Study on Anti-Aging Performance Enhancement of Polymer Modified Asphalt with High Linear SBS Content

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiment Materials

2.2. Binder Test Descriptions

2.2.1. Dynamic Shear Rheological Test

2.2.2. Fluorescence Microscopy Image Acquisition

2.2.3. Infrared Spectroscopy Test

3. Results

3.1. Effects of Aging on Rheological Properties of Different High Content SBS Polymer Composite Modified Asphalts

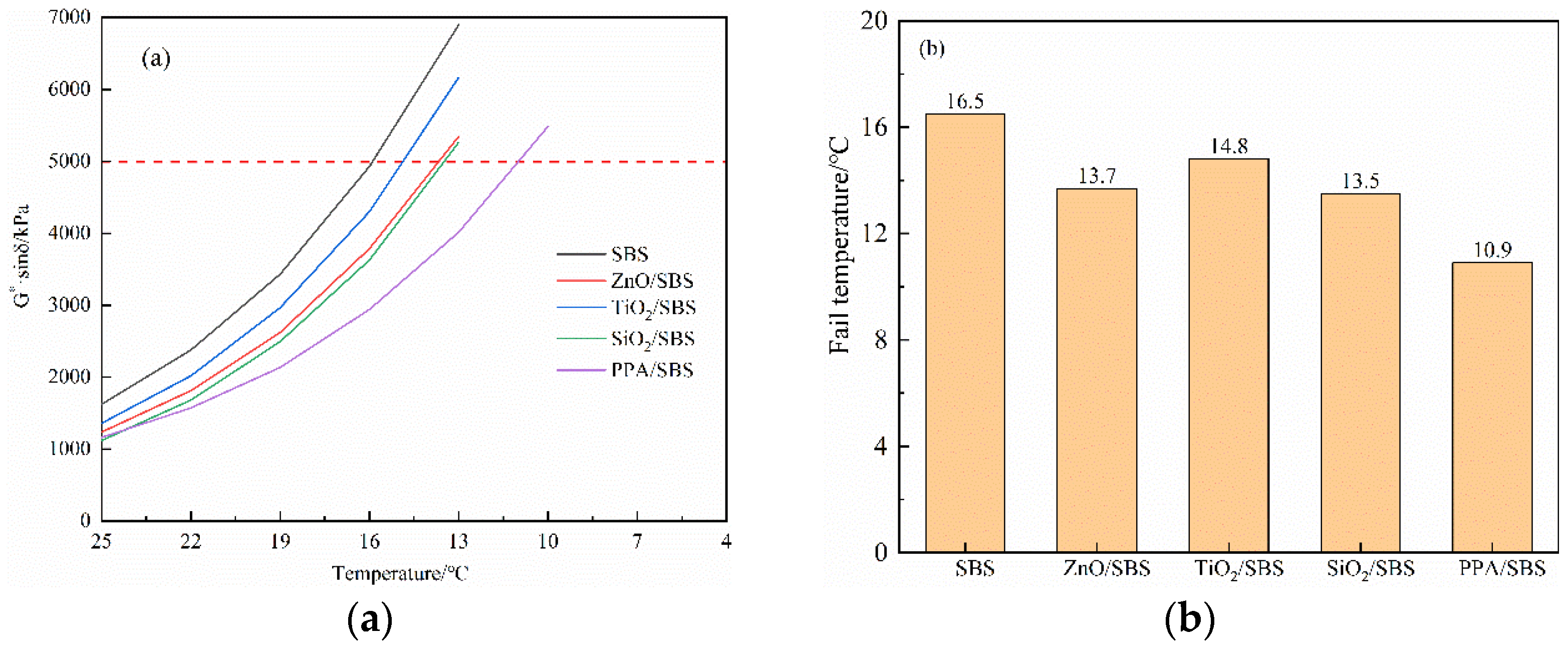

3.1.1. Rheological Analysis

3.1.2. Analysis of MSCR Test Results

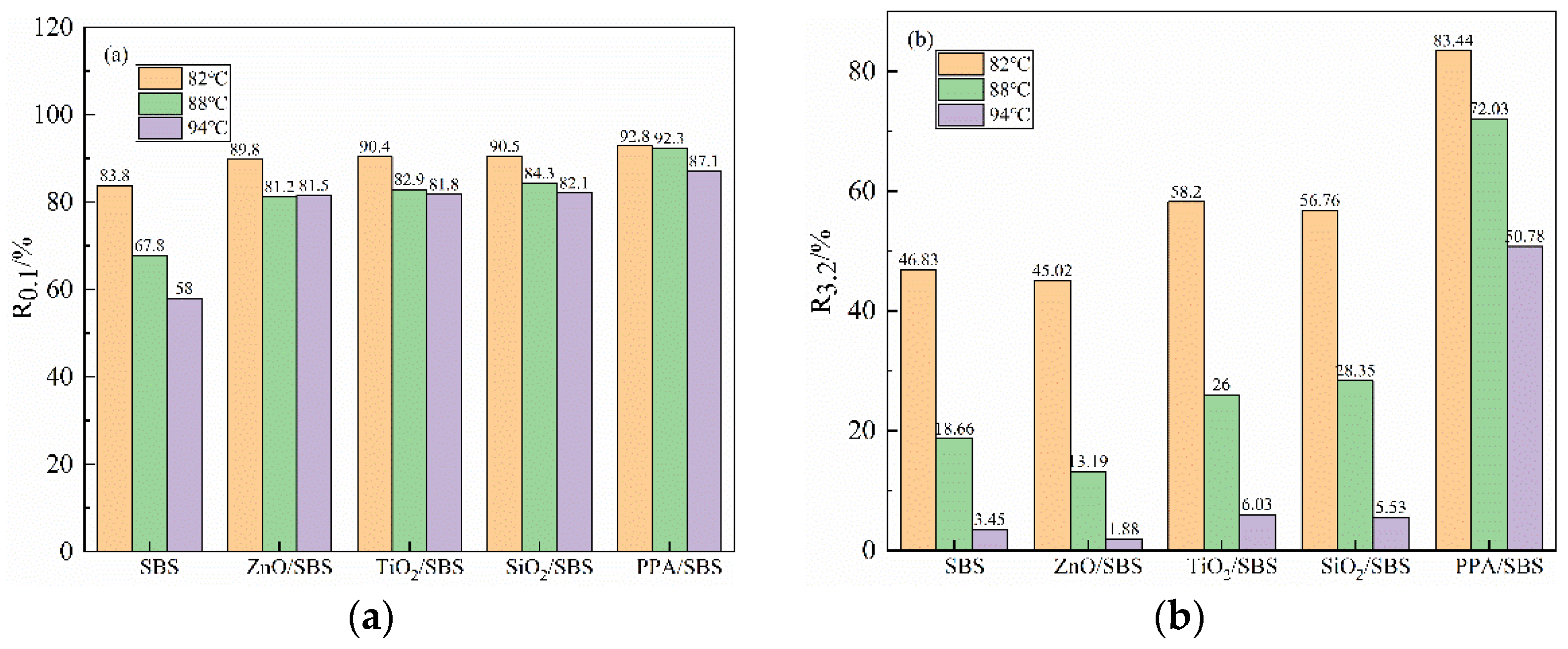

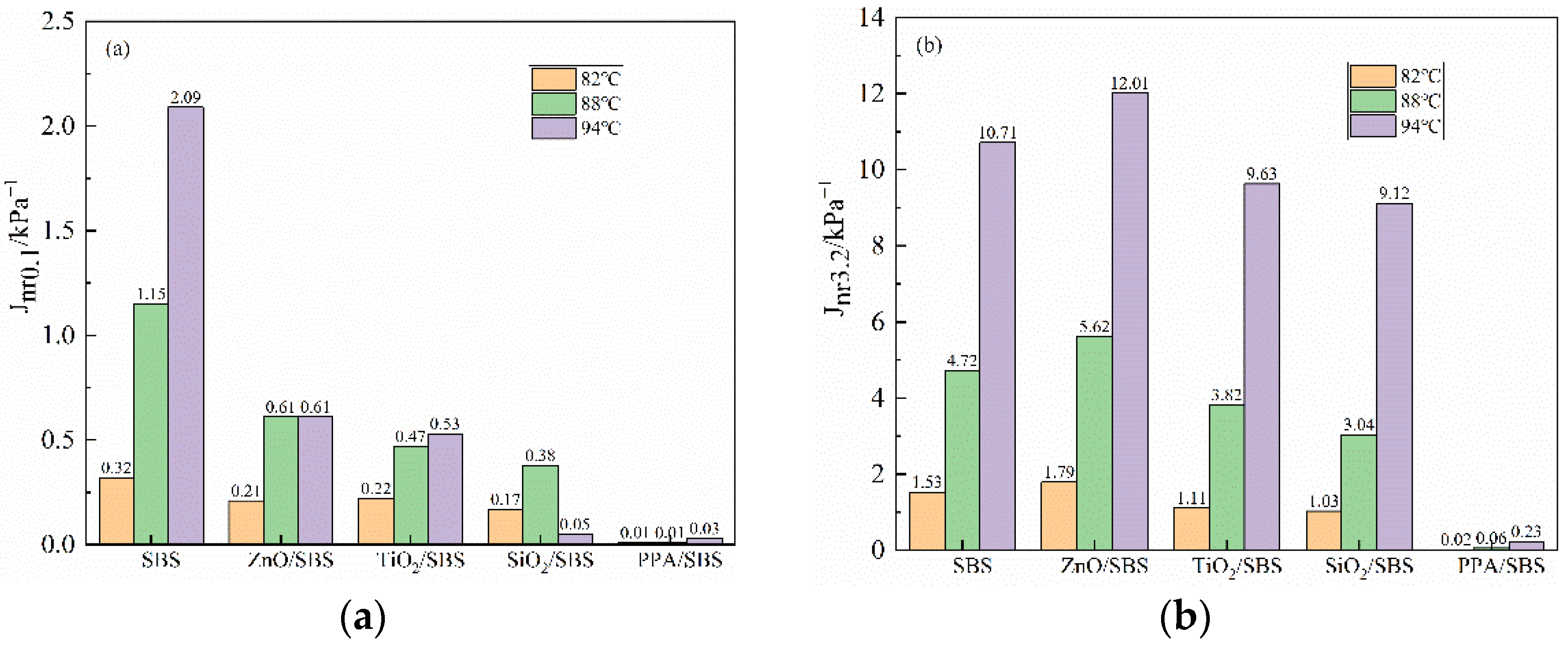

- (1)

- R Analysis of deformation recovery

- (2)

- Jnr Analysis of Non-recoverable Compliance

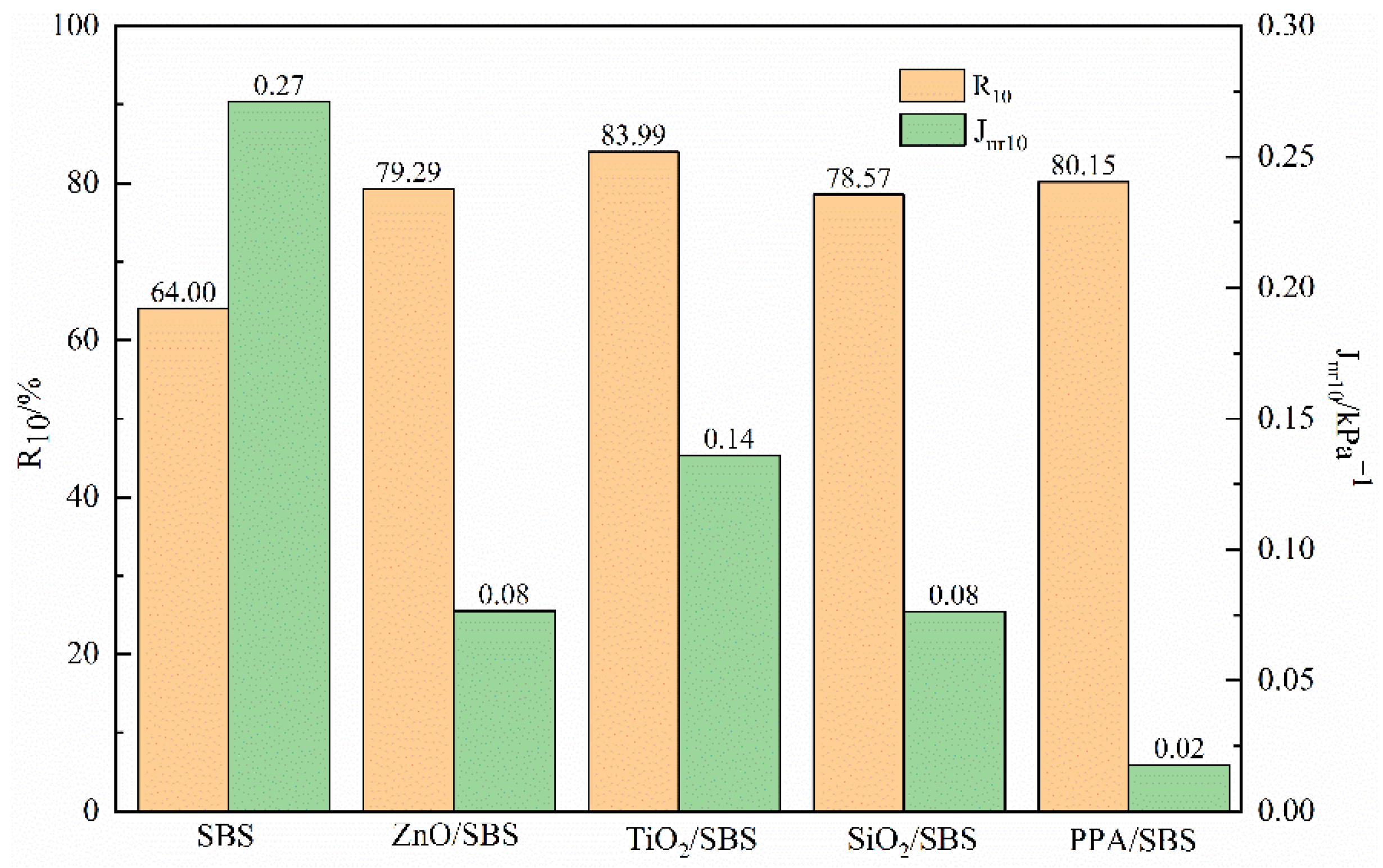

3.2. Effects of PAV Aging on Medium Temperature Fatigue Properties of Different High Content SBS Polymer Composite Modified Asphalts

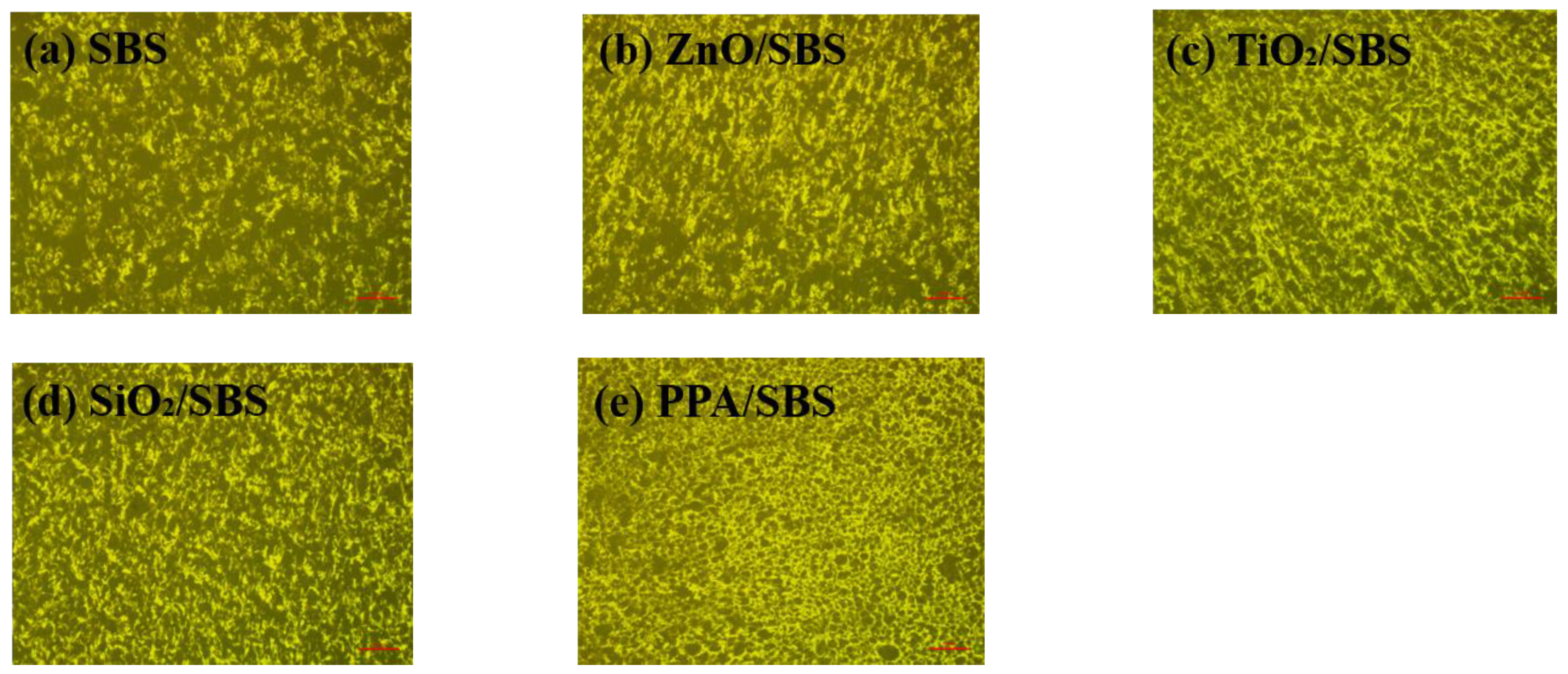

3.3. Micromorphological Analysis of Different Polymer Modified Asphalts with a High Content of Linear SBS

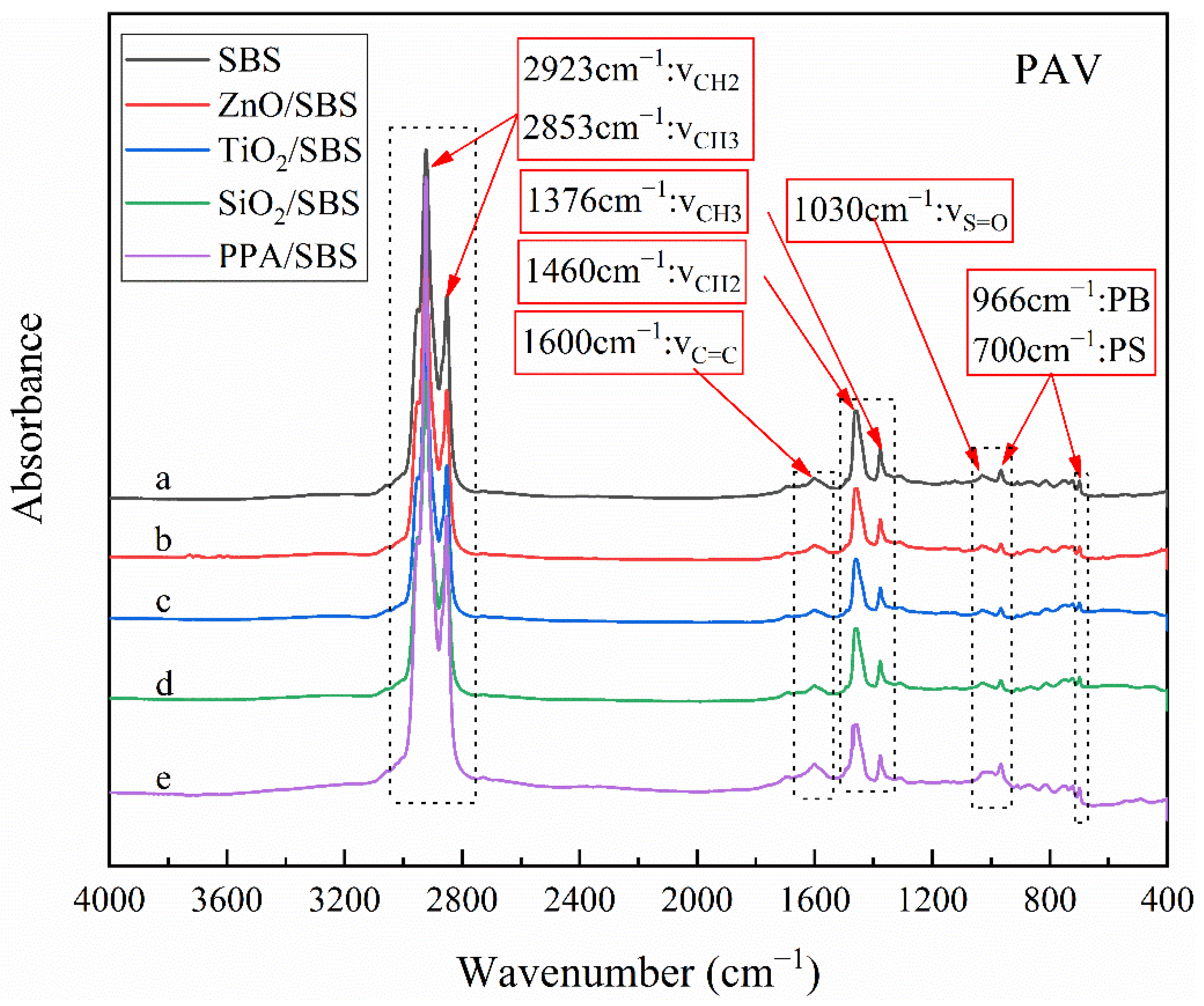

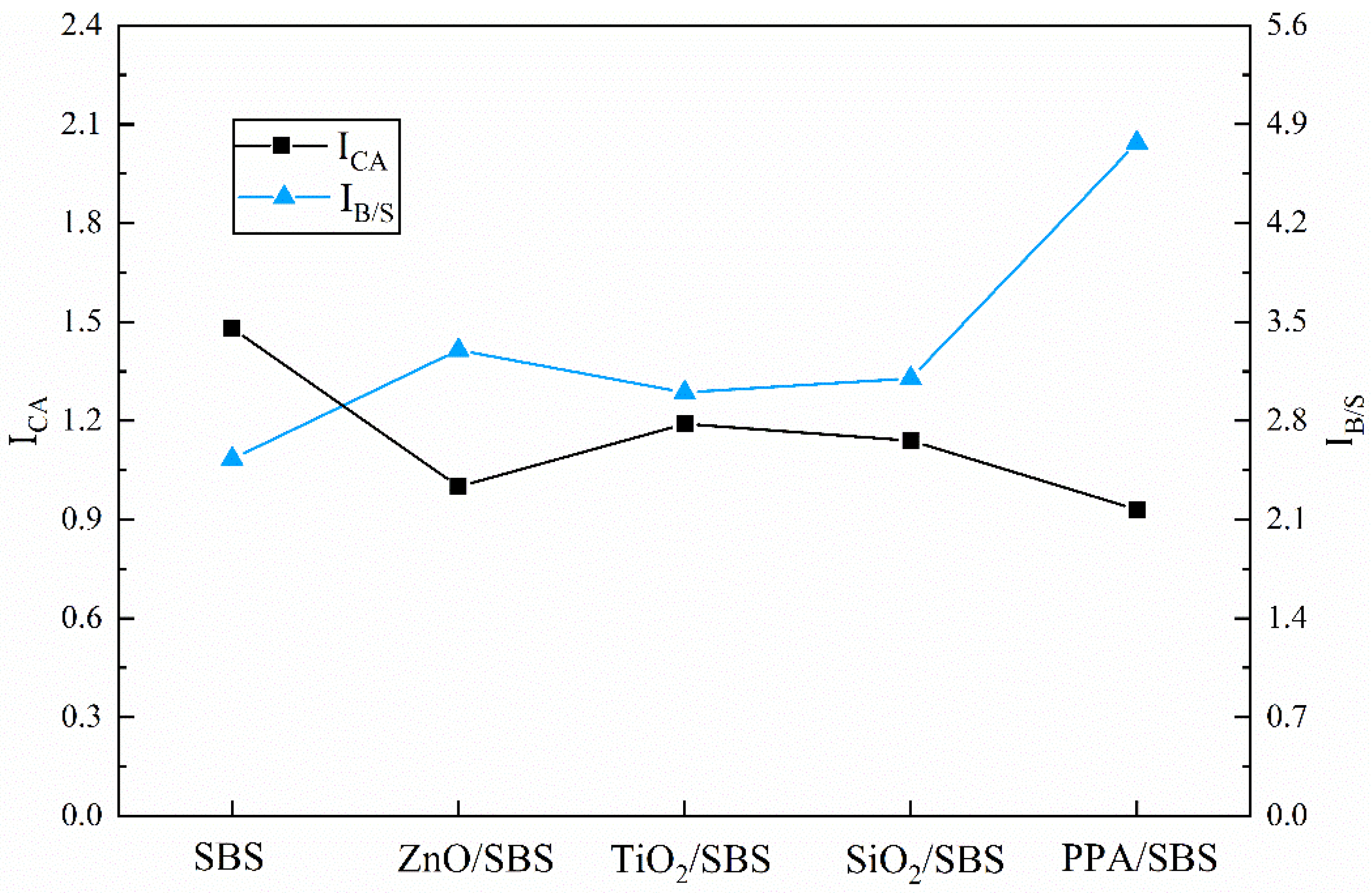

3.4. Analysis of Infrared Spectroscopy of Different High Content SBS Polymer Composite Modified Asphalts

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, L.; Wu, C.; Cheng, Y.; Ai, Y.; Li, H.; Tan, X. Comparative analysis of viscoelastic properties of open graded friction course under dynamic and static loads. Polymers 2021, 13, 1250. [Google Scholar] [CrossRef] [PubMed]

- Yuan, D.; Xing, C.; Jiang, W.; Xiao, J.; Wu, W.; Li, P.; Li, Y. Viscoelastic behavior and phase structure of high-content SBS-modified asphalt. Polymers 2022, 14, 2476. [Google Scholar] [CrossRef]

- Cuciniello, G.; Leandri, P.; Filippi, S.; Lo Presti, D.; Losa, M.; Airey, G. Effect of ageing on the morphology and creep and recovery of polymer-modified bitumens. Mater. Struct. 2018, 51, 136. [Google Scholar] [CrossRef] [Green Version]

- Cortizo, M.S.; Larsen, D.O.; Bianchetto, H.; Alessandrini, J.L. Effect of the thermal degradation of SBS copolymers during the ageing of modified asphalts. Polym. Degrad. Stabil. 2004, 86, 275–282. [Google Scholar] [CrossRef]

- Alsolieman, H.A.; Babalghaith, A.M.; Memon, Z.A.; Al-Suhaibani, A.S.; Milad, A. Evaluation and comparison of mechanical properties of polymer-modified asphalt mixtures. Polymers 2021, 13, 2282. [Google Scholar] [CrossRef]

- Abdalrhman, M.; Ahmed, S.B.A.; Nur, I.M.Y. A review of the utilisation of recycled waste material as an alternative modifier in asphalt mixtures. Civ. Eng. J. 2020, 6, 42–60. [Google Scholar] [CrossRef]

- Xiao, R.; Huang, B.S. Moisture damage mechanism and thermodynamic properties of hot-mix asphalt under aging conditions. ACS Sustain. Chem. Eng. 2022, 10, 14865–14887. [Google Scholar] [CrossRef]

- Zhang, Y. Extending the Lifespan of Porous Asphalt Concrete. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Apeagyei, A.K. Laboratory evaluation of antioxidants for asphalt binders. Constr. Build. Mater. 2011, 25, 47–53. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Jin, L.; He, S.; Zhao, Y.F.; Evans, G.D.; Duan, X. A structured catalyst based on cobalt phthalocyanine/calcined Mg-Al hydrotalcite film for the oxidation of mercaptan. Green Chem. 2012, 14, 1909–1916. [Google Scholar] [CrossRef]

- Yamaguchi, K.; Sasaki, I.; Meiarashi, S. Mechanism of asphalt binder aging by ultraviolet irradiation and aging resistance by adding carbon black. J. Jpn. Pet. Inst. 2004, 47, 266–273. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.H.; Zhang, H.L.; Li, S. The effect of surface modified nano-titania on the ultraviolet aging properties of bitumen. Pet. Sci. Technol. 2014, 32, 2995–3001. [Google Scholar] [CrossRef]

- Zhang, H.B.; Zhang, H.L.; Ke, N.X. The effect of different nanomaterials on the long-term aging properties of bitumen. Pet. Sci. Technol. 2015, 33, 388–396. [Google Scholar] [CrossRef]

- Ellie, H.F.; Pouria, H.; Mohammad, R. Physiochemical, rheological, and oxidative aging characteristics of asphalt binder in the presence of mesoporous silica nanoparticles. J. Mater. Civil. Eng. 2017, 28, 04015133. [Google Scholar]

- Zhang, H.L.; Su, M.M.; Zhao, S.F.; Zhang, Y.P.; Zhang, Z.P. High and low temperature properties of nano-particles/polymer modified asphalt. Constr. Build. Mater. 2016, 114, 323–332. [Google Scholar] [CrossRef]

- Guo, Q.; Xue, Y.B.; Ma, J.S.; Liu, Z.M. Research progress of nano-material/SBS composite modified asphalt. Contemp. Chem. Ind. 2022, 51, 2709–2712. [Google Scholar]

- Ramayya, V.V.; Ram, V.V.; Krishnaiah, S.; Sandra, A.K. Performance of VG30 paving grade bitumen modified with polyphosphoric acid at medium and high temperature regimes. Constr. Build. Mater. 2016, 105, 157–164. [Google Scholar] [CrossRef]

- Feng, Z.; Yu, J. A study on the aging kinetics of PPA modified asphalt. Liq. Fuels Technol. 2010, 28, 1338–1344. [Google Scholar] [CrossRef]

- Xiao, F.; Serji, A.; Hainian, W.; Hao, P. Rheological property investigations for polymer and polyphosphoric acid modified asphalt binders at high temperatures. Constr. Build. Mater. 2014, 64, 316–323. [Google Scholar] [CrossRef]

- Naresh, B.; Ramasamy, B.S. Effect of Polyphosphoric Acid on Aging Characteristics of PG 64-22 Asphalt Binder. Master’s Thesis, University of North Texas, Denton, TX, USA, 2010. [Google Scholar]

- Masson, J.F.; Collins, P.; Woods, J.R.; Bundalo, S.; Margeson, J. Chemistry and effects of polyphosphoric acid on the microstructure, molecular mass, glass transition temperatures and performance grades of asphalts. J. Assoc. Asph. Pav. Technol. 2009, 78, 403–430. [Google Scholar]

- Liu, S.; Zhou, S.; Peng, A. Evaluation of polyphosphoric acid on the performance of polymer modified asphalt binders. J. Appl. Polym. Sci. 2020, 137, 34. [Google Scholar] [CrossRef]

- Yan, C.Q.; Huang, W.D.; Xiao, F.P.; Wang, L.F.; Li, Y.W. Proposing a new infrared index quantifying the aging extent of SBS-modified asphalt. Road Mater. Pavement 2018, 19, 1406–1421. [Google Scholar] [CrossRef]

- Yan, C.Q.; Huang, W.D.; Tang, N.P. Evaluation of the temperature effect on rolling thin film oven aging for polymer modified asphalt. Constr. Build. Mater. 2017, 137, 485–493. [Google Scholar] [CrossRef]

- Xing, C.; Liu, L.; Cui, Y.; Ding, D. Analysis of base bitumen chemical composition and aging behaviors via atomic force microscopy-based infrared spectroscopy. Fuel 2020, 264, 116845. [Google Scholar] [CrossRef]

- Xing, C.W.; Jiang, W.; Li, M.C.; Wang, M.; Xiao, J.J.; Xu, Z.C. Application of atomic force microscopy in bitumen materials at the nanoscale: A review. Constr. Build. Mater. 2022, 342, 128059. [Google Scholar] [CrossRef]

| Samples | δ/° | G*/Kpa | G*/Sin δ/Kpa | Failure Temperature/°C |

|---|---|---|---|---|

| SBS | 63.10 | 2.74 | 3.07 | 86.1 |

| ZnO/SBS | 64.31 | 2.39 | 2.65 | 84.4 |

| TiO2/SBS | 56.80 | 2.32 | 2.78 | 85.6 |

| SiO2/SBS | 57.20 | 2.41 | 2.87 | 85.9 |

| PPA/SBS | 40.20 | 16.05 | 24.86 | 125.7 |

| Samples | Rdiff (%) | ||

|---|---|---|---|

| 82 °C | 88 °C | 94 °C | |

| SBS | 44.1 | 72.49 | 94.04 |

| ZnO/SBS | 49.87 | 83.76 | 97.70 |

| TiO2/SBS | 35.70 | 68.60 | 92.62 |

| SiO2/SBS | 37.31 | 66.37 | 90.30 |

| PPA/SBS | 10.10 | 21.93 | 41.73 |

| Samples | A | B | α | 2.5%Nf | 5%Nf | 10%Nf |

|---|---|---|---|---|---|---|

| SBS | 8.341 × 106 | 3.648 | 1.824 | 294,850 | 23,522 | 1877 |

| ZnO/SBS | 2.524 × 107 | 3.775 | 1.888 | 793,882 | 57,976 | 4234 |

| TiO2/SBS | 9.978 × 106 | 3.588 | 1.794 | 372,679 | 30,997 | 2578 |

| SiO2/SBS | 1.385 × 107 | 3.483 | 1.741 | 569,319 | 50,919 | 4554 |

| PPA/SBS | 1.252 × 1010 | 5.423 | 2.712 | 87,004,865 | 2,027,422 | 47,244 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Hu, G.; Zhang, J. Study on Anti-Aging Performance Enhancement of Polymer Modified Asphalt with High Linear SBS Content. Polymers 2023, 15, 256. https://doi.org/10.3390/polym15020256

Han D, Hu G, Zhang J. Study on Anti-Aging Performance Enhancement of Polymer Modified Asphalt with High Linear SBS Content. Polymers. 2023; 15(2):256. https://doi.org/10.3390/polym15020256

Chicago/Turabian StyleHan, Daqian, Guosheng Hu, and Jingting Zhang. 2023. "Study on Anti-Aging Performance Enhancement of Polymer Modified Asphalt with High Linear SBS Content" Polymers 15, no. 2: 256. https://doi.org/10.3390/polym15020256