Application of Synchrotron Radiation-Based Fourier-Transform Infrared Microspectroscopy for Thermal Imaging of Polymer Thin Films

Abstract

:1. Introduction

2. Materials and Methods

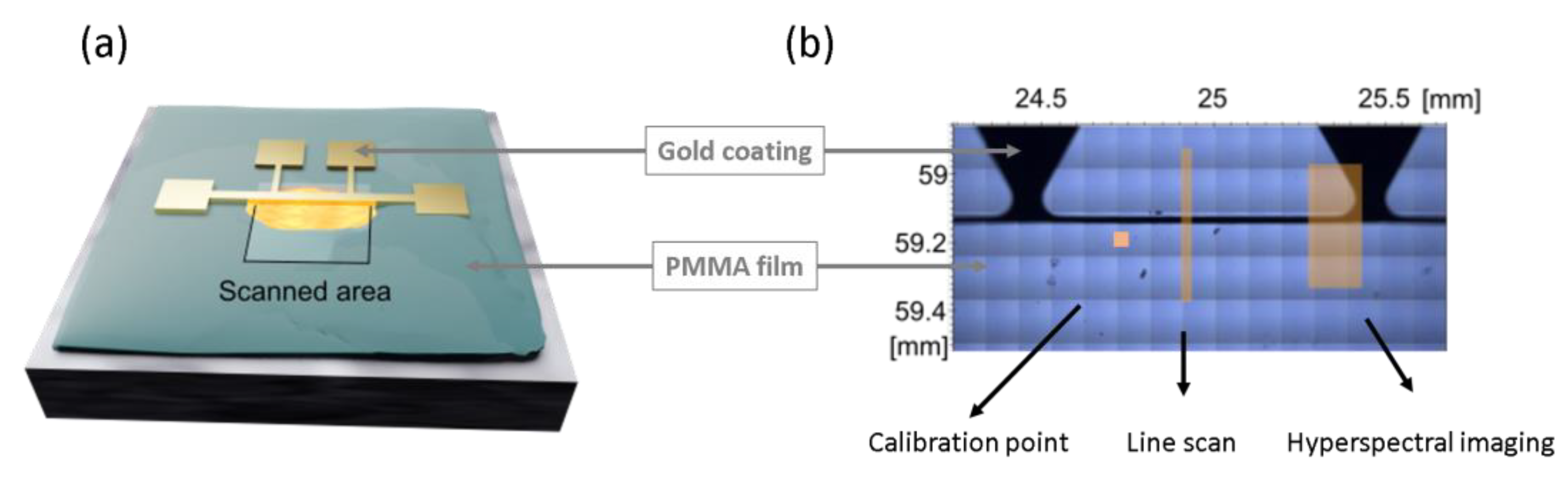

2.1. Sample Preparation

2.2. Metal Wire Preparation and Temperature Calibration

2.3. Synchrotron Radiation-Based Fourier-Transform Infrared (SR-FTIR) Microspectroscopy

2.4. Machine Learning

3. Results and Discussion

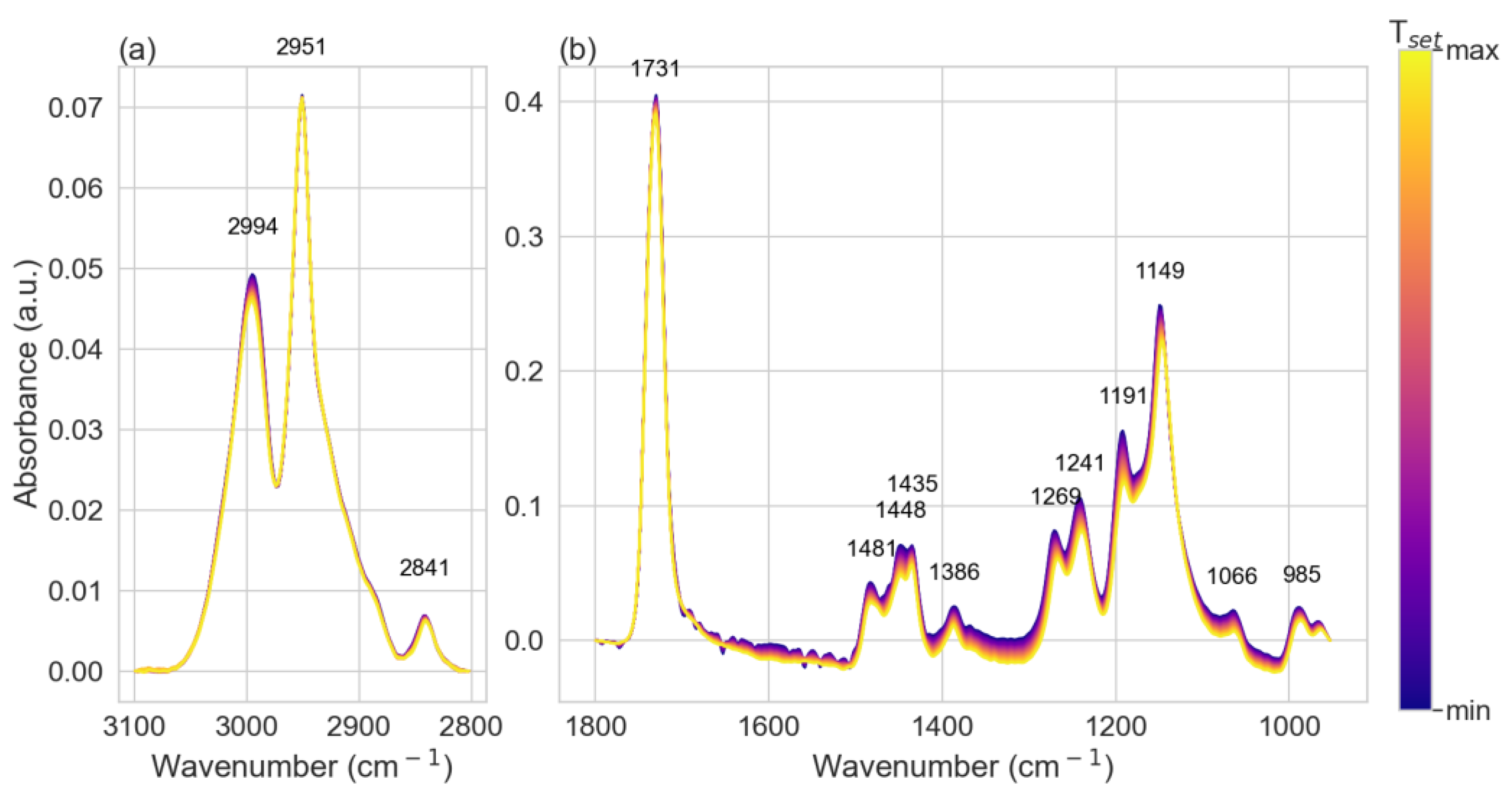

3.1. PMMA Infrared Absorption (Calibration Data)

3.2. Line Scans (Test Sample)

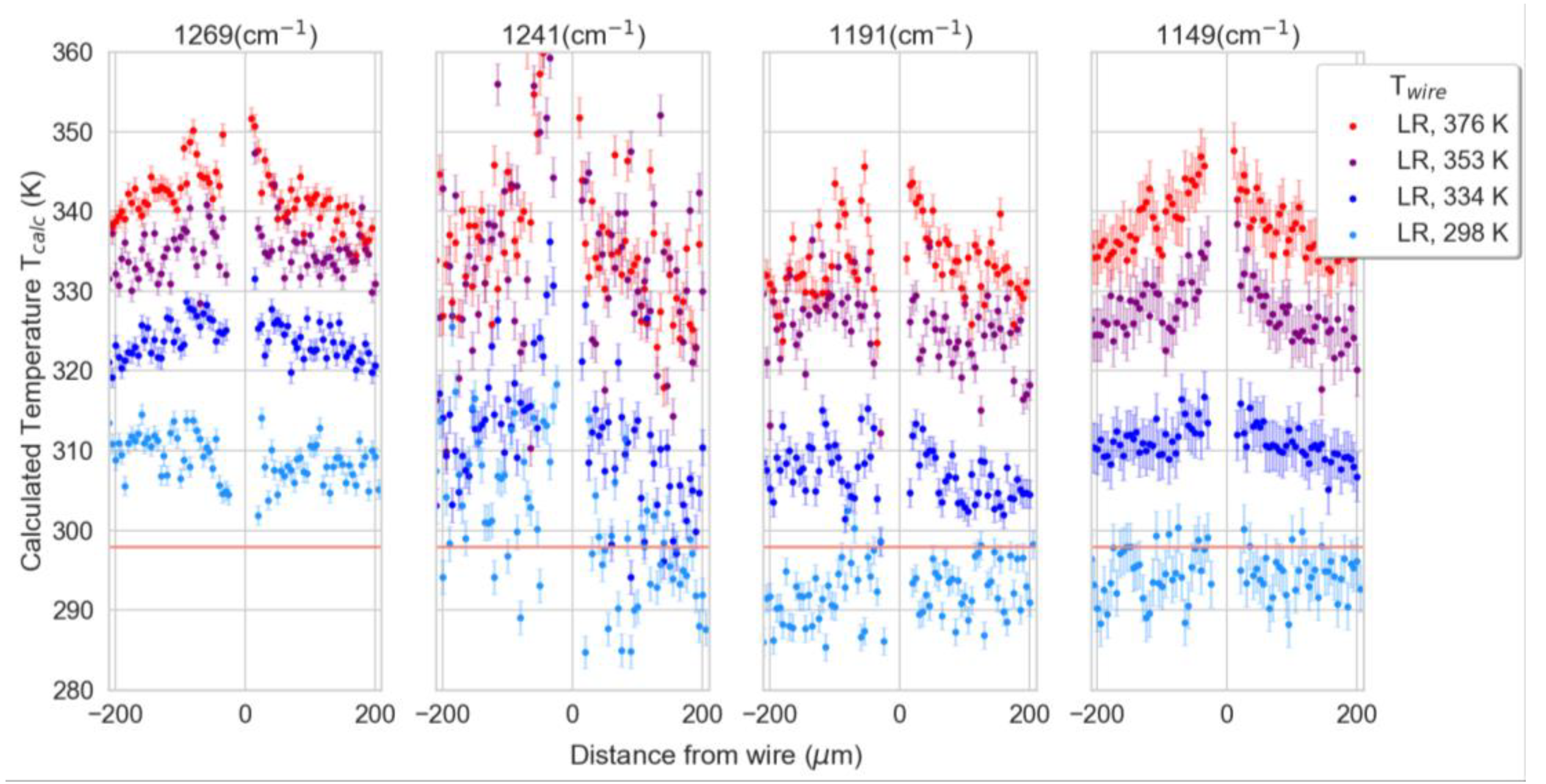

3.2.1. Temperature Prediction by Linear Regression Model

3.2.2. Temperature Prediction by Machine Learning Approach

3.3. Hyperspectral Imaging

4. Summary

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, M.M.; Giry, A.; Mastiani, M.; Rodrigues, G.O.; Reis, A.; Mandin, P. Microscale thermometry: A review. Microelectron. Eng. 2015, 148, 129–142. [Google Scholar] [CrossRef]

- McCabe, K.M.; Hernandez, M. Molecular thermometry. Pediatr. Res. 2010, 67, 469–475. [Google Scholar] [CrossRef] [PubMed]

- Mehboudi, M.; Sanpera, A.; Correa, L.A. Thermometry in the quantum regime: Recent theoretical progress. J. Phys. A Math. Theor. 2019, 52, 303001. [Google Scholar] [CrossRef] [Green Version]

- Chihara, T.; Umezawa, M.; Miyata, K.; Sekiyama, S.; Hosokawa, N.; Okubo, K.; Kamimura, M.; Soga, K. Biological Deep Temperature Imaging with Fluorescence Lifetime of Rare-Earth-Doped Ceramics Particles in the Second NIR Biological Window. Sci. Rep. 2019, 9, 12806. [Google Scholar] [CrossRef] [Green Version]

- Katsumata, T.; Morita, K.; Komuro, S.; Aizawa, H. Fiber-optic thermometer application of thermal radiation from rare-earth end-doped SiO2 fiber. Rev. Sci. Instrum. 2014, 85, 84903. [Google Scholar] [CrossRef]

- Jaramillo-Fernandez, J.; Chavez-Angel, E.; Sotomayor-Torres, C.M. Raman thermometry analysis: Modelling assumptions revisited. Appl. Therm. Eng. 2018, 130, 1175–1181. [Google Scholar] [CrossRef]

- Lahiri, B.B.; Bagavathiappan, S.; Jayakumar, T.; Philip, J. Medical applications of infrared thermography: A review. Infrared Phys. Technol. 2012, 55, 221–235. [Google Scholar] [CrossRef]

- Childs, P.R.N. Chapter 1. Nanoscale Thermometry and Temperature Measurement. In Thermometry at the Nanoscale: Techniques and Selected Applications; Dias Carlos, L., Palacio, F., Eds.; Royal Society of Chemistry (RSC): London, UK, 2015; pp. 1–22. [Google Scholar]

- Meola, C.; Carlomagno, G.M. Recent advances in the use of infrared thermography. Meas. Sci. Technol. 2004, 15, R27–R58. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared thermography for temperature measurement and non-destructive testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef] [Green Version]

- Kirimtat, A.; Krejcar, O. A review of infrared thermography for the investigation of building envelopes: Advances and prospects. Energy Build. 2018, 176, 390–406. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M. Composite material overview and its testing for aerospace components. In Sustainable Composites for Aerospace Applications; Jawaid, M., Thariq, M., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 69–108. ISBN 9780081021316. [Google Scholar]

- Herraiz, Á.H.; Marugán, A.P.; Márquez, F.P.G. A review on condition monitoring system for solar plants based on thermography. In Non-Destructive Testing and Condition Monitoring Techniques for Renewable Energy Industrial Assets; Elsevier: Amsterdam, The Netherlands, 2020; pp. 103–118. [Google Scholar]

- May, D.; Wunderle, B.; Ras, M.A.; Faust, W.; Gollhard, A.; Schacht, R.; Michel, B. Material characterization and non-destructive failure analysis by transient pulse generation and IR-thermography. In Proceedings of the 14th International Workshop on THERMal INvestigation of ICs and Systems, THERMINIC 2008, Rome, Italy, 24–26 September 2008; pp. 47–51. [Google Scholar]

- Szentkuti, A.; Kavanagh, H.S.; Grazio, S. Infrared thermography and image analysis for biomedical use. Period. Biol. 2011, 113, 385–392. [Google Scholar]

- Malekpour, H.; Balandin, A.A. Raman-based technique for measuring thermal conductivity of graphene and related materials. J. Raman Spectrosc. 2018, 49, 106–120. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Chen, Y.; Luo, Z.; Xu, X. Temperature and Strain Effects in Micro-Raman Thermometry for Measuring In-Plane Thermal Conductivity of Thin Films. Nanoscale Microscale Thermophys. Eng. 2021, 25, 91–100. [Google Scholar] [CrossRef]

- Xu, D.; Sang, Y.; Chu, Y.; Yu, Y.; Liu, F.; Hou, Y.; Wang, X. Optothermal Raman measurement determined thermal conductivity characteristics in NiMn2O4 films grown by chemical solution deposition. Mater. Res. Express 2021, 8, 056403. [Google Scholar] [CrossRef]

- Wang, H.; Thomas, J.; Okuniewski, M.A.; Tomar, V. Microstructure dependent thermal conductivity measurement of Zircaloy-4 using an extended Raman thermometry method. J. Nucl. Mater. 2020, 539, 152338. [Google Scholar] [CrossRef]

- Stoib, B.; Filser, S.; Stötzel, J.; Greppmair, A.; Petermann, N.; Wiggers, H.; Schierning, G.; Stutzmann, M.; Brandt, M.S. Spatially resolved determination of thermal conductivity by Raman spectroscopy. Semicond. Sci. Technol. 2014, 29, 124005. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Prasher, R.; Li, D. From nanowires to super heat conductors. J. Appl. Phys. 2021, 130, 220901. [Google Scholar] [CrossRef]

- Reparaz, J.S.; Chavez-Angel, E.; Wagner, M.R.; Graczykowski, B.; Gomis-Bresco, J.; Alzina, F.; Sotomayor Torres, C.M. A novel contactless technique for thermal field mapping and thermal conductivity determination: Two-laser Raman thermometry. Rev. Sci. Instrum. 2014, 85, 034901. [Google Scholar] [CrossRef] [Green Version]

- Sett, S.; Aggarwal, V.K.; Singha, A.; Raychaudhuri, A.K. Temperature-dependent Thermal Conductivity of a Single Germanium Nanowire Measured by Optothermal Raman Spectroscopy. Phys. Rev. Appl. 2020, 13, 054008. [Google Scholar] [CrossRef]

- Soini, M.; Zardo, I.; Uccelli, E.; Funk, S.; Koblmüller, G.; Fontcuberta i Morral, A.; Abstreiter, G. Thermal conductivity of GaAs nanowires studied by micro-Raman spectroscopy combined with laser heating. Appl. Phys. Lett. 2010, 97, 263107. [Google Scholar] [CrossRef]

- Cong, X.; Liu, X.L.; Lin, M.L.; Tan, P.H. Application of Raman spectroscopy to probe fundamental properties of two-dimensional materials. npj 2D Mater. Appl. 2020, 4, 13. [Google Scholar] [CrossRef]

- McGrane, S.D.; Moore, D.S.; Goodwin, P.M.; Dattelbaum, D.M. Quantitative tradeoffs between spatial, temporal, and thermometric resolution of nonresonant Raman thermometry for dynamic experiments. Appl. Spectrosc. 2014, 68, 1279–1288. [Google Scholar] [CrossRef] [PubMed]

- Liao, B.; Maznev, A.A.; Nelson, K.A.; Chen, G. Photo-excited charge carriers suppress sub-terahertz phonon mode in silicon at room temperature. Nat. Commun. 2016, 7, 13174. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gallego Lluesma, E.; Mendes, G.; Arguello, C.A.; Leite, R.C.C. Very high non-thermal equilibrium population of optical phonons in GaAs. Solid State Commun. 1974, 14, 1195–1197. [Google Scholar] [CrossRef]

- Tretinnikov, O.N.; Ohta, K. Conformation-sensitive infrared bands and conformational characteristics of stereoregular poly(methyl methacrylate)s by variable-temperature FTIR spectroscopy. Macromolecules 2002, 35, 7343–7353. [Google Scholar] [CrossRef]

- O’Reilly, J.M.; Mosher, R.A. Conformational Energies of Stereoregular Poly(methyl methacrylate) by Fourier Transform Infrared Spectroscopy. Macromolecules 1981, 14, 602–608. [Google Scholar] [CrossRef]

- Shin, H.S.; Jung, Y.M.; Oh, T.Y.; Chang, T.; Bin Kim, S.; Lee, D.H.; Noda, I. Glass transition temperature and conformational changes of poly(methyl methacrylate) thin films determined by a two-dimensional map representation of temperature-dependent reflection-absorption FTIR spectra. Langmuir 2002, 18, 5953–5958. [Google Scholar] [CrossRef]

- Mahendia, S.; Heena; Kandhol, G.; Deshpande, U.P.; Kumar, S. Determination of glass transition temperature of reduced graphene oxide-poly(vinyl alcohol) composites using temperature dependent Fourier transform infrared spectroscopy. J. Mol. Struct. 2016, 1111, 46–54. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Lu, Y.; Duan, Y.; Yan, S.; Shen, D. Glass Transition Temperature Determination of Poly(ethylene terephthalate) Thin Films Using Reflection-Absorption FTIR. Macromolecules 2004, 37, 2532–2537. [Google Scholar] [CrossRef]

- Havriliak, S.; Roman, N. The infra-red absorption characteristics of syndiotactic poly(methyl methacrylate) from 1050 cm-1 to 1300 cm−1. Polymer 1966, 7, 387–400. [Google Scholar] [CrossRef]

- Painter, P.; Zhao, H.; Park, Y. Infrared spectroscopic study of thermal transitions in poly(methyl methacrylate). Vib. Spectrosc. 2011, 55, 224–234. [Google Scholar] [CrossRef]

- Dybal, J.; Štokr, J.; Schneider, B. Vibrational spectra and structure of stereoregular poly(methyl methacrylates) and of the stereocomplex. Polymer 1983, 24, 971–980. [Google Scholar] [CrossRef]

- Gomes Rios, T.; Larios, G.; Marangoni, B.; Oliveira, S.L.; Cena, C.; Alberto do Nascimento Ramos, C. FTIR spectroscopy with machine learning: A new approach to animal DNA polymorphism screening. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2021, 261, 120036. [Google Scholar] [CrossRef] [PubMed]

- Enders, A.A.; North, N.M.; Fensore, C.M.; Velez-Alvarez, J.; Allen, H.C. Functional Group Identification for FTIR Spectra Using Image-Based Machine Learning Models. Anal. Chem. 2021, 93, 9711–9718. [Google Scholar] [CrossRef]

- Yousef, I.; Ribó, L.; Crisol, A.; Šics, I.; Ellis, G.; Ducic, T.; Kreuzer, M.; Benseny-Cases, N.; Quispe, M.; Dumas, P.; et al. MIRAS: The Infrared Synchrotron Radiation Beamline at ALBA. Synchrotron Radiat. News 2017, 30, 4–6. [Google Scholar] [CrossRef]

- Toplak, M.; Read, S.T.; Sandt, C.; Borondics, F.; Vaccari, L.; Byrne, H.J.; Wrobel, T.P. Quasar: Easy Machine Learning for Biospectroscopy. Cells 2021, 10, 2300. [Google Scholar] [CrossRef]

- Demsar, J.; Curk, T.; Erjavec, A.; Gorup, C.; Hocevar, T.; Milutinovic, M.; Mozina, M.; Polajnar, M.; Toplak, M.; Staric, A.; et al. Orange: Data Mining Toolbox in Python. J. Mach. Learn. Res. 2013, 14, 2349–2353. [Google Scholar]

- Toplak, M.; Birarda, G.; Read, S.; Sandt, C.; Rosendahl, S.M.; Vaccari, L.; Demšar, J.; Borondics, F. Infrared Orange: Connecting Hyperspectral Data with Machine Learning. Synchrotron Radiat. News 2017, 30, 40–45. [Google Scholar] [CrossRef]

- Forte, M.; Silva, R.; Tavares, C.; Silva, R. Is Poly(methyl methacrylate) (PMMA) a Suitable Substrate for ALD?: A Review. Polymers 2021, 13, 1346. [Google Scholar] [CrossRef]

- Zhao, Y.; Schultz, N.E.; Truhlar, D.G. Design of Density Functionals by Combining the Method of Constraint Satisfaction with Parametrization for Thermochemistry, Thermochemical Kinetics, and Noncovalent Interactions. J. Chem. Theory Comput. 2006, 2, 364–382. [Google Scholar] [CrossRef]

- Ditchfield, R.; Hehre, W.J.; Pople, J.A. Self-Consistent Molecular-Orbital Methods. IX. An Extended Gaussian-Type Basis for Molecular-Orbital Studies of Organic Molecules. J. Chem. Phys. 1971, 54, 724–728. [Google Scholar] [CrossRef]

- Ünal, Y.; Nassif, W.; Özaydin, B.C.; Sayin, K. Scale factor database for the vibration frequencies calculated in M06-2X, one of the DFT methods. Vib. Spectrosc. 2020, 112, 103189. [Google Scholar] [CrossRef]

- Zhurko, G.A. Chemcraft, 1.8. Available online: http://www.chemcraftprog.com (accessed on 1 December 2022).

- Neugebauer, J.; Reiher, M.; Kind, C.; Hess, B.A. Quantum chemical calculation of vibrational spectra of large molecules?Raman and IR spectra for Buckminsterfullerene. J. Comput. Chem. 2002, 23, 895–910. [Google Scholar] [CrossRef] [PubMed]

- Duan, G.; Zhang, C.; Li, A.; Yang, X.; Lu, L.; Wang, X. Preparation and characterization of mesoporous zirconia made by using a poly (methyl methacrylate) template. Nanoscale Res. Lett. 2008, 3, 118–122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, R.M. Optical study on poly(methyl methacrylate)/poly(vinyl acetate) blends. Int. J. Photoenergy 2009, 2009, 150389. [Google Scholar] [CrossRef]

- Ghorbel, E.; Hadriche, I.; Casalino, G.; Masmoudi, N. Characterization of thermo-mechanical and fracture behaviors of thermoplastic polymers. Materials 2014, 7, 375–398. [Google Scholar] [CrossRef]

- National Institute of Advanced Industrial Science and Technology, SDBSWeb. Available online: https://sdbs.db.aist.go.jp (accessed on 1 December 2022).

- Stuart, B.H. Infrared Spectroscopy: Fundamentals and Applications; Wiley: New York, NY, USA, 2005. [Google Scholar]

- Lasch, P.; Noda, I. Two-Dimensional Correlation Spectroscopy (2D-COS) for Analysis of Spatially Resolved Vibrational Spectra. Appl. Spectrosc. 2019, 73, 359–379. [Google Scholar] [CrossRef]

- Noda, I.; Ozaki, Y. Generalized Two-Dimensional Correlation Spectroscopy in Practice. In Two-Dimensional Correlation Spectroscopy. In Applications in Vibrational and Optical Spectroscopy; John Wiley & Sons, Ltd: Chichester, UK, 2005; pp. 47–64. [Google Scholar]

- Dames, C. Measuring the thermal conductivity of thin films: 3 omega and related electrothermal methods. Annu. Rev. Heat Transf. 2013, 16, 7–49. [Google Scholar] [CrossRef]

- MIT: Material Property Database. Available online: https://www.mit.edu/~6.777/matprops/pmma.htm (accessed on 1 December 2022).

- Sandell, S.; Maire, J.; Chávez-Ángel, E.; Sotomayor Torres, C.M.; Kristiansen, H.; Zhang, Z.; He, J. Enhancement of Thermal Boundary Conductance of Metal–Polymer System. Nanomaterials 2020, 10, 670. [Google Scholar] [CrossRef]

| Vibrational Mode | Fitted Peaks [cm−1] | Lit. Values [cm−1] | Ref. | Slope (dIPP/dTset) [cm-1/K] |

|---|---|---|---|---|

| C-H stretch region: | ||||

| C–H stretching vibrations of the –CH3 | 2995 | 2997 | [49] | 0.007 |

| C–H stretching vibrations of the –CH2 | 2951 | 2952 | [49] | 0.001 |

| methoxy carbon (O–CH3) | 2841 | 2841.6 | [50] | −0.013 |

| Fingerprint region: | ||||

| C=O stretch (Ketone) | 1731 | 1727, 1732 | [49,50,51] | 0.001 |

| CH2 bending | 1481 | 1485 | [52] | −0.014 |

| C–H bending (Alkane) | 1448 | 1450, 1444 | [49,51] | 0.000 |

| asymmetrical bending vibration (CH3) | 1434 | 1435.3 | [50] | −0.008 |

| methyl group (C-CH3) | 1386 | 1388 | [49] | 0.009 |

| C-C-O bending | 1269 | 1265 | [52,53] | −0.032 |

| C-C-O bending | 1241 | 1238 | [52,53] | −0.029 |

| CH3 wagging | 1191 | 1197 | [52] | −0.022 |

| C-O-C | 1149 | 1149 | [49,50,51] | −0.028 |

| stretching vibration of C–O–C group | 1066 | 1063.6 | [49,50] | −0.007 |

| C-C stretching | 985 | 990 | [52] | −0.017 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chavez-Angel, E.; Ng, R.C.; Sandell, S.; He, J.; Castro-Alvarez, A.; Torres, C.M.S.; Kreuzer, M. Application of Synchrotron Radiation-Based Fourier-Transform Infrared Microspectroscopy for Thermal Imaging of Polymer Thin Films. Polymers 2023, 15, 536. https://doi.org/10.3390/polym15030536

Chavez-Angel E, Ng RC, Sandell S, He J, Castro-Alvarez A, Torres CMS, Kreuzer M. Application of Synchrotron Radiation-Based Fourier-Transform Infrared Microspectroscopy for Thermal Imaging of Polymer Thin Films. Polymers. 2023; 15(3):536. https://doi.org/10.3390/polym15030536

Chicago/Turabian StyleChavez-Angel, Emigdio, Ryan C. Ng, Susanne Sandell, Jianying He, Alejandro Castro-Alvarez, Clivia M. Sotomayor Torres, and Martin Kreuzer. 2023. "Application of Synchrotron Radiation-Based Fourier-Transform Infrared Microspectroscopy for Thermal Imaging of Polymer Thin Films" Polymers 15, no. 3: 536. https://doi.org/10.3390/polym15030536