Ultra-High Molecular Weight Polyethylene Modifications Produced by Carbon Nanotubes and Fe2O3 Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

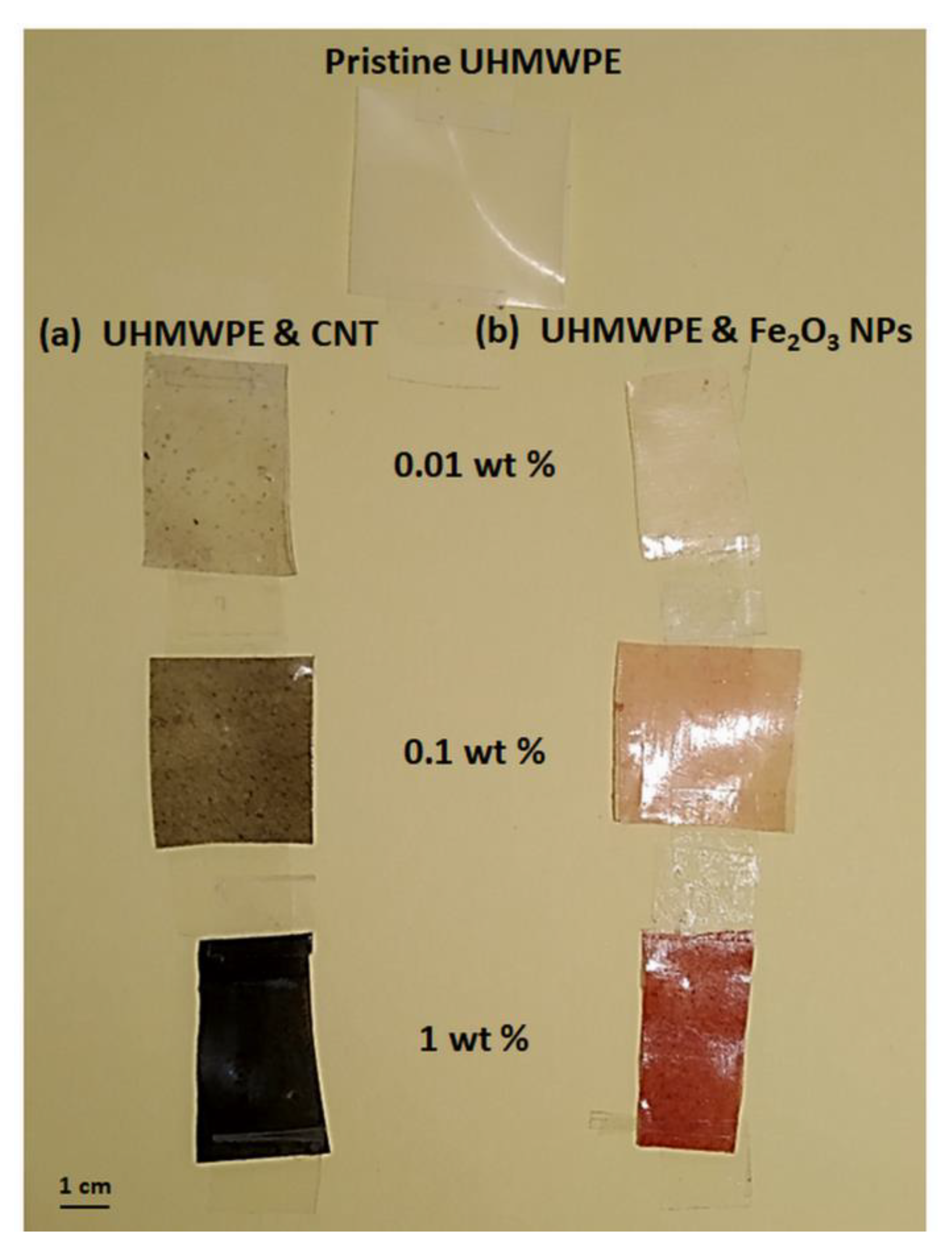

3. Results and Discussion

3.1. ATR-FTIR Spectroscopy

3.2. UV–Vis Spectroscopy

4. Challenges and Future Outlook

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Patil, N.A.; Njuguna, J.; Kandasubramanian, B. UHMWPE for biomedical applications: Performance and functionalization. Eur. Polym. J. 2020, 125, 109529. [Google Scholar] [CrossRef]

- Chang, B.P.; Akil, H.M.; Nasir, R.M. Mechanical and Tribological Properties of Zeolite-reinforced UHMWPE Composite for Implant Application. Procedia Eng. 2013, 68, 88–94. [Google Scholar] [CrossRef]

- Gao, C.; Lu, H.; Ni, H.; Chen, J. Structure, thermal conductive, dielectric and electrical insulating properties of UHMWPE/BN composites with a segregated structure. J. Polym. Res. 2017, 25, 1–9. [Google Scholar] [CrossRef]

- Spiegelberg, S.; Kozak, B.S.A.; Braithwaite, G. Characterization of Physical, Chemical, and Mechanical Properties of UHMWPE. In UHMWPE Biomaterials Handbook, 3rd ed.; Kurtz, S.M., Ed.; Elsevier: Philadelphia, PA, USA, 2016; pp. 531–552. [Google Scholar]

- Torrisi, L.; Cutroneo, M.; Calcagno, L.; Rosinski, M.; Ullschmied, J. TNSA ion acceleration at 1016 W/cm2 sub-nanosecond laser intensity. J. Phys. Conf. Ser. 2014, 508, 012002. [Google Scholar] [CrossRef]

- Torrisi, L.; Torrisi, A. Shockwave and spallation in silver and other materials by sub-ns laser pulse at 1016 W/cm2 intensity. Contrib. Plasma Phys. 2023, 63, 1–15. [Google Scholar] [CrossRef]

- Torrisi, L.; Cutroneo, M.; Torrisi, A.; Silipigni, L.; Costa, G.; Rosinski, M.; Badziak, J.; Wołowski, J.; Zaraś-Szydłowska, A.; Parys, P. Protons accelerated in the target normal sheath acceleration regime by a femtosecond laser. Phys. Rev. Accel. Beams 2019, 22, 021302. [Google Scholar] [CrossRef] [Green Version]

- Hussain, M.; Naqvi, R.A.; Abbas, N.; Khan, S.M.; Nawaz, S.; Hussain, A.; Zahra, N.; Khalid, M.W. Ultra-High-Molecular-Weight-Polyethylene (UHMWPE) as a Promising Polymer Material for Biomedical Applications: A Concise Review. Polymers 2020, 12, 323. [Google Scholar] [CrossRef] [Green Version]

- Candadai, A.A.; Weibel, A.J.; Marconnet, A.M. Thermal Conductivity of Ultrahigh Molecular Weight Polyethylene: From Fibers to Fabrics. ACS Appl. Polym. Mater. 2020, 2, 437–447. [Google Scholar] [CrossRef]

- Cutroneo, M.; Hnatowicz, V.; Mackova, A.; Malinsky, P.; Miksova, R.; Ceccio, G.; Maly, J.; Smejkal, J.; Štofik, M.; Havranek, V. Ion Lithography of Single Ions Irradiation for Spatially Regular Arrays of Pores in Membranes of Polyethylene Terephthalate. Nanomaterials 2022, 12, 3927. [Google Scholar] [CrossRef]

- Valenza, A.; Visco, A.M.; Torrisi, L.; Campo, N. Characterization of ultra-high-molecular weight polyethylene (UHMWPE) modified by ion Implantation. Polym. J. 2004, 45, 1707–1715. [Google Scholar] [CrossRef]

- Vancha, A.R.; Govindaraju, S.; Parsa, K.V.; Jasti, M.; González-García, M.; Ballestero, R.P. Use of polyethyleneimine polymer in cell culture as attachment factor and lipofection enhancer. BMC Biotechnol. 2004, 4, 1–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dangsheng, X. Friction and wear properties of UHMWPE composites reinforced with carbon fiber. Mater. Lett. 2005, 59, 175–179. [Google Scholar] [CrossRef]

- Senna, C.M.; Santos, D.; Geraldi, T.S. Coatings for saltwater Pipelines. IRJAES 2018, 5, 266–272. [Google Scholar]

- Hermann, K.P.; Geworski, L.; Muth, M.; Harder, D. Polyethylene-based water-equivalent phantom material for x-ray dosimetry at tube voltages from 10 to 100 kV. Phys. Med. Biol. 1985, 30, 1195–1200. [Google Scholar] [CrossRef] [PubMed]

- Torrisi, L. Ion Acceleration and D-D Nuclear Fusion in Laser-Generated Plasma from Advanced Deuterated Polyethylene. Molecules 2014, 19, 17052–17065. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Visco, A.M.; Brancato, V.; Torrisi, L.; Cutroneo, M. Employment of Carbon Nano Materials for the Welding of Polyethylene Joints with a Nd:YAG Laser. Int. J. Polym. Anal. 2014, 19, 489–499. [Google Scholar] [CrossRef]

- Chmutin, I.; Novokshonova, L.; Brevnov, P.; Yukhayeva, G.; Ryvkina, N. Electrical properties of UHMWPE/graphite nanoplates composites obtained by in-situ polymerization method. Polyolefins J. 2017, 4, 1–12. [Google Scholar]

- Zhang, Z.; Zhao, Y.; Li, H.; Percec, S.; Yin, J.; Ren, F. Nanoparticle-Infused UHMWPE Layer as Multifunctional Coating for High-Performance PPTA Single Fibers. Sci. Rep. 2019, 9, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Xie, K.; Wang, W.; Li, Y.; Xu, M.; Han, Z.; Zhang, Y.; Gao, W. Study on structure-performance relationship of RGO enhanced polypropylene composites with improved atomic oxygen resistance. Compos. Part B Eng. 2022, 239, 109970. [Google Scholar] [CrossRef]

- Gao, W.; Ma, Y.; Zhang, Y.; Chen, Q.; Chen, H.; Zhu, B.; Jia, J.; Huang, A.; Xie, K.; Bai, Y. Architecture & functionalization evolution of RGO affect physicomechanical properties of polyolefin/RGO composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 479–488. [Google Scholar]

- Fung, M.; Bowsher, J.G.; Van Citters, D.W. Variation of mechanical properties and oxidation with radiation dose and source in highly crosslinked remelted UHMWPE. J. Mech. Behav. Biomed. Mater. 2018, 82, 112–119. [Google Scholar] [CrossRef] [PubMed]

- Visco, A.M.; Brancato, V.; Cutroneo, M.; Torrisi, L. Nd:Yag laser irradiation of single lap joints made by polyethylene and polyethylene doped by carbon nanomaterials. J. Phys. Conf. Ser. 2014, 508, 012027. [Google Scholar] [CrossRef] [Green Version]

- Visco, A.M.; Torrisi, L.; Campo, N.; Picciotto, A. Comparison of Surface modifications induced by ion implantation in UHMWPE. Int. J. Polym. Anal. 2010, 15, 73–86. [Google Scholar] [CrossRef]

- Lorusso, A.; Nassisi, V.; Velardi, L.; Torrisi, L.; Margarone, D.; Mezzasalma, A. Characteristic modification of UHMWPE by laser-assisted ion implantation. Rad. Eff. Def. Solids 2008, 163, 447–452. [Google Scholar] [CrossRef]

- Torrisi, L.; Auditore, L.; Barnà, R.C.; De Pasquale, D.; Emanuele, U.; Loria, D.; Trifirò, A.; Trimarchi, M.; Campo, N.; Visco, A.; et al. Measurements of gas desorption from polyethylene-UHMWPE irradiated by 5 MeV Electrons. Rad. Eff. Def. Solids 2007, 162, 809–819. [Google Scholar] [CrossRef]

- Visco, A.M.; Brancato, V.; Campo, N.; Torrisi, L.; Caridi, F.; Cutroneo, M. Modification in polyethylene-iron oxide joints induced by laser irradiation. Appl. Surf. Sci. 2013, 272, 99–103. [Google Scholar] [CrossRef]

- Alnefaie, K.A. Strength and modulus of carbon nanotubes under a tensile load. J. Mech. Behav. Biomed. Mater. 2014, 23, 15–19. [Google Scholar] [CrossRef]

- Samad, M.A.; Sinha, S.K. Mechanical, thermal and tribological characterization of a UHMWPE film reinforced with carbon nanotubes coated on steel. Tribol. Int. 2011, 44, 2. [Google Scholar] [CrossRef]

- Galtieri, G.; Visco, A.; Nocita, D.; Torrisi, L.; Ceccio, G.; Scolaro, C. Polyethylene laser welding based on optical absorption variations. J. Instrum. 2016, 11, C04013. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Jawad, S.A.; El Ghanem, H.M. Electrical and dielectric behaviors of dry-mixed CNT/UHMWPE Nanocomposites. High Perform. Polym. 2014, 26, 205–211. [Google Scholar] [CrossRef]

- Visco, A.M.; Torrisi, L.; Scolaro, C. Effect of the filler amount on the optical absorption properties and the surface features of polymeric joints based on biomedical UHMWPE welded by a Nd:YAG laser. J. Thermoplast. Compos. Mater. 2016, 30, 1675–1692. [Google Scholar] [CrossRef]

- Zabolotnov, A.S.; Brevnov, P.N.; Akul’shin, V.V.; Novokshonova, L.A.; Doronin, F.A.; Evdokimov, A.G.; Nazarov, V.G. The Wear Resistance of Composite Materials Based on Ultra-High-Molecular-Weight Polyethylene with Fillers of Various Types. Polym. Sci. Ser. D 2018, 11, 297–302. [Google Scholar] [CrossRef]

- Drakopoulos, S.X.; Psarras, G.C.; Ronca, S. Oriented ultra-high molecular weight polyethylene/gold nanocomposites: Electrical conductivity and chain entanglement dynamics. Express Polym. Lett. 2021, 15, 492–502. [Google Scholar] [CrossRef]

- Scolaro, C.; Visco, A.; Torrisi, L.; Pedullà, E. White-white polymer joints made with different laser absorbing nano fillers: Physical-mechanical features. AIP Conf. Proc. 2018, 1981, 020153. [Google Scholar]

- Kang, X.; Yao, C.; Qiao, L.; Ge, G.; Feng, P. Processing and Mechanical Properties of Ultra-high Molecular Weight Polyethylene Reinforced by Silver Nanoparticles. Polym. Polym. Compos. 2017, 25, 683–688. [Google Scholar] [CrossRef]

- Kumar, V.; Alam, M.N.; Park, S.S. Soft Composites Filled with Iron Oxide and Graphite Nanoplatelets under Static and Cyclic Strain for Different Industrial Applications. Polymers 2022, 11, 2393. [Google Scholar] [CrossRef]

- Merck Carbon Nanotube, Multi-Walled. Available online: https://www.sigmaaldrich.com/IT/it/product/aldrich/698849 (accessed on 11 January 2023).

- Merck Fe2O3 Nanoparticles. Available online: https://www.sigmaaldrich.com/IT/it/search/fe2o3-nanoparticles?focus=products&page=1&perpage=30&sort=relevance&term=fe2o3%20nanoparticles&type=product_name (accessed on 11 January 2023).

- Sigle, W. Analytical transmission electron microscopy. Annu. Rev. Mater. Res. 2005, 35, 239–314. [Google Scholar] [CrossRef] [Green Version]

- De Geyter, N.; Morent, R.; Leys, C. Surface characterization of plasma-modified polyethylene by contact angle experiments and ATR-FTIR spectroscopy. Surf. Interface Anal. 2008, 40, 608–611. [Google Scholar] [CrossRef]

- Ozkahraman, B.; Tamahkar Irmak, E. Carbon nanotube based polyvinylalcohol-polyvinylpyrolidone nanocomposite hydrogels for controlled drug delivery applications. Anadolu Univ. J. Sci. Technol. A-Appl. Sci. Eng. 2007, 18, 543–553. [Google Scholar]

- Sbai, K.; Rahmani, A.; Chadli, H.; Bantignies, J.L.; Hermet, P.; Sauvajol, J.L. Infrared Spectroscopy of Single-Walled Carbon Nanotubes. J. Phys. Chem. B 2006, 110, 12388–12393. [Google Scholar] [CrossRef]

- Branca, C.; Frusteri, F.; Magazu`, V.; Mangione, A. Characterization of Carbon Nanotubes by TEM and Infrared Spectroscopy. J. Phys. Chem. B 2004, 108, 3469–3473. [Google Scholar] [CrossRef]

- Farahmandjou, M.; Soflaee, F. Synthesis and Characterization of α-Fe2O3 Nanoparticles by Simple Co-Precipitation Method. Phys. Chem. Res. 2015, 3, 191–196. [Google Scholar]

- Visco, A.; Scolaro, C.; Terracciano, T.; Montanini, R.; Quattrocchi, A.; Torrisi, L.; Restuccia, N. Static and dynamic characterization of biomedical polyethylene laser welding using biocompatible nanoparticles. EPJ Web Conf. 2018, 167, 05009. [Google Scholar] [CrossRef] [Green Version]

- Mott, N.F.; Davis, E.A. Electronic Processes in Non-Crystalline Materials, 1st ed.; Clarendon-Press: Oxford, UK, 1971; pp. 273–293. [Google Scholar]

- Abdul-Kader, A.M. The optical band gap and surface free energy of polyethylene modified by electron beam Irradiations. J. Nucl. Mater. 2013, 435, 231–235. [Google Scholar] [CrossRef]

- Sabet, M.; Soleimani, H. Mechanical and electrical properties of low density polyethylene filled with carbon nanotubes. IOP Conf. Ser. Mater. Sci. Eng. 2014, 64, 012001. [Google Scholar] [CrossRef]

- Mizuno, S.; Yao, H. On the electronic transitions of α-Fe2O3 hematite nanoparticles with different size and morphology: Analysis by simultaneous deconvolution of UV–vis absorption and MCD spectra. J. Magn. Magn. Mater. 2021, 517, 167389. [Google Scholar] [CrossRef]

- Vakhshouri, A.R.; Azizov, A.; Aliyeva, R.; Bagirova, S. Synthesis, Structure, and Thermo-Physical Properties of Fe2O3.Al2O3 and Polyethylene Nanocomposites. J. Appl. Polym. Sci. 2012, 124, 5106–5112. [Google Scholar] [CrossRef]

- Oleiwi, J.K.; Anaee, R.A.; Radhi, S.H. Roughness, wear and thermal analysis of UHMWPE nanocomposites as acetabular cup in hip joint replacement. Int. J. Mech. Prod. Eng. Res. Dev. (IJMPERD) 2018, 8, 855–864. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torrisi, A.; Torrisi, L.; Cutroneo, M.; Michalcova, A.; D’Angelo, M.; Silipigni, L. Ultra-High Molecular Weight Polyethylene Modifications Produced by Carbon Nanotubes and Fe2O3 Nanoparticles. Polymers 2023, 15, 1169. https://doi.org/10.3390/polym15051169

Torrisi A, Torrisi L, Cutroneo M, Michalcova A, D’Angelo M, Silipigni L. Ultra-High Molecular Weight Polyethylene Modifications Produced by Carbon Nanotubes and Fe2O3 Nanoparticles. Polymers. 2023; 15(5):1169. https://doi.org/10.3390/polym15051169

Chicago/Turabian StyleTorrisi, Alfio, Lorenzo Torrisi, Mariapompea Cutroneo, Alena Michalcova, Milena D’Angelo, and Letteria Silipigni. 2023. "Ultra-High Molecular Weight Polyethylene Modifications Produced by Carbon Nanotubes and Fe2O3 Nanoparticles" Polymers 15, no. 5: 1169. https://doi.org/10.3390/polym15051169

APA StyleTorrisi, A., Torrisi, L., Cutroneo, M., Michalcova, A., D’Angelo, M., & Silipigni, L. (2023). Ultra-High Molecular Weight Polyethylene Modifications Produced by Carbon Nanotubes and Fe2O3 Nanoparticles. Polymers, 15(5), 1169. https://doi.org/10.3390/polym15051169