Biocomposites Based on Electrospun Fibers of Poly(3-hydroxybutyrate) and Nanoplatelets of Graphene Oxide: Thermal Characteristics and Segmental Dynamics at Hydrothermal and Ozonation Impact

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

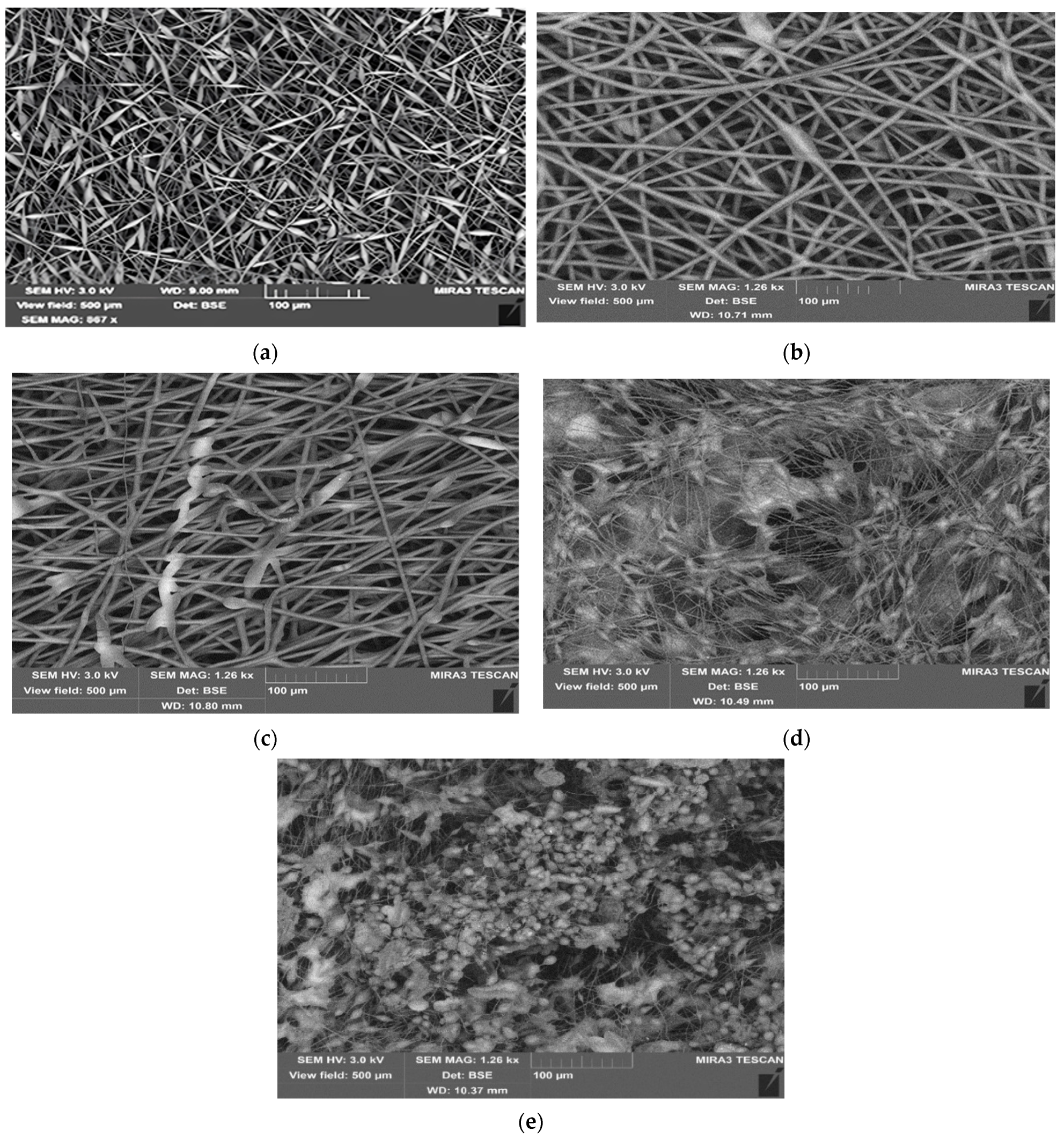

3.1. Influence of Graphene Oxide Concentration on the Morphology and Geometric Characteristics of the Fibrillar Composites

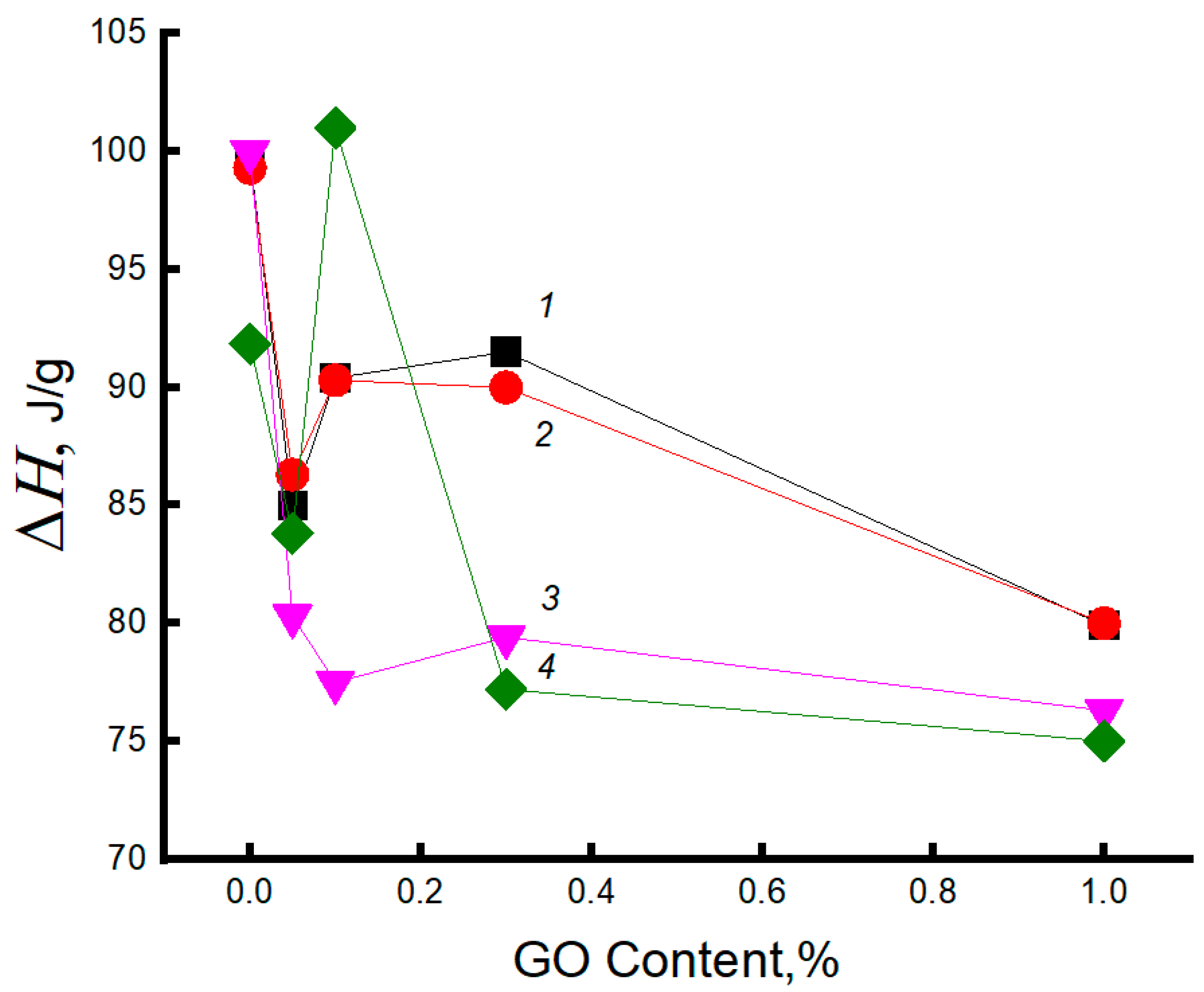

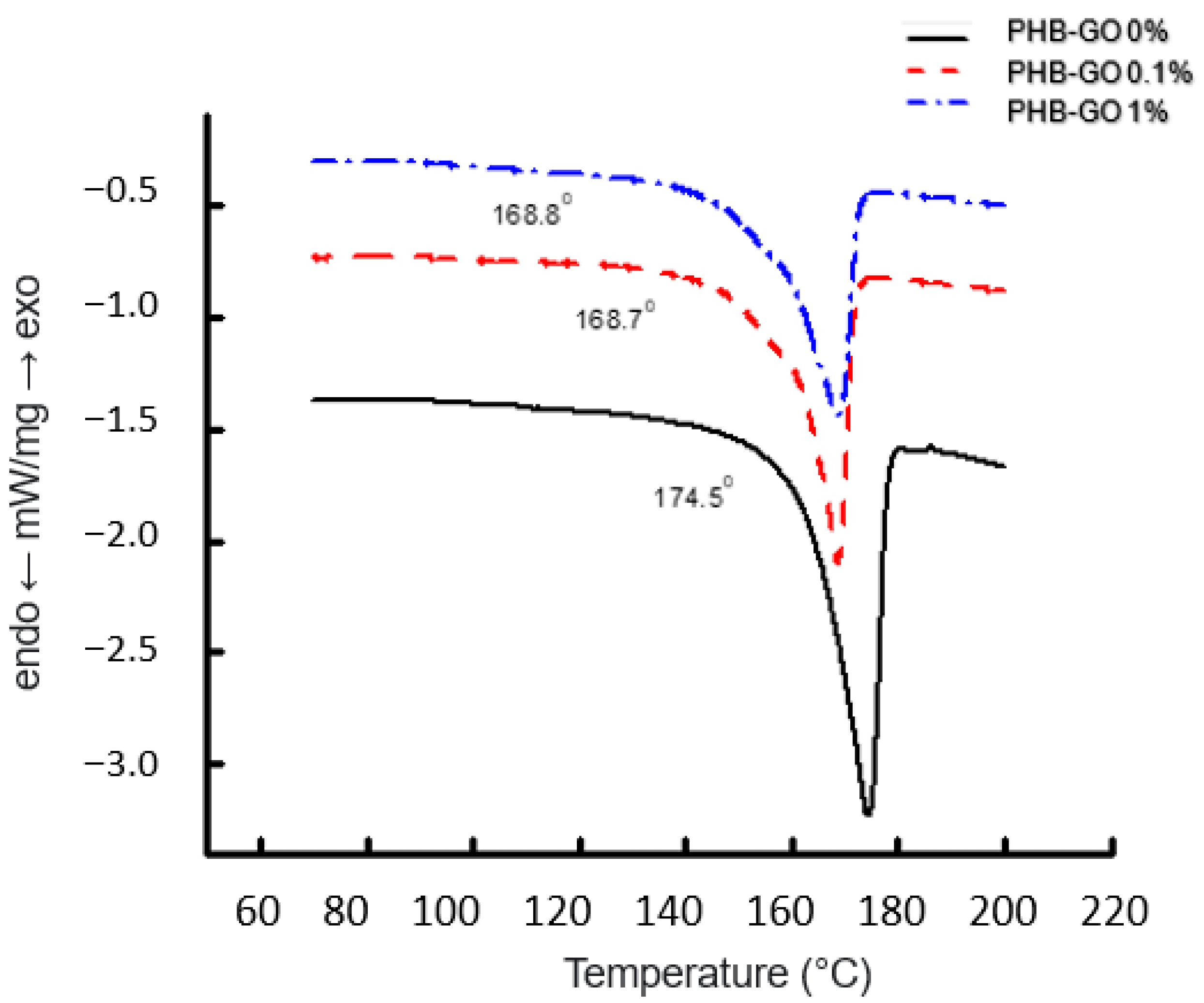

3.2. Thermal Characterization of the Crystalline Phase of PHB in Its Composites with GO

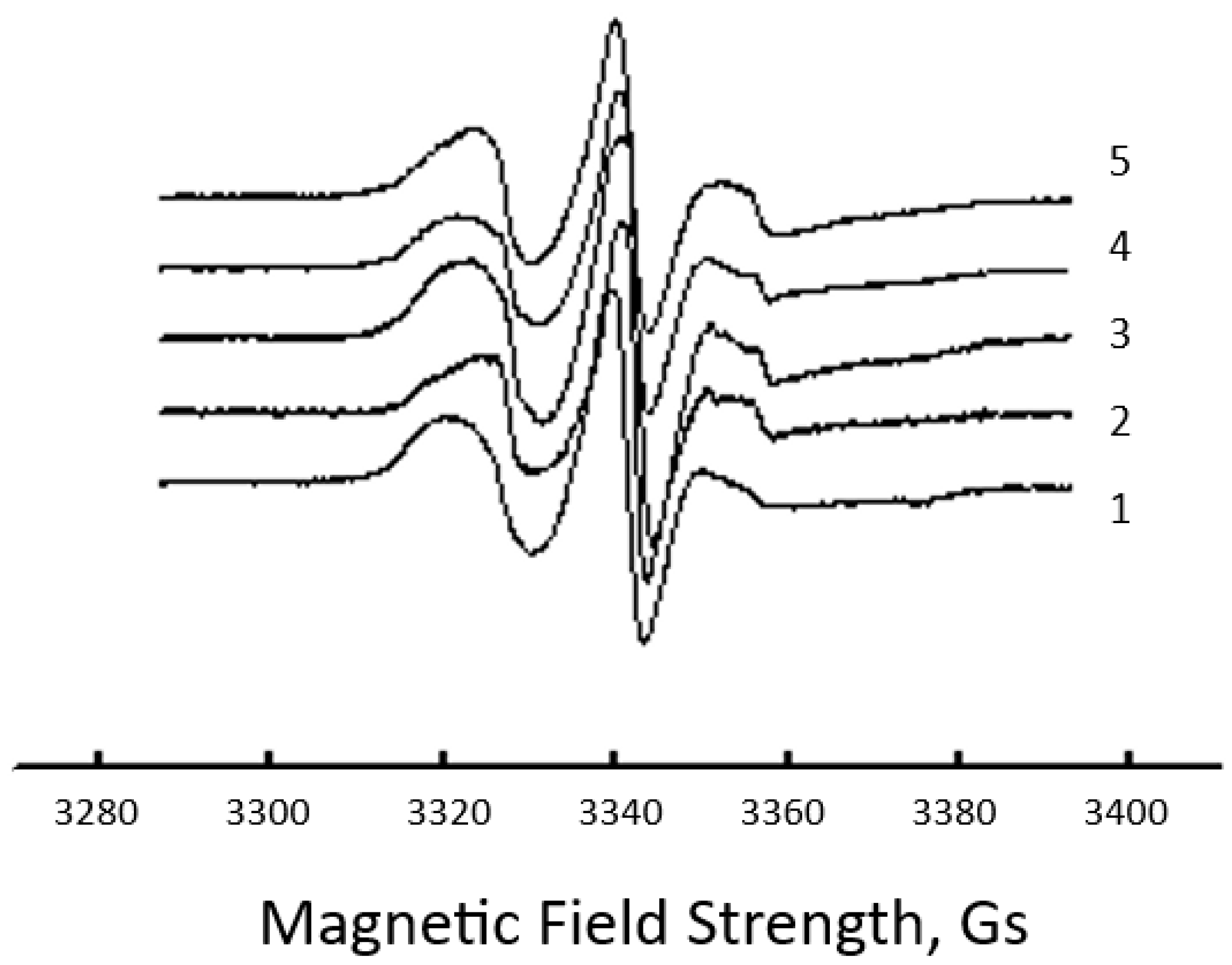

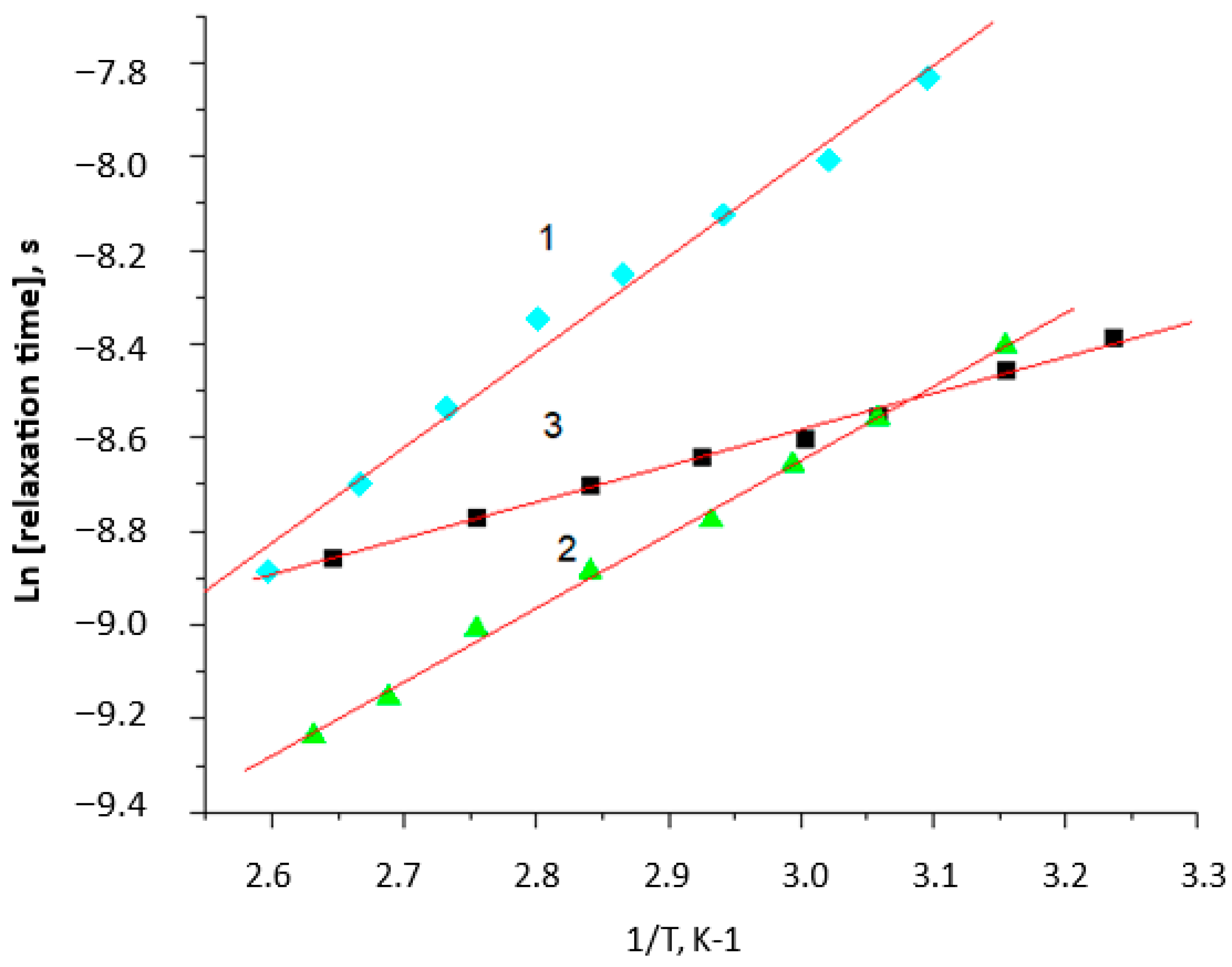

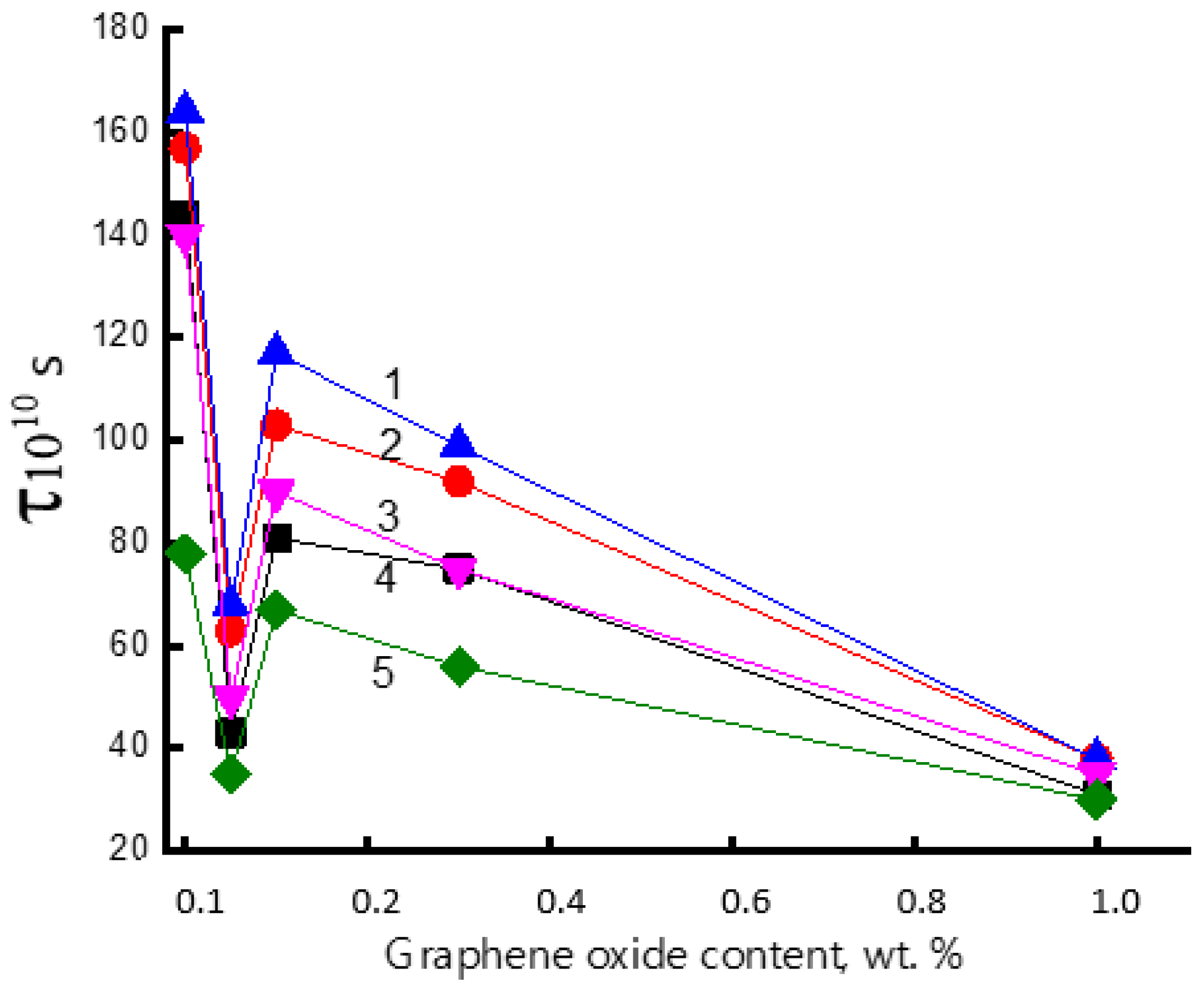

3.3. Segmental Dynamics of PHB–Graphene Oxide Biocomposites

3.4. Thermal Characteristics and Segmental Mobility in PHB–GO Composites under the Hydrothermal Effect

3.5. The Impact of Ozonolysis on the Dynamics of Radical Rotation in Fibers of PHB–Graphene Oxide Compositions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bosworth, L.A.; Turner, L.-A.; Cartmell, S.H. State of the art composites comprising electrospun fibres coupled with hydrogels: A review. Nanomed. Nanotechnol. Biol. Med. 2013, 9, 322–335. [Google Scholar] [CrossRef]

- Jayakumar, A.; Mathew, S.; Radoor, S.; Kim, J.T.; Rhim, J.-W.; Siengchin, S. Recent advances in two-dimensional nanomaterials: Properties, antimicrobial, and drug delivery application of nanocomposites. Mater. Today Chem. 2023, 30, 01492. [Google Scholar] [CrossRef]

- Ojijo, V.; Ray, S.S. Processing strategies in bionanocomposites. Prog. Polym. Sci. 2013, 38, 1543–1589. [Google Scholar] [CrossRef]

- Idumah, C.I.; Nwabanne, J.T.; Tanjung, F.A. Novel trends in poly (lactic) acid hybrid bionanocomposites. Clean. Mater. 2021, 2, 100022. [Google Scholar] [CrossRef]

- Zafar, R.; Zia, K.M.; Tabasum, S.; Jabeen, F.; Noreen, A.; Zuber, M. Polysaccharide based bionanocomposites, properties and applications: A review. Int. J. Biol. Macromol. 2016, 92, 1012–1024. [Google Scholar] [CrossRef]

- Anjum, M.N.; Malik, S.A.; Bilal, C.H.; Rashid, U.; Nasif, M.; Zia, K.M. Polyhydroxyalkanoates-based bionanocomposites. In Bionanocomposites Green Synthesis and Applications Micro and Nano Technologies; Zia, K.M., Jabeen, F., Anjum, M.N., Ikram, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; Volume 13, pp. 321–333. ISBN 978-0-12-816751-9. [Google Scholar] [CrossRef]

- Ansari, S.; Sami, N.; Yasin, D.; Ahmad, N.; Fatma, T. Biomedical applications of environmental friendly poly-hydroxyalkanoates. Int. J. Biol. Macromol. 2021, 183, 549–563. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, N. A tool for biomedical application: Synthesis and modification of polyhydroxyalkanoates. Sustain. Chem. Pharm. 2023, 32, 101041. [Google Scholar] [CrossRef]

- Briassoulis, D.; Tserotas, P.; Athanasoulia, I.-G. Alternative optimization routes for improving the performance of poly(3-hydroxybutyrate) (PHB) based plastics. J. Clean. Prod. 2021, 318, 128555. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L.; Raimo, M.; Cascone, E.; Martuscelli, E. Poly(3-hydroxybutyrate)-based copolymers and blends: Influence of a second component on crystallization and thermal behavior. J. Macromol. Sci. B 2001, 40, 639–667. [Google Scholar] [CrossRef]

- Bucci, D.; Tavares, L.; Sell, I. PHB packaging for the storage of food products. Polym. Test. 2005, 24, 564–571. [Google Scholar] [CrossRef]

- Martins, G.; Gogola, J.L.; Budni, L.H.; Papi, M.A.; Bom, M.A.; Budel, M.L.; de Souza, E.M.; Müller-Santos, M.; Beirão, B.C.; Banks, C.E.; et al. Novel approach based on GQD-PHB as anchoring platform for the development of SARS-CoV-2 electrochemical immunosensor. Anal. Chim. Acta 2022, 1232, 340442. [Google Scholar] [CrossRef]

- Villegas, M.; Cid, A.G.; Briones, C.A.; Romero, A.I.; Pistán, F.A.; Gonzo, E.E.; Gottifredi, J.C.; Bermúdez, J.M. Films based on the biopolymer poly(3-hydroxybutyrate) as platforms for the controlled release of dexamethasone. Saudi Pharm. J. 2019, 27, 694–701. [Google Scholar] [CrossRef]

- Novikov, L.N.; Novikova, L.N.; Mosahebi, A.; Wiberg, M.; Terenghi, G.; Kellerth, J.-O. Novel biodegradable implant for neuronal rescue and regeneration after spinal cord injury. Biomaterials 2002, 23, 3369–3376. [Google Scholar] [CrossRef] [PubMed]

- Yeo, J.C.C.; Muiruri, J.K.; Thitsartarn, W.; Li, Z.; He, C. Recent advances in the development of biodegradable PHB-based toughening materials: Approaches, advantages and applications. Mater. Sci. Eng. C 2018, 92, 1092–1116. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, D.; Quiles-Carrillo, L.; Balart, R.; Torres-Giner, S.; Arrieta, M.P. Innovative solutions and challenges to increase the use of Poly(3-hydroxybutyrate) in food packaging and disposables. Eur. Polym. J. 2022, 178, 111505. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H. Sustainable biobased composites for advanced applications: Recent trends and future opportunities—A critical review. Compos. Part C 2022, 7, 100220. [Google Scholar] [CrossRef]

- Panaitescu, D.M.; Frone, A.N.; Nicolae, C.-A.; Gabor, A.R.; Miu, D.M.; Soare, M.-G.; Vasile, B.S.; Lupescu, I. Poly(3-hydroxybutyrate) nanocomposites modified with even and odd chain length polyhydroxyalkanoates. Int. J. Biol. Macromol. 2023, 244, 125324. [Google Scholar] [CrossRef]

- D’amico, D.A.; Manfredi, L.B.; Cyras, V.P. Crystallization behavior of poly(3-hydroxybutyrate) nanocomposites based on modified clays: Effect of organic modifiers. Thermochim. Acta 2012, 544, 47–53. [Google Scholar] [CrossRef]

- Quispe, M.M.; Lopez, O.V.; Boina, D.A.; Stumbé, J.-F.; Villar, M.A. Glycerol-based additives of poly(3-hydroxybutyrate) films. Polym. Test. 2021, 93, 107005. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Arif, Z.U. Novel biopolymer-based sustainable composites for food packaging applications: A narrative review. Food Packag. Shelf Life 2022, 33, 100892. [Google Scholar] [CrossRef]

- Ray, S.S.; Banerjee, R. 13—Polylactide—Poly(hydroxyalkanoate) blends. In Sustainable Polylactide-Based Blends; Elsevier: Amsterdam, The Netherlands, 2022; Volume Ch13, pp. 271–289. [Google Scholar] [CrossRef]

- Valente, B.F.A.; Silvestre, A.J.D.; Neto, C.P.; Vilela, C.; Freire, C.S.R. Improving the Processability and Performance of Micronized Fiber-Reinforced Green Composites through the Use of Biobased Additives. Polymers 2022, 14, 3451. [Google Scholar] [CrossRef] [PubMed]

- Bandehali, S.; Sanaeepur, H.; Amooghin, A.E.; Shirazian, S.; Ramakrishna, S. Biodegradable polymers for membrane separation. Sep. Purif. Technol. 2021, 269, 118731. [Google Scholar] [CrossRef]

- Siracusa, V.; Karpova, S.; Olkhov, A.; Zhulkina, A.; Kosenko, R.; Iordanskii, A. Gas Transport Phenomena and Polymer Dynamics in PHB/PLA Blend Films as Potential Packaging Materials. Polymers 2020, 12, 647. [Google Scholar] [CrossRef] [PubMed]

- Wernert, V.; Coasne, B.; Levitz, P.; Nguyen, K.L.; Garcia, E.J.; Denoyel, R. Tortuosity of hierarchical porous materials: Diffusion experiments and random walk simulations. Chem. Eng. Sci. 2022, 264, 118136. [Google Scholar] [CrossRef]

- Khan, R.H.; Hazra, R.S.; Nair, G.; Mohammad, J.; Jiang, L.; Reindl, K.; Jawed, M.K.; Ganai, S.; Quadir, M. Cellulose nanofibers as Scaffold-forming materials for thin film drug delivery systems. Int. J. Pharm. 2022, 627, 122189. [Google Scholar] [CrossRef]

- Bychkova, A.V.; Iordanskii, A.L.; Kovarski, A.L.; Sorokina, O.N.; Kosenko, R.Y.; Markin, V.S.; Filatova, A.G.; Gumargalieva, K.Z.; Rogovina, S.Z.; Berlin, A.A. Magnetic and transport properties of magneto-anisotropic nanocomposites for controlled drug delivery. Nanotechnol. Russ. 2015, 10, 325–335. [Google Scholar] [CrossRef]

- Shanmugam, V.; Mensah, R.A.; Försth, M.; Sas, G.; Restás, A.; Addy, C.; Xu, Q.; Jiang, L.; Neisiany, R.E.; Singha, S.; et al. Circular economy in biocomposite development: State-of-the-art, challenges and emerging trends. Compos. Part C 2021, 5, 100138. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Shan, L.; Tan, C.; Shen, X.; Ramesh, S.; Zarei, M.; Kolahchi, R.; Hajmohammad, M. The effects of nano-additives on the mechanical, impact, vibration, and buckling/post-buckling properties of composites: A review. J. Mater. Res. Technol. 2023, 24, 7570–7598. [Google Scholar] [CrossRef]

- Kumar, P.C.M.; Ashok, R.B.; Kumar, M.; Roopa, C.P. Natural nano-fillers materials for the Bio-composites: A review. J. Indian Chem. Soc. 2022, 99, 100715. [Google Scholar] [CrossRef]

- Avcu, E.; Bastan, F.E.; Guney, M.; Avcu, Y.Y.; Rehman, M.A.U.; Boccaccini, A.R. Biodegradable Polymer Matrix Composites Containing Graphene-Related Materials for Antibacterial Applications: A Critical Review. Acta Biomater. 2022, 151, 1–44. [Google Scholar] [CrossRef] [PubMed]

- Chernozem, R.V.; Romanyuk, K.N.; Grubova, I.; Chernozem, P.V.; Surmeneva, M.A.; Mukhortova, Y.R.; Wilhelm, M.; Ludwig, T.; Mathur, S.; Kholkin, A.L.; et al. Enhanced piezoresponse and surface electric potential of hybrid biodegradable polyhydroxybutyrate scaffolds functionalized with reduced graphene oxide for tissue engineering. Nano Energy Part B 2021, 89, 06473. [Google Scholar] [CrossRef]

- Teixeira, S.C.; Gomes, N.O.; de Oliveira, T.V.; Fortes-Da-Silva, P.; Soares, N.d.F.F.; Raymundo-Pereira, P.A. Review and Perspectives of sustainable, biodegradable, eco-friendly and flexible electronic devices and (Bio)sensors. Biosens. Bioelectron. 2023, 14, 100371. [Google Scholar] [CrossRef]

- Hashem, A.H.; Hasanin, M.; Kamel, S.; Dacrory, S. A new approach for antimicrobial and antiviral activities of biocompatible nanocomposite based on cellulose, amino acid and graphene oxide. Colloids Surf. B Biointerfaces 2022, 209 Pt 1, 112172. [Google Scholar] [CrossRef]

- Homem, N.C.; Miranda, C.S.; Teixeira, M.O.; Domingues, J.M.; Seibert, D.; Antunes, J.C.; Amorim, M.T.P.; Felgueiras, H.P. Graphene oxide-based platforms for wound dressings and drug delivery systems: A 10 year overview. J. Drug Deliv. Sci. Technol. 2022, 78, 103992. [Google Scholar] [CrossRef]

- Chella, E.R.A.; Kumar, N.; Nadene, N. Curcumin and Gymnema sylvestre extract loaded graphene oxide-polyhydroxybutyrate-sodium alginate composite for diabetic wound regeneration. React. Funct. Polym. 2020, 154, 104671. [Google Scholar] [CrossRef]

- Mukhortova, Y.R.; Pryadko, A.S.; Chernozem, R.V.; Pariy, I.O.; Akoulina, E.A.; Demianova, I.V.; Zharkova, I.I.; Ivanov, Y.F.; Wagner, D.V.; Bonartsev, A.P.; et al. Fabrication and characterization of a magnetic biocomposite of magnetite nanoparticles and reduced graphene oxide for biomedical applications. Nano-Struct. Nano-Objects 2022, 29, 100843. [Google Scholar] [CrossRef]

- Hosseini, E.S.; Dervin, S.; Ganguly, P.; Dahiya, R. Biodegradable Materials for Sustainable Health Monitoring Devices. ACS Appl. Bio Mater. 2021, 4, 163–194. [Google Scholar] [CrossRef]

- Fu, X.; Lin, J.; Liang, Z.; Yao, R.; Wu, W.; Fang, Z.; Zou, W.; Wu, Z.; Ning, H.; Peng, J. Graphene oxide as a promising nanofiller for polymer composite. Surf. Interfaces 2023, 37, 102747. [Google Scholar] [CrossRef]

- Liu, F.; Zhang, L.; Wang, L.; Zhao, B.; Wu, W. Graphene Oxide for Electronics. In Oxide Electronics; Ray, A., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; Volume 1, pp. 1–19. ISBN 9781119529477. [Google Scholar] [CrossRef]

- Govindaraj, P.; Sokolova, A.; Salim, N.; Juodkazis, S.; Fuss, F.K.; Fox, B.; Hameed, N. Distribution states of graphene in polymer nanocomposites: A review. Compos. Part B Eng. 2021, 226, 109353. [Google Scholar] [CrossRef]

- Lu, X.; Munief, W.-M.; Heib, F.; Schmitt, M.; Britz, A.; Grandthyl, S.; Müller, F.; Neurohr, J.-U.; Jacobs, K.; Benia, H.M.; et al. Front-End-of-Line Integration of Graphene Oxide for Graphene-Based Electrical Platforms. Adv. Mater. Technol. 2018, 3, 1700318. [Google Scholar] [CrossRef]

- Wang, N.; Samani, M.K.; Li, H.; Dong, L.; Zhang, Z.; Su, P.; Chen, S.; Chen, J.; Huang, S.; Yuan, G.; et al. Tailoring the Thermal and Mechanical Properties of Graphene Film by Structural Engineering. Small 2018, 14, 1801346. [Google Scholar] [CrossRef]

- Xu, Y.; Li, Z.; Duan, W. Thermal and Thermoelectric Properties of Graphene. Special Issue: Graphene Research in China. Small 2014, 10, 2182–2199. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Klinowski, J.; Forster, M.; Lerf, A. A new structural model for graphite oxide. Chem. Phys. Lett. 1998, 287, 53–56. [Google Scholar] [CrossRef]

- Mohammed, S. Graphene oxide: A mini-review on the versatility and challenges as a membrane material for solvent-based separation. Chem. Eng. J. Adv. 2022, 12, 100392. [Google Scholar] [CrossRef]

- Ghamkhari, A.; Abbaspour-Ravasjani, S.; Talebi, M.; Hamishehkar, H.; Hamblin, M.R. Development of a graphene oxide-poly lactide nanocomposite as a Smart Drug Delivery System. Int. J. Biol. Macromol. 2020, 169, 521–531. [Google Scholar] [CrossRef] [PubMed]

- Azizi-Lalabadi, M.; Jafari, S.M. Bio-nanocomposites of graphene with biopolymers; fabrication, properties, and applications. Adv. Colloid Interface Sci. 2021, 292, 102416. [Google Scholar] [CrossRef]

- Deng, J.; You, Y.; Bustamante, H.; Sahajwalla, V.; Joshi, R.K. Mechanism of water transport in graphene oxide laminates. Chem. Sci. 2017, 8, 1701–1704. [Google Scholar] [CrossRef]

- Moghadam, F.; Zhai, M.; Zouaoui, T.; Li, K. Hybrid graphene oxide membranes with regulated water and ion permeation channels via functional materials. Curr. Opin. Chem. Eng. 2023, 40, 100907. [Google Scholar] [CrossRef]

- Mouhat, F.; Coudert, F.-X.; Bocquet, M.-L. Structure and chemistry of graphene oxide in liquid water from first principles. Nat. Commun. 2020, 11, 1566. [Google Scholar] [CrossRef]

- Austria, H.F.M.; Subrahmanya, T.M.; Setiawan, O.; Widakdo, J.; Chiao, Y.-H.; Hung, W.-S.; Wang, C.-F.; Hu, C.-C.; Lee, K.-R.; Lai, J.-Y. A review on the recent advancements in graphene-based membranes and their applications as stimuli-responsive separation materials. J. Mater. Chem. A Mater. 2021, 9, 21510–21531. [Google Scholar] [CrossRef]

- Idumah, C.I. Recent advances on graphene polymeric bionanoarchitectures for biomedicals. JCIS Open 2023, 9, 100070. [Google Scholar] [CrossRef]

- Tayouri, M.I.; Estaji, S.; Mousavi, S.R.; Khasraghi, S.S.; Jahanmardi, R.; Nouranian, S.; Arjmand, M.; Khonakdar, H.A. Degradation of polymer nanocomposites filled with graphene oxide and reduced graphene oxide nanoparticles: A review of current status. Polym. Degrad. Stab. 2022, 206, 110179. [Google Scholar] [CrossRef]

- Jing, X.; Qiu, Z. Effect of Low Thermally Reduced Graphene Loadings on the Crystallization Kinetics and Morphology of Biodegradable Poly(3-hydroxybutyrate). Ind. Eng. Chem. Res. 2012, 51, 13686–13691. [Google Scholar] [CrossRef]

- Beć, K.B.; Morisawa, Y.; Kobashi, K.; Grabska, J.; Tanabe, I.; Tanimura, E.; Sato, H.; Wójcik, M.J.; Ozaki, Y. Rydberg transitions as a probe for structural changes and phase transition at polymer surfaces: An ATR-FUV-DUV and quantum chemical study of poly(3-hydroxybutyrate) and its nanocomposite with graphene. Phys. Chem. Chem. Phys. 2018, 20, 8859–8873. [Google Scholar] [CrossRef] [PubMed]

- Manikandan, N.A.; Pakshirajan, K.; Pugazhenthi, G. Preparation and characterization of environmentally safe and highly biodegradable microbial polyhydroxybutyrate (PHB) based graphene nanocomposites for potential food packaging applications. Int. J. Biol. Macromol. 2020, 154, 866–877. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zeng, T.H.; Hofmann, M.; Burcombe, E.; Wei, J.; Jiang, R.; Kong, J.; Chen, Y. Antibacterial Activity of Graphite, Graphite Oxide, Graphene Oxide, and Reduced Graphene Oxide: Membrane and Oxidative Stress. ACS Nano 2011, 5, 6971–6980. [Google Scholar] [CrossRef] [PubMed]

- Cataldi, P.; Steiner, P.; Raine, T.; Lin, K.; Kocabas, C.; Young, R.J.; Bissett, M.; Kinloch, I.A.; Papageorgiou, D.G. Multifunctional Biocomposites Based on Polyhydroxyalkanoate and Graphene/Carbon Nanofiber Hybrids for Electrical and Thermal Applications. ACS Appl. Polym. Mater. 2020, 2, 3525–3534. [Google Scholar] [CrossRef]

- Chernozem, R.V.; Surmeneva, M.A.; Abalymov, A.A.; Parakhonskiy, B.V.; Rigole, P.; Coenye, T.; Surmenev, R.A.; Skirtach, A.G. Piezoelectric hybrid scaffolds mineralized with calcium carbonate for tissue engineering: Analysis of local enzyme and small-molecule drug delivery, cell response and antibacterial performance. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 122, 111909. [Google Scholar] [CrossRef]

- Pramanik, N.; Bhattacharya, S.; Rath, T.; De, J.; Adhikary, A.; Basu, R.K.; Kundu, P.P. Polyhydroxybutyrate-co-hydroxyvalerate copolymer modified graphite oxide based 3D scaffold for tissue engineering application. Mater. Sci. Eng. C 2019, 94, 534–546. [Google Scholar] [CrossRef] [PubMed]

- Kirkland, N.T.; Schiller, T.; Medhekar, N.; Birbilis, N. Exploring graphene as a corrosion protection barrier. Corros. Sci. 2012, 56, 1–4. [Google Scholar] [CrossRef]

- Chen, J.; Yao, B.; Li, C.; Shi, G. An improved Hummers method for eco-friendly synthesis of graphene oxide. Carbon 2013, 64, 225–229. [Google Scholar] [CrossRef]

- Asgharzadeh, H.; Sedigh, M. Synthesis and mechanical properties of Al matrix composites reinforced with few-layer graphene and graphene oxide. J. Alloy. Comp. 2017, 728, 47–62. [Google Scholar] [CrossRef]

- Alam, S.N.; Sharma, N.; Kumar, L. Synthesis of Graphene Oxide (GO) by Modified Hummers Method and Its Thermal Reduction to Obtain Reduced Graphene Oxide (rGO). Graphene 2017, 6, 1–18. [Google Scholar] [CrossRef]

- Zhang, K.; Monteiro, M.J.; Jia, Z. Stable organic radical polymers: Synthesis and applications. Polym. Chem. 2016, 7, 5589–5614. [Google Scholar] [CrossRef]

- Li, T.; Ding, X.; Tian, L.; Hu, J.; Yang, X.; Ramakrishna, S. The control of beads diameter of bead-on-string electrospun nanofibers and the corresponding release behaviors of embedded drugs. Mater. Sci. Eng. C 2017, 74, 471–477. [Google Scholar] [CrossRef]

- Shao, Z.; Kang, G.; Chen, H.; Jiang, J.; Wang, X.; Li, W.; Liu, Y.; Zheng, G. Preparation, characterization, and air filtration property of electrospun bimodal fibrous membrane based on low conductivity blended polymers solution. Mater. Today Commun. 2023, 34, 105014. [Google Scholar] [CrossRef]

- Shahdan, D.; Chen, R.S.; Ahmad, S. Optimization of graphene nanoplatelets dispersion and nano-filler loading in bio-based polymer nanocomposites based on tensile and thermogravimetry analysis. J. Mater. Res. Technol. 2021, 15, 1284–1299. [Google Scholar] [CrossRef]

- Trivedi, D.N.; Rachchh, N.V. Graphene and its application in thermoplastic polymers as nano-filler—A review. Polymer 2022, 240, 124486. [Google Scholar] [CrossRef]

- Roilo, D.; Patil, P.N.; Brusa, R.S.; Miotello, A.; Aghion, S.; Ferragut, R.; Checchetto, R. Polymer rigidification in graphene based nanocomposites: Gas barrier effects and free volume reduction. Polymer 2017, 121, 17–25. [Google Scholar] [CrossRef]

- Righetti, M.C.; Gazzano, M.; Delpouve, N.; Saiter, A. Contribution of the rigid amorphous fraction to physical ageing of semi-crystalline PLLA. Polymer 2017, 125, 241–253. [Google Scholar] [CrossRef]

- Klonos, P.; Terzopoulou, Z.; Koutsoumpis, S.; Zidropoulos, S.; Kripotou, S.; Papageorgiou, G.Z.; Bikiaris, D.N.; Kyritsis, A.; Pissis, P. Rigid amorphous fraction and segmental dynamics in nanocomposites based on poly(l–lactic acid) and nano-inclusions of 1–3D geometry studied by thermal and dielectric techniques. Eur. Polym. J. 2016, 82, 16–34. [Google Scholar] [CrossRef]

- Karpova, S.G.; Ol’khov, A.A.; Krivandin, A.V.; Shatalova, O.V.; Lobanov, A.V.; Popov, A.A.; Iordanskii, A.L. Effect of Zinc–Porphyrin Complex on the Structure and Properties of Poly(3-hydroxybutyrate) Ultrathin Fibers. Polym. Sci. Ser. A 2019, 61, 70–84. [Google Scholar] [CrossRef]

- Chernova, D.A.; Vorobiev, A.K. Molecular mobility of nitroxide spin probes in glassy polymers: Models of the complex motion of spin probes. J. Appl. Polym. Sci. 2011, 121, 102–110. [Google Scholar] [CrossRef]

- Buchachenko, A.L.; Vasserman, A.M. Stable Radicals; Khimiya: Moscow, Russia, 1973. [Google Scholar]

- Shiraishi, M.; Ikoma, T. Molecular spintronics. Phys. E Low-Dimens. Syst. Nanostruct. 2011, 43, 1295–1317. [Google Scholar] [CrossRef]

- Poole, R.J. The Deborah and Weissenberg numbers. Br. Soc.Rheol. Rheol. Bull. 2012, 53, 32–39. [Google Scholar]

- Nitta, K. On the Orientation-Induced Crystallization of Polymers. Polymers 2016, 8, 229. [Google Scholar] [CrossRef]

- Karpova, S.G.; Ol’khov, A.A.; Popov, A.A.; Zhul’kina, A.L.; Iordanskii, A.L. Analysis of the Structure of Ultrafine Fibers Based on Poly(3-hydroxybutyrate) and Polylactide: Effect of External Factors. Polym. Sci. Ser. A 2019, 61, 480–490. [Google Scholar] [CrossRef]

- Yang, H.; Sun, M.; Zhou, P. Investigation of water diffusion in poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) by generalized two-dimensional correlation ATR–FTIR spectroscopy. Polymer 2009, 50, 1533–1540. [Google Scholar] [CrossRef]

- Iordanskii, A.; Karpova, S.; Olkhov, A.; Borovikov, P.; Kildeeva, N.; Liu, Y. Structure-morphology impact upon segmental dynamics and diffusion in the biodegradable ultrafine fibers of polyhydroxybutyrate-polylactide blends. Eur. Polym. J. 2019, 117, 208–216. [Google Scholar] [CrossRef]

- Karpova, S.G.; Olkhov, A.A.; Popov, A.A.; Iordanskii, A.L.; Shilkina, N.G. Characteristics of the Parameters of Superfine Fibers of Poly(3-hydroxybutyrate) Modified with Tetraphenylporphyrin. Inorg. Mater. Appl. Res. 2021, 12, 44–54. [Google Scholar] [CrossRef]

- Olkhov, A.A.; Tyubaeva, P.M.; Vetcher, A.A.; Karpova, S.G.; Kurnosov, A.S.; Rogovina, S.Z.; Iordanskii, A.L.; Berlin, A.A. Aggressive Impacts Affecting the Biodegradable Ultrathin Fibers Based on Poly(3-Hydroxybutyrate), Polylactide and Their Blends: Water Sorption, Hydrolysis and Ozonolysis. Polymers 2021, 13, 941. [Google Scholar] [CrossRef] [PubMed]

- Saalmueller, J.W.; Long, H.W.; Volkmer, T.; Wiesner, U.; Maresch, G.G.; Spiess, H.W. Characterization of the motion of spin probes and spin labels in amorphous polymers with two-dimensional field-step ELDOR. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 1093–1104. [Google Scholar] [CrossRef]

- Karpova, S.G.; Ol’khov, A.A.; Zhul’kina, A.L.; Popov, A.A.; Iordanskii, A.L. Nonwoven Materials Based on Electrospun Ultrathin Fibers of Poly(3-hydroxybutyrate) and Complex Tin Chloride–Porphyrin. Polym. Sci. Ser. A 2021, 63, 369–381. [Google Scholar] [CrossRef]

- Tertyshnaya, Y.; Podzorova, M.; Moskovskiy, M. Impact of Water and UV Irradiation on Nonwoven Polylactide/Natural Rubber Fiber. Polymers 2021, 13, 461. [Google Scholar] [CrossRef] [PubMed]

- Tyubaeva, P.; Zykova, A.; Podmasteriev, V.; Olkhov, A.; Popov, A.; Iordanskii, A. The Investigation of the Structure and Properties of Ozone-Sterilized Nonwoven Biopolymer Materials for Medical Applications. Polymers 2021, 13, 1268. [Google Scholar] [CrossRef]

- Olkhov, A.A.; Mastalygina, E.E.; Ovchinnikov, V.A.; Kurnosov, A.S.; Popov, A.A.; Iordanskii, A.L. Biological and Oxidative Degradation of Ultrathin-Fibrous Nonwovens Based on Poly(lactic Acid)/Poly(3-Hydroxybutyrate) Blends. Int. J. Mol. Sci. 2023, 24, 7979. [Google Scholar] [CrossRef] [PubMed]

- Popov, A.A.; Rapoport, N.; Zaikov, G. Oxidation of Stressed Polymers; Gordon and Breach Science Publishers: Philadelphia, PA, USA, 1991; 335p, ISBN 2881247350/9782881247354. [Google Scholar]

| Initial | |||||

|---|---|---|---|---|---|

| PHB | PHB/0.05% | PHB/0.1% | PHB/0.3% | PHB/1% | |

| ΔH, J/g | 99.7 | 85 | 90.5 | 91 | 79.9 |

| Tm, °C | 172.4 | 167.6 | 165.5 | 167 | 164 |

| Ozonolysis for 6 h | |||||

| ΔH, J/g | 99 | 84.3 | 80.7 | 73.2 | 73 |

| Tm, °C | 175 | 155; 169 | 154; 168 | 155; 169 | 154; 169 |

| Exposure to water for 6 h | |||||

| ΔH, J/g | 99.97 | 84.3 | 77.5 | 84.4 | 76.35 |

| Tm, °C | 174.5 | 169 | 168.7 | 169 | 168.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karpova, S.G.; Olkhov, A.A.; Varyan, I.A.; Shilkina, N.G.; Berlin, A.A.; Popov, A.A.; Iordanskii, A.L. Biocomposites Based on Electrospun Fibers of Poly(3-hydroxybutyrate) and Nanoplatelets of Graphene Oxide: Thermal Characteristics and Segmental Dynamics at Hydrothermal and Ozonation Impact. Polymers 2023, 15, 4171. https://doi.org/10.3390/polym15204171

Karpova SG, Olkhov AA, Varyan IA, Shilkina NG, Berlin AA, Popov AA, Iordanskii AL. Biocomposites Based on Electrospun Fibers of Poly(3-hydroxybutyrate) and Nanoplatelets of Graphene Oxide: Thermal Characteristics and Segmental Dynamics at Hydrothermal and Ozonation Impact. Polymers. 2023; 15(20):4171. https://doi.org/10.3390/polym15204171

Chicago/Turabian StyleKarpova, Svetlana G., Anatoly A. Olkhov, Ivetta A. Varyan, Natalia G. Shilkina, Alexander A. Berlin, Anatoly A. Popov, and Alexey L. Iordanskii. 2023. "Biocomposites Based on Electrospun Fibers of Poly(3-hydroxybutyrate) and Nanoplatelets of Graphene Oxide: Thermal Characteristics and Segmental Dynamics at Hydrothermal and Ozonation Impact" Polymers 15, no. 20: 4171. https://doi.org/10.3390/polym15204171

APA StyleKarpova, S. G., Olkhov, A. A., Varyan, I. A., Shilkina, N. G., Berlin, A. A., Popov, A. A., & Iordanskii, A. L. (2023). Biocomposites Based on Electrospun Fibers of Poly(3-hydroxybutyrate) and Nanoplatelets of Graphene Oxide: Thermal Characteristics and Segmental Dynamics at Hydrothermal and Ozonation Impact. Polymers, 15(20), 4171. https://doi.org/10.3390/polym15204171