Enhancement of 3D Printability by FDM and Electrical Conductivity of PLA/MWCNT Filaments Using Lignin as Bio-Dispersant

Abstract

:1. Introduction

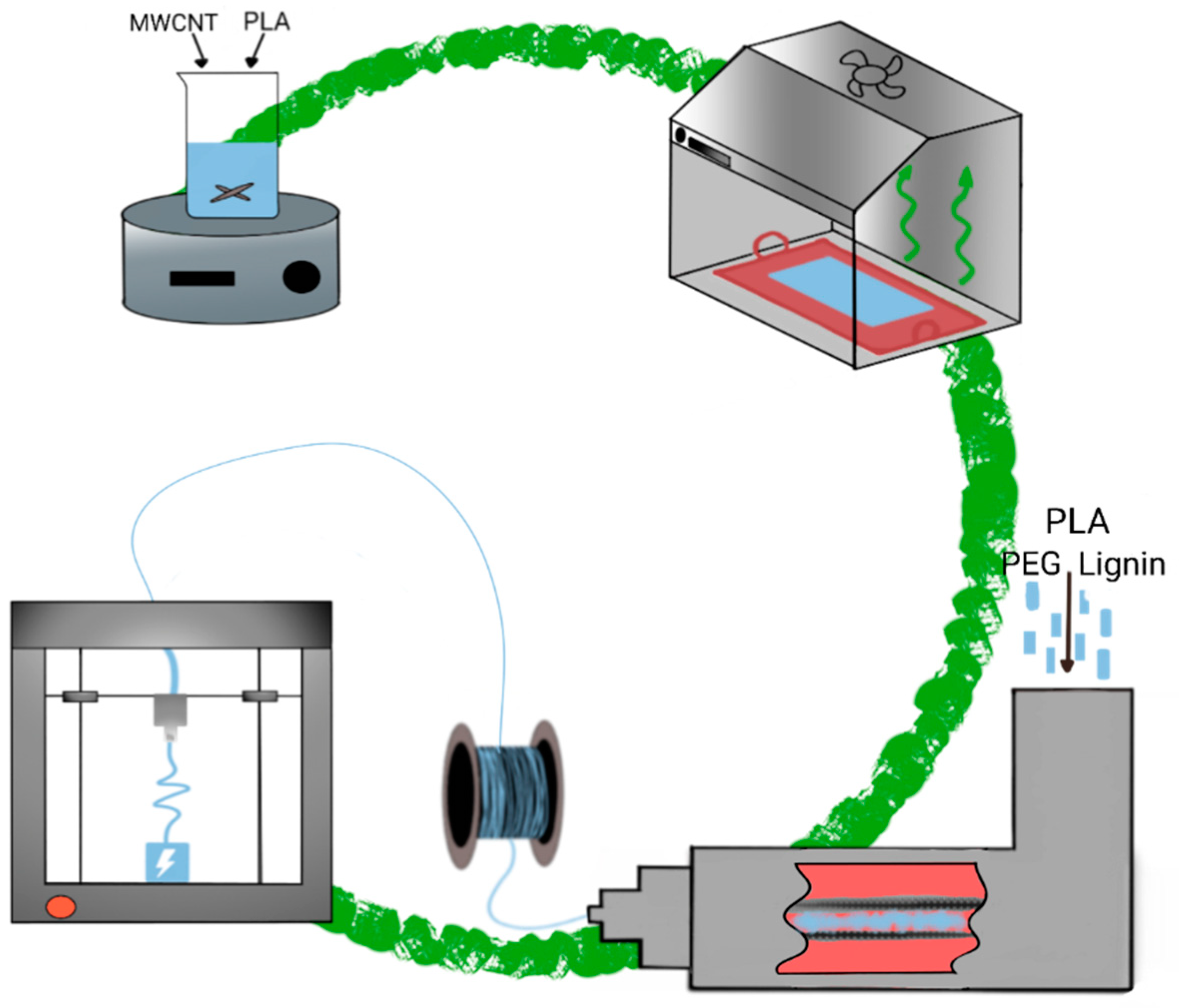

2. Materials and Methods

2.1. Preparation of the Composites

2.2. Three-Dimensional Printing Process

2.3. Characterization Methods

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. Electrical Conductivity

2.3.3. Rheology

2.3.4. Tensile Test

2.3.5. Differential Scanning Calorimeter (DSC)

2.3.6. Thermogravimetric Analyses (TGA)

3. Results and Discussions

3.1. Solvent Optimization Study

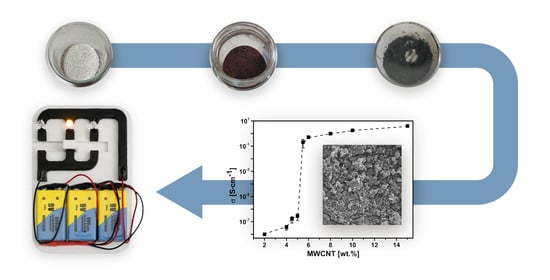

3.2. Optimization of MWCNT Content

3.3. Optimization of Additives Content

3.4. Electrically Conductive 3D Printed Prototype

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| 3D | three dimensional |

| ABS | Acrylonitrile Butadiene Styrene |

| AM | Additive Manufacturing |

| ATCB | Acetyl Tributyl Citrate |

| CNF | carbon nano fiber |

| CPC | Conductive Polymer Composites |

| DCM | dichloromethane |

| DSC | Differential scanning calorimeter |

| FDM | Fusion Deposition Modelling |

| LED | Light Emitting Diode |

| MWCNT | multi walled carbon nanotube |

| PEG | Polyethylene Glycol |

| PETG | Polyethylene Terephthalate Glycol |

| PLA | Polylactic Acid |

| S.I. | Supplementary information |

| TEC | Triethyl Citrate |

References

- Ambrosi, A.; Pumera, M. 3D-printing technologies for electrochemical applications. Chem. Soc. Rev. 2016, 45, 2740–2755. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Zhou, Y.; Lin, L.; Corker, J.; Fan, M. Overview of 3D additive manufacturing (AM) and corresponding AM composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106114. [Google Scholar] [CrossRef]

- Criado-Gonzalez, M.; Dominguez-Alfaro, A.; Lopez-Larrea, N.; Alegret, N.; Mecerreyes, D. Additive Manufacturing of Conducting Polymers: Recent Advances, Challenges, and Opportunities. ACS Appl. Polym. Mater. 2021, 3, 2865–2883. [Google Scholar] [CrossRef] [PubMed]

- Hamzah, H.H.; Shafiee, S.A.; Abdalla, A.; Patel, B.A. 3D printable conductive materials for the fabrication of electrochemical sensors: A mini review. Electrochem. Commun. 2018, 96, 27–31. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D printing of polymer and associated composite: A review on mechanical properties, defects and treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Maurel, A.; Grugeon, S.; Armand, M.; Fleutot, B.; Courty, M.; Prashantha, K.; Davoisne, C.; Tortajada, H.; Panier, S.; Dupont, L. Overview on Lithium-Ion Battery 3D-Printing By Means of Material Extrusion. ECS Meet. Abstr. 2020, MA2020-02, 3690. [Google Scholar] [CrossRef]

- Barrasa, J.O.; Ferrández-Montero, A.; Ferrari, B.; Pastor, J.Y. Characterisation and Modelling of PLA Filaments and Evolution with Time. Polymers 2021, 13, 2899. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.W.; Zhang, J.; Wu, J.R.; Wang, X.Z.; Deng, Y.H. Incorporation of graphitic nano-filler and poly(lactic acid) in fused deposition modeling. J. Appl. Polym. Sci. 2017, 134, 44703. [Google Scholar] [CrossRef]

- Nath, S.D.; Nilufar, S. An overview of additive manufacturing of polymers and associated composites. Polymers 2020, 12, 2719. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Development of Pure Poly Vinyl Chloride (PVC) with Excellent 3D Printability and Macro- and Micro-Structural Properties. Macromol. Mater. Eng. 2022, 14, 2200568. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 3D printing of PLA-TPU with different component ratios: Fracture toughness, mechanical properties, and morphology. J. Mater. Res. Technol. 2022, 21, 3970–3981. [Google Scholar] [CrossRef]

- Angelopoulos, P.M.; Samouhos, M.; Taxiarchou, M. Functional fillers in composite filaments for fused filament fabrication: A review. Mater. Today Proc. 2019, 37, 4031–4043. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.; Yuan, Q.; Zhang, W. Effects of carbon nanotube on the thermal, mechanical, and electrical properties of PLA/CNT printed parts in the FDM process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Lage-Rivera, S.; Ares-Pernas, A.; Abad, M.J. Last developments in polymers for wearable energy storage devices. Int. J. Energy Res. 2022, 46, 10475–10498. [Google Scholar] [CrossRef]

- Gao, W.; Pumera, M. 3D Printed Nanocarbon Frameworks for Li-Ion Battery Cathodes. Adv. Funct. Mater. 2021, 31, 2007285. [Google Scholar] [CrossRef]

- Maurel, A.; Russo, R.; Grugeon, S.; Panier, S.; Dupont, L. Environmentally Friendly Lithium-Terephthalate/Polylactic Acid Composite Filament Formulation for Lithium-Ion Battery 3D-Printing via Fused Deposition Modeling. ECS J. Solid State Sci. Technol. 2021, 10, 037004. [Google Scholar] [CrossRef]

- Maurel, A.; Grugeon, S.; Fleutot, B.; Courty, M.; Prashantha, K.; Tortajada, H.; Armand, M.; Panier, S.; Dupont, L. Three-Dimensional Printing of a LiFePO4/Graphite Battery Cell via Fused Deposition Modeling. Sci. Rep. 2019, 9, 18031. [Google Scholar] [CrossRef] [Green Version]

- Maurel, A.; Armand, M.; Grugeon, S.; Fleutot, B.; Davoisne, C.; Tortajada, H.; Courty, M.; Panier, S.; Dupont, L. Poly(Ethylene Oxide)−LiTFSI Solid Polymer Electrolyte Filaments for Fused Deposition Modeling Three-Dimensional Printing. J. Electrochem. Soc. 2020, 167, 070536. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, Y.; Jang, M.G.; Han, C.; Kim, W.N. Comparative study of EMI shielding effectiveness for carbon fiber pultruded polypropylene/poly(lactic acid)/multiwall CNT composites prepared by injection molding versus screw extrusion. J. Appl. Polym. Sci. 2017, 134, 45222. [Google Scholar] [CrossRef]

- Chizari, K.; Arjmand, M.; Liu, Z.; Sundararaj, U.; Therriault, D. Three-dimensional printing of highly conductive polymer nanocomposites for EMI shielding applications. Mater. Today Commun. 2017, 11, 112–118. [Google Scholar] [CrossRef]

- Hu, C.; Li, Z.; Wang, Y.; Gao, J.; Dai, K.; Zheng, G.; Liu, C.; Shen, C.; Song, H.; Guo, Z. Comparative assessment of the strain-sensing behaviors of polylactic acid nanocomposites: Reduced graphene oxide or carbon nanotubes. J. Mater. Chem. C 2017, 5, 2318–2328. [Google Scholar] [CrossRef]

- Mao, H.; Ye, X.; Chen, W.; Geng, W.; Chen, G. Fabrication of carbon nanotube-polylactic acid composite electrode by melt compounding for capillary electrophoretic determination of tectoridin and irigenin in Belamcandae Rhizoma. J. Pharm. Biomed. Anal. 2019, 175, 112769. [Google Scholar] [CrossRef] [PubMed]

- DeStefano, V.; Khan, S.; Tabada, A. Applications of PLA in modern medicine. Eng. Regen. 2020, 1, 76–87. [Google Scholar] [CrossRef]

- Gonçalves, C.; Gonçalves, I.C.; Magalhães, F.D.; Pinto, A.M. Poly(lactic acid) composites containing carbon-based nanomaterials: A review. Polymers 2017, 9, 269. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Soares, B.G.; Cordeiro, E.; Maia, J.; Pereira, E.C.L.; Silva, A.A. The effect of the noncovalent functionalization of CNT by ionic liquid on electrical conductivity and electromagnetic interference shielding effectiveness of semi-biodegradable polypropylene/poly(lactic acid) composites. Polym. Compos. 2020, 41, 82–93. [Google Scholar] [CrossRef]

- Zheng, T.; Yue, Z.; Wallace, G.G.; Du, Y.; Higgins, M.J. Nanoscale piezoelectric effect of biodegradable {PLA}-based composite fibers by piezoresponse force microscopy. Nanotechnology 2020, 31, 375708. [Google Scholar] [CrossRef]

- Santo, J.; Penumakala, P.K.; Adusumalli, R.B. Mechanical and electrical properties of three-dimensional printed polylactic acid–graphene–carbon nanofiber composites. Polym. Compos. 2021, 42, 3231–3242. [Google Scholar] [CrossRef]

- He, T.; Liao, X.; He, Y.; Li, G. Novel electric conductive polylactide/carbon nanotubes foams prepared by supercritical CO2. Prog. Nat. Sci. Mater. Int. 2013, 23, 395–401. [Google Scholar] [CrossRef] [Green Version]

- Mora, A.; Verma, P.; Kumar, S. Electrical conductivity of CNT/polymer composites: 3D printing, measurements and modeling. Compos. Part B Eng. 2020, 183, 107600. [Google Scholar] [CrossRef]

- Mousavi, Z.; Heuzey, M.C.; Kamal, M.R.; Flahaut, E.; Carreau, P.J. Rheological, electrical, and dynamic thermomechanical properties: Comparison between multiwall and double-wall carbon nanotubes in polylactide and polyamide 11. Phys. Fluids 2021, 33, 113103. [Google Scholar] [CrossRef]

- Lebedev, S.M.; Gefle, O.S.; Amitov, E.T.; Berchuk, D.Y.; Zhuravlev, D.V. Poly(lactic acid)-based polymer composites with high electric and thermal conductivity and their characterization. Polym. Test. 2017, 58, 241–248. [Google Scholar] [CrossRef]

- Lei, L.; Qiu, J.; Sakai, E. Preparing conductive poly(lactic acid) (PLA) with poly(methyl methacrylate) (PMMA) functionalized graphene (PFG) by admicellar polymerization. Chem. Eng. J. 2012, 209, 20–27. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.; Jia, X.; Bi, H.; Yang, H.; Ji, T.; Xu, M.; Cai, L. Preparation and characterization of 3D printed PLA-based conductive composites using carbonaceous fillers by masterbatch melting method. Polymers 2019, 11, 1589. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kar, K.K.; Pandey, J.K.; Rana, S. Handbook of Polymer Nanocomposites. Processing, Performance and Application: Volume B: Carbon Nanotube Based Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2015; pp. 283–297. [Google Scholar] [CrossRef]

- Norazlina, H.; Hadi, A.A.; Qurni, A.U.; Amri, M.; Mashelmie, S.; Kamal, Y. Effects of multi-walled carbon nanotubes (MWCNTs) on the degradation behavior of plasticized PLA nanocomposites. Polym. Bull. 2019, 76, 1453–1469. [Google Scholar] [CrossRef]

- Jia, S.; Yu, D.; Zhu, Y.; Su, X.; Wang, Z.; Chen, L. A feasible strategy to constructing hybrid conductive networks in PLA-based composites modified by CNT-d-RGO particles and PEG for mechanical and electrical properties. Polym. Adv. Technol. 2020, 31, 699–712. [Google Scholar] [CrossRef]

- Norazlina, H.; Kamal, Y. Elucidating the plasticizing effect on mechanical and thermal properties of poly(lactic acid)/carbon nanotubes nanocomposites. Polym. Bull. 2020, 78, 6911–6933. [Google Scholar] [CrossRef]

- Fehri, M.K.; Mugoni, C.; Cinelli, P.; Anguillesi, I.; Coltelli, M.B.; Fiori, S.; Montorsi, M.; Lazzeri, A. Composition dependence of the synergistic effect of nucleating agent and plasticizer in poly(lactic acid): A mixture design study. Express Polym. Lett. 2016, 10, 274–288. [Google Scholar] [CrossRef]

- Wasti, S.; Triggs, E.; Farag, R.; Auad, M.; Adhikari, S.; Bajwa, D.; Li, M.; Ragauskas, A.J. Influence of plasticizers on thermal and mechanical properties of biocomposite filaments made from lignin and polylactic acid for 3D printing. Compos. Part B Eng. 2020, 205, 108483. [Google Scholar] [CrossRef]

- Collins, M.N.; Nechifor, M.; Tanasă, F.; Zănoagă, M.; McLoughlin, A.; Stróżyk, M.A.; Culebras, M.; Teacă, C.A. Valorization of lignin in polymer and composite systems for advanced engineering applications—A review. Int. J. Biol. Macromol. 2019, 131, 828–849. [Google Scholar] [CrossRef]

- Agustiany, E.A.; Falah, F.; Adly, M.; Lubis, R.; Solihat, N.N.; Syamani, F.A.; Karungamye, P.; Sohail, A. Recent developments in lignin modification and its application in lignin-based green composites: A review. Polym. Compos. 2022, 43, 4848–4865. [Google Scholar] [CrossRef]

- Talwar, B.S.; Chizari, K.; Guo, S.; Therriault, D.; Chizari, K.; Therriault, D. Investigation of carbon nanotubes mixing methods and functionalizations for electrically conductive polymer composites. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Montreal, QC, Canada, 14–20 November 2014; Volume 2B, pp. 1–5. [Google Scholar] [CrossRef]

- Ivanov, E.; Kotsilkova, R.; Xia, H.; Chen, Y.; Donato, R.K.; Donato, K.; Godoy, A.P.; Di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT composites with improved electrical and thermal properties suitable for FDM 3D printing applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Cheng, K.; Liu, D. Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl. Microbiol. Biotechnol. 2009, 82, 815–827. [Google Scholar] [CrossRef] [PubMed]

- Villaverde, J.J.; Li, J.; Ek, M.; Ligero, P.; De Vega, A. Native lignin structure of Miscanthus x giganteus and its changes during acetic and formic acid fractionation. J. Agric. Food Chem. 2009, 57, 6262–6270. [Google Scholar] [CrossRef] [PubMed]

- Arias-Ferreiro, G.; Ares-Pernas, A.; Lasagabáster-Latorre, A.; Dopico-García, M.S.; Ligero, P.; Pereira, N.; Costa, P.; Lanceros-Mendez, S.; Abad, M.J. Photocurable Printed Piezocapacitive Pressure Sensor Based on an Acrylic Resin Modified with Polyaniline and Lignin. Adv. Mater. Technol. 2022, 7, 2101503. [Google Scholar] [CrossRef]

- Maurel, A.; Courty, M.; Fleutot, B.; Tortajada, H.; Prashantha, K.; Armand, M.; Grugeon, S.; Panier, S.; Dupont, L. Highly Loaded Graphite-Polylactic Acid Composite-Based Filaments for Lithium-Ion Battery Three-Dimensional Printing. Chem. Mater. 2018, 30, 7484–7493. [Google Scholar] [CrossRef]

- Razaq, A.; Bibi, F.; Zheng, X.; Papadakis, R.; Hassan, S.; Jafri, M. Review on Graphene-, Graphene Oxide-, Reduced Graphene Oxide-Based Flexible Composites: From Fabrication to Applications. Materials 2022, 15, 1012. [Google Scholar] [CrossRef]

- Zhou, S.; Hrymak, A.N.; Kamal, M.R. Properties of microinjection-molded multi-walled carbon nanotubes-filled poly(lactic acid)/poly[(butylene succinate)-co-adipate] blend nanocomposites. J. Mater. Sci. 2018, 53, 9013–9025. [Google Scholar] [CrossRef]

- Pang, H.; Xu, L.; Yan, D.X.; Li, Z.M. Conductive polymer composites with segregated structures. Prog. Polym. Sci. 2014, 39, 1908–1933. [Google Scholar] [CrossRef]

- Elbadawi, M. Polymeric Additive Manufacturing: The Necessity and Utility of Rheology. In Polymer Rheology; InTech: Tokyo, Japan, 2018. [Google Scholar]

- Arboleda-Clemente, L.; Ares-Pernas, A.; García, X.; Dopico, S.; Abad, M.J. Segregated Conductive Network of MWCNT in PA12/PA6 Composites: Electrical and Rheological Behavior Laura. Polym. Compos. 2015, 38, 2679–2686. [Google Scholar] [CrossRef]

- Arboleda-Clemente, L.; Ares-Pernas, A.; García, X.; Dopico, S.; Abad, M.J. Influence of polyamide ratio on the CNT dispersion in polyamide 66/6 blends by dilution of PA66 or PA6-MWCNT masterbatches. Synth. Met. 2016, 221, 134–141. [Google Scholar] [CrossRef]

- Arboleda-Clemente, L.; García-Fonte, X.; Abad, M.J.; Ares-Pernas, A. Role of rheology in tunning thermal conductivity of polyamide 12/polyamide 6 composites with a segregated multiwalled carbon nanotube network. J. Compos. Mater. 2018, 52, 2549–2557. [Google Scholar] [CrossRef]

- Penu, C.; Hu, G.-H.; Fernandez, A.; Marchal, P.; Choplin, L. Rheological and Electrical Percolation Thresholds of Carbon Nanotube/Polymer Nanocomposites. Polym. Eng. Sci. 2012, 52, 2173–2181. [Google Scholar] [CrossRef]

- Bai, T.; Zhu, B.; Liu, H.; Wang, Y.; Song, G.; Liu, C.; Shen, C. Biodegradable poly(lactic acid) nanocomposites reinforced and toughened by carbon nanotubes/clay hybrids. Int. J. Biol. Macromol. 2020, 151, 628–634. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Jiang, Y.; Lv, S.; Liu, X.; Gu, J.; Chen, Q.; Zhang, Y. Preparation of plasticized poly (lactic acid) and its influence on the properties of composite materials. PLoS ONE 2018, 13, 0193520. [Google Scholar] [CrossRef] [Green Version]

- Behera, K.; Chang, Y.H.; Yadav, M.; Chiu, F.C. Enhanced thermal stability, toughness, and electrical conductivity of carbon nanotube-reinforced biodegradable poly(lactic acid)/poly(ethylene oxide) blend-based nanocomposites. Polymer 2020, 186, 122002. [Google Scholar] [CrossRef]

- Tarani, E.; Wurm, A.; Schick, C.; Bikiaris, D.N.; Chrissafis, K.; Vourlias, G. Effect of graphene nanoplatelets diameter on non-isothermal crystallization kinetics and melting behavior of high density polyethylene nanocomposites. Thermochim. Acta 2016, 643, 94–103. [Google Scholar] [CrossRef]

- Tarani, E.; Papageorgiou, D.G.; Valles, C.; Wurm, A.; Terzopoulou, Z.; Bikiaris, D.N.; Schick, C.; Chrissafis, K.; Vourlias, G. Insights into crystallization and melting of high density polyethylene/graphene nanocomposites studied by fast scanning calorimetry. Polym. Test. 2018, 67, 349–358. [Google Scholar] [CrossRef] [Green Version]

- Patanair, B.; Saiter-Fourcin, A.; Thomas, S.; Thomas, M.G.; Pundarikashan, P.P.; Nair, K.G.; Kumar, V.K.; Maria, H.J.; Delpouve, N. Promoting interfacial interactions with the addition of lignin in poly(Lactic acid) hybrid nanocomposites. Polymers 2021, 13, 272. [Google Scholar] [CrossRef]

| Materials | Filler [%] | σ [S∙cm−1] | Obtaining Method | Disadvantages | Ref |

|---|---|---|---|---|---|

| Graphene acting as nanofiller | |||||

| PLA/graphene | 2.75 | 2.58 × 10−4 | Polymerization | Lack of scalability, low electrical conductivity | [32] |

| PLA + TPU/reduced graphene | 9 | 10−5 | Solvent casting + melt mixing | Low electrical conductivity | [33] |

| PLA/SWCNT/graphite | 1 | 1.25 × 10−6 | Melt mixing | Low electrical conductivity | [31] |

| Carbon nanotubes acting as nanofiller | |||||

| PLA/MWCNT/Carbon black | 1.5 + 1.5 | 9.63 × 10−2 | Melt mixing with a third component | Lack of scalability | [25] |

| PLA/MWCNT | 1.2 | 2.36 × 10−6 | Solution blending + hot compression molding | Lack of scalability, low electrical conductivity | [21] |

| PLA/MWCNT | 5 | 2.52 × 10−1 | Extrusion method with a robot | Lack of scalability | [42] |

| PLA/MWCNT | 6 | 2.1 × 10−4 | Melt mixing | Low electrical conductivity | [43] |

| PLA/MWCNT | 8 | 1 × 10−3 | Melt mixing | Low electrical conductivity | [8] |

| PLA/CNT | 8 | 102 | Melt mixing | High nanofiller concentration | [13] |

| PLA | Code | Acetone [%] | DCM [%] | E [MPa] | σB [MPa] | εB [%] |

|---|---|---|---|---|---|---|

| Injected | S0 | 0 | 0 | 1042 ± 121 | 40.1 ± 1.4 | 122.1 ± 21.4 |

| Extruded and injected | S1 | 0 | 0 | 1072 ± 242 | 58.6 ± 3.5 | 14.1 ± 3.8 |

| Solved in acetone | S2 | 100 | 0 | 839 ± 224 | 55.9 ± 2.9 | 16.9 ± 2.9 |

| Solved in dichloromethane | S3 | 0 | 100 | 966 ± 150 | 57.4 ± 1.8 | 14.4 ± 1.6 |

| Solved in 4:1 DCM:acetone | S4 | 20 | 80 | 781 ± 186 | 42.1 ± 4.1 | 68.6 ± 9.2 |

| Solved in 3:2 DCM:acetone | S5 | 40 | 60 | 954 ± 111 | 55.3 ± 0.9 | 12.8 ± 0.9 |

| PLA | MWCNT [wt.% (vol%)] | Tonset [°C] | R500 [%] | Tg [°C] | E [MPa] | σB [MPa] | εB [%] |

|---|---|---|---|---|---|---|---|

| S4 | - | 326.3 | 0.5 | 62.03 | 781 ± 186 | 42.1 ± 4.1 | 68.6 ± 9.2 |

| P2C | 2 (26.6) | 338.2 | 2.8 | 62.3 | - | - | - |

| P4C | 4 (42.5) | 337.0 | 4.2 | 62.5 | - | - | - |

| P4.5C | 4.5 (45.5) | 340.7 | 4.5 | 62.4 | - | - | - |

| P5C | 5 (48.3) | 334.4 | 5.4 | 62.9 | 1209 ± 107 | 53.7 ± 8.1 | 6.7 ± 1.5 |

| P5.5C | 5.5 (50.8) | 336.3 | 5.7 | 62.2 | - | - | - |

| P6C | 6 (53.1) | 328.7 | 6.3 | 62.1 | - | - | - |

| P8C | 8 (60.6) | 327.7 | 8.1 | 62.4 | - | - | - |

| P10C | 10 (66.3) | 328.4 | 10.0 | 62.4 | 1233 ± 140 | 57.4 ± 8.7 | 8.1 ± 0.8 |

| P15C | 15 (75.8) | 326.2 | 15.3 | 62.4 | 1517 ± 183 | 68.1 ± 8.1 | 9.2 ± 1.0 |

| Sample | Lignin [wt.%] | PEG [wt.%] | σ [Scm−1] | E [MPa] | σB [MPa] | εB [%] |

|---|---|---|---|---|---|---|

| P5C1L | 1 | - | (1.5 ± 0.7) × 10−1 | 1114 ± 142 | 47.7 ± 14.6 | 7.8 ± 2.0 |

| P5C2L | 2 | - | (0.6 ± 0.1) × 10−1 | 1084 ± 168 | 49.3 ± 9.7 | 7.8 ± 2.3 |

| P5C3L | 3 | - | (0.3 ± 0.1) × 10−1 | 1101 ± 171 | 54.6 ± 2.5 | 8.9 ± 2.0 |

| P5C1G | - | 1 | (1.4 ± 0.5) × 10−1 | 1462 ± 61 | 39.0 ± 10.7 | 3.1 ± 0.9 |

| P5C2G | - | 2 | (1.1 ± 3.1) × 10−1 | 840 ± 164 | 58.6 ± 3.0 | 10.5 ± 0.9 |

| P5C3G | - | 3 | (0.7 ± 0.4) × 10−1 | 894 ± 229 | 51.1 ± 6.6 | 11.0 ± 2.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lage-Rivera, S.; Ares-Pernas, A.; Becerra Permuy, J.C.; Gosset, A.; Abad, M.-J. Enhancement of 3D Printability by FDM and Electrical Conductivity of PLA/MWCNT Filaments Using Lignin as Bio-Dispersant. Polymers 2023, 15, 999. https://doi.org/10.3390/polym15040999

Lage-Rivera S, Ares-Pernas A, Becerra Permuy JC, Gosset A, Abad M-J. Enhancement of 3D Printability by FDM and Electrical Conductivity of PLA/MWCNT Filaments Using Lignin as Bio-Dispersant. Polymers. 2023; 15(4):999. https://doi.org/10.3390/polym15040999

Chicago/Turabian StyleLage-Rivera, Silvia, Ana Ares-Pernas, Juan Carlos Becerra Permuy, Anne Gosset, and María-José Abad. 2023. "Enhancement of 3D Printability by FDM and Electrical Conductivity of PLA/MWCNT Filaments Using Lignin as Bio-Dispersant" Polymers 15, no. 4: 999. https://doi.org/10.3390/polym15040999

APA StyleLage-Rivera, S., Ares-Pernas, A., Becerra Permuy, J. C., Gosset, A., & Abad, M.-J. (2023). Enhancement of 3D Printability by FDM and Electrical Conductivity of PLA/MWCNT Filaments Using Lignin as Bio-Dispersant. Polymers, 15(4), 999. https://doi.org/10.3390/polym15040999