Geopolymer Materials for Extrusion-Based 3D-Printing: A Review

Abstract

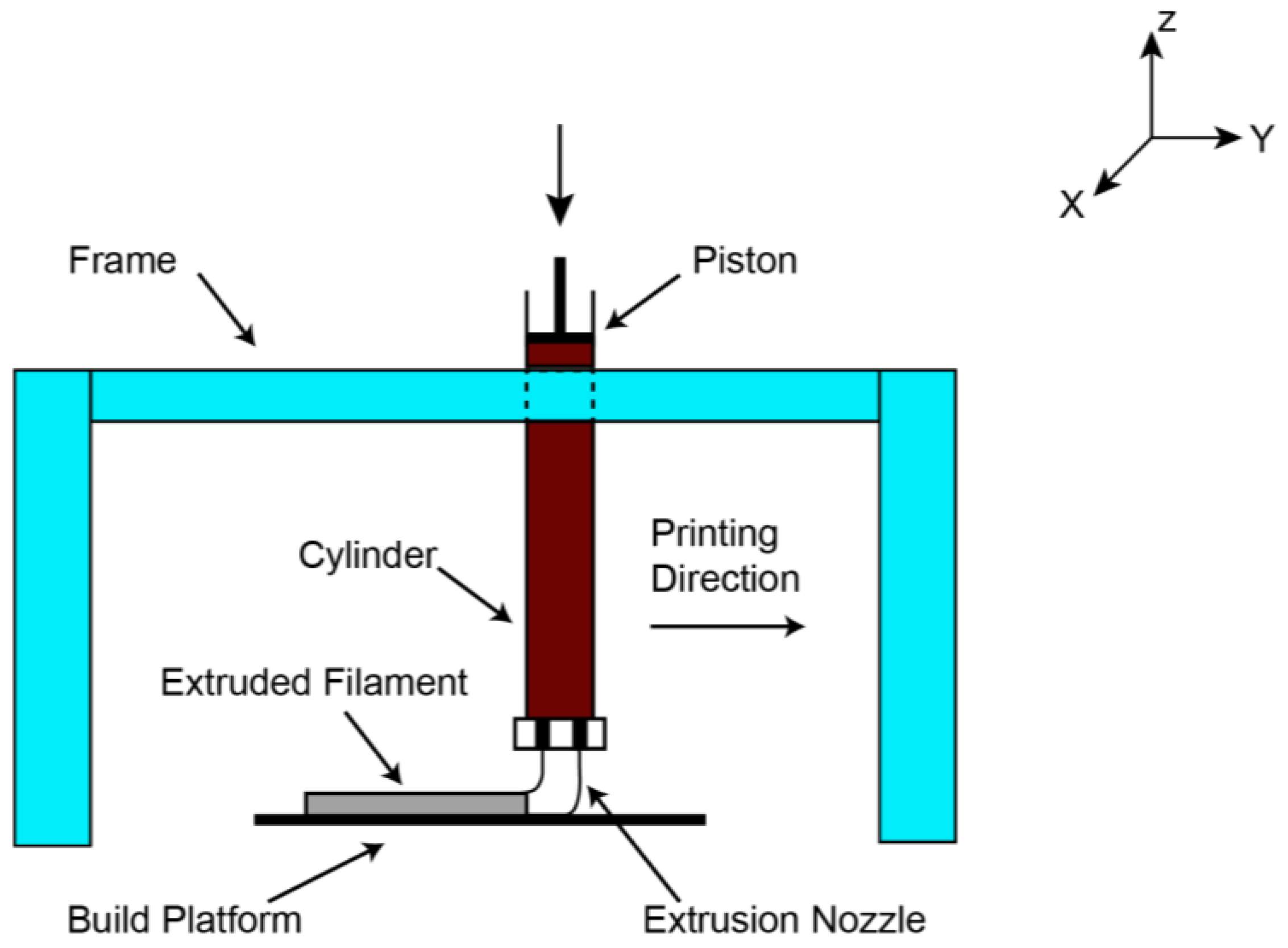

:1. Introduction

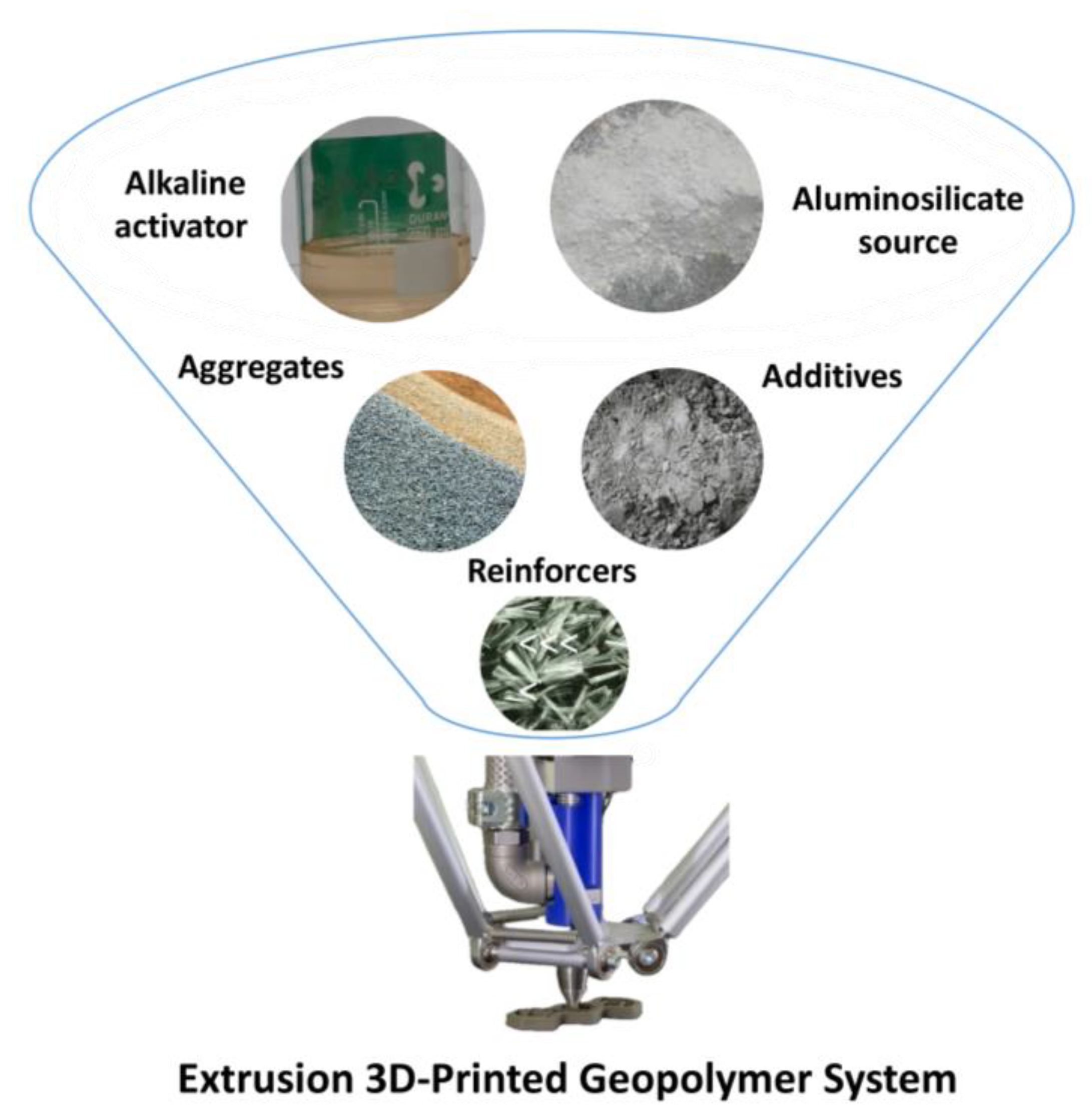

2. Geopolymer Materials: Synthesis and Applications

- -

- High strength and rapid hardening. Due to a rapid polymerisation rate, the three-dimensional network structure of geopolymer materials is simple to produce. For instance, after curing for 4 h at room temperature, metakaolin-based geopolymers’ compressive strength can reach 15–30 MPa and continues to increase over time [19,63,64];

- -

- High-temperature resistance and good thermal stability. A compact oxide network structure protects the inner material from oxidation in the air. With a linear shrinkage of 0.2% to 2% and preservation of more than 60% of its initial strength at 800 °C, geopolymer exhibits higher temperature mechanical strength and more thermostable behaviour than Portland cement [65,66,67,68,69];

- -

- Strong capacity to bind at material interfaces. Ordinary Portland cement has a poor interfacial binding force because it is susceptible to calcium hydroxide enrichment. The transition zone is preferred and orientated at the interface where it is coupled with aggregate. The final product of the geopolymer materials is primarily a three-dimensional network gel with covalent bonds tightly bound to the aggregate interface and strong bonding ability [70,71]. There is no hydration reaction of calcium silicate in the geopolymer materials;

- -

- Good durability and corrosion resistance. The geopolymer has superior resistance to sulphate corrosion since the hardening process does not produce sulphate minerals like ettringite. The geopolymer breakdown rate in a 5% solution of sulfuric acid or hydrochloric acid is just around 1/13 or 1/12 of the rate of Portland cement under the same conditions, demonstrating good stability in acid conditions. Geopolymers can create compact structures that have high durability and impermeability [28,72,73,74,75,76,77,78].

3. Characteristics for Geopolymer Printability

3.1. Aluminosilicate Raw Materials

3.2. Alkali Activators

3.3. Aggregates and Fillers

3.4. Additives for Printability

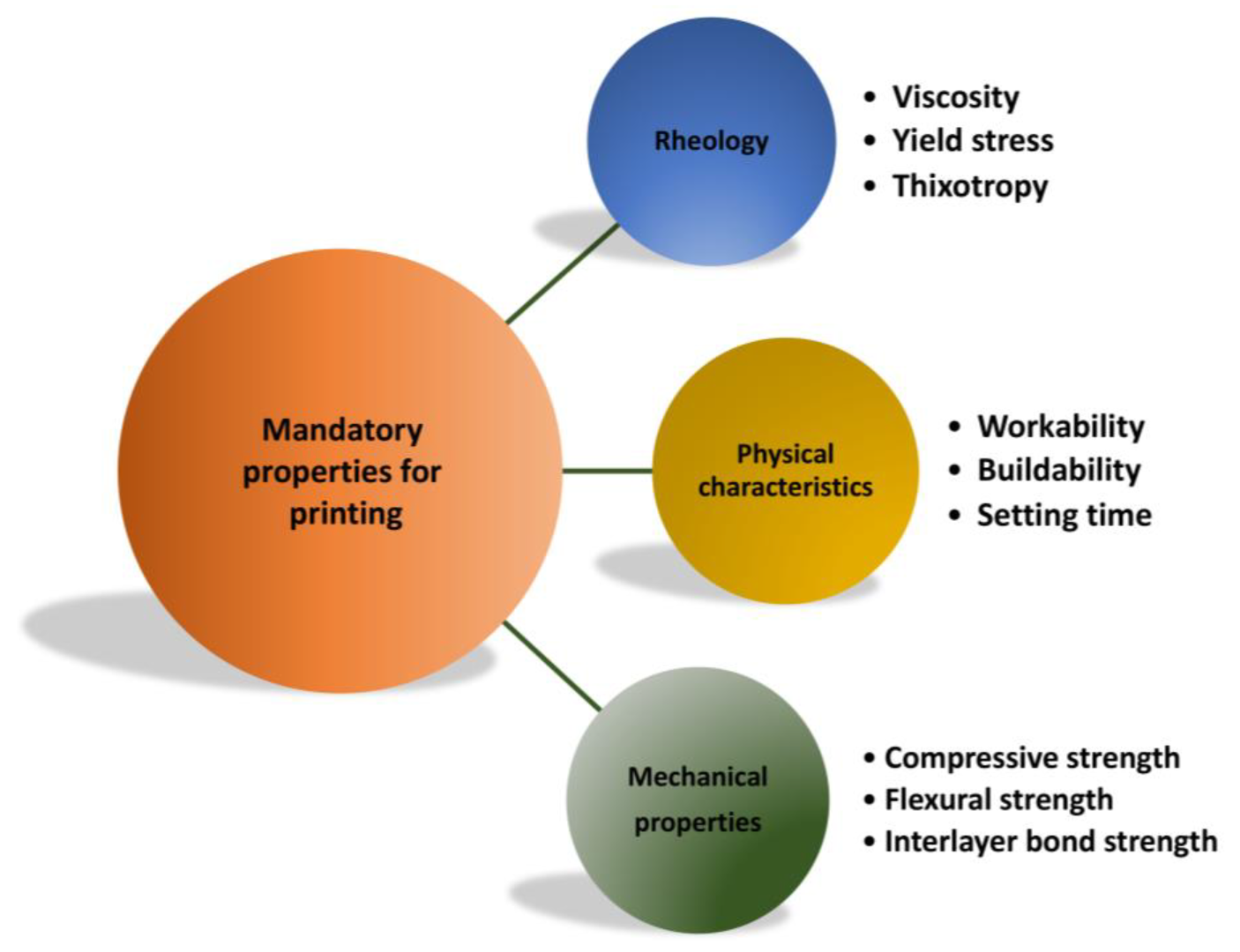

4. Fresh-State Properties

4.1. Rheology

4.2. Buildability

4.3. Open Time

5. Hardened-State Properties

5.1. Density

5.2. Mechanical Properties

5.3. Shrinkage

5.4. Layer Adhesion

5.5. Durability

6. One Part Geopolymers

6.1. Rheology

6.2. Mechanical Properties

6.3. Economic and Environmental Considerations

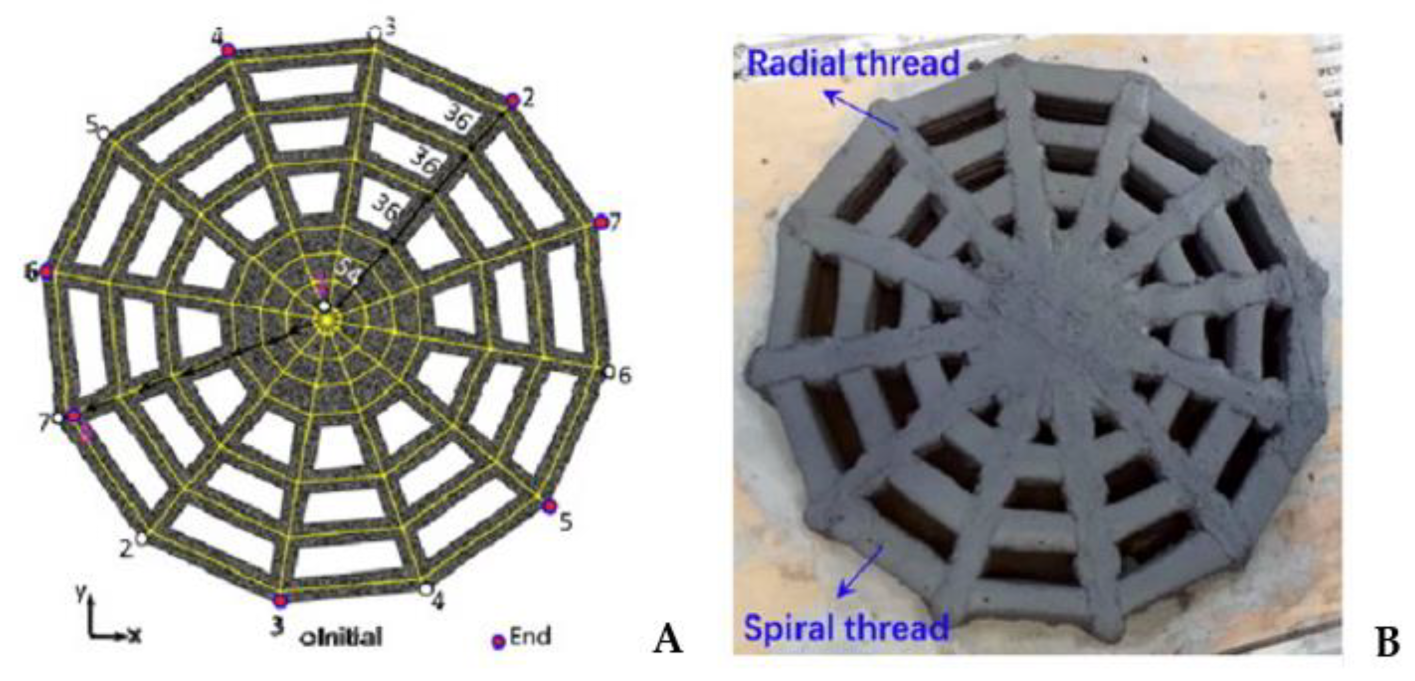

7. Applications

8. Summary and Outlook

- The main problem is selecting materials and determining their composition because conventional materials cannot be used in 3D-printing without formwork. Fresh material should have sufficient yield stress to be easily extrudable and preserve its shape after printing. As a result, the materials’ thixotropic qualities must be carefully preserved to achieve a fair trade-off between workability and buildability;

- The printing orientation of complex structures must be carefully chosen to ensure enough mechanical strength of delicate features and joints of assembly components due to the anisotropic behaviour of 3D-printed concretes, which is not a problem with traditional casting.

- Due to the weaker green strength of fresh material upon extrusion, overhanging features are difficult to produce with the generally used extrusion-based 3D-printer. Binder jetting or D-shaped technology, on the other hand, offers the capacity to produce complicated shapes due to the bed’s supporting unbounded powder layers. However, in terms of productivity, this technology falls short of extrusion-based printing. More study is needed to improve the mechanical performance of BJ 3D-printed components (green compressive and flexural strength);

- The poor surface quality of 3D-printed structures is primarily due to layer stacking and dimensional problems, which typically increase post-processing. Inadequate control and higher flowability also cause the printing layers to flow outside, resulting in poor surface quality. If the material’s yield stress and plastic viscosity are kept high to prevent the abovementioned difficulties, surface cracks and voids form, weakening the structure. To a limited extent, inserting trowels into the nozzle aperture can minimise surface roughness.

8.1. Concluding Remarks

- Various activators, additives, and superplasticisers are added to geopolymers to make them workable and printable for large-scale printing because they are not workable in their native state. Two opposing reaction characteristics, workability and buildability, need to be balanced in the new qualities for additive manufacturing. The best parameters for obtaining good fresh and hardened features in geopolymer additive manufacturing are presented in this study. However, these figures are only appropriate for the specific conditions provided in each paper;

- Different studies used various methods to assess the workability and buildability of geopolymers for extrusion-based 3D-printing. Because of the numerous standards used, defining the ideal range based on the recommended values of the sheets is problematic. However, these recommended settings are an excellent starting point for achieving decent workability and buildability;

- Based on the slump values advocated in various studies, it can be inferred that superior buildability can be attained in extrusion-based printing with slump values ranging from 8.8 to 20 mm. However, the workability investigation shows that geopolymers with a slump flow diameter (SFD) range of 120–206 mm can be easily produced;

- The essential concerns for extrusion-based 3D-printing of concrete materials are open time and setting time, which may be regulated by modifying their composition. Many researchers indicated that the optimal open and setting times are 20–80 min and 22.9–90 min, respectively. These numbers may vary for large-scale fabrication since printing large components requires more time, and shorter open and setting times can impair workability;

- Because of their low green strength, BJ 3D-printed components require post-processing. Post-processing typically entails curing at high temperatures (relative to ambient temperature) or curing in various alkaline solutions for several days, raising the final cost and affecting the sustainability of the 3D-printed geopolymers.

8.2. Future Perspective

- When an alkaline-activated reactive paste is cured, low molecular weight monomers or oligomers are changed from a liquid to a rubbery and solid state. This is because a polymeric network is formed through the chemical reaction between the reactive silico and alluminate groups, which has a significant impact on the three-dimensional structure [20];

- In order to achieve the required parameters for 3D-printing technology, geopolymer materials need to have a variety of properties, including mechanical, rheological, and physical properties. Key parameters include activator compositions and raw materials made of aluminosilicate, the potential for reinforcing fillers, geometric printing variables, temperature and duration of curing, and post-processing of the 3D-printed specimens [20];

- Based on a thorough analysis of the literature, it has been determined that reinforcement substantially affects the fresh and hardened properties of 3D-printed geopolymers. The size of the reinforcement fibres must also be evaluated to improve the reinforcement effects and identify a viable steel reinforcement alternative. The effects of natural fibres in alkali-activated geopolymers must also be investigated for additive manufacturing processes;

- Although printing speed impacts the mechanical characteristics of geopolymers, there has been little research on the implications of printing parameters (printing speed, extrusion rate, etc.) on the ultimate workability and buildability of geopolymers. Aside from material composition, printing parameters can potentially improve geopolymer printing qualities, which can be examined in future studies;

- Na2SiO3 and NaOH are required to activate geopolymers, making them less sustainable in terms of cost and environmental impact. Due to the increased cost of alkali activators, this also limits the industrial applications of geopolymers. An inexpensive and environmentally friendly substitute for the alkali activator is desirable to improve the practical applications of geopolymers;

- Previous research has identified geopolymers and 3D-printing as ecologically friendly materials and a sustainable construction technology, respectively. However, a combined sustainability study of geopolymer 3D-printing is essential in providing a greener direction to the building business;

- In addition to the one-part geopolymer mixtures that have been successfully generated for 3D-printing, further studies ought to tackle additional challenges. Even though one-part geopolymers have better mechanical properties, further investigation is needed to lessen mechanical anisotropies in 3D-printed filaments by examining the impact of different printing setups and the addition of fibre reinforcement. Furthermore, since most research focuses on mechanical properties, notably compressive strength, it is imperative to investigate the durability of 3D-printed one-part geopolymers. It is also important to investigate how different nanoparticles affect the properties of fresh and hardened materials. The majority of studies focused on how different mix patterns affected the mechanical and rheological characteristics of one-part 3D-printed geopolymers. This is a competitive 3D-printing solution for a range of industrial applications, such as prefabrication and onsite building, thanks to its strong performance and OPC-like preparatory procedures. Because of the quick development of yield stress, open time has seldom been examined and often has a limited window when a solid activator is present. This restricts the use of one-part geopolymers in 3D-printing applications. Therefore, in order to overcome this difficulty and for them to be used in building applications, the effect of different parameters on the open time need to be investigated in order to design a one-part geopolymer combination with a suitable printing window. Additionally, the issue of limited printing open time needs to be resolved by investigating the effects of various retarder and superplasticiser types and dosages, changing the precursor materials, and adjusting the preparation parameters;

- The viscoelastic behaviour typical of good processability, the mechanical and energetic requirements for material extrusion and deposition, and their final mechanical characteristics can all be understood through the application of a chemorheological approach to the assessment of more ideal processing conditions of a particular alkaline-activated aluminosilicate formulation [20].

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- BS EN ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: West Conshohocken, PA, USA, 2021.

- Mohan, M.K.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Extrusion-based concrete 3D printing from a material perspective: A state-of-the-art review. Cem. Concr. Compos. 2021, 115, 103855. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A review of the current progress and application of 3D printed concrete. Compos. Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Khan, M.S.; Sanchez, F.; Zhou, H. 3-D printing of concrete: Beyond horizons. Cem. Concr. Res. 2020, 133, 106070. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Hwang, D.; Yao, K.-T.; Yeh, Z. Mega-scale fabrication by contour crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301–320. [Google Scholar] [CrossRef]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Zhang, C.; Nerella, V.N.; Krishna, A.; Wang, S.; Zhang, Y.; Mechtcherine, V.; Banthia, N. Mix design concepts for 3D printable concrete: A review. Cem. Concr. Compos. 2021, 122, 104155. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; Van Tittelboom, K.; De Schutter, G. Rheological and pumping behaviour of 3D printable cementitious materials with varying aggregate content. Cem. Concr. Res. 2021, 139, 106258. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, F.; Liu, J.-C.; Wang, S. Eco-friendly high strength, high ductility engineered cementitious composites (ECC) with substitution of fly ash by rice husk ash. Cem. Concr. Res. 2020, 137, 106200. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem. Concr. Compos. 2018, 94, 307–314. [Google Scholar] [CrossRef]

- Bong, S.H.; Xia, M.; Nematollahi, B.; Shi, C. Ambient temperature cured ‘just-addwater’ geopolymer for 3D concrete printing applications. Cem. Concr. Compos. 2021, 121, 104060. [Google Scholar] [CrossRef]

- Xia, M.; Sanjayan, J.G. Methods of enhancing strength of geopolymer produced from powder-based 3D printing process. Mater. Lett. 2018, 227, 281–283. [Google Scholar] [CrossRef]

- Voney, V.; Odaglia, P.; Brumaud, C.; Dillenburger, B.; Habert, G. From casting to 3D printing geopolymers: A proof of concept. Cem. Concr. Res. 2021, 143, 106374. [Google Scholar] [CrossRef]

- Provis, J.L.; Duxson, P.; van Deventer, J.S. The role of particle technology in developing sustainable construction materials. Adv. Powder Technol. 2010, 21, 2–7. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Aversa, R.; Ricciotti, L.; Perrotta, V.; Apicella, A. Chemorheology of a Si/Al > 3 Alkali Activated Metakaolin Paste through Parallel Differential Scanning Calorimetry (DSC) and Dynamic Mechanical Analysis (DMA). Polymers 2023, 15, 3922. [Google Scholar] [CrossRef]

- Xia, M.; Sanjayan, J. Method of formulating geopolymer for 3D printing for construction applications. Mater. Des. 2016, 110, 382–390. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Gibbons, G.J.; Williams, R.; Purnell, P.; Farahi, E. 3D printing of cement composites. Adv. Appl. Ceram. 2010, 109, 287–290. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J. Post-processing methods to improve strength of particle-bed 3D printed geopolymer for digital construction applications. Front. Mater. 2019, 6, 160. [Google Scholar] [CrossRef]

- Habert, G.; De Lacaillerie, J.D.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Cement: A Review; Geopolymer Institute Technics Paper; Geopolymer Institute: Saint-Quentin, France, 2013; Volume 21, pp. 1–11. [Google Scholar]

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746. [Google Scholar] [CrossRef]

- Ricciotti, L.; Occhicone, A.; Ferone, C.; Cioffi, R.; Tarallo, O.; Roviello, G. Development of Geopolymer-Based Materials with Ceramic Waste for Artistic and Restoration Applications. Materials 2022, 15, 8600. [Google Scholar] [CrossRef] [PubMed]

- Ricciotti, L.; Occhicone, A.; Manzi, S.; Saccani, A.; Ferone, C.; Tarallo, O.; Roviello, G. Sustainable materials based on geopolymer-polyvinyl acetate composites for Art&Design applications. Polymers 2022, 14, 5461. [Google Scholar] [PubMed]

- Roviello, G.; Chianese, E.; Ferone, C.; Ricciotti, L.; Roviello, V.; Cioffi, R.; Tarallo, O. Hybrid geopolymeric foams for the removal of metallic ions from aqueous waste solutions. Materials 2019, 12, 4091. [Google Scholar] [CrossRef]

- Roviello, G.; Ricciotti, L.; Ferone, C.; Colangelo, F.; Cioffi, R.; Tarallo, O. Synthesis and Characterization of Novel Epoxy Geopolymer Hybrid Composites. Materials 2013, 6, 3943–3962. [Google Scholar] [CrossRef]

- Roviello, G.; Ricciotti, L.; Ferone, C.; Colangelo, F.; Tarallo, O. Fire resistant melamine based organic-geopolymer hybrid composites. Cem. Concr. Compos. 2015, 59, 89–99. [Google Scholar] [CrossRef]

- Ricciotti, L.; Occhicone, A.; Petrillo, A.; Ferone, C.; Cioffi, R.; Roviello, G. Geopolymer-based hybrid foams: Lightweight materials from a sustainable production process. J. Clean. Prod. 2020, 250, 119588. [Google Scholar] [CrossRef]

- Roviello, G.; Menna, C.; Tarallo, O.; Ricciotti, L.; Ferone, C.; Colangelo, F.; Asprone, D.; di Maggio, R.; Cappelletto, E.; Prota, A.; et al. Preparation, structure and properties of hybrid materials based on geopolymers and polysiloxanes. Mater. Des. 2015, 87, 82–94. [Google Scholar] [CrossRef]

- Roviello, G.; Ricciotti, L.; Molino, A.J.; Menna, C.; Ferone, C.; Cioffi, R.; Tarallo, O. Hybrid Geopolymers from Fly Ash and Polysiloxanes. Molecules 2019, 24, 3510. [Google Scholar] [CrossRef]

- Ricciotti, L.; Molino, A.J.; Roviello, V.; Chianese, E.; Cennamo, P.; Roviello, G. Geopolymer Composites for Potential Applications in Cultural Heritage. Environments 2017, 4, 91. [Google Scholar] [CrossRef]

- Zhang, D.W.; Wang, D.M.; Liu, Z.; Xie, F.Z. Rheology, agglomerate structure, and particle shape of fresh geopolymer paste with different NaOH activators content. Constr. Build. Mater. 2018, 187, 674–680. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, D.; Xie, F. Microrheology of fresh geopolymer pastes with different NaOH amounts at room temperature. Constr. Build. Mater. 2019, 207, 284–290. [Google Scholar] [CrossRef]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibers, their fiber fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Shaikh, F. Review of mechanical properties of short fiber reinforced geopolymer composites. Constr. Build. Mater. 2013, 43, 37–49. [Google Scholar] [CrossRef]

- Sakulich, A. Reinforced geopolymer composites for enhanced material greenness and durability. Sustain. Cities Soc. 2011, 1, 195–210. [Google Scholar] [CrossRef]

- Palomo, A.; Krivenko, P.; Garcia-Lodeiro, I.; Kavalerova, E.; Maltseva, O.; Fernandez-Jimenez, A. A review on alkaline activation: New analytical perspectives. Mater. Constr. 2014, 64, 315. [Google Scholar] [CrossRef]

- Hu, Z.; Wyrzykowski, M.; Lura, P. Estimation of reaction kinetics of geopolymers at early ages. Cem. Concr. Res. 2020, 129, 105971. [Google Scholar] [CrossRef]

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Bone Tissue Applications: Recent Advances and Future Perspectives. Polymers 2023, 15, 1087. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Kuenzel, C.; Ranjbar, N. Dissolution mechanism of fly ash to quantify the reactive aluminosilicates in geopolymerisation. Resour. Conserv. Recycl. 2019, 150, 104421. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C.; Spangenberg, J.; Mehrali, M. Hardening evolution of geopolymers from setting to equilibrium: A review. Cem. Concr. Compos. 2020, 114, 103729. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Luo, W. A novel waterproof, fast setting and high early strength repair material derived from metakaolin geopolymer. Constr. Build. Mater. 2016, 124, 69–73. [Google Scholar] [CrossRef]

- Salazar, R.A.R.; Jesús, C.; de Gutiérrez, R.M.; Pacheco-Torgal, F. Alkali-activated binary mortar based on natural volcanic pozzolan for repair applications. J. Build. Eng. 2019, 25, 100785. [Google Scholar] [CrossRef]

- Ahmad Zailani, W.W.; Bouaissi, A.; Abdullah, M.M.A.B.; Abd Razak, R.; Yoriya, S.; Mohd Salleh, M.A.A.; Mohd Remy Rozainy, M.A.Z.; Fansuri, H. Bonding strength characteristics of FA-based geopolymer paste as a repair material when applied on OPC substrate. Appl. Sci. 2020, 10, 3321. [Google Scholar] [CrossRef]

- Palomoa, A.; Grutzeck, M.W.; Blancoa, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of tensile bond strength of 3D printed geopolymer mortar. Measurement 2018, 113, 108–116. [Google Scholar] [CrossRef]

- Panda, B.; Ruan, S.; Unluer, C.; Tan, M.J. Investigation of the properties of alkali-activated slag mixes involving the use of nanoclay and nucleation seeds for 3D printing. Compos. Part B Eng. 2020, 186, 107826. [Google Scholar] [CrossRef]

- Sellami, M.; Barre, M.; Toumi, M. Synthesis, thermal properties and electrical conductivity of phosphoric acid-based geopolymer with metakaolin. Appl. Clay Sci. 2019, 180, 105192. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Wongsa, A.; Srinavin, K.; Chindaprasirt, P. Recycled aggregate high calcium fly ash geopolymer concrete with inclusion of OPC and nano-SiO2. Constr. Build. Mater. 2018, 174, 244–252. [Google Scholar] [CrossRef]

- Shi, W.; Ren, H.; Li, M.; Shu, K.; Xu, Y.; Yan, C.; Tang, Y. Tetracycline removal from aqueous solution by visible-light-driven photocatalytic degradation with low cost red mud wastes. Chem. Eng. J. 2020, 382, 122876. [Google Scholar] [CrossRef]

- Zhang, Y.J.; He, P.Y.; Yang, M.Y.; Kang, L. A new graphene bottom ash geopolymeric composite for photocatalytic H-2 production and degradation of dyeing wastewater. Int. J. Hydrogen Energy 2017, 42, 20589–20598. [Google Scholar] [CrossRef]

- Zhang, Y.; He, P.; Zhang, Y.; Chen, H. A novel electroconductive graphene/fly ash-based geopolymer composite and its photocatalytic performance. Chem. Eng. J. 2018, 334, 2459–2466. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, L.; Ma, G.; Zhao, X.; Zhao, X. Preparation and properties of bio-geopolymer composites with waste cotton stalk materials. J. Clean. Prod. 2020, 245, 118842. [Google Scholar] [CrossRef]

- Yu, J.; Chen, Y.; Chen, G.; Wang, L. Experimental study of the feasibility of using anhydrous sodium metasilicate as a geopolymer activator for soil stabilization. Eng. Geol. 2020, 264, 105316. [Google Scholar] [CrossRef]

- Yu, Z.; Song, W.; Li, J.; Li, Q. Improved simultaneous adsorption of Cu(II) and Cr(VI) of organic modified metakaolin-based geopolymer. Arab. J. Chem. 2020, 13, 4811–4823. [Google Scholar] [CrossRef]

- Burciaga-Diaz, O.; Escanlante-Garcia, J.I. Strength and durability in acid media of alkali silicate-activated metakaolin geopolymers. J. Am. Ceram. Soc. 2012, 95, 2307–2313. [Google Scholar] [CrossRef]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Van Deventer, J.S. The role of inorganic polymer technology in the development of ‘Green Concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of geopolymer cements. Proceedings of the first international conference on alkaline cements and concretes. Kiev Ukr. 1994, 1, 131–149. [Google Scholar]

- Ali, A.M.; Sanjayan, J.; Guerrieri, M. Performance of geopolymer high strength concrete wall panels and cylinders when exposed to a hydrocarbon fire. Constr. Build. Master. 2017, 137, 195–207. [Google Scholar]

- Lahoti, M.; Tan, K.H.; Yang, E.H. A critical review of geopolymer properties for structural fire-resistance applications. Constr. Build. Master. 2019, 221, 514–526. [Google Scholar] [CrossRef]

- Nazari, A.; Bagheri, A.; Sanjayan, J.G.; Dao, M.; Mallawa, C.; Zannis, P.; Zumbo, S. Thermal shock reactions of ordinary Portland cement and geopolymer concrete: Microstructural and mechanical investigation. Constr. Build. Master. 2019, 196, 492–498. [Google Scholar] [CrossRef]

- Peng, J.; Yan, Z.B. Recent research progress of geopolymer. China Non Met. Miner. Ind. 2014, 1, 16–19. (In Chinese) [Google Scholar]

- Davidovits, J. Geopolymer: Chemistry and Applications, 2nd ed.; Geopolymer Institute: St. Quentin, France, 2008. [Google Scholar]

- Albitar, M.; Ali, M.S.M.; Visintin, P.; Drechsler, M. Durability evaluation of geopolymer and conventional concretes. Constr. Build. Master. 2017, 136, 374–385. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.B. Sulfate attack on alkali-activated slag concrete. Cem. Concr. Res. 2002, 32, 211–216. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.B. Resistance of alkali-activated slag concrete to acid attack. Cem. Concr. Res. 2003, 33, 1607–1611. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Lim, J.H.; Li, M.; Tan, M.J. Creating functionally graded concrete materials with varying 3D printing parameters. Virtual Phys. Prototyp. 2022, 17, 662–681. [Google Scholar] [CrossRef]

- Zhuang, H.J.; Zhang, H.Y.H. Resistance of geopolymer mortar to acid and chloride attacks. Procedia Eng. 2017, 210, 126–131. [Google Scholar] [CrossRef]

- Weng, L.Q.; Song, S.H. Development of novel cementious geopolymers. Mater. Rep. 2005, 19, 67–68. (In Chinese) [Google Scholar]

- Duxson, P.; Provis, J.L.; Lukey, G.C.; Mallicoat, S.W.; Kriven, W.M.; Van Deventer, J.S. Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloid. Surface. Physicochem. Eng. Aspect. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Panda, B.; Singh, G.B.; Unluer, C.; Tan, M.J. Synthesis and characterization of one-part geopolymers for extrusion based 3D concrete printing. J. Clean. Prod. 2019, 220, 610–619. [Google Scholar] [CrossRef]

- Singh, N.B. Fly Ash-Based Geopolymer Binder: A Future Construction Material. Minerals 2018, 8, 299. [Google Scholar] [CrossRef]

- Panda, B.; Unluer, C.; Tan, M.J. Extrusion and rheology characterization of geopolymer nanocomposites used in 3D printing. Compos. Part B Eng. 2019, 176, 107290. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J. Method of optimisation for ambient temperature cured sustainable geopolymers for 3D printing construction applications. Materials 2019, 16, 902. [Google Scholar] [CrossRef]

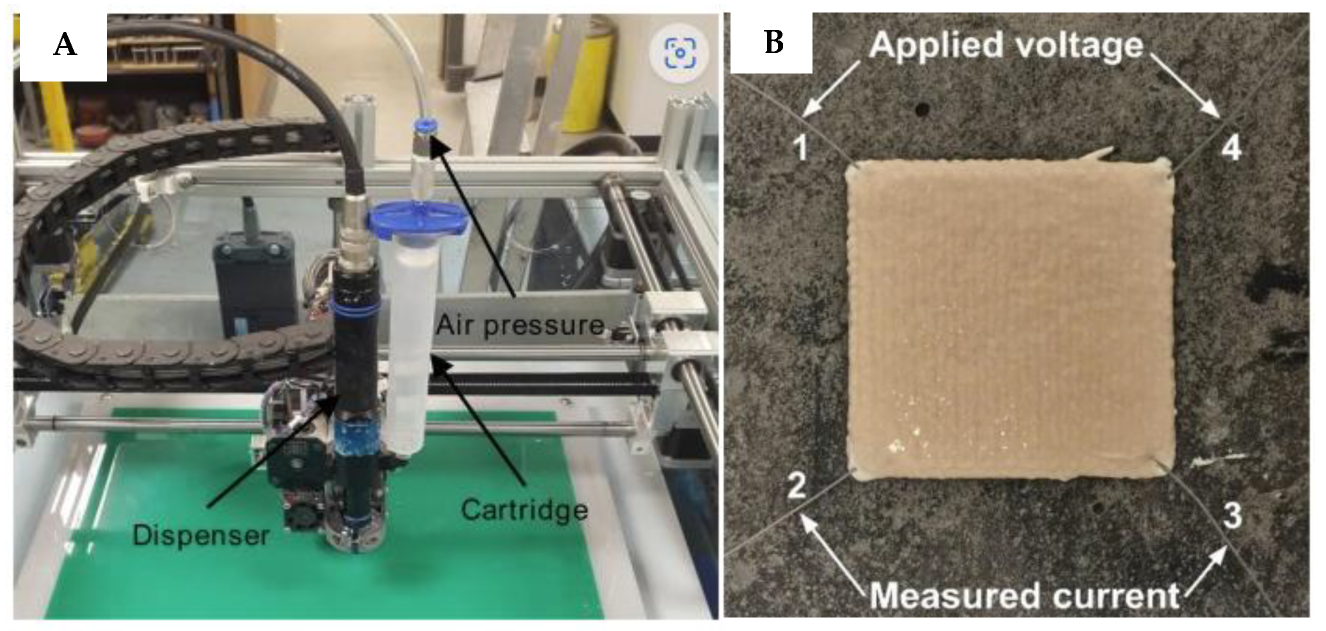

- Albar, A.; Chougan, M.; Kheetan, M.J.A.; Swash, M.R.; Ghaffar, S.H. Effective extrusion-based 3D printing system design for cementitious-based materials. Results Eng. 2020, 6, 100135. [Google Scholar] [CrossRef]

- Sun, C.; Xiang, J.; Xu, M.; He, Y.; Tong, Z.; Cui, X. 3D extrusion free forming of geopolymer composites: Materials modification and processing optimization. J. Clean. Prod. 2020, 258, 120986. [Google Scholar] [CrossRef]

- Rehman, A.U.; Sglavo, V.M. 3D printing of geopolymer-based concrete for building applications. Rapid Prototyp. J. 2020, 26, 1783–1788. [Google Scholar] [CrossRef]

- Guo, X.; Yang, J.; Xiong, G. Influence of supplementary cementitious materials on rheological properties of 3D printed fly ash based geopolymer. Cem. Concr. Compos. 2020, 114, 103820. [Google Scholar] [CrossRef]

- Ly, O.; Yoris-Nobile, A.I.; Sebaibi, N.; Blanco-Fernandez, E.; Boutouil, M.; Castro-Fresno, D.; Hall, A.E.; Herbert, R.J.H.; Deboucha, W.; Reis, B.; et al. Optimisation of 3D printed concrete for artificial reefs: Biofouling and mechanical analysis. Constr. Build. Mater. 2021, 272, 121649. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265. [Google Scholar] [CrossRef]

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving flexural characteristics of 3D printed geopolymer composites with in-process steel cable reinforcement. Constr. Build. Mater. 2018, 178, 32–41. [Google Scholar] [CrossRef]

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Nerella, V.N.; Mechtcherine, V. Effect of polypropylene fibre addition on properties of geopolymers made by 3D printing for digital construction. Materials 2018, 11, 2352. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Wang, L.; Ma, G. Mechanical improvement of continuous steel microcable reinforced geopolymer composites for 3D printing subjected to different loading conditions. Compos. Part B Eng. 2020, 187, 107796. [Google Scholar] [CrossRef]

- Chougan, M.; Ghaffar, S.H.; Jahanzat, M.; Albar, A.; Mujaddedi, N.; Swash, R. The influence of nano-additives in strengthening mechanical performance of 3D printed multi-binder geopolymer composites. Constr. Build. Mater. 2020, 250, 118928. [Google Scholar] [CrossRef]

- Alghamdi, H.; Neithalath, N. Synthesis and characterization of 3D-printable geopolymeric foams for thermally efficient building envelope materials. Cem. Concr. Compos. 2019, 104, 103377. [Google Scholar] [CrossRef]

- Santos, L.K.D.; Botti, R.F.; Innocentini, M.D.D.M.; Marques, R.F.C.; Colombo, P.; de Paula, A.V.; Flumignan, D.L. 3D printed geopolymer: An efficient support for immobilization of Candida rugosa lipase. Chem. Eng. J. 2021, 414, 128843. [Google Scholar] [CrossRef]

- Coppola, B.; Tardivat, C.; Richaud, S.; Tulliani, J.-M.; Montanaro, L.; Palmero, P. 3D printing of dense and porous alkali-activated refractory wastes via Direct Ink Writing (DIW). J. Eur. Ceram. Soc. 2021, 41, 3798–3808. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857. [Google Scholar] [CrossRef]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and application. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Mehrotra, S.P. Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer . J. Mater. Sci. 2010, 45, 607–615. [Google Scholar] [CrossRef]

- Mehta, A.; Ashish, D.K. Silica fume and waste glass in cement concrete production: A review. J. Build. Eng. 2020, 29, 100888. [Google Scholar] [CrossRef]

- Liew, Y.-M.; Heah, C.-Y.; Mustafa, A.B.M.; Kamarudin, H. Structure and properties of clay-based geopolymer cements: A review. Prog. Mater. Sci. 2016, 83, 595–629. [Google Scholar] [CrossRef]

- Panagiotopoulou, C.; Kontori, E.; Perraki, T.; Kakali, G. Dissolution of aluminosilicate minerals and by-products in alkaline media. J. Mater. Sci. 2007, 42, 2967–2973. [Google Scholar] [CrossRef]

- Khan, S.A.; Koç, M.; Al-Ghamdi, S.G. Sustainability assessment, potentials and challenges of 3D printed concrete structures: A systematic review for built environmental applications. J. Clean. Prod. 2021, 303, 127027. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Bai, G. Micro-cable reinforced geopolymer composite for extrusion-based 3D printing. Mater. Lett. 2019, 235, 144–147. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Nazari, A.; Sanjayan, J.; Pan, J. Properties of 3D-Printable Ductile Fibre-Reinforced Geopolymer Composite for Digital Construction Applications; RILEM Bookseries; Springer: Cham, Switzerland, 2020; Volume 23, pp. 363–372. [Google Scholar] [CrossRef]

- Archez, J.; Maitenaz, S.; Demont, L.; Charrier, M.; Mesnil, R.; Texier-Mandoki, N.; Bourbon, X.; Rossignol, S.; Caron, J.F. Strategy to shape; on a half-meter scale, a geopolymer composite structure by additive manufacturing. Open Ceram. 2021, 5, 100071. [Google Scholar] [CrossRef]

- Lowke, D.; Talke, D.; Dressler, I.; Weger, D.; Gehlen, C.; Ostertag, C.; Rael, R. Particle bed 3D printing by selective cement activation—Applications, material and process technology. Cem. Concr. Res. 2020, 134, 106077. [Google Scholar] [CrossRef]

- Sahin, H.G.; Mardani-Aghabaglou, A. Assessment of materials, design parameters and some properties of 3D printing concrete mixtures; a state-of-the-art review. Constr. Build. Mater. 2022, 316, 125865. [Google Scholar] [CrossRef]

- Archez, J.; Texier-Mandoki, N.; Bourbon, X.; Caron, J.F.; Rossignol, S. Shaping of geopolymer composites by 3D printing. J. Build. Eng. 2021, 34, 101894. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of microwave heating on interlayer bonding and buildability of geopolymer 3D concrete printing. Constr. Build. Mater. 2020, 265, 120786. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. 3D printing geopolymers: A review. Cem. Concr. Compos. 2022, 128, 104455. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Constr. Build. Mater. 2018, 163, 600–610. [Google Scholar] [CrossRef]

- Ma, S.; Fu, S.; Zhao, S.; He, P.; Ma, G.; Wang, M.; Jia, D.; Zhou, Y. Direct ink writing of geopolymer with high spatial resolution and tunable mechanical properties. Addit. Manuf. 2021, 46, 102202. [Google Scholar] [CrossRef]

- Sun, Q.; Peng, Y.; Georgolamprou, X.; Li, D.; Kiebach, R. Synthesis and characterization of a geopolymer/hexagonal-boron nitride composite for free forming 3D extrusion-based printing. Appl. Clay Sci. 2020, 199, 105870. [Google Scholar] [CrossRef]

- Sahin, O.; Ilcan, H.; Atesli, A.T.; Kul, A.; Yıldırım, G.; Sahmaran, M. Construction and demolition waste-based geopolymers suited for use in 3-dimensional additive manufacturing. Cem. Concr. Compos. 2021, 121, 104088. [Google Scholar] [CrossRef]

- Ranjbar, N.; Mehrali, M.; Kuenzel, C.; Gundlach, C.; Pedersen, D.B.; Dolatshahi-Pirouz, A.; Spangenberg, J. Rheological characterization of 3D printable geopolymers. Cem. Concr. Res. 2021, 147, 106498. [Google Scholar] [CrossRef]

- Ma, S.; Yang, H.; Zhao, S.; He, P.; Zhang, Z.; Duan, X.; Yang, Z.; Jia, D.; Zhou, Y. 3D-printing of architectured short carbon fiber-geopolymer composite. Compos. Part B Eng. 2021, 226, 109348. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J.G. Fresh and Hardened Properties of 3D Printable Geopolymer Cured in Ambient Temperature; RILEM Bookseries; Springer: Cham, Switzerland, 2019; Volume 19, pp. 3–11. [Google Scholar] [CrossRef]

- Pilehvar, S.; Arnhof, M.; Pamies, R.; Valentini, L.; Kjøniksen, A.-L. Utilization of urea as an accessible superplasticizer on the moon for lunar geopolymer mixtures. J. Clean. Prod. 2020, 247, 119177. [Google Scholar] [CrossRef]

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of alkali reactions on the rheology of one-part 3D printable geopolymer concrete. Cem. Concr. Compos. 2021, 116, 103899. [Google Scholar] [CrossRef]

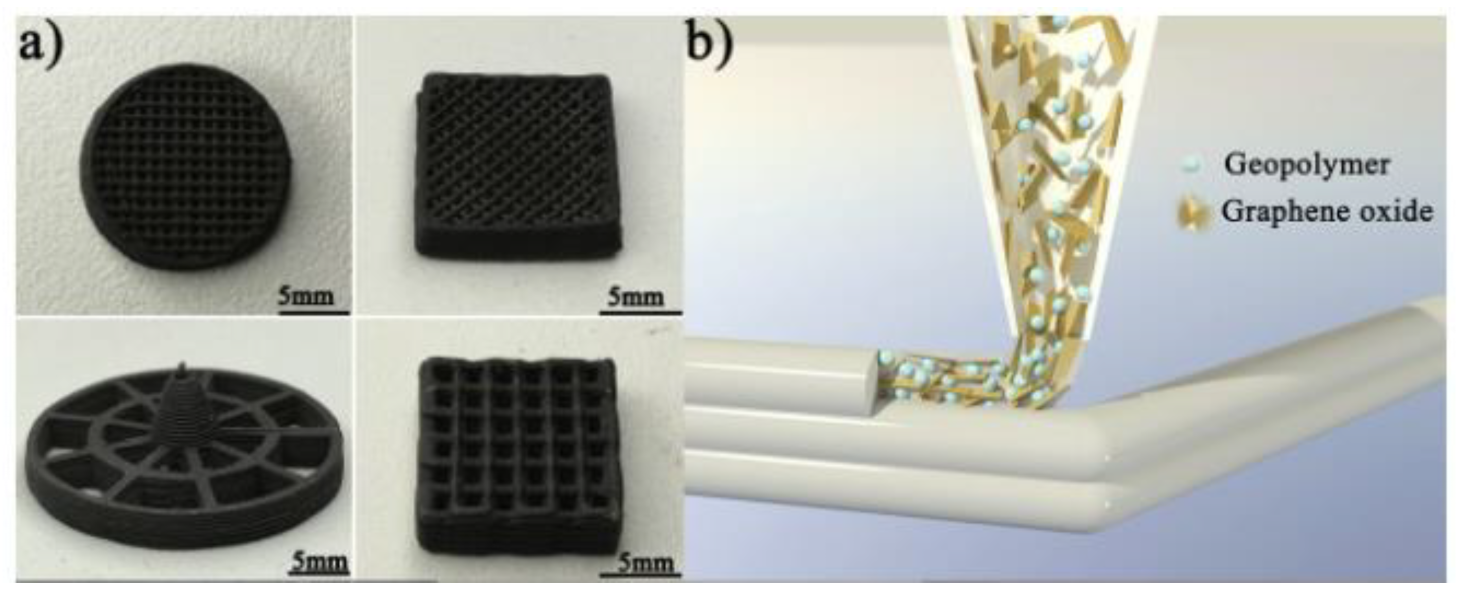

- Zhong, J.; Zhou, G.-X.; He, P.-G.; Yang, Z.-H.; Jia, D.-C. 3D printing strong and conductive geo-polymer nanocomposite structures modified by graphene oxide. Carbon 2017, 117, 421–426. [Google Scholar] [CrossRef]

- Pilehvar, S.; Arnhof, M.; Erichsen, A.; Valentini, L.; Anna, K. Investigation of severe lunar environmental conditions on the physical and mechanical properties of lunar regolith geopolymers. J. Mater. Res. Technol. 2021, 11, 1506–1516. [Google Scholar] [CrossRef]

- Zhang, D.-W.; Wang, D.-M.; Lin, X.-Q.; Zhang, T. The study of the structure rebuilding and yield stress of 3D printing geopolymer pastes. Constr. Build. Mater. 2018, 184, 575–580. [Google Scholar] [CrossRef]

- Souza, M.T.; Simao, L.; de Moraes, E.G.; Senff, L.; de Castro Pessoa, J.R.; Ribeiro, M.J.; de Oliveira, A.P.N. Role of temperature in 3D printed geopolymers: Evaluating rheology and buildability. Mater. Lett. 2021, 293, 129680. [Google Scholar] [CrossRef]

- Munir, Q.; Peltonen, R.; Karki, T. Printing parameter requirements for 3d printable geopolymer materials prepared from industrial side streams. Materials 2021, 14, 4758. [Google Scholar] [CrossRef] [PubMed]

- Al-Qutaifi, S.; Nazari, A.; Bagheri, A. Mechanical properties of layered geopolymer structures applicable in concrete 3D-printing. Constr. Build. Mater. 2018, 176, 690–699. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A review on properties of fresh and hardened geopolymer mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Elyamany, H.E.; Elmoaty, A.E.M.A.; Elshaboury, A.M. Setting time and 7-day strength of geopolymer mortar with various binders. Constr. Build. Mater. 2018, 187, 974–983. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Arnoult, M.; Perronnet, M.; Autef, A.; Rossignol, S. How to control the geopolymer setting time with the alkaline silicate solution. J. Non-Cryst. Solids 2018, 495, 59–66. [Google Scholar] [CrossRef]

- Topark-Ngarm, P.; Chindaprasirt, P.; Sata, V. Setting time, strength, and bond of high-calcium fly ash geopolymer concrete. J. Mater. Civ. Eng. 2015, 27, 04014198. [Google Scholar] [CrossRef]

- Perna, I.; Hanzlícek, T. The setting time of a clay-slag geopolymer matrix: The influence of blast-furnace-slag addition and the mixing method. J. Clean. Prod. 2016, 112, 1150–1155. [Google Scholar] [CrossRef]

- Rahmiati, T.; Azizli, K.A.; Man, Z.; Ismail, L.; Nuruddin, M.F. The effect of KOH concentration on setting time and compressive strength of fly ash-based geopolymer. Appl. Mech. Mater. 2014, 625, 94–97. [Google Scholar] [CrossRef]

- Sikora, P.; Chougan, M.; Cuevas, K.; Liebscher, M.; Mechtcherine, V.; Ghaffar, S.H.; Liard, M.; Lootens, D.; Krivenko, P.; Sanytsky, M.; et al. The effects of nanoand micro-sized additives on 3D printable cementitious and alkali-activated composites: A review. Appl. Nanosci. 2021, 12, 805–823. [Google Scholar] [CrossRef]

- Xia, M.; Nematollahi, B.; Sanjayan, J. Influence of binder saturation level on compressive strength and dimensional accuracy of powder-based 3D printed geopolymer. Mater. Sci. Forum 2018, 939, 177–183. [Google Scholar] [CrossRef]

- Alghamdi, H.; Nair, S.A.O.; Neithalath, N. Insights into material design, extrusion rheology, and properties of 3D-printable alkali-activated fly ash-based binders. Mater. Des. 2019, 167, 107634. [Google Scholar] [CrossRef]

- Mo, B.-H.; Zhu, H.; Cui, X.-M.; He, Y.; Gong, S.-Y. Effect of curing temperature on geopolymerization of metakaolin-based geopolymers. Appl. Clay Sci. 2014, 99, 144–148. [Google Scholar] [CrossRef]

- Hounsi, A.D.; Lecomte-Nana, G.; Djétéli, G.; Blanchart, P.; Alowanou, D.; Kpelou, P.; Napo, K.; Tchangb, G.; Praisler, M. How does Na, K alkali metal concentration change the early age structural characteristic of kaolin-based geopolymers. Ceram. Int. 2014, 40 Pt A, 8953–8962. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Ma, G.; Sanjayan, J.; Feng, D. Strength and ductility enhancement of 3D printing structure reinforced by embedding continuous micro-cables. Constr. Build. Mater. 2020, 264, 120196. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Chou, S.-Y.; Lin, W.-T.; Cheng, A.; Hebdowska-Krupa, M.; Gadek, S.; Mikuła, J. Mechanical properties of short fiber-reinforced geopolymers made by casted and 3D printing methods: A comparative study. Materials 2020, 13, 579. [Google Scholar] [CrossRef]

- Lv, X.; Qin, Y.; Liang, H.; Cui, X. Effects of modifying agent on rheology and workability of alkali-activated slag paste for 3D extrusion forming. Constr. Build. Mater. 2021, 302, 124062. [Google Scholar] [CrossRef]

- Ma, S.; Zhao, S.; Zheng, Y.; Wang, Q.; Yang, H.; Liu, X.; He, P.; Duan, X. Preparation and mechanical performance of SiCw/geopolymer composites through direct ink writing. J. Am. Ceram. Soc. 2022, 105, 3555–3567. [Google Scholar] [CrossRef]

- Ling, Y.; Wang, K.; Fu, C. Shrinkage behavior of fly ash based geopolymer pastes with and without shrinkage reducing admixture. Cem. Concr. Compos. 2019, 98, 74–82. [Google Scholar] [CrossRef]

- Khan, I.; Xu, T.; Castel, A.; Gilbert, R.I.; Babaee, M. Risk of early age cracking in geopolymer concrete due to restrained shrinkage. Constr. Build. Mater. 2019, 229, 116840. [Google Scholar] [CrossRef]

- Mermerdaş, K.; Algın, Z.; Ekmen, Ş. Experimental assessment and optimization of mix parameters of fly ash-based lightweight geopolymer mortar with respect to shrinkage and strength. J. Build. Eng. 2020, 31, 101351. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, Z.; Feng, W.; Nong, Y.; Yao, M.; Tang, Y. Shrinkage compensation design and mechanism of geopolymer pastes. Constr. Build. Mater. 2021, 299, 123916. [Google Scholar] [CrossRef]

- Vlachakis, C.; Perry, M.; Biondi, L.; McAlorum, J. 3D printed temperature-sensing repairs for concrete structures. Addit. Manuf. 2020, 34, 101238. [Google Scholar] [CrossRef]

- Nematollahi, B.; Xia, M.; Sanjayan, J.; Vijay, P. Effect of type of fiber on inter-layer bond and flexural strengths of extrusion-based 3D printed geopolymer. Mater. Sci. Forum 2018, 939, 155–162. [Google Scholar] [CrossRef]

- Li, V.C.; Bos, F.P.; Yu, K.; McGee, W.; Ng, T.Y.; Figueiredo, S.C.; Nefs, K.; Mechtcherine, V.; Nerella, V.N.; Pan, J.; et al. On the emergence of 3D printable engineered, strain hardening cementitious composites (ECC/SHCC). Cem. Concr. Res. 2020, 132, 106038. [Google Scholar] [CrossRef]

- Kaze, R.C.; Naghizadeh, A.; Tchadjie, L.; Adesina, A.; Djobo, J.N.Y.; Nemaleu, J.G.D.; Kamseu, E.; Melo, U.C.; Tayeh, B.A. Lateritic soils based geopolymer materials: A review. Constr. Build. Mater. 2022, 344, 128157. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T.; Ng, C.T. Ambient- and oven-cured geopolymer concretes under active confinement. Constr. Build. Mater. 2019, 228, 116722. [Google Scholar] [CrossRef]

- Phoo-Ngernkham, T.; Maegawa, A.; Mishima, N.; Hatanaka, S.; Chindaprasirt, P. Effects of sodium hydroxide and sodium silicate solutions on compressive and shear bond strengths of FA-GBFS geopolymer. Constr. Build. Mater. 2015, 91, 1–8. [Google Scholar] [CrossRef]

- Aupoil, J.; Champenois, J.B.; de Lacaillerie, J.B.D.; Poulesquen, A. Interplay between silicate and hydroxide ions during geopolymerization. Cem. Concr. Res. 2019, 115, 426–432. [Google Scholar] [CrossRef]

- Vinai, R.; Soutsos, M. Production of sodium silicate powder from waste glass cullet for alkali activation of alternative binders. Cem. Concr. Res. 2019, 116, 45–56. [Google Scholar] [CrossRef]

- Hu, W.; Nie, Q.; Huang, B.; Su, A.; Du, Y.; Shu, X.; He, Q. Mechanical property and microstructure characteristics of geopolymer stabilized aggregate base. Constr. Build. Mater. 2018, 191, 1120–1127. [Google Scholar] [CrossRef]

- Nie, Q.; Hu, W.; Ai, T.; Huang, B.; Shu, X.; He, Q. Strength properties of geopolymers derived from original and desulfurized red mud cured at ambient temperature. Constr. Build. Mater. 2016, 125, 905–911. [Google Scholar] [CrossRef]

- van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Lukey, G.C. Reaction mechanisms in the geopolymeric conversion of inorganic waste to useful products. J. Hazard Mater. 2007, 139, 506–513. [Google Scholar] [CrossRef] [PubMed]

- Adesanya, E.; Ohenoja, K.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. One-part geopolymer cement from slag and pretreated paper sludge. J. Clean. Prod. 2018, 185, 168–175. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. Comparison of alkali and silica sources in one-part alkali-activated blast furnace slag mortar. J. Clean. Prod. 2018, 187, 171–179. [Google Scholar] [CrossRef]

- Provis, J.L.; Van Deventer, J.S. Alkali Activated Materials: State-of-the-Art Report; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A. Geopolymer additive manufacturing: A review. Addit. Manuf. 2022, 55, 102782. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Nerella, V.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Shah, S.F.A.; Chen, B.; Oderji, S.Y.; Haque, M.A.; Ahmad, M.R. Improvement of early strength of fly ash-slag based one-part alkali activated mortar. Constr. Build. Mater. 2020, 246, 118533. [Google Scholar] [CrossRef]

- Oderji, S.Y.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: Effect of slag and alkali activators. J. Clean. Prod. 2019, 225, 1–10. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Nazari, A.; Sanjayan, J. Properties of one-part geopolymer incorporating wollastonite as partial replacement of geopolymer precursor or sand. Mater. Lett. 2020, 263, 127236. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Ghaffar, S.H.; Pan, J.; Dai, J.G. Properties of additively manufactured geopolymer incorporating mineral wollastonite microfibers. Constr. Build. Mater. 2022, 331, 127282. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Feleko, B.; Türkel, S.; Baradan, B. Effect of water/cement ratio on the fresh and hardened properties of self-compacting concrete. Build. Environ. 2007, 42, 1795–1802. [Google Scholar] [CrossRef]

- Cheng, Y.; Cong, P.; Hao, H.; Zhao, Q.; Mei, L.; Zhang, A.; Han, Z.; Hu, M. Improving workability and mechanical properties of one-part waste brick power based-binders with superplasticizers. Constr. Build. Mater. 2022, 335, 127535. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Wang, Y.S.; Dai, J.G.; Xu, Q.F. Effect of superplasticizers on properties of one-part Ca(OH)2/Na2SO4 activated geopolymer pastes. Constr. Build. Mater. 2020, 241, 117990. [Google Scholar] [CrossRef]

- Kaze, C.R.; Lecomte-Nana, G.L.; Adesina, A.; Nemaleu, J.G.D.; Kamseu, E.; Melo, U.C. Influence of mineralogy and activator type on the rheology behaviour and setting time of laterite based geopolymer paste. Cem. Concr. Compos. 2022, 126, 104345. [Google Scholar] [CrossRef]

- Kaze, C.R.; Alomayri, T.; Hasan, A.; Tome, S.; Lecomte-Nana, G.L.; Nemaleu, J.G.D.; Tchakoute, H.K.; Kamseu, E.; Melo, U.C.; Rahier, H. Reaction kinetics and rheological behaviour of meta-halloysite based geopolymer cured at room temperature: Effect of thermal activation on physicochemical and microstructural properties. Appl. Clay Sci. 2020, 196, 105773. [Google Scholar] [CrossRef]

- Ma, G.; Yan, Y.; Zhang, M.; Sanjayan, J. Effect of steel slag on 3D concrete printing of geopolymer with quaternary binders. Ceram. Int. 2022, 48, 26233–26247. [Google Scholar] [CrossRef]

- Kaze, C.R.; Adesina, A.; Alomayri, T.; Assaedi, H.; Kamseu, E.; Melo, U.C.; Leonelli, C. Characterization, reactivity and rheological behaviour of metakaolin and Metahalloysite based geopolymer binders. Clean. Mater. 2021, 2, 100025. [Google Scholar] [CrossRef]

- Kaze, C.R.; Adesina, A.; Lecomte-Nana, G.L.; Alomayri, T.; Kamseu, E.; Melo, U.C. Alkali-activated laterite binders: Influence of silica modulus on setting time, rheological behaviour and strength development. Clean. Eng. Technol. 2021, 4, 100175. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Dong, M.; Elchalakani, M.; Karrech, A. Development of high strength one-part geopolymer mortar using sodium metasilicate. Constr. Build. Mater. 2020, 236, 117611. [Google Scholar] [CrossRef]

- Ma, C.; Zhao, B.; Guo, S.; Long, G.; Xie, Y. Properties and characterization of green one-part geopolymer activated by composite activators. J. Clean. Prod. 2019, 220, 188–199. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Luukkonen, T.; Mastali, M.; Kinnunen, P.; Illikainen, M. Development of one-part alkali-activated ceramic/slag binders containing recycled ceramic aggregates. J. Mater. Civ. Eng. 2019, 31, 1–13. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Properties of metakaolin-high calcium fly ash geopolymer concrete containing recycled aggregate from crushed concrete specimens. Constr. Build. Mater. 2018, 161, 365–373. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. Mechanical characterization of 3D printable concrete. Constr. Build. Mater. 2019, 227, 116710. [Google Scholar] [CrossRef]

- Dey, D.; Srinivas, D.; Panda, B.; Suraneni, P.; Sitharam, T.G. Use of industrial waste materials for 3D printing of sustainable concrete: A review. J. Clean. Prod. 2022, 340, 130749. [Google Scholar] [CrossRef]

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D concrete printing for sustainable and economical construction: A comparative study. Autom. Constr. 2022, 134, 104087. [Google Scholar] [CrossRef]

- Weng, Y.; Li, M.; Ruan, S.; Wong, T.N.; Tan, M.J.; Yeong, K.L.O.; Qian, S. Comparative economic, environmental and productivity assessment of a concrete bathroom unit fabricated through 3D printing and a precast approach. J. Clean. Prod. 2020, 261, 121245. [Google Scholar] [CrossRef]

- de Soto, B.G.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Mohammad, M.; Masad, E.; Al-Ghamdi, S.G. 3D concrete printing sustainability: A comparative life cycle assessment of four construction method scenarios. Buildings 2020, 10, 245. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. Constr. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Yao, Y.; Hu, M.; Di Maio, F.; Cucurachi, S. Life cycle assessment of 3D printing geo-polymer concrete: An ex-ante study. J. Ind. Ecol. 2020, 24, 116–127. [Google Scholar] [CrossRef]

- Liu, S.; Lu, B.; Li, H.; Pan, Z.; Jiang, J.; Qian, S. A comparative study on environmental performance of 3D printing and conventional casting of concrete products with industrial wastes. Chemosphere 2022, 298, 134310. [Google Scholar] [CrossRef]

- Kwek, S.Y.; Awang, H.; Cheah, C.B. Influence of liquid-to-solid and alkaline activator (Sodium silicate to sodium hydroxide) ratios on fresh and hardened properties of alkali-activated palm oil fuel ash geopolymer. Materials 2021, 14, 4253. [Google Scholar] [CrossRef] [PubMed]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Petrillo, A.; Cioffi, R.; Ferone, C.; Colangelo, F.; Borrelli, C. Eco-sustainable geopolymer concrete blocks production process. Agric. Agric. Sci. Procedia 2016, 8, 408–418. [Google Scholar] [CrossRef]

- Yang, K.H.; Lee, K.H.; Song, J.K.; Gong, M.H. Properties and sustainability of alkali-activated slag foamed concrete. J. Clean. Prod. 2014, 68, 226–233. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and hardened properties of 3D printable cementitious materials for building and construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Zhou, G.-X.; Li, C.; Zhao, Z.; Qi, Y.-Z.; Yang, Z.-H.; Jia, D.-C.; Zhong, J.; Zhou, Y. 3D printing geopolymer nanocomposites structure: Graphene oxide size effects on a reactive matrix. Carbon 2020, 164, 215–223. [Google Scholar] [CrossRef]

- Fu, S.; He, P.; Wang, M.; Wang, M.; Wang, R.; Yuan, J.; Jia, D.; Cui, J. Monoclinic celsian ceramics formation: Through thermal treatment of ion-exchanged 3D printing geopolymer precursor. J. Eur. Ceram. Soc. 2019, 39, 563–573. [Google Scholar] [CrossRef]

- Franchin, G.; Pesonen, J.; Luukkonen, T.; Bai, C.; Scanferla, P.; Botti, R.; Carturan, S.; Innocentini, M.; Colombo, P. Removal of ammonium from wastewater with geopolymer sorbents fabricated via additive manufacturing. Mater. Des. 2020, 195, 109006. [Google Scholar] [CrossRef]

- Luukkonen, T.; Yliniemi, J.; Sreenivasan, H.; Ohenoja, K.; Finnil, M.; Franchin, G.; Colombo, P. Ag- or Cu-modified geopolymer filters for water treatment manufactured by 3D printing, direct foaming, or granulation. Sci. Rep. 2020, 10, 7233. [Google Scholar] [CrossRef]

- Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. Do geopolymers actually contain nanocrystalline zeolites? A reexamination of existing results. Chem. Mater. 2005, 17, 3075–3085. [Google Scholar] [CrossRef]

- Dedenis, M.; Sonebi, M.; Amziane, S.; Perrot, A.; Amato, G. Effect of Metakaolin, Fly Ash and Polypropylene Fibres on Fresh and Rheological Properties of 3D Printing Based Cement Materials; RILEM Bookseries; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

| Aluminosilicate Raw Material | Alkali Activator | Aggregates | Rheological and Functional Additives | Reinforcement | Refs. |

|---|---|---|---|---|---|

| FA + slag | ASM | Fine silica sand | 2-Pyrrolidone | N.F. | [21] |

| Slag | ASM | Fine silica sand | 2-Pyrrolidone | N.F. | [22,25] |

| FA + BFS + SF | KOH + K2SiO3 | River sand | Actigel and cellulose | N.F. | [13] |

| FA + BFS + SF | K2SiO3 | Fine river sand | N.R. | N.F. | [53] |

| FA + BFS | APS + KOH | Fine river sand | N.F. | N.F. | [79] |

| FA | ASM | N.F. | N.F. | N.F. | [80] |

| FA + BFS | KOH + K2SiO3 | Fine river sand | Attapulgite clay | N.F. | [81] |

| FA + BFS | KOH + K2SiO3 | Fine and coarse silica sand | CMC, anhydrous borax | N.F. | [82] |

| FA + BFS | NaOH + Na2SiO3 | Fine and coarse silica sand | CMC, anhydrous borax | N.F. | [82] |

| FA + BFS + SF | NaOH + Na2SiO3 | Different grain-sized sands | N.F. | N.F. | [83] |

| BFS | NaOH + Na2SiO3 | Calcium carbonate | CMC | N.F. | [84] |

| MK | NaOH + Na2SiO3 | Fine silica sand | N.F. | N.F. | [85] |

| FA + BFS + SF | ASM | Fine silica sand | Attapulgite clay, SF, slag | N.F. | [86] |

| MK | NaOH, silica gel | Fine silica sand | N.F. | N.F. | [17] |

| MK | NaOH + Na2SiO3 | N.F. | Bentonite, microalgal biomass | N.F. | [87] |

| FA + BFS + SF | K2SiO3 | Fine river sand | Hydroxypropyl methylcellulose | Glass bers (3, 6, 8 mm) | [88] |

| FA + BFS + SF | NaOH + K2SiO3 | Fine river sand | Attapulgite clay | Glass bers (4 mm) | [89] |

| FA + BFS + SF | K2SiO3 | Fine river sand | Attapulgite clay | Glass bers (3, 6, 8 mm) | [90] |

| FA | NaOH, Na2SiO3 | Fine river sand | Carboxymethyl cellulose | PP bers (6 mm) | [91] |

| FA, BFS, and SF | PSM | Silica sand | N.F. | Nylon, carbon, PE, aramid, steel micro-cables | [92] |

| FA + BFS + SF | NaOH + Na2SiO3 | Different grain-sized sands | N.F. | Nano-graphite platelets | [93] |

| FA | NaOH + Na2SiO3, Na2SO4 | N.F. | SF, OPC, limestone, Lightcrete 02 | N.F. | [94] |

| MK | NaOH + Na2SiO3 | N.F. | Polyethylene glycol | N.F. | [95] |

| CH, AZS | NaOH + Na2SiO3 | N.F. | Polyethylene glycol PMMA sphere | N.F. | [96] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Extrusion-Based 3D-Printing: A Review. Polymers 2023, 15, 4688. https://doi.org/10.3390/polym15244688

Ricciotti L, Apicella A, Perrotta V, Aversa R. Geopolymer Materials for Extrusion-Based 3D-Printing: A Review. Polymers. 2023; 15(24):4688. https://doi.org/10.3390/polym15244688

Chicago/Turabian StyleRicciotti, Laura, Antonio Apicella, Valeria Perrotta, and Raffaella Aversa. 2023. "Geopolymer Materials for Extrusion-Based 3D-Printing: A Review" Polymers 15, no. 24: 4688. https://doi.org/10.3390/polym15244688

APA StyleRicciotti, L., Apicella, A., Perrotta, V., & Aversa, R. (2023). Geopolymer Materials for Extrusion-Based 3D-Printing: A Review. Polymers, 15(24), 4688. https://doi.org/10.3390/polym15244688