Evaluation of Selected Cellulose Macromolecular Properties after Its Chemical Treatment Using Size Exclusion Chromatography

Abstract

1. Introduction

Formulation of Individual Scientific Goals

2. Materials and Methods

2.1. Material

2.2. Methods

2.2.1. Derivatization of Cellulose into the Form of Cellulose Tricarbanilates (CTCs)

2.2.2. Size Exclusion Chromatography (SEC)

2.2.3. Calculations and Statistical Evaluation

3. Results and Discussion

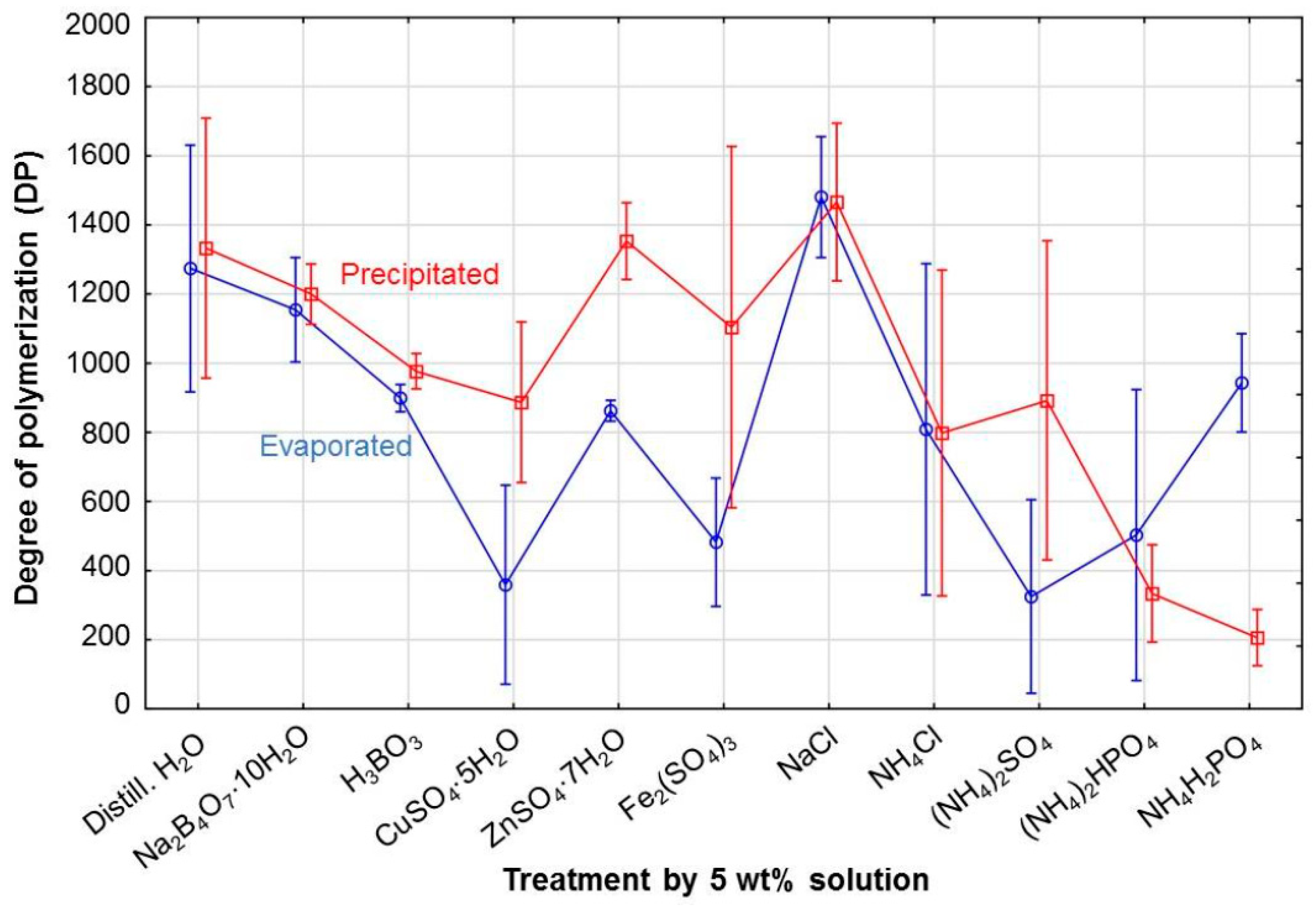

3.1. Degree of Polymerization (DP)

3.2. Accumulated Degree of Polymerization Loss (ωDP)

3.3. Polydispersity Index (PDI)

3.4. Statistical Evaluation of the Experiment

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Winandy, J. Effects of waterborne preservative treatment on mechanical properties: A review. In Proceedings of the 91st Annual Meeting of the American Wood-Preservers’ Association, New York, NY, USA, 21–24 May 1995; Volume 91, pp. 17–34. [Google Scholar]

- Kögl, J.; Hartmann, P.; Beikircher, W. Performance of different fire retardant products applied on Norway spruce tested in a Cone calorimeter. MATEC Web Conf. 2013, 9, 02011. [Google Scholar] [CrossRef]

- Tsapko, Y.; Lomaha, V.; Vasylyshyn, R.; Melnyk, O.; Balanyuk, V.; Tsapko, A.; Bondarenko, O.; Karpuk, A. Establishing regularities in the reduction of flammable properties of wood protected with two-component intumescent varnish. East.-Eur. J. Enterp. Technol. 2022, 3, 63–71. [Google Scholar] [CrossRef]

- Lebow, S. Leaching of Wood Preservative Components and Their Mobility in the Environment—Summary of Pertinent Literature; General Technical Report FPL–GTR–93; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1996. [Google Scholar]

- Cook, D.R. Making the connection; corrosive effects of new wood preservatives on steel fasteners and connections. Struct. Eng. 2003, 5, 28–31. [Google Scholar]

- Zelinka, S.L.; Glass, S.V. Water Vapor Sorption Isotherms for Southern Pine Treated with Several Waterborne Preservatives. J. Test. Eval. 2010, 38, 1–5. [Google Scholar] [CrossRef]

- Sonowal, J.; Gogoi, P.K. Dimensional Stability, Thermal Degradation and Termite Resistant Studies of Chemically Treated Wood. Int. J. Chem. 2010, 2, 218–225. [Google Scholar] [CrossRef]

- Tsapko, Y.; Tsapko, А. Establishment of the mechanism and fireproof efficiency of wood treated with an impregnating solution and coatings. East.-Eur. J. Enterp. Technol. 2017, 3, 50–55. [Google Scholar] [CrossRef]

- Ayrilmis, N. Effect of fire retardants on internal bond strength and bond durability of structural fiberboard. Build. Environ. 2007, 42, 1200–1206. [Google Scholar] [CrossRef]

- Kartal, S.N.; Hwang, W.-J.; Imamura, Y. Combined effect of boron compounds and heat treatments on wood properties: Chemical and strength properties of wood. J. Mater. Process. Technol. 2008, 198, 234–240. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Zuo, Y.; Lu, J.; Yuan, G.; Wu, Y. Preparation and characterization of sodium silicate impregnated Chinese fir wood with high strength, water resistance, flame retardant and smoke suppression. J. Mater. Res. Technol. 2020, 9, 1043–1053. [Google Scholar] [CrossRef]

- Tribulová, T.; Kačík, F.; Evtuguin, D.V.; Čabalová, I.; Ďurkovič, J. The effects of transition metal sulfates on cellulose crys-tallinity during accelerated ageing of silver fir wood. Cellulose 2019, 26, 2625–2638. [Google Scholar] [CrossRef]

- Sun, L.; Han, J.; Wu, J.; Huang, W.; Li, Y.; Mao, Y.; Wang, L.; Wang, Y. Cellulose pretreatment with inorganic salt hydrate: Dissolution, regeneration, structure and morphology. Ind. Crop. Prod. 2022, 180, 114722. [Google Scholar] [CrossRef]

- Malešič, J.; Marinšek, M.; Cigić, I.K. Evaluation of Bookkeeper mass deacidification based on historical book papers. Cellulose 2002, 29, 6889–6905. [Google Scholar] [CrossRef]

- Zou, X.; Uesaka, T.; Gurnagul, N. Prediction of paper permanence by accelerated ageing. I. Kinetic analysis of the ageing process. Cellulose 1996, 3, 243–267. [Google Scholar] [CrossRef]

- Dupont, A.-L.; Tetreault, J. Cellulose Degradation in an Acetic Acid Environment. Stud. Conserv. 2000, 45, 201–210. [Google Scholar] [CrossRef]

- Eronen, P.; Österberg, M.; Jääskeläinen, A.-S. Effect of alkaline treatment on cellulose supramolecular structure studied with combined confocal Raman spectroscopy and atomic force microscopy. Cellulose 2009, 16, 167–178. [Google Scholar] [CrossRef]

- Hon, D.N.; Shiraishi, N. Wood and Cellulosic Chemistry, 2nd ed.; CRC Press: New York, NY, USA, 2000; p. 928. [Google Scholar]

- Han, J.; Seo, Y. Comparison of Cellulose Dissolution Behavior by Alkaline and Sulfuric Acid Solvents and Their Films’ Physical Properties. Materials 2021, 14, 5273. [Google Scholar] [CrossRef]

- Thango, B.A. Feedforward Artificial Neural Network (FFANN) Application in Solid Insulation Evaluation Methods for the Prediction of Loss of Life in Oil-Submerged Transformers. Energies 2022, 15, 8548. [Google Scholar] [CrossRef]

- Ghoneim, S. Determination of Transformers’ Insulating Paper State Based on Classification Techniques. Processes 2021, 9, 427. [Google Scholar] [CrossRef]

- Eugenio, M.E.; Ruiz-Montoya, M.; Martín-Sampedro, R.; Ibarra, D.; Díaz, M.J. Influence of Cellulose Characteristics on Pyrolysis Suitability. Processes 2021, 9, 1584. [Google Scholar] [CrossRef]

- Špérová, M.; Nasadil, P.; Průšová, A.; Kučerík, J. A hint on the correlation between cellulose fibers polymerization degree and their thermal and thermo-oxidative degradation. J. Therm. Anal. Calorim. 2012, 110, 71–76. [Google Scholar] [CrossRef]

- Dupont, A.-L.; Mortha, G. Comparative evaluation of size-exclusion chromatography and viscometry for the characterisation of cellulose. J. Chromatogr. A 2004, 1026, 129–141. [Google Scholar] [CrossRef] [PubMed]

- Malešič, J.; Kraševec, I.; Cigić, I.K. Determination of Cellulose Degree of Polymerization in Historical Papers with High Lignin Content. Polymers 2021, 13, 1990. [Google Scholar] [CrossRef]

- ISO 187; Paper, Board and Pulps—Standard Atmosphere for Conditioning and Testing and Procedure for Monitoring the Atmosphere and Conditioning of Samples. ISO: Geneva, Switzerland, 2022.

- ISO 5630-3; Paper and Board—Accelerated Ageing. Part 3: Moist Heat Treatment at 80 °C and 65% Relative Humidity. ISO: Geneva, Switzerland, 1996.

- Pitkänen, L.; Sixta, H. Size-exclusion chromatography of cellulose: Observations on the low-molar-mass fraction. Cellulose 2020, 27, 9217–9225. [Google Scholar] [CrossRef]

- Josefsson, T.; Lennholm, H.; Gellerstedt, G. Changes in cellulose supramolecular structure and molecular weight distribu-tion during steam explosion of aspen wood. Cellulose 2001, 8, 289–296. [Google Scholar] [CrossRef]

- Hubbell, C.A.; Ragauskas, A.J. Effect of acid-chlorite delignification on cellulose degree of polymerization. Bioresour. Technol. 2010, 101, 7410–7415. [Google Scholar] [CrossRef] [PubMed]

- Wood, B.F.; Conner, A.H.; Hill, C.G., Jr. The effect of precipitation on the molecular weight distribution of cellulose tricarbanilate. J. Appl. Polym. Sci. 1986, 32, 3703–3712. [Google Scholar] [CrossRef]

- Kačík, F.; Podzimek, Š.; Vizárová, K.; Kačíková, D.; Čabalová, I. Characterization of cellulose degradation during accelerat-ed ageing by SEC-MALS, SEC-DAD, and A4F-MALS methods. Cellulose 2016, 23, 357–366. [Google Scholar] [CrossRef]

- Bansa, H. Accelerated Ageing of Paper: Some Ideas on its Practical Benefit. Restaurator 2002, 23, 106–117. [Google Scholar] [CrossRef]

- Havermans, J.B. The impact of European research on paper ageing and preventive conservation strategies. Protection and treatment of paper, leather and parchment. In Proceedings of the EC 5th Conference, Krakow, Poland, 16–18 May 2002; pp. 87–91. [Google Scholar]

- Kumar, R.; Mago, G.; Balan, V.; Wyman, C.E. Physical and chemical characterizations of corn stover and poplar solids resulting from leading pretreatment technologies. Bioresour. Technol. 2009, 100, 3948–3962. [Google Scholar] [CrossRef]

- Sweet, M.; Winandy, J. Influence of Degree of Polymerization of Cellulose and Hemicellulose on Strength Loss in Fire-Retardant-Treated Southern Pine. Holzforschung 1999, 53, 311–317. [Google Scholar] [CrossRef]

- Berggren, R. Cellulose Degradation in Pulp Fibres Studied as Changes in Molar Mass Distributions. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2003; 183p. [Google Scholar]

- Inagaki, T.; Siesler, H.W.; Mitsui, K.; Tsuchikawa, S. Difference of the Crystal Structure of Cellulose in Wood after Hydro-thermal and Aging Degradation: A NIR Spectroscopy and XRD Study. Biomacromolecules 2010, 11, 2300–2305. [Google Scholar] [CrossRef] [PubMed]

- Lionetto, F.; Del Sole, R.; Cannoletta, D.; Vasapollo, G.; Maffezzoli, A. Monitoring Wood Degradation during Weathering by Cellulose Crystallinity. Materials 2012, 5, 1910–1922. [Google Scholar] [CrossRef]

- Jasiukaityté-Grojzdek, E.; Kunaver, M.; Poljanšek, I. Influence of cellulose polymerization degree and crystallinity on kinetics of cellulose degradation. Bioresources 2012, 7, 3008–3027. [Google Scholar]

- Kačík, F.; Šmíra, P.; Kačíková, D.; Reinprecht, L.; Nasswettrová, A. Chemical changes in fir wood from old buildings due to ageing. Cellul. Chem. Technol. 2014, 48, 79–88. [Google Scholar]

- Chamberlain, D.C.; Priest, D.J. Comparison of physical and chemical methods for analysing cellulose degradation following artificial ageing treatment. Cellul. Chem. Technol. 1998, 32, 35–41. [Google Scholar]

- Ding, H.Z.; Wang, Z.D. On the degradation evolution equations of cellulose. Cellulose 2008, 15, 205–224. [Google Scholar] [CrossRef]

- Jablonský, M.; Kazíková, J.; Botková, M.; Holúbková, S. Kinetic dependences for the decrease of polymerization of paper undergoing accelerated ageing. Cellul. Chem. Technol. 2012, 46, 625–630. [Google Scholar]

- Emsley, A.; Ali, M.; Heywood, R. A size exclusion chromatography study of cellulose degradation. Polymer 2000, 41, 8513–8521. [Google Scholar] [CrossRef]

- Strobin, G.; Wlochowicz, A.; Ciechanska, D.; Boryniec, S.; Struszczyk, H.; Sobczak, S. Molecular parameters of bacterial cellulose. Effect of temperature and pH biosynthesis medium. Polimery 2003, 48, 779–783. [Google Scholar] [CrossRef]

- Dupont, A.L. Gelatin Sizing of Paper and Its Impact on the Degradation of Cellulose during Aging. Ph.D. Thesis, University of Amsterdam, Amsterdam, The Netherlands, 2003; 251p. [Google Scholar]

- Tribulová, T.; Kačík, F.; Evtuguin, D.V.; Čabalová, I. Assessment of Chromophores in Chemically Treated and Aged Wood by UV-Vis Diffuse Reflectance Spectroscopy. Cellul. Chem. Technol. 2016, 50, 659–667. [Google Scholar]

- Bewick, V.; Cheek, L.; Ball, J. Statistics review 9: One-way analysis of variance. Crit. Care 2004, 8, 130–136. [Google Scholar] [CrossRef] [PubMed]

| Samples | DP of Treated Samples | DP of Treated and Aged Samples | Accumulated DP Loss (ωDP) | |||

|---|---|---|---|---|---|---|

| Evaporated | Precipitated | Evaporated | Precipitated | Evaporated | Precipitated | |

| Standard | 1444 ± 3 | 1516 ± 17 | ----- | ----- | ----- | ----- |

| Reference | 1673 ± 6 | 1754 ± 5 | 875 ± 4 | 912 ± 4 | 0.48 | 0.48 |

| Na2B4O7.10H2O | 1308 ± 106 | 1261 ± 114 | 1002 ± 53 | 1139 ± 49 | 0.23 | 0.10 |

| H3BO3 | 913 ± 68 | 1029 ± 37 | 885 ± 1 | 925 ± 9 | 0.03 | 0.10 |

| CuSO4.5H2O | 681 ± 5 | 1145 ± 25 | 37 ± 1 | 630 ± 47 | 0.95 | 0.45 |

| ZnSO4.7H2O | 877 ± 39 | 1244 ± 88 | 847 ± 30 | 1463 ± 40 | 0.03 | −0.18 |

| Fe2(SO4)3 | 689 ± 5 | 1689 ± 21 | 275 ± 8 | 520 ± 9 | 0.60 | 0.31 |

| NaCl | 1675 ± 7 | 1721 ± 26 | 1285 ± 23 | 1212 ± 4 | 0.23 | 0.30 |

| NH4Cl | 1344 ± 53 | 1326 ± 12 | 273 ± 1 | 271 ± 5 | 0.20 | 0.80 |

| (NH4)2SO4 | 638 ± 26 | 1409 ± 16 | 12 ± 0 | 376 ± 3 | 0.98 | 0.73 |

| (NH4)2HPO4 | 972 ± 67 | 490 ± 20 | 34 ± 3 | 176 ± 13 | 0.97 | 0.64 |

| NH4H2PO4 | 1090 ± 71 | 296 ± 19 | 796 ± 67 | 116 ± 6 | 0.27 | 0.61 |

| Samples | PDI of Treated Samples | PDI of Treated and Aged Samples | ||

|---|---|---|---|---|

| Evaporated | Precipitated | Evaporated | Precipitated | |

| Standard | 3.71 ± 0.07 | 2.66 ± 0.03 | ----- | ----- |

| Reference | 3.38 ± 0.03 | 2.12 ± 0.01 | 2.94 ± 0.05 | 2.43 ± 0.03 |

| Na2B4O7.10H2O | 3.81 ± 0.27 | 2.27 ± 0.18 | 3.38 ± 0.16 | 2.84 ± 0.08 |

| H3BO3 | 3.74 ± 0.21 | 3.15 ± 0.21 | 3.02 ± 0.01 | 2.72 ± 0.06 |

| CuSO4.5H2O | 3.69 ± 0.07 | 8.45 ± 0.26 | 2.14 ± 0.07 | 8.53 ± 0.29 |

| ZnSO4.7H2O | 4.04 ± 0.03 | 11.00 ± 0.70 | 3.22 ± 0.09 | 5.83 ± 0.06 |

| Fe2(SO4)3 | 12.32 ± 0.44 | 17.18 ± 0.23 | 10.56 ± 0.67 | 8.01 ± 0.03 |

| NaCl | 3.31 ± 0.10 | 2.37 ± 0.02 | 5.45 ± 0.28 | 3.48 ± 0.05 |

| NH4Cl | 3.24 ± 0.10 | 2.98 ± 0.04 | 2.42 ± 0.01 | 2.53 ± 0.02 |

| (NH4)2SO4 | 4.42 ± 0.09 | 5.73 ± 0.12 | 1.34 ± 0.03 | 11.28 ± 0.44 |

| (NH4)2HPO4 | 4.12 ± 0.03 | 6.52 ± 0.12 | 2.24 ± 0.14 | 6.33 ± 0.41 |

| NH4H2PO4 | 4.58 ± 0.19 | 5.36 ± 0.28 | 31.36 ± 1.78 | 5.07 ± 0.20 |

| Source of Variation | Sum of Squares | Degrees of Freedom | Mean Square (Variance) | F-Test | p-Significance Level |

|---|---|---|---|---|---|

| Total mean | 140,282,339 | 1 | 140,282,339 | 86,771.49 | 0.000 |

| Solution (a) | 18,125,070 | 10 | 1,812,507 | 1121.12 | 0.000 |

| Aging (b) | 11,334,045 | 1 | 11,334,045 | 7010.66 | 0.000 |

| Method (c) | 775,295 | 1 | 775,295 | 479.56 | 0.000 |

| Solution*Aging (a*b) | 5,319,434 | 10 | 531,943 | 329.03 | 0.000 |

| Solution *Method (a*c) | 6,479,499 | 10 | 647,950 | 400.79 | 0.000 |

| Aging*Method (b*c) | 663 | 1 | 663 | 0.41 | 0.523 |

| Solution*Aging*Method (a*b*c) | 1,272,813 | 10 | 127,281 | 78.73 | 0.000 |

| Random effect | 213,403 | 132 | 1617 | ----- | ----- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jurczyková, T.; Kačík, F.; Čabalová, I.; Hájková, K. Evaluation of Selected Cellulose Macromolecular Properties after Its Chemical Treatment Using Size Exclusion Chromatography. Polymers 2023, 15, 573. https://doi.org/10.3390/polym15030573

Jurczyková T, Kačík F, Čabalová I, Hájková K. Evaluation of Selected Cellulose Macromolecular Properties after Its Chemical Treatment Using Size Exclusion Chromatography. Polymers. 2023; 15(3):573. https://doi.org/10.3390/polym15030573

Chicago/Turabian StyleJurczyková, Tereza, František Kačík, Iveta Čabalová, and Kateřina Hájková. 2023. "Evaluation of Selected Cellulose Macromolecular Properties after Its Chemical Treatment Using Size Exclusion Chromatography" Polymers 15, no. 3: 573. https://doi.org/10.3390/polym15030573

APA StyleJurczyková, T., Kačík, F., Čabalová, I., & Hájková, K. (2023). Evaluation of Selected Cellulose Macromolecular Properties after Its Chemical Treatment Using Size Exclusion Chromatography. Polymers, 15(3), 573. https://doi.org/10.3390/polym15030573