Effect of Sulfonated Inorganic Additives Incorporated Hybrid Composite Polymer Membranes on Enhancing the Performance of Microbial Fuel Cells

Abstract

:1. Introduction

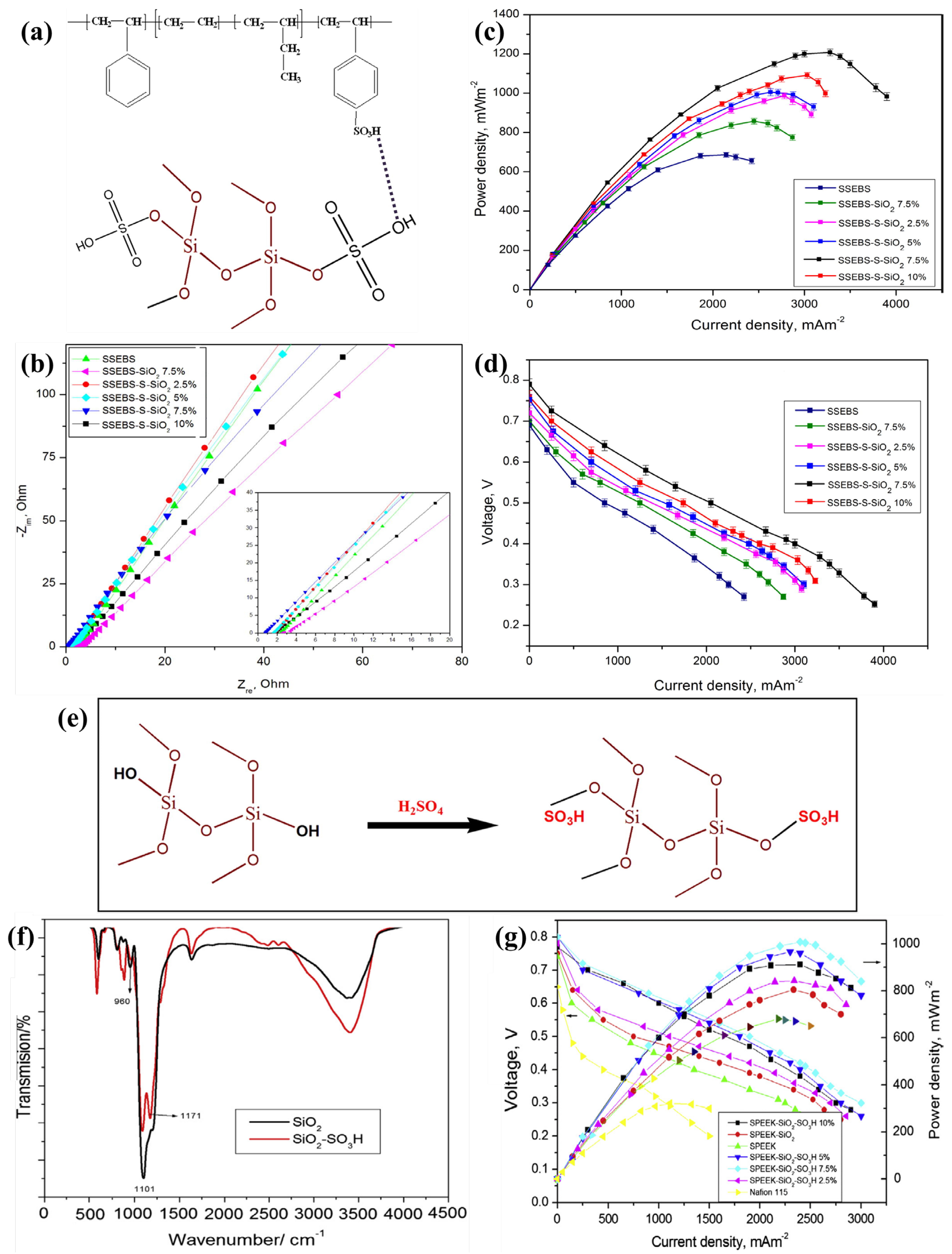

2. Sulfonated Silica Incorporated Polymer Membrane for MFC Applications

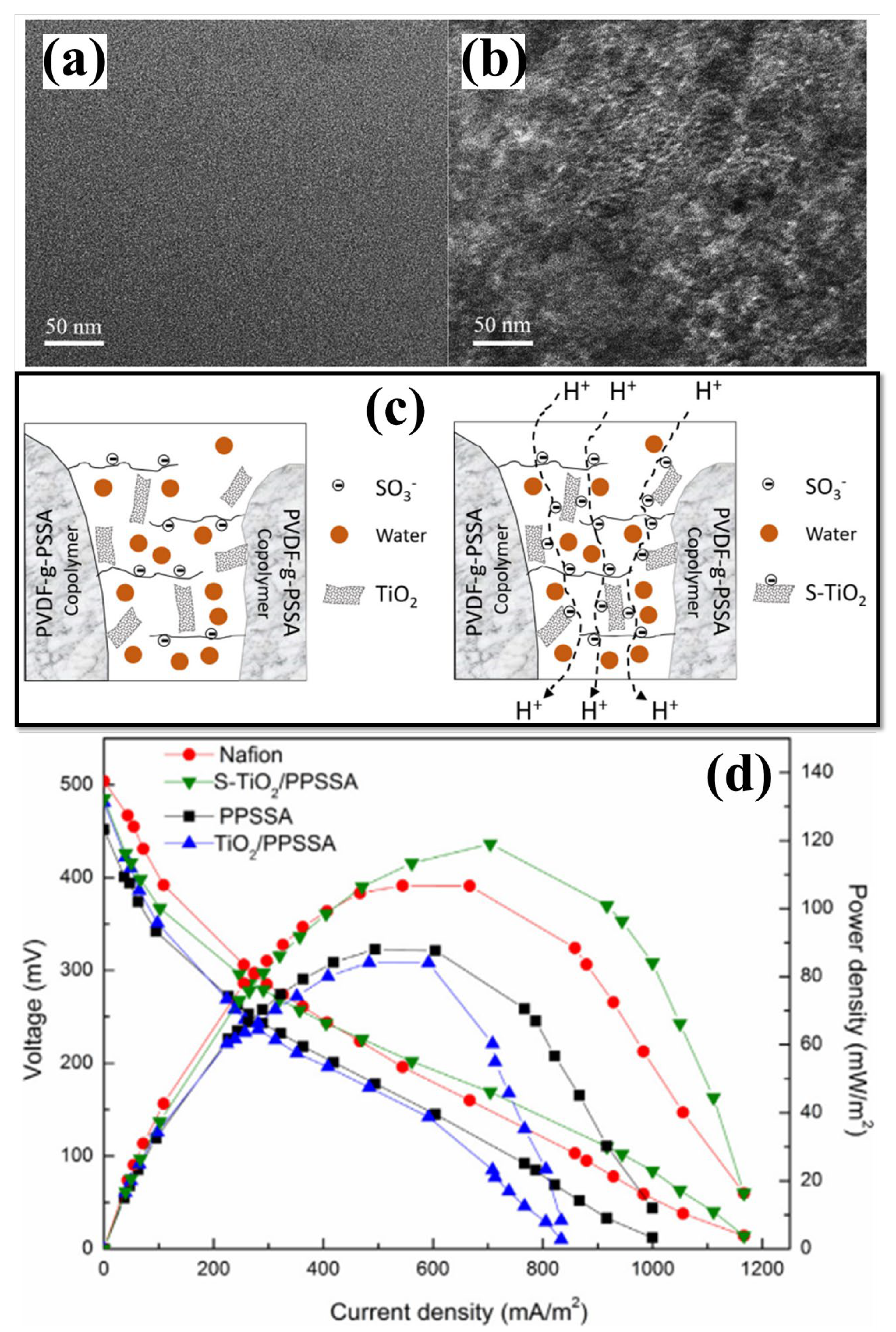

3. Sulfonated TiO2 Containing Polymer Membrane for MFC Applications

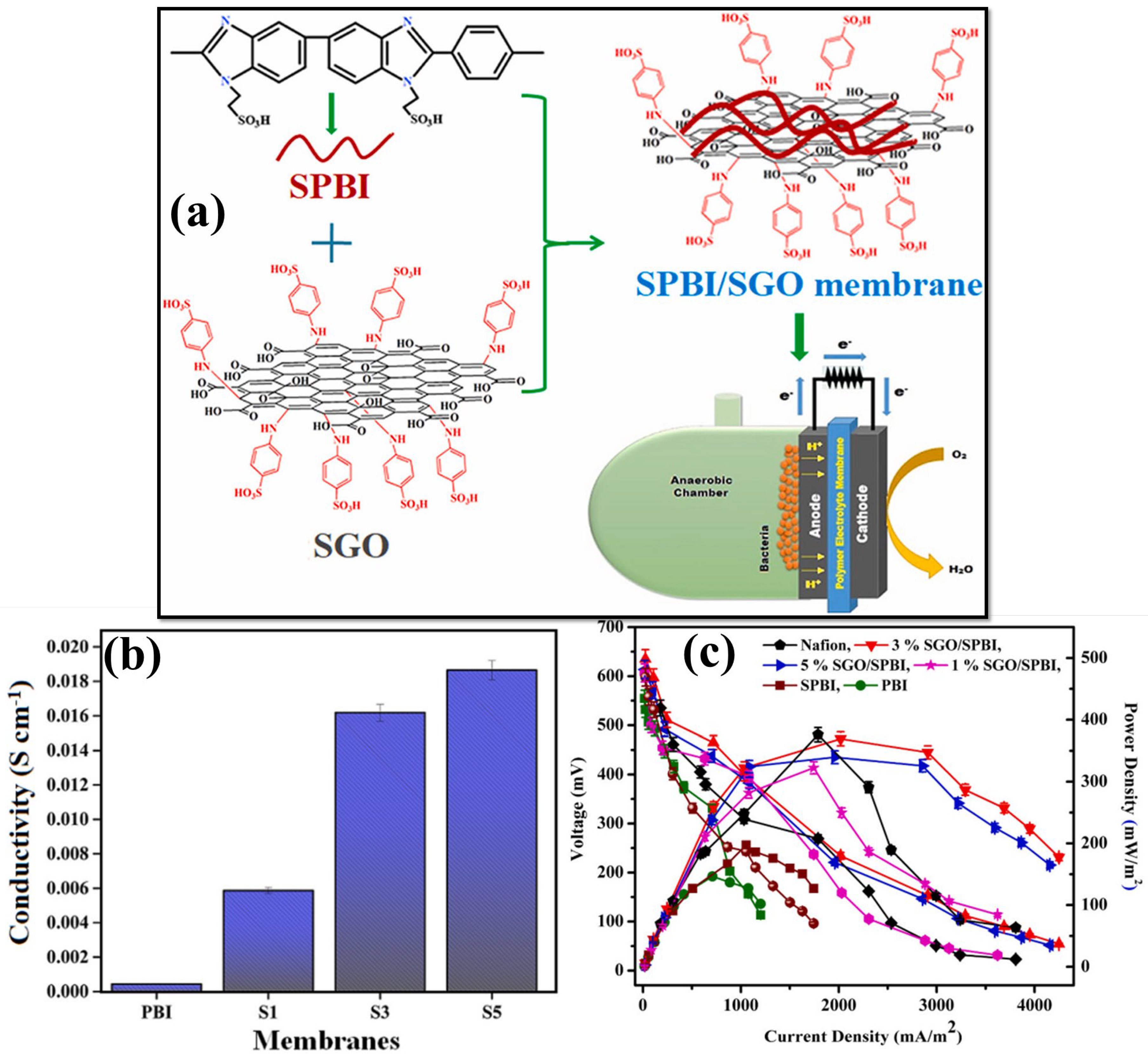

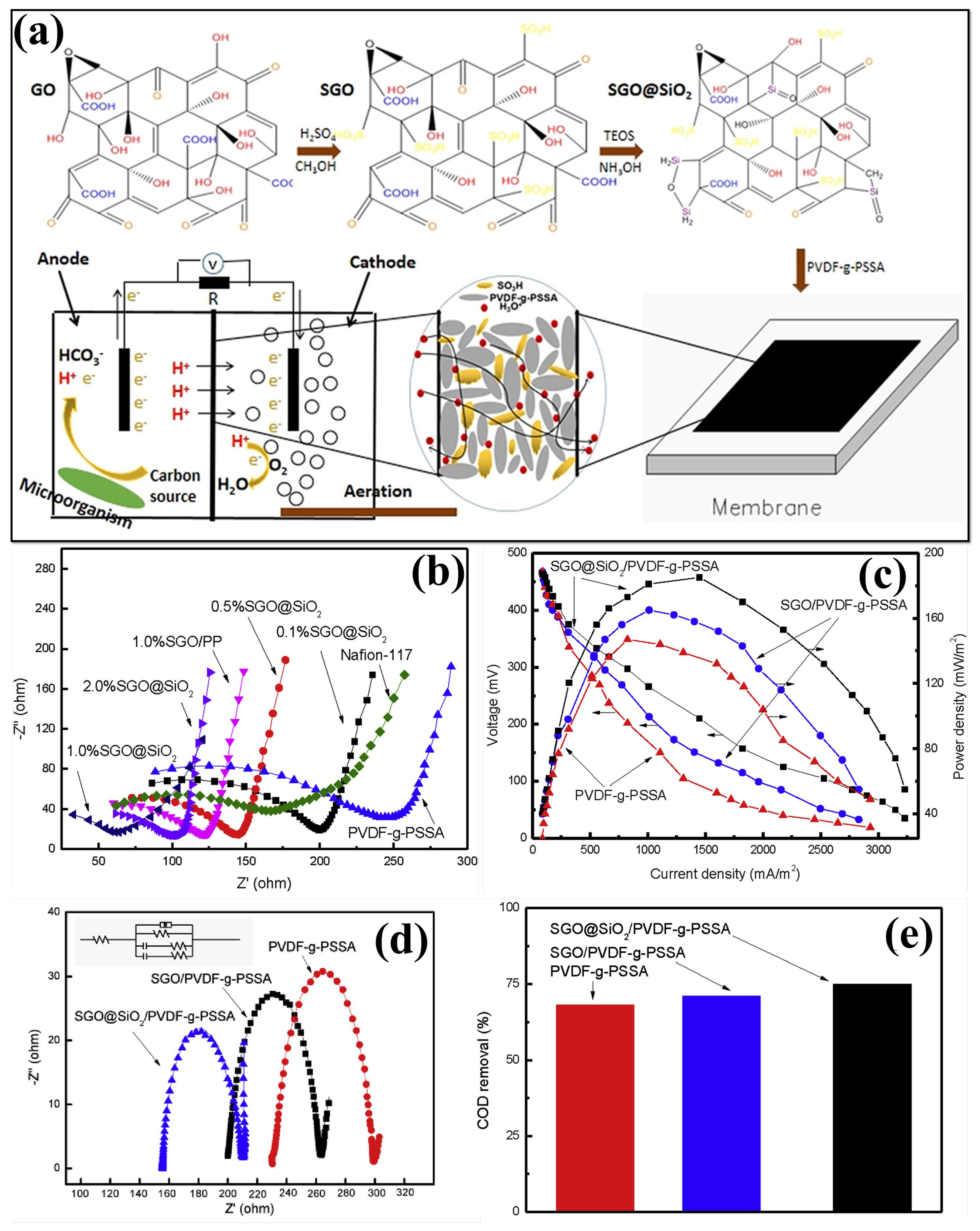

4. Sulfonated Graphene Oxide Containing Polymer Membrane for MFC Applications

5. Sulfonated Fe3O4 Containing Polymer Membrane for MFC Applications

6. Different Kinds of Sulfonated Additives in Polymer Membrane for MFC Applications

7. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Abdelkareem, M.A.; Elsaid, K.; Wilberforce, T.; Kamil, M.; Sayed, E.T.; Olabi, A. Environmental aspects of fuel cells: A review. Sci. Total. Environ. 2021, 752, 141803. [Google Scholar] [CrossRef] [PubMed]

- Sazali, N.; Wan Salleh, W.N.; Jamaludin, A.S.; Mhd Razali, M.N. New Perspectives on Fuel Cell Technology: A Brief Review. Membranes 2020, 10, 99. [Google Scholar] [CrossRef] [PubMed]

- Olabi, A.; Wilberforce, T.; Abdelkareem, M.A. Fuel cell application in the automotive industry and future perspective. Energy 2021, 214, 118955. [Google Scholar] [CrossRef]

- Stambouli, A.B.; Traversa, E. Fuel cells, an alternative to standard sources of energy. Renew. Sustain. Energy Rev. 2002, 6, 295–304. [Google Scholar] [CrossRef]

- Ang, T.-Z.; Salem, M.; Kamarol, M.; Das, H.S.; Nazari, M.A.; Prabaharan, N. A comprehensive study of renewable energy sources: Classifications, challenges and suggestions. Energy Strat. Rev. 2022, 43, 100939. [Google Scholar] [CrossRef]

- Zhao, J.; Patwary, A.K.; Qayyum, A.; Alharthi, M.; Bashir, F.; Mohsin, M.; Hanif, I.; Abbas, Q. The determinants of renewable energy sources for the fueling of green and sustainable economy. Energy 2022, 238, 122029. [Google Scholar] [CrossRef]

- Sadhasivam, T.; Jung, H.Y. Chapter 3—Nanostructured bifunctional electrocatalyst support materials for unitized regenerative fuel cells. In Nanostructured, Functional, and Flexible Materials for Energy Conversion and Storage Systems; Pandikumar, A., Rameshkumar, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 69–103. [Google Scholar]

- Thangarasu, S.; Oh, T.H. Progress in poly(phenylene oxide) based cation exchange membranes for fuel cells and redox flow batteries applications. Int. J. Hydrogen Energy 2021, 46, 38381–38415. [Google Scholar] [CrossRef]

- Thangarasu, S.; Oh, T.-H. Recent Developments on Bioinspired Cellulose Containing Polymer Nanocomposite Cation and Anion Exchange Membranes for Fuel Cells (PEMFC and AFC). Polymers 2022, 14, 5248. [Google Scholar] [CrossRef]

- Roh, S.-H.; Palanisamy, G.; Sadhasivam, T.; Jin, J.-E.; Shim, J.-Y.; Jung, H.-Y. Techno-Economical Feasibility of Biocellulose Membrane along with Polyethylene Film as a Separator for Lead-Acid Batteries. ACS Sustain. Chem. Eng. 2019, 7, 8789–8797. [Google Scholar] [CrossRef]

- Palanisamy, G.; Sadhasivam, T.; Park, W.-S.; Bae, S.T.; Roh, S.-H.; Jung, H.-Y. Tuning the Ion Selectivity and Chemical Stability of a Biocellulose Membrane by PFSA Ionomer Reinforcement for Vanadium Redox Flow Battery Applications. ACS Sustain. Chem. Eng. 2020, 8, 2040–2051. [Google Scholar] [CrossRef]

- Magdum, S.S.; Thangarasu, S.; Oh, T.H. Three-Dimensional Ternary rGO/VS2/WS2 Composite Hydrogel for Supercapacitor Applications. Inorganics 2022, 10, 229. [Google Scholar] [CrossRef]

- Lin, T.W.; Sadhasivam, T.; Wang, A.Y.; Chen, T.Y.; Lin, J.Y.; Shao, L.D. Ternary Composite Nanosheets with MoS2/WS2/Graphene Heterostructures as High-Performance Cathode Materials for Supercapacitors. ChemElectroChem 2018, 5, 1024–1031. [Google Scholar] [CrossRef]

- Winter, M.; Brodd, R.J. What Are Batteries, Fuel Cells, and Supercapacitors? Chem. Rev. 2004, 104, 4245–4270. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cyril, P.H.; Saravanan, G. Development of advanced materials for cleaner energy generation through fuel cells. N. J. Chem. 2020, 44, 19977–19995. [Google Scholar] [CrossRef]

- Fan, L.; Tu, Z.; Chan, S.H. Recent development of hydrogen and fuel cell technologies: A review. Energy Rep. 2021, 7, 8421–8446. [Google Scholar] [CrossRef]

- Golubenko, D.V.; Korchagin, O.V.; Voropaeva, D.Y.; Bogdanovskaya, V.A.; Yaroslavtsev, A.B. Membranes Based on Polyvinylidene Fluoride and Radiation-Grafted Sulfonated Polystyrene and Their Performance in Proton-Exchange Membrane Fuel Cells. Polymers 2022, 14, 3833. [Google Scholar] [CrossRef] [PubMed]

- Samsudin, A.M.; Bodner, M.; Hacker, V. A Brief Review of Poly(Vinyl Alcohol)-Based Anion Exchange Membranes for Alkaline Fuel Cells. Polymers 2022, 14, 3565. [Google Scholar] [CrossRef]

- Wang, R.-T.; Chang, H.-Y.; Wang, J.-C. An Overview on the Novel Core-Shell Electrodes for Solid Oxide Fuel Cell (SOFC) Using Polymeric Methodology. Polymers 2021, 13, 2774. [Google Scholar] [CrossRef]

- Jang, I.; Ahn, M.; Lee, S.; Yoo, S.J. Surfactant assisted geometric barriers on PtNi@C electrocatalyst for phosphoric acid fuel cells. J. Ind. Eng. Chem. 2022, 110, 198–205. [Google Scholar] [CrossRef]

- Luo, J.; Tian, W.; Jin, H.; Yang, J.; Li, J.; Wang, Y.; Shen, W.; Ren, Y.; Zhou, M. Recent advances in microbial fuel cells: A review on the identification technology, molecular tool and improvement strategy of electricigens. Curr. Opin. Electrochem. 2023, 37, 101187. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, J.; Zhang, Y.; Guo, Q.; Hu, T.; Xiao, H.; Lu, W.; Jia, J. Progress on anodic modification materials and future development directions in microbial fuel cells. J. Power Sources 2023, 556, 232486. [Google Scholar] [CrossRef]

- Palanisamy, G.; Thangarasu, S.; Dharman, R.K.; Patil, C.S.; Negi, T.P.P.S.; Kurkuri, M.D.; Pai, R.K.; Oh, T.H. The growth of biopolymers and natural earthen sources as membrane/separator materials for microbial fuel cells: A comprehensive review. J. Energy Chem. 2023; in press. [Google Scholar] [CrossRef]

- Pasquini, L.; Zhakisheva, B.; Sgreccia, E.; Narducci, R.; Di Vona, M.; Knauth, P. Stability of Proton Exchange Membranes in Phosphate Buffer for Enzymatic Fuel Cell Application: Hydration, Conductivity and Mechanical Properties. Polymers 2021, 13, 475. [Google Scholar] [CrossRef] [PubMed]

- Palanisamy, G.; Oh, T.H.; Thangarasu, S. Modified Cellulose Proton-Exchange Membranes for Direct Methanol Fuel Cells. Polymers 2023, 15, 659. [Google Scholar] [CrossRef] [PubMed]

- Milewski, J.; Zdeb, J.; Szczęśniak, A.; Martsinchyk, A.; Kupecki, J.; Dybiński, O. Concept of a solid oxide electrolysis-molten carbonate fuel cell hybrid system to support a power-to-gas installation. Energy Convers. Manag. 2023, 276, 116582. [Google Scholar] [CrossRef]

- Saritha, D.; Reddy, N.M.; Ramesh, G.V. Pt- and Pd- based intermetallic anode catalysts for direct ethanol fuel cell (DEFC): An overview. Mater. Today Proc. 2022, 64, 357–362. [Google Scholar] [CrossRef]

- Thangarasu, S.; Jung, H.-Y.; Wee, J.-H.; Kim, Y.A.; Roh, S.-H. A new strategy of carbon—Pb composite as a bipolar plate material for unitized regenerative fuel cell system. Electrochim. Acta 2021, 391, 138921. [Google Scholar] [CrossRef]

- SRoh, S.-H.; Sadhasivam, T.; Kim, H.; Park, J.-H.; Jung, H.-Y. Carbon free SiO2–SO3H supported Pt bifunctional electrocatalyst for unitized regenerative fuel cells. Int. J. Hydrogen Energy 2016, 41, 20650–20659. [Google Scholar]

- Gouda, M.H.; Elessawy, N.A.; Al-Hussain, S.A.; Toghan, A. Design of Promising Green Cation-Exchange-Membranes-Based Sulfonated PVA and Doped with Nano Sulfated Zirconia for Direct Borohydride Fuel Cells. Polymers 2021, 13, 4205. [Google Scholar] [CrossRef]

- Cheng, Y.; Sun, Y.; Deng, X.; Zhang, M.; Zhang, L.; Wang, W. High-performance high-entropy quinary-alloys as anode catalysts for direct ethylene glycol fuel cells. Int. J. Hydrogen Energy 2022, 48, 8156–8164. [Google Scholar] [CrossRef]

- Banjong, J.; Therdthianwong, A.; Therdthianwong, S.; Yongprapat, S.; Wongyao, N. High performance alkaline-acid direct glycerol fuel cells for portable power supplies via electrode structure design. Int. J. Hydrogen Energy 2020, 45, 2244–2256. [Google Scholar] [CrossRef]

- Jałowiecka, M.; Bojarska, Z.; Małolepszy, A.; Makowski, Ł. Mass transport enhancement in direct formic acid fuel cell with a novel channel design. Chem. Eng. J. 2023, 451, 138474. [Google Scholar] [CrossRef]

- Palanisamy, G.; Jung, H.-Y.; Sadhasivam, T.; Kurkuri, M.D.; Kim, S.C.; Roh, S.-H. A comprehensive review on microbial fuel cell technologies: Processes, utilization, and advanced developments in electrodes and membranes. J. Clean. Prod. 2019, 221, 598–621. [Google Scholar] [CrossRef]

- Mukimin, A.; Vistanty, H. Low carbon development based on microbial fuel cells as electrical generation and wastewater treatment unit. Renew. Energy Focus 2023, 44, 132–138. [Google Scholar] [CrossRef]

- Sonawane, J.M.; Mahadevan, R.; Pandey, A.; Greener, J. Recent progress in microbial fuel cells using substrates from diverse sources. Heliyon 2022, 8, e12353. [Google Scholar] [CrossRef] [PubMed]

- Bhagat, M.S.; Mungray, A.K.; Mungray, A.A. Mungray, Recent advances in osmotic microbial fuel cell technology: A review. J. Indian Chem. Soc. 2022, 99, 100552. [Google Scholar] [CrossRef]

- Barakat, N.A.M.; Amen, M.T.; Ali, R.H.; Nassar, M.M.; Fadali, O.A.; Ali, M.A.; Kim, H.Y. Carbon Nanofiber Double Active Layer and Co-Incorporation as New Anode Modification Strategies for Power-Enhanced Microbial Fuel Cells. Polymers 2022, 14, 1542. [Google Scholar] [CrossRef] [PubMed]

- Yaqoob, A.A.; Serrà, A.; Bhawani, S.A.; Ibrahim, M.N.M.; Khan, A.; Alorfi, H.S.; Asiri, A.M.; Hussein, M.A.; Khan, I.; Umar, K. Utilizing Biomass-Based Graphene Oxide–Polyaniline–Ag Electrodes in Microbial Fuel Cells to Boost Energy Generation and Heavy Metal Removal. Polymers 2022, 14, 845. [Google Scholar] [CrossRef]

- Erensoy, A.; Çek, N. Investigation of Polymer Biofilm Formation on Titanium-Based Anode Surface in Microbial Fuel Cells with Poplar Substrate. Polymers 2021, 13, 1833. [Google Scholar] [CrossRef]

- WXue, W.; Chanamarn, W.; Tabucanon, A.S.; Cruz, S.G.; Hu, Y. Treatment of agro-food industrial waste streams using osmotic microbial fuel cells: Performance and potential improvement measures. Environ. Technol. Innov. 2022, 27, 102773. [Google Scholar]

- Sahu, O. Sustainable and clean treatment of industrial wastewater with microbial fuel cell. Results Eng. 2019, 4, 100053. [Google Scholar] [CrossRef]

- Gude, V.G. Wastewater treatment in microbial fuel cells—An overview. J. Clean. Prod. 2016, 122, 287–307. [Google Scholar] [CrossRef]

- Moqsud, M.A.; Omine, K.; Yasufuku, N.; Hyodo, M.; Nakata, Y. Microbial fuel cell (MFC) for bioelectricity generation from organic wastes. Waste Manag. 2013, 33, 2465–2469. [Google Scholar] [CrossRef]

- Rojas-Flores, S.; Benites, S.; De La Cruz-Noriega, M.; Cabanillas-Chirinos, L.; Valdiviezo-Dominguez, F.; Álvarez, M.Q.; Vega-Ybañez, V.; Angelats-Silva, L. Bioelectricity Production from Blueberry Waste. Processes 2021, 9, 1301. [Google Scholar] [CrossRef]

- Naseer, M.N.; Zaidi, A.A.; Khan, H.; Kumar, S.; bin Owais, M.T.; Jaafar, J.; Suhaimin, N.S.; Wahab, Y.A.; Dutta, K.; Asif, M.; et al. Mapping the field of microbial fuel cell: A quantitative literature review (1970–2020). Energy Rep. 2021, 7, 4126–4138. [Google Scholar] [CrossRef]

- Wang, J.; Ren, K.; Zhu, Y.; Huang, J.; Liu, S. A Review of Recent Advances in Microbial Fuel Cells: Preparation, Operation, and Application. Biotech 2022, 11, 44. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Yang, J.; He, X.; Wang, R.-J.; Lu, Z.-S.; Qiao, Y. Cellulose Aerogel Derived Hierarchical Porous Carbon for Enhancing Flavin-Based Interfacial Electron Transfer in Microbial Fuel Cells. Polymers 2020, 12, 664. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Niu, H.; Yang, D.; Wang, S.; Jiang, N.; Wang, J.; Lin, J.; Hu, C. Polyaniline/Carbon Nanotubes Composite Modified Anode via Graft Polymerization and Self-Assembling for Microbial Fuel Cells. Polymers 2018, 10, 759. [Google Scholar] [CrossRef] [Green Version]

- Saravanan, A.; Karishma, S.; Kumar, P.S.; Yaashikaa, P.R.; Jeevanantham, S.; Gayathri, B. Microbial electrolysis cells and microbial fuel cells for biohydrogen production: Current advances and emerging challenges. Biomass-Convers. Biorefinery 2020, 1–21. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Mofijur, M.; Islam, N.; Parisa, T.A.; Rafa, N.; Bokhari, A.; Klemeš, J.J.; Mahlia, T.M.I. Insights into the development of microbial fuel cells for generating biohydrogen, bioelectricity, and treating wastewater. Energy 2022, 254, 124163. [Google Scholar] [CrossRef]

- Thulasinathan, B.; Jayabalan, T.; Arumugam, N.; Kulanthaisamy, M.R.; Kim, W.; Kumar, P.; Govarthanan, M.; Alagarsamy, A. Wastewater substrates in microbial fuel cell systems for carbon-neutral bioelectricity generation: An overview. Fuel 2022, 317, 123369. [Google Scholar] [CrossRef]

- Ren, H.; Lee, H.-S.; Chae, J. Miniaturizing microbial fuel cells for potential portable power sources: Promises and challenges. Microfluid. Nanofluidics 2012, 13, 353–381. [Google Scholar] [CrossRef]

- Mateo, S.; Mascia, M.; Fernandez-Morales, F.J.; Rodrigo, M.A.; Di Lorenzo, M. Assessing the impact of design factors on the performance of two miniature microbial fuel cells. Electrochim. Acta 2019, 297, 297–306. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, L.; Zularisam, A.W. Microbial Fuel Cells: Types and Applications. In Waste Biomass Management—A Holistic Approach; Singh, L., Kalia, V.C., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 367–384. [Google Scholar]

- Logan, B.E.; Hamelers, B.; Rozendal, R.; Schröder, U.; Keller, J.; Freguia, S.; Aelterman, P.; Verstraete, W.; Rabaey, K. Microbial Fuel Cells: Methodology and Technology. Environ. Sci. Technol. 2006, 40, 5181–5192. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Nazario-Naveda, R.; Benites, S.M.; Delfín-Narciso, D.; Rojas-Villacorta, W.; Romero, C.V. Bioelectricity through microbial fuel cells using avocado waste. Energy Rep. 2022, 8, 376–382. [Google Scholar] [CrossRef]

- Aiswaria, P.; Mohamed, S.N.; Singaravelu, D.L.; Brindhadevi, K.; Pugazhendhi, A. A review on graphene/graphene oxide supported electrodes for microbial fuel cell applications: Challenges and prospects. Chemosphere 2022, 296, 133983. [Google Scholar]

- ANawaz, A.; Haq, I.U.; Qaisar, K.; Gunes, B.; Raja, S.I.; Mohyuddin, K.; Amin, H. Microbial fuel cells: Insight into simultaneous wastewater treatment and bioelectricity generation. Process. Saf. Environ. Prot. 2022, 161, 357–373. [Google Scholar]

- Roshanravan, B.; Younesi, H.; Abdollahi, M.; Rahimnejad, M.; Pyo, S.-H. Application of proton-conducting sulfonated polysulfone incorporated MIL-100(Fe) composite materials for polymer-electrolyte membrane microbial fuel cells. J. Clean. Prod. 2021, 300, 126963. [Google Scholar] [CrossRef]

- Sharif, H.M.A.; Farooq, M.; Hussain, I.; Ali, M.; Mujtaba, M.; Sultan, M.; Yang, B. Recent innovations for scaling up microbial fuel cell systems: Significance of physicochemical factors for electrodes and membranes materials. J. Taiwan Inst. Chem. Eng. 2021, 129, 207–226. [Google Scholar] [CrossRef]

- Souza, L.; Antônio, R.; Hotza, D.; Carminatti, C.; Pineda-Vásquez, T.; Watzko, E.; Pezzin, A.P.; Duarte, D.; Recouvreux, D. Lignin-incorporated bacterial nanocellulose for proton exchange membranes in microbial fuel cells. Mater. Chem. Phys. 2023, 293, 126963. [Google Scholar] [CrossRef]

- Nayak, J.K.; Shankar, U.; Samal, K. Fabrication and development of SPEEK/PVdF-HFP/SiO2 proton exchange membrane for microbial fuel cell application. Chem. Eng. J. Adv. 2023, 14, 100459. [Google Scholar] [CrossRef]

- Terbish, N.; Popuri, S.R.; Lee, C.-H. Improved performance of organic–inorganic nanocomposite membrane for bioelectricity generation and wastewater treatment in microbial fuel cells. Fuel 2023, 332, 126167. [Google Scholar] [CrossRef]

- Ramirez-Nava, J.; Martínez-Castrejón, M.; García-Mesino, R.L.; López-Díaz, J.A.; Talavera-Mendoza, O.; Sarmiento-Villagrana, A.; Rojano, F.; Hernández-Flores, G. The Implications of Membranes Used as Separators in Microbial Fuel Cells. Membranes 2021, 11, 738. [Google Scholar] [CrossRef] [PubMed]

- Ramírez-Carmona, M.; Gálvez-Gómez, M.P.; González-Perez, L.; Pinedo-Rangel, V.; Pineda-Vasquez, T.; Hotza, D. Production of Bacterial Cellulose Hydrogel and its Evaluation as a Proton Exchange Membrane. J. Polym. Environ. 2023, 1–11. [Google Scholar] [CrossRef]

- Uddin, M.J.; Jeong, Y.K.; Lee, W. Microbial fuel cells for bioelectricity generation through reduction of hexavalent chromium in wastewater: A review. Int. J. Hydrogen Energy 2021, 46, 11458–11481. [Google Scholar] [CrossRef]

- Rahman, W.; Yusup, S.; Mohammad, S.N.A.A. Mohammad, Screening of fruit waste as substrate for microbial fuel cell (MFC). AIP Conf. Proc. 2021, 2332, 020003. [Google Scholar]

- Din, M.I.; Ahmed, M.; Ahmad, M.; Iqbal, M.; Ahmad, Z.; Hussain, Z.; Khalid, R.; Samad, A. Investigating the Activity of Carbon Fiber Electrode for Electricity Generation from Waste Potatoes in a Single-Chambered Microbial Fuel Cell. J. Chem. 2023, 2023, 8520657. [Google Scholar] [CrossRef]

- Muthukrishnan, L.; Kamaraj, S.K.; Sánchez-Olmos, L.A.; Cardenas, M.S.; Caballero-Briones, F. Chapter 24—Toward sustainable feasibility of microbial electrochemical systems to reality. In Scaling Up of Microbial Electrochemical Systems; Jadhav, D.A., Pandit, S., Gajalakshmi, S., Shah, M.P., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 457–483. [Google Scholar]

- Rismani-Yazdi, H.; Carver, S.M.; Christy, A.D.; Tuovinen, O.H. Cathodic limitations in microbial fuel cells: An overview. J. Power Sources 2008, 180, 683–694. [Google Scholar] [CrossRef]

- Ghosh, S.; Das, S.; Mosquera, M.E.G. Conducting Polymer-Based Nanohybrids for Fuel Cell Application. Polymers 2020, 12, 2993. [Google Scholar] [CrossRef]

- Abdallah, M.; Feroz, S.; Alani, S.; Sayed, E.T.; Shanableh, A. Continuous and scalable applications of microbial fuel cells: A critical review. Rev. Environ. Sci. Bio/Technology 2019, 18, 543–578. [Google Scholar] [CrossRef]

- Tofighi, A.; Rahimnejad, M. Chapter 14—Synthetic polymer-based membranes for microbial fuel cells. In Synthetic Polymeric Membranes for Advanced Water Treatment, Gas Separation, and Energy Sustainability; Ismail, A.F., Salleh, W.N.W., Yusof, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 309–335. [Google Scholar]

- Vilela, C.; Cordeiro, D.M.; Boas, J.V.; Barbosa, P.; Nolasco, M.; Vaz, P.D.; Rudić, S.; Ribeiro-Claro, P.; Silvestre, A.J.; Oliveira, V.B.; et al. Poly(4-styrene sulfonic acid)/bacterial cellulose membranes: Electrochemical performance in a single-chamber microbial fuel cell. Bioresour. Technol. Rep. 2020, 9, 100376. [Google Scholar] [CrossRef]

- Noori, T.; Ghangrekar, M.; Mukherjee, C.; Min, B. Biofouling effects on the performance of microbial fuel cells and recent advances in biotechnological and chemical strategies for mitigation. Biotechnol. Adv. 2019, 37, 107420. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, A.; Calay, R.K.; Eregno, F.E. Role and Important Properties of a Membrane with Its Recent Advancement in a Microbial Fuel Cell. Energies 2022, 15, 444. [Google Scholar] [CrossRef]

- Das, I.; Das, S.; Dixit, R.; Ghangrekar, M.M. Goethite supplemented natural clay ceramic as an alternative proton exchange membrane and its application in microbial fuel cell. Ionics 2020, 26, 3061–3072. [Google Scholar] [CrossRef]

- Koók, L.; Žitka, J.; Bakonyi, P.; Takács, P.; Pavlovec, L.; Otmar, M.; Kurdi, R.; Bélafi-Bakó, K.; Nemestóthy, N. Electrochemical and microbiological insights into the use of 1,4-diazabicyclo[2.2.2]octane-functionalized anion exchange membrane in microbial fuel cell: A benchmarking study with Nafion. Sep. Purif. Technol. 2020, 237, 116478. [Google Scholar] [CrossRef]

- Subhadarshini, S.; Sravan, J.S.; Sarkar, O.; Mohan, S.V.; Roy, T.K.; Jana, T. Sulfonated Polybenzimidazole as a PEM in a Microbial Fuel Cell: An Efficient Strategy for Green Energy Generation and Wastewater Cleaning. ACS Appl. Energy Mater. 2023, 6, 1422–1438. [Google Scholar] [CrossRef]

- Di Palma, L.; Bavasso, I.; Sarasini, F.; Tirillò, J.; Puglia, D.; Dominici, F.; Torre, L. Synthesis, characterization and performance evaluation of Fe3O4/PES nano composite membranes for microbial fuel cell. Eur. Polym. J. 2018, 99, 222–229. [Google Scholar] [CrossRef]

- Rozendal, R.A.; Hamelers, H.V.M.; Buisman, C.J.N. Effects of Membrane Cation Transport on pH and Microbial Fuel Cell Performance. Environ. Sci. Technol. 2006, 40, 5206–5211. [Google Scholar] [CrossRef]

- Koók, L.; Kaufer, B.; Bakonyi, P.; Rózsenberszki, T.; Rivera, I.; Buitrón, G.; Bélafi-Bakó, K.; Nemestóthy, N. Supported ionic liquid membrane based on [bmim][PF6] can be a promising separator to replace Nafion in microbial fuel cells and improve energy recovery: A comparative process evaluation. J. Membr. Sci. 2019, 570–571, 215–225. [Google Scholar] [CrossRef]

- Lim, S.S.; Daud, W.R.W.; Jahim, J.M.; Ghasemi, M.; Chong, P.S.; Ismail, M. Sulfonated poly(ether ether ketone)/poly(ether sulfone) composite membranes as an alternative proton exchange membrane in microbial fuel cells. Int. J. Hydrogen Energy 2012, 37, 11409–11424. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Bakeri, G.; Ghasemi, M.; Zirepour, A. A review on the role of proton exchange membrane on the performance of microbial fuel cell. Polym. Adv. Technol. 2014, 25, 1426–1432. [Google Scholar] [CrossRef]

- Nagar, H.; Badhrachalam, N.; Rao, V.B.; Sridhar, S. A novel microbial fuel cell incorporated with polyvinylchloride/4A zeolite composite membrane for kitchen wastewater reclamation and power generation. Mater. Chem. Phys. 2019, 224, 175–185. [Google Scholar] [CrossRef]

- Zinadini, S.; Zinatizadeh, A.; Rahimi, M.; Vatanpour, V.; Rahimi, Z. High power generation and COD removal in a microbial fuel cell operated by a novel sulfonated PES/PES blend proton exchange membrane. Energy 2017, 125, 427–438. [Google Scholar] [CrossRef]

- Singha, S.; Jana, T.; Modestra, J.A.; Kumar, A.N.; Mohan, S.V. Highly efficient sulfonated polybenzimidazole as a proton exchange membrane for microbial fuel cells. J. Power Sources 2016, 317, 143–152. [Google Scholar] [CrossRef]

- Kumar, V.; Mondal, S.; Nandy, A.; Kundu, P.P. Analysis of polybenzimidazole and polyvinylpyrrolidone blend membranes as separating barrier in single chambered microbial fuel cells. Biochem. Eng. J. 2016, 111, 34–42. [Google Scholar] [CrossRef]

- Kamaraj, S.-K.; Romano, S.M.; Moreno, V.C.; Poggi-Varaldo, H.; Solorza-Feria, O. Use of Novel Reinforced Cation Exchange Membranes for Microbial Fuel Cells. Electrochim. Acta 2015, 176, 555–566. [Google Scholar] [CrossRef]

- Rudra, R.; Kumar, V.; Kundu, P.P. Acid catalysed cross-linking of poly vinyl alcohol (PVA) by glutaraldehyde: Effect of crosslink density on the characteristics of PVA membranes used in single chambered microbial fuel cells. RSC Adv. 2015, 5, 83436–83447. [Google Scholar] [CrossRef]

- Terbish, N.; Lee, C.-H.; Popuri, S.R.; Nalluri, L.P. An investigation into polymer blending, plasticization and cross-linking effect on the performance of chitosan-based composite proton exchange membranes for microbial fuel cell applications. J. Polym. Res. 2020, 27, 280. [Google Scholar] [CrossRef]

- Ying, Y.; Kamarudin, S.; Masdar, M. Silica-related membranes in fuel cell applications: An overview. Int. J. Hydrogen Energy 2018, 43, 16068–16084. [Google Scholar] [CrossRef]

- Zhang, H.; Shen, P.K. Recent Development of Polymer Electrolyte Membranes for Fuel Cells. Chem. Rev. 2012, 112, 2780–2832. [Google Scholar] [CrossRef]

- Salarizadeh, P.; Javanbakht, M.; Pourmahdian, S.; Hazer, M.S.A.; Hooshyari, K.; Askari, M.B. Novel proton exchange membranes based on proton conductive sulfonated PAMPS/PSSA-TiO2 hybrid nanoparticles and sulfonated poly (ether ether ketone) for PEMFC. Int. J. Hydrogen Energy 2019, 44, 3099–3114. [Google Scholar] [CrossRef]

- Tripathi, B.P.; Shahi, V.K. Organic–inorganic nanocomposite polymer electrolyte membranes for fuel cell applications. Prog. Polym. Sci. 2011, 36, 945–979. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, J.; Byun, J.J.; Cai, R.; Perez-Page, M.; Sahoo, M.; Ji, Z.; Haigh, S.J.; Holmes, S.M. High-performance polymer electrolyte membranes incorporated with 2D silica nanosheets in high-temperature proton exchange membrane fuel cells. J. Energy Chem. 2022, 64, 323–334. [Google Scholar] [CrossRef]

- Yoonoo, C.; Dawson, C.P.; Roberts, E.P.; Holmes, S.M. Nafion®/mordenite composite membranes for improved direct methanol fuel cell performance. J. Membr. Sci. 2011, 369, 367–374. [Google Scholar] [CrossRef]

- Al-Batty, S.; Dawson, C.; Shanmukham, S.P.; Roberts, E.P.L.; Holmes, S.M. Improvement of direct methanol fuel cell performance using a novel mordenite barrier layer. J. Mater. Chem. A 2016, 4, 10850–10857. [Google Scholar] [CrossRef] [Green Version]

- Xi, J.; Wu, Z.; Qiu, X.; Chen, L. Nafion/SiO2 hybrid membrane for vanadium redox flow battery. J. Power Sources 2007, 166, 531–536. [Google Scholar] [CrossRef]

- Sadhasivam, T.; Kim, H.-T.; Park, W.-S.; Lim, H.; Ryi, S.-K.; Roh, S.-H.; Jung, H.-Y. Low permeable composite membrane based on sulfonated poly(phenylene oxide) (sPPO) and silica for vanadium redox flow battery. Int. J. Hydrogen Energy 2017, 42, 19035–19043. [Google Scholar] [CrossRef]

- Kou, W.; Li, X.; Liu, Y.; Zhang, X.; Yang, S.; Jiang, X.; He, G.; Dai, Y.; Zheng, W.; Yu, G. Triple-Layered Carbon-SiO2 Composite Membrane for High Energy Density and Long Cycling Li–S Batteries. ACS Nano 2019, 13, 5900–5909. [Google Scholar] [CrossRef] [PubMed]

- Bisht, S.; Balaguru, S.; Ramachandran, S.K.; Gangasalam, A.; Kweon, J. Proton exchange composite membranes comprising SiO2, sulfonated SiO2, and metal–organic frameworks loaded in SPEEK polymer for fuel cell applications. J. Appl. Polym. Sci. 2021, 138, 50530. [Google Scholar] [CrossRef]

- Sivasankaran, A.; Sangeetha, D.; Ahn, Y.-H. Nanocomposite membranes based on sulfonated polystyrene ethylene butylene polystyrene (SSEBS) and sulfonated SiO2 for microbial fuel cell application. Chem. Eng. J. 2016, 289, 442–451. [Google Scholar] [CrossRef]

- Sivasankaran, A.; Sangeetha, D. Influence of sulfonated SiO2 in sulfonated polyether ether ketone nanocomposite membrane in microbial fuel cell. Fuel 2015, 159, 689–696. [Google Scholar] [CrossRef]

- Kircheva, N.; Outin, J.; Perrier, G.; Ramousse, J.; Merlin, G.; Lyautey, E. Bio-electrochemical characterization of air-cathode microbial fuel cells with microporous polyethylene/silica membrane as separator. Bioelectrochemistry 2015, 106, 115–124. [Google Scholar] [CrossRef]

- Gaurav, K.; Singh, R.; Tiwari, B.K.; Srivastava, R. Novel proton exchange membranes based on PVC for microbial fuel cells (MFCs). J. Polym. Eng. 2019, 39, 360–367. [Google Scholar] [CrossRef]

- Angioni, S.; Millia, L.; Bruni, G.; Tealdi, C.; Mustarelli, P.; Quartarone, E. Quartarone, Improving the performances of Nafion™-based membranes for microbial fuel cells with silica-based, organically-functionalized mesostructured fillers. J. Power Sources 2016, 334, 120–127. [Google Scholar] [CrossRef]

- Bi, C.; Zhang, H.; Zhang, Y.; Zhu, X.; Ma, Y.; Dai, H.; Xiao, S. Fabrication and investigation of SiO2 supported sulfated zirconia/Nafion® self-humidifying membrane for proton exchange membrane fuel cell applications. J. Power Sources 2008, 184, 197–203. [Google Scholar] [CrossRef]

- Nunes, S.P.; Ruffmann, B.; Rikowski, E.; Vetter, S.; Richau, K. Inorganic modification of proton conductive polymer membranes for direct methanol fuel cells. J. Membr. Sci. 2002, 203, 215–225. [Google Scholar] [CrossRef]

- Kugarajah, V.; Sugumar, M.; Dharmalingam, S. Nanocomposite membrane and microbial community analysis for improved performance in microbial fuel cell. Enzym. Microb. Technol. 2020, 140, 109606. [Google Scholar] [CrossRef] [PubMed]

- Bajestani, M.B.; Mousavi, S.A. Effect of casting solvent on the characteristics of Nafion/TiO2 nanocomposite membranes for microbial fuel cell application. Int. J. Hydrogen Energy 2016, 41, 476–482. [Google Scholar] [CrossRef]

- Kim, S.H.; Kwak, S.-Y.; Sohn, B.-H.; Park, T.H. Design of TiO2 nanoparticle self-assembled aromatic polyamide thin-film-composite (TFC) membrane as an approach to solve biofouling problem. J. Membr. Sci. 2003, 211, 157–165. [Google Scholar] [CrossRef]

- Bae, T.-H.; Tak, T.-M. Effect of TiO2 nanoparticles on fouling mitigation of ultrafiltration membranes for activated sludge filtration. J. Membr. Sci. 2005, 249, 1–8. [Google Scholar] [CrossRef]

- Pagnout, C.; Jomini, S.; Dadhwal, M.; Caillet, C.; Thomas, F.; Bauda, P. Role of electrostatic interactions in the toxicity of titanium dioxide nanoparticles toward Escherichia coli. Colloids Surf. B Biointerfaces 2012, 92, 315–321. [Google Scholar] [CrossRef]

- Martinez-Morlanes, M.J.; De La Torre-Gamarra, C.; Pérez-Prior, M.T.; Lara-Benito, S.; Del Rio, C.; Várez, A.; Levenfeld, B. Sulfonated Polysulfone/TiO2(B) Nanowires Composite Membranes as Polymer Electrolytes in Fuel Cells. Polymers 2021, 13, 2030. [Google Scholar] [CrossRef]

- Kim, A.R.; Vinothkannan, M.; Lee, K.H.; Chu, J.Y.; Park, B.; Han, M.; Yoo, D.J. Enhanced performance and durability of composite membranes containing anatase titanium oxide for fuel cells operating under low relative humidity. Int. J. Energy Res. 2022, 46, 4835–4851. [Google Scholar] [CrossRef]

- Kumar, K.S.; Prabhu, M.R. Enhancing Proton Conduction of Poly(benzimidazole) with Sulfonated Titania Nano Composite Membrane for PEM Fuel Cell Applications. Macromol. Res. 2021, 29, 111–119. [Google Scholar] [CrossRef]

- Palanisamy, G.; Oh, T.H. TiO2 Containing Hybrid Composite Polymer Membranes for Vanadium Redox Flow Batteries. Polymers 2022, 14, 1617. [Google Scholar] [CrossRef]

- Wang, G.; Wang, F.; Li, A.; Zhang, M.; Zhang, J.; Chen, J.; Wang, R. Sulfonated poly(ether ether ketone)/s–TiO2 composite membrane for a vanadium redox flow battery. J. Appl. Polym. Sci. 2020, 137, 48830. [Google Scholar] [CrossRef]

- Harun, N.A.M.; Shaari, N.; Zaiman, N.F.H.N. A review of alternative polymer electrolyte membrane for fuel cell application based on sulfonated poly(ether ether ketone). Int. J. Energy Res. 2021, 45, 19671–19708. [Google Scholar] [CrossRef]

- Wu, J.; Nie, S.; Liu, H.; Gong, C.; Zhang, Q.; Xu, Z.; Liao, G. Design and development of nucleobase modified sulfonated poly(ether ether ketone) membranes for high-performance direct methanol fuel cells. J. Mater. Chem. A 2022, 10, 19914–19924. [Google Scholar] [CrossRef]

- Mahimai, B.M.; Sivasubramanian, G.; Sekar, K.; Kannaiyan, D.; Deivanayagam, P. Sulfonated poly(ether ether ketone): Efficient ion-exchange polymer electrolytes for fuel cell applications—A versatile review. Mater. Adv. 2022, 3, 6085–6095. [Google Scholar] [CrossRef]

- Venkatesan, P.N.; Dharmalingam, S. Effect of cation transport of SPEEK—Rutile TiO2 electrolyte on microbial fuel cell performance. J. Membr. Sci. 2015, 492, 518–527. [Google Scholar] [CrossRef]

- Vidhyeswari, D.; Surendhar, A.; Bhuvaneshwari, S. Evaluation of power generation and treatment efficiency of dairy wastewater in microbial fuel cell using TiO2—SPEEK as proton exchange membrane. Water Sci. Technol. 2021, 84, 3388–3402. [Google Scholar] [CrossRef]

- Bhowmick, G.D.; Dhar, D.; Ghangrekar, M.M.; Banerjee, R. TiO2-Si- or SrTiO3-Si-impregnated PVA–based low-cost proton exchange membranes for application in microbial fuel cell. Ionics 2020, 26, 6195–6205. [Google Scholar] [CrossRef]

- Martinelli, A.; Matic, A.; Jacobsson, P.; Börjesson, L.; Navarra, M.; Fernicola, A.; Panero, S.; Scrosati, B. Structural analysis of PVA-based proton conducting membranes. Solid State Ion. 2006, 177, 2431–2435. [Google Scholar] [CrossRef]

- Münch, W.; Kreuer, K.D.; Seifert, G.; Maier, J. Proton diffusion in perovskites: Comparison between BaCeO3, BaZrO3, SrTiO3, and CaTiO3 using quantum molecular dynamics. Solid State Ion. 2000, 136–137, 183–189. [Google Scholar] [CrossRef]

- Soria, R.B.; Chinchin, B.D.; Arboleda, D.; Zhao, Y.; Bonilla, P.; Van der Bruggen, B.; Luis, P. Effect of the bio-inspired modification of low-cost membranes with TiO2:ZnO as microbial fuel cell membranes. Chemosphere 2022, 291, 132840. [Google Scholar] [CrossRef]

- Kugarajah, V.; Dharmalingam, S. Investigation of a cation exchange membrane comprising Sulphonated Poly Ether Ether Ketone and Sulphonated Titanium Nanotubes in Microbial Fuel Cell and preliminary insights on microbial adhesion. Chem. Eng. J. 2020, 398, 125558. [Google Scholar] [CrossRef]

- Ayyaru, S.; Dharmalingam, S. A study of influence on nanocomposite membrane of sulfonated TiO2 and sulfonated polystyrene-ethylene-butylene-polystyrene for microbial fuel cell application. Energy 2015, 88, 202–208. [Google Scholar] [CrossRef]

- Pal, A.; Dey, T.K.; Debnath, A.K.; Bhushan, B.; Sahu, A.K.; Bindal, R.C.; Kar, S. Mixed-matrix membranes with enhanced antifouling activity: Probing the surface-tailoring potential of Tiron and chromotropic acid for nano-TiO2. R. Soc. Open Sci. 2017, 4, 170368. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ayyaru, S.; Dharmalingam, S. Improved performance of microbial fuel cells using sulfonated polyether ether ketone (SPEEK) TiO2–SO3H nanocomposite membrane. RSC Adv. 2013, 3, 25243–25251. [Google Scholar] [CrossRef]

- Sugumar, M.; Dharmalingam, S. Statistical assessment of operational parameters using optimized sulphonated titanium nanotubes incorporated sulphonated polystyrene ethylene butylene polystyrene nanocomposite membrane for efficient electricity generation in microbial fuel cell. Energy 2022, 242, 123000. [Google Scholar] [CrossRef]

- Kumar, V.; Rudra, R.; Hait, S. Sulfonated polyvinylidene fluoride-crosslinked-aniline-2-sulfonic acid as ion exchange membrane in single-chambered microbial fuel cell. J. Environ. Chem. Eng. 2021, 9, 106467. [Google Scholar] [CrossRef]

- Jung, H.-Y.; Roh, S.-H. Polyvinylidene Fluoride Nanofiber Composite Membrane Coated with Perfluorinated Sulfuric Acid for Microbial Fuel Cell Application. J. Nanosci. Nanotechnol. 2020, 20, 5711–5715. [Google Scholar] [CrossRef] [PubMed]

- Sharma, M.; Das, P.P.; Sood, T.; Chakraborty, A.; Purkait, M.K. Reduced graphene oxide incorporated polyvinylidene fluoride/cellulose acetate proton exchange membrane for energy extraction using microbial fuel cells. J. Electroanal. Chem. 2022, 907, 115890. [Google Scholar] [CrossRef]

- Li, C.; Wang, L.; Wang, X.; Kong, M.; Zhang, Q.; Li, G. Synthesis of PVDF-g-PSSA proton exchange membrane by ozone-induced graft copolymerization and its application in microbial fuel cells. J. Membr. Sci. 2017, 527, 35–42. [Google Scholar] [CrossRef]

- Li, C.; Song, Y.; Wang, X.; Zhang, Q. Synthesis, characterization and application of S-TiO2/PVDF-g-PSSA composite membrane for improved performance in MFCs. Fuel 2020, 264, 116847. [Google Scholar] [CrossRef]

- Leong, J.X.; Daud, W.R.W.; Ghasemi, M.; Ahmad, A.; Ismail, M.; Ben Liew, K. Composite membrane containing graphene oxide in sulfonated polyether ether ketone in microbial fuel cell applications. Int. J. Hydrogen Energy 2015, 40, 11604–11614. [Google Scholar] [CrossRef]

- Cao, Y.C.; Xu, C.; Wu, X.; Wang, X.; Xing, L.; Scott, K. A poly (ethylene oxide)/graphene oxide electrolyte membrane for low temperature polymer fuel cells. J. Power Sources 2011, 196, 8377–8382. [Google Scholar] [CrossRef]

- Chien, H.-C.; Tsai, L.-D.; Huang, C.-P.; Kang, C.-Y.; Lin, J.-N.; Chang, F.-C. Sulfonated graphene oxide/Nafion composite membranes for high-performance direct methanol fuel cells. Int. J. Hydrogen Energy 2013, 38, 13792–13801. [Google Scholar] [CrossRef]

- Shabani, M.; Younesi, H.; Rahimpour, A.; Rahimnejad, M. Upgrading the electrochemical performance of graphene oxide-blended sulfonated polyetheretherketone composite polymer electrolyte membrane for microbial fuel cell application. Biocatal. Agric. Biotechnol. 2019, 22, 101369. [Google Scholar] [CrossRef]

- Ben Liew, K.; Leong, J.X.; Daud, W.R.W.; Ahmad, A.; Hwang, J.J.; Wu, W. Incorporation of silver graphene oxide and graphene oxide nanoparticles in sulfonated polyether ether ketone membrane for power generation in microbial fuel cell. J. Power Sources 2020, 449, 227490. [Google Scholar] [CrossRef]

- Ali, A.K.; Ali, M.E.; Younes, A.A.; El Fadl, M.M.A.; Farag, A. Proton exchange membrane based on graphene oxide/polysulfone hybrid nano-composite for simultaneous generation of electricity and wastewater treatment. J. Hazard. Mater. 2021, 419, 126420. [Google Scholar] [CrossRef]

- Khilari, S.; Pandit, S.; Ghangrekar, M.M.; Pradhan, D.; Das, D. Graphene Oxide-Impregnated PVA–STA Composite Polymer Electrolyte Membrane Separator for Power Generation in a Single-Chambered Microbial Fuel Cell. Ind. Eng. Chem. Res. 2013, 52, 11597–11606. [Google Scholar] [CrossRef]

- Rudra, R.; Kumar, V.; Pramanik, N.; Kundu, P.P. Graphite oxide incorporated crosslinked polyvinyl alcohol and sulfonated styrene nanocomposite membrane as separating barrier in single chambered microbial fuel cell. J. Power Sources 2017, 341, 285–293. [Google Scholar] [CrossRef]

- Sharma, M.; Das, P.P.; Sood, T.; Chakraborty, A.; Purkait, M.K. Ameliorated polyvinylidene fluoride based proton exchange membrane impregnated with graphene oxide, and cellulose acetate obtained from sugarcane bagasse for application in microbial fuel cell. J. Environ. Chem. Eng. 2021, 9, 106681. [Google Scholar] [CrossRef]

- Holder, S.L.; Lee, C.-H.; Popuri, S.R. Simultaneous wastewater treatment and bioelectricity production in microbial fuel cells using cross-linked chitosan-graphene oxide mixed-matrix membranes. Environ. Sci. Pollut. Res. 2017, 24, 13782–13796. [Google Scholar] [CrossRef]

- Mondal, S.; Papiya, F.; Ash, S.N.; Kundu, P.P. Composite membrane of sulfonated polybenzimidazole and sulfonated graphene oxide for potential application in microbial fuel cell. J. Environ. Chem. Eng. 2021, 9, 104945. [Google Scholar] [CrossRef]

- Li, C.; Wang, L.; Wang, X.; Li, C.; Xu, Q.; Li, G. Fabrication of a SGO/PVDF-g-PSSA composite proton-exchange membrane and its enhanced performance in microbial fuel cells. J. Chem. Technol. Biotechnol. 2019, 94, 398–408. [Google Scholar] [CrossRef]

- Ayyaru, S.; Ahn, Y.-H. Application of sulfonic acid group functionalized graphene oxide to improve hydrophilicity, permeability, and antifouling of PVDF nanocomposite ultrafiltration membranes. J. Membr. Sci. 2017, 525, 210–219. [Google Scholar] [CrossRef]

- Angioni, S.; Millia, L.; Bruni, G.; Ravelli, D.; Mustarelli, P.; Quartarone, E. Novel composite polybenzimidazole-based proton exchange membranes as efficient and sustainable separators for microbial fuel cells. J. Power Sources 2017, 348, 57–65. [Google Scholar] [CrossRef]

- Shabani, M.; Younesi, H.; Pontié, M.; Rahimpour, A.; Rahimnejad, M.; Guo, H.; Szymczyk, A. Enhancement of microbial fuel cell efficiency by incorporation of graphene oxide and functionalized graphene oxide in sulfonated polyethersulfone membrane. Renew. Energy 2021, 179, 788–801. [Google Scholar] [CrossRef]

- Xu, Q.; Wang, L.; Li, C.; Wang, X.; Li, C.; Geng, Y. Study on improvement of the proton conductivity and anti-fouling of proton exchange membrane by doping SGO@SiO2 in microbial fuel cell applications. Int. J. Hydrogen Energy 2019, 44, 15322–15332. [Google Scholar] [CrossRef]

- Ranjani, M.; Yoo, D.J.; Kumar, G.G. Sulfonated Fe3O4@SiO2 nanorods incorporated sPVdF nanocomposite membranes for DMFC applications. J. Membr. Sci. 2018, 555, 497–506. [Google Scholar] [CrossRef]

- Nie, S.; Wu, J.; Wang, L.; Cheng, F.; Sun, Z.; Chen, X.; Liu, H.; Wen, S.; Gong, C. Hierarchical Fe3O4@LDH-incorporated composite anion exchange membranes for fuel cells based on magnetic field orientation. Surf. Interfaces 2023, 37, 102640. [Google Scholar] [CrossRef]

- Lo, C.-F.; Wu, J.-F.; Li, H.-Y.; Hung, W.-S.; Shih, C.-M.; Hu, C.-C.; Liu, Y.-L.; Lue, S.J. Novel polyvinyl alcohol nanocomposites containing carbon nano-tubes with Fe3O4 pendants for alkaline fuel cell applications. J. Membr. Sci. 2013, 444, 41–49. [Google Scholar] [CrossRef]

- Prabhu, N.V.; Sangeetha, D. Characterization and performance study of sulfonated poly ether ether ketone/Fe3O4 nano composite membrane as electrolyte for microbial fuel cell. Chem. Eng. J. 2014, 243, 564–571. [Google Scholar] [CrossRef]

- Tjong, S. Structural and mechanical properties of polymer nanocomposites. Mater. Sci. Eng. R Rep. 2006, 53, 73–197. [Google Scholar] [CrossRef]

- Bavasso, I.; Di Palma, L.; Puglia, D.; Luzi, F.; Dominici, F.; Tirillò, J.; Sarasini, F.; Torre, L. Effect of Pretreatment of Nanocomposite PES-Fe3O4 Separator on Microbial Fuel Cells Performance. Polym. Eng. Sci. 2020, 60, 371–379. [Google Scholar] [CrossRef]

- Bavasso, I.; Bracciale, M.P.; Sbardella, F.; Puglia, D.; Dominici, F.; Torre, L.; Tirillò, J.; Sarasini, F.; De Rosa, I.M.; Xin, W.; et al. Sulfonated Fe3O4/PES nanocomposites as efficient separators in microbial fuel cells. J. Membr. Sci. 2021, 620, 118967. [Google Scholar] [CrossRef]

- Sugumar, M.; Dharmalingam, S. Statistical optimization of process parameters in microbial fuel cell for enhanced power production using Sulphonated Polyhedral Oligomeric Silsesquioxane dispersed Sulphonated Polystyrene Ethylene Butylene Polystyrene nanocomposite membranes. J. Power Sources 2020, 469, 228400. [Google Scholar] [CrossRef]

- Kugarajah, V.; Dharmalingam, S. Sulphonated polyhedral oligomeric silsesquioxane/sulphonated poly ether ether ketone nanocomposite membranes for microbial fuel cell: Insights to the miniatures involved. Chemosphere 2020, 260, 127593. [Google Scholar] [CrossRef]

- Kugarajah, V.; Sugumar, M.; Swaminathan, E.; Balasubramani, N.; Dharmalingam, S. Investigation on sulphonated zinc oxide nanorod incorporated sulphonated poly (1,4-phenylene ether ether sulfone) nanocomposite membranes for improved performance of microbial fuel cell. Int. J. Hydrogen Energy 2021, 46, 22134–22148. [Google Scholar] [CrossRef]

- Sugumar, M.; Kugarajah, V.; Dharmalingam, S. Dharmalingam, Optimization of operational factors using statistical design and analysis of nanofiller incorporated polymer electrolyte membrane towards performance enhancement of microbial fuel cell. Process. Saf. Environ. Prot. 2022, 158, 474–485. [Google Scholar] [CrossRef]

- Kugarajah, V.; Dharmalingam, S. Effect of silver incorporated sulphonated poly ether ether ketone membranes on microbial fuel cell performance and microbial community analysis. Chem. Eng. J. 2021, 415, 128961. [Google Scholar] [CrossRef]

- Swamidoss, V.F.; Bangaru, M.; Nalathambi, G.; Sangeetha, D.; Selvam, A.K. Silver-incorporated poly vinylidene fluoride nanofibers for bacterial filtration. Aerosol Sci. Technol. 2019, 53, 196–206. [Google Scholar] [CrossRef]

- Ma, M.; You, S.; Gong, X.; Dai, Y.; Zou, J.; Fu, H. Silver/iron oxide/graphitic carbon composites as bacteriostatic catalysts for enhancing oxygen reduction in microbial fuel cells. J. Power Sources 2015, 283, 74–83. [Google Scholar] [CrossRef]

- Davies, R.L.; Etris, S.F. The development and functions of silver in water purification and disease control. Catal. Today 1997, 36, 107–114. [Google Scholar] [CrossRef]

- Noori, M.T.; Tiwari, B.R.; Mukherjee, C.K.; Ghangrekar, M.M. Enhancing the performance of microbial fuel cell using AgPt bimetallic alloy as cathode catalyst and anti-biofouling agent. Int. J. Hydrogen Energy 2018, 43, 19650–19660. [Google Scholar] [CrossRef]

- Tiwari, B.; Noori, M.; Ghangrekar, M. A novel low cost polyvinyl alcohol-Nafion-borosilicate membrane separator for microbial fuel cell. Mater. Chem. Phys. 2016, 182, 86–93. [Google Scholar] [CrossRef]

- Venkatesan, P.N.; Dharmalingam, S. Characterization and performance study of phase inversed Sulfonated Poly Ether Ether Ketone—Silico tungstic composite membrane as an electrolyte for microbial fuel cell applications. Renew. Energy 2017, 102, 77–86. [Google Scholar] [CrossRef]

- Samaei, S.H.; Bakeri, G.; Lashkenari, M.S. Performance of the sulfonated poly ether ether ketone proton exchange membrane modified with sulfonated polystyrene and phosphotungstic acid for microbial fuel cell applications. J. Appl. Polym. Sci. 2021, 138, 50430. [Google Scholar] [CrossRef]

- Saniei, N.; Ghasemi, N.; Zinatizadeh, A.; Zinadini, S.; Ramezani, M.; Derakhshan, A. Electricity generation enhancement in microbial fuel cell via employing a new SPEEK based proton exchange membrane modified by goethite nanoparticles functionalized with tannic acid and sulfanilic acid. Environ. Technol. Innov. 2022, 25, 102168. [Google Scholar] [CrossRef]

- Yang, W.; Chata, G.; Zhang, Y.; Peng, Y.; Lu, J.E.; Wang, N.; Mercado, R.; Li, J.; Chen, S. Graphene oxide-supported zinc cobalt oxides as effective cathode catalysts for microbial fuel cell: High catalytic activity and inhibition of biofilm formation. Nano Energy 2019, 57, 811–819. [Google Scholar] [CrossRef]

- Muthukumar, H.; Mohammed, S.N.; Chandrasekaran, N.; Sekar, A.D.; Pugazhendhi, A.; Matheswaran, M. Effect of iron doped Zinc oxide nanoparticles coating in the anode on current generation in microbial electrochemical cells. Int. J. Hydrogen Energy 2019, 44, 2407–2416. [Google Scholar] [CrossRef]

| IA | Polymer | WU (%) | IEC(meqg−1) | PC S/cm) | K0 (cms−1) | IR (Ω) | PD (mWm−2) | CE (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Nafion | 0.085 | [108] | |||||||

| Mesoporous silica (SBA-15) | Nafion | 0.028 | |||||||

| SBA-SO3H10 | Nafion | 0.062 | 34 | ||||||

| SBA-SO3H50 | Nafion | 0.088 | |||||||

| SSEBS | 164 ± 7 | 1.825 | 3.5 × 10−5 | 66 | 680 ± 13 | 75 | [104] | ||

| SiO2-7.5% | SSEBS | 185 ± 8 | 1.622 | 0.9 × 10−5 | 60 | 852 ± 11 | 78 | ||

| S-SiO2-2.5% | SSEBS | 175 ± 10 | 1.990 | 0.98 × 10−5 | 55 | 82 | |||

| S-SiO2-5% | SSEBS | 187 ± 9 | 2.55 | 0.8 × 10−5 | 45 | 80 | |||

| S-SiO2-7.5% | SSEBS | 210 ± 8 | 3.015 | 3.21 × 10−2 | 0.75 × 10−5 | 37 | 1209 ± 17 | 85 | |

| S-SiO2-10% | SSEBS | 200 ± 11 | 2.821 | 0.67 × 10−5 | 39 | 83 | |||

| Nafion | 22 | 0.982 | 2 × 10−2 | 1.6 × 10−4 | 290 ± 7 | ||||

| SPEEK | 23 | 1.12 | 3 × 10−6 | 71 ± 3 | 680 | 75 ± 4 | [105] | ||

| SiO2-5% | SPEEK | 39 | 1.41 | 0.9 × 10−6 | 62 ± 2 | 802 | 79 ± 4 | ||

| S-SiO2-2.5% | SPEEK | 35 | 1.65 | 1.2 × 10−6 | 55 ± 2 | 864 | 85 ± 5 | ||

| S-SiO2-5% | SPEEK | 40 | 1.73 | 1 × 10−6 | 50 ± 1 | 912 | 87 ± 6 | ||

| S-SiO2-7.5% | SPEEK | 42 | 1.80 | 1.018 × 10−2 | 0.84 × 10−6 | 46 ± 0.5 | 1008 ± 17 | 90 ± 7 | |

| S-SiO2-10% | SPEEK | 37 | 1.74 | 0.7 × 10−6 | 52 ± 1 | 810 | 85 ± 6 | ||

| 22 | 3.0 × 10−2 | 1.6 × 10−5 | 320 ± 6 | ||||||

| SPEEK | 37 ± 0.3 | 1.15 ± 0.06 | 0.96 × 10−2 | 2.2 × 10−6 | 39 | 59 ± 1.2 | [111] | ||

| 2.5wt% S-SiO2 | SPEEK | 38 ± 0.5 | 1.34 ± 0.03 | 0.99 × 10−2 | 1.74 × 10−6 | 37 | 72 ± 1.6 | ||

| 5wt% S-SiO2 | SPEEK | 39 ± 0.4 | 1.54 ± 0.05 | 1.14 × 10−2 | 1.64 × 10−6 | 32 | |||

| 7.5wt% S-SiO2 | SPEEK | 40 ± 0.6 | 1.82 ± 0.08 | 1.24 × 10−2 | 1.42 × 10−6 | 29 | 154 ± 1.5 | ||

| 10 wt% S-SiO2 | SPEEK | 39 ± 0.3 | 1.71 ± 0.04 | 1.1 × 10−2 | 1.49 × 10−6 | 34 | |||

| Nafion | 22 ± 0.4 | 1.2 ± 0.05 | 0.85 × 10−2 | 2.42 × 10−6 | 45 | 145 ± 1.6 |

| IA | Polymer | WU (%) | IEC (meqg−1) | PC S/cm) | K0 (cms−1) | IR (Ω) | PD (mWm−2) | CE (%) | COD (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| S-TiO2-5% | SPEEK | 37 | 0.99 | 0.7 × 10−6 | [133] | |||||

| TiO2-5% | SPEEK | 25 | 0.75 | 0.7 × 10−6 | ||||||

| SPEEK | 20 | 0.9 | 3 × 10−6 | |||||||

| S-TiO2-2.5% | SPEEK | 32 | 0.95 | 0.5 × 10−6 | ||||||

| S-TiO2-7.5% | SPEEK | 39 | 1.05 | 1.382 × 10−2 | 0.8 × 10−6 | 37 | 1202.5 | |||

| S-TiO2-10% | SPEEK | 38 | 0.94 | 0.87 × 10−6 | ||||||

| Nafion | 22 | 0.30 × 10−2 | 1.6 × 10−5 | 125 | 300 | |||||

| SPEEK | 37.2 | 1.8 | 0.97 × 10−2 | 2.2 × 10−6 | 39 | 59 | [130] | |||

| S-TNT-2.5% | SPEEK | 37.9 | 2.5 | 1.1 × 10−2 | 1.74 × 10−6 | 35 | 70 | |||

| S-TNT-5% | SPEEK | 38.5 | 2.8 | 1.24 × 10−2 | 1.54 × 10−6 | 33 | ||||

| S-TNT-7.5% | SPEEK | 39 | 3.2 | 1.37 × 10−2 | 1.32 × 10−6 | 30 | 121 | 51 ± 2 | 79.37 | |

| S-TNT-10% | SPEEK | 38.2 | 2.9 | 1.0 × 10−2 | 1.49 × 10−6 | 37 | ||||

| Nafion | 22 | 1.2 | 0.81 × 10−2 | 2.4 × 10−6 | 45 | 117 | ||||

| S-TiO2-7.5% | SPEEK | 37.6 | 2.5 | 1.18 × 10−2 | 1.42 × 10−6 | 35 | 102 | |||

| SPSEBS | 163 ± 3 | 1.89 | 1.52 × 10−2 | 3.5 × 10−5 | 66 ± 4 | 695 ± 7 | 75 ± 3 | [131] | ||

| TiO2-7.5% | SPSEBS | 170 ± 5 | 1.62 | 1.08 × 10−2 | 0.8 × 10−5 | 60 ± 3 | 835 ± 8 | 72 ± 2 | ||

| S-TiO2-2.5% | SPSEBS | 185 ± 8 | 2.25 | 1.75 × 10−2 | 0.8 8 × 10−5 | 55 ± 2 | 975 ± 11 | 80 ± 4 | ||

| S-TiO2-5% | SPSEBS | 200 ± 9 | 3.02 | 2.51 × 10−2 | 0.7 × 10−5 | 45 ± 1 | 1200 ± 15 | 83 ± 3 | ||

| S-TiO2-7.5% | SPSEBS | 220 ± 11 | 3.35 | 3.57 × 10−2 | 0.64 × 10−5 | 35 ± 0.8 | 1345 ± 17 | 87 ± 4 | ||

| S-TiO2-10% | SPSEBS | 218 ± 10 | 3.02 | 2.72 × 10−2 | 0.60 × 10−5 | 37 ± 0.5 | 1105 ± 13 | 85 ± 5 | ||

| PVDF-g-PSSA | 25 ± 0.2 | 0.046 ± 0.003 | 243.95 | 106.67 | 85 | [139] | ||||

| TiO2-1% | PVDF-g-PSSA | 28.3 ± 0.3 | 0.041 ± 0.002 | 309.67 | 98.18 | 86 | ||||

| S-TiO2-1% | PVDF-g-PSSA | 33.2 ± 0.2 | 0.048 ± 0.003 | |||||||

| S-TiO2-2.5% | PVDF-g-PSSA | 36.4 ± 0.2 | 0.053 ± 0.002 | |||||||

| S-TiO2-5% | PVDF-g-PSSA | 40.9 ± 0.1 | 0.067 ± 0.002 | 224.24 | 130.54 | 91 | ||||

| S-TiO2-7.5% | PVDF-g-PSSA | 32.6 ± 0.2 | 0.052 ± 0.003 | |||||||

| Nafion 117 | 20 ± 0.1 | 0.078 ± 0.003 | 210.57 | 132.02 | 74 |

| IA | Polymer | WU (%) | IEC (meqg−1) | PC (S/cm) | OCV (mV) | IR (Ω) | CD (mAm−2) | PD (mWm−2) | CE (%) | COD (%) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nafion | ~716 ± 21 | 481.3 | [150] | ||||||||

| PBI | 4.28 × 10−4 | ~477 ± 13 | 709.19 | ||||||||

| SGO-1% | SPBI | ~567 ± 16 | |||||||||

| SGO-3% | SPBI | 0.912 | ~669 ± 18 | 2019.06 | 472.46 | ||||||

| SGO-5% | SPBI | 21 | 1.001 | 0.018 | ~625 ± 18 | 1959.43 | |||||

| Nafion | 17.5 | 0.86 ± 0.1 | 0.0013 | 233.3 ± 3 | 35.9 ± 2 | 2.28 ± 0.2 | 82.71 ± 5 | [154] | |||

| PES | 5.41 | 0.28 ± 0.1 | 0.00021 | ||||||||

| SPES | 12.33 | 0.36 ± 0.1 | 0.00032 | 216.7 ± 3 | 27.8 ± 2 | 2.19 ± 0.2 | 79.76 ± 5 | ||||

| GO-0.6% | SPES | 20.71 | 0.42 ± 0.1 | 0.00044 | 218.7 ± 7 | 28.5 ± 2 | 2.04 ± 0.2 | 75.2 ± 5 | |||

| GO-1.2% | SPES | 22 | 0.54 ± 0.1 | 0.00052 | 222.1 ± 3 | 32.1 ± 2 | 2.20 ± 0.2 | 80.74 ± 5 | |||

| GO-1.8% | SPES | 23.13 | 0.74 ± 0.1 | 0.00056 | 225 ± 3±3 | 39.2 ± 2 | 2.28 ± 0.2 | 86.47 ± 5 | |||

| SGO-0.6% | SPES | 28.41 | 0.61 ± 0.1 | 0.00105 | 233.5 ± 3 | 46.8 ± 2 | 2.13 ± 0.2 | 78.21 ± 5 | |||

| SGO-1.2% | SPES | 33.54 | 0.72 ± 0.1 | 0.00125 | 276.4 ± 3 | 61.5 ± 2 | 2.64 ± 0.2 | 85.41 ± 5 | |||

| SGO-1.8% | SPES | 36.32 | 0.84 ± 0.1 | 0.00142 | 300 ± 3 | 66.4 ± 2 | 3.73 ± 0.2 | 89.85 ± 5 | |||

| TGO-0.6% | SPES | 24.55 | 0.55 ± 0.1 | 0.00084 | 223.6 ± 3 | 43.4 ± 2 | 2.18 ± 0.2 | 72.53 ± 5 | |||

| TGO-1.2% | SPES | 26.22 | 0.63 ± 0.1 | 0.00101 | 255 ± 3 | 51.7 ± 2 | 2.51 ± 0.2 | 85.22 ± 5 | |||

| TGO-1.8% | SPES | 30 | 0.77 ± 0.1 | 0.00125 | 275 ± 3 | 54.13 ± 2 | 3.20 ± 0.2 | 88.07 ± 5 | |||

| PVDF-g-PSSA | 25.00 | 0.58 | 0.046 | 243.9 | 106.67 | [151] | |||||

| GO-1.0% | PVDF-g-PSSA | 29.32 | 0.79 | 0.065 | 189. | 138.02 | |||||

| SGO-0.1% | PVDF-g-PSSA | 26.45 | 0.64 | 0.056 | |||||||

| SGO-0.5% | PVDF-g-PSSA | 30.14 | 0.81 | 0.068 | |||||||

| SGO-1.0% | PVDF-g-PSSA | 32.56 | 1.24 | 0.083 | 167.9 | 180.27 | |||||

| SGO-1.5% | PVDF-g-PSSA | 33.05 | 1.08 | 0.079 | |||||||

| SGO-2.0% | PVDF-g-PSSA | 34.24 | 0.85 | 0.070 | |||||||

| Nafion | 20.00 | 0.89 | 0.078 | 210.5 | 132.02 | ||||||

| Nafion | 20.1 ± 0.1 | 1.0 ± 0.1 | 0.071 ± 0.003 | 210 | 132 | 74 | [155] | ||||

| PVDF-g-PSSA | 25.0 ± 0.2 | 0.60 ± 0.2 | 0.046 ± 0.003 | 228 | 147 | 68 | |||||

| SGO-1.0% | PP | 32.4 ± 0.2 | 1.4 ± 0.2 | 0.073 ± 0.002 | 191 | 166 | 71 | ||||

| SGO@SiO2-0.1% | PVDF-g-PSSA | 26.1 ± 0.3 | 1.0 ± 0.2 | 0.068 ± 0.002 | |||||||

| SGO@SiO2-0.5% | PVDF-g-PSSA | 30.1 ± 0.1 | 1.2 ± 0.2 | 0.072 ± 0.004 | |||||||

| SGO@SiO2-1.0% | PVDF-g-PSSA | 34.2 ± 0.2 | 1.6 ± 0.1 | 0.078 ± 0.004 | 152 | 1338 | 185 | 75 | |||

| SGO@SiO2-2.0% | PVDF-g-PSSA | 33.6 ± 0.2 | 1.4 ± 0.2 | 0.074 ± 0.003 |

| IA | Polymer | WU (%) | IEC (meqg−1) | PC (S/cm) | K0 (cms−1) | OCV (mv) | IR (Ω) | CD (mAm−2) | PD (mWm−2) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Fe3O4-10% | PES | 1.56 ± 0.24 | 0.07 ± 0.02 | 1.26 × 10−3 | 550.50 ± 3.53 | 13.87 ± 1.79 | 20.78 ± 0.30 | 5.72 ± 0.81 | [162] | |

| SFe3O4-5% | PES | 1.99 ± 0.04 | 2.08 ± 0.19 | 1.10 × 10−4 | 580.90 ± 32.4 | 7.92 ± 0.75 | 47.96 ± 3.58 | 18.70 ± 0.48 | ||

| SFe3O4-10% | PES | 3.78 ± 0.20 | 5.49 ± 0.43 | 1.28 × 10−4 | 150.67 ± 8.45 | 5.77 ± 0.96 | 150.67 ± 8.4 | 65.24 ± 5.79 | ||

| SFe3O4-15% | PES | 3.98 ± 0.01 | 6.49 ± 0.19 | 1.45 × 10−4 | 132.84 ± 4.29 | 5.42 ± 0.25 | 132.84 ± 4.2 | 47.82 ± 4.32 | ||

| SFe3O4-20% | PES | 5.23 ± 0.30 | 9.76 ± 0.52 | 1.46 × 10−4 | 104.91 ± 5.62 | 5.91 ± 0.33 | 104.91 ± 5.6 | 32.52 ± 3.34 | ||

| SPSEBS | 37.9 | 1.9 | 0.98 × 10−2 | 2.2 × 10−6 | 42 | [163] | ||||

| SPOSS-2% | SPSEBS | 38.2 | 2.6 | 1.2 × 10−2 | 1.7 × 10−6 | 38 | ||||

| SPOSS-4% | SPSEBS | 39.9 | 2.9 | 1.36 × 10−2 | 1.9 × 10−6 | 36 | ||||

| SPOSS-6% | SPSEBS | 41 | 3.7 | 1.40 × 10−2 | 1.6 × 10−6 | 31 | 126 | |||

| SPOSS-8% | SPSEBS | 39.4 | 2.9 | 1.3 × 10−2 | 1.9 × 10−6 | 35 | ||||

| Nafion | 22 | 1.2 | 0.77 × 10−2 | 2.4 × 10−6 | 45 | |||||

| SPEEK | 29 ± 0.05 | 1.4 ± 0.3 | 0.92 × 10−2 | 2.1 × 10−6 | 37 | 100 ± 1.2 | [164] | |||

| S-POSS-2.5% | SPEEK | 33.8 ± 0.03 | 1.5 ± 0.06 | 1.25 × 10−2 | 1.65 × 10−6 | 31 | ||||

| S-POSS-5% | SPEEK | 35.5 ± 0.08 | 1.8 ± 0.05 | 1.31 × 10−2 | 1.42 × 10−6 | 28 | 162 ± 1.4 | |||

| S-POSS-7.5% | SPEEK | 34.6 ± 0.07 | 1.7 ± 0.02 | 1.12 × 10−2 | 1.69 × 10−6 | 33 | ||||

| S-POSS-10% | SPEEK | 32.4 ± 0.02 | 1.6 ± 0.07 | 1.02 × 10−2 | 1.82 × 10−6 | 35 | ||||

| Nafion | 22 ± 0.03 | 1.2 ± 0.05 | 0.81 × 10−2 | 2.4 × 10−6 | 40 | 154 ± 1.7 | ||||

| SPEES | 29.8 ± 0.3 | 1.4 ± 0.05 | 1.12 × 10−2 | 1.9 × 10−6 | 36 | 75 | [165] | |||

| ZnO-7.5% | SPEES | 30.5 ± 0.2 | 1.3 ± 0.05 | 1.19 × 10−2 | 1.83 × 10−6 | 34 | ||||

| S-ZnO NR-2.5% | SPEES | 32.5 ± 0.2 | 1.6 ± 0.03 | 1.29 × 10−2 | 1.71 × 10−6 | 32 | ||||

| S-ZnO NR-5% | SPEES | 33.7 ± 0.5 | 1.8 ± 0.07 | 1.36 × 10−2 | 1.67 × 10−6 | 30 | ||||

| S-ZnO NR-7.5% | SPEES | 34.6 ± 0.6 | 2.0 ± 0.05 | 1.4 × 10−2 | 1.51 × 10−6 | 29 | 142 | |||

| S-ZnO NR-10% | SPEES | 31.8 ± 0.9 | 1.9 ± 0.04 | 1.21 × 10−2 | 2.45 × 10−6 | 34 | ||||

| Nafion | 22 ± 0.5 | 1.2 ± 0.06 | 0.81 × 10−2 | 40 | 130 | |||||

| 6% SZnO NR | SPSEBS | 1.49 × 10−2 | 147 | [166] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palanisamy, G.; Thangarasu, S.; Oh, T.H. Effect of Sulfonated Inorganic Additives Incorporated Hybrid Composite Polymer Membranes on Enhancing the Performance of Microbial Fuel Cells. Polymers 2023, 15, 1294. https://doi.org/10.3390/polym15051294

Palanisamy G, Thangarasu S, Oh TH. Effect of Sulfonated Inorganic Additives Incorporated Hybrid Composite Polymer Membranes on Enhancing the Performance of Microbial Fuel Cells. Polymers. 2023; 15(5):1294. https://doi.org/10.3390/polym15051294

Chicago/Turabian StylePalanisamy, Gowthami, Sadhasivam Thangarasu, and Tae Hwan Oh. 2023. "Effect of Sulfonated Inorganic Additives Incorporated Hybrid Composite Polymer Membranes on Enhancing the Performance of Microbial Fuel Cells" Polymers 15, no. 5: 1294. https://doi.org/10.3390/polym15051294

APA StylePalanisamy, G., Thangarasu, S., & Oh, T. H. (2023). Effect of Sulfonated Inorganic Additives Incorporated Hybrid Composite Polymer Membranes on Enhancing the Performance of Microbial Fuel Cells. Polymers, 15(5), 1294. https://doi.org/10.3390/polym15051294