Combined Use of Polyurethane Prepolymer and Aromatic Oil in Physicochemical Rejuvenation of Aged SBS Modified Bitumen for Performance Recovery

Abstract

:1. Introduction

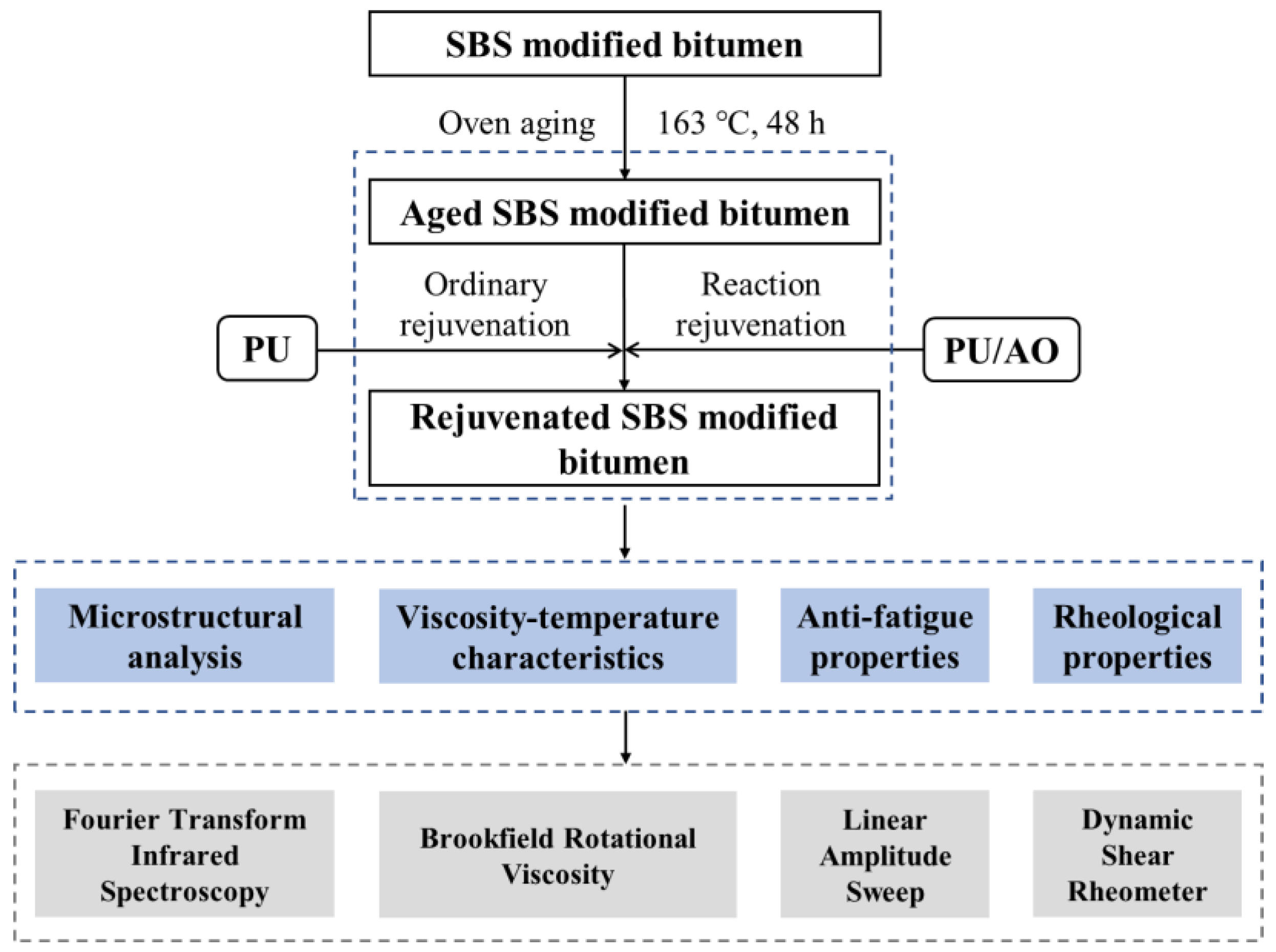

2. Materials and Methods

2.1. Raw Materials

2.1.1. SBS Modified Bitumen

2.1.2. Single-Component Polyurethane (PU)

2.1.3. Aromatic Oil (AO)

2.2. Preparation of Aged SBSmB

2.3. Preparation of Rejuvenated SBSmB

2.4. Test Methods

2.4.1. Fourier Transform Infrared Spectroscopy (FTIR) Test

2.4.2. Brookfield Rotational Viscosity Test

2.4.3. Linear Amplitude Sweep (LAS) Tests

2.4.4. Dynamic Shear Rheometer (DSR) Tests

3. Results and Discussion

3.1. Effect of Reaction Rejuvenation on Molecular Structure of aSBSmB

3.2. Effect of Reaction Rejuvenation on Viscosity–Temperature Characteristic of aSBSmB

3.3. Anti-Fatigue Properties of Rejuvenated SBSmB

3.3.1. Variation of Integrity Parameter (C) with Cumulative Fatigue Damage Parameter (D)

3.3.2. Number of Cycles to Fatigue Failure (Nf)

3.4. Evaluation of Anti-Deformation and Fatigue Performance of Reaction Rejuvenation SBSmB

3.5. Temperature Response of Viscoelastic Behavior of Reaction Rejuvenation SBSmB

3.6. Frequency Response of Viscoelastic Behavior of Rejuvenated SBSmB at Different Temperatures

4. Conclusions

- (1)

- This study proposed a new physicochemical rejuvenation method based on the novel idea of rebuilding the molecular structure of aged SBS. PU prepolymer was used as a reactive substance to react with active oxygen-containing groups from the degradation products of SBS, and AO was used as a common rejuvenator to supplement the lost light fractions of asphalt molecules in aged SBSmB. With respect to the structure and performance characterizations, a series of tests, including infrared spectra, viscosity, and dynamic shear rheology, were carried out for the rejuvenation analysis of aged SBSmB. Based on this, the main conclusions can be drawn: FTIR results indicated that PU can react with oxidative degradation products of SBS, such as -OH and -COOH, for structural reconstruction, while AO can soften the aged virgin bitumen through the reduction of heavy fractions.

- (2)

- RV results suggested that the increased viscosity of aged SBSmB after adding PU can be effectively decreased to a better workability with a certain incorporation of PU.

- (3)

- LAS results demonstrated that the combined use of PU and AO can reach a better resistance of aged SBSmB to fatigue by contrast to single use of PU, because of chemical rejuvenation of the network structure of aged SBS and the physical softening rejuvenation of aged bitumen components.

- (4)

- Combined results of rutting and fatigue factors stated that the chemical reaction between PU and SBS degradation products dominates the high-temperature stability of rejuvenated SBSmB, while AO supplements the light components in aged bitumen and improves the fatigue performance of rejuvenated SBSmB.

- (5)

- Viscoelasticity results identify that, compared to virgin SBSmB, PU/AO rejuvenated SBSmB has a similar viscoelastic behavior at low temperature, while it also has better resistance to elastic deformation at medium and high temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jin, J.; Liu, S.; Gao, Y.; Liu, R.; Huang, W.; Wang, L.; Xiao, T.; Lin, F.; Xu, L.; Zheng, J. Fabrication of cooling asphalt pavement by novel material and its thermodynamics model. Constr. Build. Mater. 2021, 272, 121930. [Google Scholar] [CrossRef]

- Zhu, J.; Ma, T.; Fan, J.; Fang, Z.; Chen, T.; Zhou, Y. Experimental study of high modulus asphalt mixture containing reclaimed asphalt pavement. J. Clean. Prod. 2020, 263, 121447. [Google Scholar] [CrossRef]

- Xu, X.; Luo, Y.; Sreeram, A.; Wu, Q.; Chen, G.; Cheng, S.; Chen, Z.; Chen, X. Potential use of recycled concrete aggregate (RCA) for sustainable asphalt pavements of the future: A state-of-the-art review. J. Clean. Prod. 2022, 344, 130893. [Google Scholar] [CrossRef]

- Xu, X.; Leng, Z.; Lan, J.; Wang, W.; Yu, J.; Bai, Y.; Sreeram, A.; Hu, J. Sustainable Practice in Pavement Engineering through Value-Added Collective Recycling of Waste Plastic and Waste Tyre Rubber. Engineering 2021, 7, 857–867. [Google Scholar] [CrossRef]

- Nian, T.; Li, P.; Mao, Y.; Zhang, G.; Liu, Y. Connections between chemical composition and rheology of aged base asphalt binders during repeated freeze-thaw cycles. Constr. Build. Mater. 2018, 159, 338–350. [Google Scholar] [CrossRef]

- Guo, R.; Nian, T.; Zhou, F. Analysis of factors that influence anti-rutting performance of asphalt pavement. Constr. Build. Mater. 2020, 254, 119237. [Google Scholar] [CrossRef]

- Kaya, D.; Topal, A.; McNally, T. Relationship between processing parameters and aging with the rheological behaviour of SBS modified bitumen. Constr. Build. Mater. 2019, 221, 345–350. [Google Scholar] [CrossRef]

- Kaya, D.; Topal, A.; Gupta, J.; McNally, T. Aging effects on the composition and thermal properties of styrene-butadiene-styrene (SBS) modified bitumen. Constr. Build. Mater. 2020, 235, 117450. [Google Scholar] [CrossRef]

- Nian, T.; Li, P.; Wei, X.; Wang, P.; Li, H.; Guo, R. The effect of freeze-thaw cycles on durability properties of SBS-modified bitumen. Constr. Build. Mater. 2018, 187, 77–88. [Google Scholar] [CrossRef]

- Hamid, A.; Baaj, H.; El-Hakim, M. Predicting the recovery and nonrecoverable compliance behaviour of asphalt binders using artificial neural networks. Processes 2022, 10, 2633. [Google Scholar] [CrossRef]

- Al-Adham, K.; Dalhat, M.A.; Al-Abdul Wahhab, H.I. Strain recovery rate and absolute percent recovery of polymer-modified asphalt binders. Int. J. Pavement Eng. 2020, 21, 919–929. [Google Scholar] [CrossRef]

- Hamid, A.; Baaj, H.; El-Hakim, M. Effect of high temperature on the behaviour of geopolymer modified asphalt binder. In Proceedings of the Transportation Association of Canada 2022 Conference and Exhibition, Vancouver, BC, Canada, 2–5 October 2022; pp. 1–11. [Google Scholar]

- Hamid, A.; Baaj, H.; El-Hakim, M. Predicting the potential pmpact of geopolymers on the recovery properties of asphalt binder. Int. Symp. Bitum. Mater. 2020, 27, 1481–1487. [Google Scholar]

- Hamid, A.; Baaj, H.; El-Hakim, M. Rutting behaviour of geopolymer and styrene butadiene styrene-modified asphalt binder. Polymers 2022, 14, 2780. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H.; Rahman, A.; Wang, W. Damage characteristics of waste engine oil bottom rejuvenated asphalt binder in the non-linear range and its microstructure. Constr. Build. Mater. 2018, 174, 202–209. [Google Scholar] [CrossRef]

- Yan, C.; Huang, W.; Lin, P.; Zhang, Y.; Lv, Q. Chemical and rheological evaluation of aging properties of high content SBS polymer modified asphalt. Fuel 2019, 252, 417–426. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, H.; Duan, H. Effect of catalytic-reactive rejuvenator on structure and properties of aged SBS modified asphalt binders. Constr. Build. Mater. 2020, 246, 118531. [Google Scholar] [CrossRef]

- Cao, Z.; Huang, X.; Yu, J.; Han, X.; Wang, R.; Li, Y. Study on all-components regeneration of ultraviolet aged SBS modified asphalt for high-performance recycling. J. Clean. Prod. 2020, 276, 123376. [Google Scholar] [CrossRef]

- Leng, Z.; Sreeram, A.; Padhan, R.K.; Tan, Z. Value-added application of waste PET based additives in bituminous mixtures containing high percentage of reclaimed asphalt pavement (RAP). J. Clean. Prod. 2018, 196, 615–625. [Google Scholar] [CrossRef]

- Eltwati, A.; Mohamed, A.; Hainin, M.R.; Jusli, E.; Enieb, M. Rejuvenation of aged asphalt binders by waste engine oil and SBS blend: Physical, chemical, and rheological properties of binders and mechanical evaluations of mixtures. Constr. Build. Mater. 2022, 346, 128441. [Google Scholar] [CrossRef]

- Spadoni, S.; Ingrassia, L.P.; Mariani, E.; Cardone, F.; Canestrari, F. Long-term performance assessment of a warm recycled motorway pavement. Case Stud. Constr. Mater. 2022, 17, e01451. [Google Scholar] [CrossRef]

- Ingrassia, L.P.; Cardone, F.; Ferrotti, G.; Canestrari, F. Monitoring the evolution of the structural properties of warm recycled pavements with Falling Weight Deflectometer and laboratory tests. Road Mater. Pavement Des. 2021, 22, 69–82. [Google Scholar] [CrossRef]

- Yan, K.; Lan, H.; Duan, Z.; Liu, W.; You, L.; Wu, S.; Miljković, M. Mechanical performance of asphalt rejuvenated with various vegetable oils. Constr. Build. Mater. 2021, 293, 123485. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, M.; Liu, Z.; He, B.; Yu, J.; Xue, L. Effect of different rejuvenators on the rheological properties of aged SBS modified bitumen in long term aging. Constr. Build. Mater. 2019, 215, 709–717. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, M.; Han, X.; Wang, R.; Yu, J.; Xu, X.; Xue, L. Influence of characteristics of recycling agent on the early and long-term performance of regenerated SBS modified bitumen. Constr. Build. Mater. 2020, 237, 117631. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Lin, P.; Gao, Y.; Erkens, S. Insight into the compatibility behaviors between various rejuvenators and aged bitumen: Molecular dynamics simulation and experimental validation. Mater. Des. 2022, 223, 111141. [Google Scholar] [CrossRef]

- Chen, H.; Xie, J.; Wu, S.; Yang, C.; Gao, B.; Yang, D.; Chen, J. Evolution of selective absorption for bitumen from Basic Oxygen Furnace Slag (BOF) during aging and rejuvenation in bituminous mixtures. Constr. Build. Mater. 2022, 351, 128894. [Google Scholar] [CrossRef]

- Matolia, S.; Guduru, G.; Gottumukkala, B.; Kuna, K.K. An investigation into the influence of aging and rejuvenation on surface free energy components and chemical composition of bitumen. Constr. Build. Mater. 2020, 245, 118378. [Google Scholar] [CrossRef]

- Han, X.; Mao, S.; Zeng, S.; Cao, Z.; He, P.; Du, W.; Yu, J. Influence of novel long-chain active composite rejuvenators on interfacial adhesion between aged SBS modified asphalt and aggregate. Constr. Build. Mater. 2022, 328, 127108. [Google Scholar] [CrossRef]

- Xu, X.; Sreeram, A.; Leng, Z.; Yu, J.; Li, R.; Peng, C. Challenges and opportunities in the high-quality rejuvenation of unmodified and SBS modified asphalt mixtures: State of the art. J. Clean. Prod. 2022, 378, 134634. [Google Scholar] [CrossRef]

- Polo-Mendoza, R.; Martinez-Arguelles, G.; Walubita, L.F.; Moreno-Navarro, F.; Giustozzi, F.; Fuentes, L.; Navarro-Donado, T. Ultraviolet ageing of bituminous materials: A comprehensive literature review from 2011 to 2022. Constr. Build. Mater. 2022, 350, 128889. [Google Scholar] [CrossRef]

- Anupam, B.R.; Sahoo, U.C.; Chandrappa, A.K. A methodological review on self-healing asphalt pavements. Constr. Build. Mater. 2022, 321, 126395. [Google Scholar] [CrossRef]

- Sarkar, S.; Mestry, S.; Mhaske, S.T. Developments in phase change material (PCM) doped energy efficient polyurethane (PU) foam for perishable food cold-storage applications: A review. J. Energy Storage 2022, 50, 104620. [Google Scholar] [CrossRef]

- Oenema, J.; Liu, H.; Coensel, N.D.; Eschenbacher, A.; Van de Vijver, R.; Weng, J.; Li, L.; Wang, C.; Van Geem, K.M. Review on the pyrolysis products and thermal decomposition mechanisms of polyurethanes. J. Anal. Appl. Pyrolysis 2022, 168, 105723. [Google Scholar] [CrossRef]

- Huang, G.; Yang, T.; He, Z.; Yu, L.; Xiao, H. Polyurethane as a modifier for road asphalt: A literature review. Constr. Build. Mater. 2022, 356, 129058. [Google Scholar] [CrossRef]

- Li, T.; Guo, Z.; Liang, D.; Luo, S.; Zhang, Y.; Hong, B.; Lu, G.; Wang, D.; Oeser, M. Chemical and physical effects of polyurethane-precursor-based reactive modifier on the low-temperature performance of bitumen. Constr. Build. Mater. 2022, 328, 127055. [Google Scholar] [CrossRef]

- Khairuddin, F.H.; Alamawi, M.Y.; Yusoff, N.I.M.; Badri, K.H.; Ceylan, H.; Tawil, S.N.M. Physicochemical and thermal analyses of polyurethane modified bitumen incorporated with Cecabase and Rediset: Optimization using response surface methodology. Fuel 2019, 254, 115662. [Google Scholar] [CrossRef]

- Lu, G.; Renken, L.; Li, T.; Wang, D.; Li, H.; Oeser, M. Experimental study on the polyurethane-bound pervious mixtures in the application of permeable pavements. Constr. Build. Mater. 2019, 202, 838–850. [Google Scholar] [CrossRef]

- Sabouri, M.; Mirzaiyan, D.; Moniri, A. Effectiveness of Linear Amplitude Sweep (LAS) asphalt binder test in predicting asphalt mixtures fatigue performance. Constr. Build. Mater. 2018, 171, 281–290. [Google Scholar] [CrossRef]

| Parameters | Measured Results | Technical Criterion | Specifications | |

|---|---|---|---|---|

| SBSmB | aSBSmB | |||

| Softening point (°C) | 63.8 | 72.4 | >60 | ASTM D36 |

| Penetration at 25 °C, 100 g, 5 s (0.1 mm) | 58 | 46 | 40~60 | ASTM D5 |

| Viscosity at 135 °C (mPa·s) | 1930 | 3530 | ≤3000 | AASHTO TP48 |

| Viscosity at 150 °C (mPa·s) | 904 | 2220 | ≤3000 | AASHTO TP48 |

| Rutting factor at 76 °C (kPa) | 1.83 | 6.09 | >1.0 kPa | ASTM D6373 |

| Wave Number (cm−1) | Attribution | Vibration Type |

|---|---|---|

| 2275 | -NCO | -N=C=O Asymmetric Stretching |

| 1696 | C=O | C=O Stretching |

| 1577, 1542, 1465 | Benzene ring | Respiratory skeleton |

| 1302 | C-NH2 or C-NH- | C-N Stretching |

| 1260 | Olefin | C-H Bending |

| 1014 | S=O | S=O Stretching |

| 965, 699 | -CH2=CH2- | C-H Bending |

| Types of Binder | Viscosity–Temperature Equations | m | R2 |

|---|---|---|---|

| SBSmB | 1.293 | 0.992 | |

| aSBSmB | 1.446 | 0.981 | |

| 3PU/aSBSmB | 0.951 | 0.978 | |

| 3PU/10AO/aSBSmB | 1.459 | 0.950 |

| Binder Type | Equations Related to the Fatigue Curves |

|---|---|

| SBSmB | |

| aSBSmB | |

| 3PU/aSBSmB | |

| 3PU/10AO/aSBSmB |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shu, S.; Chen, G.; Yan, J.; Li, Z.; Shen, W.; Gong, K.; Luo, Y. Combined Use of Polyurethane Prepolymer and Aromatic Oil in Physicochemical Rejuvenation of Aged SBS Modified Bitumen for Performance Recovery. Polymers 2023, 15, 1120. https://doi.org/10.3390/polym15051120

Shu S, Chen G, Yan J, Li Z, Shen W, Gong K, Luo Y. Combined Use of Polyurethane Prepolymer and Aromatic Oil in Physicochemical Rejuvenation of Aged SBS Modified Bitumen for Performance Recovery. Polymers. 2023; 15(5):1120. https://doi.org/10.3390/polym15051120

Chicago/Turabian StyleShu, Suxun, Guofu Chen, Jiaming Yan, Ziqing Li, Weili Shen, Kai Gong, and Yi Luo. 2023. "Combined Use of Polyurethane Prepolymer and Aromatic Oil in Physicochemical Rejuvenation of Aged SBS Modified Bitumen for Performance Recovery" Polymers 15, no. 5: 1120. https://doi.org/10.3390/polym15051120