Enhancing Stiffness and Oil Resistance of Fluorosilicone Rubber Composites through Untreated Cellulose Reinforcement

Abstract

:1. Introduction

2. Materials and Methods

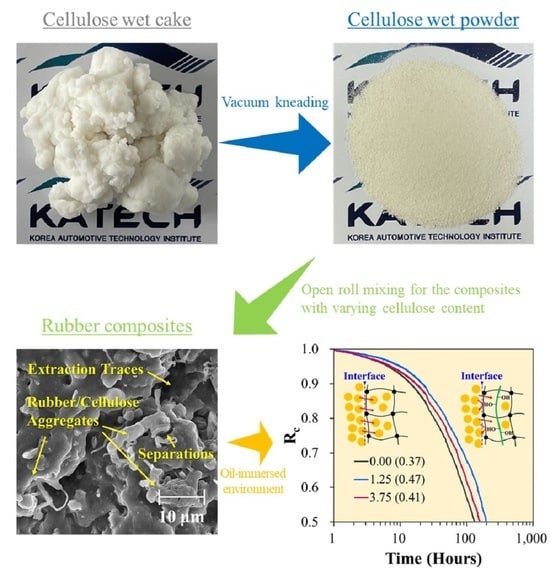

2.1. Preparation of Fibrillated Cellulose

2.2. Sample Preparation

2.3. Testing Procedures

2.3.1. Tensile Testing

2.3.2. Compression Testing

2.3.3. Compressive Stress-Relaxation Testing

3. Results and Discussion

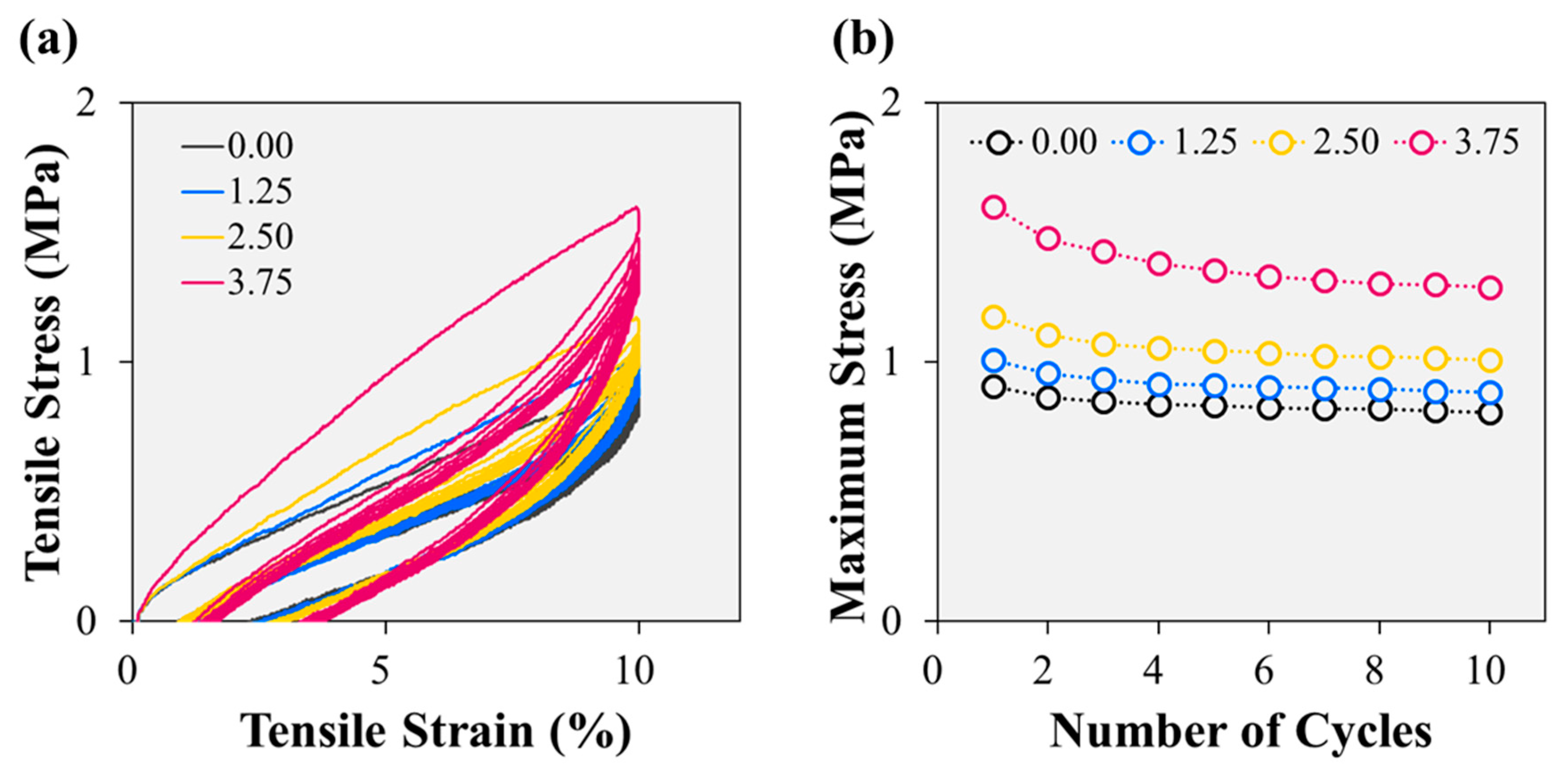

3.1. Enhancement of Mechanical Properties

3.1.1. Tensile Properties

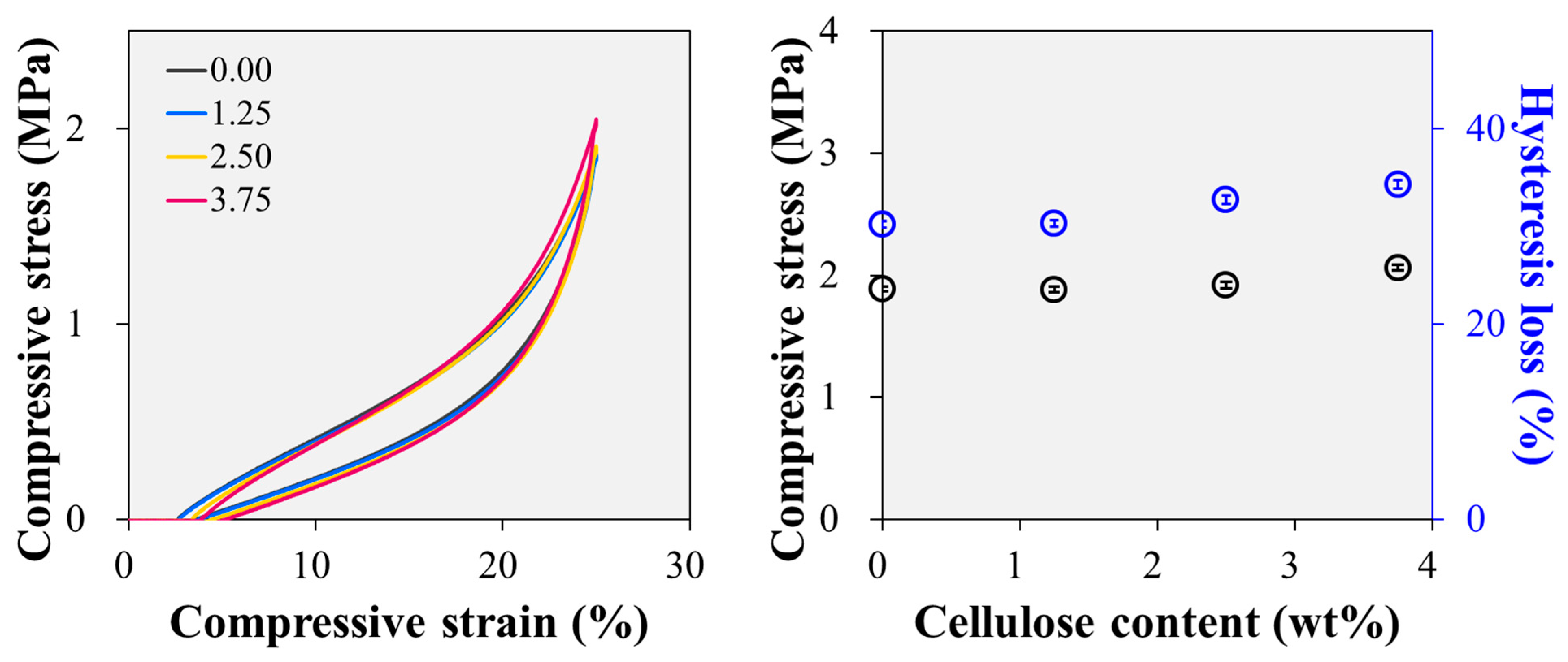

3.1.2. Compression Strength

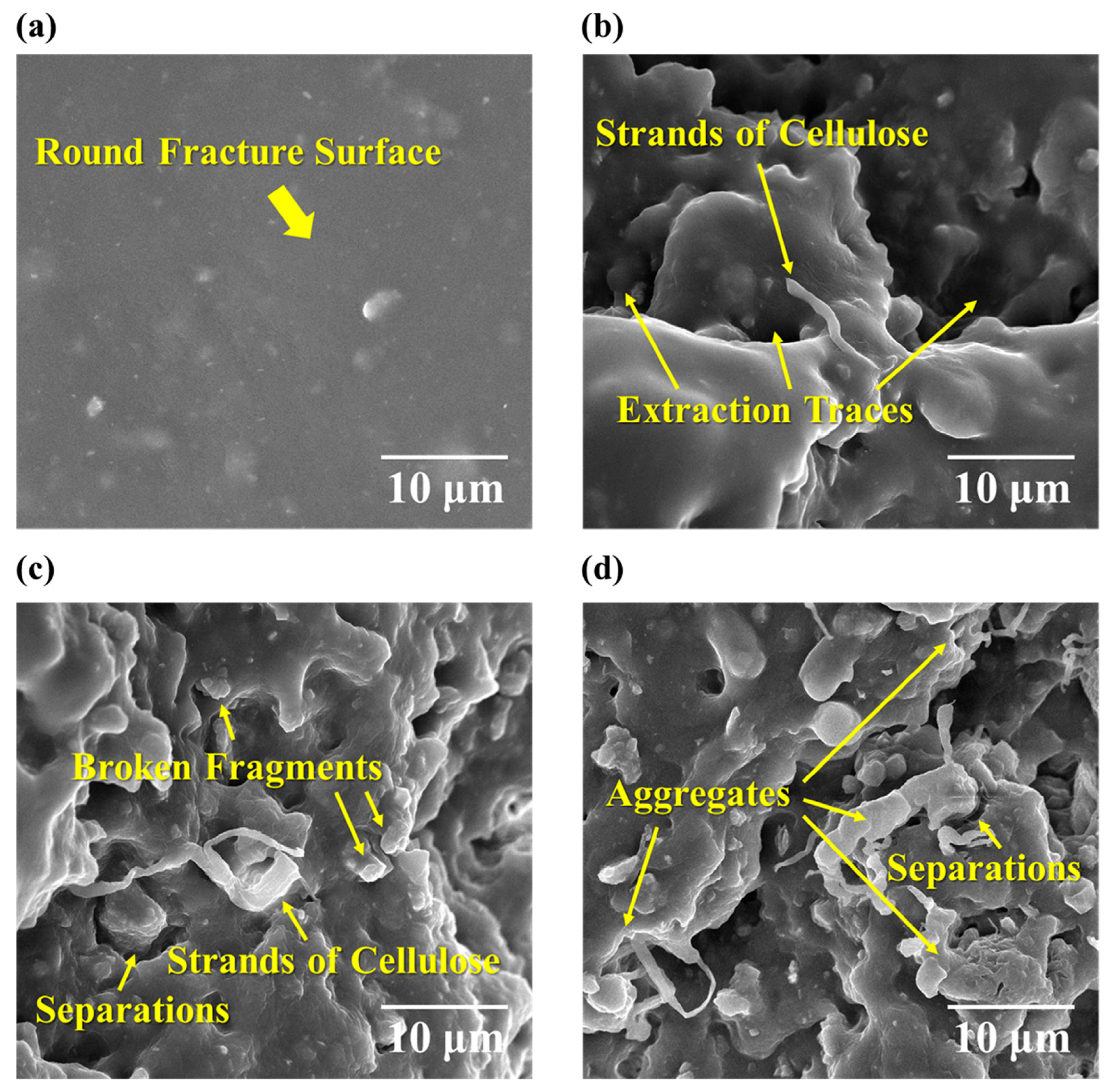

3.2. Morphological Analysis of Fracture Surfaces

3.3. Oil Resistance

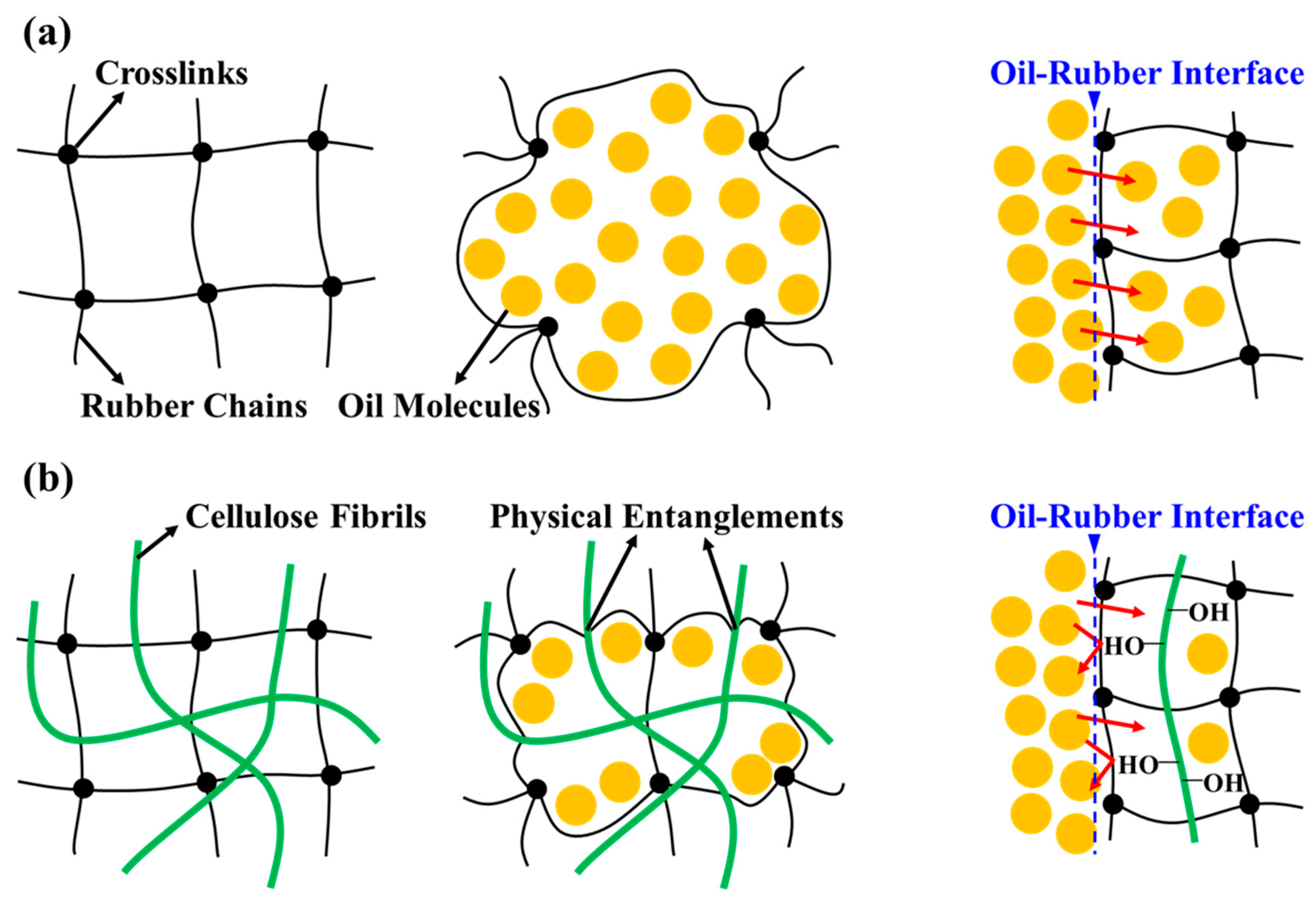

3.4. Mechanistic Insights for Probing Mechanisms

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Lin, Y.; Li, Z.; Yang, Y.; Lin, J.; He, S. Effect of fluorosilicone rubber on mechanical properties, dielectric breakdown strength and hydrophobicity of methyl vinyl silicone rubber. Polymers 2023, 15, 3448. [Google Scholar] [CrossRef]

- Qi, M.; Jia, X.; Wang, G.; Xu, Z.; Zhang, Y.; He, Q. Research on high temperature friction properties of PTFE/fluorosilicone rubber/silicone rubber. Polym. Test. 2020, 91, 106817. [Google Scholar] [CrossRef]

- Zhao, R.; Yin, Z.; Zou, W.; Yang, H.; Yan, J.; Zheng, W.; Li, H. Preparation of high-strength and excellent compatibility fluorine/silicone rubber composites under the synergistic effect of fillers. ACS Omega 2023, 8, 3905–3916. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Liu, J.; Chen, P.; Wei, D.; Guan, Y.; Lu, X.; Xiao, H. The effect of ceria nanoparticles on improving heat resistant properties of fluorosilicone rubber. J. Appl. Polym. Sci. 2016, 133, 44117. [Google Scholar] [CrossRef]

- Iz, M.; Lee, J.; Choi, M.; Yun, Y.; Kang, H.; Kim, J.; Bae, J. The effect of fumed silica loading on the thermal stability of fluorosilicone composites. Elastomers Compos. 2022, 57, 165–174. [Google Scholar]

- Abdul Salim, Z.A.S.; Hassan, A.; Ismail, H. A review on hybrid fillers in rubber composites. Polym. Plast. Technol. Eng. 2018, 57, 523–539. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A critical review on the utilization of various reinforcement modifiers in filled rubber composites. J. Elastomers Plast. 2020, 52, 167–193. [Google Scholar] [CrossRef]

- Mohamad Aini, N.A.; Othman, N.; Hussin, M.H.; Sahakaro, K.; Hayeemasae, N. Lignin as alternative reinforcing filler in the rubber industry: A review. Front. Mater. 2020, 6, 329. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A review on recent trends and future prospects of lignin based green rubber composites. J. Polym. Environ. 2020, 28, 367–387. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Pongwisuthiruchte, A.; Potiyaraj, P. Up-to-date review on the development of high performance rubber composites based on halloysite nanotube. Appl. Clay Sci. 2019, 183, 105300. [Google Scholar] [CrossRef]

- Barrera, C.S.; Cornish, K. High performance waste-derived filler/carbon black reinforced guayule natural rubber composites. Ind. Crops Prod. 2016, 86, 132–142. [Google Scholar] [CrossRef]

- Tyagi, U.; Anand, N. Facile depolymerization of microcrystalline cellulose in ionic liquid medium catalyzed by carbon materials as catalysts. Curr. Res. Green Sustain. Chem. 2021, 4, 100068. [Google Scholar] [CrossRef]

- Zainal, S.H.; Mohd, N.H.; Suhaili, N.; Anuar, F.H.; Lazim, A.M.; Othaman, R. Preparation of cellulose-based hydrogel: A review. J. Mater. Res. Technol. 2021, 10, 935–952. [Google Scholar] [CrossRef]

- Pérez-Madrigal, M.M.; Edo, M.G.; Alemán, C. Powering the future: Application of cellulose-based materials for supercapacitors. Green Chem. 2016, 18, 5930–5956. [Google Scholar] [CrossRef]

- Jiang, W.; Shen, P.; Yi, J.; Li, L.; Wu, C.; Gu, J. Surface modification of nanocrystalline cellulose and its application in natural rubber composites. J. Appl. Polym. Sci. 2020, 137, e49163. [Google Scholar] [CrossRef]

- Li, X.; Wu, Q.; Zheng, M.; Li, Q.; Wang, S.; Zhang, C. Mechanical, thermal properties and curing kinetics of liquid silicone rubber filled with cellulose nanocrystal. Cellulose 2018, 25, 473–483. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, M.; Chen, L.; Zhuang, J. Lignocellulosic fiber mediated rubber composites: An overview. Compos. B. Eng. 2015, 76, 180–191. [Google Scholar] [CrossRef]

- Sinclair, A.; Zhou, X.; Tangpong, S.; Bajwa, D.S.; Quadir, M.; Jiang, L. High-performance styrene-butadiene rubber nanocomposites reinforced by surface-modified cellulose nanofibers. ACS Omega 2019, 4, 13189–13199. [Google Scholar] [CrossRef]

- Low, D.Y.S.; Supramaniam, J.; Soottitantawat, A.; Charinpanitkul, T.; Tanthapanichakoon, W.; Tan, K.W.; Tang, S.Y. Recent developments in nanocellulose-reinforced rubber matrix composites: A review. Polymers 2021, 13, 550. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From fundamentals to advanced applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef]

- Patel, D.K.; Dutta, S.D.; Lim, K.T. Nanocellulose-based polymer hybrids and their emerging applications in biomedical engineering and water purification. RSC Adv. 2019, 9, 19143–19162. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.-Y.; Aitomäki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the use of nanocellulose as reinforcement in polymer matrix composites. Compos. Sci. Technol. 2014, 105, 15–27. [Google Scholar] [CrossRef]

- Zinge, C.; Kandasubramanian, B. Nanocellulose based biodegradable polymers. Eur. Polym. J. 2020, 133, 109758. [Google Scholar] [CrossRef]

- Dominic, M.; Joseph, R.; Sabura Begum, P.M.; Kanoth, B.P.; Chandra, J.; Thomas, S. Green tire technology: Effect of rice husk derived nanocellulose (RHNC) in replacing carbon black (CB) in natural rubber (NR) compounding. Carbohydr. Polym. 2020, 230, 115620. [Google Scholar] [CrossRef] [PubMed]

- Qu, L.; Wang, L.; Xie, X.; Yu, G.; Bu, S. Contribution of silica–rubber interactions on the viscoelastic behaviors of modified solution polymerized styrene butadiene rubbers (M-S-SBRs) filled with silica. RSC Adv. 2014, 4, 64354–64363. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, J. Excellent chemical and material cellulose from tunicates: Diversity in cellulose production yield and chemical and morphological structures from different tunicate species. Cellulose 2014, 21, 3427–3441. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Ariffin, H.; Norrrahim, M.N.F.; Hassan, M.A.; Andou, Y.; Tsukegi, T.; Nishida, H. Well-dispersed cellulose nanofiber in low density polyethylene nanocomposite by liquid-assisted extrusion. Polymers 2020, 12, 927. [Google Scholar] [CrossRef]

- ISO 37:2017; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/68116.html (accessed on 30 October 2023).

- ISO 7743:2017; Rubber, Vulcanized or Thermoplastic—Determination of Compression Stress-Strain Properties. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/72784.html (accessed on 30 October 2023).

- ISO 3384:2019; Rubber, Vulcanized or Thermoplastic—Determination of Stress Relaxation in Compression. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/72787.html (accessed on 30 October 2023).

- Oksman, K.; Aitomäki, Y.; Mathew, A.P.; Siqueira, G.; Zhou, Q.; Butylina, S.; Tanpichai, S.; Zhou, X.; Hooshmand, S. Review of the recent developments in cellulose nanocomposite processing. Compos. A 2016, 83, 2–18. [Google Scholar] [CrossRef]

- Soulestin, J.; Quiévy, N.; Sclavons, M.; Devaux, J. Polyolefins–biofibre composites: A new way for an industrial production. Polym. Eng. Sci. 2007, 47, 467–476. [Google Scholar] [CrossRef]

- Herrera, N.; Mathew, A.P.; Oksman, K. Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: Mechanical, thermal and optical properties. Compos. Sci. Technol. 2015, 106, 149–155. [Google Scholar] [CrossRef]

- Favier, V.; Cavaille, J.Y.; Canova, G.R.; Shrivastava, S.C. Mechanical percolation in cellulose whisker nanocomposites. Polym. Eng. Sci. 1997, 37, 1732–1739. [Google Scholar] [CrossRef]

- Efendy, M.G.A.; Pickering, K.L. Fibre orientation of novel dynamically sheet formed discontinuous natural fibre PLA composites. Compos. A 2016, 90, 82–89. [Google Scholar] [CrossRef]

- Yang, T.T.; Shui, Y.; Wei, C.S.; Huang, L.Z.; Yang, C.W.; Sun, G.A.; Han, J.J.; Xu, J.Z.; Li, Z.M.; Liu, D. Effect of cyclic straining with various rates on stress softening/hysteresis and structural evolution of filled rubber: A time-resolved sans study. Compos. B. Eng. 2022, 242, 110100. [Google Scholar] [CrossRef]

- Mullins, L.; Tobin, N.R. Stress softening in rubber vulcanizates. Part I. Use of a strain amplification factor to describe the elastic behavior of filler-reinforced vulcanized rubber. J. Appl. Polym. Sci. 1965, 9, 2993–3009. [Google Scholar] [CrossRef]

- Zhang, C.; Gou, X.; Xiao, R. Hysteresis in glass microsphere filled elastomers under cyclic loading. Polym. Test. 2021, 95, 107081. [Google Scholar] [CrossRef]

- Zaghdoudi, M.; Kömmling, A.; Jaunich, M.; Wolff, D. Erroneous or arrhenius: A degradation rate-based model for EPDM during homogeneous ageing. Polymers 2020, 12, 2152. [Google Scholar] [CrossRef] [PubMed]

- Obaid, N.; Kortschot, M.T.; Sain, M. Understanding the stress relaxation behavior of polymers reinforced with short elastic fibers. Materials 2017, 10, 472. [Google Scholar] [CrossRef] [PubMed]

- Kutty, S.K.N.; Nando, G.B. Short Kevlar fiber-thermoplastic polyurethane composite. J. Appl. Polym. Sci. 1991, 43, 1913–1923. [Google Scholar] [CrossRef]

- Suhara, F.; Kutty, S.K.N.; Nando, G.B. Stress relaxation of polyester fiber-polyurethane elastomer composite with different interfacial bonding agents. J. Elastomers Plast. 1998, 30, 103–117. [Google Scholar] [CrossRef]

- Pothan, L.A.; Neelakantan, N.R.; Rao, B.; Thomas, S. Stress relaxation behavior of banana fiber-reinforced polyester composites. J. Reinf. Plast. Compos. 2004, 23, 153–165. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Manikath, J.; Jayaraman, K. Stress relaxation of woodfiber-thermoplastic composites. J. Appl. Polym. Sci. 2006, 102, 401–407. [Google Scholar] [CrossRef]

- Saeed, U.; Hussain, K.; Rizvi, G. HDPE reinforced with glass fibers: Rheology, tensile properties, stress relaxation, and orientation of fibers. Polym. Compos. 2014, 35, 2159–2169. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, J.; Zhu, L.; Zhao, G. Interfacial compatibility of wood flour/polypropylene composites by stress relaxation method. J. Appl. Polym. Sci. 2012, 126, 89–95. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Joseph, R.; Thomas, S. Stress-relaxation behavior in composites based on short oil-palm fibres and phenol formaldehyde resins. Compos. Sci. Technol. 2001, 61, 1175–1188. [Google Scholar] [CrossRef]

- Stan, F.; Fetecau, C. Study of stress relaxation in polytetrafluoroethylene composites by cylindrical macroindentation. Compos. B. Eng. 2013, 47, 298–307. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S.; Bhagawan, S.S.; Neelakantan, N.R. Stress relaxation behavior of short pineapple fiber reinforced polyethylene composites. J. Reinf. Plast. Compos. 1998, 17, 651–672. [Google Scholar] [CrossRef]

- Geethamma, V.G.; Pothen, L.A.; Rhao, B.; Neelakantan, N.R.; Thomas, S. Tensile stress relaxation of short-coir-fiber-reinforced natural rubber composites. J. Appl. Polym. Sci. 2004, 94, 96–104. [Google Scholar] [CrossRef]

- Mirzaei, B.; Tajvidi, M.; Falk, R.H.; Felton, C. Stress-relaxation behavior of lignocellulosic high-density polyethylene composites. J. Reinf. Plast. Compos. 2011, 30, 875–881. [Google Scholar] [CrossRef]

- Chai, A.B.; Andriyana, A.; Verron, E.; Johan, M.R. Mechanical characteristics of swollen elastomers under cyclic loading. Mater. Des. 2013, 44, 566–572. [Google Scholar] [CrossRef]

- Jankauskaitė, V.; Abzalbekuly, B.; Lisauskaitė, A.; Procyčevas, I.; Fataraitė, E.; Vitkauskienė, A.; Janakhmetov, U. Silicone rubber and microcrystalline cellulose composites with antimicrobial properties. Mater. Sci. 2014, 20, 42–49. [Google Scholar] [CrossRef]

- George, S.C.; Knörgen, M.; Thomas, S. Effect of nature and extent of crosslinking on swelling and mechanical behavior of styrene-butadiene rubber membranes. J. Membr. Sci. 1999, 163, 1–17. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, Y.-W.; Yoon, J.-H.; Shin, K.-H.; Cho, Y.-J.; Yun, J.-H.; Han, W.-H.; Hong, M.-H.; Kang, D.-G.; Kim, H.-Y. Enhancing Stiffness and Oil Resistance of Fluorosilicone Rubber Composites through Untreated Cellulose Reinforcement. Polymers 2023, 15, 4489. https://doi.org/10.3390/polym15234489

Park Y-W, Yoon J-H, Shin K-H, Cho Y-J, Yun J-H, Han W-H, Hong M-H, Kang D-G, Kim H-Y. Enhancing Stiffness and Oil Resistance of Fluorosilicone Rubber Composites through Untreated Cellulose Reinforcement. Polymers. 2023; 15(23):4489. https://doi.org/10.3390/polym15234489

Chicago/Turabian StylePark, Ye-Won, Jeong-Hwan Yoon, Kyoung-Ho Shin, Yeon-Jee Cho, Ju-Ho Yun, Won-Hee Han, Min-Hyuk Hong, Dong-Gug Kang, and Hye-Young Kim. 2023. "Enhancing Stiffness and Oil Resistance of Fluorosilicone Rubber Composites through Untreated Cellulose Reinforcement" Polymers 15, no. 23: 4489. https://doi.org/10.3390/polym15234489

APA StylePark, Y.-W., Yoon, J.-H., Shin, K.-H., Cho, Y.-J., Yun, J.-H., Han, W.-H., Hong, M.-H., Kang, D.-G., & Kim, H.-Y. (2023). Enhancing Stiffness and Oil Resistance of Fluorosilicone Rubber Composites through Untreated Cellulose Reinforcement. Polymers, 15(23), 4489. https://doi.org/10.3390/polym15234489