Research on Adaptability Evaluation Method of Polymer by Nuclear Magnetic Resonance Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

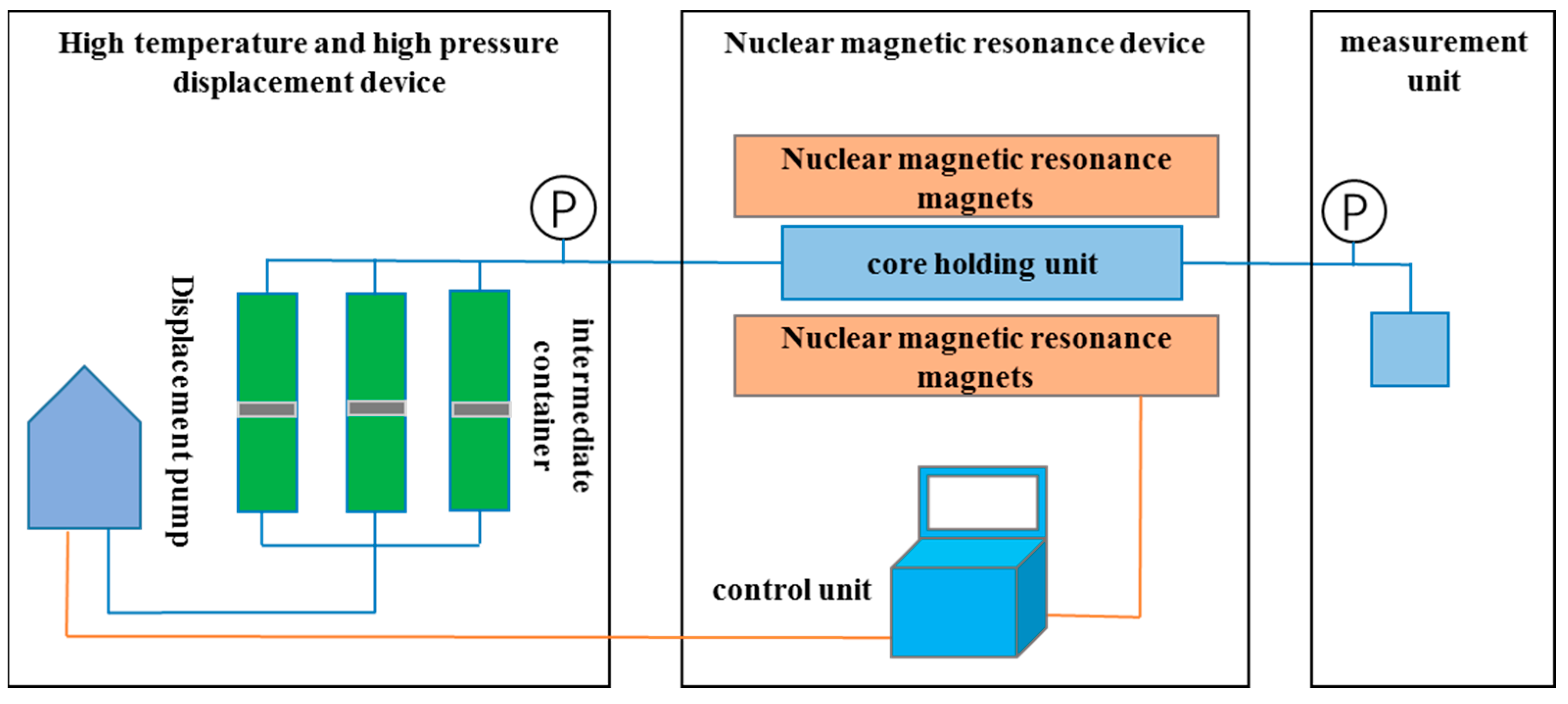

2.2. Experimental Equipment

2.3. Experimental Principle

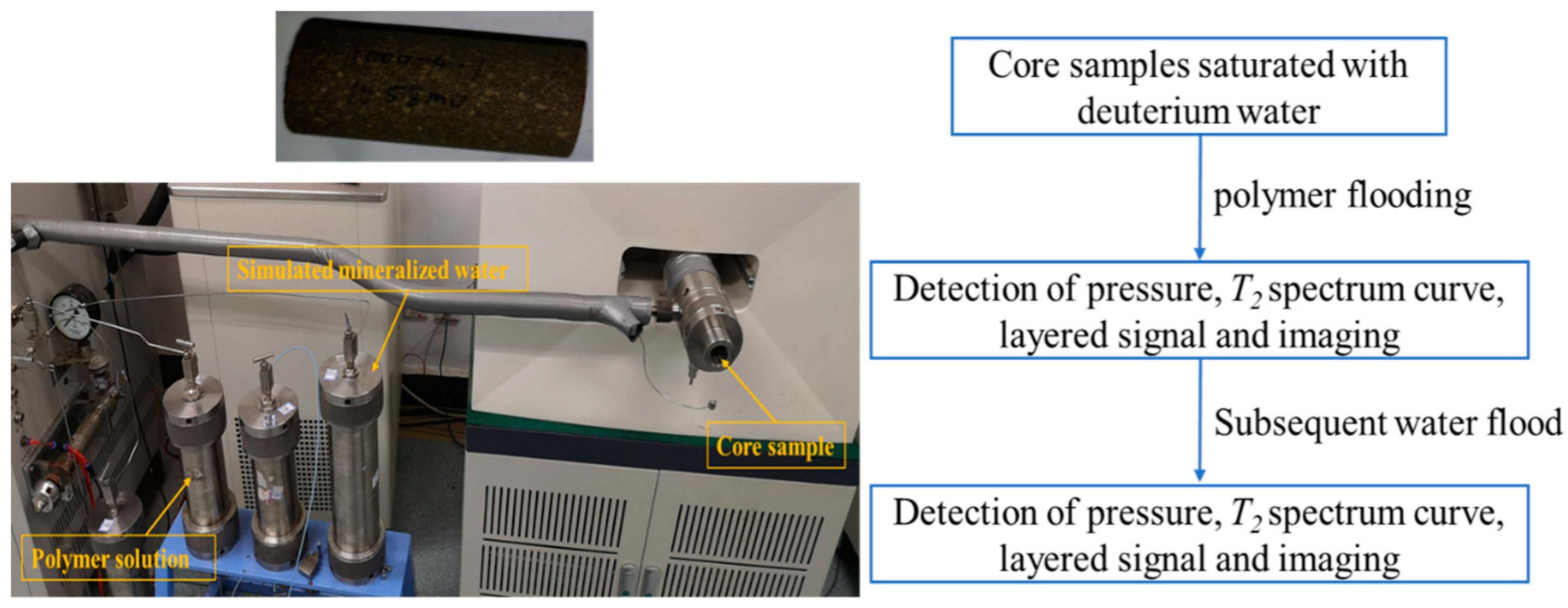

2.4. Experimental Method

- (1)

- The core is dried, and then vacuumed and saturated with deuterium water;

- (2)

- Inject the prepared polymer solution at a constant flow of 0.3 mL/min until the injection pressure is constant, and obtain the NMR T2 spectrum curve, layered signal, and imaging of polymer flooding;

- (3)

- Continue to inject simulated mineralized water at a constant flow rate of 0.3 mL/min until the injection pressure is constant, and obtain the nuclear magnetic resonance T2 spectrum curve, layered signal, and imaging of subsequent water flooding.

3. Results and Discussion

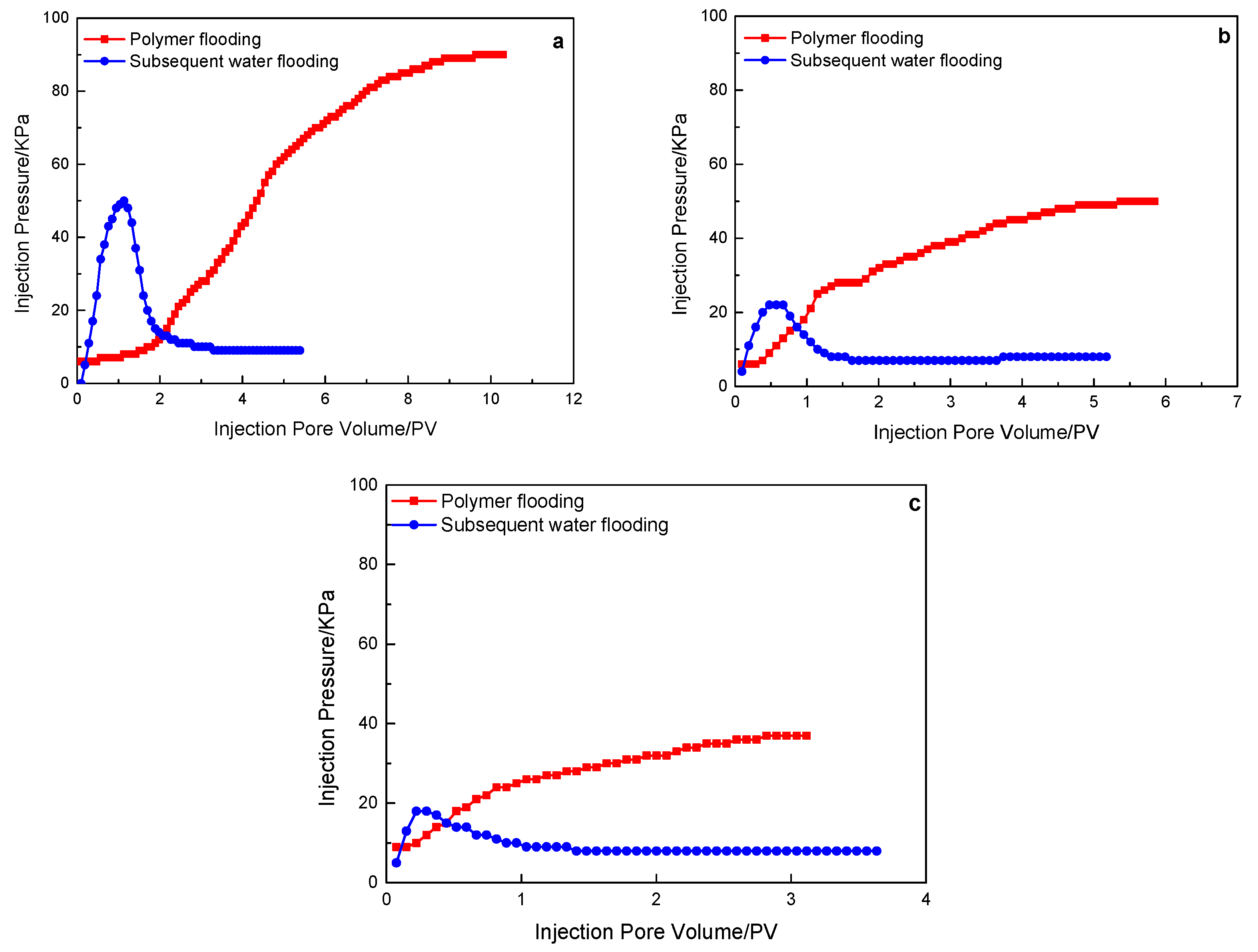

3.1. Variation Characteristics of Injection Pressure during Core Displacement

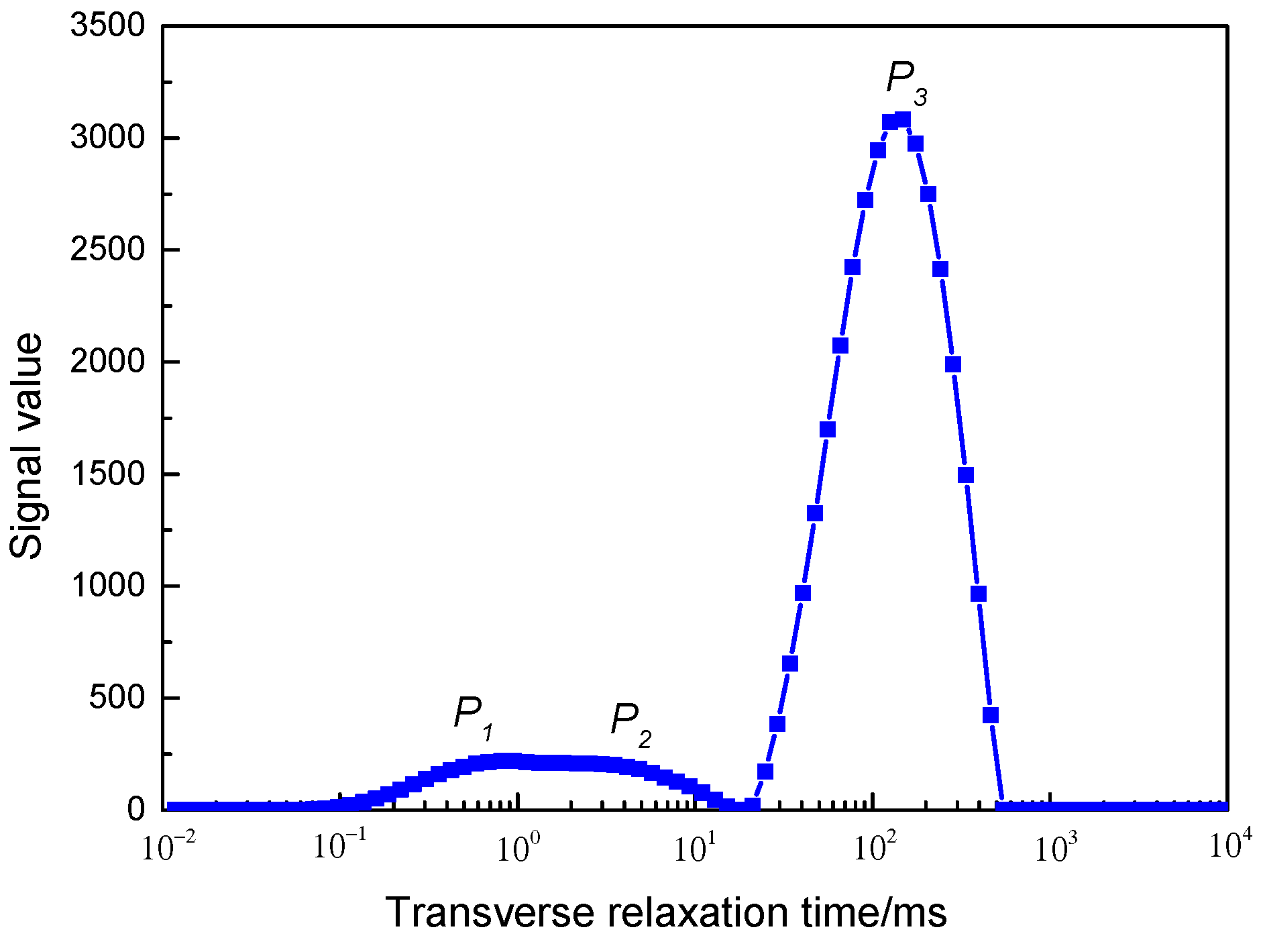

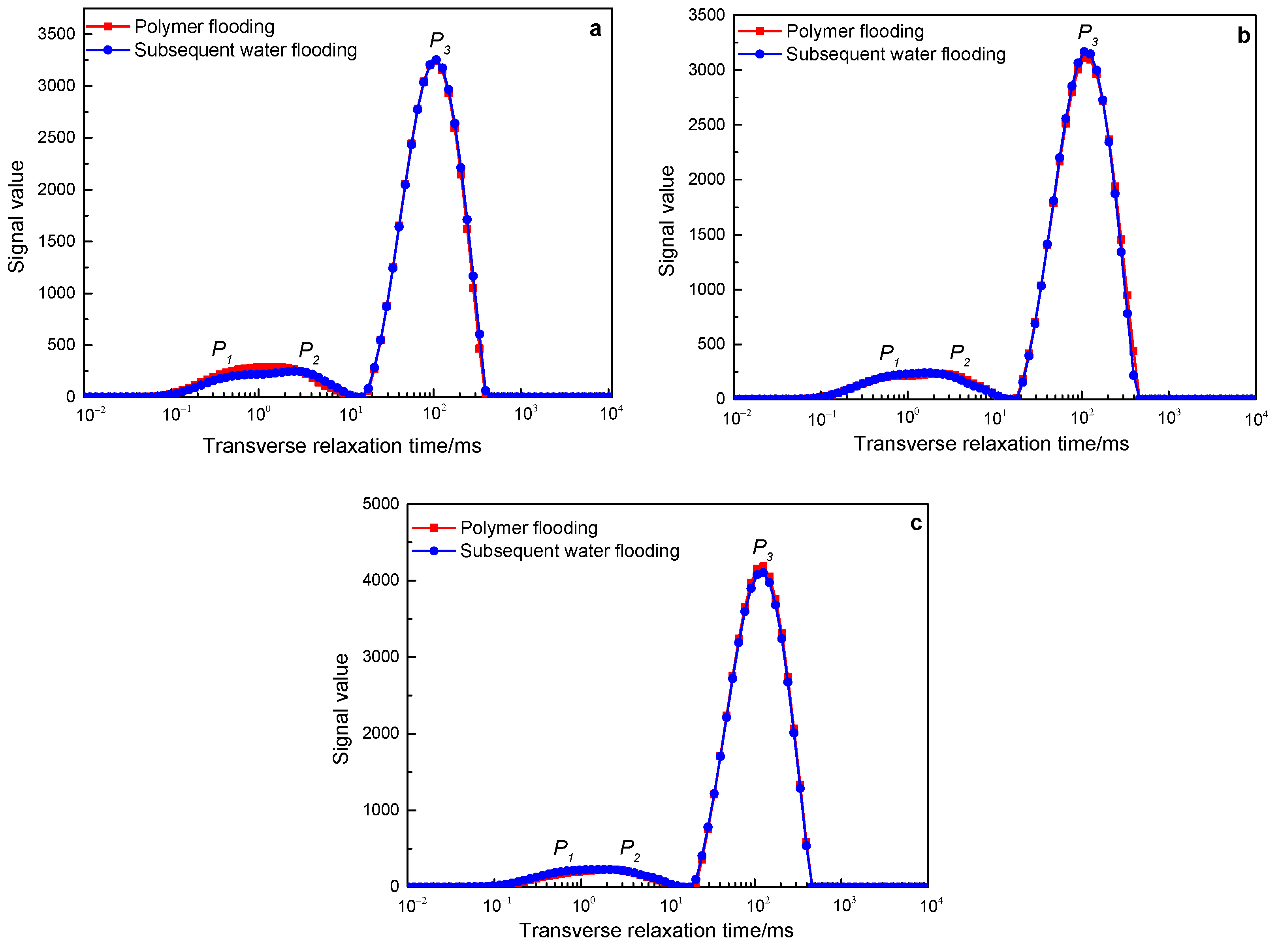

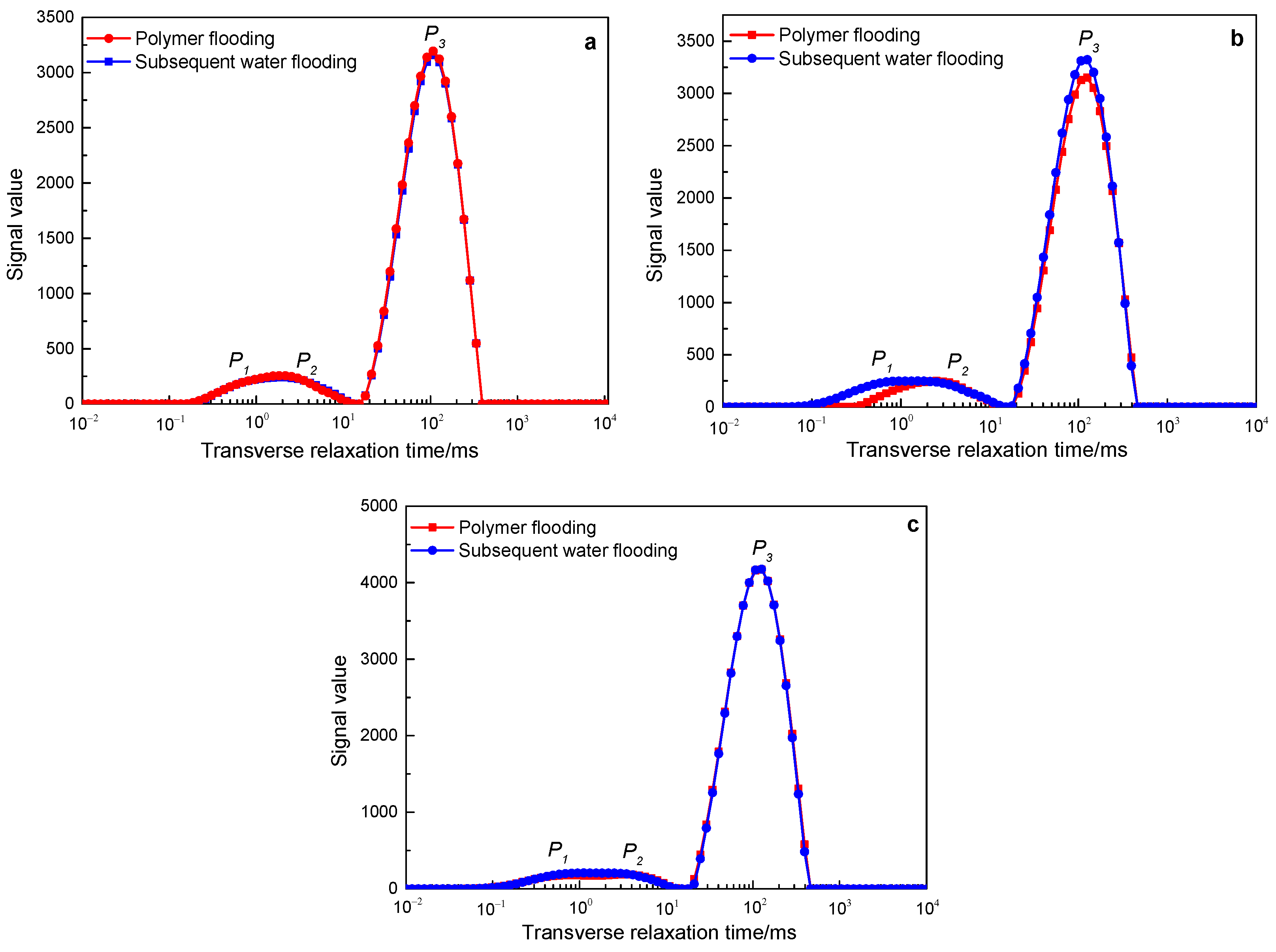

3.2. Change Characteristics of NMR T2 Spectrum in Core Displacement Experiments

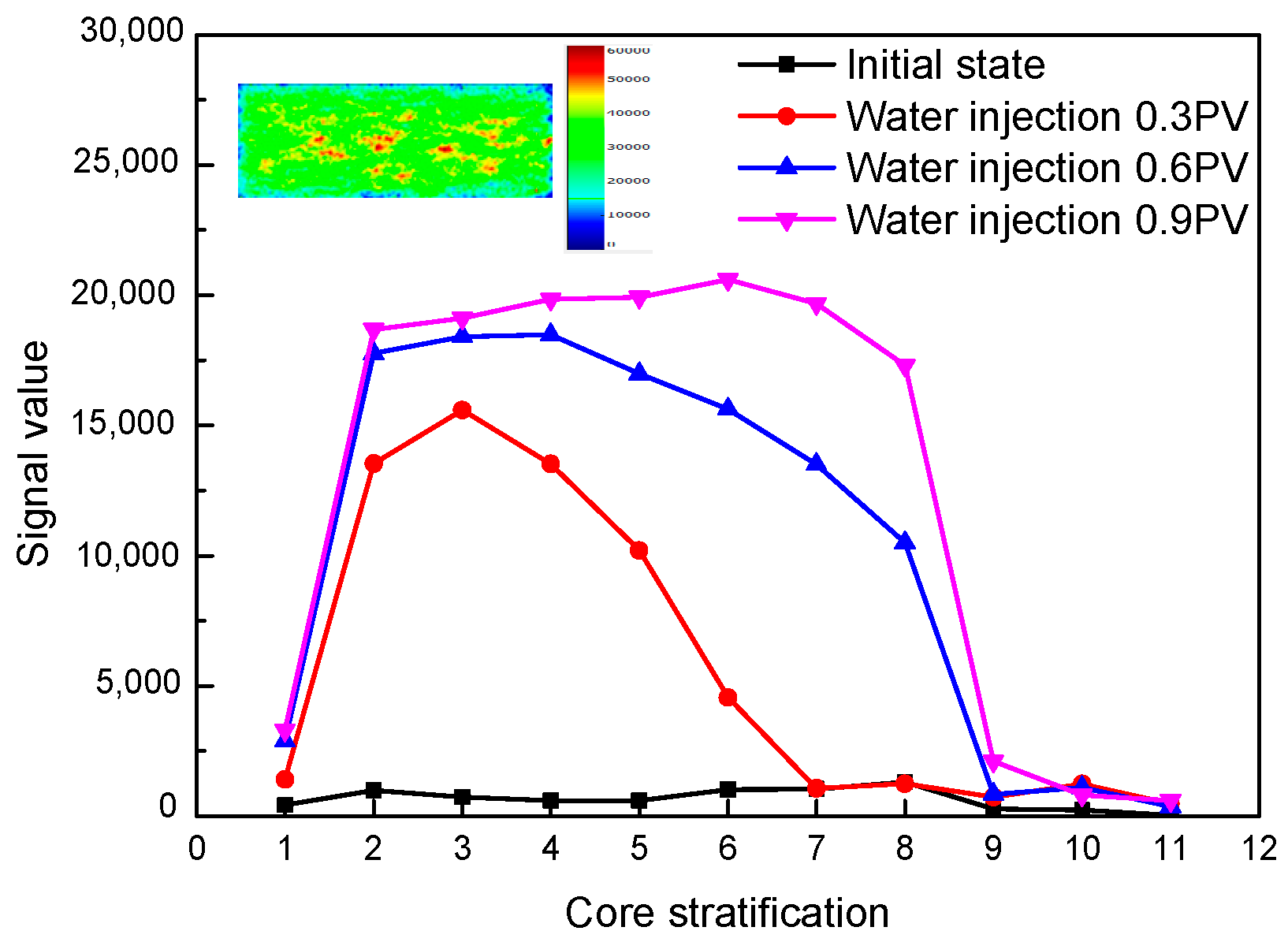

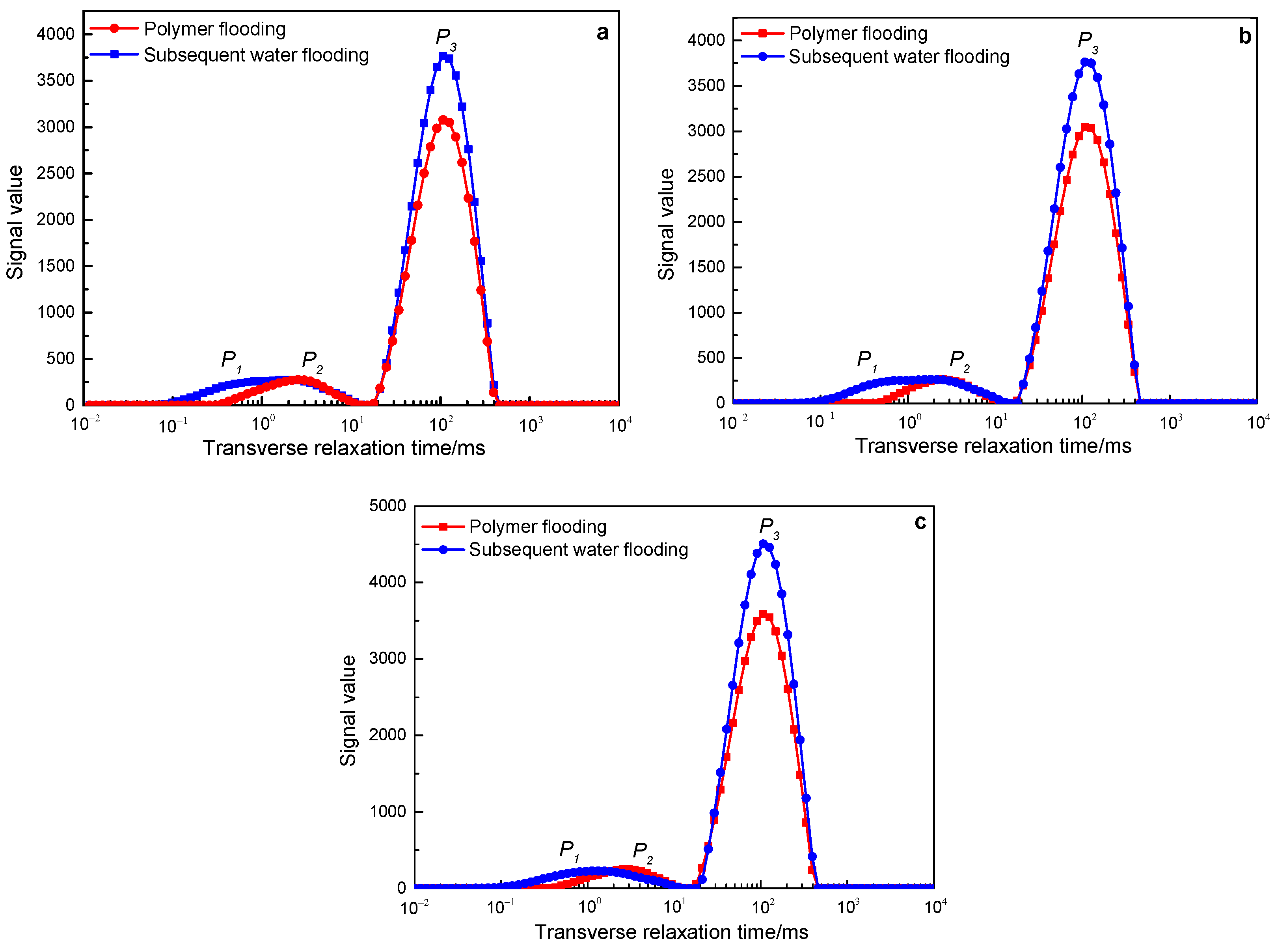

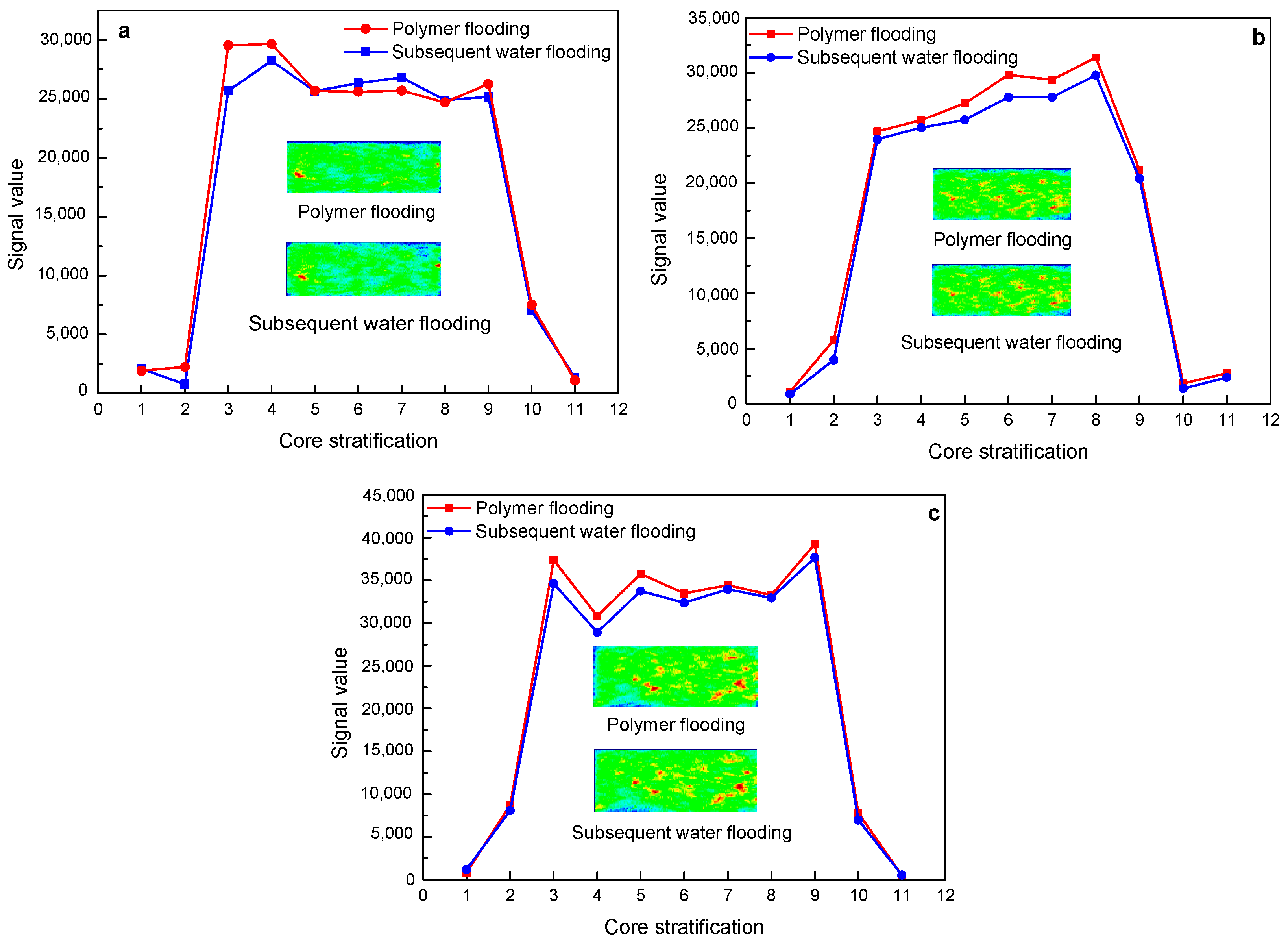

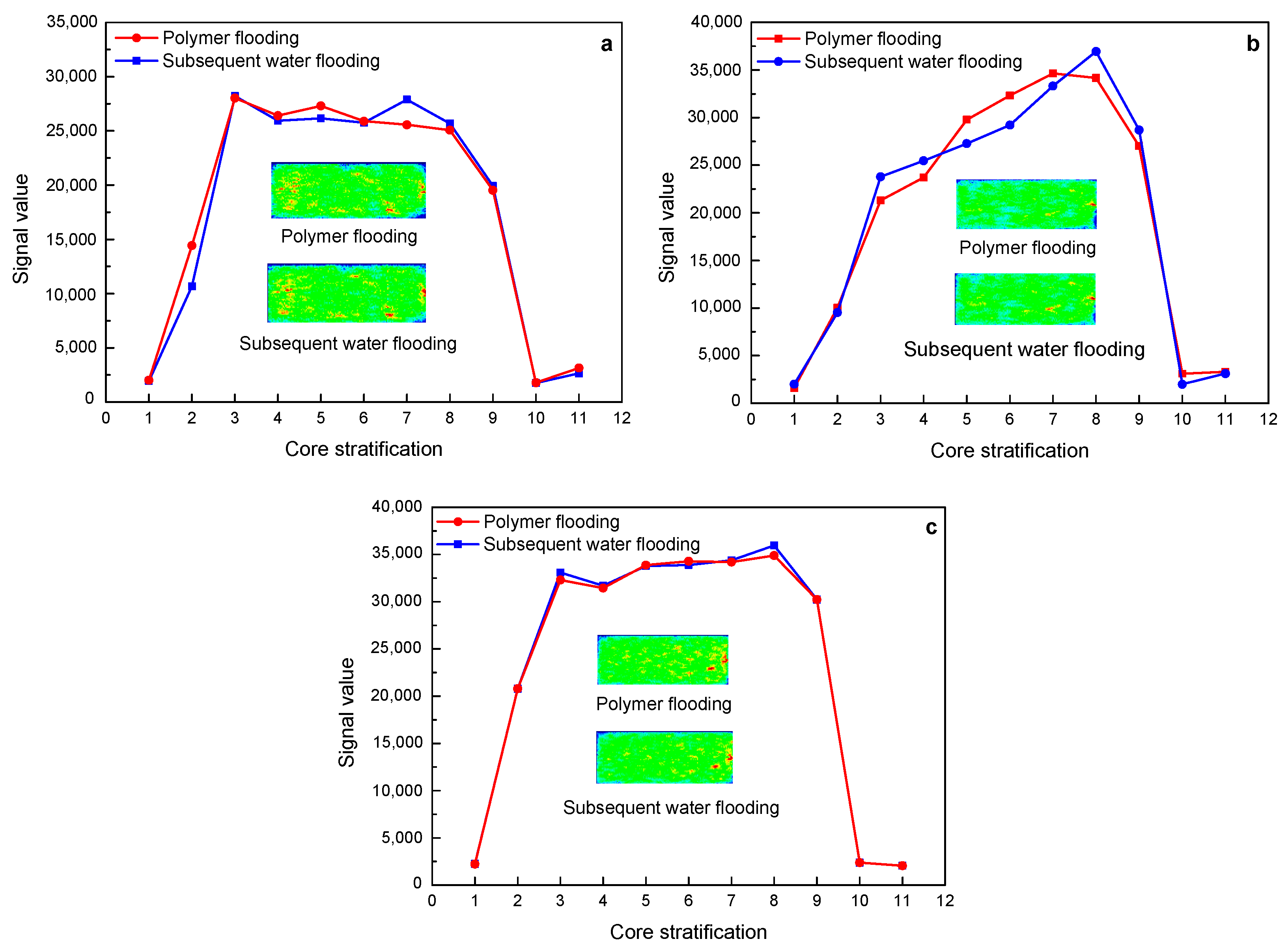

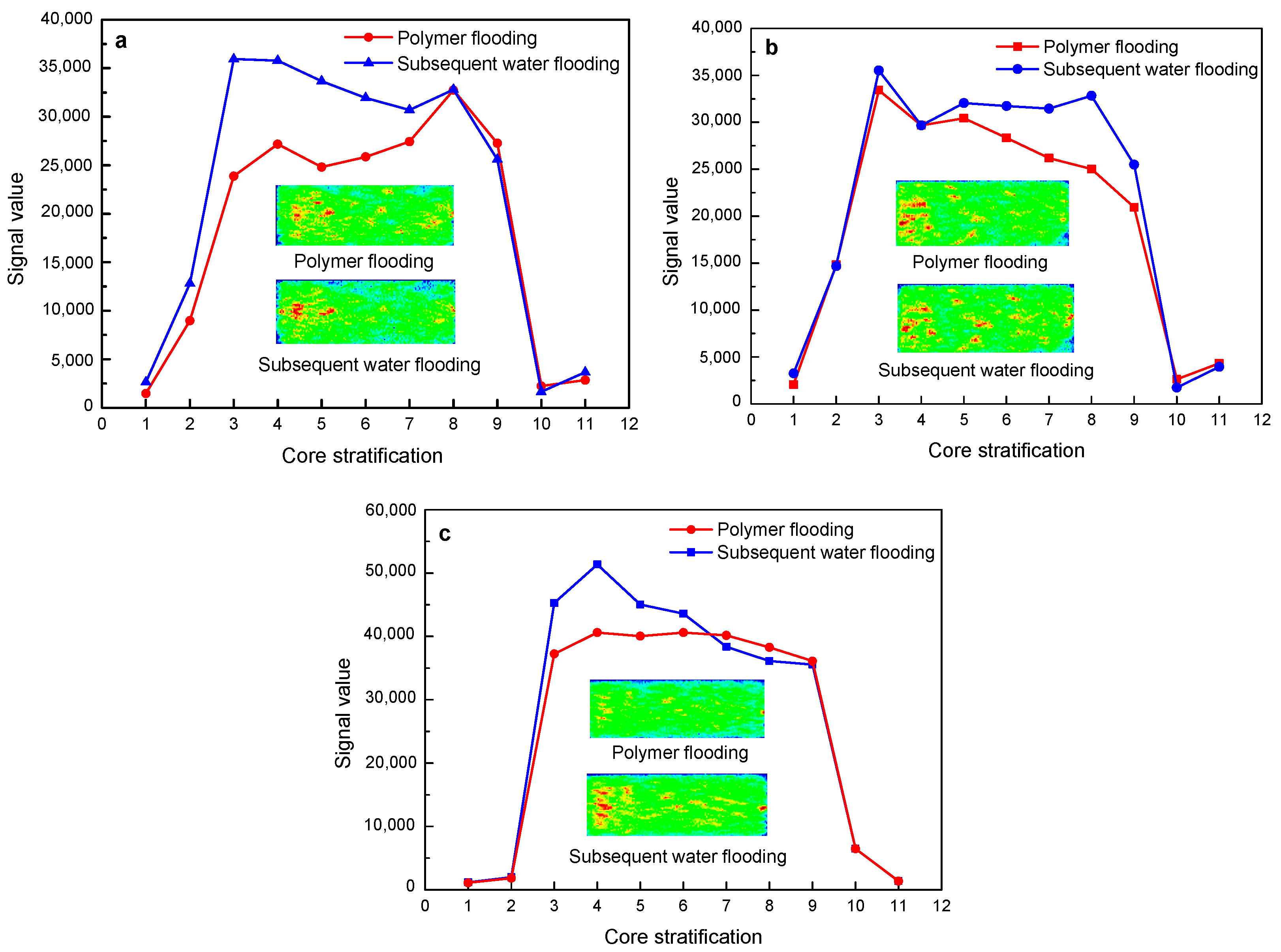

3.3. Change Characteristics of NMR Layering Signals and Imaging in Core Displacement Experiments

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muhammad, A.M.; Divlan, A.S. Characteristics and performance of carabiner remodeling using 3D printing with graded filler and different orientation methods. Eng. Fail. Anal. 2021, 130, 105795. [Google Scholar]

- Naufal, A.S.A.; Gil, N.C.S.; Rachmadi, N.; Jayan, S.; Nikmatul, A.; Muhammad, A.M. Model Optimization and performance evaluation of hand cranked music box base structure manufactured via 3D printing. Heliyon 2021, 7, e08432. [Google Scholar]

- Anindityo, P.; Mohammmad, A.M.; Muhammad, N.; She, Y.; Wang, W.C.; Muhammad, A.M.; Tetsuya, S. Stereolithography 3D Printer for Micromodel Fabrications with Comprehensive Accuracy Evaluation by Using Microtomography. Geosciences 2022, 12, 183. [Google Scholar] [CrossRef]

- Lu, X.; Cao, B.; Xie, K.; Liu, Y.; Zhang, Y.; Wang, X.; Zhang, J. EOR mechanisms of polymer flooding in a heterogeneous oil reservoir. Pet. Explor. Dev. 2021, 48, 148–155. [Google Scholar] [CrossRef]

- Gbadamosi, A.; Patil, S.; Kamal, M.S.; Adewunmi, A.A.; Yusuff, A.S.; Agi, A.; Oseh, J. Application of Polymers for Chemical Enhanced Oil Recovery: A Review. Polymers 2022, 14, 1433. [Google Scholar] [CrossRef] [PubMed]

- Gbadamosi, A.; Zhou, X.; Murtaza, M.; Kamal, M.S.; Patil, S.; Al Shehri, D.; Barri, A. Experimental Study on the Application of Cellulosic Biopolymer for Enhanced Oil Recovery in Carbonate Cores under Harsh Conditions. Polymers 2022, 14, 4621. [Google Scholar] [CrossRef] [PubMed]

- Tan, F.; Xu, C.; Wang, X.; Chen, Y.; Cheng, H.; Zhang, J.; Peng, S. Difference in microscopic porous flow mechanism of water flooding and polymer flooding for conglomerate reservoir. Acta Pet. Sin. 2016, 37, 1414–1427. [Google Scholar]

- Zhu, Y.; Hou, Q.; Jian, G.; Ma, D.; Wang, Z. Current development and application of chemical combination flooding technique. Pet. Explor. Dev. 2013, 40, 90–96. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, B.; Xiong, J.; Zhao, Y.; Han, T.; Sun, M. A Method for Qualitative Evaluation of Hydrodynamic Radius of the Same Series of Polymers. Oilfield Chem. 2022, 39, 93–99. [Google Scholar]

- Raeini, A.; Bijeljic, B.; Blunt, M. Modeling capillary trapping using finite-volume simulation of two-phase flow directly on micro-CT images. Adv. Water Resour. 2015, 83, 102–110. [Google Scholar] [CrossRef]

- LI, Y.; Yang, Y.; Sun, X.; Yang, D.; Zhang, N.; Yang, H.; Guo, H.; Zheng, J. The application of laser confocal method in microscopic oil analysis. J. Pet. Sci. Eng. 2014, 120, 52–60. [Google Scholar] [CrossRef]

- Freedman, R.; Heaton, N.; Flaum, M. Wet ability, saturation, and viscosity from NMR measurements. SPE J. 2003, 8, 317–327. [Google Scholar] [CrossRef]

- Liang, B.; Jiang, H.; Li, J.; Chen, F.; Miao, W.; Yang, H.; Qiao, H.; Chen, W. Mechanism study of disproportionate permeability reduction using nuclear magnetic resonance T2. Energy Fuels 2018, 32, 4959–4968. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Leng, R.; Liu, Z.; Chen, X.; Hejazi, H. Effects of pore structure on surfactant/polymer flooding-based enhanced oil recovery in conglomerate reservoirs. Pet. Explor. Dev. 2020, 47, 129–139. [Google Scholar] [CrossRef]

- Di, Q.; Zhang, J.; Hua, S.; Chen, H.; Gu, C. Visualization experiments on polymer-weak gel profile control and displacement by NMR technique. Pet. Explor. Dev. 2017, 44, 270–274. [Google Scholar] [CrossRef]

- Meiboom, S.; Gill, D. Modified Spin-Echo Method for Measuring Nuclear Relaxation Times. Rev. Sci. Instrum. 1958, 29, 688–691. [Google Scholar] [CrossRef]

- Cheng, Y.; Di, Q.; Gu, C.; Ye, F.; Hua, S. Visualization study on fluid distribution and end effects in core flow experiments with low-field mri method. J. Hydrodyn. 2015, 27, 187–194. [Google Scholar] [CrossRef]

- Lei, Q.; Luo, J.; Peng, B.; Wang, X.; Xiao, P.; Wang, P.; He, L.; Ding, B.; Geng, X. Mechanism of expanding swept volume by nano-sized oil-displacement agent. Pet. Explor. Dev. 2019, 46, 937–942. [Google Scholar] [CrossRef]

- Wang, X.; Lei, Q.; Xiao, P.; Wang, P.; Yang, Z.; Han, X.; Luo, J.; Ye, Y. Preparation of nano-oil-displacing agent with on-site water and its oil displacement mechanism. Acta Pet. Sin. 2021, 42, 350–357. [Google Scholar]

| Core Number | Diameter × Length/cm | Permeability/mD | Porosity/% |

|---|---|---|---|

| 500-1 | 2.51 × 4.94 | 519 | 26.4 |

| 500-2 | 2.51 × 4.92 | 519 | 26.3 |

| 500-3 | 2.51 × 4.89 | 512 | 26.5 |

| 1000-1 | 2.51 × 4.76 | 1036 | 26.8 |

| 1000-2 | 2.51 × 4.93 | 983 | 27.0 |

| 1000-3 | 2.51 × 4.98 | 983 | 27.3 |

| 2000-1 | 2.51 × 5.13 | 2058 | 32.1 |

| 2000-2 | 2.51 × 4.88 | 2076 | 32.3 |

| 2000-3 | 2.51 × 5.24 | 2076 | 37.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Lei, Q.; Luo, J.; Xiao, P.; Wang, P.; Ye, Y.; Cong, S.; Han, X.; He, L. Research on Adaptability Evaluation Method of Polymer by Nuclear Magnetic Resonance Technology. Polymers 2023, 15, 930. https://doi.org/10.3390/polym15040930

Wang X, Lei Q, Luo J, Xiao P, Wang P, Ye Y, Cong S, Han X, He L. Research on Adaptability Evaluation Method of Polymer by Nuclear Magnetic Resonance Technology. Polymers. 2023; 15(4):930. https://doi.org/10.3390/polym15040930

Chicago/Turabian StyleWang, Xiaocong, Qun Lei, Jianhui Luo, Peiwen Xiao, Pingmei Wang, Yinzhu Ye, Sunan Cong, Xue Han, and Lipeng He. 2023. "Research on Adaptability Evaluation Method of Polymer by Nuclear Magnetic Resonance Technology" Polymers 15, no. 4: 930. https://doi.org/10.3390/polym15040930

APA StyleWang, X., Lei, Q., Luo, J., Xiao, P., Wang, P., Ye, Y., Cong, S., Han, X., & He, L. (2023). Research on Adaptability Evaluation Method of Polymer by Nuclear Magnetic Resonance Technology. Polymers, 15(4), 930. https://doi.org/10.3390/polym15040930