Interfacial Engineering Methods in Thermoplastic Composites: An Overview

Abstract

:1. Introduction

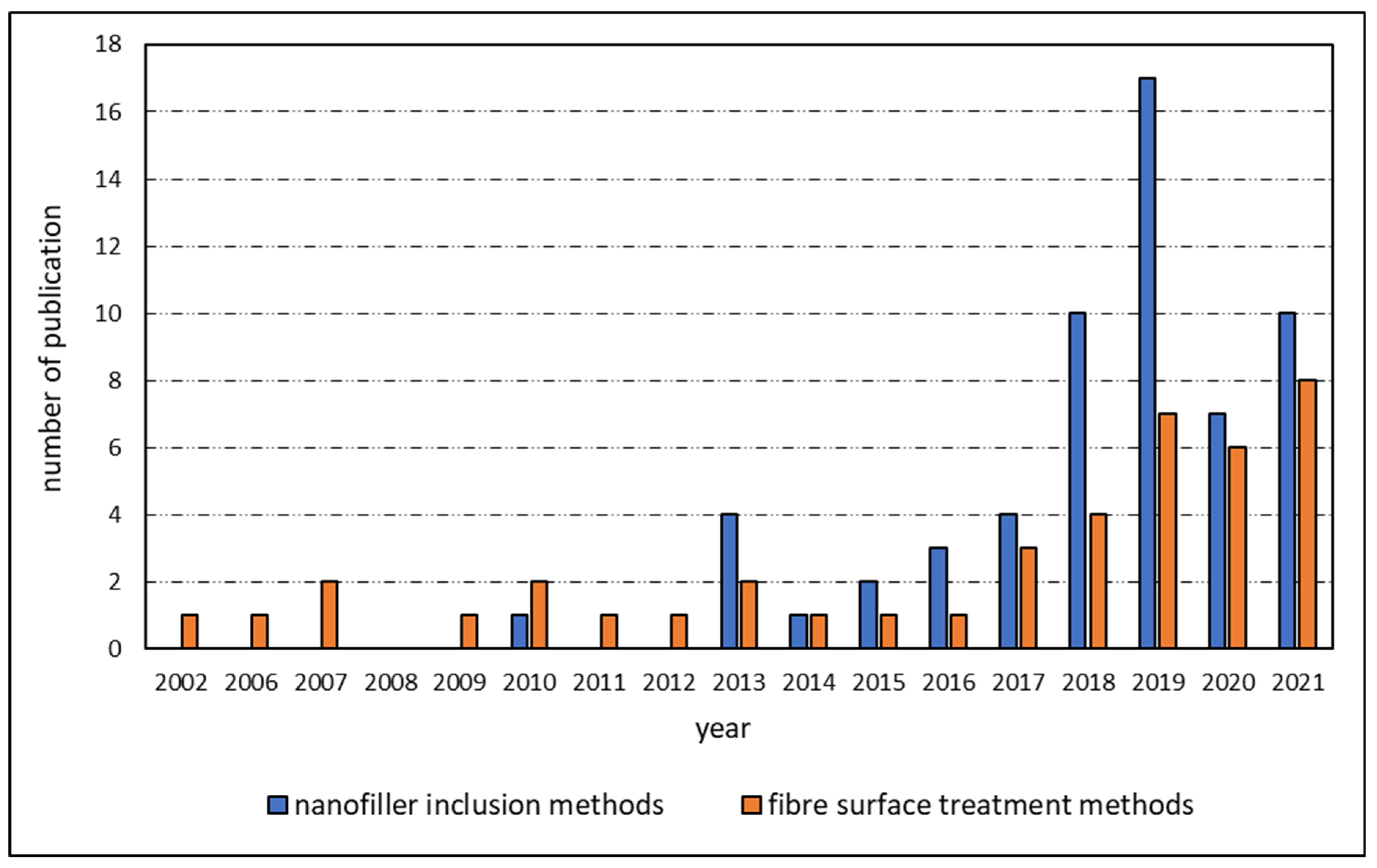

2. Nanofiller Inclusion Methods

2.1. Electrophoretic Deposition

- When acid-oxidized graphene nanoplatelets (GNPs) were deposited on CFs, this led to an increase in the interfacial strength between CF and epoxy. The improvement in the interfacial strength was attributed to the creation of a multiple crack propagation zone [16]. It should be noted that the deflection of cracks into various paths is more prevalent in thermosets than in cases of thermoplastic matrices due to the relatively higher intrinsic toughness of thermoplastic matrices. The stiffness and brittle nature of the thermoset matrix support the nanoparticles to deflect the propagating crack in multiple pathways, which is rare in the case of relatively ductile thermoplastics.

- The EPD is an automated process suitable for large-scale industrial applications, and it has the potential to damage fibres.

- The EPD technique may not achieve a uniform deposition of the nanoparticles leading to agglomeration.

- The EPD method is suitable for fibre reinforcements with relatively high electrical conductivity, such as carbon fibres. This technique is unsuitable for electrically insulative fibres such as glass and aramid [12].

2.2. Chemical Vapor Deposition (CVD)

- The CVD method is very effective in forming an even deposition throughout the fibre surface, but it can result in thermal-induced fibre damage, ultimately degrading the composite mechanical properties [18].

- While thermosetting polymers can form covalent chemical bonds with the treated nanoparticles or with the surface functional groups on the carbon fibre surface, thermoplastic polymers can form only non-covalent chemical bonding [24]. The absence of strong chemical bond formation could be the primary reason behind the relatively low research effort to enhance interfacial bonding in thermoplastic composites using CVD and other chemical-based techniques like chemical coating or nano grafting.

- While the CVD method provides a homogeneous deposition at the nanoscale level, the requirement for hydrocarbon gases and quartz tube testing apparatus makes it an expensive approach.

- Catalyst contamination during processing can also be a drawback in the CVD process [25].

2.3. Direct Immersion Sizing (DIZ) of Nanoparticles

2.3.1. GO Nanoparticles

2.3.2. MWCNT Nanoparticles

2.3.3. Nano Silica Particles

2.3.4. Mixing of Nanoparticles

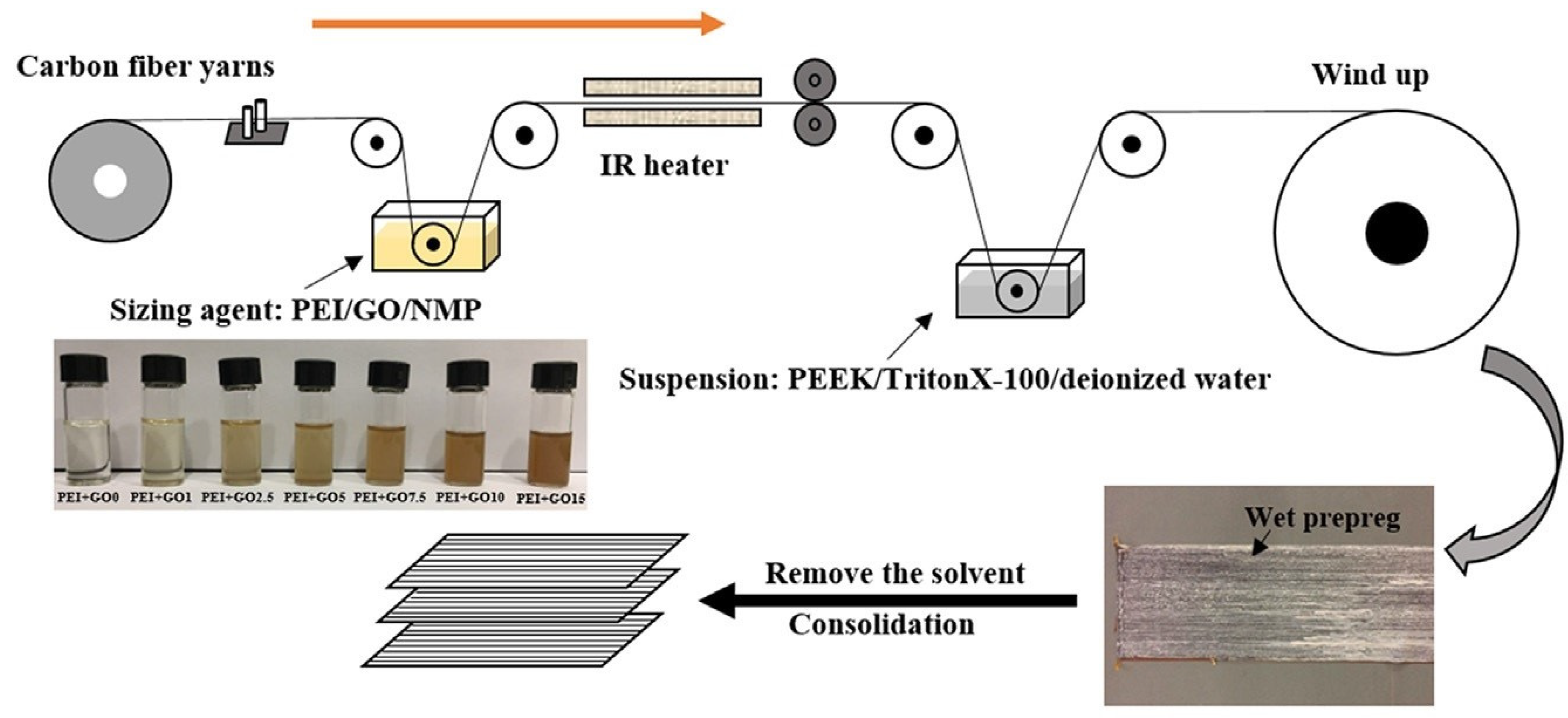

2.3.5. Innovative Non-Conventional Sizing Approaches

- Immersing carbon fibres in hydroxylated PEEK grafted multiwalled carbon nanotubes (HPEEK-g-MWCNT) solution to improve the bonding strength with the PEEK matrix [47]. Flexural strength and ILSS were increased by 94% and 55%, respectively, for the modified samples. The formation of chemical bonding between the PEEK matrix and HPEEK-g-MWCNT, along with the mechanical interlocking between fibre and matrix provided by MWCNT, contributed to the improvement in interfacial bonding between CF and PEEK.

- Creating a sizing agent made of polyetherimide (PEI) and in situ-grown nanocrystals made of zeolitic imidazolate framework-67 (ZIF-67) to enhance the strength of CF/PEEK composite laminates [48]. Miscibility of PEI with PEEK and rough structure of ZIF-67 helped to increase the IFSS between CF and PEEK up to 41%.

- Using the pie-shaped PEI nanoparticles to size the CF surface and heating the PEI-coated fibres to melt a few nanoparticles to increase the surface energy of CF when used to fabricate thermoplastic composites [49]. PEI surface modification increased the IFSS for CF/PVC, CF/PC, CF/PA6, CF/PP, CF/PA66, and CF/PEI by 21%, 38%, 53%, 50%, 43%, and 58%, respectively. The compatibility of thermoplastic resins and PEI coating increased the IFSS between CF and thermoplastic resins. The effect is even better if the surface of PEI coating is in nanoparticle morphology.

- Modifying the short flax fibre surfaces using cellulose nanocrystals, xyloglucan CNC/XG, and maleic anhydride-grafted polypropylene (MAPP) coupling agent. This CNC/XG biomass by-product adsorption on the flax fibres and the covalent bond provided by the MAPP coupling agent with the fibres enhanced the bonding strength between flax fibre and polypropylene (PP) in flax fibre/PP bio composite [50]. The work of rupture of the flax fibre/PP samples measured by micromechanical tensile tests was improved by 13% and 22% for CNC and CNC/XG treatments, respectively.

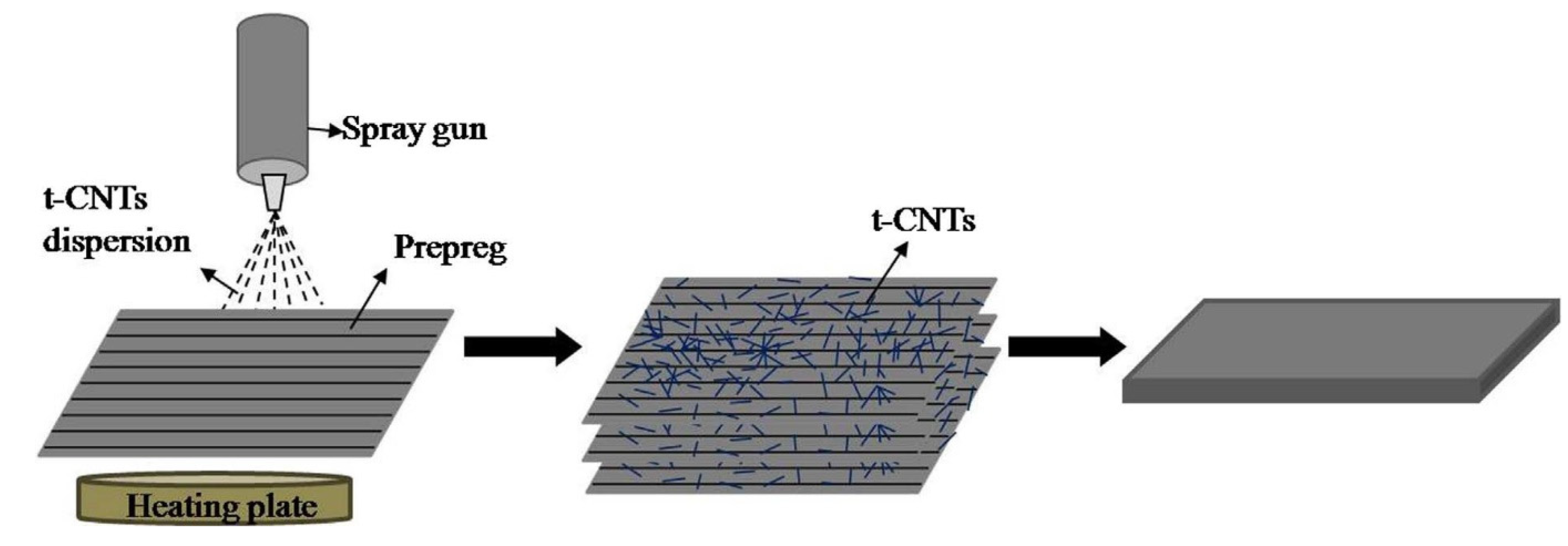

2.4. Spray Gun Technology

2.5. Grafting of Nanoparticles

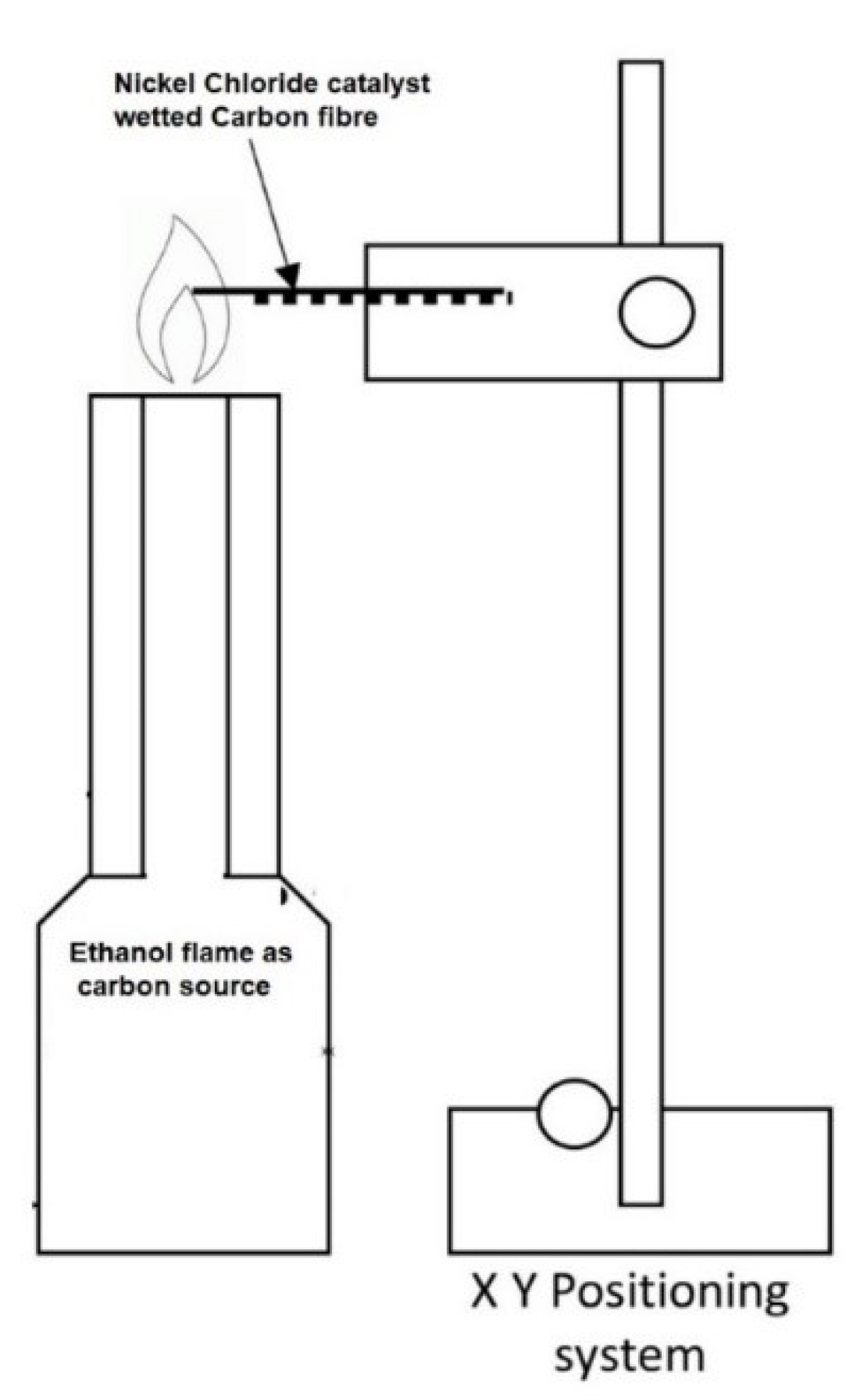

2.6. Flame Synthesis of CNTs

2.7. Miscellaneous Methods

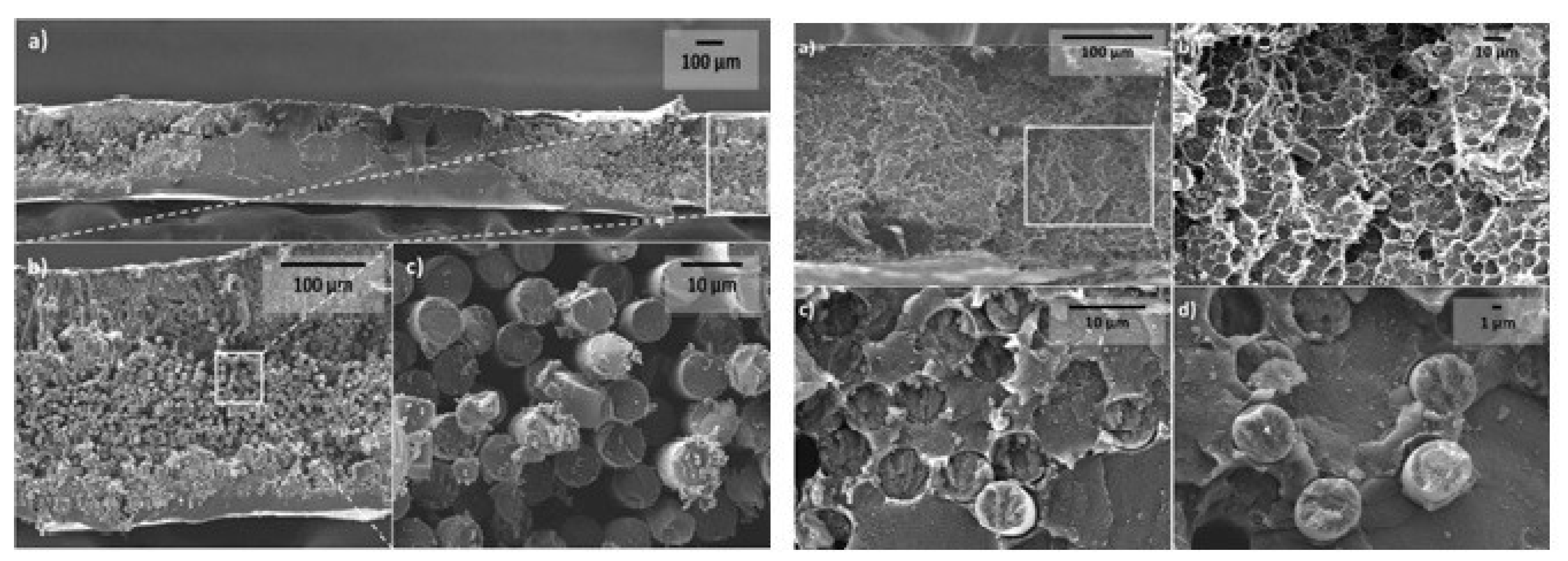

2.8. Discussion: Nanoparticle Incorporation

3. Fibre Surface Treatment Methods

3.1. Wet Chemical Surface Treatment Processes

3.1.1. Polymer Sizing

3.1.2. Chemical Grafting and Chemical Coating

3.1.3. Rare Earth Solution Treatment

3.2. Dry Chemical Surface Treatment Processes

3.2.1. Plasma Treatment

3.2.2. Ozone Treatment

3.2.3. Gamma Irradiation

3.2.4. Electron Beam Irradiation

3.3. Discussion on Fibre Surface Treatment

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Description | Symbol | Description |

| AFM | Atomic force microscope | HDI | Hexamethylene diisocyanate |

| AgNWs | Silver nanowires | HDPE | High-density polyethylene |

| AM | Acrylamide monomer | HPEEK-g-MWCNTs | Hydroxylated poly (ether ether ketone) grafted multi-walled carbon nanotubes. |

| APP | Ammonium polyphosphate | IFSS | Interfacial shear strength |

| AS | Acrylic-styrene | ILFT | Interlaminar fracture toughness |

| CF | Carbon fibre | ILSS | Interlaminar shear strength |

| CF-CNT | Carbon nanotube grafted carbon fibre | KOH | Potassium hydroxide |

| CF/PA6 | Carbon fibre reinforced polyamide 6 | LaCl3 | Lanthanum chloride |

| CF/PAEK | Carbon fibre reinforced poly aryl ether ketone | LDPE | Low-density polyethylene |

| CF/PASS | Carbon fibre-reinforced poly (arylene sulfide sulfone) | LLDPE | Linear low-density polyethylene |

| CF/PC | Carbon fibre-reinforced polycarbonate | LPP | Low-pressure plasma treatment |

| CF/PEEK | Carbon fibre reinforced poly (ether ether ketone) | LRGO | Large size reduced graphene oxide |

| CF/PES | Carbon fibre-reinforced poly (ether sulfone) | MAPP | Maleic anhydride grafted polypropylene |

| CF/PI | Carbon fibre-reinforced polyimide | MEKP | Methyl ethyl ketone peroxide |

| CF/PP | Carbon fibre-reinforced polypropylene | MMA | Methyl methacrylate |

| CF/PPS | Carbon fibre reinforced poly phenylene sulfide | MoS2 | Molybdenum disulfide |

| CF/PTFE | Carbon fibre-reinforced polytetrafluoroethylene | MPSR | Methyl phenyl silicone resin |

| CFRTP | Carbon fibre-reinforced thermoplastic composite | MWCNTs | Multiwalled carbon nanotubes |

| CGF | Continuous glass fibre | NBR | Nitrile butadiene rubber |

| CGF/PP | Continuous glass fibre-reinforced polypropylene | nCMBN | Non-covalent modified boron nitride |

| CNC | Cellulose nanocrystals | NH2-PASS | Aminated poly (arylene sulfide sulfone) |

| CNTs | Carbon nanotubes | NH4HCO3 | Ammonium bicarbonate |

| CPL | Caprolactam monomer | NMP | N-methyl-pyrrolidone |

| CVD | Chemical vapor deposition | PA6 | Polyamide6 |

| DDE | 4,4′-diamino diphenyl ether | PASS | Poly (arylene sulfide sulfone) |

| DDS | 4,4′-diamino diphenyl sulfone | PBO | Poly (P-phenylene benzobisoxazole) |

| DI water | Deionized water | PBT | Polybutylene terephthalate |

| DIZ | Direct immersion sizing | PC | Polycarbonate |

| DMAC | Dimethyl acetamide | PCL | Poly (ɛ caprolactone) |

| DPL | Date palm leaf | PCM | Phase change material |

| EB | Electron beam | PDA | Polydopamine |

| ECP | Epoxy chloropropane | PEEK | Poly (ether ether ketone) |

| EG | Expanded graphite | PEEK-NH2 | Aminated Poly (ether ether ketone) |

| EPC | Ethylene-propylene copolymer | PEI | Polyetherimide |

| EPD | Electrophoretic deposition | PEKK | Poly (ether ketone ketone) |

| EVA | Ethylene-vinyl acetate | PES | Poly (ether sulfone) |

| Fe3O4 | Iron oxide | PI | Polyimide |

| FDM | Fused deposition modelling | PLA | Polylactic acid |

| GF | Glass fibre | PMDA-ODA | Poly (pyromellitic dianhydride-co-4,40-oxydianiline) |

| GF/PEI | Glass fibre-reinforced polyetherimide | PMMA | Poly (methyl methacrylate) |

| GF/PP | Glass fibre-reinforced polypropylene | PP | Polypropylene |

| GF/PTFE | Glass fibre-reinforced polytetrafluoroethylene | PPEK | Poly (phthalazinone ether ketone) |

| GO | Graphene oxide | PPESK | Poly (phthalazinone ether sulfone ketone) |

| PPS | Polyphenylene sulfide | SiO2 | Silica (silicon dioxide) |

| PPS-COOH | Carboxylic polyphenylene sulfide | SRGO | Shellac-derived reduced graphene oxide |

| PU | Polyurethane | TGA | Thermogravimetric analysis |

| PVA | Poly vinyl alcohol | TPI | Thermoplastic polyimide |

| PVDF | Poly (vinylidene fluoride) | TPU | Thermoplastic polyurethane |

| RES | Rare earth solution | UHMWPE | Ultra-high-molecular-weight polyethylene |

| RGO | Reduced graphene oxide | UV rays | Ultraviolet rays |

| s-PEEK | Sulfonated poly (ether ether ketone) | VARIM | Vacuum-assisted resin infusion molding |

| S-PSF | sulfonated poly (ether sulfone) | WCF | Woven carbon fibre |

| SA-PI | Semi aliphatic polyimide | WCF/PA6 | Woven carbon fibre-reinforced polyamide 6 |

| SCFs | Short carbon fibres | XG | Xyloglucan |

| SEM | Scanning electron microscope | xGNP | Exfoliated graphene nanoplatelets |

| SGFs | Short glass fibres | ZIF-67 | Zeolitic imidazolate framework-67 |

| SiC | Silicon carbide | ZnO NR | Zinc oxide nanorods |

References

- Mallick, P.K. Thermoplastics and Thermoplastic–Matrix Composites for Lightweight Automotive Structures; Woodhead Publishing: Sawston, UK, 2010; pp. 174–207. [Google Scholar] [CrossRef]

- Mandal, L.; Verma, B.; Patel, P.K. Review on polymer nanocomposite for ballistic & aerospace applications. Mater. Today: Proc. 2020, 26, 3161–3166. [Google Scholar] [CrossRef]

- Teoh, S.H.; Tang, Z.G.; Hastings, G.W. Thermoplastic Polymers In Biomedical Applications: Structures, Properties and Processing. In Handbook of Biomaterial Properties; Black, J., Hastings, G., Eds.; Springer: Boston, MA, USA, 1998; pp. 270–301. [Google Scholar] [CrossRef]

- Bajurko, P. Comparison of damage resistance of thermoplastic and thermoset carbon fibre-reinforced composites. J. Thermoplast. Compos. Mater. 2019, 34, 303–315. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, T.; Wang, K.; Zhao, Y. Multiscale enhancement behavior of nano-silica modified CF/PEEK composites prepared by wet powder impregnation. Polym. Compos. 2019, 40, 1187–1197. [Google Scholar] [CrossRef]

- Tran, L.Q.N.; Fuentes, C.A.; Dupont-Gillain, C.; Van Vuure, A.W.; Verpoest, I. Understanding the interfacial compatibility and adhesion of natural coir fibre thermoplastic composites. Compos. Sci. Technol. 2013, 80, 23–30. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 1–19. [Google Scholar] [CrossRef]

- He, Q.; Wang, H.; Fu, K.; Ye, L. 3D printed continuous CF/PA6 composites: Effect of microscopic voids on mechanical performance. Compos. Sci. Technol. 2020, 191, 1–9. [Google Scholar] [CrossRef]

- Wu, D.C.; Shen, L.; Low, J.E.; Wong, S.Y.; Li, X.; Tjiu, W.C.; Liu, Y.; He, C.B. Multi-walled carbon nanotube/polyimide composite film fabricated through electrophoretic deposition. Polymer 2010, 51, 2155–2160. [Google Scholar] [CrossRef]

- Liu, Y.-T.; Song, H.-Y.; Yao, T.-T.; Zhang, W.-S.; Zhu, H.; Wu, G.-P. Effects of carbon nanotube length on interfacial properties of carbon fiber reinforced thermoplastic composites. J. Mater. Sci. 2020, 55, 15467–15480. [Google Scholar] [CrossRef]

- Qin, Q.H. Introduction to the composite and its toughening mechanisms. In Toughening Mechanisms in Composite Materials; Qin, Q., Ye, J., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 1–32. [Google Scholar] [CrossRef]

- An, Q.; Rider, A.; Thostenson, E. Electrophoretic deposition of carbon nanotubes onto carbon-fiber fabric for production of carbon/epoxy composites with improved mechanical properties. Carbon 2012, 50, 4130–4143. [Google Scholar] [CrossRef]

- Park, M.; Park, J.H.; Yang, B.J.; Cho, J.; Kim, S.Y.; Jung, I. Enhanced interfacial, electrical, and flexural properties of polyphenylene sulfide composites filled with carbon fibers modified by electrophoretic surface deposition of multi-walled carbon nanotubes. Compos. Part A: Appl. Sci. Manuf. 2018, 109, 124–130. [Google Scholar] [CrossRef]

- Wu, Y.; Dhamodharan, D.; Wang, Z.; Wang, R.; Wu, L. Effect of electrophoretic deposition followed by solution pre-impregnated surface modified carbon fiber-carbon nanotubes on the mechanical properties of carbon fiber reinforced polycarbonate composites. Compos. Part B Eng. 2020, 195, 1–11. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, W.B.; Hao, L.F.; Jiao, W.C.; Yang, F.; Wang, R.G. Preparation of carbon nanotube/carbon fiber hybrid fiber by combining electrophoretic deposition and sizing process for enhancing interfacial strength in carbon fiber composites. Compos. Sci. Technol. 2013, 88, 120–125. [Google Scholar] [CrossRef]

- Nandi, A.; Das, S.; Halder, S.; Chakraborty, A.; Imam, M.A. Ultrasonically assisted electrophoretic deposition of oxidized graphite nanoparticle onto carbon fiber, amending interfacial property of CFRP. J. Compos. Mater. 2019, 54, 1615–1625. [Google Scholar] [CrossRef]

- Jianguo, Z.; Gang, D. Mechanical properties of polyimide composite reinforced with carbon nanotubes and carbon fibers. J. Thermoplast. Compos. Mater. 2014, 28, 1250–1259. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Md Akil, H.; Abdul Kudus, M.H.; Ullah, F.; Javed, F.; Nosbi, N. Hybrid carbon fiber-carbon nanotubes reinforced polymer composites: A review. Compos. Part B Eng. 2019, 176, 1–20. [Google Scholar] [CrossRef]

- Yumitori, S.; Arao, Y.; Tanaka, T.; Naito, K.; Tanaka, K.; Katayama, T. Increasing the interfacial strength in carbon fiber/polypropylene composites by growing CNTs on the fibers. Comput. Methods Exp. Meas. XVI 2013, 55, 275. [Google Scholar]

- Tanaka, K.; Hosoo, N.; Katayama, T. Influence of Unsizing and Carbon Nanotube Grafting of Carbon Fibre on Fibre Matrix Interfacial Shear Strength of Carbon Fibre and Polyamide 6. Key Eng. Mater. 2019, 827, 178–183. [Google Scholar] [CrossRef]

- Tanaka, K.; Okuda, S.; Hinoue, Y.; Katayama, T. Effect of CNT Grafting on Carbon Fibers on Impact Properties of CFRTP Laminate. Key Eng. Mater. 2018, 774, 410–415. [Google Scholar] [CrossRef]

- Tanaka, K.; Uzumasa, K.; Katayama, T. Effects of Water Absorption on the Fiber–Matrix Interfacial Shear Strength of Carbon Nanotube-Grafted Carbon Fiber Reinforced Polyamide Resin. J. Compos. Sci. 2019, 3, 4. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, K.; Yamada, K.; Hinoue, Y.; Katayama, T. Effects of Temperature on the Fiber Matrix Interfacial Properties of Carbon Fiber Reinforced Highly Heat Resistant Polyamide Resin. J. Soc. Mater. Sci. Jpn. 2017, 66, 746–751. [Google Scholar] [CrossRef] [Green Version]

- Luo, W.; Zhang, B.; Zou, H.; Liang, M.; Chen, Y. Enhanced interfacial adhesion between polypropylene and carbon fiber by graphene oxide/polyethyleneimine coating. J. Ind. Eng. Chem. 2017, 51, 129–139. [Google Scholar] [CrossRef]

- Anthony, D.B.; Qian, H.; Clancy, A.J.; Greenhalgh, E.S.; Bismarck, A.; Shaffer, M.S.P. Applying a potential difference to minimise damage to carbon fibres during carbon nanotube grafting by chemical vapour deposition. Nanotechnology 2017, 28, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, K.; Zhao, Y. Enhanced interfacial interactions of carbon fiber reinforced PEEK composites by regulating PEI and graphene oxide complex sizing at the interface. Compos. Sci. Technol. 2018, 154, 175–186. [Google Scholar] [CrossRef]

- Liu, L.; Yan, F.; Li, M.; Zhang, M.; Xiao, L.; Shang, L.; Ao, Y. A novel thermoplastic sizing containing graphene oxide functionalized with structural analogs of matrix for improving interfacial adhesion of CF/PES composites. Compos. Part A: Appl. Sci. Manuf. 2018, 114, 418–428. [Google Scholar] [CrossRef]

- Cho, B.-G.; Ram Joshi, S.; Hun Han, J.; Kim, G.-H.; Park, Y.-B. Interphase strengthening of carbon fiber/polyamide 6 composites through mixture of sizing agent and reduced graphene oxide coating. Compos. Part A: Appl. Sci. Manuf. 2021, 149, 1–16. [Google Scholar] [CrossRef]

- Ren, T.; Zhu, G.; Hou, X.; Li, B.; Hao, Y. Improvement of interfacial interactions in CF / PEEK composites by an s-PSF /graphene oxide compound sizing agent. J. Appl. Polym. Sci. 2021, 138, 1–13. [Google Scholar] [CrossRef]

- Wang, C.-C.; Zhao, Y.-Y.; Ge, H.-Y.; Qian, R.-S. Enhanced mechanical and thermal properties of short carbon fiber reinforced polypropylene composites by graphene oxide. Polym. Compos. 2018, 39, 405–413. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, F.-L.; Wu, X.-P.; Li, Y.-Q.; Zeng, W.; Chen, Q.; Huang, T.; Huang, P.; Fu, Y.-Q.; Ma, X.-Y.; et al. Experimental and simulation investigations of the effect of hybrid GO-thermoplastic polyimide sizing on the temperature-dependent tensile behavior of short carbon fiber/polyetherimide composites. Compos. Sci. Technol. 2022, 218, 1–11. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, B.; Yuan, B.; Yuan, Y.; Liew, K.M.; Song, L.; Hu, Y. Preparation of Large-Size Reduced Graphene Oxide-Wrapped Ammonium Polyphosphate and Its Enhancement of the Mechanical and Flame Retardant Properties of Thermoplastic Polyurethane. Ind. Eng. Chem. Res. 2017, 56, 7468–7477. [Google Scholar] [CrossRef]

- Bowman, S.; Hu, X.; Jiang, Q.; Qiu, Y.; Liu, W.; Wei, Y. Effects of Graphene-Oxide-Modified Coating on the Properties of Carbon-Fiber-Reinforced Polypropylene Composites. Coatings 2018, 8, 149. [Google Scholar] [CrossRef] [Green Version]

- Shanmugam, L.; Feng, X.; Yang, J. Enhanced interphase between thermoplastic matrix and UHMWPE fiber sized with CNT-modified polydopamine coating. Compos. Sci. Technol. 2019, 174, 212–220. [Google Scholar] [CrossRef]

- Shanmugam, L.; Kazemi, M.E.; Rao, Z.; Lu, D.; Wang, X.; Wang, B.; Yang, L.; Yang, J. Enhanced Mode I fracture toughness of UHMWPE fabric/thermoplastic laminates with combined surface treatments of polydopamine and functionalized carbon nanotubes. Compos. Part B Eng. 2019, 178, 1–9. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, J.; Wang, K.; Zhao, Y. Improved interlaminar crack resistance of glass fiber/poly (phenylene sulfide) thermoplastic composites modified with multiwalled carbon nanotubes. Polym. Compos. 2019, 40, 4186–4195. [Google Scholar] [CrossRef]

- Yang, B.; Xuan, F.-Z.; Wang, Z.; Chen, L.; Lei, H.; Liang, W.; Xiang, Y.; Yang, K. Multi-functional interface sensor with targeted IFSS enhancing, interface monitoring and self-healing of GF/EVA thermoplastic composites. Compos. Sci. Technol. 2018, 167, 86–95. [Google Scholar] [CrossRef]

- Wu, G.; Ma, L.; Liu, L.; Wang, Y.; Xie, F.; Zhong, Z.; Zhao, M.; Jiang, B.; Huang, Y. Interface enhancement of carbon fiber reinforced methylphenylsilicone resin composites modified with silanized carbon nanotubes. Mater. Des. 2016, 89, 1343–1349. [Google Scholar] [CrossRef]

- Hassan, E.A.M.; Ge, D.; Zhu, S.; Yang, L.; Zhou, J.; Yu, M. Enhancing CF/PEEK composites by CF decoration with polyimide and loosely-packed CNT arrays. Compos. Part A: Appl. Sci. Manuf. 2019, 127, 1–7. [Google Scholar] [CrossRef]

- Li, J.; Qiao, Y.; Li, D.; Zhang, S.; Liu, P. Improving interfacial and mechanical properties of glass fabric/polyphenylene sulfide composites via grafting multi-walled carbon nanotubes. RSC Adv. 2019, 9, 32634–32643. [Google Scholar] [CrossRef] [Green Version]

- Fang, J.; Zhang, L.; Li, C. Polyamide 6 composite with highly improved mechanical properties by PEI-CNT grafted glass fibers through interface wetting, infiltration and crystallization. Polymer 2019, 172, 253–264. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Pegoretti, A. Silica nanoparticles as coupling agents for polypropylene/glass composites. Compos. Sci. Technol. 2013, 76, 77–83. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, J.; Zhou, L.; Lu, M.; Liang, W.; Wang, Z. Effect of fiber surface modification on water absorption and hydrothermal aging behaviors of GF/pCBT composites. Compos. Part B Eng. 2015, 82, 84–91. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, J.; Zhou, L.; Wang, Z.; Liang, W. Effect of fiber surface modification on the lifetime of glass fiber reinforced polymerized cyclic butylene terephthalate composites in hygrothermal conditions. Mater. Des. 2015, 85, 14–23. [Google Scholar] [CrossRef]

- Sharma, S.; Rawal, J.; Dhakate, S.R.; Singh, B.P. Synergistic bridging effects of graphene oxide and carbon nanotube on mechanical properties of aramid fiber reinforced polycarbonate composite tape. Compos. Sci. Technol. 2020, 199, 1–12. [Google Scholar] [CrossRef]

- Hao, R.; Jiao, X.; Zhang, X.; Tian, Y. Fe3O4/graphene modified waterborne polyimide sizing agent for high modulus carbon fiber. Appl. Surf. Sci. 2019, 485, 304–313. [Google Scholar] [CrossRef]

- Lyu, H.; Jiang, N.; Li, Y.; Lee, H.; Zhang, D. Enhanced interfacial and mechanical properties of carbon fiber/PEEK composites by hydroxylated PEEK and carbon nanotubes. Compos. Part A: Appl. Sci. Manuf. 2021, 145, 1–10. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Y.; Li, N.; Zhao, X.; Han, X.; Li, S.; Lu, W.; Wang, K.; Du, S. Enhanced interfacial strength of carbon fiber/PEEK composites using a facile approach via PEI&ZIF-67 synergistic modification. J. Mater. Res. Technol. 2019, 8, 6289–6300. [Google Scholar] [CrossRef]

- Zhu, P.; Shi, J.; Bao, L. Effect of polyetherimide nanoparticle coating on the interfacial shear strength between carbon fiber and thermoplastic resins. Appl. Surf. Sci. 2020, 509, 1–8. [Google Scholar] [CrossRef]

- Doineau, E.; Coqueugniot, G.; Pucci, M.F.; Caro, A.S.; Cathala, B.; Benezet, J.C.; Bras, J.; Le Moigne, N. Hierarchical thermoplastic biocomposites reinforced with flax fibres modified by xyloglucan and cellulose nanocrystals. Carbohydr. Polym. 2021, 254, 1–10. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, S.; Zhang, X.; Zhao, Z.; Jing, D. Preparation and properties of carbon nanotubes/carbon fiber/poly (ether ether ketone) multiscale composites. Compos. Part A: Appl. Sci. Manuf. 2018, 108, 89–98. [Google Scholar] [CrossRef]

- Cortes, L.Q.; Racagel, S.; Lonjon, A.; Dantras, E.; Lacabanne, C. Electrically conductive carbon fiber / PEKK / silver nanowires multifunctional composites. Compos. Sci. Technol. 2016, 137, 159–166. [Google Scholar] [CrossRef] [Green Version]

- He, H.; Yang, P.; Duan, Z.; Wang, Z.; Liu, Y. Reinforcing effect of hybrid nano-coating on mechanical properties of basalt fiber/poly(lactic acid) environmental composites. Compos. Sci. Technol. 2020, 199, 1–10. [Google Scholar] [CrossRef]

- Kim, B.-J.; Cha, S.-H.; Kong, K.; Ji, W.; Park, H.W.; Park, Y.-B. Synergistic interfacial reinforcement of carbon fiber/polyamide 6 composites using carbon-nanotube-modified silane coating on ZnO-nanorod-grown carbon fiber. Compos. Sci. Technol. 2018, 165, 362–372. [Google Scholar] [CrossRef]

- Ma, Y.; Yan, C.; Xu, H.; Liu, D.; Shi, P.; Zhu, Y.; Liu, J. Enhanced interfacial properties of carbon fiber reinforced polyamide 6 composites by grafting graphene oxide onto fiber surface. Appl. Surf. Sci. 2018, 452, 286–298. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, Y.; Li, H.; Zhang, B. Interfacial adhesion between carbon fibers and nylon 6: Effect of fiber surface chemistry and grafting of nano-SiO2. Compos. Part A: Appl. Sci. Manuf. 2019, 121, 157–168. [Google Scholar] [CrossRef]

- Cheon, J.; Kim, M. Impact resistance and interlaminar shear strength enhancement of carbon fiber reinforced thermoplastic composites by introducing MWCNT-anchored carbon fiber. Compos. Part B Eng. 2021, 217, 1–13. [Google Scholar] [CrossRef]

- Du, X.; Liu, H.-Y.; Xu, F.; Zeng, Y.; Mai, Y.-W. Flame synthesis of carbon nanotubes onto carbon fiber woven fabric and improvement of interlaminar toughness of composite laminates. Compos. Sci. Technol. 2014, 101, 159–166. [Google Scholar] [CrossRef]

- Hamzah, N.; Mohd Yasin, M.F.; Mohd Yusop, M.Z.; Saat, A.; Mohd Subha, N.A. Growth region characterization of carbon nanotubes synthesis in heterogeneous flame environment with wire-based macro-image analysis. Diam. Relat. Mater. 2019, 99, 1–10. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, H.-Y.; Du, X.; Zhou, H.; Pan, Z.; Mai, Y.-W.; Jia, Y.-Y.; Yan, W. Flame synthesis of carbon nanotubes on glass fibre fabrics and their enhancement in electrical and thermal properties of glass fibre/epoxy composites. Compos. Part B Eng. 2020, 198, 1–11. [Google Scholar] [CrossRef]

- Zhao, P.; Xiong, X.; Liu, S.; Ren, R.; Zhang, Z.; Cui, X.; Ji, S.; Qi, W. Resistance welded thermoplastic composites joint strengthened via carbon nanotubes from flame: Interface strength, mechanical properties and microstructure. Mater. Res. Express 2019, 6, 1–7. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, H.-Y.; Cui, X.; Du, X.; Zhou, H.; Mai, Y.-W.; Jia, Y.-Y.; Yan, W. Tensile properties of 3D-printed CNT-SGF reinforced PLA composites. Compos. Sci. Technol. 2022, 230, 1–11. [Google Scholar] [CrossRef]

- Kim, B.-J.; Cha, S.-H.; Park, Y.-B. Ultra-high-speed processing of nanomaterial-reinforced woven carbon fiber/polyamide 6 composites using reactive thermoplastic resin transfer molding. Compos. Part B Eng. 2018, 143, 36–46. [Google Scholar] [CrossRef]

- Rasana, N.; Jayanarayanan, K.; Pavithra, R.; Nandhini, G.R.; Ramya, P.; Veeraraagavan, A.V. Mechanical and Thermal Properties Modeling, Sorption Characteristics of Multiscale (Multiwalled Carbon Nanotubes/Glass Fiber) Filler Reinforced Polypropylene Composites. J. Vinyl Addit. Technol. 2019, 25, E94–E107. [Google Scholar] [CrossRef]

- Rudresh, B.M.; Ravi Kumar, B.N.; Madhu, D. Combined effect of micro- and nano-fillers on mechanical, thermal, and morphological behavior of glass–carbon PA66/PTFE hybrid nano-composites. Adv. Compos. Hybrid Mater. 2019, 2, 176–188. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, Z.-K.; Zhang, Y.-Y.; Li, Y.-Q.; Fu, Y.-Q.; Sun, B.-G.; Shi, H.-Q.; Huang, P.; Hu, N.; Fu, S.-Y. Mechanical, tribological and thermal properties of injection molded short carbon fiber/expanded graphite/polyetherimide composites. Compos. Sci. Technol. 2021, 201, 1–10. [Google Scholar] [CrossRef]

- Arao, Y.; Yumitori, S.; Suzuki, H.; Tanaka, T.; Tanaka, K.; Katayama, T. Mechanical properties of injection-molded carbon fiber/polypropylene composites hybridized with nanofillers. Compos. Part A: Appl. Sci. Manuf. 2013, 55, 19–26. [Google Scholar] [CrossRef]

- Hwang, S.-H.; Kim, B.-J.; Baek, J.-B.; Shin, H.S.; Bae, I.-J.; Lee, S.-Y.; Park, Y.-B. Effects of process parameters and surface treatments of graphene nanoplatelets on the crystallinity and thermomechanical properties of polyamide 6 composite fibers. Compos. Part B Eng. 2016, 100, 220–227. [Google Scholar] [CrossRef]

- Qi, Z.; Liu, H.; Wang, J.; Yan, F. The enhanced transfer behavior and tribological properties in deep sea environment of poly(butylene terephthalate) composites reinforced by silica nanoaerogels. Tribol. Int. 2021, 160, 1–11. [Google Scholar] [CrossRef]

- Liu, X.; Gao, Y.; Shang, Y.; Zhu, X.; Jiang, Z.; Zhou, C.; Han, J.; Zhang, H. Non-covalent modification of boron nitride nanoparticle-reinforced PEEK composite: Thermally conductive, interfacial, and mechanical properties. Polymer 2020, 203, 1–8. [Google Scholar] [CrossRef]

- Lee, S.M. Influence of fiber/matrix interfacial adhesion on composite fracture behavior. Compos. Sci. Technol. 1992, 43, 317–327. [Google Scholar] [CrossRef]

- Wu, G.; Chen, L.; Liu, L. Effects of silanization and silica enrichment of carbon fibers on interfacial properties of methylphenylsilicone resin composites. Compos. Part A: Appl. Sci. Manuf. 2017, 98, 159–165. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, B.; Cai, X.; Qiao, K.; Zhao, S.; Zhang, M. Nanoscale toughening of carbon fiber-reinforced epoxy composites through different surface treatments. Polym. Eng. Sci. 2019, 59, 625–632. [Google Scholar] [CrossRef]

- Fu, S.; Sun, Z.; Huang, P.; Li, Y.; Hu, N. Some basic aspects of polymer nanocomposites: A critical review. Nano Mater. Sci. 2019, 1, 2–30. [Google Scholar] [CrossRef]

- Asmatulu, R.; Erukala, K.S.; Shinde, M.; Alarifi, I.M.; Rahimi Gorji, M. Investigating the effects of surface treatments on adhesion properties of protective coatings on carbon fiber-reinforced composite laminates. Surf. Coat. Technol. 2019, 380, 1–11. [Google Scholar] [CrossRef]

- Xie, J.; Xin, D.; Cao, H.; Wang, C.; Zhao, Y.; Yao, L.; Ji, F.; Qiu, Y. Improving carbon fiber adhesion to polyimide with atmospheric pressure plasma treatment. Surf. Coat. Technol. 2011, 206, 191–201. [Google Scholar] [CrossRef]

- Li, N.; Chen, J.; Liu, H.; Dong, A.; Wang, K.; Zhao, Y. Effect of preheat treatment on carbon fiber surface properties and fiber/PEEK interfacial behavior. Polym. Compos. 2018, 40, E1407–E1415. [Google Scholar] [CrossRef]

- Kiss, P.; Glinz, J.; Stadlbauer, W.; Burgstaller, C.; Archodoulaki, V.-M. The effect of thermally desized carbon fibre reinforcement on the flexural and impact properties of PA6, PPS and PEEK composite laminates: A comparative study. Compos. Part B Eng. 2021, 215, 1–13. [Google Scholar] [CrossRef]

- Veazey, D.; Hsu, T.; Gomez, E.D. Next generation high-performance carbon fiber thermoplastic composites based on polyaryletherketones. J. Appl. Polym. Sci. 2017, 134, 1–17. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Y.; Li, N.; Li, S.; Li, X.; Liu, Z.; Cheng, S.; Wang, K.; Du, S. Effect of polyetherimide sizing on surface properties of carbon fiber and interfacial strength of carbon fiber/polyetheretherketone composites. Polym. Compos. 2020, 42, 931–943. [Google Scholar] [CrossRef]

- Gao, X.; Huang, Z.; Zhou, H.; Li, D.; Li, Y.; Wang, Y. Higher mechanical performances of CF /PEEK composite laminates via reducing interlayer porosity based on the affinity of functional s-PEEK. Polym. Compos. 2019, 40, 3749–3757. [Google Scholar] [CrossRef]

- Pan, L.; Guo, H.; Zhong, L.; Wang, M.; Xue, P.; Yuan, X. Influence of surface-modified glass fibers on interfacial properties of GF/PEEK composites using molecular dynamics. Comput. Mater. Sci. 2021, 188, 1–11. [Google Scholar] [CrossRef]

- Yuan, C.; Li, D.; Yuan, X.; Liu, L.; Huang, Y. Preparation of semi-aliphatic polyimide for organic-solvent-free sizing agent in CF/PEEK composites. Compos. Sci. Technol. 2021, 201, 1–7. [Google Scholar] [CrossRef]

- Wang, S.; Yang, Y.; Mu, Y.; Shi, J.; Cong, X.; Luan, J.; Wang, G. Synergy of electrochemical grafting and crosslinkable crystalline sizing agent to enhance the interfacial strength of carbon fiber/PEEK composites. Compos. Sci. Technol. 2021, 203, 1–8. [Google Scholar] [CrossRef]

- Yan, T.; Yan, F.; Li, S.; Li, M.; Liu, Y.; Zhang, M.; Jin, L.; Shang, L.; Liu, L.; Ao, Y. Interfacial enhancement of CF/PEEK composites by modifying water-based PEEK-NH2 sizing agent. Compos. Part B Eng. 2020, 199, 1–8. [Google Scholar] [CrossRef]

- Giraud, I.; Franceschi-Messant, S.; Perez, E.; Lacabanne, C.; Dantras, E. Preparation of aqueous dispersion of thermoplastic sizing agent for carbon fiber by emulsion/solvent evaporation. Appl. Surf. Sci. 2013, 266, 94–99. [Google Scholar] [CrossRef] [Green Version]

- Hassan, E.A.M.; Ge, D.; Yang, L.; Zhou, J.; Liu, M.; Yu, M.; Zhu, S. Highly boosting the interlaminar shear strength of CF/PEEK composites via introduction of PEKK onto activated CF. Compos. Part A Appl. Sci. Manuf. 2018, 112, 155–160. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, C.; Yao, L.; Li, Z.; Li, S.; Lu, Y. Effect of polyurethane sizing agent on interface properties of carbon fiber reinforced polycarbonate composites. J. Appl. Polym. Sci. 2019, 136, 1–10. [Google Scholar] [CrossRef]

- Hendlmeier, A.; Marinovic, L.I.; Al-Assafi, S.; Stojcevski, F.; Henderson, L.C. Sizing effects on the interfacial shear strength of a carbon fibre reinforced two-component thermoplastic polymer. Compos. Part A Appl. Sci. Manuf. 2019, 127, 1–9. [Google Scholar] [CrossRef]

- Yamamoto, T.; Uematsu, K.; Irisawa, T.; Tanabe, Y. Controlling of the interfacial shear strength between thermoplastic resin and carbon fiber by adsorbing polymer particles on carbon fiber using electrophoresis. Compos. Part A Appl. Sci. Manuf. 2016, 88, 75–78. [Google Scholar] [CrossRef]

- Yamamoto, T.; Uematsu, K.; Yabushita, S. Enhancement of mechanical properties of carbon fiber reinforced thermoplastic using colloidal techniques. Procedia Manuf. 2018, 15, 1738–1745. [Google Scholar] [CrossRef]

- Yamamoto, T.; Ota, Y. Creating a laminated carbon fiber-reinforced thermoplastic using polypropylene and nylon with a polypropylene colloid. Compos. Struct. 2021, 255, 1–6. [Google Scholar] [CrossRef]

- Dong, Y.; Yu, T.; Wang, X.-j.; Zhang, G.; Lu, J.-h.; Zhang, M.-l.; Long, S.-r.; Yang, J. Improved interfacial shear strength in polyphenylene sulfide/carbon fiber composites via the carboxylic polyphenylene sulfide sizing agent. Compos. Sci. Technol. 2020, 190, 1–9. [Google Scholar] [CrossRef]

- Won, J.S.; Kwon, M.; Lee, J.E.; Lee, J.M.; Kwak, T.J.; Lee, S.G. Polyphenylene sulfide-modified carbon fiber reinforced high-strength composites via electrophoretic deposition. J. Sci Adv. Mater. Dev. 2022, 7, 1–10. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, Y.; Liu, X.; Wang, X.; Yang, B. Mussel-inspired modification of carbon fiber via polyethyleneimine/polydopamine co-deposition for the improved interfacial adhesion. Compos. Sci. Technol. 2017, 151, 164–173. [Google Scholar] [CrossRef]

- Kyutoku, H.; Maeda, N.; Sakamoto, H.; Nishimura, H.; Yamada, K. Effect of surface treatment of cellulose fiber (CF) on durability of PLA/CF bio-composites. Carbohydr. Polym. 2019, 203, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Cai, C.L. The Friction and Wear Properties of ECP Surface-Treated Kevlar Fiber-Reinforced Thermoplastic Polymide Composites. Polym. -Plast. Technol. Eng. 2010, 49, 178–181. [Google Scholar] [CrossRef]

- Luo, N.; Xu, R.; Yang, M.; Yuan, X.; Zhong, H.; Fan, Y. Preparation and characterization of PVDF-glass fiber composite membrane reinforced by interfacial UV-grafting copolymerization. J. Environ. Sci. 2015, 38, 24–35. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.; Wang, Z.; Zhang, G.; Liu, S.-L.; Long, S.-R.; Yang, J.; Yang, J.-C.; Wang, X.-j. Improvement of interfacial interaction between poly(arylene sulfide sulfone) and carbon fiber via molecular chain grafting. Compos. Sci. Technol. 2022, 224, 1–13. [Google Scholar] [CrossRef]

- Panyasart, K.; Chaiyut, N.; Amornsakchai, T.; Santawitee, O. Effect of Surface Treatment on the Properties of Pineapple Leaf Fibers Reinforced Polyamide 6 Composites. Energy Procedia 2014, 56, 406–413. [Google Scholar] [CrossRef] [Green Version]

- Ray, R.; Narayan Das, S.; Das, A. Mechanical, thermal, moisture absorption and biodegradation behaviour of date palm leaf reinforced PVA/starch hybrid composites. Mater. Today Proc. 2021, 41, 376–381. [Google Scholar] [CrossRef]

- Tiwari, S.; Bijwe, J. Surface Treatment of Carbon Fibers—A Review. Procedia Technol. 2014, 14, 505–512. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Cheng, X.H. The effect of surface treatment of carbon fiber on the flexural property of thermoplastic polyimide composite. Compos. Interfaces 2012, 15, 515–526. [Google Scholar] [CrossRef]

- Cheng, X.H.; Shang-guan, Q.Q. Effect of rare earths on mechanical and tribological properties of carbon fibers reinforced PTFE composite. Tribol. Lett. 2006, 21, 153–160. [Google Scholar] [CrossRef]

- Xue, Y.-J.; Cheng, X.-H. Effect of rare earth elements’ surface treatment on tensile properties and microstructure of glass fiber-reinforced polytetrafluoroethylene composites. J. Appl. Polym. Sci. 2002, 86, 1667–1672. [Google Scholar] [CrossRef]

- Shi, Y.; Feng, X.; Wang, H.; Lu, X. Tribological properties of PTFE composites filled with surface-treated carbon fiber. J. Mater. Sci. 2007, 42, 8465–8469. [Google Scholar] [CrossRef]

- Chang, Q.; Zhao, H.; He, R. The mechanical properties of plasma-treated carbon fiber reinforced PA6 composites with CNT. Surf. Interface Anal. 2017, 49, 1244–1248. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, P.; Sun, B.; Lu, C.; Zhang, X.; Liu, D. Influence of oxygen plasma treatment on interfacial properties of poly(p-phenylene benzobisoxazole) fiber-reinforced poly(phthalazinone ether sulfone ketone) composite. J. Appl. Polym. Sci. 2009, 113, 71–77. [Google Scholar] [CrossRef]

- Lu, C.; Chen, P.; Yu, Q.; Ding, Z.; Lin, Z.; Li, W. Interfacial adhesion of plasma-treated carbon fiber/poly(phthalazinone ether sulfone ketone) composite. J. Appl. Polym. Sci. 2007, 106, 1733–1741. [Google Scholar] [CrossRef]

- Vinodhini, J.; Sudheendra, K.; Balachandran, M.; Bhowmik, S. Influence of argon plasma treatment on carbon fibre reinforced high performance thermoplastic composite. High Perform. Polym. 2020, 33, 285–294. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Paz, E.; Martínez, M.A. Influence of Low Pressure Plasma Treatment on the Durability of Thermoplastic Composites LDPE-flax/coconut under Thermal and Humidity Conditions. Fibers Polym. 2018, 19, 1327–1334. [Google Scholar] [CrossRef]

- Osbeck, S.; Bradley, R.H.; Liu, C.; Idriss, H.; Ward, S. Effect of an ultraviolet/ozone treatment on the surface texture and functional groups on polyacrylonitrile carbon fibres. Carbon 2011, 49, 4322–4330. [Google Scholar] [CrossRef]

- Hacioglu, F.; Tayfun, U.; Ozdemir, T.; Tincer, T. Characterization of carbon fiber and glass fiber reinforced polycarbonate composites and their behavior under gamma irradiation. Prog. Nucl. Energy 2021, 134, 1–14. [Google Scholar] [CrossRef]

- Shershneva, I.N.; Shershnev, V.A.; Bubnova, M.L.; Lesnichaya, V.A.; Kolesnikova, A.M.; Rabinskiy, L.N.; Kydralieva, K.A.; Dzhardimalieva, G.I. Fiber-Matrix-Coupling Agent Interactions in Glass-Fiber-Reinforced Polyethylene Composites Under Gamma Irradiation. Mech. Compos. Mater. 2019, 55, 597–606. [Google Scholar] [CrossRef]

- Gamze Karsli, N.; Aytac, A.; Akbulut, M.; Deniz, V.; Güven, O. Effects of irradiated polypropylene compatibilizer on the properties of short carbon fiber reinforced polypropylene composites. Radiat. Phys. Chem. 2013, 84, 74–78. [Google Scholar] [CrossRef]

- Gulati, K.; Lal, S.; Kumar, S.; Arora, S. Effect of gamma irradiation on thermal, mechanical and water absorption behavior of LLDPE hybrid composites reinforced with date pit (Phoenix dactylifera) and glass fiber. Polym. Bull. 2020, 78, 7019–7038. [Google Scholar] [CrossRef]

- Noura, H.; Amar, B.; Hocine, D.; Rabah, Y.; Stephane, C.; Roland, E.H.; Anne, B. Effect of gamma irradiation aging on mechanical and thermal properties of alfa fiber–reinforced polypropylene composites. J. Thermoplast. Compos. Mater. 2017, 31, 598–615. [Google Scholar] [CrossRef]

- Jung, S.; Park, S.K.; Ghim, H.-d.; Lee, D.Y.; Yoo, S.H. Synergetic effect of cross-linking and interfacial interaction in carbon fiber reinforced thermoplastic to enhance its tensile strength by electron-beam irradiation. Carbon Lett. 2019, 30, 165–175. [Google Scholar] [CrossRef]

- Park, S.K.; Choi, D.Y.; Choi, D.Y.; Lee, D.Y.; Yoo, S.H. Influences of Absorbed Dose Rate on the Mechanical Properties and Fiber-Matrix Interaction of High-Density Polyethylene-Based Carbon Fiber Reinforced Thermoplastic Irradiated by Electron-Beam. Polymers 2020, 12, 3012. [Google Scholar] [CrossRef]

- Kitagawa, S.; Kimura, H.; Uchida, H.T.; Faudree, M.C.; Kaneko, S.; Endoh, T.; Salvia, M.; Nishi, Y. A new strengthening process of thermoplastic polypropylene reinforced by interlayered activated sizing film-free carbon fiber treated by electron beam irradiation under oxygen-rich nitrogen gas prior to assembly and hot-press. J. Compos. Mater. 2021, 55, 2975–2983. [Google Scholar] [CrossRef]

- Kim, S.Y.; Gang, H.E.; Park, G.T.; Jeon, H.B.; Kim, H.B.; Oh, S.H.; Jeong, Y.G. Synergistic effect of polyurethane-coated carbon fiber and electron beam irradiation on the thermal/mechanical properties and long-term durability of polyamide-based thermoplastic composites. Polym. Compos. 2022, 43, 1685–1697. [Google Scholar] [CrossRef]

- Szabó, L.; Imanishi, S.; Tetsuo, F.; Nishio, M.; Hirose, D.; Tsukegi, T.; Taki, K.; Ninomiya, K.; Takahashi, K. Electron beam induced strengthening of a short carbon fiber reinforced green thermoplastic composite: Key factors determining materials performance. Compos. Part A Appl. Sci. Manuf. 2019, 121, 386–396. [Google Scholar] [CrossRef]

- Langston, T.A.; Granata, R.D. Influence of nitric acid treatment time on the mechanical and surface properties of high-strength carbon fibers. J. Compos. Mater. 2013, 48, 259–276. [Google Scholar] [CrossRef]

| Nanoparticle Inclusion Method | Specimen | % Of Improvement in | Ref. | ||||

|---|---|---|---|---|---|---|---|

| IFSS | ILSS | ILFT | Tensile Strength | Tensile Modulus | |||

| EPD | CF/MWCNT/PC | 68% | - | - | - | - | [10] |

| CF/CNT/PC | - | - | - | 47% | 58% | [14] | |

| MWCNT/PI | - | - | - | 14% | 50% | [9] | |

| CF/MWCNT/PPS | 42% | - | - | - | - | [13] | |

| CF/CNT/PPEK | 36% | - | - | - | - | [15] | |

| CVD | CF/CNT/PP | 35% | - | - | - | - | [18] |

| CF/CNT/PP | 35% | - | - | - | - | [18] | |

| CF/CNT/PA6 | 50% | - | - | - | - | [19] | |

| CF/CNT/PI | - | - | - | 30% | - | [17] | |

| Sizing with nanoparticles | CF/PEI+GO/PEEK | 44% | 12% | - | - | - | [26] |

| GF/MWCNTs/PPS | - | 23% | 25% Mode I | - | - | [36] | |

| CF/nano-silica/PEEK | - | 16% | - | - | - | [5] | |

| CF/PEI-ZIF 67/PEEK | 40.5% | - | - | - | - | [48] | |

| CF/PEI+GO/PP | 102% | - | - | 48% | - | [24] | |

| CF/Fe3O4-RGO/PI | - | 159% | - | - | - | [46] | |

| GF/MWCNT/EVA | 49% | - | - | - | - | [44] | |

| CF/MWCNT/PEEK | - | 55% | - | - | - | [47] | |

| CF/RGO/PA6 | - | 71% | - | - | - | [28] | |

| CF/s-PSF+GO/PEEK | - | 128% | - | - | - | [29] | |

| CF/GO+Fe3O4/PP | - | 32% | - | - | - | [33] | |

| CF/CNT/MPSR | - | 42% | - | - | - | [38] | |

| CF/PI+CNT/PEEK | - | 71% | - | - | - | [39] | |

| CF/HPEEK-g-MWCNT/PEEK | - | 55% | - | - | - | [47] | |

| CF/PEI+ZIF-67/PEEK | 41% | - | - | - | - | [48] | |

| CF/nano PEI/PVC | 21% | - | - | - | - | [49] | |

| CF/nano PEI/PC | 38% | - | - | - | - | ||

| CF/nano PEI/PA6 | 53% | - | - | - | - | ||

| CF/nano PEI/PP | 50% | - | - | - | - | ||

| CF/nano PEI/PA66 | 43% | - | - | - | - | ||

| CF/nano PEI/PEI | 58% | - | - | - | - | ||

| SCF/GO/PP | - | - | - | 94% | - | [30] | |

| SCF/TPI-GO/PEI | - | - | - | 13% | - | [31] | |

| LRGO+APP/TPU | - | - | - | 190% | - | [32] | |

| GF/MWCNT/PPS | - | - | - | 126% | - | [40] | |

| GF/PEI-CNT/PA6 | - | - | - | 7% | - | [41] | |

| Flax fibre/CNC/PP | 13% | - | - | - | - | [50] | |

| Flax fibre/CNC+XG/PP | 22% | - | - | - | - | ||

| Spray gun | CF/CNT/PEEK | - | 35.8% | - | - | - | [51] |

| BF/SiO2+PCL/PLA | - | - | 110% Mode I | 29% | - | [53] | |

| Chemically grafting | CF/MWCNTs/PA6 | - | 34% | - | [57] | ||

| CF/Silica/MPSR | - | 45.6% | - | [72] | |||

| WCF/ZnO NR+CNT/PA6 | - | - | - | 41% | 32% | [54] | |

| Flame synthesis | CF/CNT/PEI | 47% | - | - | [61] | ||

| SGF/CNT/PLA | - | - | - | 33% | 43% | [62] | |

| Nano modified monomer | CF/xGNP/PA6 | - | - | - | 18% | - | [63] |

| Nano inclusion in an extruder | GF/MWCNT/PP | - | - | - | 76% | 127% | [64] |

| CF/CNT/PP | 186% | - | - | 7% | 9% | [67] | |

| PA6 fibre/acid oxidized GNP | - | - | - | 76% | 70% | [68] | |

| Nanofiller Inclusion Method | Advantages | Disadvantages |

|---|---|---|

| Electrophoretic deposition (EPD) | Automated process suitable for large scale applications, it works well with electrically conductive fibre materials like carbon fibres. | The conducting current may damage fibres, non-uniform deposition and agglomeration of nanoparticles can occur, not suitable for electrically insulative fibres like glass and aramid. |

| Chemical vapor deposition (CVD) | Homogeneous thickness of nanoparticle deposition. | Expensive method suitable to process only small fibre surface area, catalyst contamination during processing and thermal damage to fibres can occur. |

| Direct immersion sizing (DIZ) | Simple and easy process suitable for processing large surface area of fibres. | Agglomeration and heterogeneous distribution of nanoparticles on fibre surface can occur. |

| Spray gun technology | Lesser void formation at the interfacial region, high matrix impregnation quality, nanoparticles can be deposited both at the surface and deep in between the fibres. | The coating thickness and uniform distribution of nanoparticles around the fibre surface is difficult to control. |

| Nanoparticle grafting | Chemical bond formation at the fibre matrix interface, high density of nanoparticles can be deposited on fibre surface. | Toxic chemicals are used, processing large fibre area and controlling the grafting density of nanoparticles is difficult. |

| Flame synthesis process | Longer and denser nanoparticles can be formed on fibre surface. | Toxic chemicals are heated while processing, Precise control of nanoparticle length is difficult. It is relatively new method which requires extensive optimization of processing parameters to synthesis CNTs on fibre surface. |

| Fibre Surface Treatment Method | Specimen | % Of Improvement in | Ref. | |||

|---|---|---|---|---|---|---|

| IFSS | ILSS | Tensile Strength | Tensile Modulus | |||

| Heat treatment | CF/PEEK | 15% | - | - | - | [77] |

| Fibre sizing | CF/PEKK/PEEK | - | 70% | - | - | [87] |

| CF/PEI/PEEK | 17% | 16% | - | - | [80] | |

| CF/SA-PI/PEEK | - | 24% | - | - | [83] | |

| CF/PA/Elium | 35% | - | - | - | [89] | |

| CF/PMMA colloid/PMMA | 64% | - | - | - | [91] | |

| CF/PPS-COOH/PPS | 28% | - | 15% | - | [93] | |

| CF/PU/PC | - | 25% | - | - | [88] | |

| CF/S-PEEK/PEEK | - | 46% | 11% | - | [81] | |

| GF/S-PEEK/PEEK | - | - | 21% | - | [82] | |

| CF/silane + PPS/PPS | - | - | 5% | - | [94] | |

| CF/PEI+PDA/PU | - | - | 39% | 59% | [95] | |

| CF/PA-SI/PEEK | 41% | - | - | - | [48] | |

| CF/PP colloid/PP | 300% | - | - | - | [92] | |

| CF/PP colloid/PA6 | 100% | - | - | - | [92] | |

| CF/An-biPEEK/PEEK | 138% | 67% | - | - | [84] | |

| CF/PEEK-NH2/PEEK | - | 43% | - | - | [85] | |

| Chemical grafting | CF/NH2-PASS/PASS | 28% | 72% | - | - | [99] |

| Chemical coating | Date palm leaf fibre/KOH+ Corn starch/PVA | - | - | 61% | - | [101] |

| Pineapple leaf fibre/alkaline/PA6 | - | - | 31% | 8% | [100] | |

| RES | GF/PTFE | - | - | 21% | - | [105] |

| plasma treatment | PBO/PPESK | - | 32% | - | - | [108] |

| CF/PPESK | - | 14% | - | - | [109] | |

| CF/PI | 21% | - | - | - | [76] | |

| CF/CNT/PA6 | - | - | 24% | - | [107] | |

| CF/PAEK | - | - | 10% | - | [110] | |

| Ozone treatment | CF/PI | - | - | 15% | - | [81] |

| Gamma irradiation | SCF/PP | - | - | 30% | - | [115] |

| PC | - | - | 4% | - | [113] | |

| GF/PC | - | - | 5% | - | ||

| CF/PC | - | - | 2% | - | ||

| GF/powdered date pit/LLDPE | - | - | 100% | - | [116] | |

| Electron beam irradiation | CF/HDPE | - | - | 28% | - | [118] |

| CF/cellulose propionate derived thermoplastic | - | - | 29% | - | [122] | |

| Fibre Surface Treatment Method | Advantages | Disadvantages |

|---|---|---|

Wet-chemical methods

| Direct chemical reaction resulting in a chemical bond formation between the functional groups of fibre surface and polymer matrix, large number of fibres can be processed, more suitable for industrial applications. | Toxic chemicals are involved in the chemical methods. Treating fibres using strong acids for prolonged duration can cause fibre damage. |

Dry-mechanical interlocking methods

| Increases surface roughness, surface tension and wettability of fibre surface, introduces oxygen-based functional groups on fibre surface supporting its bonding with polymer matrix. | Damages the fibre strength while increasing the surface roughness, processing large area of fibres can be difficult, radiation and high temperature hazards are major health risks while using this process. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Periasamy, K.; Kandare, E.; Das, R.; Darouie, M.; Khatibi, A.A. Interfacial Engineering Methods in Thermoplastic Composites: An Overview. Polymers 2023, 15, 415. https://doi.org/10.3390/polym15020415

Periasamy K, Kandare E, Das R, Darouie M, Khatibi AA. Interfacial Engineering Methods in Thermoplastic Composites: An Overview. Polymers. 2023; 15(2):415. https://doi.org/10.3390/polym15020415

Chicago/Turabian StylePeriasamy, Kailashbalan, Everson Kandare, Raj Das, Maryam Darouie, and Akbar A. Khatibi. 2023. "Interfacial Engineering Methods in Thermoplastic Composites: An Overview" Polymers 15, no. 2: 415. https://doi.org/10.3390/polym15020415