Preparation of Highly Stable Polymer Microstructure with Enhanced Adhesion Strength by Pushpin-like Nano/Microstructure Array

Abstract

:1. Introduction

2. Material and Methods

2.1. Raw Materials and Experimental Devices

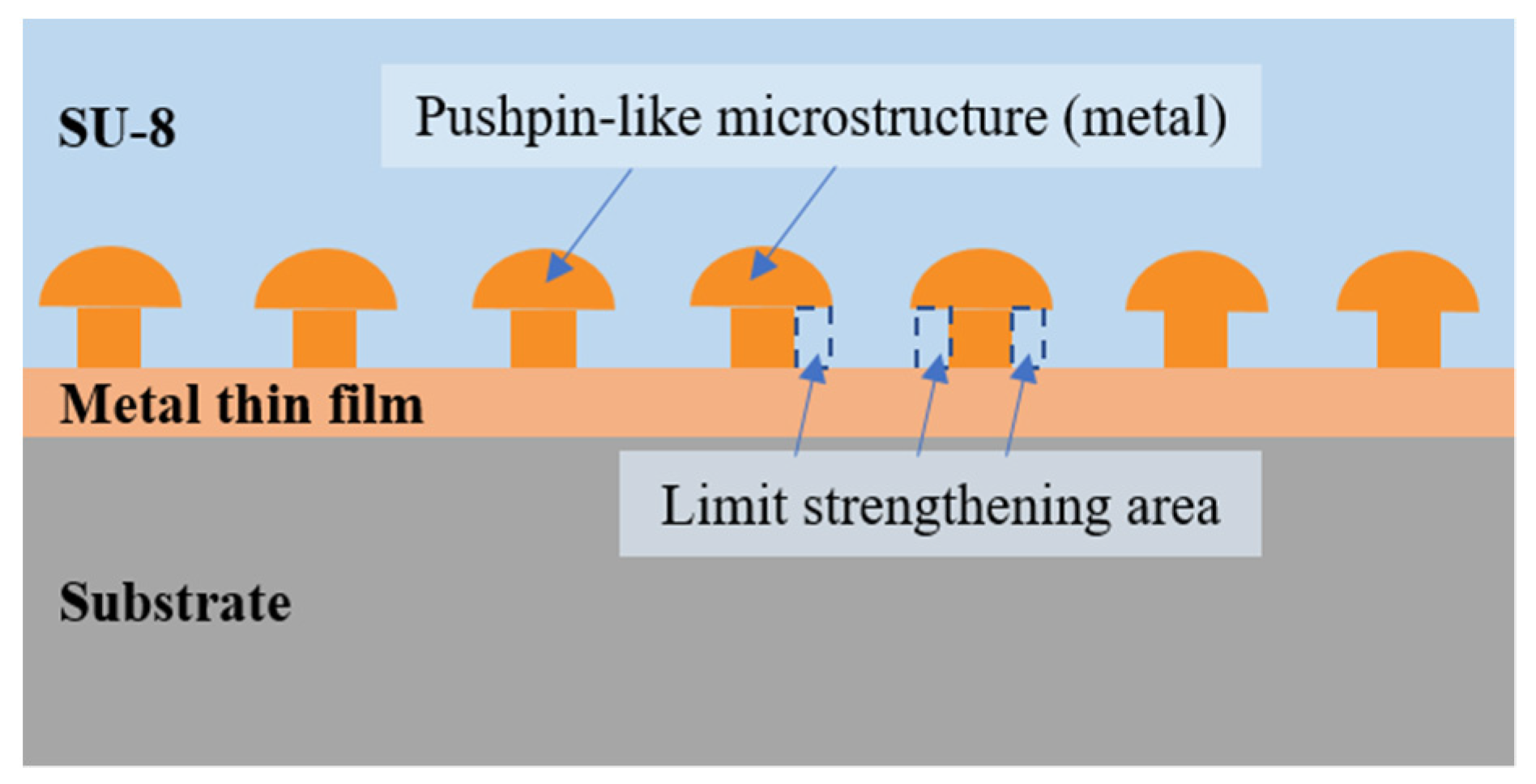

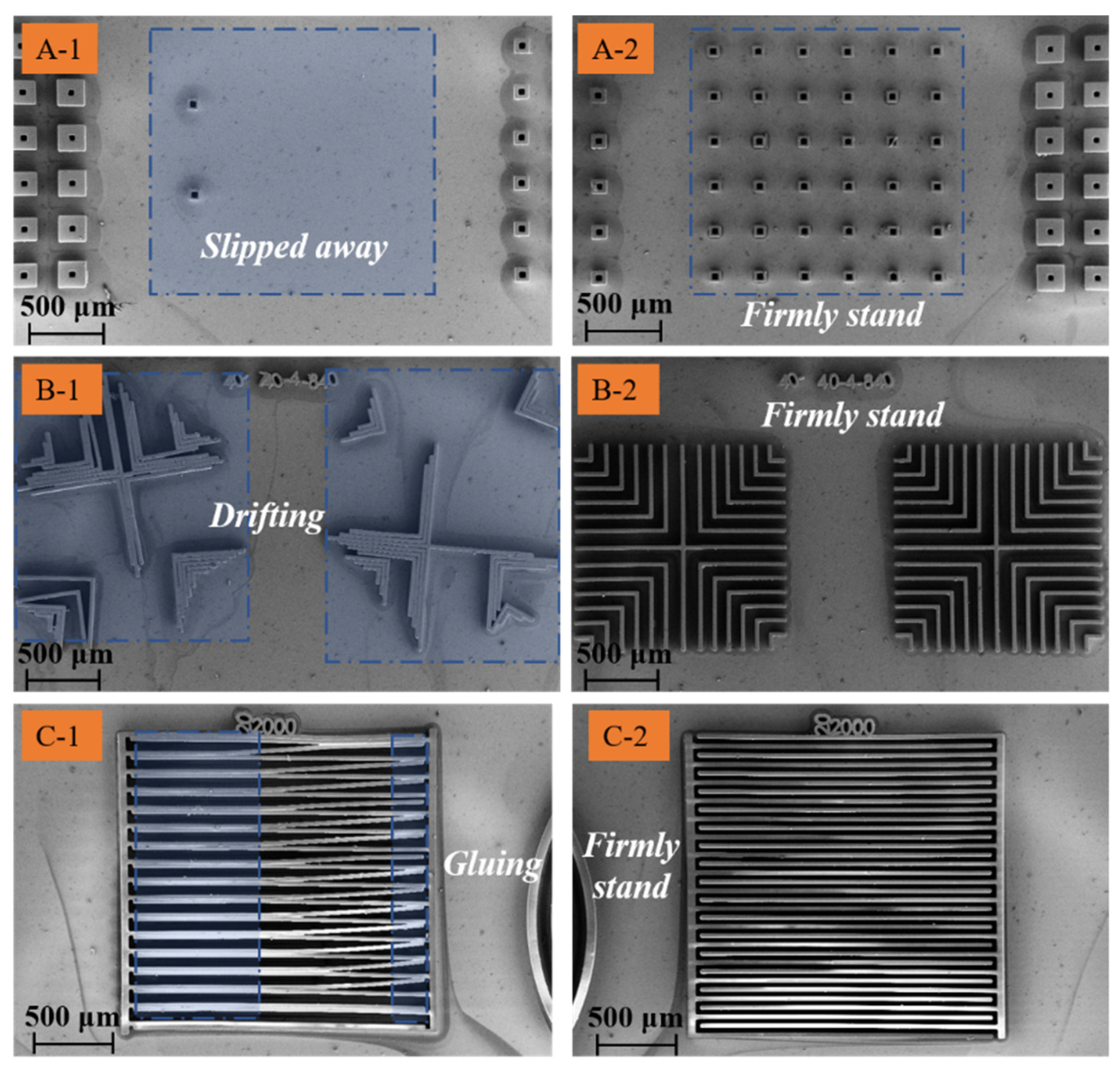

2.2. Problem Statement of Polymer Microstructure

2.3. Substrate Preparation

2.4. Nano/Microstructures Activated Strengthening Layer Preparation

2.5. SU-8 Microstructure Preparation

2.6. Adhesion Strength Testing

3. Results and Discussion

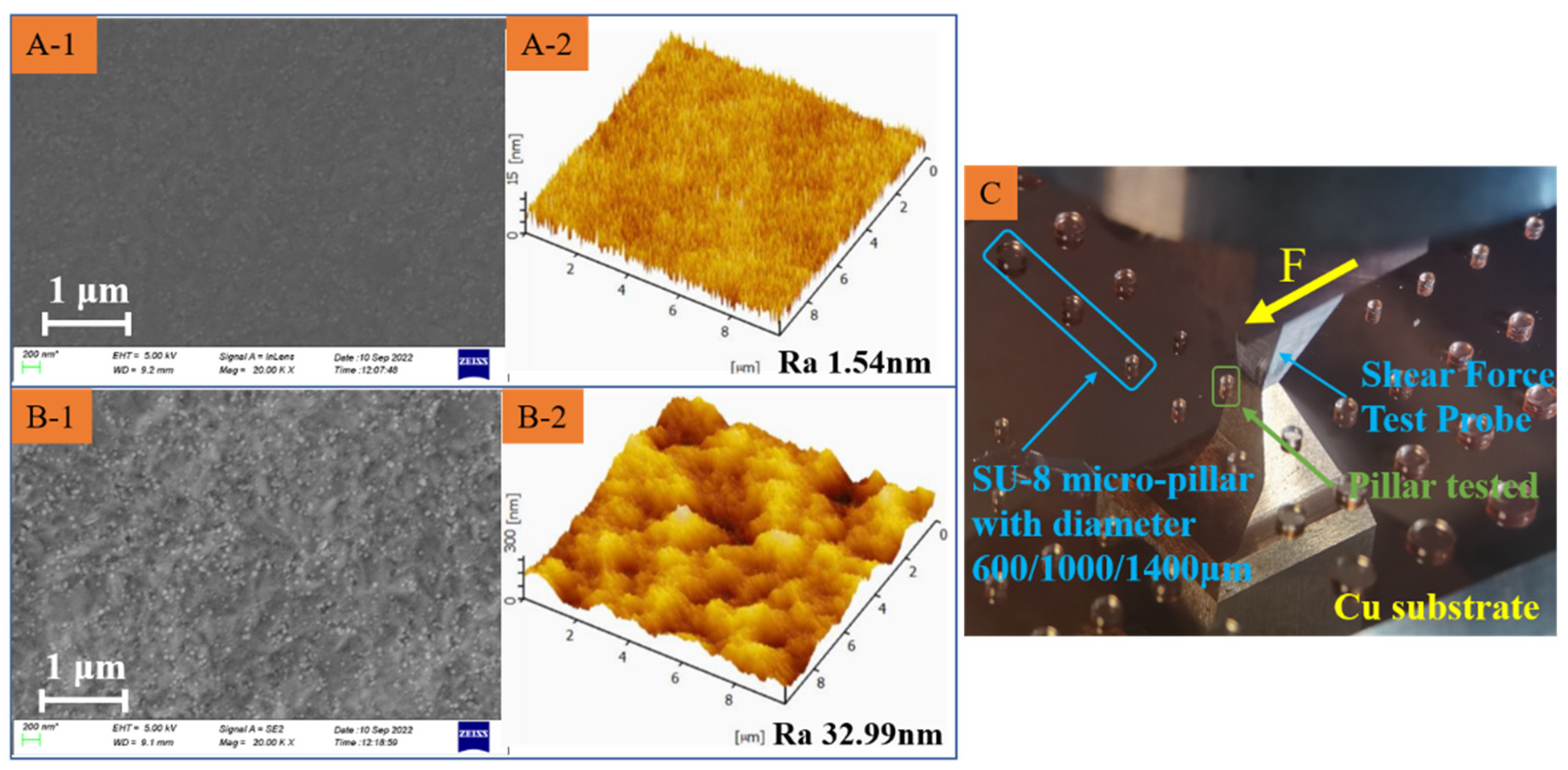

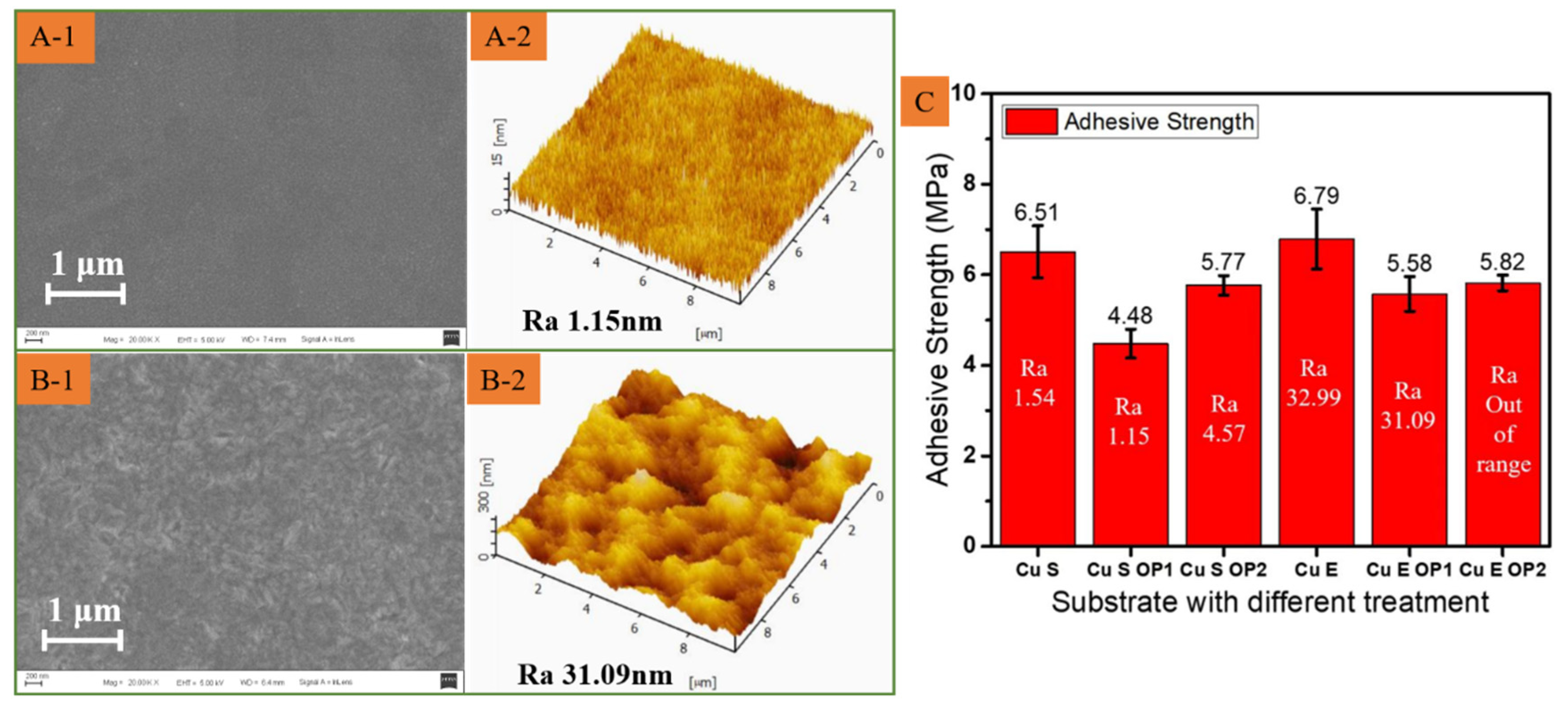

3.1. Influence of the Textured Morphology Induced by Sputtering and Electroplating

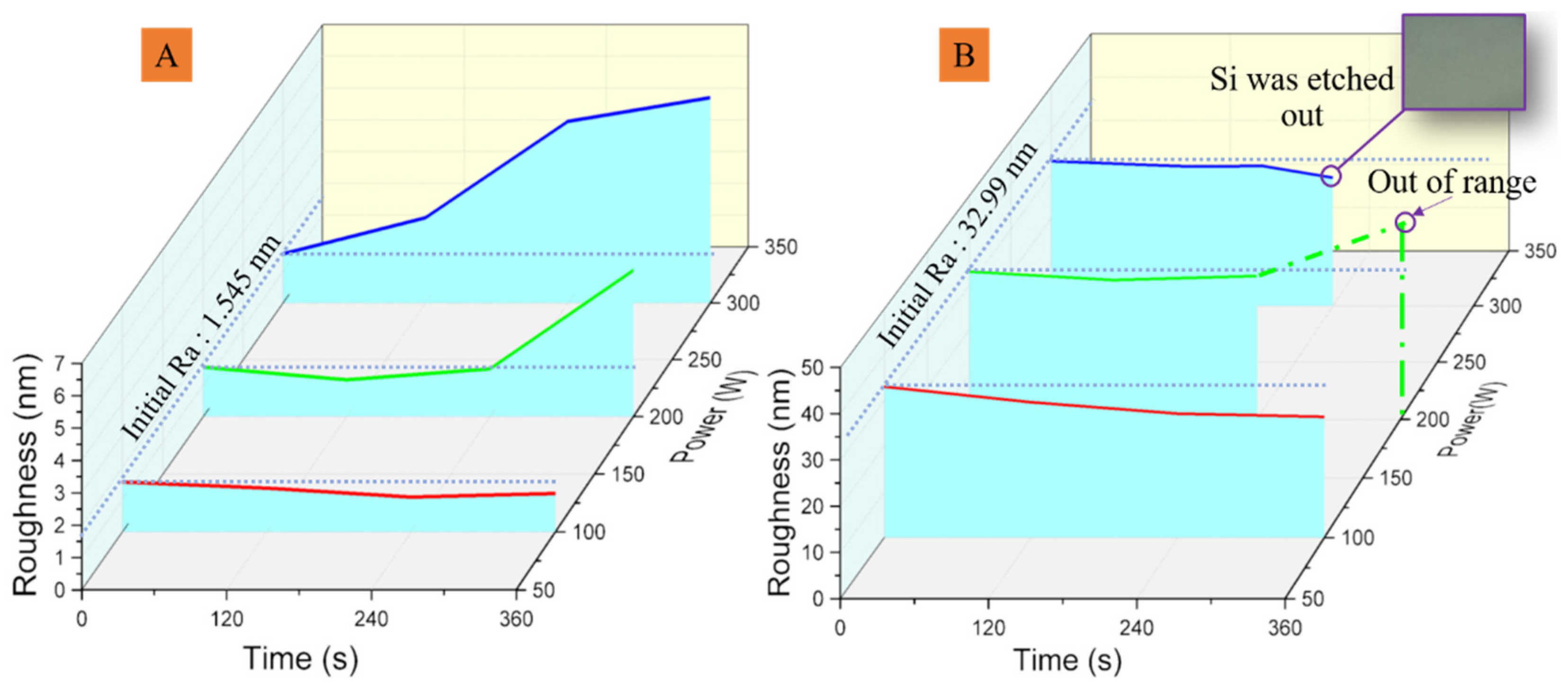

3.2. Influence of Oxygen Ion Bombardment

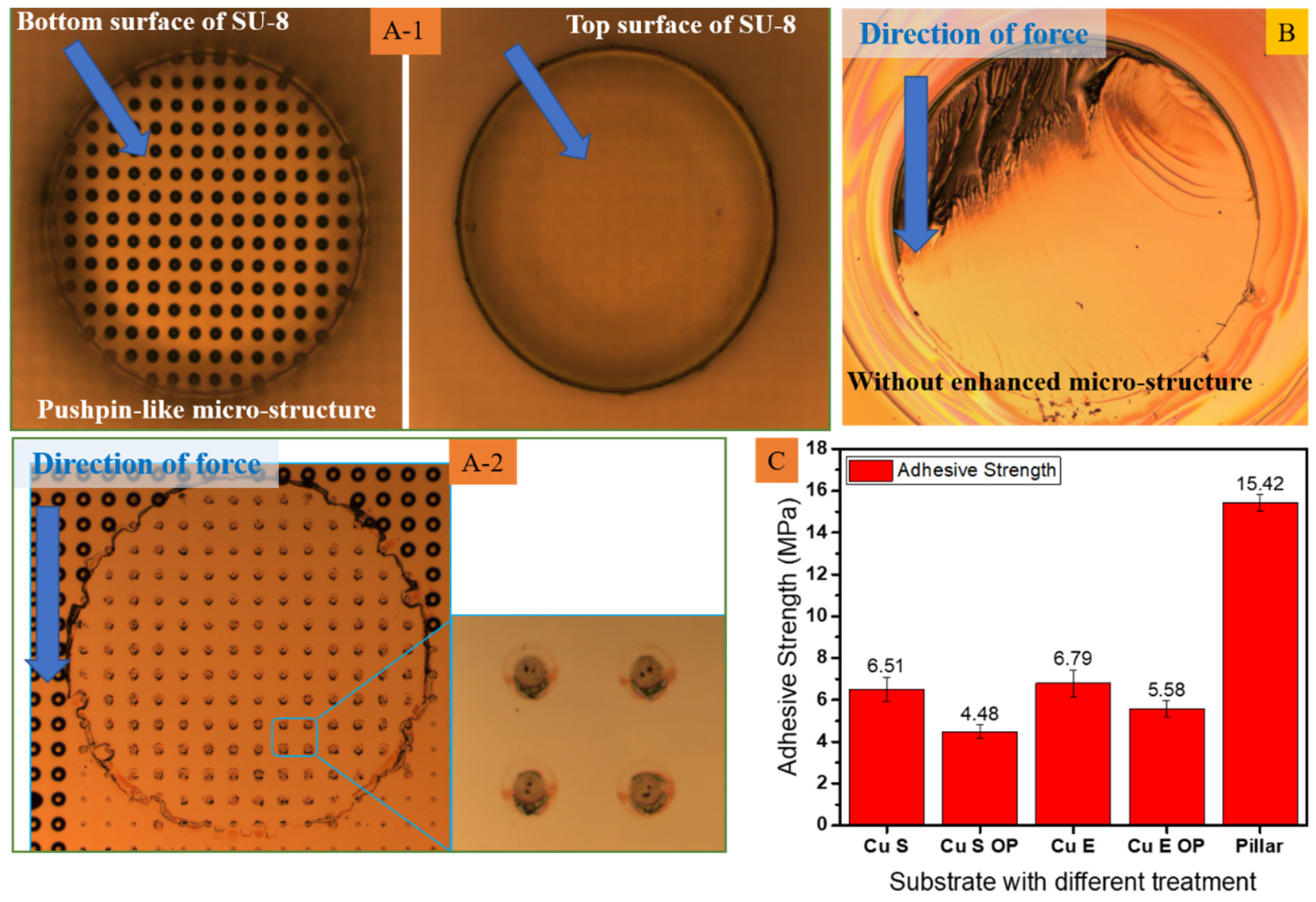

3.3. Influence of Pushpin-like Reinforced Microstructure

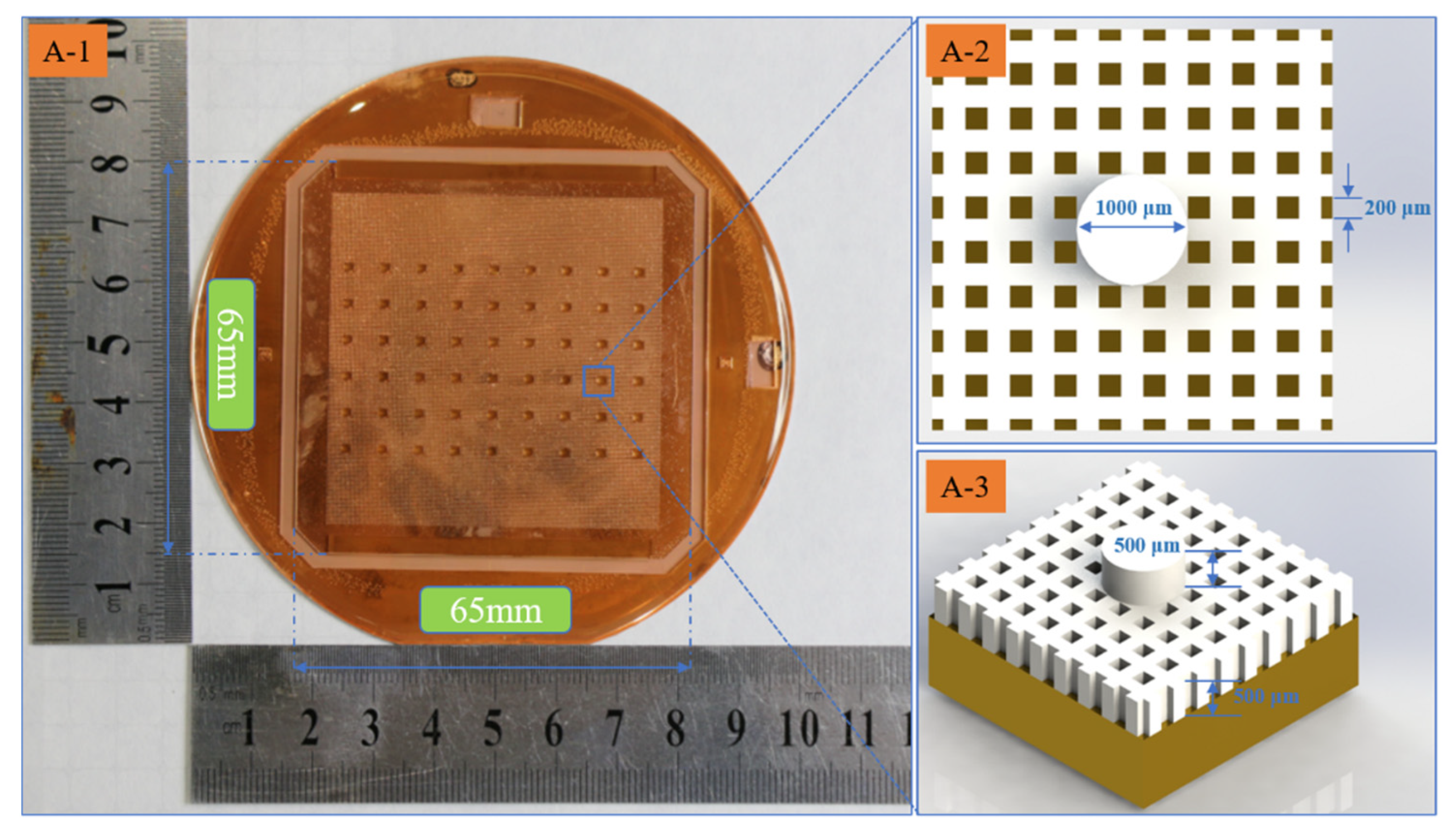

3.4. SU-8 Microstructure

4. Conclusions

- (1)

- Based on the pushpin-like reinforce microstructure array, the effective contact area is enlarged, and the mechanical interlocking effect is introduced.

- (2)

- The adhesive strength of SU-8 with pushpin-like reinforce microstructure array was improved about 2.37 times compared with the sputtering method.

- (3)

- Based on the pushpin-like reinforce microstructure array, the drifting and gluing phenomenon can be alleviated.

- (4)

- The feasibility of the transition strengthening layer and repeatability and universality of the microfabrication processes has been evaluated by the application of pushpin-like reinforce microstructure array in three typical SU-8 microstructures and large-area SU-8 microstructures.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sukhoveyev, S. Ultra high aspect-ratio MEMS and NEMS on basis of fibrous composite technology. Microsyst. Technol. 2008, 14, 1099–1110. [Google Scholar] [CrossRef]

- Kim, B.J.; Meng, E. Review of polymer MEMS micromachining. J. Micromech. Microeng. 2016, 26, 013001. [Google Scholar] [CrossRef]

- Gong, J.; Hosaka, E.; Sakai, K.; Ito, H.; Shibata, Y. Processing and thermal response of temperature-sensitive-gel(tsg)/polymer composites. Polymers 2018, 10, 486. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sun, Y.; Wu, Y.; Cai, H.; Luo, J.; Ding, G. A modified 360° netting vein bionic structure for enhancing thermal properties of polymer/nanofiber/nanoparticle composite. Compos. Part A 2021, 143, 106276. [Google Scholar] [CrossRef]

- Tao, Z.; Sun, J.; Li, H.; Huang, Y.; Wu, H. A radial-flux permanent magnet micromotor with 3D solenoid iron-core mems in-chip coils of high aspect ratio. IEEE Electron. Device Lett. 2020, 41, 1090–1093. [Google Scholar] [CrossRef]

- Klymyshyn, D.M.; Haluzan, D.T.; Borner, M.; Achenbach, S.; Mohr, J.; Mappes, T. High aspect ratio vertical cantilever RF-mems variable capacitor. IEEE Microw. Wirel. Compon. Lett. 2007, 17, 127–129. [Google Scholar] [CrossRef]

- Zheng, R.; Wu, Y.; Li, Y.; Wang, G.; Ding, G.; Sun, Y. Development of a hierarchical microchannel heat sink with flow field reconstruction and low thermal resistance for high heat flux dissipation. Int. J. Heat Mass Transfer 2022, 182, 121925. [Google Scholar] [CrossRef]

- Ma, C.; Sun, Y.; Wu, Y.; Zhang, Q.; Wang, Y.; Ding, G. A bio-inspired fractal microchannel heat sink with secondary modified structure and sub-total-sub fluid transmission mode for high heat flux and energy-saving heat dissipation. Int. J. Heat Mass Transfer 2023, 202, 12371. [Google Scholar] [CrossRef]

- Huang, I.-Y.; Lee, Y.-C.; Lin, C.-Y.; Ho, P.-E. Lifting angle of polyimide self-assembly surface-micromachined structure. J. Micro/Nanolith. MEMS MOEMS 2010, 9, 023006. [Google Scholar] [CrossRef]

- Ribeiro, J.-F.; Costa, A.-C.; Gomes, J.-M.; Costa, C.-G.; Goncalves, S.-B.; Reinoud, F. PDMS Microlenses for Optical Biopsy Microsystems. IEEE Trans. Ind. Electron. 2017, 64, 9683–9690. [Google Scholar] [CrossRef]

- Lien, D.-H.; Wang, H.-P.; Chen, S.-B.; Chi, Y.-C.; Wu, C.-L.; Lin, G.-R.; Liao, Y.-C.; He, J.-H. 360° omnidirectional, printable and transparent photodetectors for flexible optoelectronics. Npj Flex. Electron. 2008, 2, 19. [Google Scholar] [CrossRef] [Green Version]

- Paul, H.; Henning, F.; Luke, M. Combining mechanical interlocking, force fit and direct adhesion in polymer-metal-hybrid structures—Evaluation of the deformation and damage behavior. Compos. Part B 2015, 73, 158–165. [Google Scholar] [CrossRef]

- Golvari, P.; Kuebler, S.M. Fabrication of Functional Microdevices in SU-8 by Multi-Photon Lithography. Micromachines 2021, 12, 472. [Google Scholar] [CrossRef] [PubMed]

- Vellinga, W.P.; Eising, G.; Wit, F.M.D.; Mol, J.; Terryn, H.; Wit, J.H.W.D.; De Hosson, J.T.M. Adhesion at al-hydroxide-polymer interfaces: Influence of chemistry and evidence for microscopic self-pinning. Mater. Sci. Eng. A 2010, 527, 5637–5647. [Google Scholar] [CrossRef] [Green Version]

- Unger, K.; Anzengruber, M.; Coclite, A.M. Measurements of Temperature and Humidity Responsive Swelling of Thin Hydrogel Films by Interferometry in an Environmental Chamber. Polymers 2022, 14, 3987. [Google Scholar] [CrossRef]

- Lorenz, H.; Despont, M.; Fahrni, N.; Brugger, J.; Vettiger, P.; Renaud, P. High-aspect-ratio, ultrathick, negative-tone near-UV photoresist and its applications for MEMS. Sens. Actuators A 1998, 64, 33–39. [Google Scholar] [CrossRef] [Green Version]

- Chang, H.-K.; Kim, Y.-K. UV-LIGA process for high aspect ratio structure using stress barrier and C-shaped etch hole. Sens. Actuators A 2000, 84, 342–350. [Google Scholar] [CrossRef]

- Sampath, S.K.; Clair, L.S.; Wu, X.; Lvanov, D.V.; Wang, Q.; Ghosh, C.; Farmer, K.R. Rapid MEMS prototyping using SU-8, wafer bonding and deep reactive ion etching. In Proceedings of the Fourteenth Biennial University/Government/Industry Microelectronics Symposium (Cat. No.01CH37197), Richmond, VA, USA, 20–22 June 2001; pp. 158–161. [Google Scholar]

- Huang, Y.-J.; Hsieh, Y.-H.; Shih, J.-Y.; Chen, H.-C.; Leu, J.; Chen, K.-N. Adhesion Property Between Cu, Ti Metal and SU-8, AZ 4620 Polymer Dielectric. J. Nanosci. Nanotechnol. 2016, 16, 7546–7550. [Google Scholar] [CrossRef]

- Johari, S.; Tamilchelvan, N.; Nor, M.N.M.; Ramli, M.M.; Taib, B.N.; Mazalan, M.; Wahab, Y. The effect of soft baking temperature on SU-8 photoresist performance. In Proceedings of the 2014 IEEE International Conference on Semiconductor Electronics (ICSE2014), Kuala Lumpur, Malaysia, 27–29 August 2014; pp. 467–470. [Google Scholar]

- Li, B.; Liu, M.; Chen, Q. Low-stress ultra-thick SU-8 UV photolithography process for mems. J. Micro/Nanolithogr. MEMS MOEMS 2005, 4, 043008. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Lichal, C.; Cajner, H.; Berger, G.R.; Schuschnigg, S.; Cardon, L.; Holzer, C. Optimisation of the Adhesion of Polypropylene-Based Materials during Extrusion-Based Additive Manufacturing. Polymers 2018, 10, 490. [Google Scholar] [CrossRef] [Green Version]

- Chan-Park, M.B.; Zhang, J.; Yan, Y.; Yue, C.Y. Fabrication of large SU-8 mold with high aspect ratio microchannels by UV exposure dose reduction. Sens. Actuators B 2004, 101, 175–182. [Google Scholar] [CrossRef]

- Marasso, S.L.; Canavese, G.; Cocuzza, M. Cost efficient master fabrication process on copper substrates. Microelectron. Eng. 2011, 88, 2322–2324. [Google Scholar] [CrossRef]

- Son, S.-H.; Park, Y.-H.; Choi, S.-Y. New formation technology for a plasma display panel barrier-rib structure using a precise metal mold fabricated by the uv-liga process. J. Micromech. Microeng. 2002, 12, 63–69. [Google Scholar] [CrossRef]

- Byun, I.; Coleman, A.W.; Kim, B. Transfer of thin Au films to polydimethylsiloxane (PDMS) with reliable bonding using (3-mercaptopropyl) trimethoxysilane (MPTMS) as a molecular adhesive. J. Micromech. Microeng. 2013, 23, 085016. [Google Scholar] [CrossRef]

- Nordström, M.; Johansson, A.; Noguerón, E.S.; Clausen, B.; Calleja, M.; Boisen, A. Investigation of the bond strength between the photo-sensitive polymer SU-8 and gold. Microelectron. Eng. 2005, 78–79, 152–157. [Google Scholar] [CrossRef]

- Barber, R.L.; Ghantasala, M.K.; Divan, R.; Mancini, D.C.; Harvey, E.C. Study of stress and adhesion strength in SU-8 resist layers on silicon substrate with different seed layers. J. Micro/Nanolith. MEMS MOEMS 2007, 6, 033006. [Google Scholar]

- Gupta, B.; Hilborn, J.; Hollenstein, C.; Plummer, C.J.G.; Houriet, R.; Xanthopoulos, N. Surface modification of polyester films by RF plasma. J. Appl. Polym. Sci. 2000, 78, 1083–1091. [Google Scholar] [CrossRef]

- Kim, D.-H.; Song, J.H.; Choi, W.M.; Kim, H.-S.; Kim, R.-H.; Liu, H.J.; Huang, Y.Y.; Hwang, K.; Zhang, Y.-W.; Roger, J.A. Materials and noncoplanar mesh designs for integrated circuits with linear elastic responses to extreme mechanical deformations. Proc. Natl. Acad. Sci. USA 2008, 105, 18675–18680. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Viswanathan-Chettiar, S.; Sun, F.; Shi, Z.; Blackman, B. Effect of CFRP surface topography on the adhesion and strength of composite-composite and composite-metal joints. Composites Part A 2023, 164, 107275. [Google Scholar] [CrossRef]

- Kim, W.-S.; Yun, I.-H.; Lee, J.-J.; Jung, H.-T. Evaluation of mechanical interlock effect on adhesion strength of polymer–metal interfaces using micro-patterned surface topography. Int. J. Adhes. Adhes. 2010, 30, 408–417. [Google Scholar] [CrossRef]

- Boiziau, C.; Lecayon, G. Adhesion of polymers to metals: A review of the results obtained studying a model system. Surf. Interface Anal. 1988, 12, 475–485. [Google Scholar] [CrossRef]

- Lai, L.; Sun, Y.; Wu, H.; Yang, Z.; Ding, G. Enhanced adhesive strength between SU-8 photoresist and titanium substrate by improved anodic oxidation method for high aspect-ratio microstructure. J. Micromech. Microeng. 2019, 29, 047002. [Google Scholar] [CrossRef]

- Dervisevic, E.; Voelcker, N.H.; Risbridger, G.; Tuck, K.L.; Cadarso, V.J. High-aspect-ratio SU-8-based optofluidic device for ammonia detection in cell culture media. ACS Sens. 2020, 5, 2523–2529. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Ding, G.; Zhu, Y.; Wang, Y.; Liu, R.; Sun, Y. Preparation of Highly Stable Polymer Microstructure with Enhanced Adhesion Strength by Pushpin-like Nano/Microstructure Array. Polymers 2023, 15, 1015. https://doi.org/10.3390/polym15041015

Wu Y, Ding G, Zhu Y, Wang Y, Liu R, Sun Y. Preparation of Highly Stable Polymer Microstructure with Enhanced Adhesion Strength by Pushpin-like Nano/Microstructure Array. Polymers. 2023; 15(4):1015. https://doi.org/10.3390/polym15041015

Chicago/Turabian StyleWu, Yongjin, Guifu Ding, Yuan Zhu, Yan Wang, Rui Liu, and Yunna Sun. 2023. "Preparation of Highly Stable Polymer Microstructure with Enhanced Adhesion Strength by Pushpin-like Nano/Microstructure Array" Polymers 15, no. 4: 1015. https://doi.org/10.3390/polym15041015

APA StyleWu, Y., Ding, G., Zhu, Y., Wang, Y., Liu, R., & Sun, Y. (2023). Preparation of Highly Stable Polymer Microstructure with Enhanced Adhesion Strength by Pushpin-like Nano/Microstructure Array. Polymers, 15(4), 1015. https://doi.org/10.3390/polym15041015