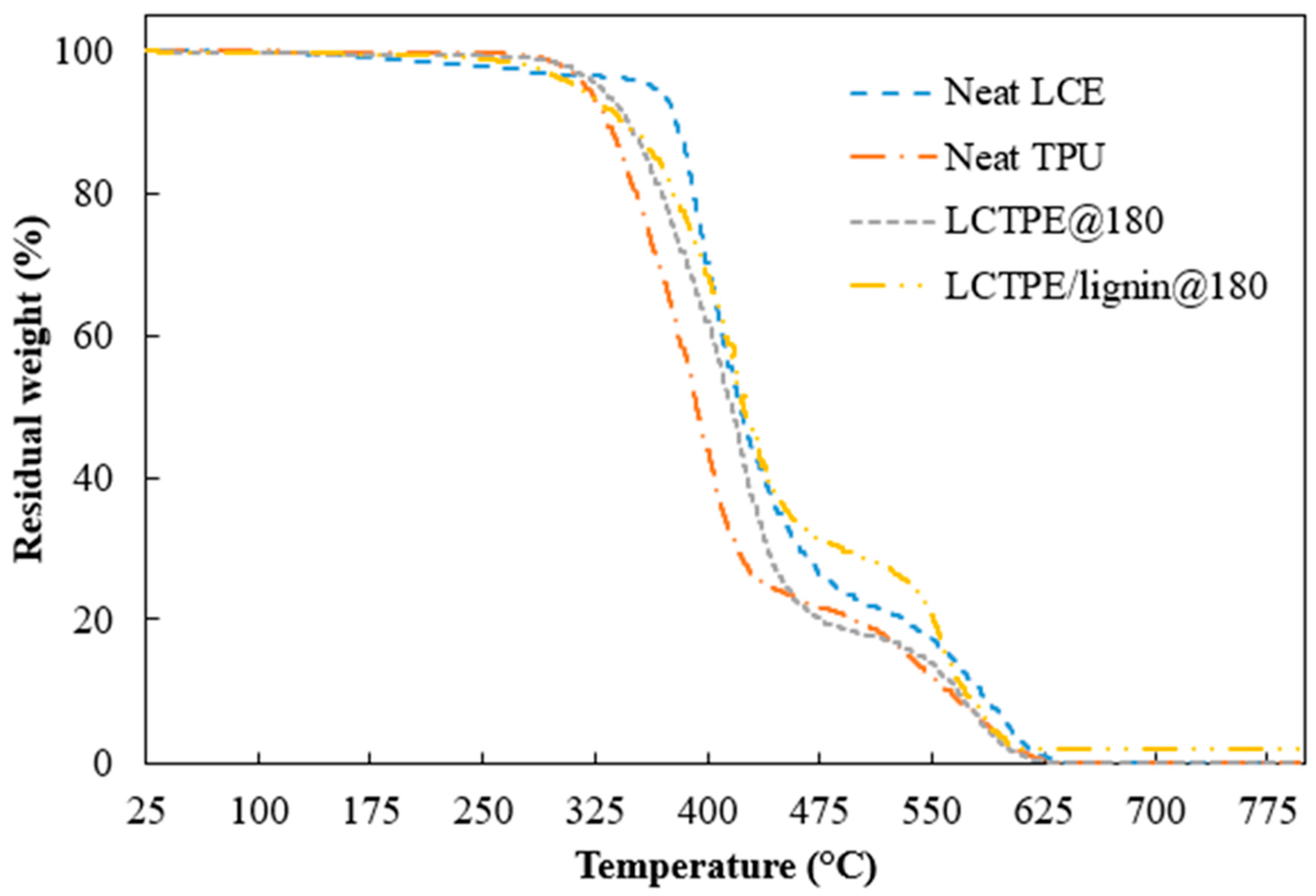

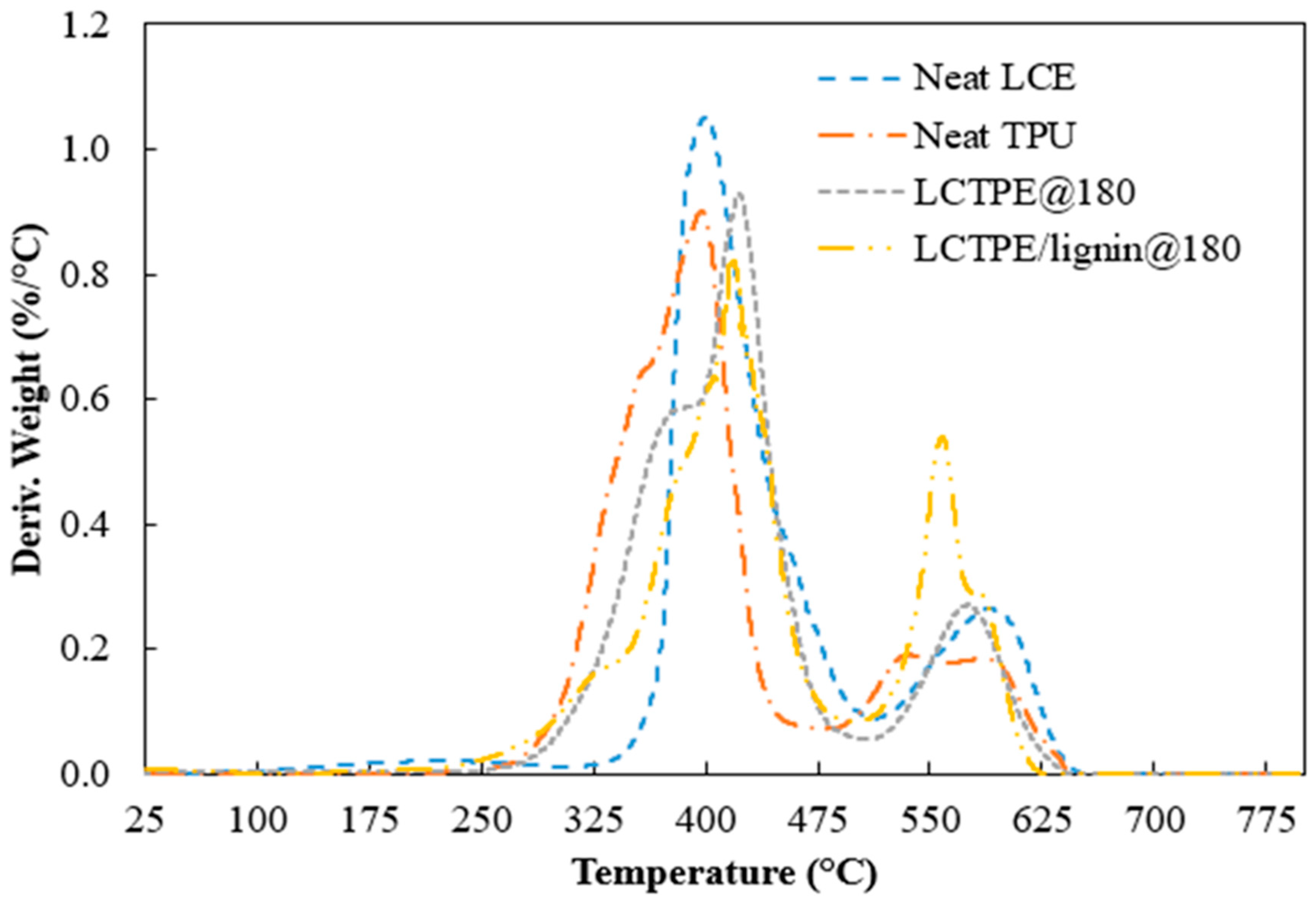

4.4. Thermal Stability of LCTPEs and Their Composites

4.5. FTIR Analysis of the Neat LCE, Neat TPU, and LCTPE Materials

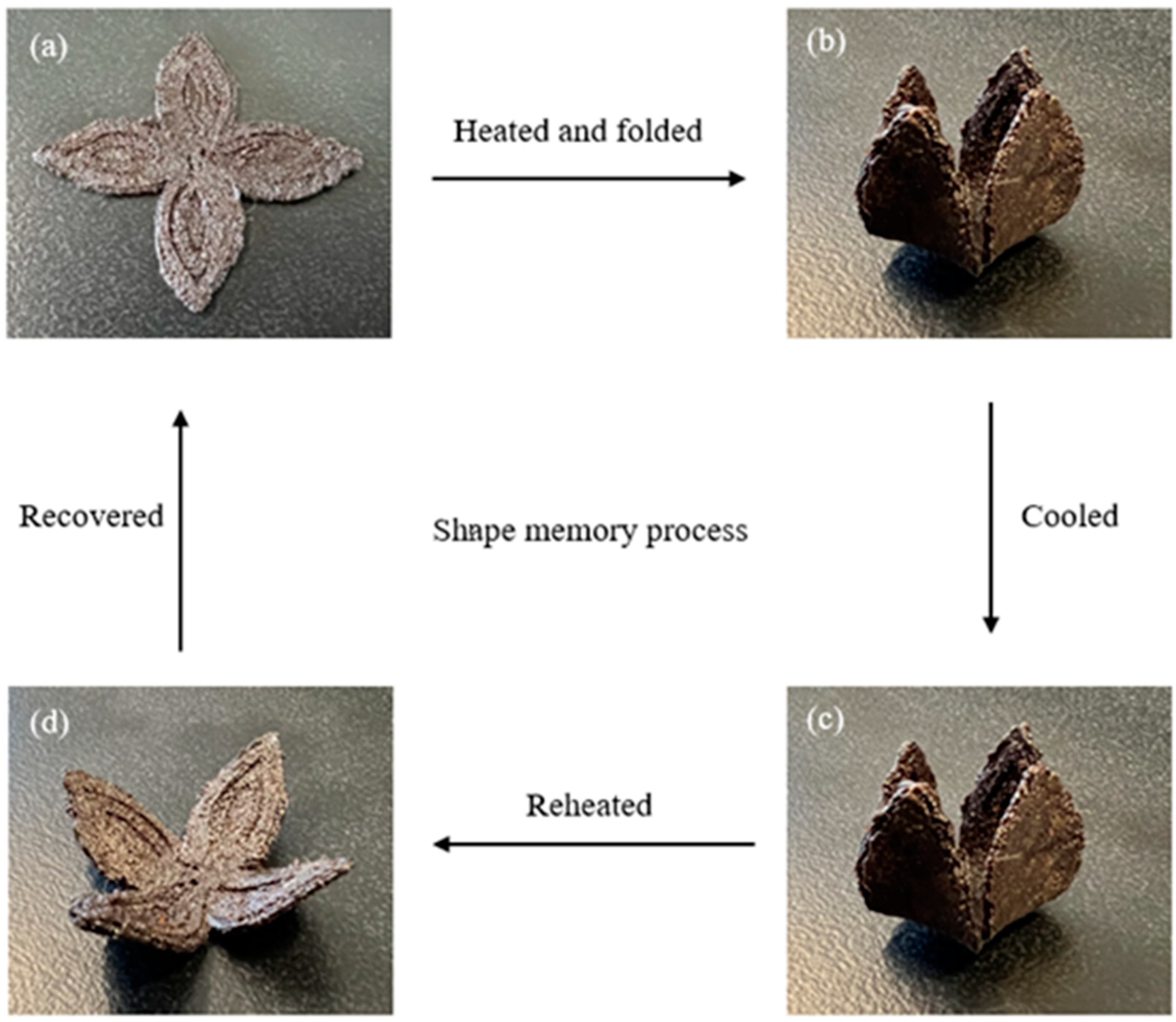

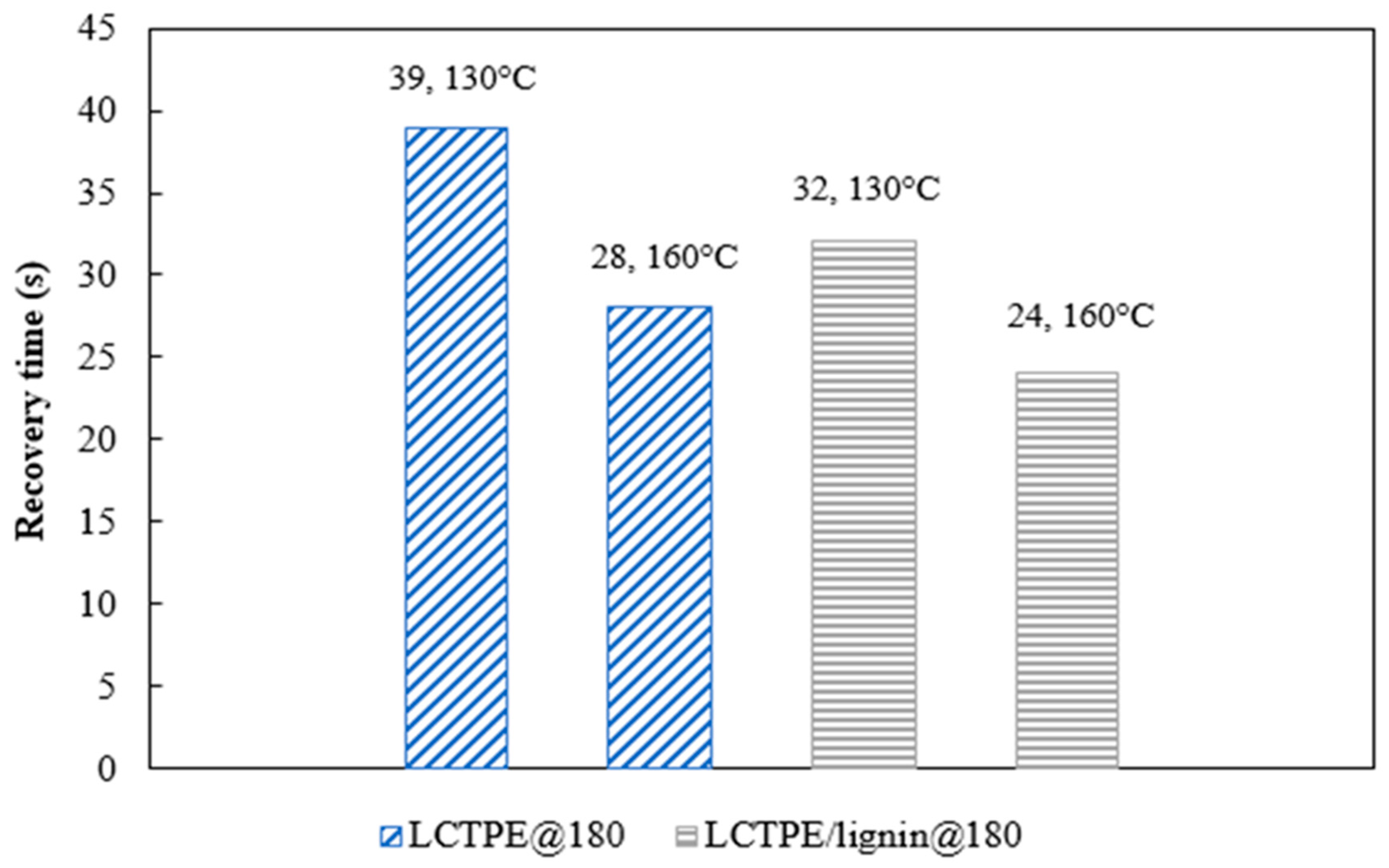

4.6. Shape Memory Behaviours of LCTPE Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent 638905, 11 March 1986. [Google Scholar]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef]

- Lai, J.; Wang, C.; Wang, M. 3D printing in biomedical engineering: Processes, materials, and applications. Appl. Phys. Rev. 2021, 8, 021322. [Google Scholar] [CrossRef]

- Macdonald, E.; Salas, R.; Espalin, D.; Perez, M.; Aguilera, E.; Muse, D.; Wicker, R.B. 3D printing for the rapid prototyping of structural electronics. IEEE Access 2014, 2, 234–242. [Google Scholar] [CrossRef]

- El-Sayegh, S.; Romdhane, L.; Manjikian, S. A critical review of 3D printing in construction: Benefits, challenges, and risks. Arch. Civ. Mech. Eng. 2020, 20, 34. [Google Scholar] [CrossRef]

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Ningbo, China, 27–29 May 2014; p. 012018. [Google Scholar]

- Saed, M.O.; Torbati, A.H.; Nair, D.P.; Yakacki, C.M. Synthesis of programmable main-chain liquid-crystalline elastomers using a two-stage thiol-acrylate reaction. JoVE (J. Vis. Exp.) 2016, 107, e53546. [Google Scholar]

- Prathumrat, P.; Nikzad, M.; Hajizadeh, E.; Okhawilai, M.; Sbarski, I. Lignin-liquid crystalline elastomeric composites for shape memory applications and their thermomechanical properties. Express Polym. Lett. 2023, 17, 104–117. [Google Scholar] [CrossRef]

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef]

- Awasthi, P.; Banerjee, S.S. Fused deposition modeling of thermoplastic elastomeric materials: Challenges and opportunities. Addit. Manuf. 2021, 46, 102177. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Li, M.; Lei, M.; Wang, Y.; Wei, Q. 3D printing thermo-responsive shape memory polymer composite based on PCL/TPU blends. J. Polym. Res. 2022, 29, 243. [Google Scholar] [CrossRef]

- Bi, H.; Xu, M.; Ye, G.; Guo, R.; Cai, L.; Ren, Z. Mechanical, Thermal, and Shape Memory Properties of Three-Dimensional Printing Biomass Composites. Polymers 2018, 10, 1234. [Google Scholar] [CrossRef]

- Huang, J.; Lu, X.; Zhang, G.; Qu, J. Study on the rheological, thermal and mechanical properties of thermoplastic polyurethane/poly (butylene terephthalate) blends. Polym. Test. 2014, 36, 69–74. [Google Scholar] [CrossRef]

- Li, H.; Sivasankarapillai, G.; McDonald, A.G. Lignin valorization by forming toughened thermally stimulated shape memory copolymeric elastomers: Evaluation of different fractionated industrial lignins. J. Appl. Polym. Sci. 2015, 132, 41389. [Google Scholar] [CrossRef]

- Zhou, X.; Ren, Z.; Sun, H.; Bi, H.; Gu, T.; Xu, M. 3D printing with high content of lignin enabled by introducing polyurethane. Int. J. Biol. Macromol. 2022, 221, 1209–1217. [Google Scholar] [CrossRef]

- León-Calero, M.; Reyburn Valés, S.C.; Marcos-Fernández, Á.; Rodríguez-Hernandez, J. 3D printing of thermoplastic elastomers: Role of the chemical composition and printing parameters in the production of parts with controlled energy absorption and damping capacity. Polymers 2021, 13, 3551. [Google Scholar] [CrossRef]

- Peleg, M. Temperature–viscosity models reassessed. Crit. Rev. Food Sci. Nutr. 2018, 58, 2663–2672. [Google Scholar] [CrossRef]

- Wang, S.; Capoen, L.; D’hooge, D.R.; Cardon, L. Can the melt flow index be used to predict the success of fused deposition modelling of commercial poly(lactic acid) filaments into 3D printed materials? Plast. Rubber Compos. 2018, 47, 9–16. [Google Scholar] [CrossRef]

- Tjong, S.C.; Xu, S.A. Mechanical properties of glass fiber and liquid crystalline polymer reinforced polypropylene hybrid composites toughened with elastomers. J. Appl. Polym. Sci. 2004, 94, 1539–1546. [Google Scholar] [CrossRef]

- Domínguez-Robles, J.; Larrañeta, E.; Fong, M.L.; Martin, N.K.; Irwin, N.J.; Mutjé, P.; Tarrés, Q.; Delgado-Aguilar, M. Lignin/poly(butylene succinate) composites with antioxidant and antibacterial properties for potential biomedical applications. Int. J. Biol. Macromol. 2020, 145, 92–99. [Google Scholar] [CrossRef]

- Klapiszewski, L.; Jamrozik, A.; Strzemiecka, B.; Matykiewicz, D.; Voelkel, A.; Jesionowski, T. Activation of magnesium lignosulfonate and kraft lignin: Influence on the properties of phenolic resin-based composites for potential applications in abrasive materials. Int. J. Mol. Sci. 2017, 18, 1224. [Google Scholar] [CrossRef]

- Sadiku-Agboola, O.; Sadiku, E.R.; Adegbola, A.T.; Biotidara, O.F. Rheological properties of polymers: Structure and morphology of molten polymer blends. Mater. Sci. Appl. 2011, 2, 30. [Google Scholar] [CrossRef]

- Roths, T.; Friedrich, C.; Marth, M.; Honerkamp, J. Dynamics and rheology of the morphology of immiscible polymer blends–on modeling and simulation. Rheol. Acta 2002, 41, 211–222. [Google Scholar] [CrossRef]

- Chapman, C.D.; Shanbhag, S.; Smith, D.E.; Robertson-Anderson, R.M. Complex effects of molecular topology on diffusion in entangled biopolymer blends. Soft Matter 2012, 8, 9177–9182. [Google Scholar] [CrossRef]

- Galeski, A. Dynamic mechanical properties of crystalline polymer blends. The influence of interface and orientation. e-Polymers 2002, 2, 346–374. [Google Scholar] [CrossRef]

- Saha, S.; Xu, D.; Gersappe, D. Effect of Compatibilizers on the Structure and Dynamics at Polymer Blend Interfaces. Tribol. Lett. 2021, 69, 61. [Google Scholar] [CrossRef]

- Holt, A.P.; Bocharova, V.; Cheng, S.; Kisliuk, A.M.; White, B.T.; Saito, T.; Uhrig, D.; Mahalik, J.P.; Kumar, R.; Imel, A.E.; et al. Controlling Interfacial Dynamics: Covalent Bonding versus Physical Adsorption in Polymer Nanocomposites. ACS Nano 2016, 10, 6843–6852. [Google Scholar] [CrossRef]

- Somdee, P.; Lassú-Kuknyó, T.; Kónya, C.; Szabó, T.; Marossy, K. Thermal analysis of polyurethane elastomers matrix with different chain extender contents for thermal conductive application. J. Therm. Anal. Calorim. 2019, 138, 1003–1010. [Google Scholar] [CrossRef]

- Ortiz-Serna, P.; Carsí, M.; Culebras, M.; Collins, M.N.; Sanchis, M.J. Exploring the role of lignin structure in molecular dynamics of lignin/bio-derived thermoplastic elastomer polyurethane blends. Int. J. Biol. Macromol. 2020, 158, 1369–1379. [Google Scholar] [CrossRef]

- Dong, M.; Li, Q.; Liu, H.; Liu, C.; Wujcik, E.K.; Shao, Q.; Ding, T.; Mai, X.; Shen, C.; Guo, Z. Thermoplastic polyurethane-carbon black nanocomposite coating: Fabrication and solid particle erosion resistance. Polymer 2018, 158, 381–390. [Google Scholar] [CrossRef]

- Liu, H.; Dong, M.; Huang, W.; Gao, J.; Dai, K.; Guo, J.; Zheng, G.; Liu, C.; Shen, C.; Guo, Z. Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing. J. Mater. Chem. C 2017, 5, 73–83. [Google Scholar] [CrossRef]

- Pan, R.; Yang, L.; Zheng, L.; Hao, L.; Li, Y. Microscopic morphology, thermodynamic and mechanical properties of thermoplastic polyurethane fabricated by selective laser sintering. Mater. Res. Express 2020, 7, 055301. [Google Scholar] [CrossRef]

- Haryńska, A.; Gubanska, I.; Kucinska-Lipka, J.; Janik, H. Fabrication and Characterization of Flexible Medical-Grade TPU Filament for Fused Deposition Modeling 3DP Technology. Polymers 2018, 10, 1304. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, T.; Voit, B.; Karak, N. Polystyrene/thermoplastic polyurethane interpenetrating network-based nanocomposite with high-speed, thermo-responsive shape memory behavior. Polymer 2020, 200, 122575. [Google Scholar] [CrossRef]

- Hao, X.; Kaschta, J.; Liu, X.; Pan, Y.; Schubert, D.W. Entanglement network formed in miscible PLA/PMMA blends and its role in rheological and thermo-mechanical properties of the blends. Polymer 2015, 80, 38–45. [Google Scholar] [CrossRef]

- Hoy, R.S.; Robbins, M.O. Strain hardening of polymer glasses: Entanglements, energetics, and plasticity. Phys. Rev. E 2008, 77, 031801. [Google Scholar] [CrossRef]

| Samples | Mixing Process |

|---|---|

| LCTPE@60 | 60 rpm for 10 min at 190 °C |

| LCTPE@120 | 120 rpm for 10 min at 190 °C |

| LCTPE@180 | 180 rpm for 10 min at 190 °C |

| LCTPE/lignin@180 | LCE and TPU were mixed at 180 rpm for 9 min, and lignin was then added to mix for 1 min at 190 °C. |

| Parameters | Value |

|---|---|

| Print nozzle diameter (mm) | 0.8 |

| Nozzle temperature (°C) | 223 |

| Bed temperature (°C) | 50 |

| Layer thickness (mm) | 0.15 |

| Printing speed (mm/s) | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prathumrat, P.; Nikzad, M.; Jahromi, F.T.; Hajizadeh, E.; Sbarski, I. Three-Dimensional Printing of Shape Memory Liquid Crystalline Thermoplastic Elastomeric Composites Using Fused Filament Fabrication. Polymers 2023, 15, 3961. https://doi.org/10.3390/polym15193961

Prathumrat P, Nikzad M, Jahromi FT, Hajizadeh E, Sbarski I. Three-Dimensional Printing of Shape Memory Liquid Crystalline Thermoplastic Elastomeric Composites Using Fused Filament Fabrication. Polymers. 2023; 15(19):3961. https://doi.org/10.3390/polym15193961

Chicago/Turabian StylePrathumrat, Peerawat, Mostafa Nikzad, Fareed Tamaddoni Jahromi, Elnaz Hajizadeh, and Igor Sbarski. 2023. "Three-Dimensional Printing of Shape Memory Liquid Crystalline Thermoplastic Elastomeric Composites Using Fused Filament Fabrication" Polymers 15, no. 19: 3961. https://doi.org/10.3390/polym15193961

APA StylePrathumrat, P., Nikzad, M., Jahromi, F. T., Hajizadeh, E., & Sbarski, I. (2023). Three-Dimensional Printing of Shape Memory Liquid Crystalline Thermoplastic Elastomeric Composites Using Fused Filament Fabrication. Polymers, 15(19), 3961. https://doi.org/10.3390/polym15193961