Effect of Infill Parameters on the Compressive Strength of 3D-Printed Nylon-Based Material

Abstract

:1. Introduction

2. Materials and Methods

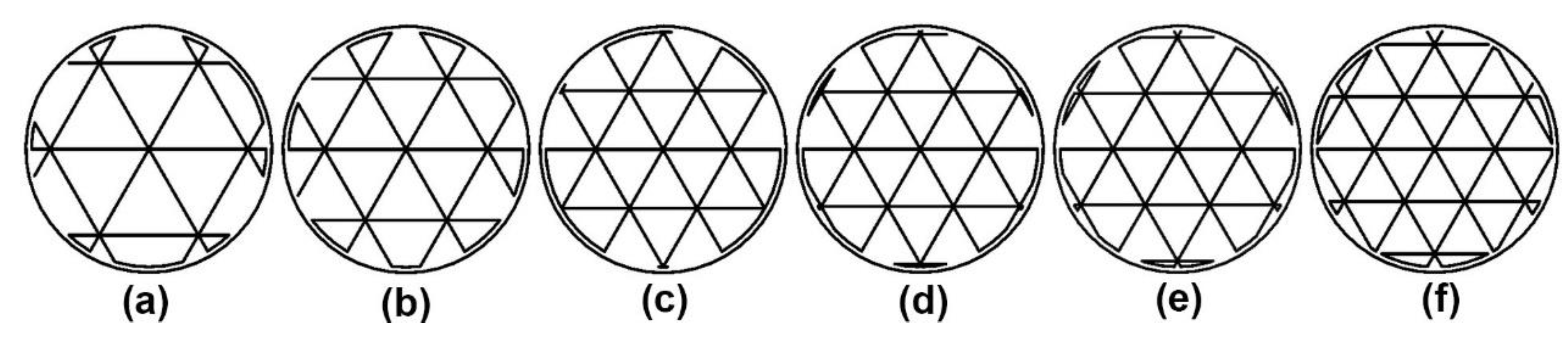

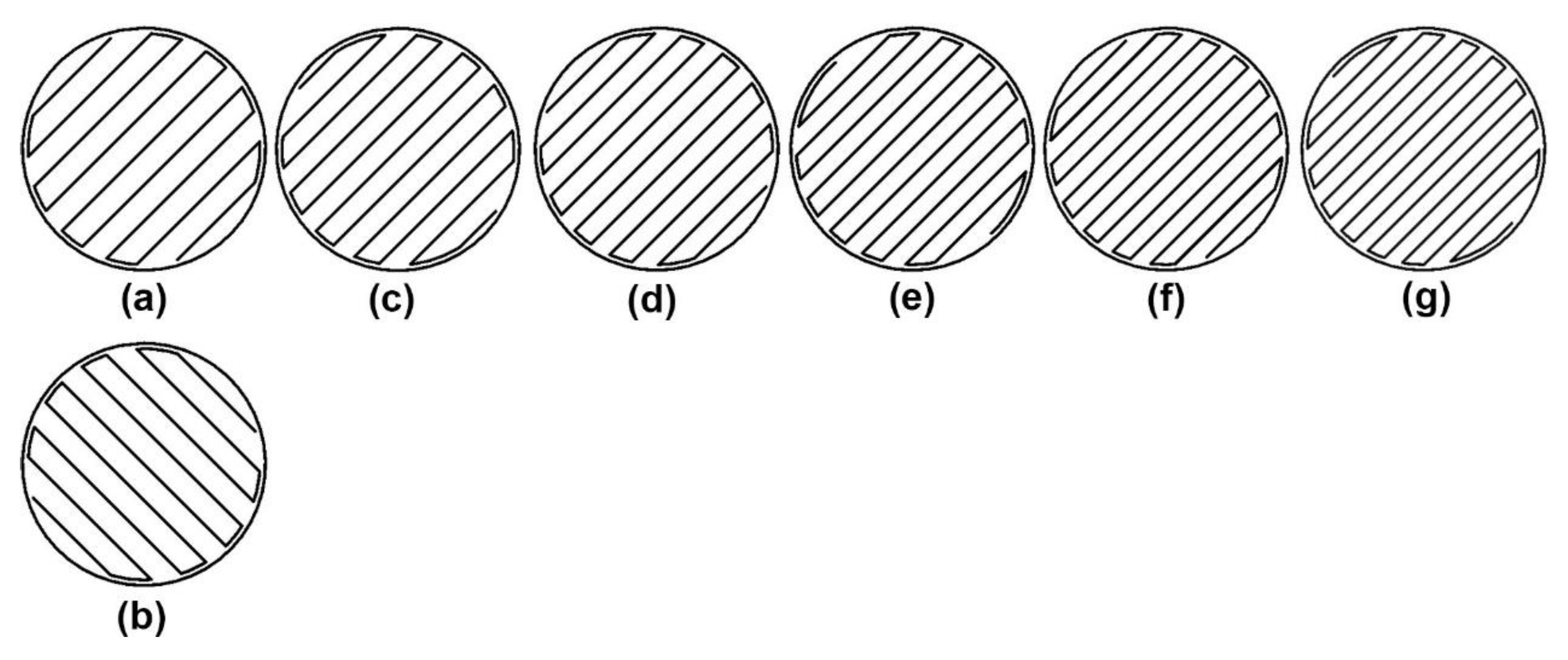

2.1. Preparation and Test of Standard Specimens

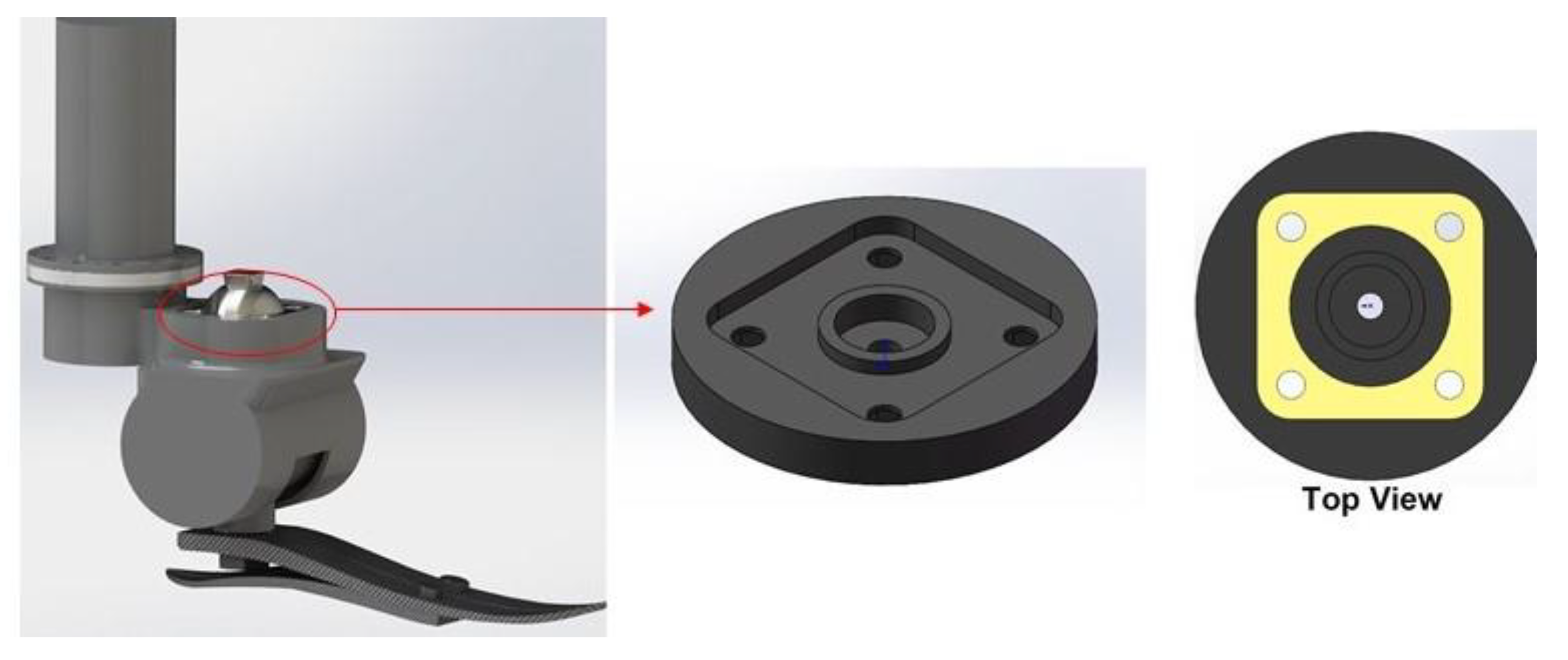

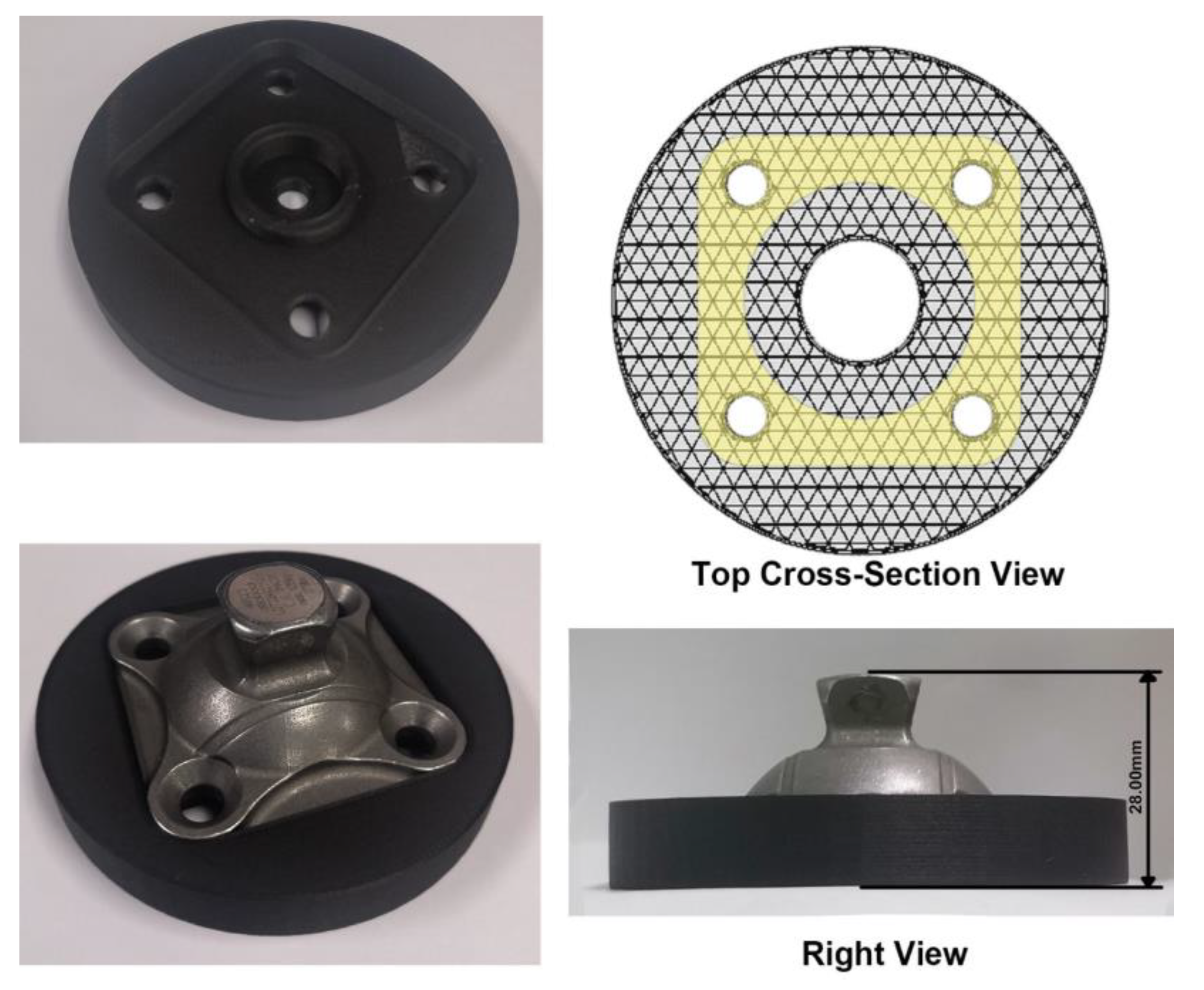

2.2. Preparation and Test of Samples of Practical Application

3. Results

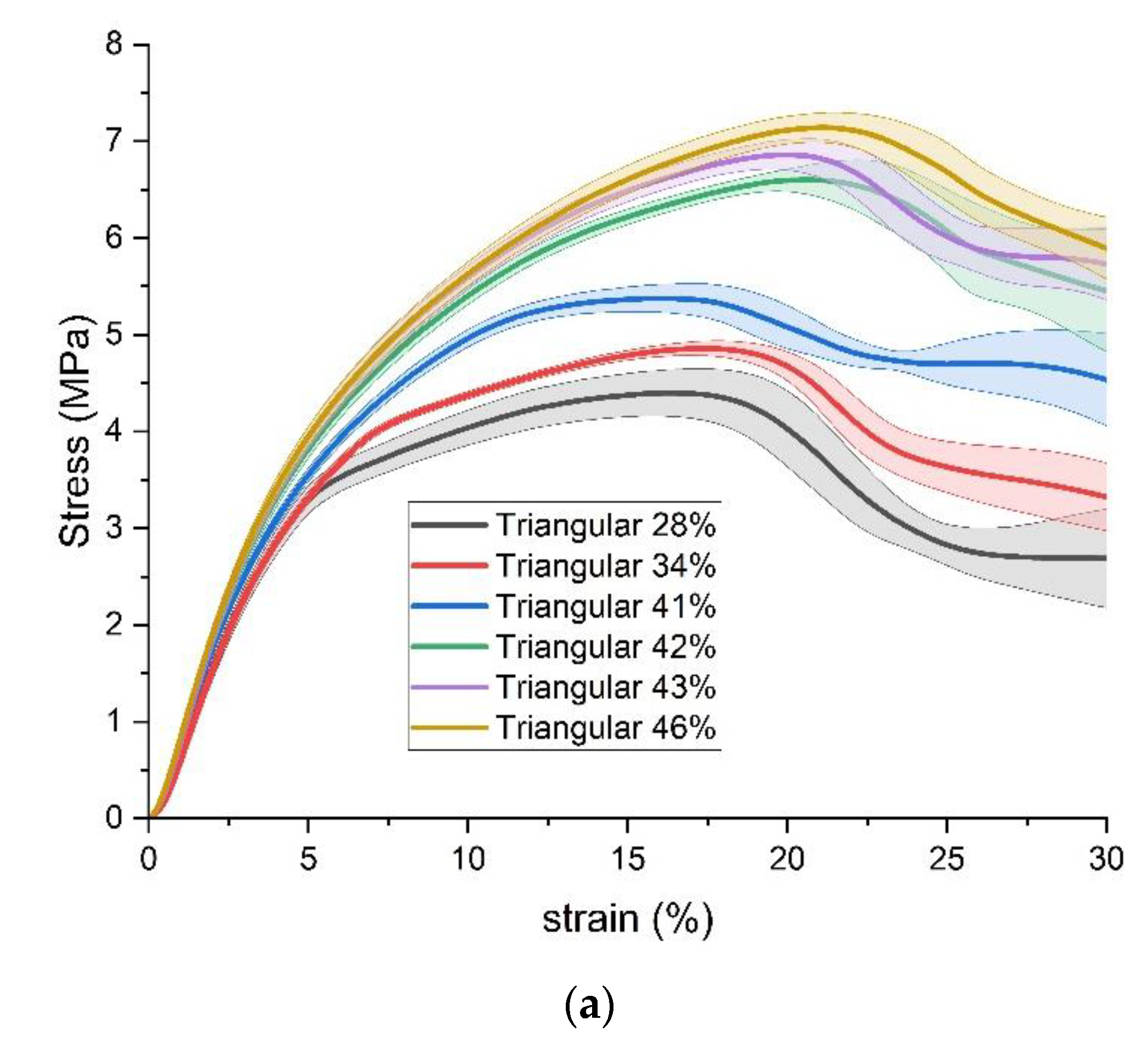

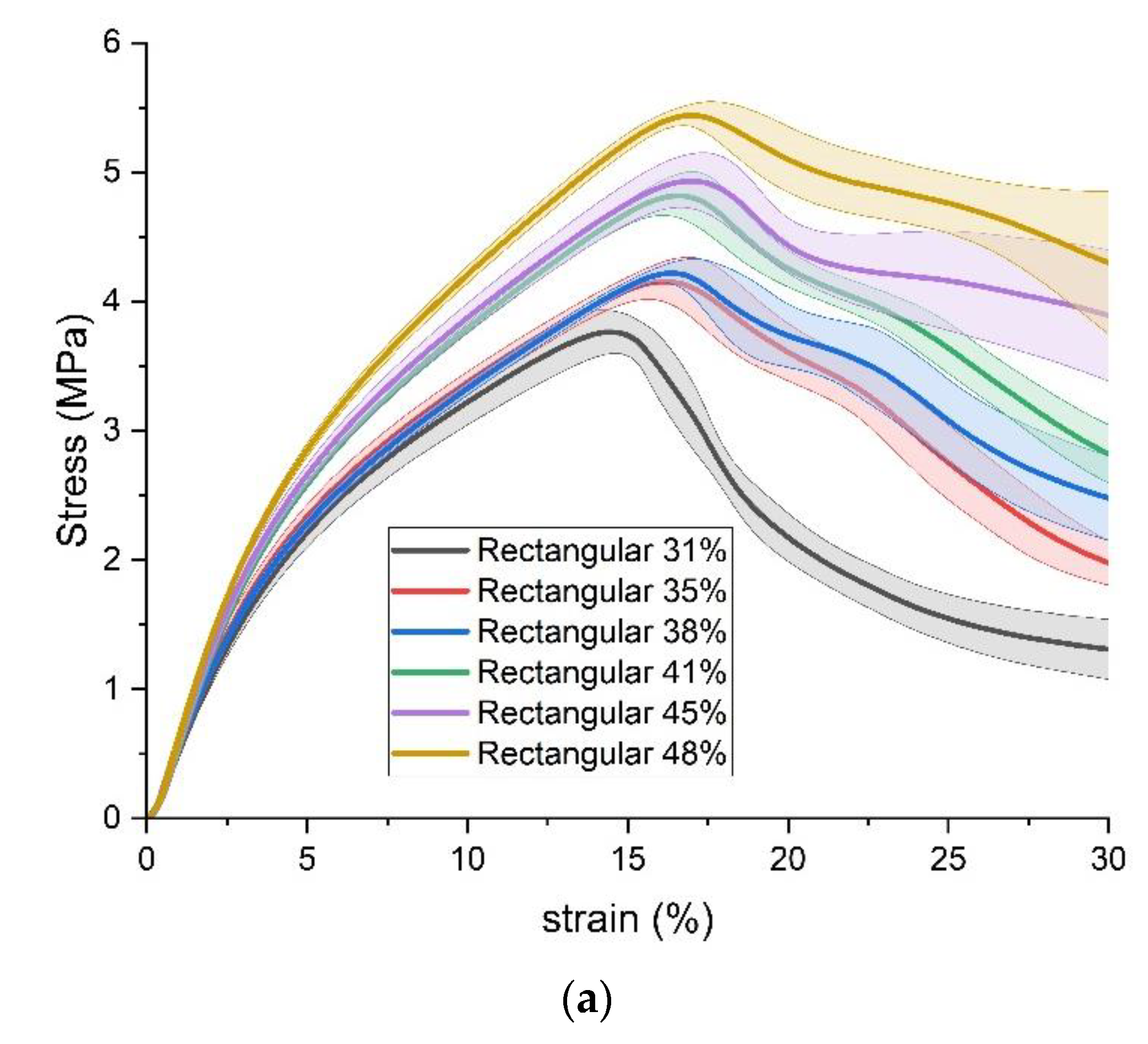

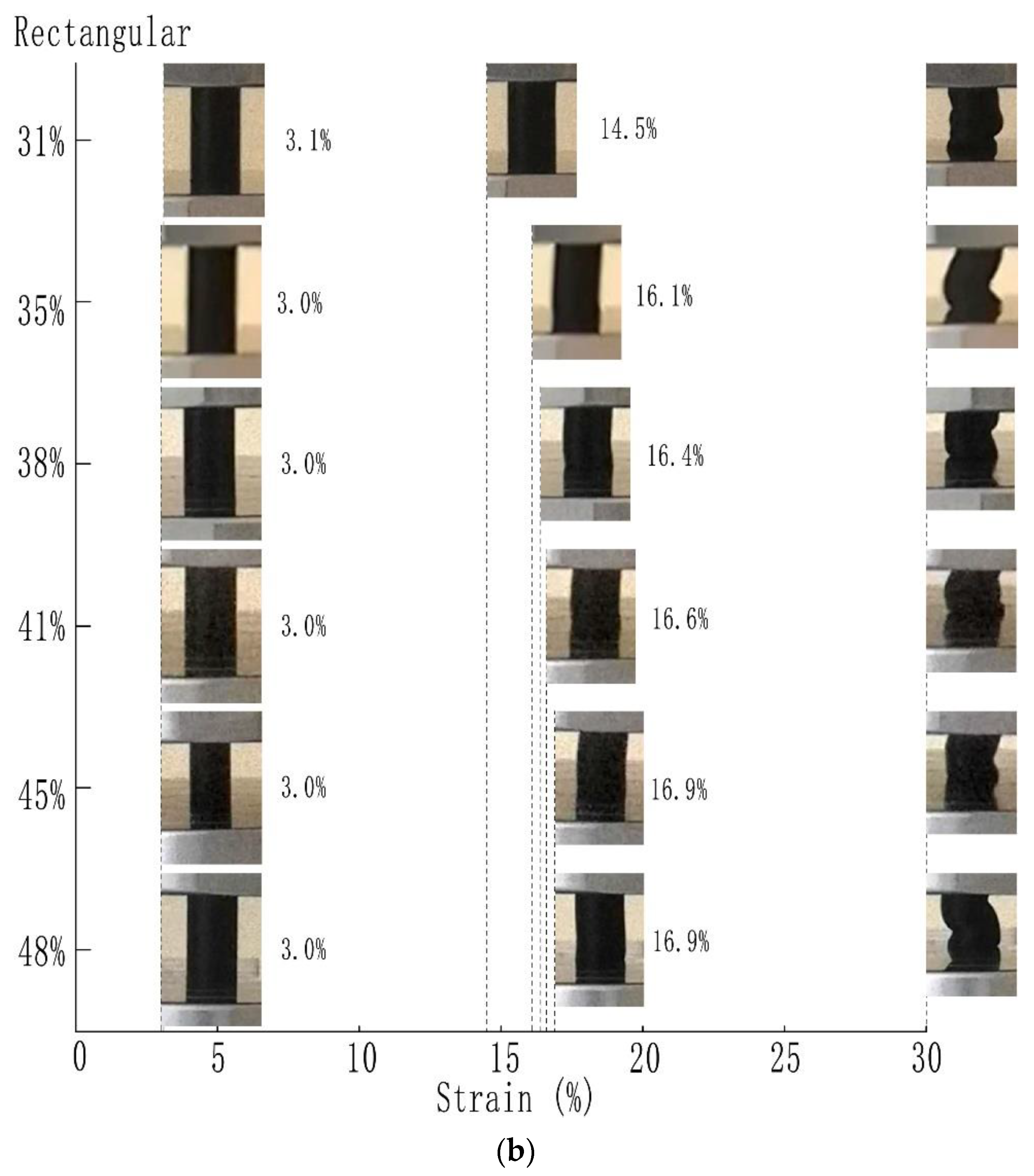

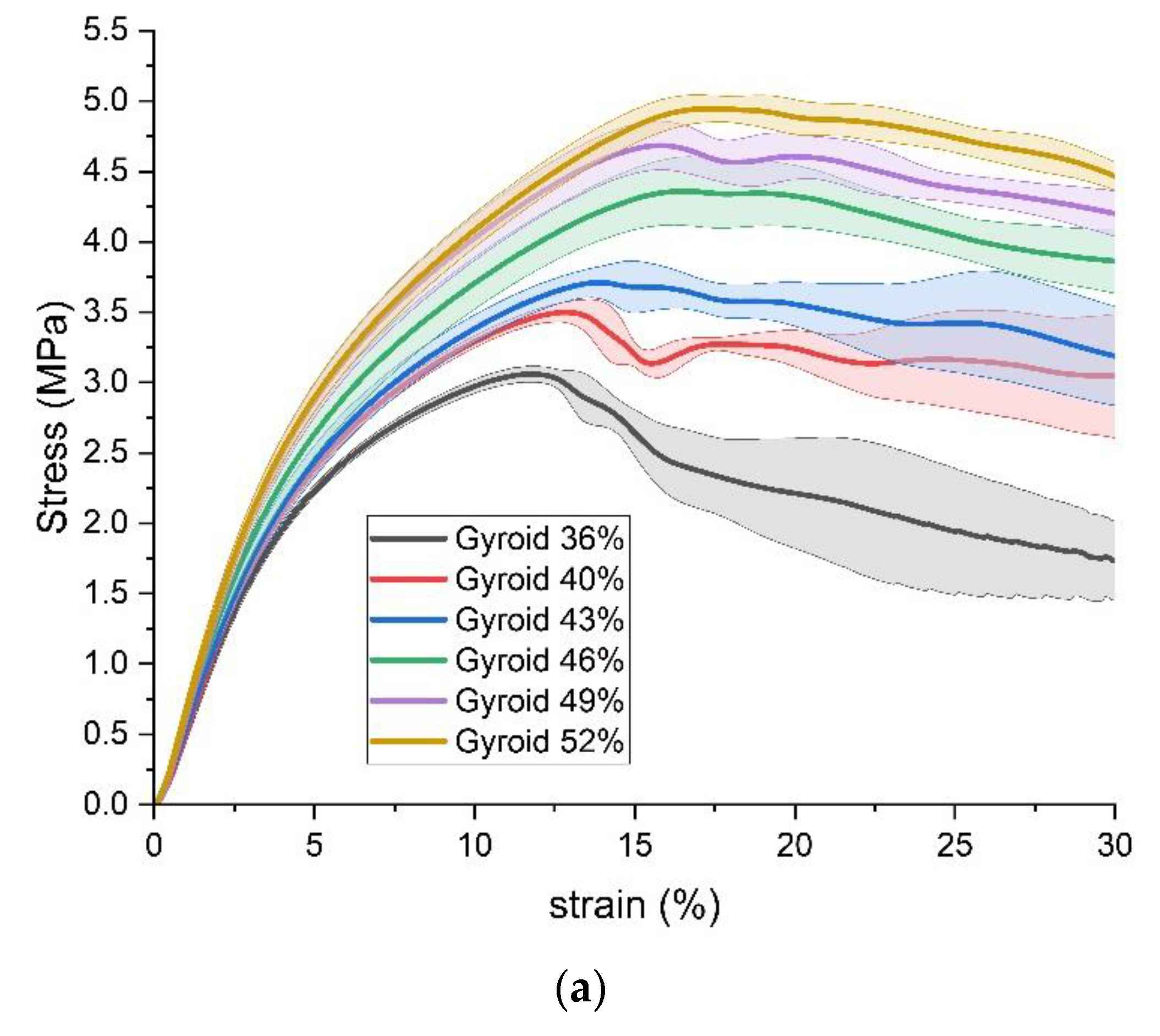

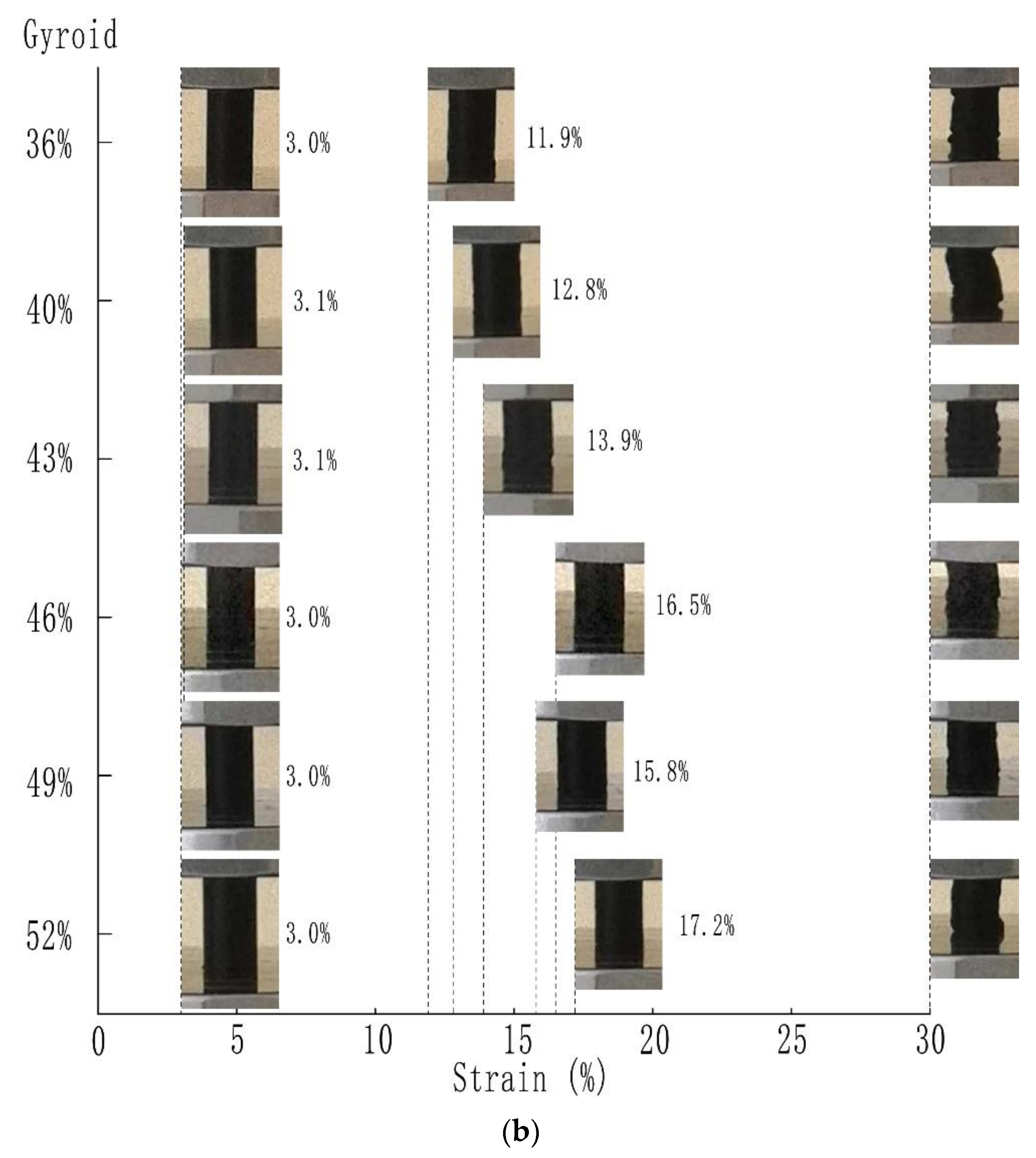

3.1. Results of Standard Specimens

3.2. Results of Samples of Practical Application

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Ul Haq, M.I. 3D Printing—A Review of Processes, Materials and Applications in Industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Salem Bala, A.; Bin Wahab, M.S.; Binti Ahmad, M. Elements and Materials Improve the FDM Products: A Review. Adv. Eng. Forum 2016, 16, 33–51. [Google Scholar] [CrossRef]

- Liu, J.; Abu Osman, N.A.; Al Kouzbary, M.; Al Kouzbary, H.; Abd Razak, N.A.; Shasmin, H.N.; Arifin, N. Classification and Comparison of Mechanical Design of Powered Ankle–Foot Prostheses for Transtibial Amputees Developed in the 21st Century: A Systematic Review. J. Med. Devices 2021, 15, 010801. [Google Scholar] [CrossRef]

- Palanisamy, C.; Raman, R.; Dhanraj, P.K. Additive Manufacturing: A Review on Mechanical Properties of Polyjet and FDM Printed Parts. Polym. Bull. 2022, 79, 7065–7116. [Google Scholar] [CrossRef]

- Sood, A.K.; Chaturvedi, V.; Datta, S.; Mahapatra, S.S. Optimization of Process Parameters in Fused Deposition Modeling Using Weighted Principal Component Analysis. J. Adv. Manuf. Syst. 2011, 10, 241–259. [Google Scholar] [CrossRef]

- Anitha, R.; Arunachalam, S.; Radhakrishnan, P. Critical Parameters Influencing the 1uality of Prototypes in Fused Deposition Modelling. J. Mater. Process. Technol. 2001, 118, 385–388. [Google Scholar] [CrossRef]

- Lužanin, O.; Movrin, D.; Plančak, M. Effect of Layer Thickness, Deposition Angle, and Infill on Maximum Flexural Force in FDM-Built Specimens. J. Technol. Plast. 2014, 39, 49–58. [Google Scholar]

- Raney, K.; Lani, E.; Kalla, D.K. Experimental Characterization of the Tensile Strength of ABS Parts Manufactured by Fused Deposition Modeling Process. Mater. Today Plast. 2017, 4, 7956–7961. [Google Scholar] [CrossRef]

- Rinaldi, M.; Ghidini, T.; Cecchini, F.; Brandao, A.; Nanni, F. Additive Layer Manufacturing of Poly (Ether Ether Ketone) via FDM. Compos. Part B Eng. 2018, 145, 162–172. [Google Scholar] [CrossRef]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical Property of FDM Printed ABS: Influence of Printing Parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Tanveer, M.Q.; Haleem, A.; Suhaib, M. Effect of Variable Infill Density on Mechanical Behaviour of 3-D Printed PLA Specimen: An Experimental Investigation. SN Appl. Sci. 2019, 1, 1701. [Google Scholar] [CrossRef] [Green Version]

- Camargo, J.C.; Machado, Á.R.; Almeida, E.C.; Silva, E.F.M.S. Mechanical Properties of PLA-Graphene Filament for FDM 3D Printing. Int. J. Adv. Manuf. Technol. 2019, 103, 2423–2443. [Google Scholar] [CrossRef]

- Moradi, M.; Meiabadi, S.; Kaplan, A. 3D Printed Parts with Honeycomb Internal Pattern by Fused Deposition Modelling; Experimental Characterization and Production Optimization. Met. Mater. Int. 2019, 25, 1312–1325. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Y.; Deng, Z.; Zhang, S.; Cai, J. Effects of Fused Deposition Modeling Process Parameters on Tensile, Dynamic Mechanical Properties of 3D Printed Polylactic Acid Materials. Polym. Test. 2020, 86, 106483. [Google Scholar] [CrossRef]

- Ramesh, M.; Panneerselvam, K. Mechanical Investigation and Optimization of Parameter Selection for Nylon Material Processed by FDM. Mater. Today Proc. 2021, 46, 9303–9307. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Parametric Appraisal of Mechanical Property of Fused Deposition Modelling Processed Parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef] [Green Version]

- Ćwikła, G.; Grabowik, C.; Kalinowski, K.; Paprocka, I.; Ociepka, P. The Influence of Printing Parameters on Selected Mechanical Properties of FDM/FFF 3D-Printed Parts. IOP Conf. Ser. Mater. Sci. Eng. 2017, 227, 012033. [Google Scholar] [CrossRef]

- Dudescu, C.; Racz, L. Effects of Raster Orientation, Infill Rate and Infill Pattern on the Mechanical Properties of 3D Printed Materials. Acta Univ. Cibiniensis. Tech. Ser. 2017, 69, 23–30. [Google Scholar] [CrossRef]

- De Toro, E.V.; Sobrino, J.C.; Martínez, A.M.; Eguía, V.M. Analysis of the Influence of the Variables of the Fused Deposition Modeling (FDM) Process on the Mechanical Properties of a Carbon Fiber-Reinforced Polyamide. Procedia Manuf. 2019, 41, 731–738. [Google Scholar] [CrossRef]

- Pandzic, A.; Hodzic, D.; Milovanovic, A. Effect of Infill Type and Density on Tensile Properties of PLA Material for FDM Process. Ann. DAAAM Proc. 2019, 30, 545. [Google Scholar]

- Srinivasan, R.; Pridhar, T.; Ramprasath, L.S.; Charan, N.S.; Ruban, W. Prediction of Tensile Strength in FDM Printed ABS Parts Using Response Surface Methodology (RSM). Mater. Today Proc. 2020, 27, 1827–1832. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Mohd Ariffin, M.K.A. The Effects of Combined Infill Patterns on Mechanical Properties in FDM Process. Polymers 2020, 12, 2792. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A.H. Effect of Filling Pattern on the Tensile and Flexural Mechanical Properties of FDM 3D Printed Products. Exp. Mech. 2019, 59, 883–897. [Google Scholar] [CrossRef]

- Dave, H.K.; Patadiya, N.H.; Prajapati, A.R.; Rajpurohit, S.R. Effect of Infill Pattern and Infill Density at Varying Part Orientation on Tensile Properties of Fused Deposition Modeling-Printed Poly-Lactic Acid Part. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 1811–1827. [Google Scholar] [CrossRef]

- Lalegani Dezaki, M.; Ariffin, M.K.A.M.; Serjouei, A.; Zolfagharian, A.; Hatami, S.; Bodaghi, M. Influence of Infill Patterns Generated by CAD and FDM 3D Printer on Surface Roughness and Tensile Strength Properties. Appl. Sci. 2021, 11, 7272. [Google Scholar] [CrossRef]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic Material Properties of Fused Deposition Modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Baich, L.; Manogharan, G. Study of Infill Print Parameters on Mechanical Strength and Production Cost-Time of 3D Printed ABS Parts. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF, Austin, TX, USA, 25–27 July 2015; pp. 209–218. [Google Scholar]

- Dave, H.K.; Rajpurohit, S.R.; Patadiya, N.H.; Dave, S.J.; Sharma, K.S.; Thambad, S.S.; Srinivasn, A.P.; Sheth, K.V. Compressive Strength of PLA Based Scaffolds: Effect of Layer Height, Infill Density and Print Speed. Int. J. Mod. Manuf. Technol. 2019, 6, 21–27. [Google Scholar]

- Abbas, T.; Othman, F.M.; Ali, H.B. Effect of Infill Parameter on Compression Property in FDM Process. Int. J. Eng. Res. Appl. 2017, 7, 16–19. [Google Scholar]

- Chicos, L.-A.; Pop, M.A.; Zaharia, S.-M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.-M. Fused Filament Fabrication of Short Glass Fiber-Reinforced Polylactic Acid Composites: Infill Density Influence on Mechanical and Thermal Properties. Polymers 2022, 14, 4988. [Google Scholar] [CrossRef] [PubMed]

- Subeshan, B.; Alonayni, A.; Rahman, M.M.; Asmatulu, E. Investigating Compression Strengths of 3D Printed Polymeric Infill Specimens of Various Geometries. In Proceedings of the SPIE 10597, Nano-, Bio-, Info-Tech Sensors, and 3D Systems II, Denver, CO, USA, 23 March 2018; p. 105970N. [Google Scholar]

- Liu, J.; Abu Osman, N.A.; Al Kouzbary, M.; Al Kouzbary, H.; Razak, N.A.A.; Shasmin, H.N.; Arifin, N. A Conceptual Design and Control of a Novel Powered Ankle–Foot Prosthesis (RoMicP™) for Heavy Amputees. In Proceedings of the 6th Kuala Lumpur International Conference on Biomedical Engineering 2021, Cham, Switzerland, 25–27 July 2021; pp. 259–267. [Google Scholar]

- Snyder, R.M. An Overview of the Past, Present, and Future of 3D Printing Technology with an Emphasis on the Present. In Proceedings of the Association Supporting Computer Users in EducatioN (ASCUE), Myrtle Beach, SC, USA, 8–12 July 2014. [Google Scholar]

- Guo, C.; Zhang, M.; Bhandari, B. Model Building and Slicing in Food 3D Printing Processes: A Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1052–1069. [Google Scholar] [CrossRef] [PubMed]

- Papon, E.A.; Haque, A. Tensile Properties, Void Contents, Dispersion and Fracture Behaviour of 3D Printed Carbon Nanofiber Reinforced Composites. J. Reinf. Plast. Compos. 2018, 37, 381–395. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A.; Mulani, S.B. Process Optimization and Stochastic Modeling of Void Contents and Mechanical Properties in Additively Manufactured Composites. Compos. Part B Eng. 2019, 177, 107325. [Google Scholar] [CrossRef]

| Reference | Parameters | Materials | Mechanical Properties |

|---|---|---|---|

| [9] | infill density; layer thickness; raster angle | PLA | flexure strength |

| [10] | infill density; build orientation | ABS | tensile strength |

| [11] | infill density; build orientation | PEEK | tensile strength |

| [12] | infill density; layer thickness; raster angle | ABS | tensile strength |

| [13] | infill density | PLA | tensile strength, impact strength |

| [14] | infill density; layer thickness | PLA-graphene | tensile strength; impact strength; flexural strength |

| [15] | infill density; layer thickness; extruder temperature | PLA | tensile strength |

| [16] | infill density; layer thickness; build orientation; extruder temperature | PLA | tensile strength |

| [17] | infill density; layer thickness; print speed | Nylon | tensile strength; impact strength; flexural strength |

| Reference | Parameters | Materials | Mechanical Properties |

|---|---|---|---|

| [20] | infill density; infill pattern; perimeters; shell thickness; extrusion multiplier | ABS | tensile strength |

| [21] | infill density; infill pattern; raster angle | ABS | tensile strength |

| [22] | infill density; infill pattern; layer thickness; nozzle diameter | Carbon Fiber-reinforced Nylon | tensile strength; impact strength; flexural strength; hardness |

| [23] | infill density; infill pattern | PLA | tensile strength |

| [24] | infill density; infill pattern; layer thickness | ABS | tensile strength |

| [25] | infill density; infill pattern; build orientation | PLA | tensile strength |

| [26] | infill density; infill pattern | PLA | tensile strength; flexural strength; |

| [27] | infill density; infill pattern; build orientation | PLA | tensile strength |

| [28] | infill density; infill pattern | PLA | tensile strength |

| Mass (g) | Weight Percentage (%) | Infill Patterns | ||

|---|---|---|---|---|

| Triangular | Rectangular | Gyroid | ||

| 1.6 | 45.71% | 28% | 31% | 36% |

| 1.7 | 48.57% | 34% | 35% | 40% |

| 1.8 | 51.43% | 41% | 38% | 43% |

| 1.9 | 54.29% | 42% | 41% | 46% |

| 2.0 | 57.14% | 43% | 45% | 49% |

| 2.1 | 60.00% | 46% | 48% | 52% |

| 3.5 | 100.00% | Solid | ||

| Infill Patterns and Densities | Weight Percentage | 0.5% Strain | 1.0% Strain | 1.5% Strain | 2.0% Strain | 2.5% Strain |

|---|---|---|---|---|---|---|

| Solid | 100% (3.5 g) | 100% (0.39 MPa) | 100% (1.22 MPa) | 100% (2.14 MPa) | 100% (3.02 MPa) | 100% (3.82 MPa) |

| Triangular 28% | 45.71% | 52.27% | 51.48% | 51.46% | 51.06% | 50.74% |

| Rectangular 31% | 53.27% | 41.91% | 37.80% | 35.75% | 34.61% | |

| Gyroid 36% | 50.39% | 42.05% | 38.70% | 37.06% | 36.04% | |

| Triangular 34% | 48.57% | 49.28% | 50.69% | 50.94% | 50.91% | 50.76% |

| Rectangular 35% | 50.55% | 43.63% | 40.20% | 38.36% | 37.22% | |

| Gyroid 40% | 46.74% | 41.50% | 39.29% | 38.25% | 37.62% | |

| Triangular 41% | 51.43% | 78.73% | 65.64% | 60.43% | 57.97% | 56.46% |

| Rectangular 38% | 54.76% | 44.07% | 39.80% | 37.63% | 36.36% | |

| Gyroid 43% | 52.41% | 44.98% | 41.65% | 39.87% | 38.80% | |

| Triangular 42% | 54.29% | 79.34% | 67.36% | 63.13% | 61.14% | 59.92% |

| Rectangular 41% | 48.79% | 45.62% | 43.08% | 41.55% | 40.56% | |

| Gyroid 46% | 66.85% | 51.62% | 46.26% | 43.70% | 42.21% | |

| Triangular 43% | 57.14% | 73.87% | 66.88% | 63.78% | 62.22% | 61.23% |

| Rectangular 45% | 55.28% | 48.99% | 45.45% | 43.42% | 42.18% | |

| Gyroid 49% | 54.11% | 50.93% | 48.21% | 46.69% | 45.61% | |

| Triangular 46% | 60.00% | 79.74% | 70.13% | 65.63% | 63.37% | 62.02% |

| Rectangular 48% | 54.87% | 51.20% | 47.91% | 45.98% | 44.78% | |

| Gyroid 52% | 66.47% | 55.12% | 50.26% | 47.76% | 46.28% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Naeem, M.A.; Al Kouzbary, M.; Al Kouzbary, H.; Shasmin, H.N.; Arifin, N.; Abd Razak, N.A.; Abu Osman, N.A. Effect of Infill Parameters on the Compressive Strength of 3D-Printed Nylon-Based Material. Polymers 2023, 15, 255. https://doi.org/10.3390/polym15020255

Liu J, Naeem MA, Al Kouzbary M, Al Kouzbary H, Shasmin HN, Arifin N, Abd Razak NA, Abu Osman NA. Effect of Infill Parameters on the Compressive Strength of 3D-Printed Nylon-Based Material. Polymers. 2023; 15(2):255. https://doi.org/10.3390/polym15020255

Chicago/Turabian StyleLiu, Jingjing, Muhammad Awais Naeem, Mouaz Al Kouzbary, Hamza Al Kouzbary, Hanie Nadia Shasmin, Nooranida Arifin, Nasrul Anuar Abd Razak, and Noor Azuan Abu Osman. 2023. "Effect of Infill Parameters on the Compressive Strength of 3D-Printed Nylon-Based Material" Polymers 15, no. 2: 255. https://doi.org/10.3390/polym15020255

APA StyleLiu, J., Naeem, M. A., Al Kouzbary, M., Al Kouzbary, H., Shasmin, H. N., Arifin, N., Abd Razak, N. A., & Abu Osman, N. A. (2023). Effect of Infill Parameters on the Compressive Strength of 3D-Printed Nylon-Based Material. Polymers, 15(2), 255. https://doi.org/10.3390/polym15020255