Characterizing Pure Polymers under High Speed Compression for the Micromechanical Prediction of Unidirectional Composites

Abstract

:1. Introduction

2. Experimental Methodology

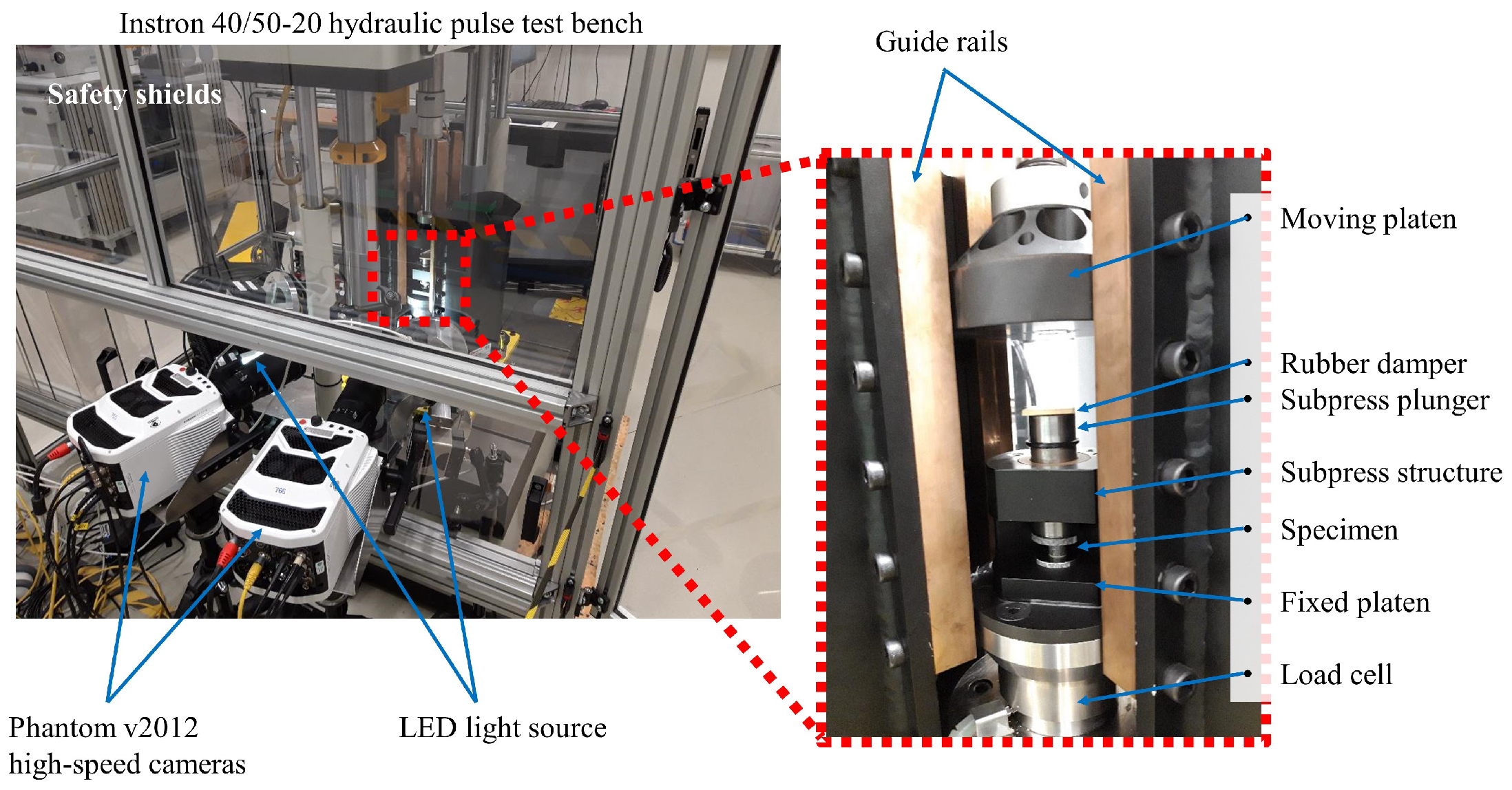

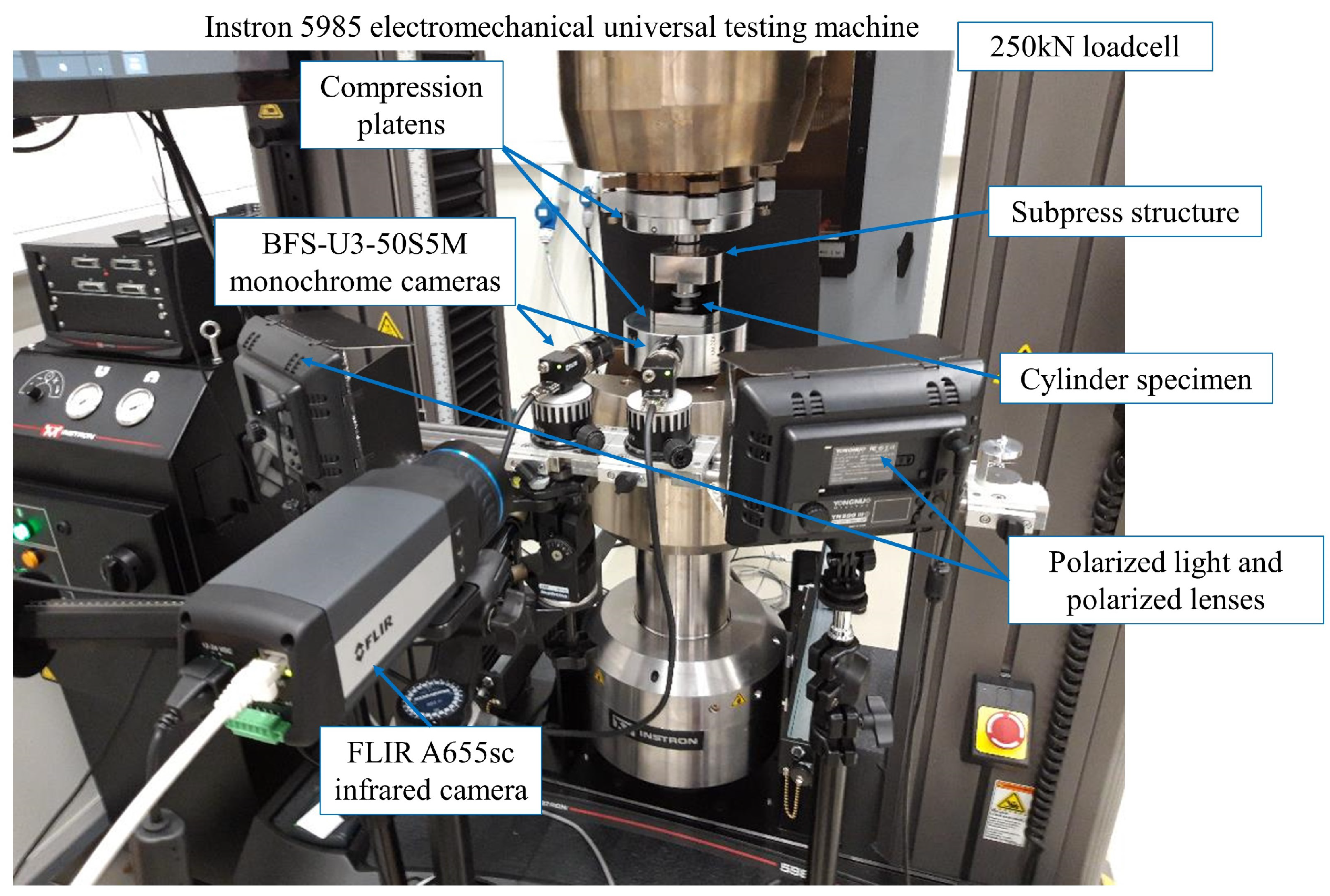

2.1. High Speed Compression Setup

2.2. Materials and Testing Conditions

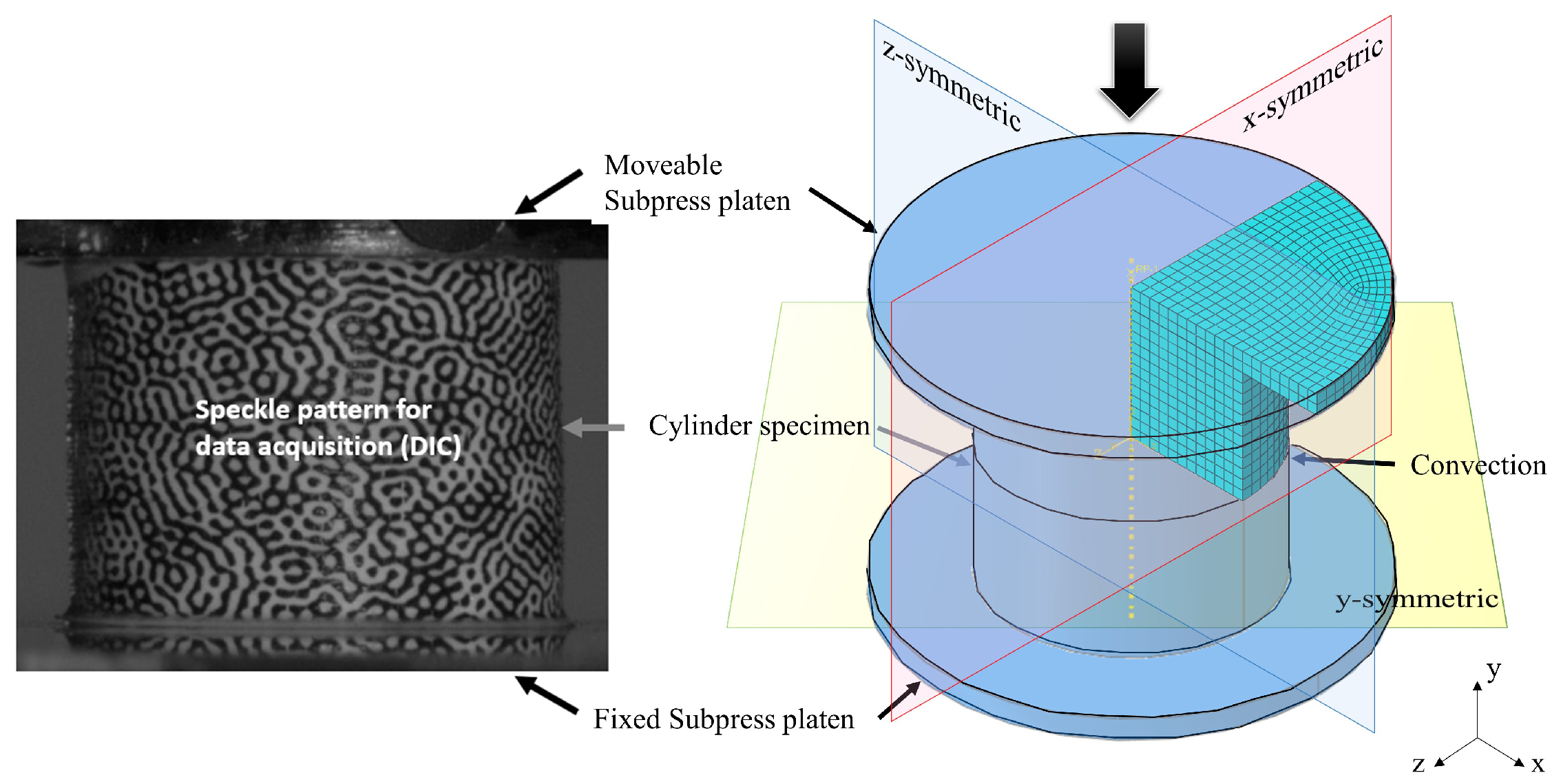

2.3. Data Acquisition

2.4. Polymer Response

2.5. Self-Heating Production and Thermal Softening

3. Constitutive Modelling

3.1. Unified Semi-Crystalline Polymer (USCP) Model

3.2. Thermomechanical Coupling

3.3. FEM Model of the High Speed Bench

3.4. Comparison FEM Versus Experiment

3.5. Predicted Temperature Profile in Quasi Static-to-Dynamic Regime

4. Application to UD Composite

4.1. RVE Micromechanical Model

4.2. Fibre–Matrix Interface

4.3. Boundary Conditions

- Case PBCs: This is the first case corresponding to the classic PBC and implemented as described in Ref. [22]. This case is considered here as the reference case.

- Case A: The RVE is uniformly and vertically loaded from the top surface, whilst the vertical displacement of the bottom surface is constrained. With respect to the lateral surfaces, in the surface pair perpendicular to the x-axis, one of the surface has blocked its movement along the x-axis. However, the other surfaces can move freely along the x-axis, but assuming that both the nodes of the fibre and the matrix are always contained in the same plane to prevent the possibility of fibre push-out when the interface is totally debonded. This condition is hereafter referred to as “Free On-plane” condition. It can be seen that Case A is very similar to considering a one-eighth model, in which the planes OX, OY and OZ are considered as symmetry planes.

- Case B: Here, the load is imposed symmetrically from the top and the bottom surfaces, but restricting the lateral displacement of the RVE. This case is highly constrained and it is used to establish an upper limit in the stress–strain response.

- Case C: this case also applies the load symmetrically, but the lateral displacement of the surfaces perpendicular to the x-axis are considered as “Free On-plane” conditions. However, the displacements of the surfaces perpendicular to the fibre direction, namely the z-axis, are set to zero. This condition can be seen as an equivalent case to the plane strain condition. Since the fibres are very stiff, in case of transverse compression, it is reasonable to assume that the in-plane displacements will be negligible compared to the transverse ones.

5. Model Prediction of UD Composites under High Compression Rate

5.1. Stress-Strain Response: General Assessment

5.2. Strain Rate Effect

5.3. Fibre Debonding Effect

5.4. Self-Heating Influence: Local vs. Global Effect

6. Conclusions

- In-house high-speed compression tests were performed for a toughened epoxy PR520 and a semi-crystalline thermoplastic PEEK. Three-dimensional stereo DIC and infrared camera systems were integrated to investigate the rate-sensitivity and self-heating effect.

- An advanced glassy polymer model (USCP) was used to characterize the rate-dependence of different thermosets and thermoplastics. The rubbery effect, double yield of SCPs, and thermal softening were accurately predicted for various polymers.

- The rate-dependence of UD composites is naturally captured by applying the USCP model for polymer matrices. The numerical results of the RVE analyses show that the nonlinear response in the small strain range () is attributed to the synergy of the viscoplastic behaviour of the polymer matrix and the interface debonding.

- An alternative boundary condition was used, which provides a similar result compared to the reference case using PBCs. This BC is proved to be very computationally efficient for the case of an adequately large RVE.

- Both CF/PR520 and CF/PEEK systems experience an excessive strain localization. A large local plastic strain up to 0.19 can be found in the matrix at a macroscopical strain level of 0.035.

- Insights of the self-heating and thermal softening induced by the polymer matrix on the global response were provided. The average temperature at a lower strain rate remains higher and more homogeneous thanks to the long testing period allowing the heat diffusion throughout the RVE.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Thermomechanical Properties and Identified Model Parameters

| Material Parameter | Unit | PA6 | PEEK | PR520 | Description |

|---|---|---|---|---|---|

| Mechanical constants | |||||

| GPa | 2.62 | 4.33 | 4.28 | Modulus at | |

| K | 296 | 298 | 298 | Reference temperature | |

| - | 0.39 | 0.37 | 0.40 | Poisson’s ratio | |

| 1/K | 0.0036 | 0.0007 | 0.0012 | Temperature dependence | |

| - | 0 | 0 | 0 | Pressure sensitivity | |

| 1/s | 3.55 × 1011 | 4.27 × 104 | 1.76 × 109 | Rate sensitivity | |

| m | - | 0.83 | 0.66 | 0.66 | Rate sensitivity |

| A | K/MPa | 104 | 177.4 | 133.8 | Rate sensitivity |

| MPa | 184 | 161.6 | 172.3 | Initial equivalent strength | |

| MPa | 196 | 174.8 | 242.5 | Athermal peak strength | |

| MPa | 193 | 169.3 | 179.5 | First saturation strength | |

| MPa | 234 | - | - | Second saturation strength | |

| MPa | 32351 | 3747 | 6798 | Pre-peak hardening | |

| MPa | 14827 | 959 | 635 | Post-peak softening | |

| MPa | 681 | - | - | Second yield hardening | |

| - | 0.009 | 0.0566 | 0.0407 | Peak plastic strain | |

| - | 0.0295 | - | - | Activation plastic strain | |

| f | - | 0.3 | 0.3 | 0.3 | Smooth factor |

| MPa | - | - | 13.5 | Rubbery modulus | |

| N | - | - | - | 1.7 | number of rigid links |

| Physical constants | |||||

| kg/m | 1200 | 1300 | 1250 | Density | |

| k | W/m K | 0.25 | 0.25 | 0.192 | Thermal conductivity |

| J/kg K | 1700 | 1330 | 1100 | Specific heat | |

| Density | Mechanical | Thermal | ||||||

|---|---|---|---|---|---|---|---|---|

| (kg/m) | (GPa) | (GPa) | (GPa) | (GPa) | (W/m K) | (W/m K) | (J/kg K) | |

| 1800 | 276 | 15 | 0.2 | 15 | 7 | 10.2 | 1.256 | 750 |

| Strength | Critical Energy Release Rates | Mixed-Mode (BK Law) | ||||

|---|---|---|---|---|---|---|

| (MPa) | (MPa) | (MPa) | (N/mm) | (N/mm) | (N/mm) | |

| 75 | 75 | 50 | 0.002 | 0.006 | 0.006 | 1.45 |

References

- Hsiao, H.; Daniel, I. Strain rate behavior of composite materials. Compos. B Eng. 1998, 29, 521–533. [Google Scholar] [CrossRef]

- Koyanagi, J.; Sato, Y.; Sasayama, T.; Okabe, T.; Yoneyama, S. Numerical simulation of strain-rate dependent transition of transverse tensile failure mode in fiber-reinforced composites. Compos. Part A Appl. Sci. 2014, 56, 136–142. [Google Scholar] [CrossRef]

- Ullah, Z.; Kaczmarczyk, L.; Pearce, C. Three-dimensional nonlinear micro/meso-mechanical response of the fibre-reinforced polymer composites. Compos. Struct. 2017, 161, 204–214. [Google Scholar] [CrossRef] [Green Version]

- Koerber, H.; Kuhn, P.; Ploeckl, M.; Otero, F.; Gerbaud, P.W.; Rolfes, R.; Camanho, P.P. Experimental characterization and constitutive modeling of the non-linear stress–strain behavior of unidirectional carbon–epoxy under high strain rate loading. Adv. Model. Simul. Eng. Sci. 2018, 5, 17. [Google Scholar] [CrossRef]

- Chevalier, J.; Camanho, P.P.; Lani, F.; Pardoen, T. Multi-scale characterization and modelling of the transverse compression response of unidirectional carbon fiber reinforced epoxy. Compos. Struct. 2019, 209, 160–176. [Google Scholar] [CrossRef]

- Massaq, A.; Rusinek, A.; Klosak, M.; Bahi, S.; Arias, A. Strain rate effect on the mechanical behavior of polyamide composites under compression loading. Compos. Struct. 2019, 214, 114–122. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects. Polym. Test. 2016, 51, 151–164. [Google Scholar] [CrossRef]

- Kim, D.H.; Kang, S.Y.; Kim, H.J.; Kim, H.S. Strain rate dependent mechanical behavior of glass fiber reinforced polypropylene composites and its effect on the performance of automotive bumper beam structure. Compos. Part B Eng. 2019, 166, 483–496. [Google Scholar] [CrossRef]

- Sommer, J.; Hajikazemi, M.; De Baere, I.; Van Paepegem, W. Experimental and numerical damage characterization of glass/polypropylene multidirectional laminates under quasi-static loading condition. Compos. Sci. Technol. 2022, 227, 109569. [Google Scholar] [CrossRef]

- Spronk, S.W.F.; Verboven, E.; Gilabert, F.A.; Sevenois, R.D.B.; Garoz, D.; Kersemans, M.; Van Paepegem, W. Stress-strain synchronization for high strain rate tests on brittle composites. Polym. Test. 2018, 67, 477–486. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Sun, L.; Li, L.; Wei, J. Effects of strain rate and high temperature environment on the mechanical performance of carbon fiber reinforced thermoplastic composites fabricated by hot press molding. Compos. Part A Appl. Sci. 2020, 134, 105905. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Omidi, M.J. Investigating the transverse behavior of Glass–Epoxy composites under intermediate strain rates. Compos. Struct. 2011, 93, 690–696. [Google Scholar] [CrossRef]

- Ploeckl, M.; Kuhn, P.; Grosser, J.; Wolfahrt, M.; Koerber, H. A dynamic test methodology for analyzing the strain-rate effect on the longitudinal compressive behavior of fiber-reinforced composites. Compos. Struct. 2017, 180, 429–438. [Google Scholar] [CrossRef]

- Koerber, H.; Xavier, J.; Camanho, P. High strain rate characterisation of unidirectional carbon-epoxy IM7-8552 in transverse compression and in-plane shear using digital image correlation. Mech. Mater. 2010, 42, 1004–1019. [Google Scholar] [CrossRef]

- Siviour, C.R.; Jordan, J.L. High Strain Rate Mechanics of Polymers: A Review. J. Dyn. Behav. Mater. 2016, 2, 15–32. [Google Scholar] [CrossRef] [Green Version]

- Koyanagi, J.; Yoneyama, S.; Nemoto, A.; Melo, J.D.D. Time and temperature dependence of carbon/epoxy interface strength. Compos. Sci. Technol. 2010, 70, 1395–1400. [Google Scholar] [CrossRef]

- Spronk, S. Investigation of the Rate-Dependency of Carbon/Epoxy and Glass/Polyamide-6 Composites in Tension, Mode-I Delamination and Low-Velocity Impact. Ph.D. Thesis, Ghent University, Ghent, The Netherlands, 2018. [Google Scholar]

- Fattahi, A.; Mondali, M. Theoretical study of stress transfer in platelet reinforced composites. J. Theor. Appl. Mech. 2014, 52, 3–14. [Google Scholar]

- Tebeta, R.; Fattahi, A.; Ahmed, N. Experimental and numerical study on HDPE/SWCNT nanocomposite elastic properties considering the processing techniques effect. Microsyst. Technol. 2020, 26, 2423–2441. [Google Scholar] [CrossRef]

- Khalid, H.M.; Ojo, S.O.; Weaver, P.M. Inverse differential quadrature method for structural analysis of composite plates. Comput. Struct. 2022, 263, 106745. [Google Scholar] [CrossRef]

- Kabir, H.; Aghdam, M.M. A generalized 2D Bézier-based solution for stress analysis of notched epoxy resin plates reinforced with graphene nanoplatelets. Thin-Walled Struct. 2021, 169, 108484. [Google Scholar] [CrossRef]

- Garoz, D.; Gilabert, F.; Sevenois, R.; Spronk, S.; Van Paepegem, W. Consistent application of periodic boundary conditions in implicit and explicit finite element simulations of damage in composites. Compos. B. Eng. 2019, 168, 254–266. [Google Scholar] [CrossRef]

- Sharma, A.; Daggumati, S.; Gupta, A.; Van Paepegem, W. On the prediction of the bi-axial failure envelope of a UD CFRP composite lamina using computational micromechanics: Effect of microscale parameters on macroscale stress–strain behavior. Compos. Struct. 2020, 251, 112605. [Google Scholar] [CrossRef]

- Melro, A.; Camanho, P.; Andrade Pires, F.; Pinho, S. Micromechanical analysis of polymer composites reinforced by unidirectional fibres: Part I—Constitutive modelling. Int. J. Solids Struct. 2013, 50, 1897–1905. [Google Scholar] [CrossRef] [Green Version]

- Arteiro, A.; Catalanotti, G.; Melro, A.; Linde, P.; Camanho, P. Micro-mechanical analysis of the effect of ply thickness on the transverse compressive strength of polymer composites. Compos. Part A Appl. Sci. 2015, 79, 127–137. [Google Scholar] [CrossRef] [Green Version]

- Varandas, L.; Dalli, D.; Catalanotti, G.; Falzon, B. Estimating the mode I through-thickness intralaminar R -curve of unidirectional carbon fibre-reinforced polymers using a micromechanics framework combined with the size effect method. Compos. Part A Appl. Sci. 2022, 162, 107141. [Google Scholar] [CrossRef]

- Arruda, E.M.; Boyce, M.C.; Jayachandran, R. Effects of strain rate, temperature and thermomechanical coupling on the finite strain deformation of glassy polymers. Mech. Mater. 1995, 19, 193–212. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, D.; Zaera, R.; Arias, A. A hyperelastic-thermoviscoplastic constitutive model for semi-crystalline polymers: Application to PEEK under dynamic loading conditions. Int. J. Plast. 2017, 88, 27–52. [Google Scholar] [CrossRef] [Green Version]

- Hao, P.; Dai, Z.; Laheri, V.; Gilabert, F.A. A unified amorphous-crystalline viscoplastic hardening law for non-isothermal modelling of thermoplastics and thermosets. Int. J. Plast. 2022, 159. [Google Scholar] [CrossRef]

- Hao, P.; Spronk, S.W.F.; Van Paepegem, W.; Gilabert, F.A. Hydraulic-based testing and material modelling to investigate uniaxial compression of thermoset and thermoplastic polymers in quasistatic-to-dynamic regime. Mater. Des. 2022, 224, 111367. [Google Scholar] [CrossRef]

- Poulain, X.; Benzerga, A.; Goldberg, R. Finite-strain elasto-viscoplastic behavior of an epoxy resin: Experiments and modeling in the glassy regime. Int. J. Plast. 2014, 62, 138–161. [Google Scholar] [CrossRef]

- Boyce, M.C.; Parks, D.M.; Argon, A.S. Large inelastic deformation of glassy polymers. part I: Rate dependent constitutive model. Mech. Mater. 1988, 7, 15–33. [Google Scholar] [CrossRef]

- Brooks, N.W.; Duckett, R.A.; Ward, I.M. Investigation into double yield points in polyethylene. Polymer 1992, 33, 1872–1880. [Google Scholar] [CrossRef]

- Plaza, A.R.; Ramos, E.; Manzur, A.; Olayo, R.; Escobar, A. Double yield points in triblends of LDPE, LLDPE and EPDM. J. Mater. Sci. 1997, 32, 549–554. [Google Scholar] [CrossRef]

- Luo, H.; Fu, Z.; Jing, B.; Shi, J.; Zou, X.; Dai, W. Tensile behaviors of polyamide 6/UHLE blends. J. Mater. Sci. 2009, 44, 3694–3701. [Google Scholar] [CrossRef]

- Laheri, V.; Hao, P.; Gilabert, F.A. Efficient non-iterative modelling of pressure-dependent plasticity using paraboloidal yield criterion. Int. J. Mech. Sci. 2022, 217, 106988. [Google Scholar] [CrossRef]

- Gilabert, F.A.; Roux, J.N.; Castellanos, A. Computer simulation of model cohesive powders: Influence of assembling procedure and contact laws on low consolidation states. Phys. Rev. E 2007, 75, 11303. [Google Scholar] [CrossRef] [Green Version]

- SIMULIA User Assistance 2022, ABAQUS; Dassault Systemes Simulia Corp.: Johnston, RI, USA, 2022.

- Dong, K.; Liu, K.; Zhang, Q.; Gu, B.; Sun, B. Experimental and numerical analyses on the thermal conductive behaviors of carbon fiber/epoxy plain woven composites. Int. J. Heat Mass Transf. 2016, 102, 501–517. [Google Scholar] [CrossRef] [Green Version]

- Benzeggagh, M.; Kenane, M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 1996, 56, 439–449. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H. Cohesive Zone Models: A Critical Review of Traction-Separation Relationships Across Fracture Surfaces. Appl. Mech. Rev. 2013, 64, 060802. [Google Scholar] [CrossRef]

- Geers, M.; Kouznetsova, V.; Brekelmans, W. Multi-scale computational homogenization: Trends and challenges. J. Comput. Appl. Math. 2010, 234, 2175–2182. [Google Scholar] [CrossRef]

- Henyš, P.; Čapek, L.; Březina, J. Comparison of current methods for implementing periodic boundary conditions in multi-scale homogenisation. Eur. J. Mech. A/Solids 2019, 78, 103825. [Google Scholar] [CrossRef]

- Sevenois, R.D.B.; Hao, P.; Van Paepegem, W.; Gilabert, F.A. Numerical Study on the Effect of Matrix Self-Heating on the Thermo-Visco-Plastic Response of Continuous Fiber-Reinforced Polymers under Transverse Tensile Loading. Polymers 2022, 14, 1941. [Google Scholar] [CrossRef]

- Terada, K.; Hori, M.; Kyoya, T.; Kikuchi, N. Simulation of the multi-scale convergence in computational homogenization approaches. Int. J. Solids Struct. 2000, 37, 2285–2311. [Google Scholar] [CrossRef]

- Geers, M.G.D.; Kouznetsova, V.G.; Brekelmans, W.A.M. Computational homogenization. In Multiscale Modelling of Plasticity and Fracture by Means of Dislocation Mechanics; Pippan, R., Gumbsch, P., Eds.; Springer: Vienna, Austria, 2010; pp. 327–394. [Google Scholar]

- Werner, H.; Gese, H. Zur Bedeutung dehnratenabhängiger Werkstoffkennwerte in der Crashsimulation. In Kennwertermittlung für die Praxis; Frenz, H., Wehrstedt, A., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2007; pp. 139–146. [Google Scholar]

| Case | A | B | C | PBCs |

|---|---|---|---|---|

| CF/PA6 | 754 | 729 | 772 | 21508 † |

| CF/PR520 | 744 | 714 | 748 | 35137 |

| CF/PEEK | 1170 | 1118 | 1181 | 71579 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, P.; Spronk, S.W.F.; Sevenois, R.D.B.; Van Paepegem, W.; Gilabert, F.A. Characterizing Pure Polymers under High Speed Compression for the Micromechanical Prediction of Unidirectional Composites. Polymers 2023, 15, 1262. https://doi.org/10.3390/polym15051262

Hao P, Spronk SWF, Sevenois RDB, Van Paepegem W, Gilabert FA. Characterizing Pure Polymers under High Speed Compression for the Micromechanical Prediction of Unidirectional Composites. Polymers. 2023; 15(5):1262. https://doi.org/10.3390/polym15051262

Chicago/Turabian StyleHao, Pei, Siebe W. F. Spronk, Ruben D. B. Sevenois, Wim Van Paepegem, and Francisco A. Gilabert. 2023. "Characterizing Pure Polymers under High Speed Compression for the Micromechanical Prediction of Unidirectional Composites" Polymers 15, no. 5: 1262. https://doi.org/10.3390/polym15051262