Automated Quantification of Interlaminar Delaminations in Carbon-Fiber-Reinforced Polymers via High-Resolution Ultrasonic Testing

Abstract

:1. Introduction

2. Materials and Methods

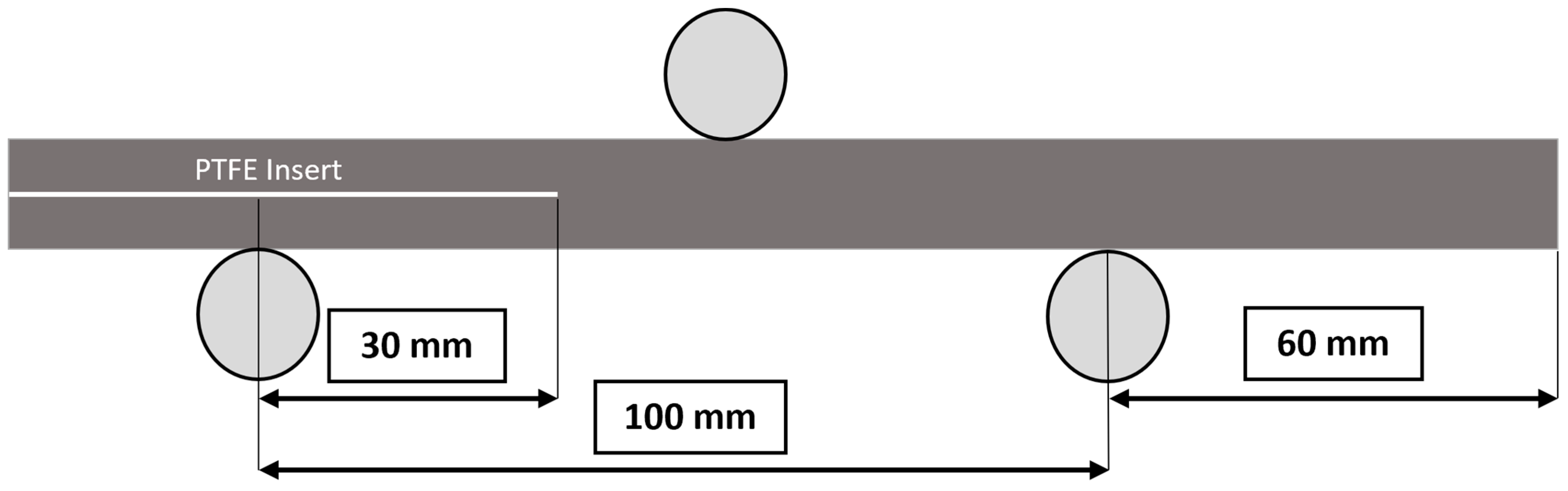

2.1. Specimen Fabrication

2.2. Fracture Test

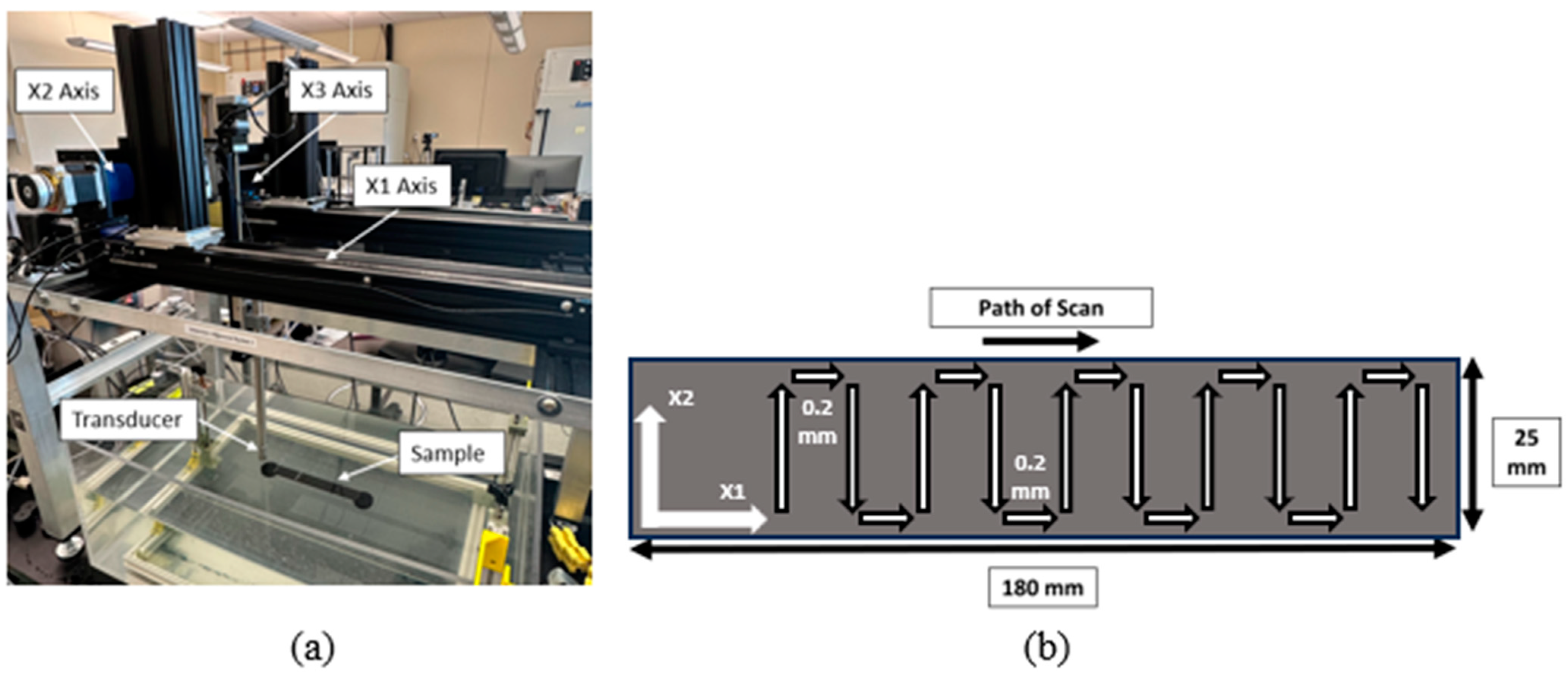

2.3. Ultrasonic Scanning Set Up

2.4. X-ray CT Scanning and Analysis

3. Analysis

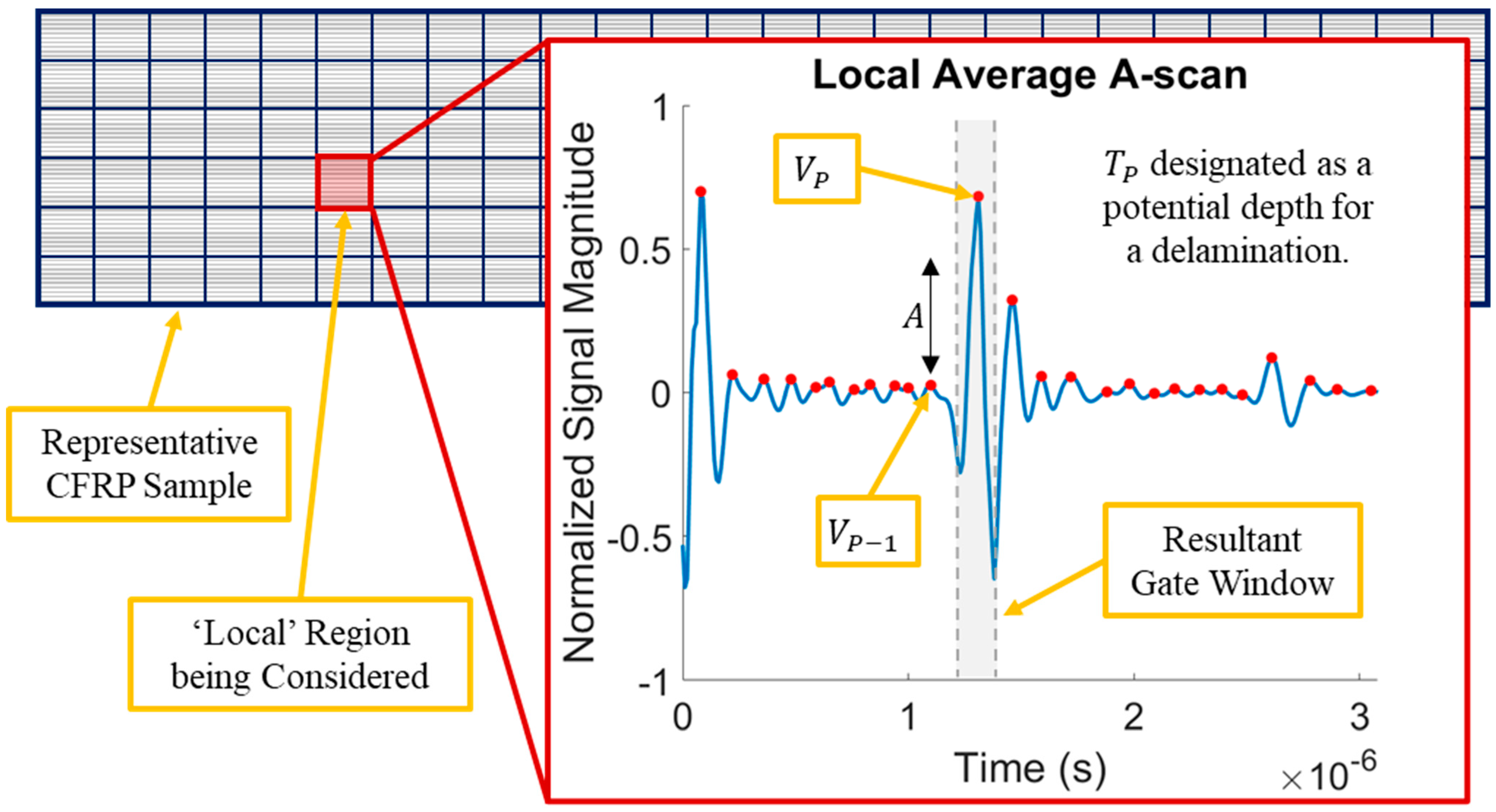

3.1. Delamination Depth Identification through UT Signal Analysis

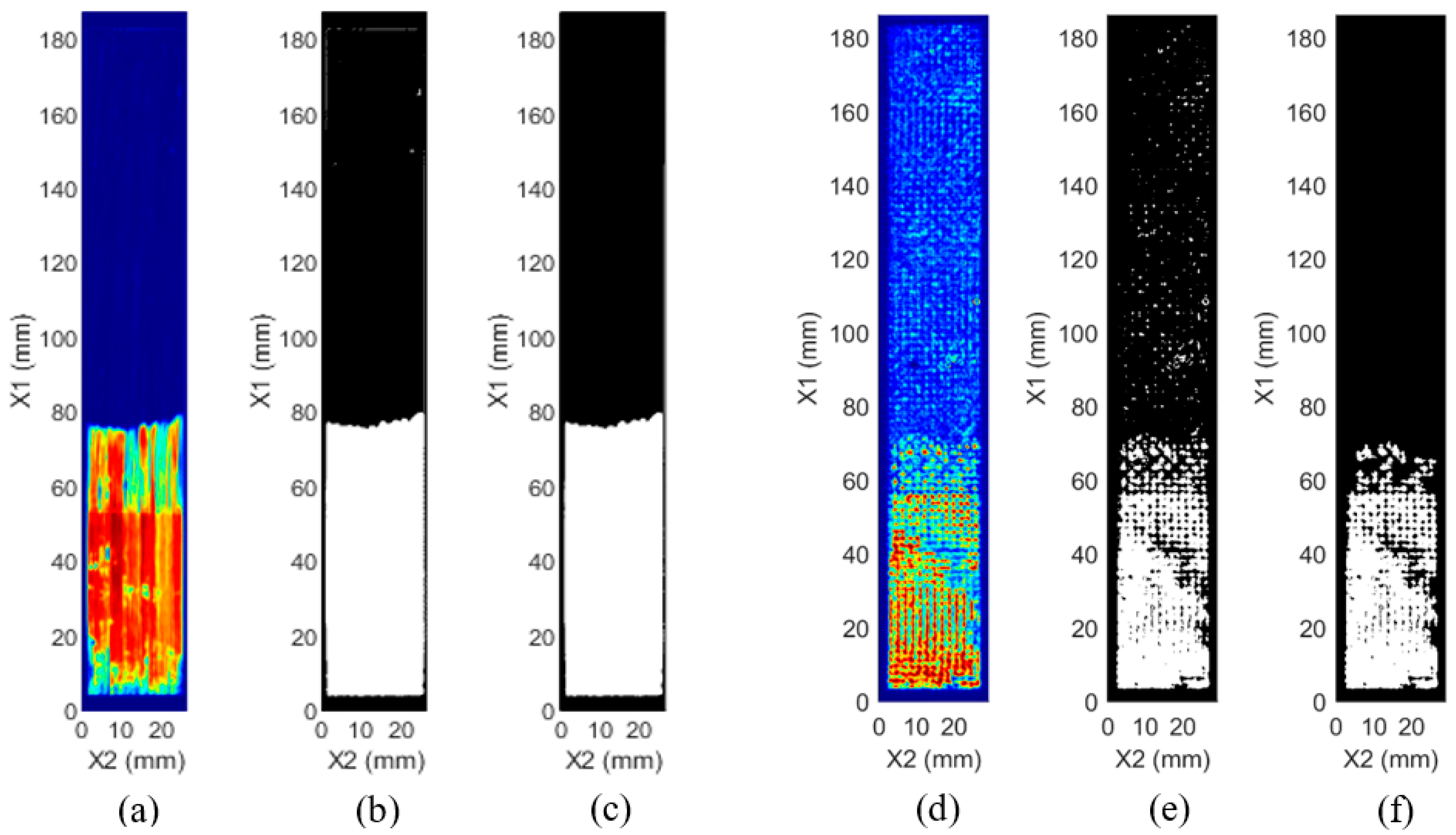

3.2. Quantification of Delamination Geometry and Spatial Location

4. Results and Discussion

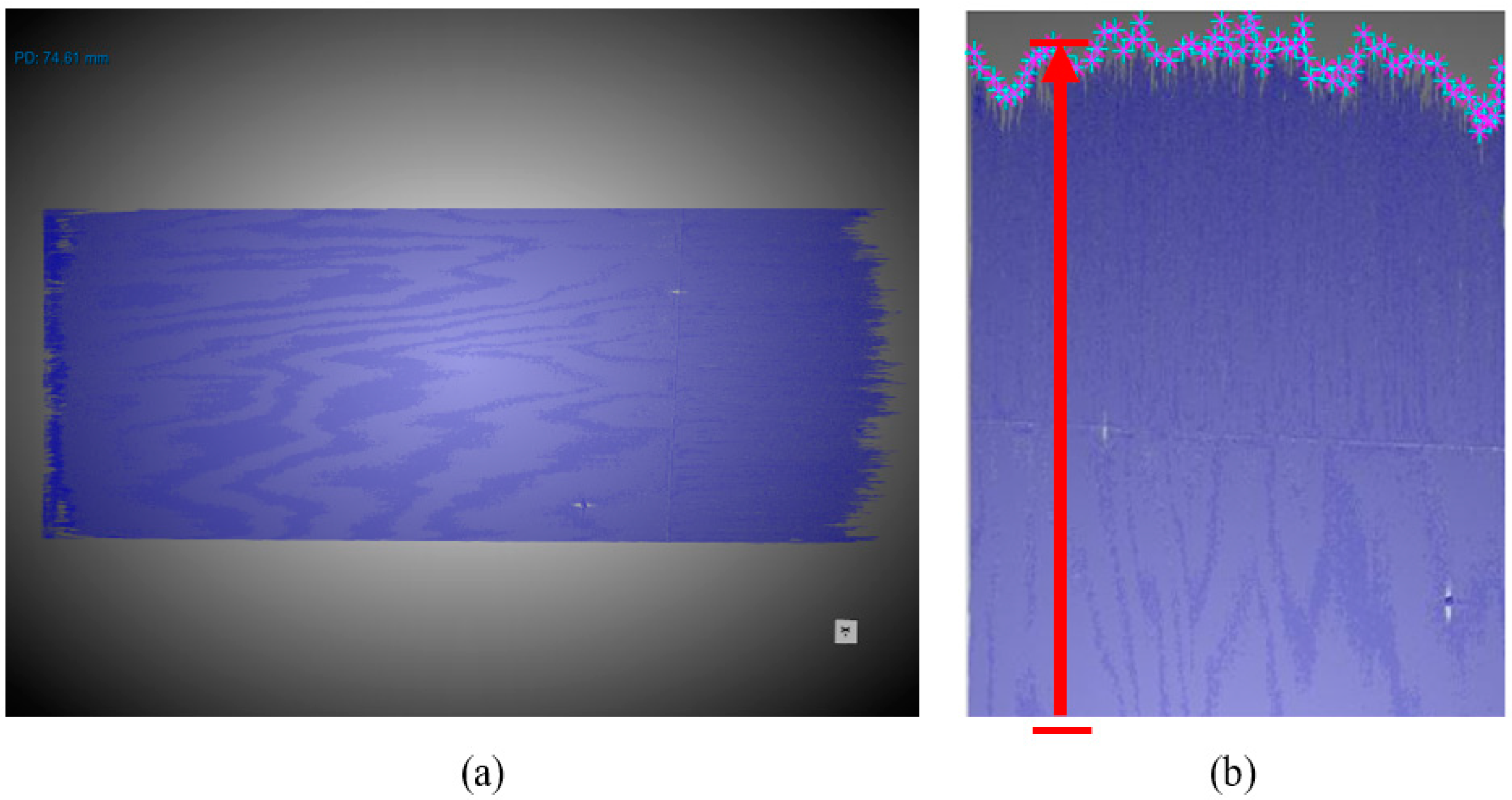

4.1. Ultrasonic Testing Results and Discussion

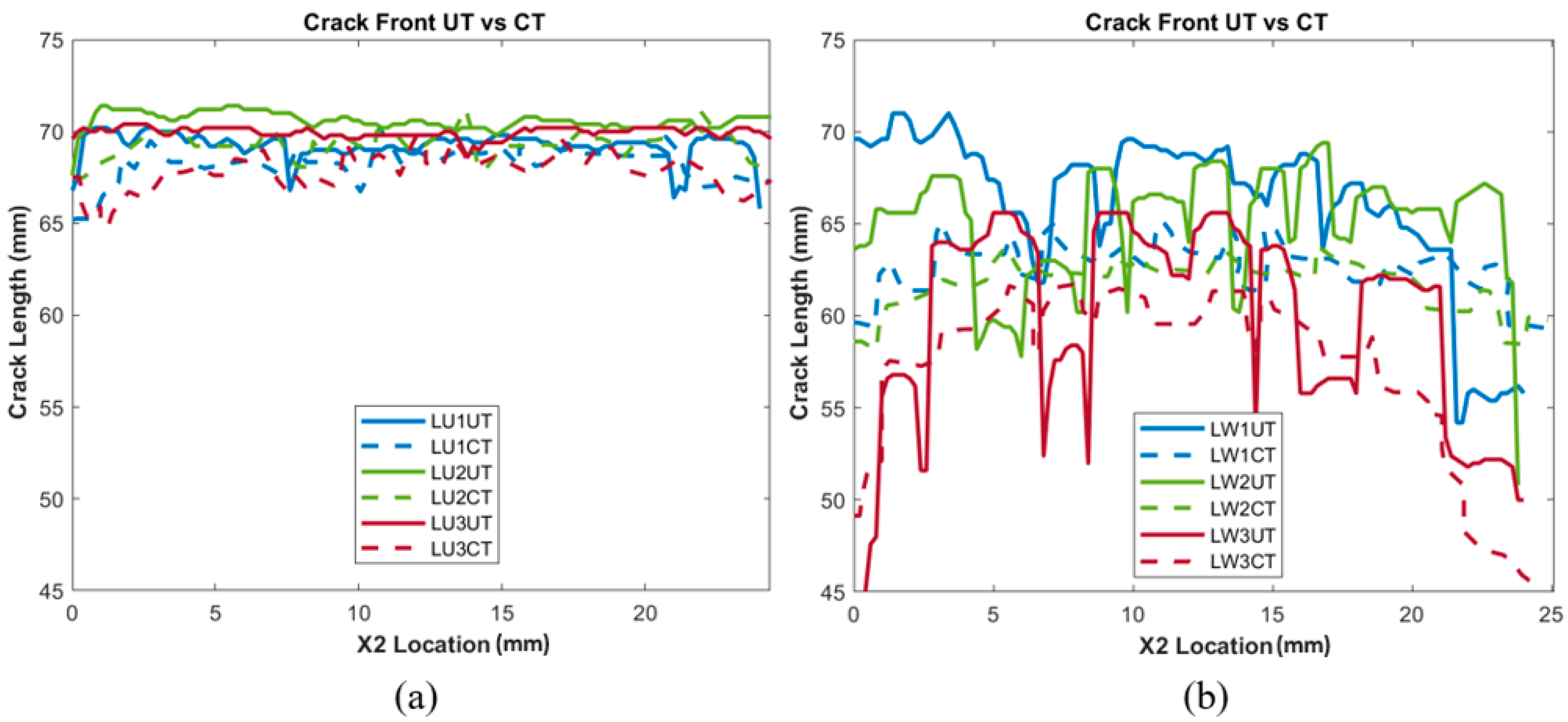

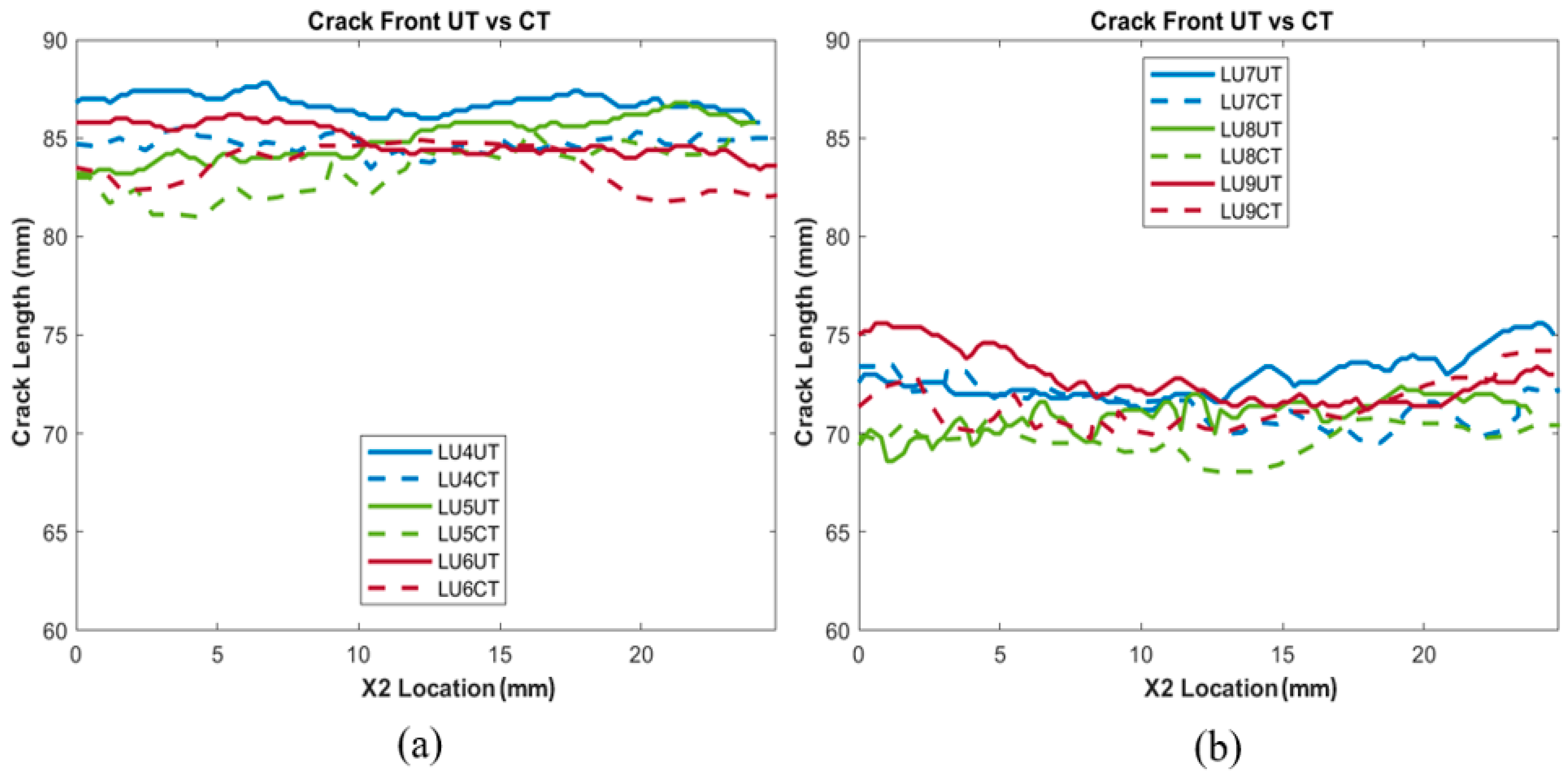

4.2. Comparison of UT and X-ray CT results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yi, Q.; Tian, G.Y.; Malekmohammadi, H.; Laureti, S.; Ricci, M.; Gao, S. Inverse reconstruction of fibre orientation in multilayer CFRP using forward FEM and eddy current pulsed thermography. NDT E Int. 2021, 122, 102474. [Google Scholar] [CrossRef]

- Liu, Y.; Zwingmann, B.; Schlaich, M. Carbon Fiber Reinforced Polymer for Cable Structures—A Review. Polymers 2015, 7, 2078–2099. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Hu, W. Casting defects induced fatigue damage in aircraft frames of ZL205A aluminum alloy—A failure analysis. Mater. Des. 2011, 32, 2570–2582. [Google Scholar] [CrossRef]

- Nakai, Y.; Hiwa, C. Effects of loading frequency and environment on delamination fatigue crack growth of CFRP. Int. J. Fatigue 2002, 24, 161–170. [Google Scholar] [CrossRef]

- Miyagawa, H.; Sato, C.; Ikegami, K. Interlaminar fracture toughness of CFRP in Mode I and Mode II determined by Raman spectroscopy. Compos. Part Appl. Sci. Manuf. 2001, 32, 477–486. [Google Scholar] [CrossRef]

- De Freitas, M.; Reis, L. Failure mechanisms on composite specimens subjected to compression after impact. Compos. Struct. 1998, 42, 365–373. [Google Scholar] [CrossRef]

- Panettieri, E.; Fanteria, D.; Danzi, F. Delaminations growth in compression after impact test simulations: Influence of cohesive elements parameters on numerical results. Compos. Struct. 2016, 137, 140–147. [Google Scholar] [CrossRef]

- Wang, B.; Zhong, S.; Lee, T.-L.; Fancey, K.S.; Mi, J. Non-destructive testing and evaluation of composite materials/structures: A state-of-the-art review. Adv. Mech. Eng. 2020, 12, 168781402091376. [Google Scholar] [CrossRef]

- De Castro, D.S.V.; Matvieieva, N.; Grosso, M.; Camerini, C.G.; Kotik, H.G.; Heuer, H. Evaluation of Mode II Delamination Area by Non-destructive Techniques: Accuracy and Influence on Fracture Toughness Calculation. J. Nondestruct. Eval. 2021, 40, 58. [Google Scholar] [CrossRef]

- Mook, G.; Lange, R.; Koeser, O. Non-destructive characterisation of carbon-fibre-reinforced plastics by means of eddy-currents. Compos. Sci. Technol. 2001, 61, 865–873. [Google Scholar] [CrossRef]

- Kersemans, M.; Verboven, E.; Segers, J.; Hedayatrasa, S.; Paepegem, W.V. Non-Destructive Testing of Composites by Ultrasound, Local Defect Resonance and Thermography. Proceedings 2018, 2, 554. [Google Scholar] [CrossRef]

- Dattoma, V.; Panella, F.W.; Pirinu, A.; Saponaro, A. Ultrasonic and thermographic studies for CFRP inspections with real and simulated defects. Mater. Today Proc. 2021, 34, 224–234. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H. Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int. J. Mach. Tools Manuf. 2005, 45, 1282–1287. [Google Scholar] [CrossRef]

- Joshi, S.; Rawat, K.; Balan, A.S.S. A novel approach to predict the delamination factor for dry and cryogenic drilling of CFRP. J. Mater. Process. Technol. 2018, 262, 521–531. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, M.; Liu, K.; Yuan, K.; He, J. Experimental analysis and prediction of CFRP delamination caused by ice impact. Eng. Fract. Mech. 2022, 273, 108757. [Google Scholar] [CrossRef]

- Tan, R.; Xu, J.; Sun, W.; Liu, Z.; Guan, Z.; Guo, X. Relationship Between Matrix Cracking and Delamination in CFRP Cross-Ply Laminates Subjected to Low Velocity Impact. Materials 2019, 12, 3990. [Google Scholar] [CrossRef]

- Haeger, A.; Schoen, G.; Lissek, F.; Meinhard, D.; Kaufeld, M.; Schneider, G.; Schuhmacher, S.; Knoblauch, V. Non-destructive Detection of Drilling-induced Delamination in CFRP and its Effect on Mechanical Properties. Procedia Eng. 2016, 149, 130–142. [Google Scholar] [CrossRef]

- Senck, S.; Scheerer, M.; Revol, V.; Plank, B.; Hannesschläger, C.; Gusenbauer, C.; Kastner, J. Microcrack characterization in loaded CFRP laminates using quantitative two- and three-dimensional X-ray dark-field imaging. Compos. Part Appl. Sci. Manuf. 2018, 115, 206–214. [Google Scholar] [CrossRef]

- Baffour, F.I.; Rajendran, K.; Glazebrook, K.N.; Thorne, J.E.; Larson, N.B.; Leng, S.; McCollough, C.H.; Fletcher, J.G. Ultra-high-resolution imaging of the shoulder and pelvis using photon-counting-detector CT: A feasibility study in patients. Eur. Radiol. 2022, 32, 7079–7086. [Google Scholar] [CrossRef]

- Garcea, S.C.; Wang, Y.; Withers, P.J. X-ray computed tomography of polymer composites. Compos. Sci. Technol. 2018, 156, 305–319. [Google Scholar] [CrossRef]

- Landstorfer, P.; Herl, G.; Hiller, J. Investigation of Non-circular Scanning Trajectories in Robot-based Industrial X-ray Computed Tomography of Multi-material Objects. In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics, Prague, Czech Republic, 29–31 July 2019; SCITEPRESS—Science and Technology Publications: Setúbal, Portugal, 2019; pp. 518–522. [Google Scholar] [CrossRef]

- Venkatakrishnan, A.R.; Kim, S.T.; Eisawy, R.; Pfister, F.; Navab, N. Self-Supervised Out-of-Distribution Detection in Brain CT Scans. arXiv 2020, arXiv:2011.05428. [Google Scholar]

- Blackman, N.J.; Jack, D.A.; Blandford, B.M. Improvement in the Quantification of Foreign Object Defects in Carbon Fiber Laminates Using Immersion Pulse-Echo Ultrasound. Materials 2021, 14, 2919. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Li, S.; Zhou, Z. Detection of disbonds in multi-layer bonded structures using the laser ultrasonic pulse-echo mode. Ultrasonics 2019, 94, 411–418. [Google Scholar] [CrossRef] [PubMed]

- Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. 2023. Available online: https://www.astm.org/d7905_d7905m-19e01.html (accessed on 19 October 2023).

- MATLAB. The Language of Technical Computing. The Mathworks Inc. Available online: https://www.mathworks.com/help/matlab/ (accessed on 1 December 2023).

- Blandford, B.M.; Jack, D.A. High resolution depth and area measurements of low velocity impact damage in carbon fiber laminates via an ultrasonic technique. Compos. Part B Eng. 2020, 188, 107843. [Google Scholar] [CrossRef]

- Ding, J.; Zheng, D.; Ding, H.; Li, K.; Ma, Q.; He, G.; Liu, J.; Chen, J. Evaluating Image Precision of Acoustical Imaging Diffraction by Focused Ultrasound Beam. Sens. Transducers 2017, 208, 50–57. [Google Scholar]

| PTFE Actual Position | PTFE Predicted Position | Lamina Inaccuracy | |

|---|---|---|---|

| LU1 | Between 15 and 16 Lamina | Between 15 and 16 Lamina | 0 |

| LU2 | Between 15 and 16 Lamina | Between 14 and 15 Lamina | 1 |

| LU3 | Between 15 and 16 Lamina | Between 14 and 15 Lamina | 1 |

| LU4 | Between 21 and 22 Lamina | Between 21 and 22 Lamina | 0 |

| LU5 | Between 21 and 22 Lamina | Between 21 and 22 Lamina | 0 |

| LU6 | Between 21 and 22 Lamina | Between 21 and 22 Lamina | 0 |

| LU7 | Between 8 and 9 Lamina | Between 9 and 10 Lamina | 1 |

| LU8 | Between 8 and 9 Lamina | Between 9 and 10 Lamina | 1 |

| LU9 | Between 8 and 9 Lamina | Between 8 and 9 Lamina | 0 |

| NDT Method | Crack Area Measurement (mm2) | |||||

|---|---|---|---|---|---|---|

| LU1 | LU2 | LU3 | LW1 | LW2 | LW3 | |

| UT | 1662.1 | 1751.0 | 1706.8 | 1589.2 | 1552.2 | 1433.4 |

| CT | 1693.0 | 1721.2 | 1690.8 | 1555.2 | 1536.0 | 1427.9 |

| % Difference | 1.83 | 1.73 | 0.95 | 2.19 | 1.05 | 0.39 |

| NDT Method | Crack Area Measurement (mm2) | |||||

|---|---|---|---|---|---|---|

| LU4 | LU5 | LU6 | LU7 | LU8 | LU9 | |

| UT | 2083.9 | 2053.6 | 2100.4 | 1793.1 | 1742.2 | 1787.3 |

| CT | 2100.7 | 2039.1 | 2105.5 | 1791.4 | 1688.5 | 1789.4 |

| % Difference | 0.81 | 0.71 | 0.24 | 0.01 | 3.08 | 0.12 |

| NDT Method | Crack Area Measurement (mm2) | |||||

|---|---|---|---|---|---|---|

| LU4 | LU5 | LU6 | LU7 | LU8 | LU9 | |

| UT | 2083.9 | 2053.6 | 2100.4 | 1793.1 | 1742.2 | 1787.3 |

| UT-Flip | 2052.3 | 2043.0 | 2097.2 | 1780.1 | 1733.8 | 1765.4 |

| % Difference | 1.52 | 0.52 | 0.15 | 0.73 | 0.48 | 1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matalgah, K.; Ravindranath, P.K.; Pulipati, D.; Fleck, T.J. Automated Quantification of Interlaminar Delaminations in Carbon-Fiber-Reinforced Polymers via High-Resolution Ultrasonic Testing. Polymers 2023, 15, 4691. https://doi.org/10.3390/polym15244691

Matalgah K, Ravindranath PK, Pulipati D, Fleck TJ. Automated Quantification of Interlaminar Delaminations in Carbon-Fiber-Reinforced Polymers via High-Resolution Ultrasonic Testing. Polymers. 2023; 15(24):4691. https://doi.org/10.3390/polym15244691

Chicago/Turabian StyleMatalgah, Khaled, Pruthul Kokkada Ravindranath, Daniel Pulipati, and Trevor J. Fleck. 2023. "Automated Quantification of Interlaminar Delaminations in Carbon-Fiber-Reinforced Polymers via High-Resolution Ultrasonic Testing" Polymers 15, no. 24: 4691. https://doi.org/10.3390/polym15244691

APA StyleMatalgah, K., Ravindranath, P. K., Pulipati, D., & Fleck, T. J. (2023). Automated Quantification of Interlaminar Delaminations in Carbon-Fiber-Reinforced Polymers via High-Resolution Ultrasonic Testing. Polymers, 15(24), 4691. https://doi.org/10.3390/polym15244691