A Mechanical Performance Study of Dual Cured Thermoset Resin Systems 3D-Printed with Continuous Carbon Fiber Reinforcement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

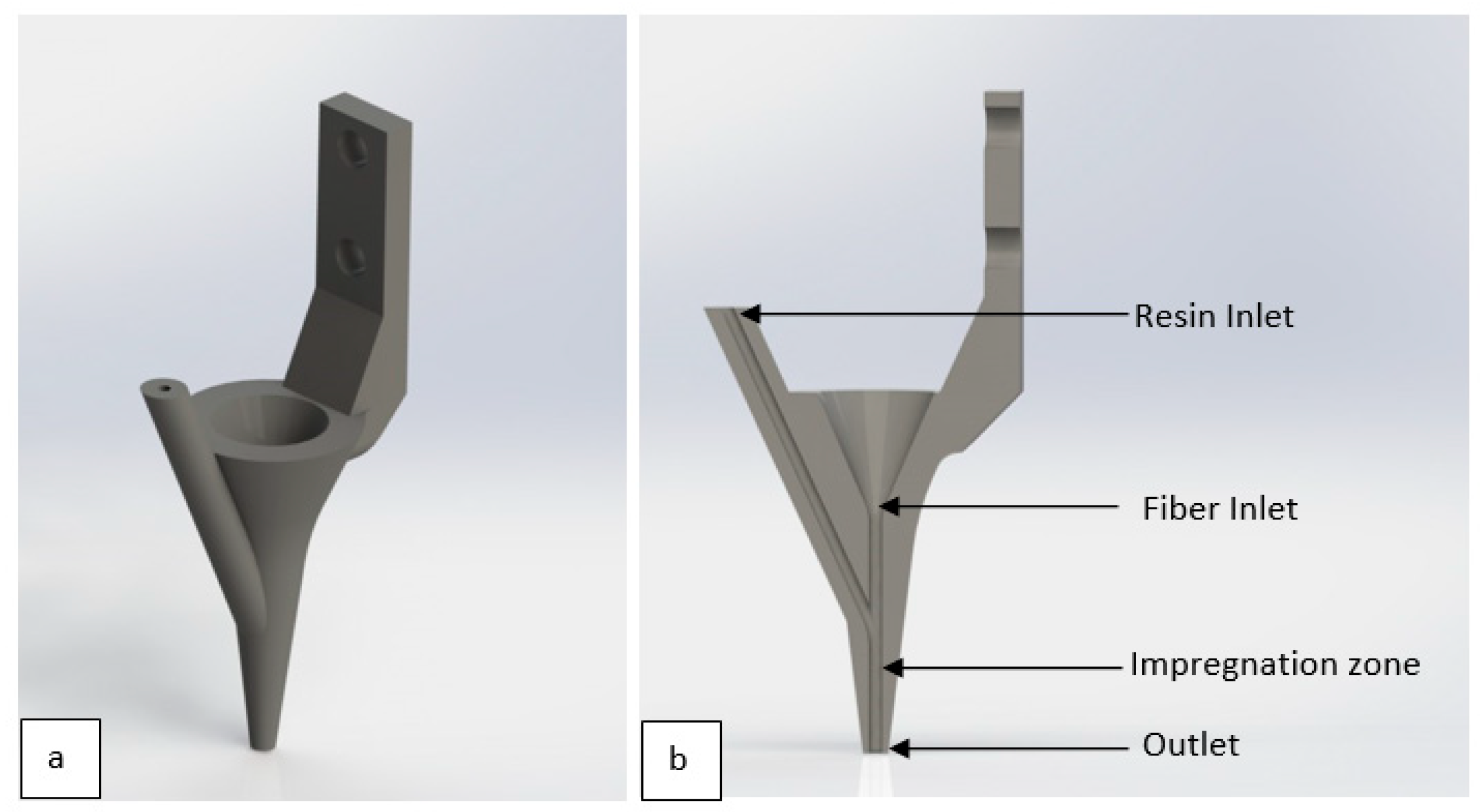

2.2. 3D Printing of Continuous Fiber Reinforced Composite

2.3. Testing

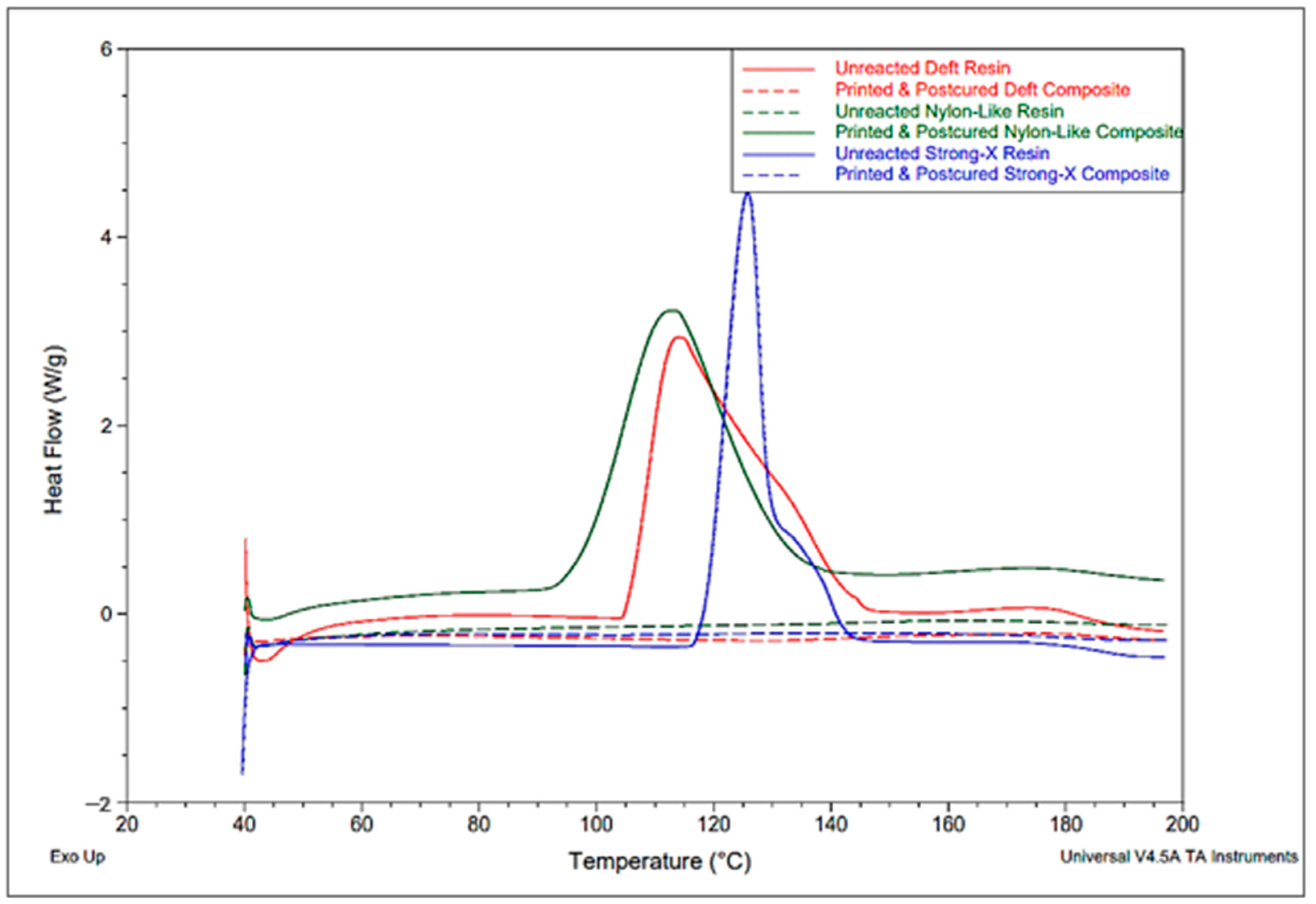

2.3.1. Differential Scanning Calorimetry (DSC)

2.3.2. Density Testing

2.3.3. Micro CT Testing

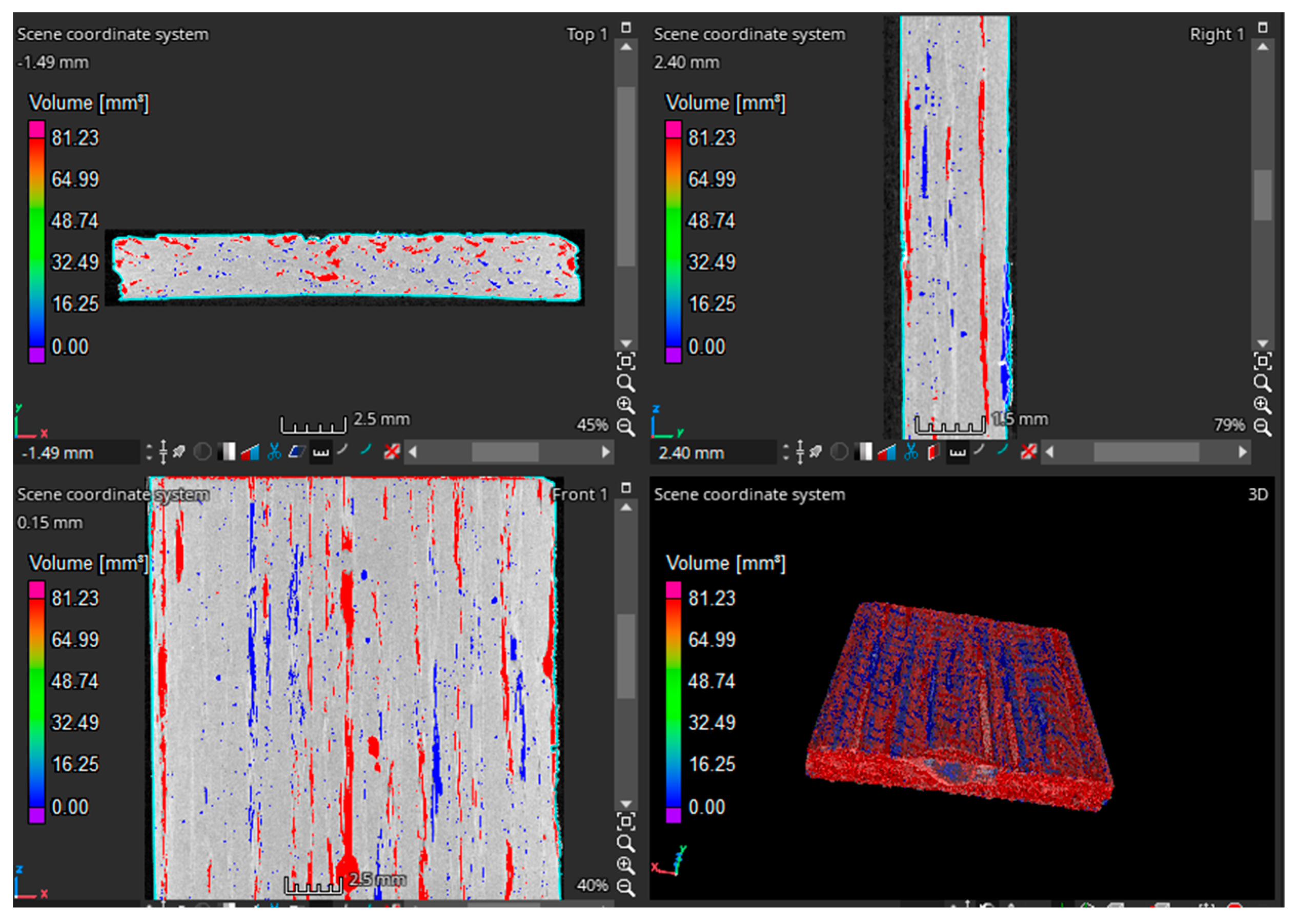

2.3.4. Burn-off Testing

2.3.5. Tensile Testing

2.3.6. Flexural Testing

3. Results and Discussion

3.1. DSC Testing

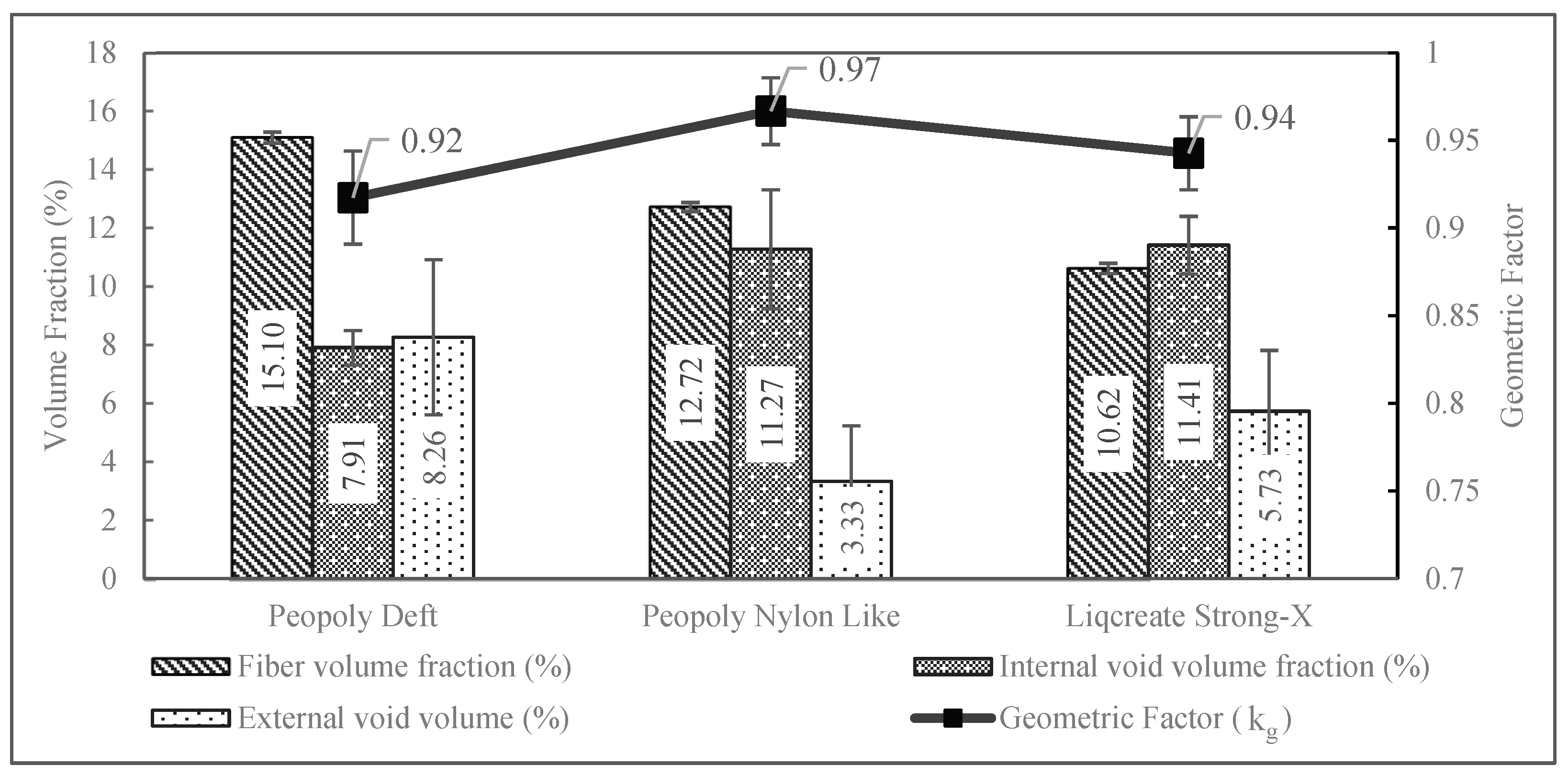

3.2. Compositional Testing and Void Analysis

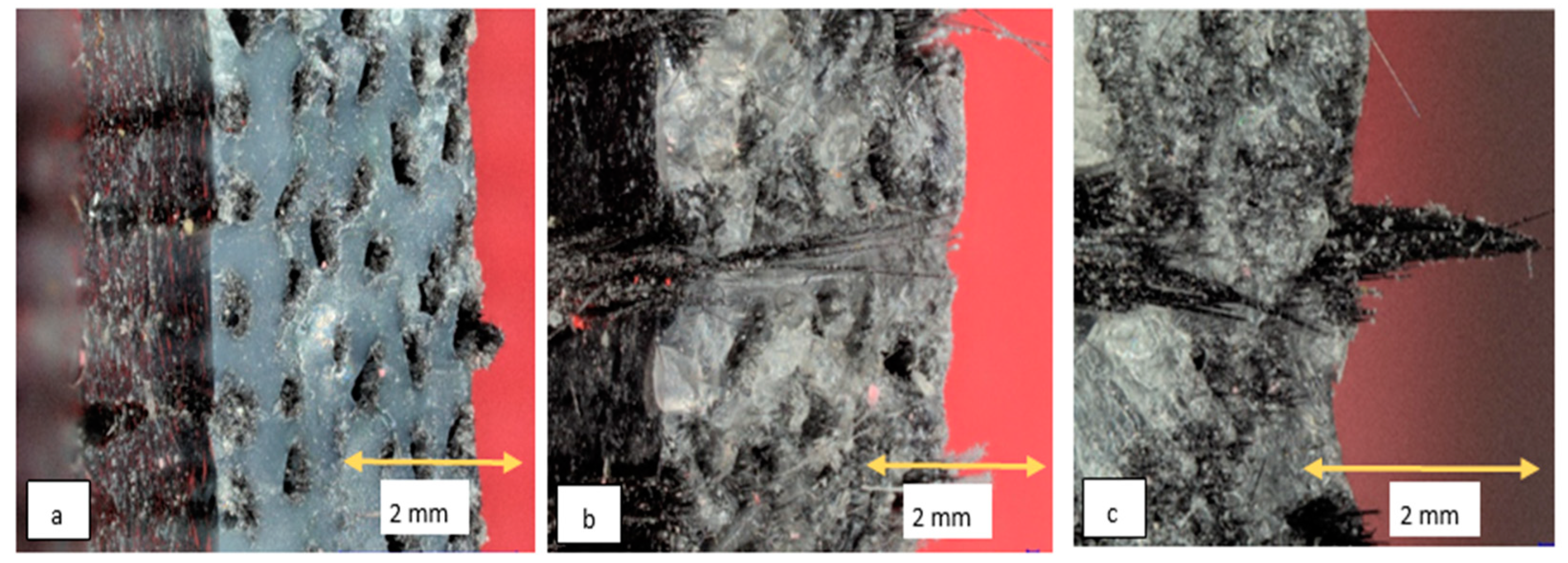

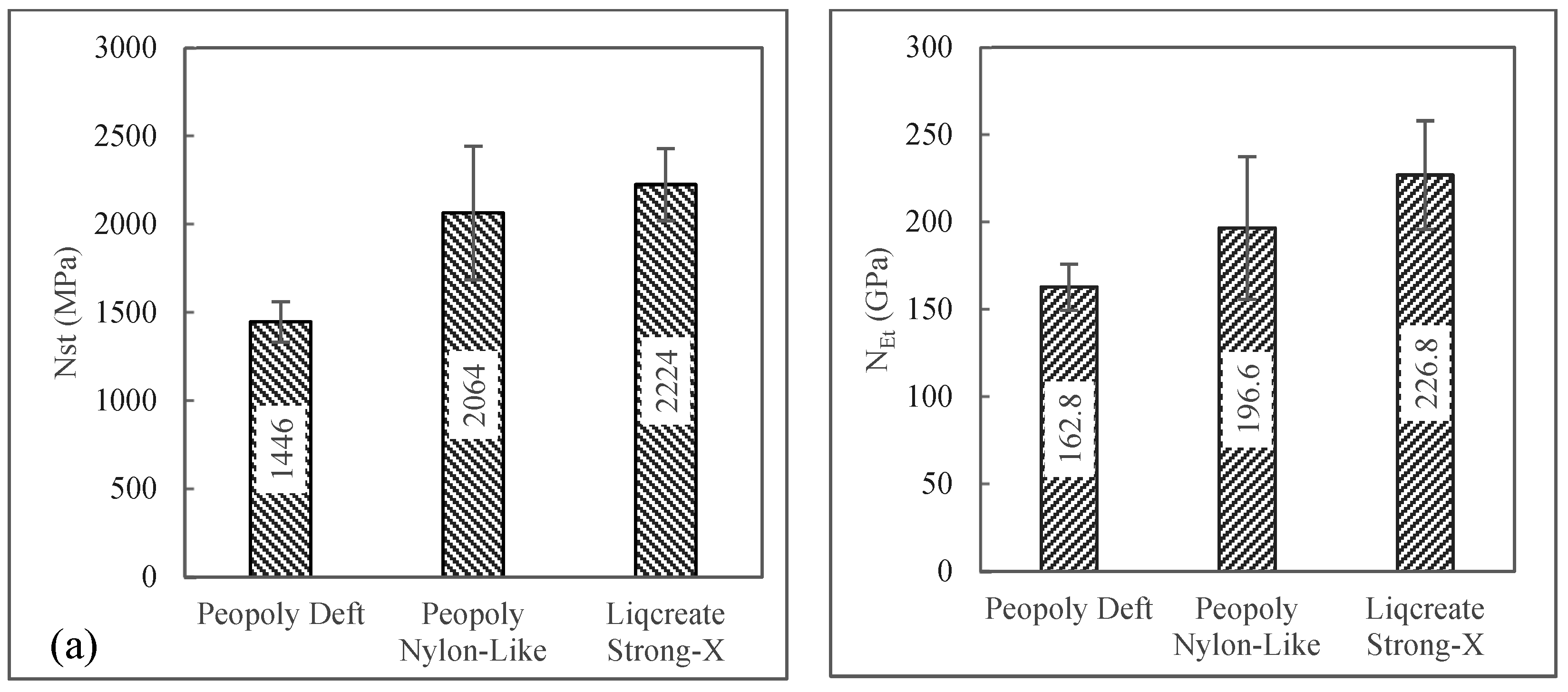

3.3. Tensile Testing

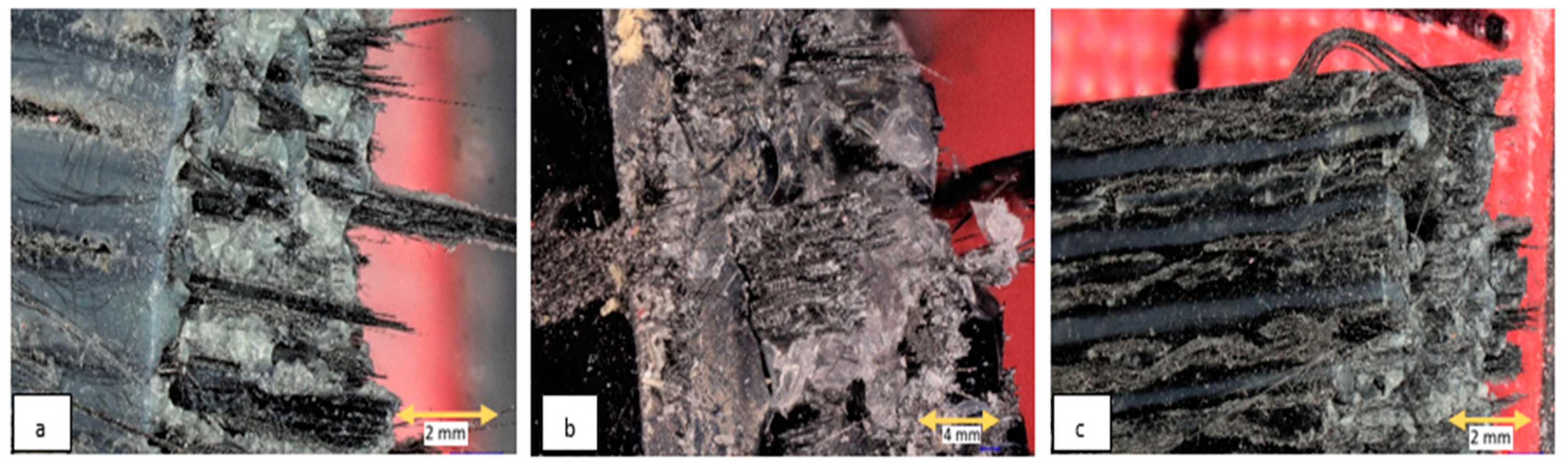

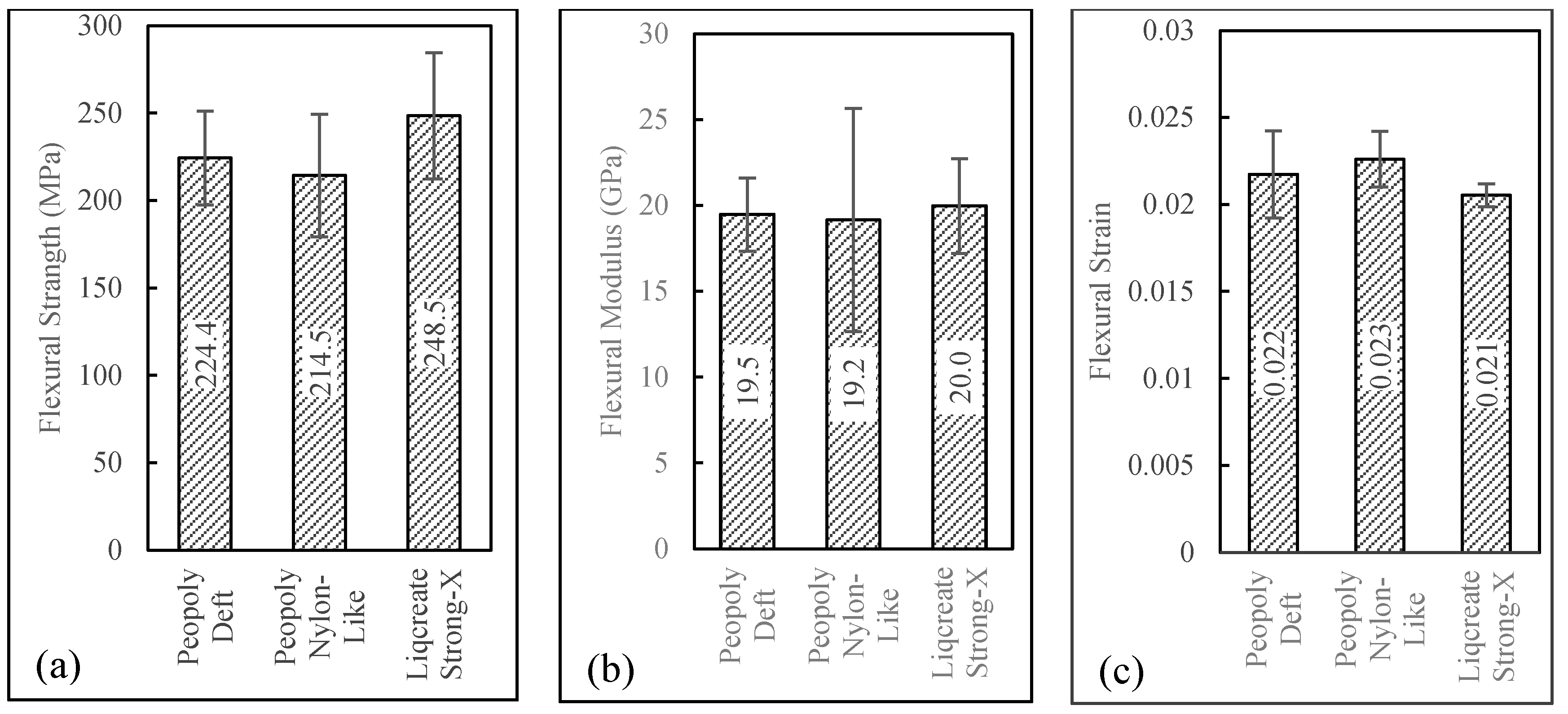

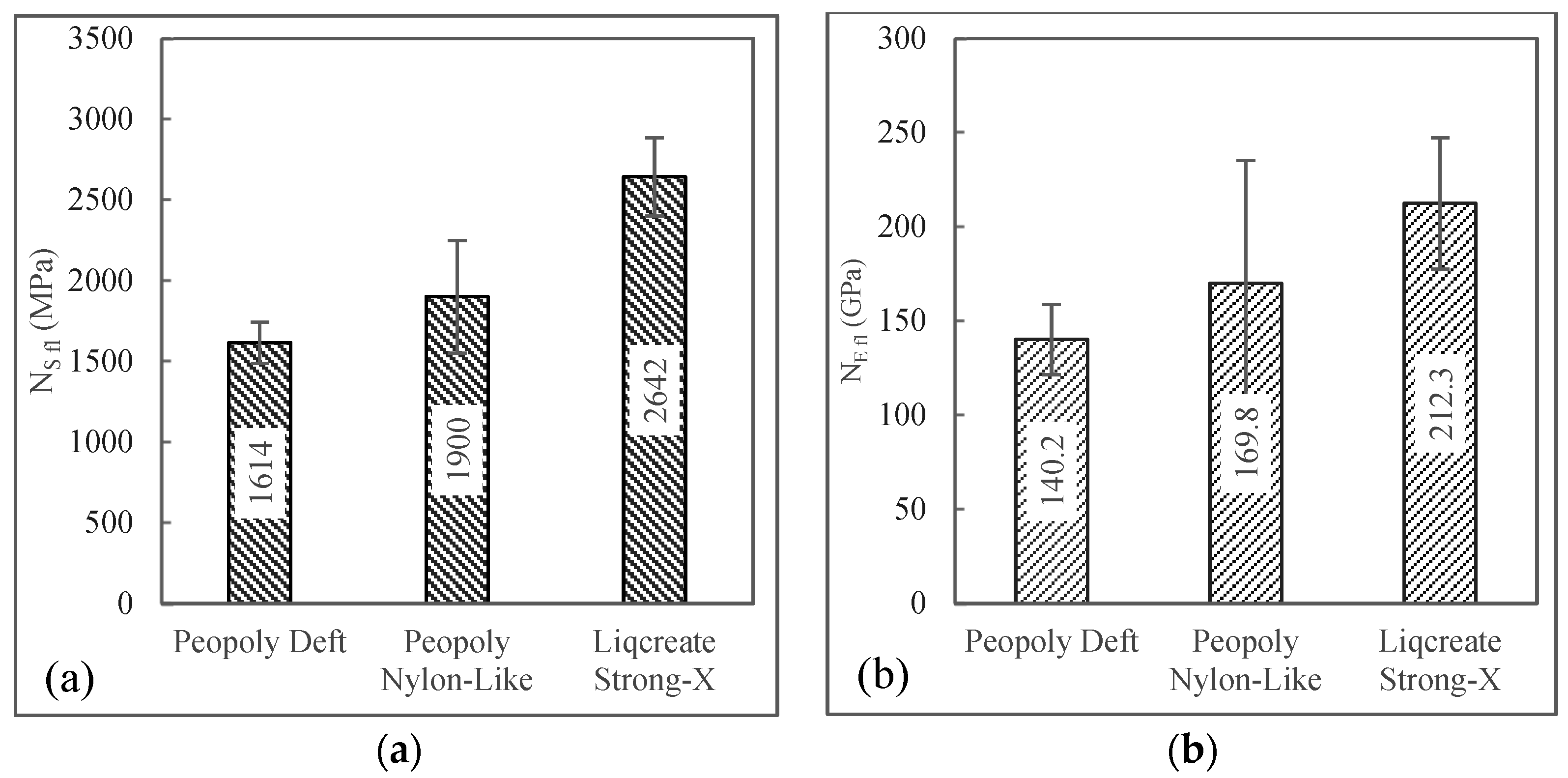

3.4. Flexural Testing

4. Conclusions and Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Horn, T.J.; Harrysson, O.L.A. Overview of Current Additive Manufacturing Technologies and Selected Applications. Sci. Prog. 2012, 95, 255–282. [Google Scholar] [CrossRef] [PubMed]

- Tamez, M.B.A.; Taha, I. A review of additive manufacturing technologies and markets for thermosetting resins and their potential for carbon fiber integration. Addit. Manuf. 2020, 37, 101748. [Google Scholar] [CrossRef]

- Lee, J.; Lee, H.; Cheon, K.-H.; Park, C.; Jang, T.-S.; Kim, H.-E.; Jung, H.-D. Fabrication of poly(lactic acid)/Ti composite scaffolds with enhanced mechanical properties and biocompatibility via fused filament fabrication (FFF)–based 3D printing. Addit. Manuf. 2019, 30, 100883. [Google Scholar] [CrossRef]

- He, F.; Ning, H.; Khan, M. Effect of 3D Printing Process Parameters on Damping Characteristic of Cantilever Beams Fabricated Using Material Extrusion. Polymers 2023, 15, 257. [Google Scholar] [CrossRef]

- Liu, J.; Naeem, M.A.; Al Kouzbary, M.; Al Kouzbary, H.; Shasmin, H.N.; Arifin, N.; Razak, N.A.A.; Abu Osman, N.A. Effect of Infill Parameters on the Compressive Strength of 3D-Printed Nylon-Based Material. Polymers 2023, 15, 255. [Google Scholar] [CrossRef]

- Bandinelli, F.; Peroni, L.; Morena, A. Elasto-Plastic Mechanical Modeling of Fused Deposition 3D Printing Materials. Polymers 2023, 15, 234. [Google Scholar] [CrossRef]

- Valencia, L.M.; Herrera, M.; de la Mata, M.; Hernández-Saz, J.; Romero-Ocaña, I.; Delgado, F.J.; Benito, J.; Molina, S.I. Stereolithography of Semiconductor Silver and Acrylic-Based Nanocomposites. Polymers 2022, 14, 5238. [Google Scholar] [CrossRef]

- Choi, Y.; Yoon, J.; Kim, J.; Lee, C.; Oh, J.; Cho, N. Development of Bisphenol-A-Glycidyl-Methacrylate- and Trimethylolpropane-Triacrylate-Based Stereolithography 3D Printing Materials. Polymers 2022, 14, 5198. [Google Scholar] [CrossRef]

- Ávila-López, M.A.; Bonilla-Cruz, J.; Méndez-Nonell, J.; Lara-Ceniceros, T.E. Strong and Lightweight Stereolithographically 3D-Printed Polymer Nanocomposites with Low Friction and High Toughness. Polymers 2022, 14, 3628. [Google Scholar] [CrossRef]

- Chaudhary, R.; Akbari, R.; Antonini, C. Rational Design and Characterization of Materials for Optimized Additive Manufacturing by Digital Light Processing. Polymers 2023, 15, 287. [Google Scholar] [CrossRef]

- Arias-Ferreiro, G.; Lasagabáster-Latorre, A.; Ares-Pernas, A.; Ligero, P.; García-Garabal, S.M.; Dopico-García, M.S.; Abad, M.-J. Lignin as a High-Value Bioaditive in 3D-DLP Printable Acrylic Resins and Polyaniline Conductive Composite. Polymers 2022, 14, 4164. [Google Scholar] [CrossRef] [PubMed]

- Košir, T.; Slavič, J. Modeling of Single-Process 3D-Printed Piezoelectric Sensors with Resistive Electrodes: The Low-Pass Filtering Effect. Polymers 2023, 15, 158. [Google Scholar] [CrossRef] [PubMed]

- Ciobanu, R.C.; Schreiner, C.; Aradoaei, M.; Hitruc, G.E.; Rusu, B.-G.; Aflori, M. Characteristics of Composite Materials of the Type: TPU/PP/BaTiO3 Powder for 3D Printing Applications. Polymers 2023, 15, 73. [Google Scholar] [CrossRef]

- Egan, P.F.; Khatri, N.R.; Parab, M.A.; Arefin, A.M.E. Mechanics of 3D-Printed Polymer Lattices with Varied Design and Processing Strategies. Polymers 2022, 14, 5515. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Kim, Y.; Kim, J.; Moon, S.Y.; Lee, J.U. Consecutive Ink Writing of Conducting Polymer and Graphene Composite Electrodes for Foldable Electronics-Related Applications. Polymers 2022, 14, 5294. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Tang, T.; Zhao, S.; Joralmon, D.; Poit, Z.; Ahire, B.; Keshav, S.; Raje, A.R.; Blair, J.; Zhang, Z. Recent Advancements and Applications in 3D Printing of Functional Optics. Addit. Manuf. 2022, 52, 102682. [Google Scholar] [CrossRef]

- Simpson, P.; Holthaus, M.J.; Gibbon, L.; Ulven, C.A. Short Glass Fiber Reinforced Perspective Chapter: Composites Manufactured by Stereolithography. IntechOpen 2021, 78. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef]

- Bekas, D.G.; Hou, Y.; Liu, Y.; Panesar, A. 3D printing to enable multifunctionality in polymer-based composites: A review. Compos. Part B Eng. 2019, 179, 107540. [Google Scholar] [CrossRef]

- Mahmood, A.; Akram, T.; Chen, H.; Chen, S. On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers 2022, 14, 4698. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Z.; Pei, Z.; Qiu, J.; Wang, S. Current progress on the 3D printing of thermosets. Adv. Compos. Hybrid Mater. 2020, 3, 462–472. [Google Scholar] [CrossRef]

- He, X.; Ding, Y.; Lei, Z.; Welch, S.; Zhang, W.; Dunn, M.; Yu, K. 3D printing of continuous fiber-reinforced thermoset composites. Addit. Manuf. 2021, 40, 101921. [Google Scholar] [CrossRef]

- Hao, W.; Liu, Y.; Zhou, H.; Chen, H.; Fang, D. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites. Polym. Test. 2018, 65, 29–34. [Google Scholar] [CrossRef]

- Rahman, A.; Islam, Z.; Gibbon, L.; Ulven, C.A.; La Scala, J.J. 3D printing of continuous carbon fiber reinforced thermoset composites using UV curable resin. Polym. Compos. 2021, 42, 5859–5868. [Google Scholar] [CrossRef]

- Rahman, M.A. Process Optimization of 3D Printing with Continuous Fiber Reinforced UV Curable Thermoset Resin; M.S., North Dakota State University: Fargo, ND, USA, 2022. [Google Scholar]

- Sano, Y.; Matsuzaki, R.; Ueda, M.; Todoroki, A.; Hirano, Y. 3D printing of discontinuous and continuous fibre composites using stereolithography. Addit. Manuf. 2018, 24, 521–527. [Google Scholar] [CrossRef]

- Justo, J.; Távara, L.; García-Guzmán, L.; París, F. Characterization of 3D printed long fibre reinforced composites. Compos. Struct. 2018, 185, 537–548. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Hu, W.; Chen, Y.; Lin, Y.; Xia, Q. Developmental and transcriptomic features characterize defects of silk gland growth and silk production in silkworm naked pupa mutant. Insect Biochem. Mol. Biol. 2019, 111, 103175. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.-K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef]

- Shi, P.; Goh, J.C. Self-assembled silk fibroin particles: Tunable size and appearance. Powder Technol. 2012, 215–216, 85–90. [Google Scholar] [CrossRef]

- O’Connor, H.J.; Dowling, D.P. Low-pressure additive manufacturing of continuous fiber-reinforced polymer composites. Polymer Composites 2019, 40, 4329–4339. [Google Scholar] [CrossRef]

- He, Q.; Wang, H.; Fu, K.; Ye, L. 3D printed continuous CF/PA6 composites: Effect of microscopic voids on mechanical performance. Compos. Sci. Technol. 2020, 191, 108077. [Google Scholar] [CrossRef]

- Imeri, A.; Fidan, I.; Allen, M.; A Wilson, D.; Canfield, S. Fatigue analysis of the fiber reinforced additively manufactured objects. Int. J. Adv. Manuf. Technol. 2018, 98, 2717–2724. [Google Scholar] [CrossRef]

- Gonzalez, J.E.A.; Wright, W.J.; Gustinvil, R.; Celik, E. Hybrid direct ink write 3D printing of high-performance composite structures. Rapid Prototyp. J. 2022. ahead of print. [Google Scholar] [CrossRef]

- Abdullah, A.M.; Ding, Y.; He, X.; Dunn, M.; Yu, K. Direct-write 3D printing of UV-curable composites with continuous carbon fiber. J. Compos. Mater. 2022. ahead of print. [Google Scholar] [CrossRef]

- Peopoly. Nylon-like Tough Resin by Peopoly. Available online: https://peopoly.net/products/nylon-like-by-peopoly-black-1kg (accessed on 28 August 2022).

- Peopoly. Deft Resin by Peopoly. Available online: https://peopoly.net/products/deft-resin-by-peopoly (accessed on 28 August 2022).

- Liqcreate. Strong-X. Available online: https://www.liqcreate.com/product/strong-x/ (accessed on 28 August 2022).

- Teijin. Tenax Filament Yarn Data-Sheet. Available online: https://www.teijincarbon.com/fileadmin/PDF/Datenbl%C3%A4tter_en/Product_Data_Sheet_TSG01en__EU_Filament_.pdf (accessed on 28 August 2022).

- Liqcreate. Linear Shrinkage of 3D Printing Resin. Available online: https://www.liqcreate.com/supportarticles/linear-shrinkage-of-3d-printing-resins/ (accessed on 5 January 2023).

- Peopoly. Peopoly Resin Shrinkage. Available online: https://forum.peopoly.net/t/shrinkage-factor/1589 (accessed on 5 January 2023).

- Aldrich, S. Luperox P. Available online: Chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/https://www.sigmaaldrich.com/specification-sheets/166/363/159042-BULK_______ALDRICH__.pdf (accessed on 28 August 2022).

- Formlabs. Tough 2000. Available online: https://formlabs-media.formlabs.com/datasheets/2001340-TDS-ENUS-0P.pdf (accessed on 26 September 2022).

- ASTM, I. D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM, I. D3171-15; Standard Test Methods for Constituent Content of Composite Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM, I. D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM, I. D7264/D7264M-21; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- Ma, Y.; Yang, Y.; Sugahara, T.; Hamada, H. A study on the failure behavior and mechanical properties of unidirectional fiber reinforced thermosetting and thermoplastic composites. Compos. Part B Eng. 2016, 99, 162–172. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Curtin, W.A. Theory of Mechanical Properties of Ceramic-Matrix Composites. J. Am. Ceram. Soc. 1991, 74, 2837–2845. [Google Scholar] [CrossRef]

- Rosen, B.W. Tensile failure of fibrous composites. AIAA J. 1964, 2, 1985–1991. [Google Scholar] [CrossRef]

- Zhou, X.-F.; Wagner, H. Stress concentrations caused by fiber failure in two-dimensional composites. Compos. Sci. Technol. 1999, 59, 1063–1071. [Google Scholar] [CrossRef]

- Liao, K.; Reifsnider, K.L. A tensile strength model for unidirectional fiber-reinforced brittle matrix composite. Int. J. Fract. 2000, 106, 95–115. [Google Scholar] [CrossRef]

| Properties | Peopoly Nylon-Like Tough | Peopoly Deft | Liqcreate Strong-X | Tenax |

|---|---|---|---|---|

| Tensile strength (MPa) | 62 | 35 | 60–84 | 4100 |

| Tensile modulus (GPa) | 2.05 | 0.75 | 3.1–3.4 | 240 |

| Elongation (%) | 44 | 6 | 3–6 | 1.7 |

| Density (gm/cm3) | 1.12 | 1.12 | 1.12 | 1.77 |

| Viscosity (cps at 25 °C) | 780 | 105 | 550 | - |

| Linear shrinkage after curing (%) | 6.5 | 6.5 | 1.5 | - |

| Layer Thickness | 0.45 ± 0.03 mm |

|---|---|

| Line Spacing | 1.0 mm |

| Nozzle Diameter | 1.0 mm |

| Post-cure (130 °C) | 3 h |

| Print Speed, (mm/min) | Peopoly Deft: 550 Peopoly Nylon-Like: 270 Liqcreate Strong-X: 310 |

| Resin Pumping Rate, (cc/hr) | Peopoly Deft: 9.5 Peopoly Nylon-Like: 5.2 Liqcreate Strong-X: 6.9 |

| Matrix | Void Source | |||

|---|---|---|---|---|

| Peopoly Deft | = 1 (no shrinkage) | 13.02 | 86.98 | 0 |

| , void = shrunk volume | 13.02 | 71.10 | 15.88 | |

| , void = shrunk volume | 13.02 | 75.86 | 11.12 | |

| Actual composition * | 15.10 | 76.99 | 7.91 | |

| Peopoly Nylon-Like | = 1 (no shrinkage) | 11.52 | 88.47 | 0 |

| , void = shrunk volume | 11.52 | 72.32 | 16.16 | |

| , void = shrunk volume | 11.52 | 78.11 | 10.37 | |

| Actual composition * | 12.72 | 76.00 | 11.27 | |

| Liqcreate Strong-X | = 1 (no shrinkage) | 10.13 | 89.87 | 0 |

| , void = shrunk volume | 10.13 | 85.88 | 3.99 | |

| , void = shrunk volume | 10.13 | 80.65 | 9.22 | |

| Actual composition * | 10.62 | 77.97 | 11.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, M.A.; Hall, E.; Gibbon, L.; Islam, M.Z.; Ulven, C.A.; La Scala, J.J. A Mechanical Performance Study of Dual Cured Thermoset Resin Systems 3D-Printed with Continuous Carbon Fiber Reinforcement. Polymers 2023, 15, 1384. https://doi.org/10.3390/polym15061384

Rahman MA, Hall E, Gibbon L, Islam MZ, Ulven CA, La Scala JJ. A Mechanical Performance Study of Dual Cured Thermoset Resin Systems 3D-Printed with Continuous Carbon Fiber Reinforcement. Polymers. 2023; 15(6):1384. https://doi.org/10.3390/polym15061384

Chicago/Turabian StyleRahman, Md Atikur, Eric Hall, Luke Gibbon, Md Zahirul Islam, Chad A. Ulven, and John J. La Scala. 2023. "A Mechanical Performance Study of Dual Cured Thermoset Resin Systems 3D-Printed with Continuous Carbon Fiber Reinforcement" Polymers 15, no. 6: 1384. https://doi.org/10.3390/polym15061384

APA StyleRahman, M. A., Hall, E., Gibbon, L., Islam, M. Z., Ulven, C. A., & La Scala, J. J. (2023). A Mechanical Performance Study of Dual Cured Thermoset Resin Systems 3D-Printed with Continuous Carbon Fiber Reinforcement. Polymers, 15(6), 1384. https://doi.org/10.3390/polym15061384