Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Fish Scale Particles (FSp) from Fresh Fish Scales

2.3. Characterizations of FSp

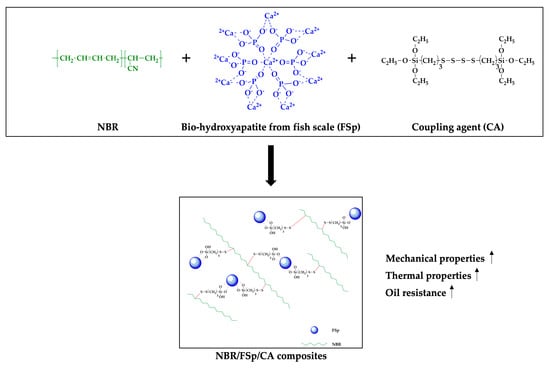

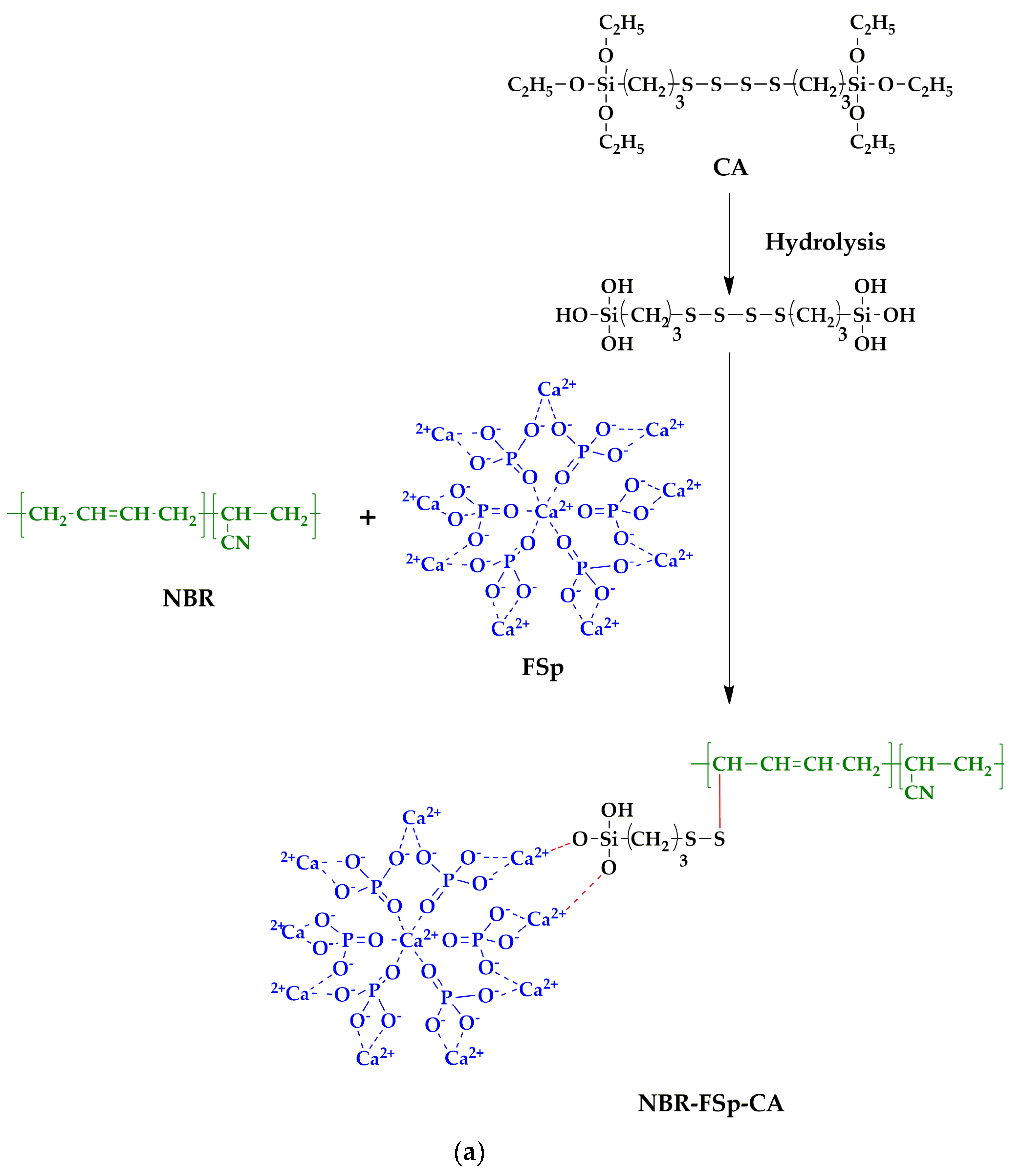

2.4. Preparation of NBR/FSp and NBR/FSp/CA Composites

2.5. Characterizations of NBR/FSp and NBR/FSp/CA Composites

3. Results and Discussion

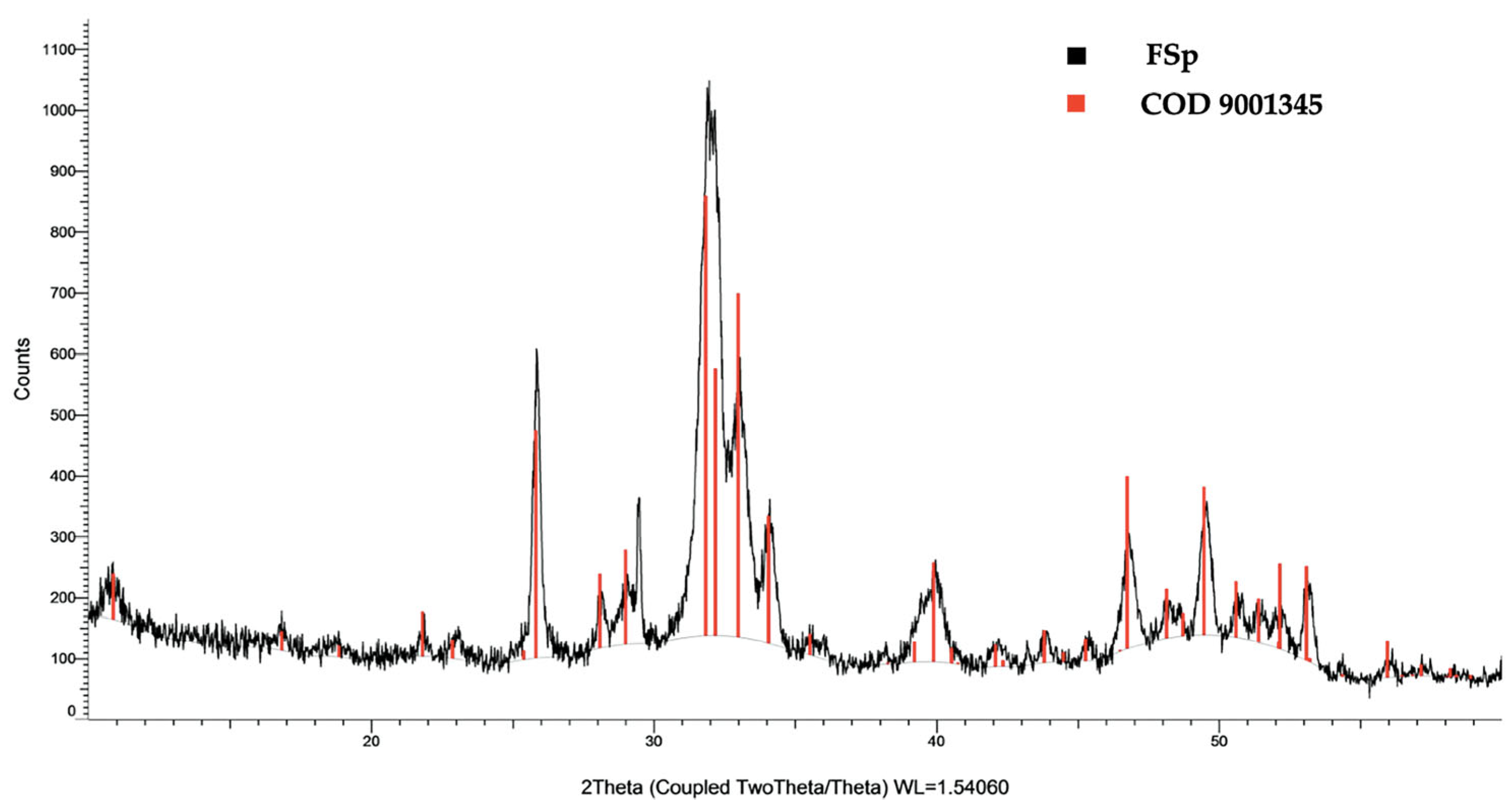

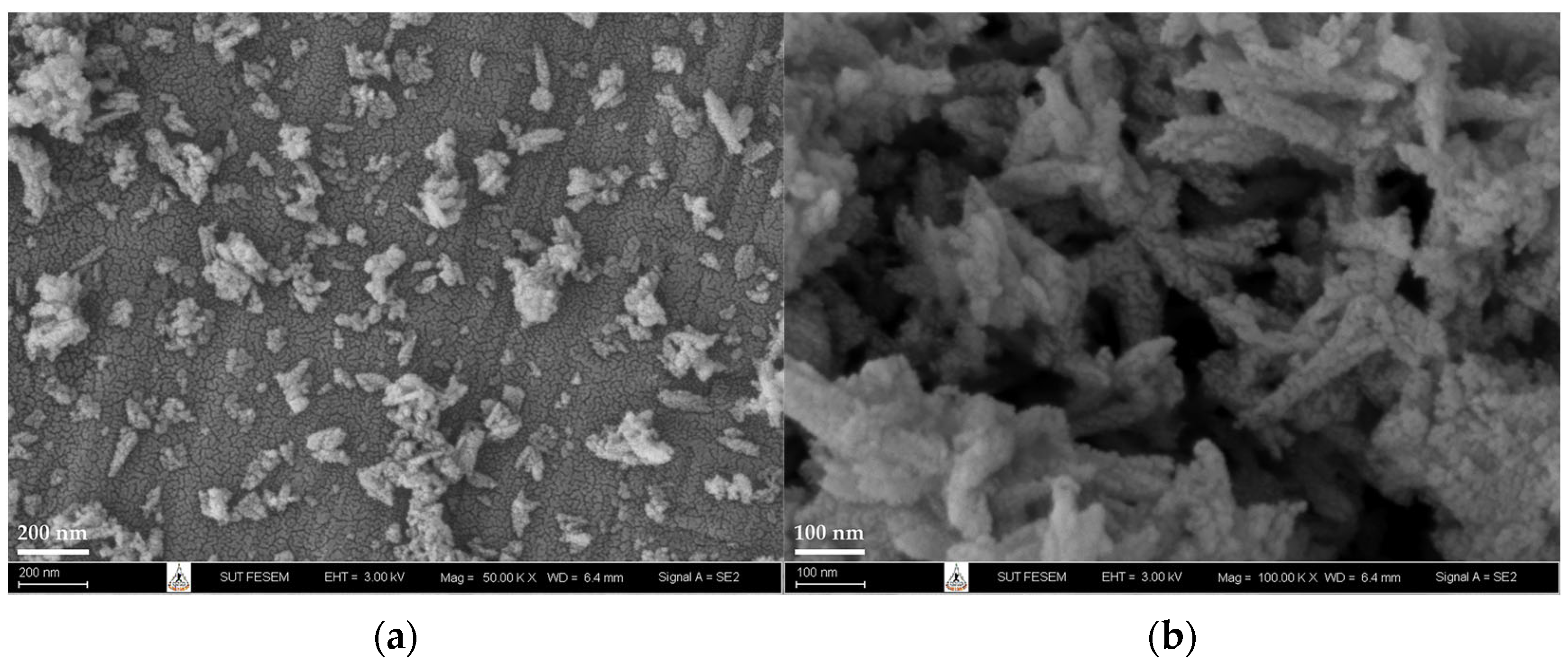

3.1. Characterizations of FSp

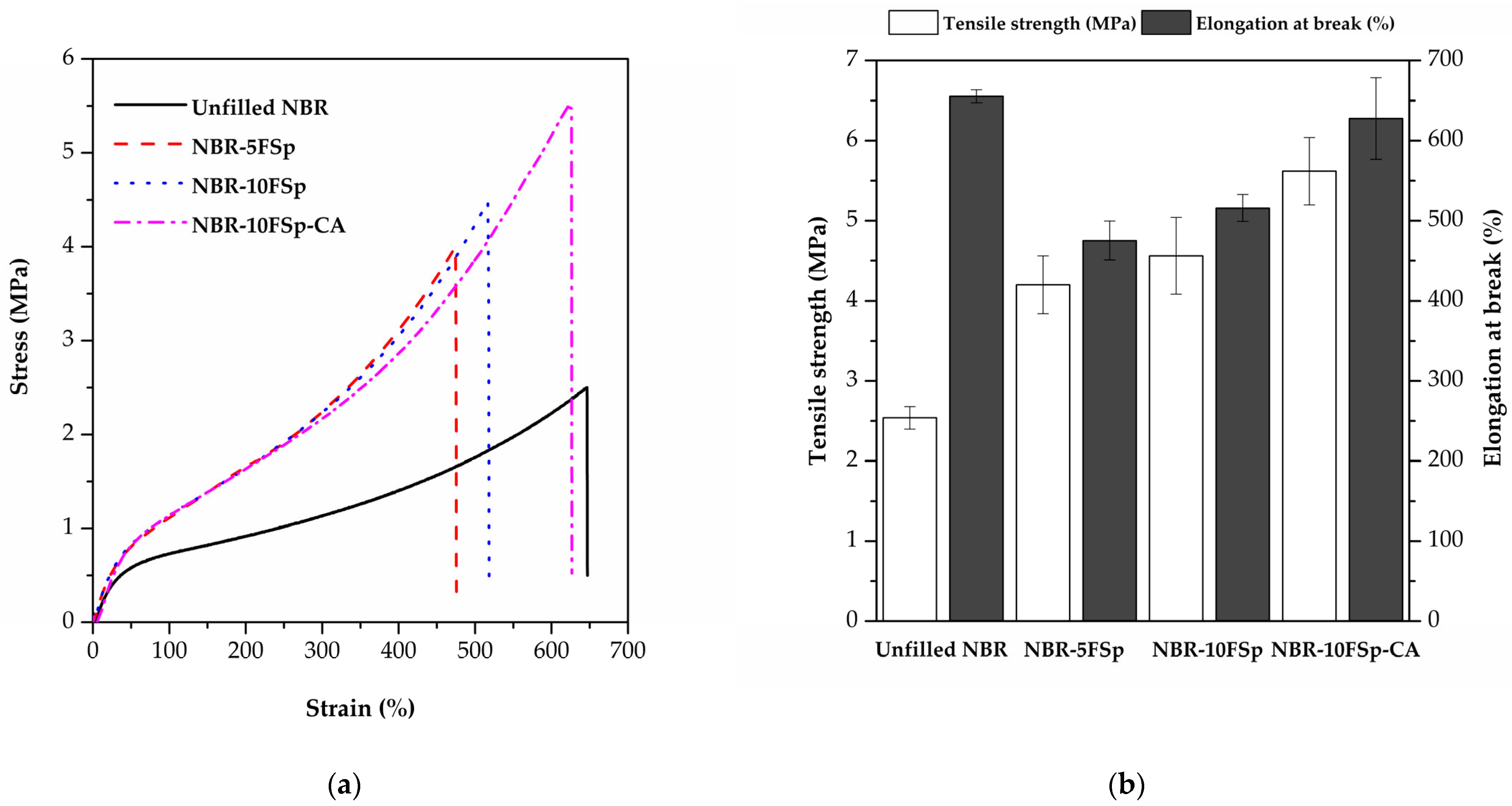

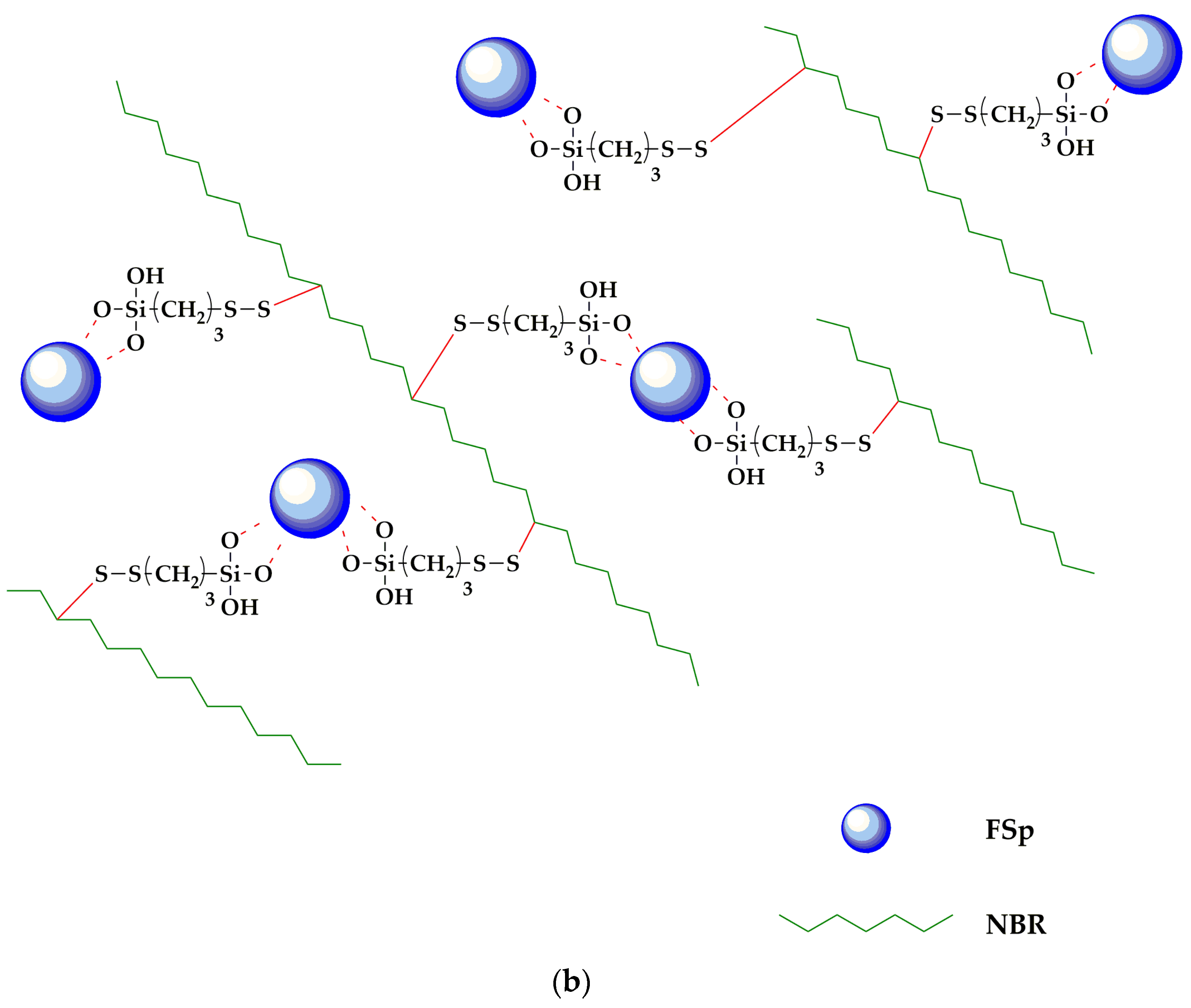

3.2. Characterizations of NBR/FSp and NBR/FSp/CA Composites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- El-Sayed, A.-F.M. Tilapia Culture; CABI Publishing: Wallingford, UK, 2006. [Google Scholar]

- Mohammad, A.W.; Kumar, A.G.; Basha, R.K. Optimization of enzymatic hydrolysis of tilapia (Oreochromis Spp.) scale gelatine. Int. Aquat. Res. 2015, 7, 27–39. [Google Scholar] [CrossRef] [Green Version]

- Kittiphattanabawon, P.; Sriket, C.; Kishimura, H.; Benjakul, S. Characteristics of acid and pepsin solubilized collagens from Nile tilapia (Oreochromis niloticus) scale. Emir. J. Food. Agric. 2019, 31, 95–101. [Google Scholar] [CrossRef]

- Akbay, İ.K.; Güngör, A.; Özdemir, T. Using fish scales (Sardina pilchardus) within ethylene-propylene-diene ter monomer rubber as bio-based filler. J. Appl. Polym. Sci. 2018, 135, 46698. [Google Scholar] [CrossRef]

- Qin, D.; Bi, S.; You, X.; Wang, M.; Cong, X.; Yuan, C.; Yu, M.; Cheng, X.; Chen, X.-G. Development and application of fish scale wastes as versatile natural biomaterials. Chem. Eng. J. 2022, 428, 131102. [Google Scholar] [CrossRef]

- Ikoma, T.; Kobayashi, H.; Tanaka, J.; Walsh, D.; Mann, S. Microstructure, mechanical, and biomimetic properties of fish scales from Pagrus major. J. Struct. Biol. 2003, 142, 327–333. [Google Scholar] [CrossRef]

- Kim, S.-K.; Dewapriya, P. Biologically active compounds form seafood processing by-products. In Biotransformation of Waste Biomass into High Value Biochemicals; Springer: Berlin/Heidelberg, Germany, 2014; pp. 299–311. [Google Scholar]

- Majhool, A.; Zainol, I.; Jaafar, C.; Jahil, M.; Ha, A.; Asaad, A.; Mezaal, F. Preparation of Fish Scales Hydroxyapatite (FsHAp) for Potential Use as Fillers in Polymer. J. Chem. Chem. Eng. 2019, 13, 97–104. [Google Scholar]

- Prasad, A.; Mohan Bhasney, S.; Sankar, M.R.; Katiyar, V. Fish Scale Derived Hydroxyapatite reinforced Poly (Lactic acid) Polymeric Bio-films: Possibilities for Sealing/locking the Internal Fixation Devices. Mater. Today Proc. 2017, 4, 1340–1349. [Google Scholar] [CrossRef]

- Yasin, T.; Ahmed, S.; Yoshii, F.; Makuuchi, K. Effect of acrylonitrile content on physical properties of electron beam irradiated acrylonitrile–butadiene rubber. React. Funct. Polym. 2003, 57, 113–118. [Google Scholar] [CrossRef]

- Degrange, J.-M.; Thomine, M.; Kapsa, P.; Pelletier, J.-M.; Chazeau, L.; Vigier, G.; Dudragne, G.; Guerbé, L. Influence of viscoelasticity on the tribological behaviour of carbon black filled nitrile rubber (NBR) for lip seal application. Wear 2005, 259, 684–692. [Google Scholar] [CrossRef]

- Liu, J.; Li, X.; Xu, L.; Zhang, P. Investigation of aging behavior and mechanism of nitrile-butadiene rubber (NBR) in the accelerated thermal aging environment. Polym. Test. 2016, 54, 59–66. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Fabrication, characterization and dielectric studies of NBR/hydroxyapatite nanocomposites. J. Inorg. Organomet. Polym. Mater. 2017, 27, 481–489. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Synthesis, characterization, processability, mechanical properties, flame retardant, and oil resistance of chlorinated acrylonitrile butadiene rubber. Polym. Adv. Technol. 2018, 29, 2165–2173. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Hydroxyapatite as a potential nanofiller in technologically useful chlorinated acrylonitrile butadiene rubber. Polym. Test. 2020, 91, 106837. [Google Scholar] [CrossRef]

- Hwang, W.G.; Wei, K.H.; Wu, C.M. Mechanical, thermal, and barrier properties of NBR/organosilicate nanocomposites. Polym. Eng. Sci. 2004, 44, 2117–2124. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Nachtane, M.; Stanishevskiy, Y.M.; Dodina, E.P.; Rejepov, D.T.; Vetcher, A.A. The Effect of Multi-Walled Carbon Nanotubes on the Heat-Release Properties of Elastic Nanocomposites. J. Compos. Sci. 2022, 6, 333. [Google Scholar] [CrossRef]

- He, S.; Xue, Y.; Lin, J.; Zhang, L.; Du, X.; Chen, L. Effect of silane coupling agent on the structure and mechanical properties of nano-dispersed clay filled styrene butadiene rubber. Polym. Compos. 2016, 37, 890–896. [Google Scholar] [CrossRef]

- Yangthong, H.; Pichaiyut, S.; Jumrat, S.; Wisunthorn, S.; Nakason, C. Mechanical, thermal, morphological, and curing properties of geopolymer filled natural rubber composites. J. Appl. Polym. Sci. 2019, 136, 47346. [Google Scholar] [CrossRef]

- Kahavita, K.; Samarasekara, A.; Amarasinghe, D.; Karunanayake, L. Nanofibrillated cellulose reinforced polypropylene composites: Influence of silane (SI-69) surface modification. Cellul. Chem. Technol. 2020, 54, 789–797. [Google Scholar] [CrossRef]

- Sae-oui, P.; Sirisinha, C.; Thepsuwan, U.; Hatthapanit, K. Roles of silane coupling agents on properties of silica-filled polychloroprene. Eur. Polym. J. 2006, 42, 479–486. [Google Scholar] [CrossRef]

- Injorhor, P.; Trongsatitkul, T.; Wittayakun, J.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Nano− Hydroxyapatite from White Seabass Scales as a Bio− Filler in Polylactic Acid Biocomposite: Preparation and Characterization. Polymers 2022, 14, 4158. [Google Scholar] [CrossRef]

- Kongsri, S.; Janpradit, K.; Buapa, K.; Techawongstien, S.; Chanthai, S. Nanocrystalline hydroxyapatite from fish scale waste: Preparation, characterization and application for selenium adsorption in aqueous solution. Chem. Eng. J. 2013, 215, 522–532. [Google Scholar] [CrossRef]

- Deb, P.; Deoghare, A.B. Effect of Acid, Alkali and Alkali–Acid Treatment on Physicochemical and Bioactive Properties of Hydroxyapatite Derived from Catla catla Fish Scales. Arab. J. Sci. Eng. 2019, 44, 7479–7490. [Google Scholar] [CrossRef]

- Pon-On, W.; Suntornsaratoon, P.; Charoenphandhu, N.; Thongbunchoo, J.; Krishnamra, N.; Tang, I.M. Hydroxyapatite from fish scale for potential use as bone scaffold or regenerative material. Mater. Sci. Eng. C. 2016, 62, 183–189. [Google Scholar] [CrossRef] [PubMed]

- Sathiskumar, S.; Vanaraj, S.; Sabarinathan, D.; Bharath, S.; Sivarasan, G.; Arulmani, S.; Preethi, K.; Ponnusamy, V.K. Green synthesis of biocompatible nanostructured hydroxyapatite from Cirrhinus mrigala fish scale–A biowaste to biomaterial. Ceram. Int. 2019, 45, 7804–7810. [Google Scholar] [CrossRef]

- Sricharoen, P.; Limchoowong, N.; Nuengmatcha, P.; Chanthai, S. Ultrasonic-assisted recycling of Nile tilapia fish scale biowaste into low-cost nano-hydroxyapatite: Ultrasonic-assisted adsorption for Hg2+ removal from aqueous solution followed by “turn-off” fluorescent sensor based on Hg2+-graphene quantum dots. Ultrason. Sonochem. 2020, 63, 104966. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Chen, K.; Zhang, T.; Chen, X.; He, Y.; Liang, X. Model construction of micro-pores in shale: A case study of Silurian Longmaxi Formation shale in Dianqianbei area, SW China. Pet. Explor. Dev. 2018, 45, 412–421. [Google Scholar] [CrossRef]

- Muhammad, N.; Gao, Y.; Iqbal, F.; Ahmad, P.; Ge, R.; Nishan, U.; Rahim, A.; Gonfa, G.; Ullah, Z. Extraction of biocompatible hydroxyapatite from fish scales using novel approach of ionic liquid pretreatment. Sep. Purif. Technol. 2016, 161, 129–135. [Google Scholar] [CrossRef]

- Rabiei, S.; Shojaei, A. Vulcanization kinetics and reversion behavior of natural rubber/styrene-butadiene rubber blend filled with nanodiamond–The role of sulfur curing system. Eur. Polym. J. 2016, 81, 98–113. [Google Scholar] [CrossRef]

- Balan, A.K.; Mottakkunnu Parambil, S.; Vakyath, S.; Thulissery Velayudhan, J.; Naduparambath, S.; Etathil, P. Coconut shell powder reinforced thermoplastic polyurethane/natural rubber blend-composites: Effect of silane coupling agents on the mechanical and thermal properties of the composites. J. Mater. Sci. 2017, 52, 6712–6725. [Google Scholar] [CrossRef]

- Srisuwan, L.; Jarukumjorn, K.; Suppakarn, N. Effect of silane treatment methods on physical properties of rice husk flour/natural rubber composites. Adv. Mater. Sci. Eng. 2018, 2018, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Nihmath, A.; Ramesan, M.T. Development of hydroxyapatite nanoparticles reinforced chlorinated acrylonitrile butadiene rubber/chlorinated ethylene propylene diene monomer rubber blends. J. Appl. Polym. Sci. 2021, 138, 50189. [Google Scholar] [CrossRef]

- Inphonlek, S.; Bureewong, N.; Jarukumjorn, K.; Chumsamrong, P.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Preparation of Poly (Acrylic Acid-co-acrylamide)-Grafted Deproteinized Natural Rubber and Its Effect on the Properties of Natural Rubber/Silica Composites. Polymers 2022, 14, 4602. [Google Scholar] [CrossRef]

- Keawkumay, C.; Jarukumjorn, K.; Wittayakun, J.; Suppakarn, N. Influences of surfactant content and type on physical properties of natural rubber/organoclay nanocomposites. J. Polym. Res. 2012, 19, 1–9. [Google Scholar] [CrossRef]

- Wu, W.; Zuo, H. Used tire rubber powder/plant cellulose composites treated with coupling agent. Cellulose. 2016, 23, 1939–1947. [Google Scholar] [CrossRef]

- Oprea, M.; Voicu, S.I. Recent advances in applications of cellulose derivatives-based composite membranes with hydroxyapatite. Materials 2020, 13, 2481. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Preparation, characterization, thermal, and electrical properties of chlorinated ethylene propylene diene monomer/hydroxyapatite nanocomposites. Polym. Compos. 2018, 39, 2093–2100. [Google Scholar] [CrossRef]

- Rakmae, S.; Lorprayoon, C.; Ekgasit, S.; Suppakarn, N. Influence of heat-treated bovine bone-derived hydroxyapatite on physical properties and in vitro degradation behavior of poly (lactic acid) composites. Polym. Plast. Technol. Eng. 2013, 52, 1043–1053. [Google Scholar] [CrossRef]

- Nihmath, A.; Ramesan, M. Fabrication, characterization, dielectric properties, thermal stability, flame retardancy and transport behavior of chlorinated nitrile rubber/hydroxyapatite nanocomposites. Polym. Bull. 2021, 78, 6999–7018. [Google Scholar] [CrossRef]

| Materials (phr *) | Unfilled NBR | NBR-5FSp | NBR-10FSp | NBR-10FSp-CA |

|---|---|---|---|---|

| NBR | 100 | 100 | 100 | 100 |

| SA | 2 | 2 | 2 | 2 |

| ZnO | 5 | 5 | 5 | 5 |

| MBTS | 1.5 | 1.5 | 1.5 | 1.5 |

| CBS | 0.5 | 0.5 | 0.5 | 0.5 |

| S | 1.5 | 1.5 | 1.5 | 1.5 |

| FSp | - | 5 | 10 | 10 |

| TESPT | - | - | - | 2 |

| Sample | BET Surface Area (m2/g) | Total Pore Volume (cm3/g) |

|---|---|---|

| FSp | 104 | 0.50 |

| Samples | Minimum Torque (dNm) | Maximum Torque (dNm) | Scorch Time (min) | Cure Time (min) | Cure Rate Index (min−1) |

|---|---|---|---|---|---|

| Unfilled NBR | 7.50 | 23.12 | 3:32 | 11:53 | 0.20 |

| NBR-5FSp | 7.86 | 30.25 | 1:32 | 2:38 | 1.52 |

| NBR-10FSp | 6.44 | 29.02 | 1:31 | 2:32 | 1.64 |

| NBR-10FSp-CA | 5.91 | 24.00 | 1:32 | 3:12 | 1.00 |

| Samples | M100 (MPa) | M300 (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Hardness (Shore A) |

|---|---|---|---|---|---|

| Unfilled NBR | 0.73 ± 0.02 | 1.14 ± 0.06 | 2.54 ± 0.14 | 655.35 ± 8.07 | 35.40 ± 0.25 |

| NBR-5FSp | 1.15 ± 0.04 | 2.39 ± 0.13 | 4.20 ± 0.36 | 475.21 ± 24.37 | 37.90 ± 0.30 |

| NBR-10FSp | 1.14 ± 0.02 | 2.21 ± 0.06 | 4.56 ± 0.48 | 515.81 ± 16.68 | 38.33 ± 0.25 |

| NBR-10FSp-CA | 1.13 ± 0.03 | 2.21 ± 0.08 | 5.62 ± 0.42 | 627.56 ± 51.10 | 41.40 ± 1.14 |

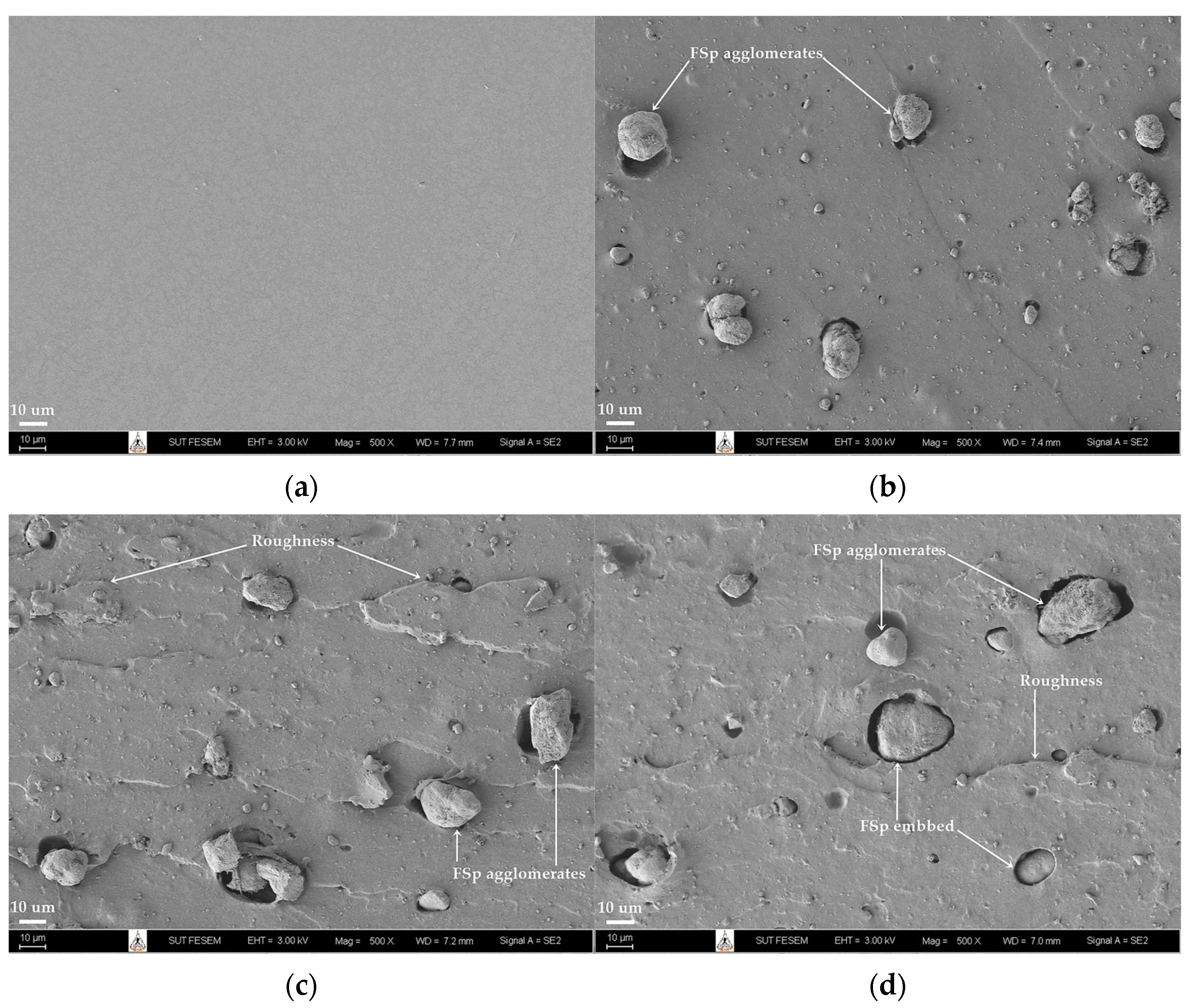

| Samples | Tonset (°C) | Tmax (°C) | Tendset (°C) | Residue (%) |

|---|---|---|---|---|

| Unfilled NBR | 410 | 445 | 475 | 10.91 |

| NBR-5FSp | 411 | 446 | 482 | 14.04 |

| NBR-10FSp | 412 | 449 | 483 | 17.47 |

| NBR-10FSp-CA | 413 | 449 | 483 | 17.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bureewong, N.; Injorhor, P.; Krasaekun, S.; Munchan, P.; Waengdongbang, O.; Wittayakun, J.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale. Polymers 2023, 15, 729. https://doi.org/10.3390/polym15030729

Bureewong N, Injorhor P, Krasaekun S, Munchan P, Waengdongbang O, Wittayakun J, Ruksakulpiwat C, Ruksakulpiwat Y. Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale. Polymers. 2023; 15(3):729. https://doi.org/10.3390/polym15030729

Chicago/Turabian StyleBureewong, Namthip, Preeyaporn Injorhor, Saifa Krasaekun, Pawida Munchan, Oatsaraphan Waengdongbang, Jatuporn Wittayakun, Chaiwat Ruksakulpiwat, and Yupaporn Ruksakulpiwat. 2023. "Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale" Polymers 15, no. 3: 729. https://doi.org/10.3390/polym15030729

APA StyleBureewong, N., Injorhor, P., Krasaekun, S., Munchan, P., Waengdongbang, O., Wittayakun, J., Ruksakulpiwat, C., & Ruksakulpiwat, Y. (2023). Preparation and Characterization of Acrylonitrile Butadiene Rubber Reinforced with Bio-Hydroxyapatite from Fish Scale. Polymers, 15(3), 729. https://doi.org/10.3390/polym15030729