Investigating the Effects of Nitric Acid Treatments on the Properties of Recycled Carbon Fiber

Abstract

:1. Introduction

2. Experimental Details

3. Results and Discussion

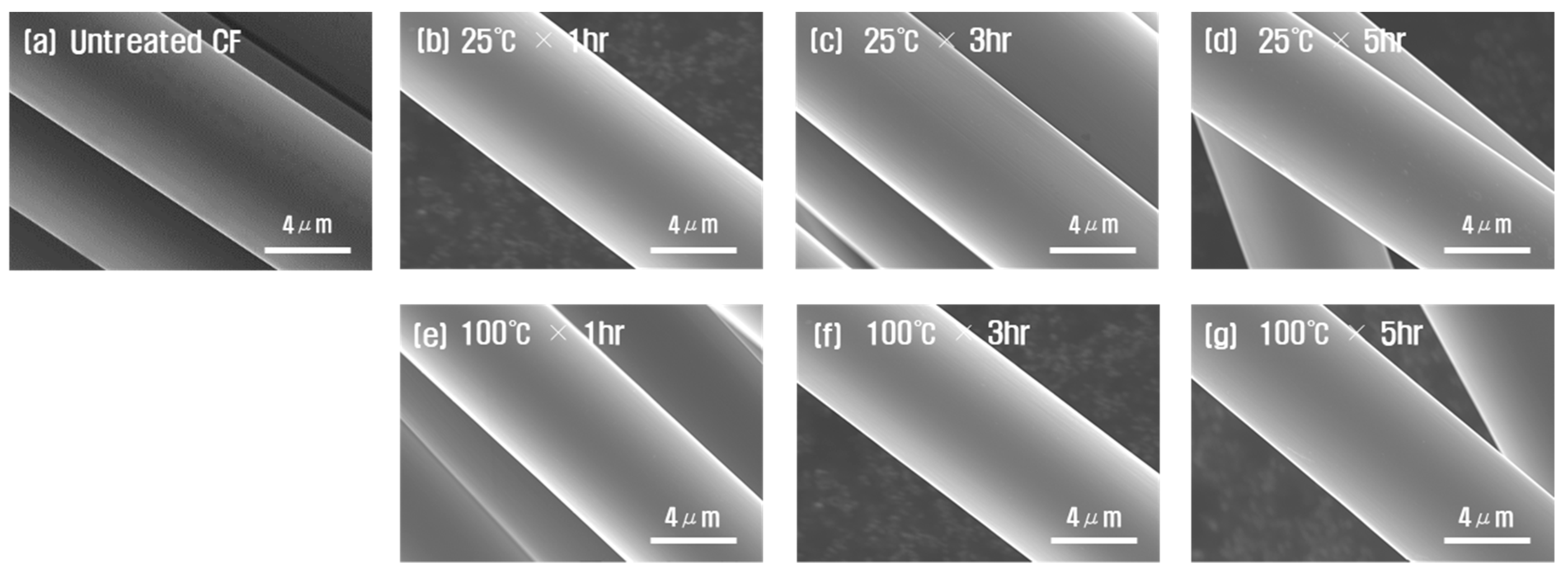

3.1. Surface Topography of Carbon Fibers

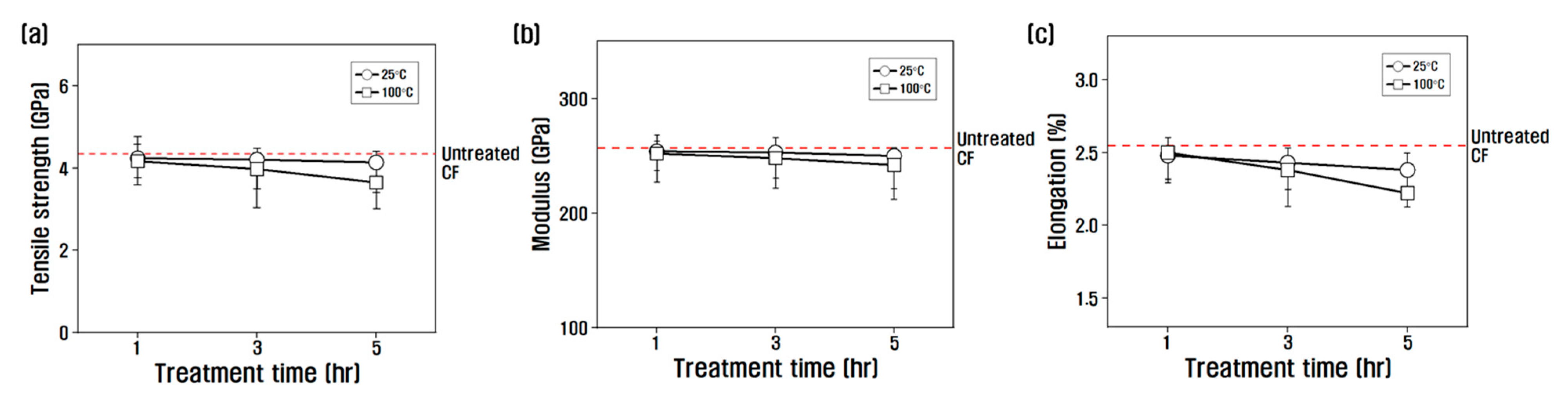

3.2. Tensile Properties of Carbon Fibers

3.3. Surface Composition of Carbon Fibers

3.4. Surface Energy Analysis

3.5. Functional Group Change Mechanism by Nitric Acid Treatment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stojcevski, F.; Hilditch, T.B.; Henderson, L.C. A comparison of interfacial testing methods and sensitivities to carbon fiber surface treatment conditions. Compos. Part A Appl. Sci. Manuf. 2019, 118, 293–301. [Google Scholar] [CrossRef]

- Zhang, J.; Duan, Y.; Wang, B.; Zhang, X. Interfacial enhancement for carbon fibre reinforced electron beam cured polymer composite by microwave irradiation. Polymer 2020, 192, 122327. [Google Scholar] [CrossRef]

- Kim, D.K.; An, K.H.; Bang, Y.H.; Kwac, L.K.; Oh, S.Y.; Kim, B.J. Effects of electrochemical oxidation of carbon fibers on interfacial shear strength using a micro-bond method. Carbon Lett. 2016, 19, 32–39. [Google Scholar] [CrossRef]

- Yan, X.; Imai, Y.; Shimamoto, D.; Hotta, Y. Relationship study between crystal structure and thermal/mechanical properties of polyamide 6 reinforced and unreinforced by carbon fiber from macro and local view. Polymer 2014, 55, 6186–6194. [Google Scholar] [CrossRef]

- Park, S.J.; Chang, Y.H.; Kim, Y.C.; Rhee, K.Y. Anodization of carbon fibers on interfacial mechanical properties of epoxy matrix composites. J. Nanosci. Nanotechnol. 2010, 10, 117–121. [Google Scholar] [CrossRef]

- Kang, H.; Kim, J.; Kim, H.; Choi, Y. Study of stabilization process of PAN precursor and its characteristics change by plasma treatment. Compos. Res. 2021, 34, 23–29. [Google Scholar] [CrossRef]

- Hayne, D.J.; Stojcevski, F.; Knorr, D.B.; Tran, N.T.; Henderson, L.C. Surface modification of carbon fibres using ring-opening metathesis polymerization. Compos. Part A Appl. Sci. Manuf. 2021, 145. [Google Scholar] [CrossRef]

- Eyckens, D.J.; Randall, J.D.; Stojcevski, F.; Sarlin, E.; Palola, S.; Kakkonen, M.; Scheffler, C.; Henderson, L.C. Examining interfacial interactions in a range of polymers using poly(ethylene oxide) functionalized carbon fibers. Compos. Part A Appl. Sci. Manuf. 2020, 138, 106053. [Google Scholar] [CrossRef]

- Sun, H.; Guo, G.; Memon, S.A.; Xu, W.; Zhang, Q.; Zhu, J.-H.; Xing, F. Recycling of carbon fibers from carbon fiber reinforced polymer using electrochemical method. Compos. Part A Appl. Sci. Manuf. 2015, 78, 10–17. [Google Scholar] [CrossRef]

- Fukui, R.; Odai, T.; Zushi, H.; Osawa, I.; Uzawa, K.; Takahashi, J. Recycle of carbon fiber reinforced plastics for automotive application. In Proceedings of the Ninth Japan International SAMPE Symposium, Tokyo, Japan, 29 November 2005; pp. 44–49. Available online: https://www.researchgate.net/publication/266887280_Recycle_of_carbon_fiber_reinforced_plastics_for_automotive_application (accessed on 10 July 2021).

- Lee, H.; Ohsawa, I.; Takahashi, J. Effect of plasma surface treatment of recycled carbon fiber on carbon fiber-reinforced plastics (CFRP) interfacial properties. Appl. Surf. Sci. 2015, 328, 241–246. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Wu, D. Recycled carbon fiber reinforced poly(butylene terephthalate) thermoplastic composites: Fabrication, crystallization behaviors and performance evaluation. Polym. Adv. Technol. 2012, 24, 364–375. [Google Scholar] [CrossRef]

- Lee, H.J.; Won, J.S.; Lim, S.C.; Lee, T.S.; Yoon, J.Y.; Lee, S.G. Preparation and characterization of PAN-based carbon fiber with carbonization temperature. J. Text. Sci. Eng. 2006, 53, 103–108. [Google Scholar] [CrossRef]

- Li, J.; Cai, C.L. The carbon fiber surface treatment and addition of PA6 on tensile properties of ABS composites. Curr. Appl. Phys. 2011, 11, 50–54. [Google Scholar] [CrossRef]

- Woodhead, A.L.; de Souza, M.L.; Church, J.S. An investigation into the surface heterogeneity of nitric acid oxidized carbon fiber. Appl. Surf. Sci. 2017, 401, 79–88. [Google Scholar] [CrossRef]

- Yu, J.; Meng, L.; Fan, D.; Zhang, C.; Yu, F.; Huang, Y. The oxidation of carbon fibers through K2S2O8/AgNO3 system that preserves fiber tensile strength. Compos. Part B Eng. 2014, 60, 261–267. [Google Scholar] [CrossRef]

- Tiwari, S.; Bijwe, J.; Panier, S. Tribological studies on polyetherimide composites based on carbon fabric with optimized oxidation treatment. Wear 2011, 271, 2252–2260. [Google Scholar] [CrossRef]

- Martínez-Landeros, V.H.; Vargas-Islas, S.Y.; Cruz-González, C.E.; Barrera, S.; Mourtazov, K.; Ramírez-Bon, R. Studies on the influence of surface treatment type, in the effectiveness of structural adhesive bonding, for carbon fiber reinforced composites. J. Manuf. Process. 2019, 39, 160–166. [Google Scholar] [CrossRef]

- Ibarra, L.; Paños, D. Carbon fibre oxidation, textural and surface changes. Angew. Makromol. Chem. 1997, 248, 201–215. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, S.; Yang, D.; Dodelet, J.P.; Sacher, E. The surface analytical characterization of carbon fibers functionalized by H2SO4/HNO3 treatment. Carbon 2008, 46, 196–205. [Google Scholar] [CrossRef]

- Wu, Z.; Pittman, C.U.; Gardner, S.D. Nitric acid oxidation of carbon fibers and the effects of subsequent treatment in refluxing aqueous NaOH. Carbon 1995, 33, 597–605. [Google Scholar] [CrossRef]

- Li, J. Effect of fiber surface treatment on wear characteristics of carbon fiber reinforced polyamide 6 composites. Iran. J. Chem. Chem. Eng. 2010, 29, 141–147. [Google Scholar] [CrossRef]

- Lee, W.H.; Lee, J.G.; Reucrof, P.J. XPS study of carbon fiber surfaces treated by thermal oxidation in a gas mixture of O2/(O2 + N2). Appl. Surf. Sci. 2001, 171, 136–142. [Google Scholar] [CrossRef]

- Kim, G.; Lee, H.; Kim, K.; Kim, D.U. Effects of heat treatment atmosphere and temperature on the properties of carbon fibers. Polymers 2022, 14, 2412. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Z.H.; Ma, W.J.; Ma, Q.S. Influence of heat treatment on physical-chemical properties of PAN-based carbon fiber. Ceram. Int. 2006, 32, 291–295. [Google Scholar] [CrossRef]

- Dai, Z.; Zhang, B.; Shi, F.; Li, M.; Zhang, Z.; Gu, Y. Effect of heat treatment on carbon fiber surface properties and fibers/epoxy interfacial adhesion. Appl. Surf. Sci. 2011, 257, 8457–8461. [Google Scholar] [CrossRef]

- Zhang, J. Different Surface Treatments of Carbon Fibers and Their Influence on the Interfacial Properties of Carbon Fiber. Ph.D. Thesis, Ecole Centrale, Paris, France, 2012. Available online: https://tel.archives-ouvertes.fr/tel-01146459 (accessed on 28 April 2015).

- Song, J.-H. Tensile strength of polypropylenses carbon fiber composite for heat treatment conditions. J. Korean Soc. Mech. Technol. 2020, 22, 107–111. [Google Scholar] [CrossRef]

- Rong, H.; Ryu, Z.; Zheng, J.; Zhang, Y. Effect of air oxidation of Rayon-based activated carbon fibers on the adsorption behavior for formaldehyde. Carbon 2002, 40, 2291–2300. [Google Scholar] [CrossRef]

- Yumitori, S.; Nakanishi, Y. Effect of anodic oxidation of coal tar pitch-based carbon fibre on adhesion in epoxy matrix: Part 2. Comparative study of three alkaline solutions. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1059–1066. [Google Scholar] [CrossRef]

- Hendlmeier, A.; Stojcevski, F.; Alexander, R.; Gupta, S.; Henderson, L.C. Examining conductivity, current density, and sizings applied to carbon fibers during manufacture and their effect on fiber-to-matrix adhesion in epoxy polymers. Compos. Part B Eng. 2019, 179, 107494. [Google Scholar] [CrossRef]

- Moon, C.W.; Jung, G.; Im, S.S.; Nah, C.; Park, S.J. Effect of anodic oxidation of H2S04/HN03 ratio for improving interfacial adhesion between carbon fibers and epoxy matrix resins. Polymer 2013, 37, 61–65. [Google Scholar] [CrossRef] [Green Version]

- Ma, K.; Chen, P.; Wang, B.; Cui, G.; Xu, X. A study of the effect of oxygen plasma treatment on the interfacial properties of carbon fiber/epoxy composites. J. Appl. Polym. Sci. 2010, 118, 1606–1614. [Google Scholar] [CrossRef]

- Jang, J.; Yang, H. The effect of surface treatment on the performance improvement of carbon fiber/polybenzoxazine composites. J. Mater. Sci. 2000, 35, 2297–2303. [Google Scholar] [CrossRef]

- Lee, H.; Wei, H.; Takahashi, J. The influence of plasma in various atmospheres on the adhesion properties of recycled carbon fiber. Macromol. Res. 2015, 23, 1026–1033. [Google Scholar] [CrossRef]

- Sun, C.; Min, J.; Lin, J.; Wan, H. Effect of atmospheric pressure plasma treatment on adhesive bonding of carbon fiber reinforced polymer. Polymers 2019, 11, 139. [Google Scholar] [CrossRef]

- Han, S.H.; Oh, H.J.; Kim, S.S. Evaluation of mechanical property of carbon fiber/polypropylene composite according to carbon fiber surface treatment. Trans. Korean Soc. Mech. Eng. 2013, 37, 791–796. [Google Scholar] [CrossRef]

- Lee, H.; Kim, G.; Kim, K.; Kim, H.; Kim, D.U. Effect of Plasma Treatment Condition on Mechanical and Chemical Properties of Carbon Fibers. J. Mater. Eng. Perform. 2022, 32, 415–422. [Google Scholar] [CrossRef]

- Lin, J.; Sun, C.; Min, J.; Wan, H.; Wang, S. Effect of atmospheric pressure plasma treatment on surface physicochemical properties of carbon fiber reinforced polymer and its interfacial bonding strength with adhesive. Compos. Part B Eng. 2020, 199, 108237. [Google Scholar] [CrossRef]

- Tiwari, S.; Bijwe, J. Surface treatment of carbon fibers—A review. Procedia Technol. 2014, 14, 505–512. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, C.J.; Min, K.D.; Hwang, B.U.; Kang, D.G.; Choi, D.H.; Joo, J.; Jung, S.B. Intense pulsed light surface treatment for improving adhesive bonding of aluminum and carbon fiber reinforced plastic (CFRP). Compos. Struct. 2020, 258, 113364. [Google Scholar] [CrossRef]

- Oliveira, V.; Sharma, S.P.; de Moura, M.F.S.F.; Moreira, R.D.F.; Vilar, R. Surface treatment of CFRP composites using femtosecond laser radiation. Opt. Lasers Eng. 2017, 94, 37–43. [Google Scholar] [CrossRef]

| Type | Untreated CF | Recycled CF |

|---|---|---|

| Tensile strength (Gpa) | 4.49 | 3.45 |

| Modulus (Gpa) | 261 | 256 |

| Elongation (%) | 2.62 | 2.08 |

| Density (g/cm3) | 1.80 | 1.80 |

| Treatment Condition | Elemental Composition (at.%) | O/C | |||

|---|---|---|---|---|---|

| Carbon | Oxygen | Nitrogen | Silicon | ||

| Untreated CF | 76.31 | 21.31 | 0.75 | 1.63 | 0.28 |

| Desized CF | 83.83 | 12.46 | 1.88 | 1.83 | 0.15 |

| 25 °C × 1 h | 76.23 | 17.76 | 3.16 | 2.85 | 0.23 |

| 25 °C × 5 h | 72.59 | 20.39 | 3.65 | 3.37 | 0.28 |

| 100 °C × 1 h | 73.91 | 22.81 | 2.73 | 0.55 | 0.31 |

| 100 °C × 5 h | 73.03 | 24.03 | 2.70 | 0.24 | 0.33 |

| Treatment Condition | C1s (at.%) | |||

|---|---|---|---|---|

| C–C, C=C | C–O, C=O | C–N | O=C–O | |

| Untreated CF | 71.09 | 26.86 | 0.98 | 1.07 |

| Desized CF | 75.59 | 20.10 | 2.21 | 2.10 |

| 25 °C × 1 h | 74.07 | 18.06 | 5.66 | 2.20 |

| 25 °C × 5 h | 66.15 | 20.11 | 8.14 | 5.60 |

| 100 °C × 1 h | 74.00 | 8.12 | 6.28 | 11.59 |

| 100 °C × 5 h | 70.59 | 8.00 | 6.05 | 15.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, G.; Lee, H.; Kim, M.; Kim, D.U. Investigating the Effects of Nitric Acid Treatments on the Properties of Recycled Carbon Fiber. Polymers 2023, 15, 824. https://doi.org/10.3390/polym15040824

Kim G, Lee H, Kim M, Kim DU. Investigating the Effects of Nitric Acid Treatments on the Properties of Recycled Carbon Fiber. Polymers. 2023; 15(4):824. https://doi.org/10.3390/polym15040824

Chicago/Turabian StyleKim, Gyungha, Hyunkyung Lee, Minsu Kim, and Dae Up Kim. 2023. "Investigating the Effects of Nitric Acid Treatments on the Properties of Recycled Carbon Fiber" Polymers 15, no. 4: 824. https://doi.org/10.3390/polym15040824