Review of Aging Evaluation Methods for Silicone Rubber Composite Insulators

Abstract

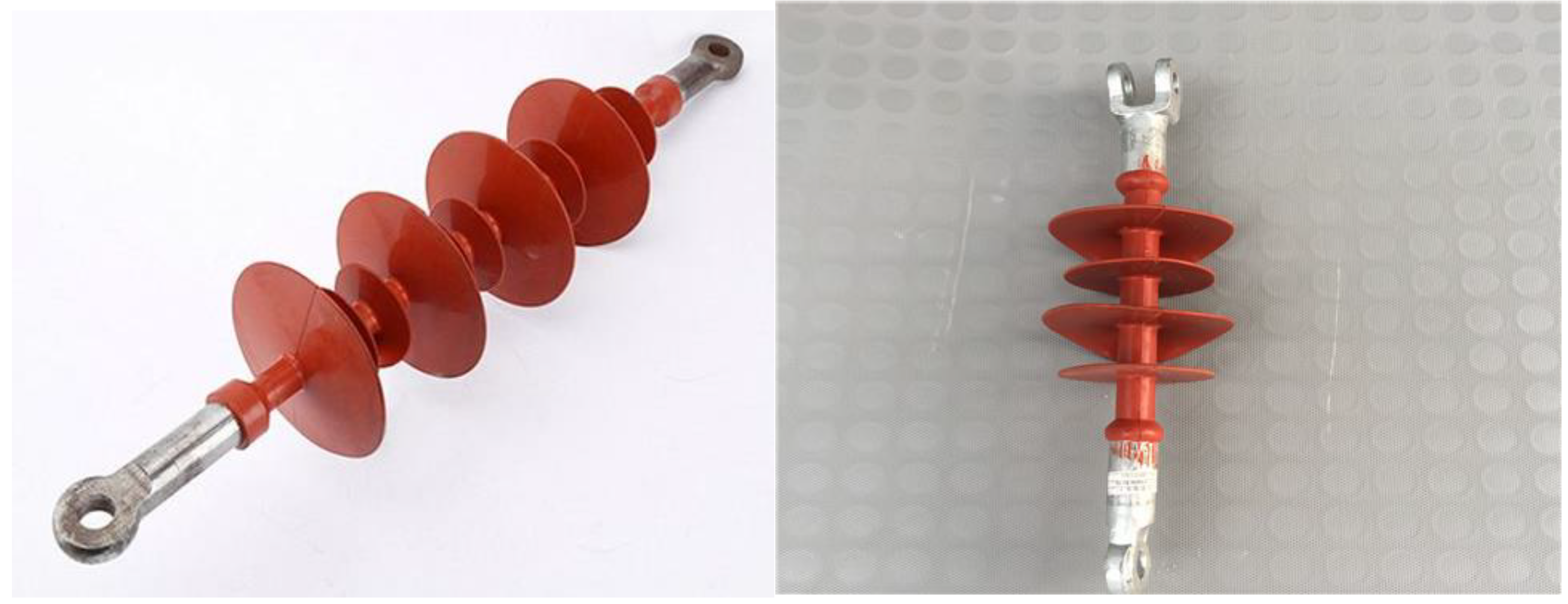

:1. Introduction

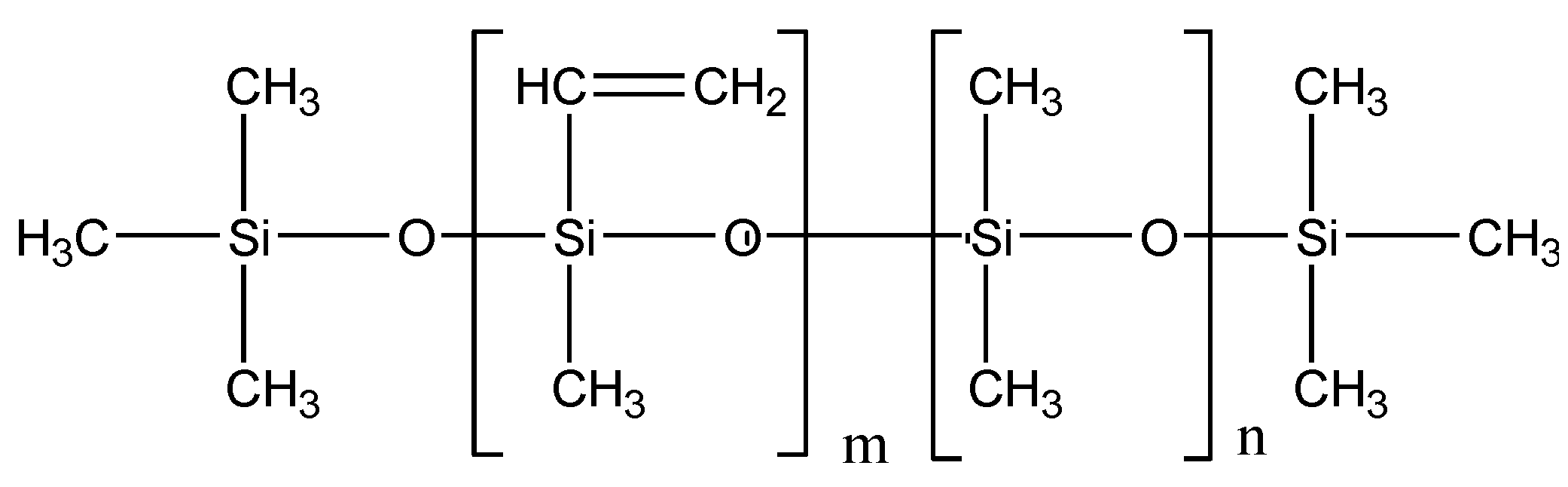

2. Aging Mechanism

3. Test Methods

3.1. Macroinspection Method for Aging of Composite Insulators

3.1.1. Appearance Inspection

3.1.2. Flashover Voltage Detection and Electric Field Distribution Test

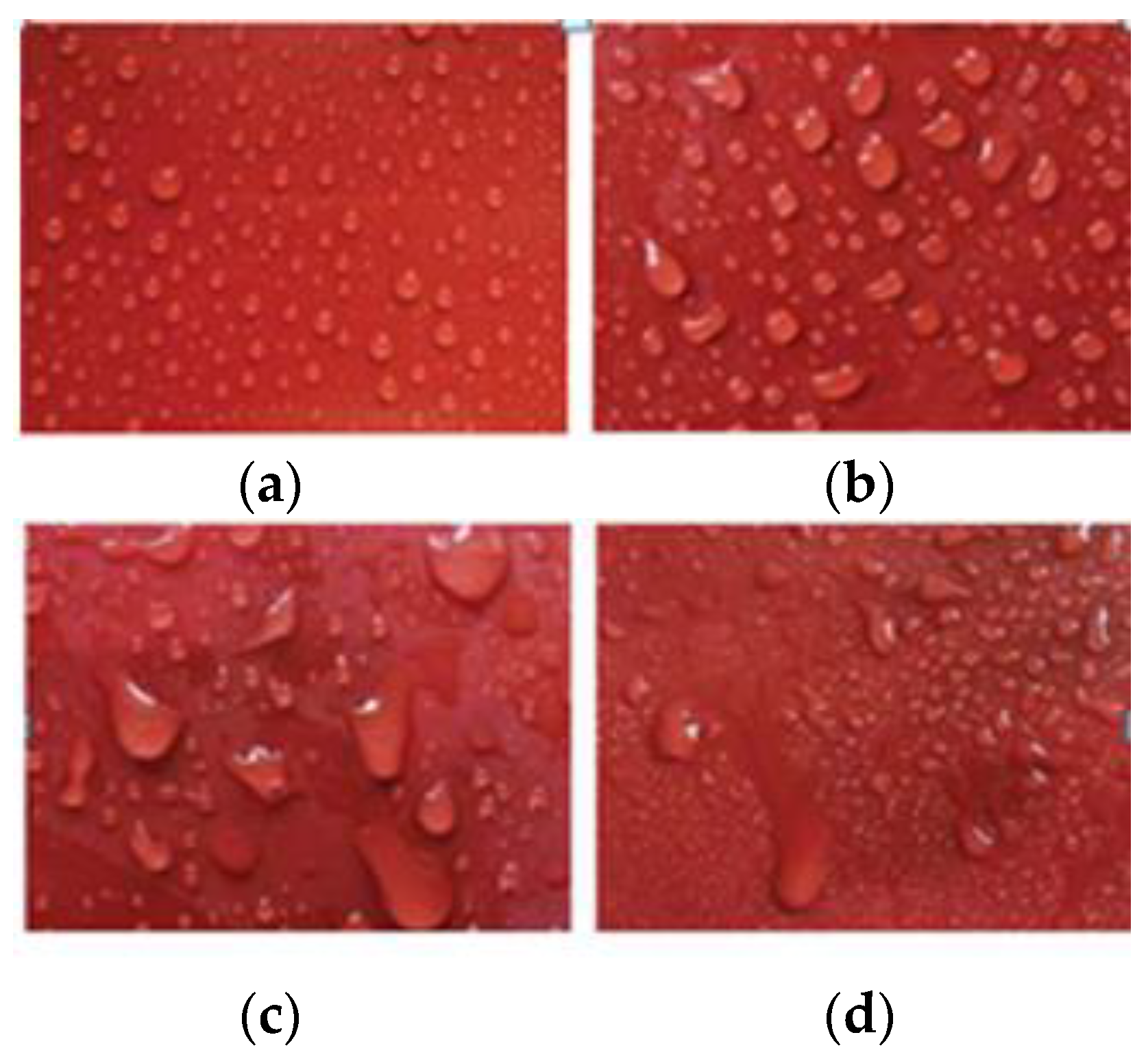

3.1.3. Hydrophobicity Test

3.1.4. Leakage Current

3.1.5. Ultrasonic Testing

3.1.6. Optical Detection

3.1.7. Mechanical Test

3.2. Microinspection Method for Aging of Composite Insulators

3.2.1. Thermal Weight-Loss Analysis

3.2.2. Thermal Stimulation Current

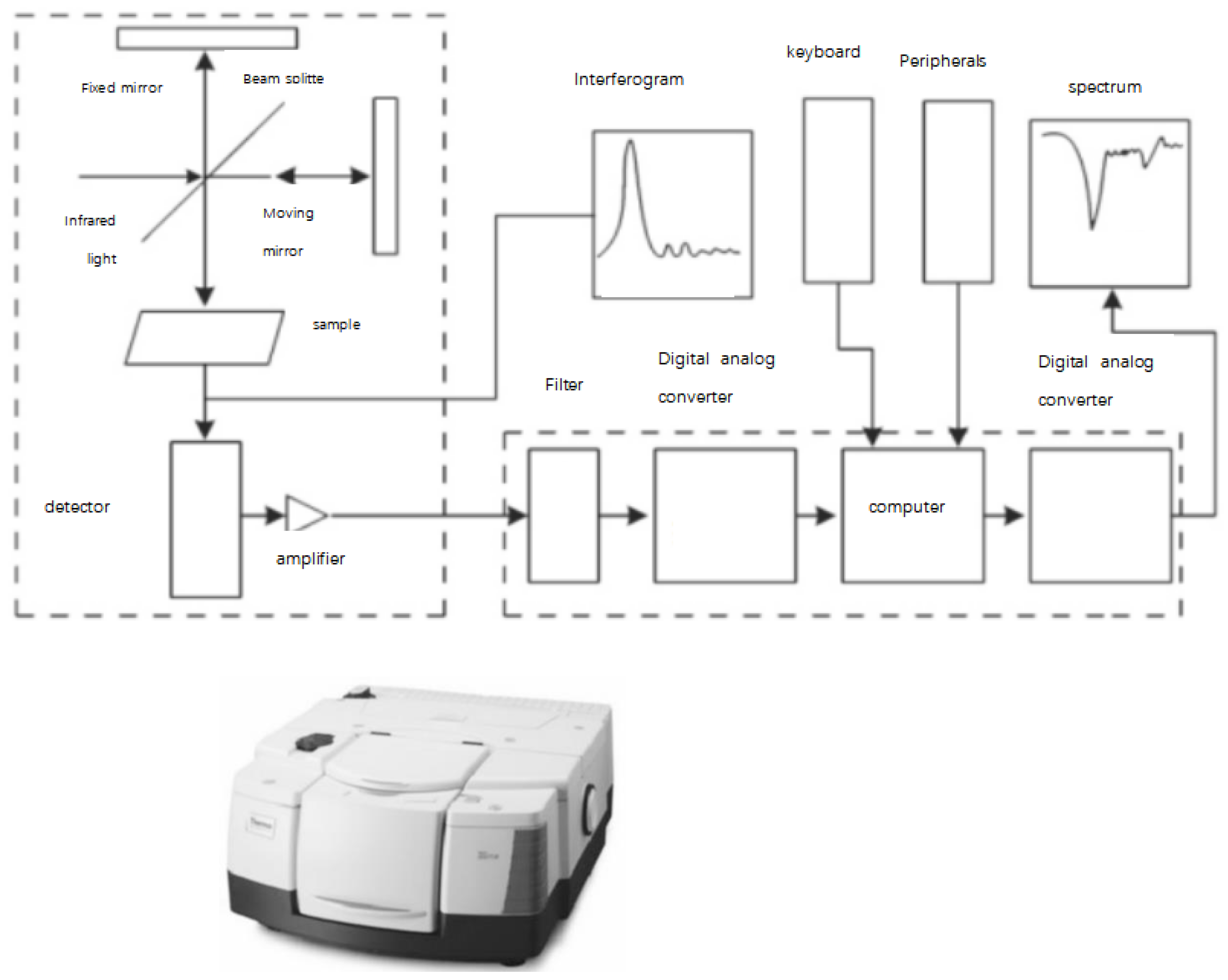

3.2.3. Infrared Spectrum

3.2.4. Slow Positron Beam

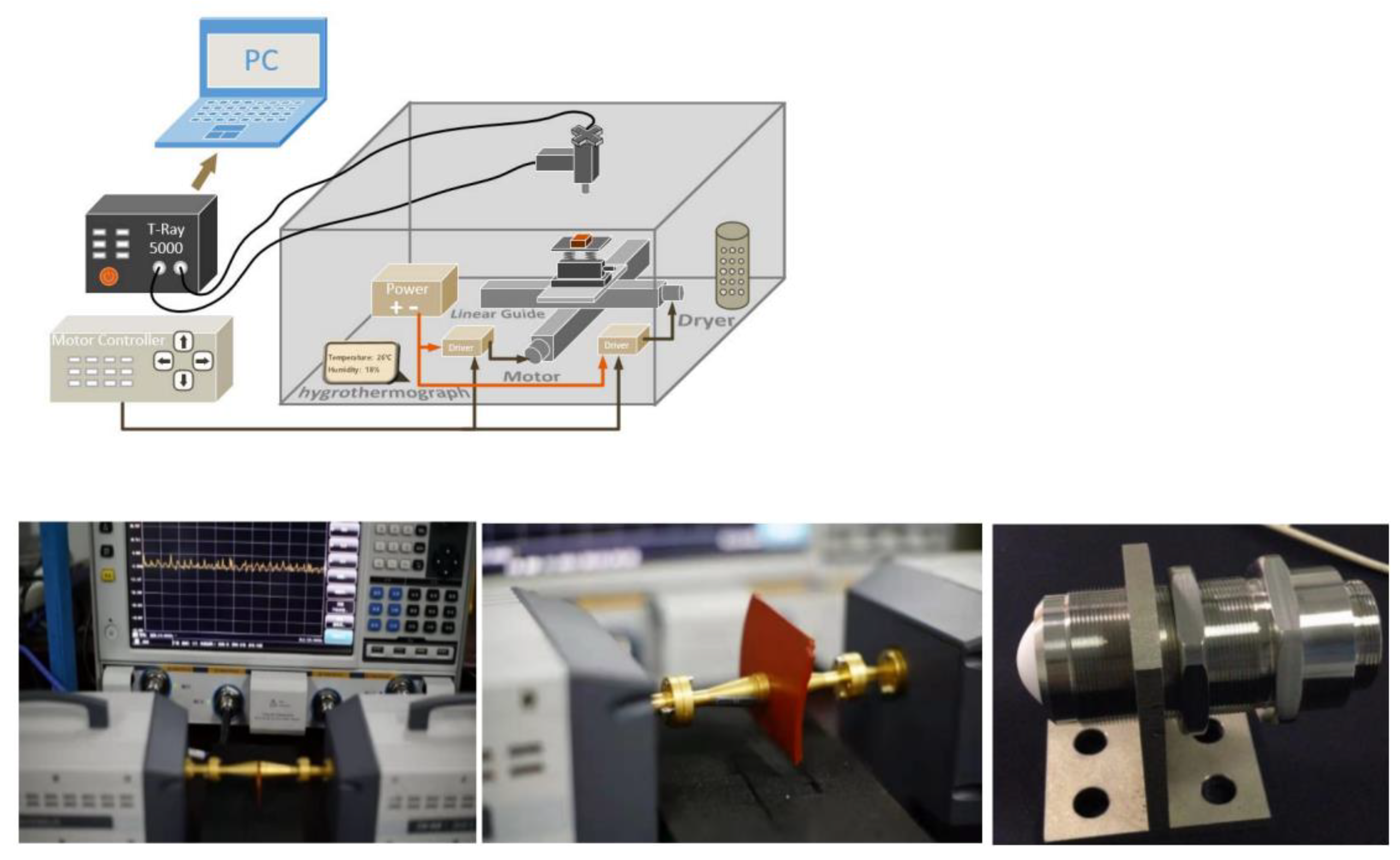

3.2.5. Terahertz Detection

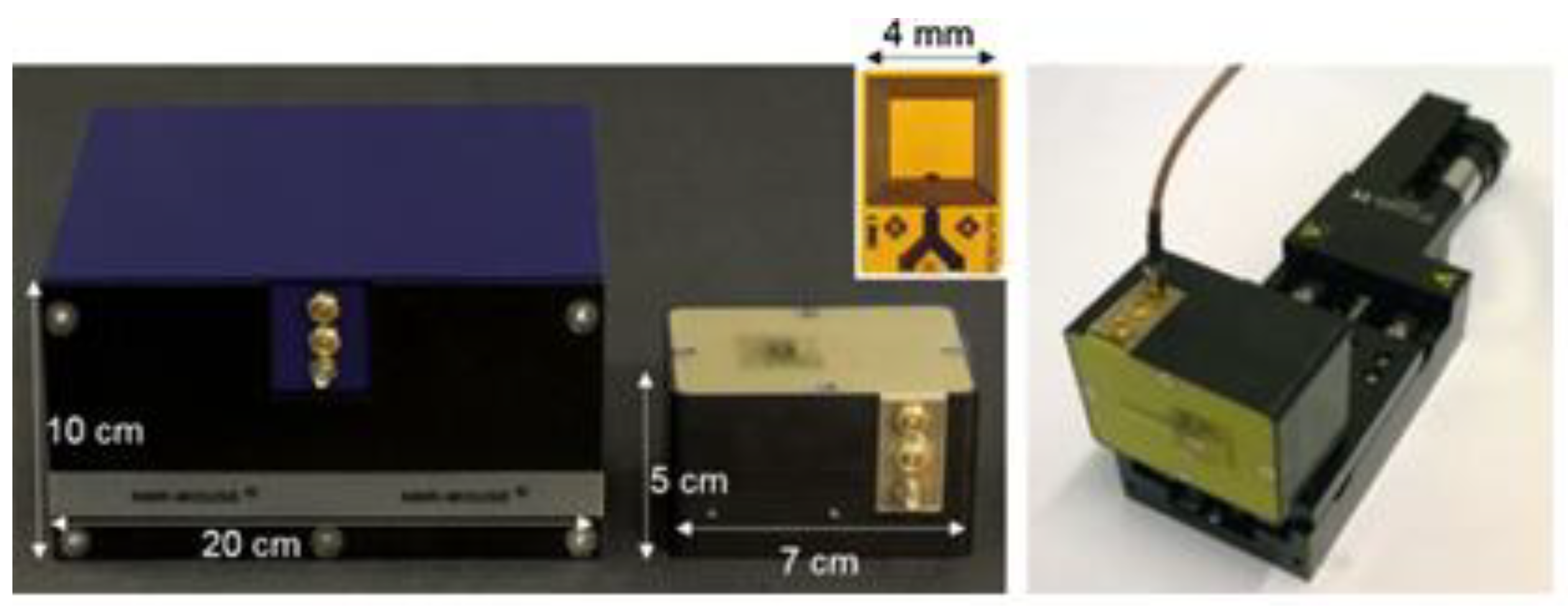

3.2.6. Magnetic Resonance Testing Method for Aging of Composite Insulators

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, X.; Guo, P.; Lu, M.; Zhao, S.; Xu, Z. Optimized Portable Unilateral Magnetic Resonance Sensor for Assessing the Aging Status of Silicon Rubber Insulators. IEEE Trans. Instrum. Meas. 2020, 70, 1–11. [Google Scholar] [CrossRef]

- Peng, X.Y.; Fang, P.F.; Huang, Z. Aging Characterization and Micro Diagnosis Technology of Composite Insulators; China Electric Power Press: Beijing, China, 2018. [Google Scholar]

- Lu, M. Insulator Application and Fault Case Analysis; China Electric Power Press: Beijing, China, 2020. [Google Scholar]

- Lu, M.; Gao, C.; Zou, Q.G. Research on Operation State Evaluation Method of Large Tonnage Porcelain Insulator for UHV AC Transmission Line. J. Proc. CSEE 2021, 41 (Suppl. S1), 392–400. [Google Scholar]

- Guan, Z.; Xue, J.; Liang, X. The Economic Analysis of Using Composite Insulators on the EHV Transmission Line of Three Gorges Project. Power Syst. Technol. 1994, 18, 12–16. [Google Scholar]

- Yin, Y.; Liang, X.-D.; Li, Q.-F.; Su, Z.-Y.; Fan, J.-B.; Shi, Z.-N. Artificial Accelerated Ageing Test of Composite Insulators. Power Syst. Technol. 2006, 30, 69–74+78. [Google Scholar]

- Su, Z.; Li, Q. Historical Review and Summary on Measures Against Pollution Flashover Occurred in Power Grids in China. Power Syst. Technol. 2010, 34, 124–130. [Google Scholar]

- Wang, J.-G.; Fang, C.-H.; Liu, Y.; Han, F.; Xue, J.; Chen, J.-J. Experimental Study on Electrical and Mechanical Properties of 220 kV Composite Insulators. High Volt. Appar. 2008, 44, 332–334+346. [Google Scholar]

- Cheng, Y.; Li, C.; Wang, X.; Wu, G.; Chen, M.; Chen, R. Analysis of Field Test of DL-1 Composite Insulator Detector. High Volt. Eng. 2003, 42–44. [Google Scholar]

- Lu, M.; Liu, Z.; Gao, C.; Wu, C.; Guo, J.; Li, L. Investigation on Typical Fault of Composite Insulator in Domestic Transmission Lines. In Insulators and Surge Arresters; 2022; pp. 214–220. [Google Scholar]

- He, W.; Zhang, F.; Zhang, F.; He, Q. Effect of CeO2 on UV aging of composite insulators prepared by template-spraying method. J. Appl. Polym. Sci. 2023, 140, e53274. [Google Scholar] [CrossRef]

- Amin, M.; Khattak, A.; Ali, M. Accelerated aging investigation of silicone rubber/silica composites for coating of high-voltage insulators. Electr. Engieering 2018, 100, 217–230. [Google Scholar] [CrossRef]

- Liu, Q. The Hydrophobicity Detection of Composite Insulator Based on Image Processing; Lanzhou Jiaotong University: Lanzhou, China, 2015. [Google Scholar]

- Wang, F.; Huang, C.; Li, Y.; Yang, S.; Zhang, Z. A New Criterion to Assess Aging Status of Silicon Rubber Composite Insulator. Power Syst. Technol. 2014, 38, 3224–3229. [Google Scholar]

- Wang, L.; Zhang, J.; Zhao, C.; Dai, H.; Zhou, Z.; Gao, S. A Forecast Method for Leakage Current of Contaminated Insulator Under Saturated Moist. High Volt. Eng. 2014, 40, 1416–1423. [Google Scholar]

- Ling, Y. Research on the On-Line Monitoring System for Leakage Current of Catenary Polluted Insulator; Lanzhou Jiaotong University: Lanzhou, China, 2016. [Google Scholar]

- Volat, C.; Meghnefi, F.; Farzaneh, M.; Ezzaidi, H. Monitoring leakage current of ice-covered station post insulators using artificial neural networks. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 443–450. [Google Scholar] [CrossRef]

- Wang, L.; Zhong, C. Insulator Leakage Current and Its Analytical Method. Electr. Switchg. 2011, 49, 9–11. [Google Scholar]

- Xie, C.; Zhang, Y.; Hao, Y.; Yuan, X.; Wei, Q. Application of Ultrasonic Flaw Detector to Internal Defects in Composite Insulators. High Volt. Eng. 2009, 35, 2464–2469. [Google Scholar]

- Li, L. Research on Live Detection System of Composite Insulator Based on Ultrasonic Phased Array; Hebei University of Technology: Tianjin, China, 2017. [Google Scholar]

- Li, Z.; Liang, X.; Zhou, Y.; Liu, W. Study on Thermal Characteristic of Silicone Rubber Material Based on Infrared Image. Insul. Mater. 2006, 36–39. [Google Scholar]

- Xie, S.; Zhou, M.; Chen, L.; Huang, H.; Song, S.; Wang, J. Mechanical Properties and Breakage Characteristics of Composite Insulator Sheds in Island. High Volt. Eng. 2021, 47, 1824–1830. [Google Scholar]

- Tu, Y.; Luo, M.; Ying, G.; Ding, L. Research on TSC Characteristics of Corona Aging of Silicone Rubber with Orthogonal Test Method. Proc. CSEE 2012, 32, 139–144+202. [Google Scholar]

- Qin, C.-X.; Lv, F.-C.; Liu, H.-C. Research on TSC Characteristic of the HTV Silicon Rubber Ageing by AC and DC Corona. Electr. Meas. Instrum. 2013, 50, 4–7. [Google Scholar]

- Kuang, F.; Yin, C.; Ye, T. Infrared Spectrum Analysis Method of Composite Insulator Aging State. Electr. Eng. 2020, 110–113. [Google Scholar]

- Teng, M.K.; Shen, D.X.; Xia, Y.F. Positron Annihilation Spectroscopy and Application; Atomic Energy Press: Beijing, China, 2000; pp. 4–18. [Google Scholar]

- Xiang, K.; Huang, G.; Zheng, J.; Wang, X.; Huang, J. Investigation on the Thermal Oxidative Aging Mechanism and Lifetime Prediction of Butyl Rubber. Macromol. Res. 2013, 21, 10–16. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, J.; Wang, Z.; Miao, C.; Wu, Z.; Cheng, Y. Aging detection of silicon rubber composite insulator based on terahertz technology. J. Guangxi Univ. Sci. Technol. 2021, 32, 1–8+34. [Google Scholar]

- Blümich, B.; Perlo, J.; Casanova, F. Mobile single-sided NMR. Prog. Nucl. Magn. Reson. Spectrosc. 2008, 52, 197–269. [Google Scholar] [CrossRef]

- Blumich, B.; Buda, A.; Kremer, K. Non-destructive testing with mobile NMR. Gummi Fasern Kunstst. 2006, 59, 290. [Google Scholar]

- Somers, A.E.; Bastow, T.J.; Burgar, M.I.; Forsyth, M.; Hill, A.J. Quantifying rubber degradation using NMR. Polym. Degrad. Stab. 2000, 70, 31–37. [Google Scholar] [CrossRef]

- Morin, D.M.; Yan, P.; Augustine, M.P.; Balcom, B.J. An Optimized 2 MHz Unilateral Magnet with a Large Homogeneous Sensitive Spot. Appl. Magn. Reson. 2022, 53, 401–415. [Google Scholar] [CrossRef]

- Guthausen, A.; Zimmer, G.; Blümler, P.; Blümich, B. Analysis of polymer materials by surface NMR via the MOUSE. J. Magn. Reson. 1998, 130, 1–7. [Google Scholar] [CrossRef]

- Halmen, N.; Kugler, C.; Kraus, E.; Baudrit, B.; Hochrein, T.; Bastian, M. Single-sided NMR for the measurement of the degree of cross-linking and curing. J. Sens. Sens. Syst. 2018, 7, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Guo, P.; He, X.-L.; Yi, S.-J. Aging Detection of Composite Insulator with Nuclear Magnetic Resonance Theory. High Volt. Appar. 2014, 48, 21–25. [Google Scholar]

- Xu, Z.; Li, L.; Guo, P.; Ji, Y.; Wu, J.; He, C. Portable Unilateral NMR Measuring System for Assessing the Aging Status of Silicon Rubber Insulators. Appl. Magn. Reson. 2019, 50, 277–291. [Google Scholar] [CrossRef]

- Utsuzawa, S.; Tang, Y.; Song, Y.-Q. Inside-out NMR with two concentric ring magnets. J. Magn. Reson. 2021, 333, 107082. [Google Scholar] [CrossRef]

- Jackson, J.A.; Burnett, L.J.; Harmon, J.F. Remote (inside-out) NMR. III. Detection of nuclear magnetic resonance in a remotely produced region of homogeneous magnetic field. J. Magn. Reson. 1980, 41, 411–421. [Google Scholar] [CrossRef]

- Danieli, E.; Blümich, B. Single-sided magnetic resonance profiling in biological and materials science-ScienceDirect. J. Magn. Reson. 2014, 45, 142–154. [Google Scholar]

- Nakashima, Y.; Sawatsubashi, T.; Fujii, S. Nondestructive quantification of moisture in powdered low-rank coal by a unilateral nuclear magnetic resonance scanner. Int. J. Coal Prep. Util. 2020, 42, 1421–1434. [Google Scholar] [CrossRef] [Green Version]

- Ross, M.M.B.; Wilbur, G.R.; Cano Barrita, P.F.J.; Balcom, B.J. A portable, submersible, MR sensor-The Proteus magnet. J. Magn. Reson. 2021, 326, 106964. [Google Scholar] [CrossRef] [PubMed]

- Xu, Z.; Cui, X.; Meng, K.; Xia, Y. Novel unilateral NMR sensor for assessing the aging status of silicone rubber insulator. IEEE Sens. J. 2016, 16, 1168–1175. [Google Scholar]

- Guo, P.; Wang, L.; Wang, R.; Li, B.; Zhao, Z. Portable Non-Destructive Magnetic Resonance Sensor for Assessing the Aging Status of Silicon Rubber Insulators. Nanomaterials 2022, 12, 3847. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Z.; Guo, P.; Zhang, R.; Zhao, Z.; Bao, J.; Wang, Q.; Xu, Z. Review of Aging Evaluation Methods for Silicone Rubber Composite Insulators. Polymers 2023, 15, 1141. https://doi.org/10.3390/polym15051141

Zeng Z, Guo P, Zhang R, Zhao Z, Bao J, Wang Q, Xu Z. Review of Aging Evaluation Methods for Silicone Rubber Composite Insulators. Polymers. 2023; 15(5):1141. https://doi.org/10.3390/polym15051141

Chicago/Turabian StyleZeng, Zhou, Pan Guo, Ruoshuang Zhang, Zhirui Zhao, Jiankang Bao, Qian Wang, and Zheng Xu. 2023. "Review of Aging Evaluation Methods for Silicone Rubber Composite Insulators" Polymers 15, no. 5: 1141. https://doi.org/10.3390/polym15051141

APA StyleZeng, Z., Guo, P., Zhang, R., Zhao, Z., Bao, J., Wang, Q., & Xu, Z. (2023). Review of Aging Evaluation Methods for Silicone Rubber Composite Insulators. Polymers, 15(5), 1141. https://doi.org/10.3390/polym15051141