A Brief Review on Selected Applications of Hybrid Materials Based on Functionalized Cage-like Silsesquioxanes

Abstract

:1. Introduction

2. What Is Unique about Silicon-Based Species?

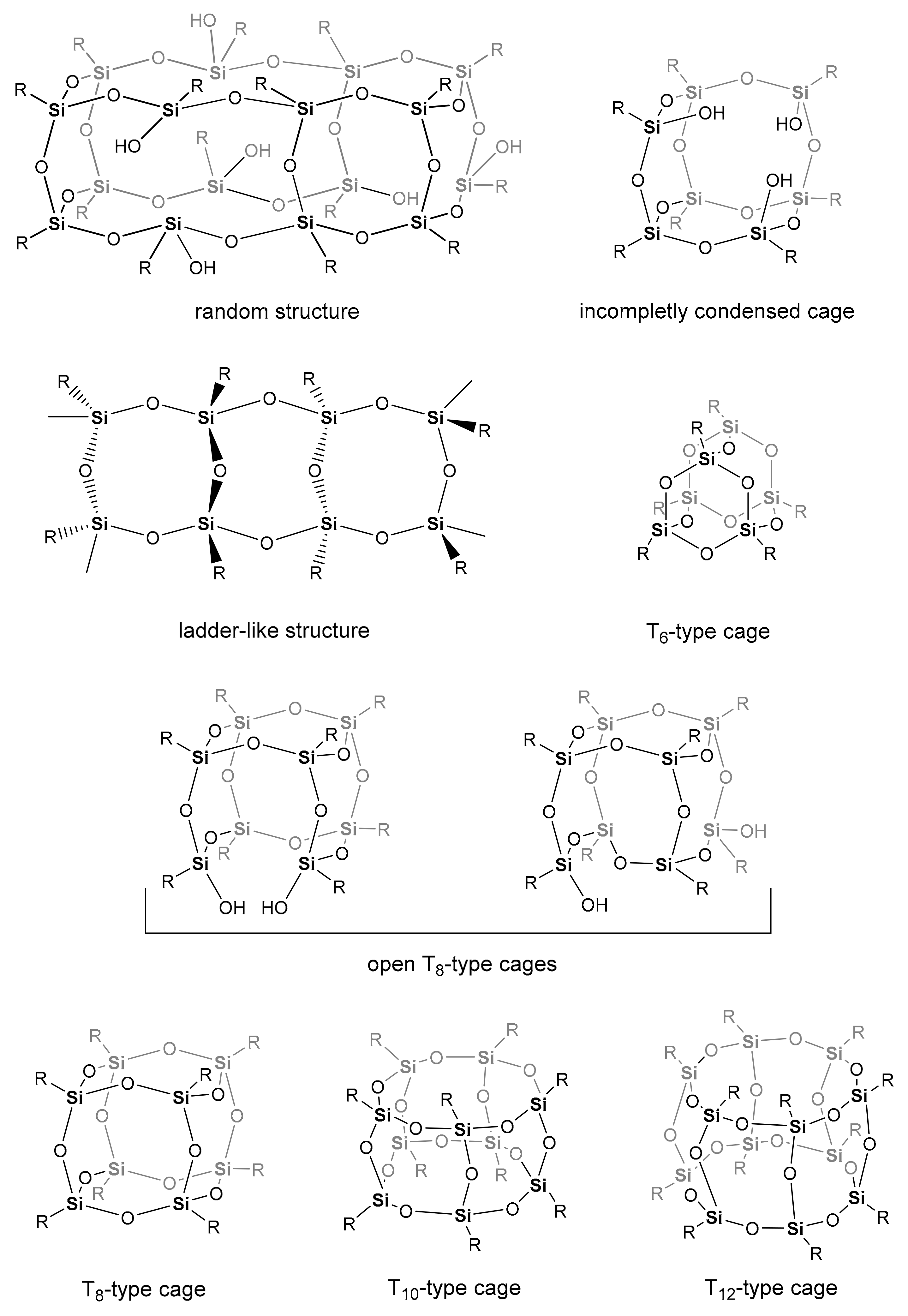

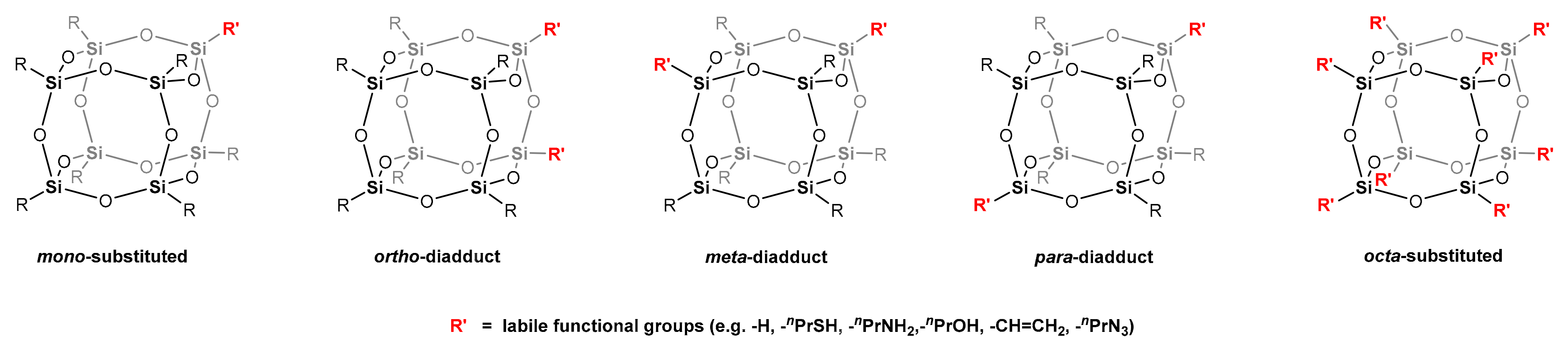

3. Cage-like Silsesquioxanes

3.1. Polyhedral Oligomeric Silsesquioxanes (POSSs)

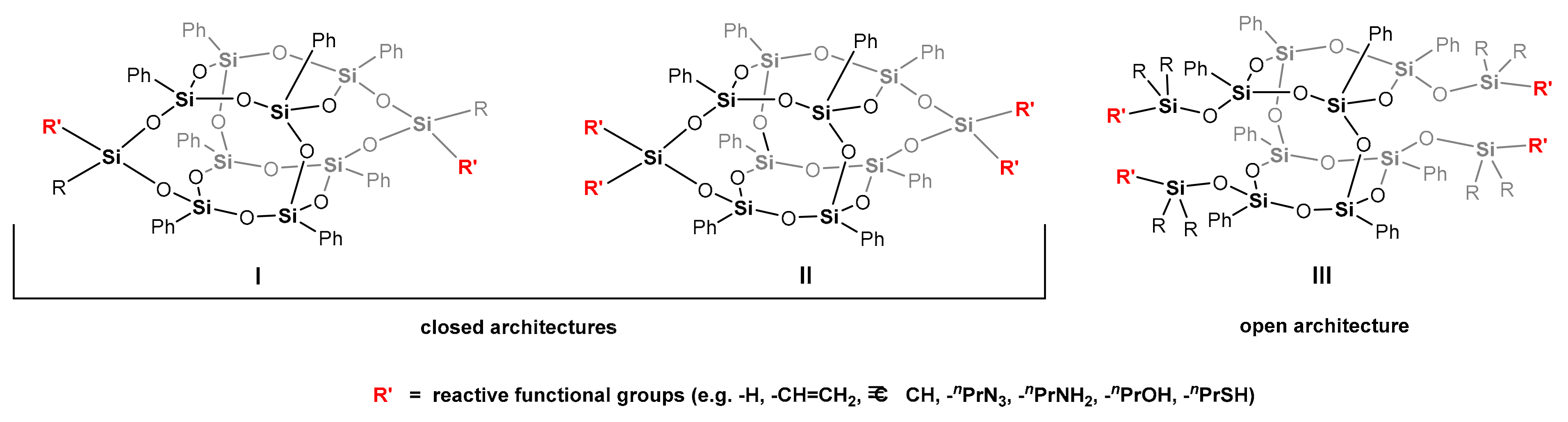

3.2. Double–Decker Silsesquioxanes (DDSQs)

4. Selected Biomaterials Based on Cage-like Silsesquioxanes

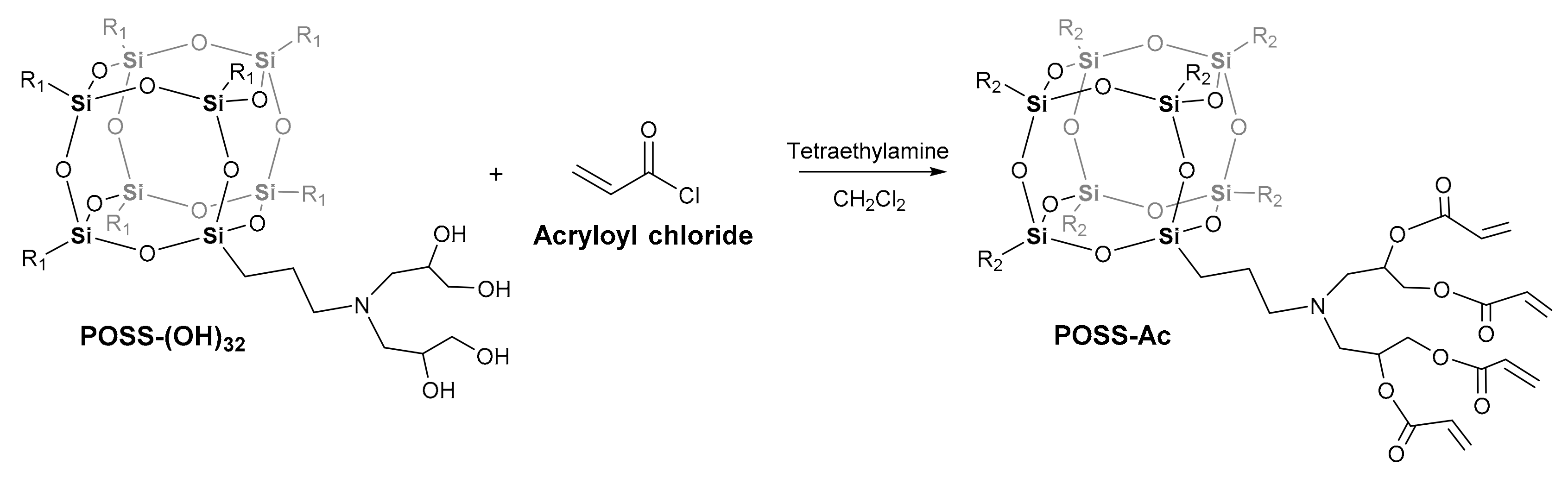

4.1. Cage-like Silsesquioxanes Incorporated into the Hydrogel Network

4.2. Cage-like Silsesquioxanes as Components in Biofabrication Techniques

4.3. Double-Decker Silsesquioxanes as Novel and Promising Components of Hybrid Biomaterials

5. Cage-like Silsesquioxanes in Materials Engineering

5.1. Flame Retardant Nanocomposites

5.2. Ziegler-Natta Catalysts

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Beyer, M.K. The mechanical strength of a covalent bond calculated by density functional theory. J. Chem. Phys. 2000, 112, 7307. [Google Scholar] [CrossRef]

- Brook, M.A. Silicon in Organic, Organometallic and Polymer Chemistry; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 1999. [Google Scholar]

- Petrucci, R.H.; Harwood, W.S.; Herring, F.G.; Madura, J.D. General Chemistry: Principles and Modern Applications, 9th ed.; Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2007. [Google Scholar]

- Atkins, P. Shriver & Atkins Inorganic Chemistry; Oxford University Press: Oxford, UK, 2006. [Google Scholar]

- Scott, D.W. Thermal rearrangement of branched-chain methylpolysiloxanes. J. Am. Chem. Soc. 1946, 68, 356. [Google Scholar] [CrossRef]

- Cordes, D.B.; Lickiss, P.D.; Rataboul, F. Recent Developments in the Chemistry of Cubic Polyhedral Oligosilsesquioxanes. Chem. Rev. 2010, 110, 2081. [Google Scholar] [CrossRef]

- John, Ł. Selected developments and medical applications of organic–inorganic hybrid biomaterials based on functionalized spherosilicates. Mater. Sci. Eng. C 2018, 88, 172. [Google Scholar] [CrossRef]

- Kowalewska, A. Self-assembling polyhedral silsesquioxanes–Structure and properties. Curr. Org. Chem. 2017, 21, 1243. [Google Scholar] [CrossRef]

- Janeta, M.; John, Ł.; Ejfler, J.; Szafert, S. Multifunctional imine-POSS as uncommon 3D nanobuilding blocks for supramolecular hybrid materials: Synthesis, structural characterization, and properties. Dalton Trans. 2016, 45, 12312. [Google Scholar] [CrossRef]

- Piec, K.; Kostera, S.; Jędrzkiewicz, D.; Ejfler, J.; John, Ł. Mono-substituted amine-oligosilsesquioxanes as functional tools in Pd(II) coordination chemistry: Synthesis and properties. New J. Chem. 2020, 44, 10786. [Google Scholar] [CrossRef]

- Michalczyk, M.; Piec, K.; Zierkiewicz, W.; Ejfler, J.; John, Ł. Possible coordination modes of copper(II) atom in model silsesquioxanes complexes at various pH conditions: DFT study. Chem. Phys. Lett. 2021, 778, 138739. [Google Scholar] [CrossRef]

- Piec, K.; Wątły, J.; Jerzykiewicz, M.; Kłak, J.; Plichta, A.; John, Ł. Mono-substituted cage-like silsesquioxanes bound by trifunctional acyl chloride as a multi-donor N,O-type ligand in copper(II) coordination chemistry: Synthesis and structural properties. New J. Chem. 2021, 45, 4156. [Google Scholar] [CrossRef]

- Wytrych, P.; Utko, J.; Stefanski, M.; Kłak, J.; Lis, T.; John, Ł. Synthesis, Crystal Structures, and Optical and Magnetic Properties of Samarium, Terbium, and Erbium Coordination Entities Containing Mono-Substituted Imine Silsesquioxane Ligands. Inorg. Chem. 2023, 62, 2913. [Google Scholar] [CrossRef]

- Jin, L.; Hong, C.; Li, X.; Sun, Z.; Feng, F.; Liu, H. Corner-opening and corner-capping of monosubstituted T8 POSS: Product distribution and isomerization. Chem. Comm. 2022, 58, 1573. [Google Scholar] [CrossRef]

- Maegawa, T.; Irie, Y.; Imoto, H.; Fueno, H.; Tanaka, K.; Naka, K. para-Bisvinylhexaisobutyl-substituted T8 caged monomer: Synthesis and hydrosilylation polymerization. Polym. Chem. 2015, 6, 7500. [Google Scholar] [CrossRef]

- Janeta, M.; John, Ł.; Ejfler, J.; Szafert, S. High-yield synthesis of amido-functionalized polyoctahedral oligomeric silsesquioxanes by using acyl chlorides. Chem.–Eur. J. 2014, 20, 15966. [Google Scholar] [CrossRef]

- John, Ł.; Janeta, M.; Rajczakowska, M.; Ejfler, J.; Łydżba, D.; Szafert, S. Synthesis and microstructural properties of the scaffold based on a 3-(trimethoxysilyl)propyl methacrylate-POSS hybrid towards potential tissue engineering applications. RSC Adv. 2016, 6, 66037. [Google Scholar] [CrossRef]

- John, Ł.; Malik, M.A.; Janeta, M.; Szafert, S. First step towards a model system of the drug delivery network based on amide-POSS nanocarriers. RSC Adv. 2017, 7, 8394. [Google Scholar] [CrossRef]

- Morimoto, Y.; Watanabe, K.; Ootake, N.; Inagaki, J.; Yoshida, K.; Ohguma, K. Silsesquioxane Derivatives and Process for Production Thereof. WO Patent 03/024870 A1, 27 March 2003. [Google Scholar]

- Dudziec, B.; Marciniec, B. Double-decker silsesquioxanes: Current chemistry and applications. Curr. Org. Chem. 2017, 21, 2794. [Google Scholar] [CrossRef]

- Władyczyn, A.; Gągor, A.; Ślepokura, K.; John, Ł. Hydroxyalkyl-substituted double-decker silsesquioxanes: Effective separation of cis and trans isomers. Inorg. Chem. Front. 2022, 9, 3999. [Google Scholar] [CrossRef]

- Jones, J.R. Reprint of: Review of bioactive glass: From Hench to hybrids. Acta Biomater. 2015, 23, S53. [Google Scholar] [CrossRef]

- Simila, H.O.; Boccaccini, A.R. Sol-gel bioactive glass containing biomaterials for restorative dentistry: A review. Dent. Mater. 2022, 38, 725. [Google Scholar] [CrossRef]

- Jones, J.R. Sol-gel materials for biomedical applications. In The Sol-Gel Handbook; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2015; Volume 3, pp. 1345–1370. [Google Scholar]

- Demir-Oğuz, Ö.; Boccaccini, A.R.; Loca, D. Injectable bone cements: What benefits the combination of calcium phosphates and bioactive glasses could bring? Bioact. Mater. 2023, 19, 217. [Google Scholar] [CrossRef]

- Rai, R.; Roether, J.A.; Boccaccini, A.R. Polyaniline based polymers in tissue engineering applications: A review. Prog. Biomed. Eng. 2022, 4, 042004. [Google Scholar] [CrossRef]

- Ege, D.; Zheng, K.; Boccaccini, A.R. Borate Bioactive Glasses (BBG): Bone regeneration, wound healing applications, and Future Directions. ACS Appl. Bio Mater. 2022, 5, 3608. [Google Scholar] [CrossRef]

- Chlanda, A.; Oberbek, P.; Heljak, M.; Kijeńska-Gawrońska, E.; Bolek, T.; Gloc, M.; John, Ł.; Janeta, M.; Woźniak, M.J. Fabrication, multi-scale characterization and in-vitro evaluation of porous hybrid bioactive glass polymer-coated scaffolds for bone tissue engineering. Mater. Sci. Eng. C 2019, 94, 516. [Google Scholar] [CrossRef] [PubMed]

- Poologasundarampillai, G.; Wang, D.; Li, S.; Nakamura, J.; Bradley, R.; Lee, P.D.; Stevens, M.M.; McPhail, D.S.; Kasuga, T.; Jones, J.R. Cotton-wool-like bioactive glasses for bone regeneration. Acta Biomater. 2014, 10, 3733. [Google Scholar] [CrossRef] [PubMed]

- John, Ł.; Janeta, M.; Szafert, S. Designing of microporous magnetic bioscaffolds based on functionalized methacrylate network covered by hydroxyapatites and doped with nano-MgFe2O4 for potential cancer hyperthermia therapy. Mater. Sci. Eng. C 2017, 78, 901. [Google Scholar] [CrossRef]

- Liu, S.; Guo, R.; Li, C.; Lu, C.; Yang, G.; Wang, F.; Nie, J.; Ma, C.; Gao, M. POSS hybrid hydrogels: A brief review of synthesis, properties and applications. Eur. Polym. J. 2021, 143, 110180. [Google Scholar] [CrossRef]

- Fan, L.; Wang, X.; Wu, D. Polyhedral oligomeric silsesquioxanes (POSS)-based hybrid materials: Molecular design, solution self assembly and biomedical applications. Chin. J. Chem. 2021, 39, 757. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Chen, M.J.; Tian, J.; Gu, P.; Cao, H.L.; Fan, X.Q.; Zhang, W.A. In situ bone regeneration enabled by a biodegradable hybrid double-network hydrogel. Biomater. Sci. 2019, 7, 3266. [Google Scholar] [CrossRef]

- Szefert, E.; Stafin, K.; Leszczyńska, A.; Zając, P.; Hebda, E.; Raftopoulos, K.N.; Pielichowski, K. Morphology, dynamics, and order development in a thermoplastic polyurethane with melt blended POSS. J. Polym. Sci. Part B Polym. Phys. 2019, 57, 1133. [Google Scholar] [CrossRef]

- Chen, M.J.; Zhang, Y.H.; Zhang, W.A.; Li, J. Polyhedral oligomeric silsesquioxane-incorporated gelatin hydrogel promotes angiogenesis during vascularized bone regeneration. ACS Appl. Mater. Interfaces 2020, 12, 22410. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Z.; Xie, T.; Sun, L.; Yang, K.; Liu, Y.; Li, Z. Enhancing thermal and mechanical properties of gelatin-based nanocomposite with aqueous dispersible multiple epoxy polyhedral oligomeric silsesquioxanes. J. Mater. Sci. 2021, 56, 8528. [Google Scholar] [CrossRef]

- Zhang, X.; He, Y.; Huang, P.; Jiang, G.; Zhang, M.; Yu, F.; Zhang, W.; Fu, G.; Wang, Y.; Li, W.; et al. A novel mineralized high strength hydrogel for enhancing cell adhesion and promoting skull bone regeneration in situ. Comp. Part B 2020, 197, 10818. [Google Scholar] [CrossRef]

- Yu, T.; Zhang, L.; Dou, X.; Bai, R.; Wang, H.; Deng, J.; Zhang, Y.; Sun, Q.; Li, Q.; Wang, X.; et al. Mechanically robust hydrogels facilitating bone regeneration through epigenetic modulation. Adv. Sci. 2022, 9, 2203734. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Huang, H.; Fan, S.; Yang, C.; Chen, Y.; Yu, B.; Li, W.; Liao, J. A novel dual-crosslinked functional hydrogel activated by POSS for accelerating wound healing. Adv. Mater. Technol. 2021, 6, 2001012. [Google Scholar] [CrossRef]

- John, Ł.; Podgórska, M.; Nedelec, J.-M.; Cwynar-Zając, Ł.; Dzięgiel, P. Strontium-doped organic-inorganic hybrids towards three-dimmentional scaffolds for osteogenic cells. Mater. Sci. Eng. C 2016, 68, 117. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ye, M.; Wang, X.; Li, W.; Chen, W. Functionalized gelatin/strontium hydrogel bearing endothelial progenitor cells for accelerating angiogenesis in wound tissue regeneration. Biomater. Adv. 2022, 136, 212803. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Huang, P.; Jiang, G.; Zhang, M.; Yu, F.; Dong, X.; Wang, L.; Chen, Y.; Zhang, W.; Qi, Y.; et al. A novel magnesium ion-incorporating dual-crosslinked hydrogel to improve bone scaffold-mediated osteogenesis and angiogenesis. Mater. Sci. Eng. C 2021, 121, 111868. [Google Scholar] [CrossRef]

- Kitana, W.; Apsite, I.; Hazur, J.; Boccaccini, A.R.; Ionov, L. 4D Biofabrication of T-Shaped Vascular Bifurcation. Adv. Mater. Technol. 2023, 8, 2200429. [Google Scholar] [CrossRef]

- Shamsabadi, Z.A.; Mahdavi, H.; Shojaei, S.; Salehi, H.; Valiani, A. Physicomechanical and cellular behavior of 3D printed polycaprolactone/poly(lactic-co-glycolic acid) scaffold containing polyhedral oligomeric silsesquioxane and extracellular matrix nanoparticles for cartilage tissue engineering. Polym. Adv. Technol. 2022, 33, 2774. [Google Scholar] [CrossRef]

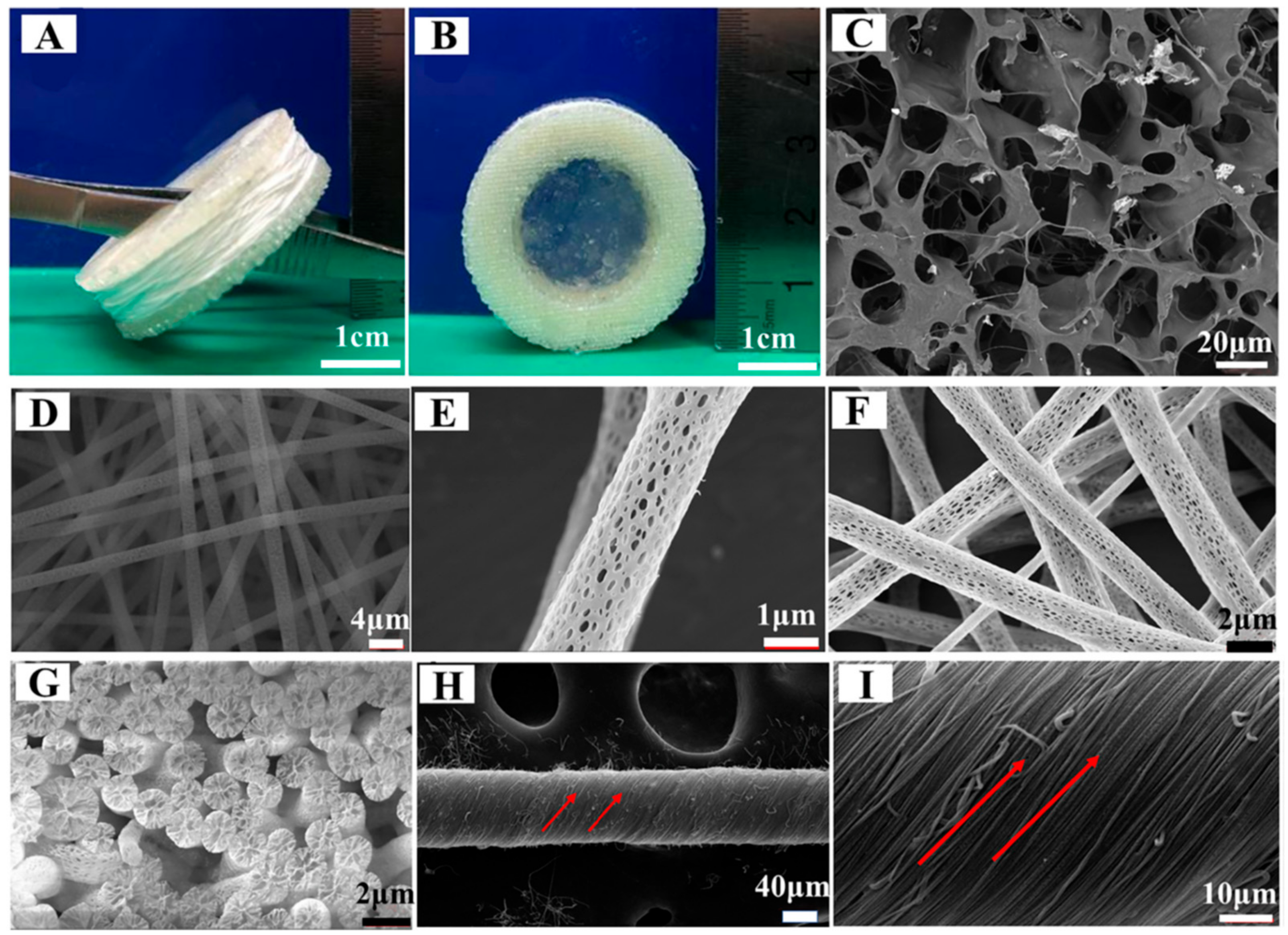

- Zhu, M.; Tan, J.; Liu, L.; Tian, J.; Li, L.; Luo, B.; Zhou, C.; Lu, L. Construction of biomimetic artificial intervertebral disc scaffold via 3D printing and electrospinning. Mater. Sci. Eng. C 2021, 128, 112310. [Google Scholar] [CrossRef]

- Han, Y.; Wang, F.; Lim, C.Y.; Chi, H.; Chen, D.; Wang, F.; Jiao, X. High-performance nano-photoinitiators with improved safety for 3D printing. ACS Appl. Mater. Interfaces 2017, 9, 32418. [Google Scholar] [CrossRef]

- Jiang, Z.; Song, Y.; Li, A.; Sun, D. MethacrylPhenyl POSS modified UV-curing materials for three-dimensional printing. SN Appl. Sci. 2019, 1, 957. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Wang, Z.; Wang, Y.; Dong, W.; Ma, W.; Zhao, S.; Sun, D. 3D-printed porous PEEK scaffold combined with CSMA/POSS bioactive surface: A strategy for enhancing osseointegration of PEEK implants. Comp. Part B 2022, 230, 109512. [Google Scholar] [CrossRef]

- Gong, H.; Zhao, Y.; Chen, Q.; Wang, Y.; Zhao, H.; Zhong, J.; Lan, Q.; Jiang, Y.; Huang, W. 3D bio-printing of photocrosslinked anatomically tooth-shaped scaffolds for alveolar ridge preservation after tooth extraction. J. Mater. Chem. B 2022, 10, 8502. [Google Scholar] [CrossRef]

- Mehrabi, T.; Mesgar, A.S.; Mohammadi, Z. Bioactive glasses: A promising therapeutic ion release strategy for enhancing wound healing. ACS Biomater. Sci. Eng. 2020, 6, 5399. [Google Scholar] [CrossRef]

- Władyczyn, A.; Simiczyjew, A.; Nowak, D.; Wądzyńska, J.; John, Ł. Novel hybrid composites based on double-decker silsesquioxanes functionalized by methacrylate derivatives and polyvinyl alcohol as potential materials utilized in biomedical applications. Biomater. Adv. 2023, 146, 213290. [Google Scholar] [CrossRef]

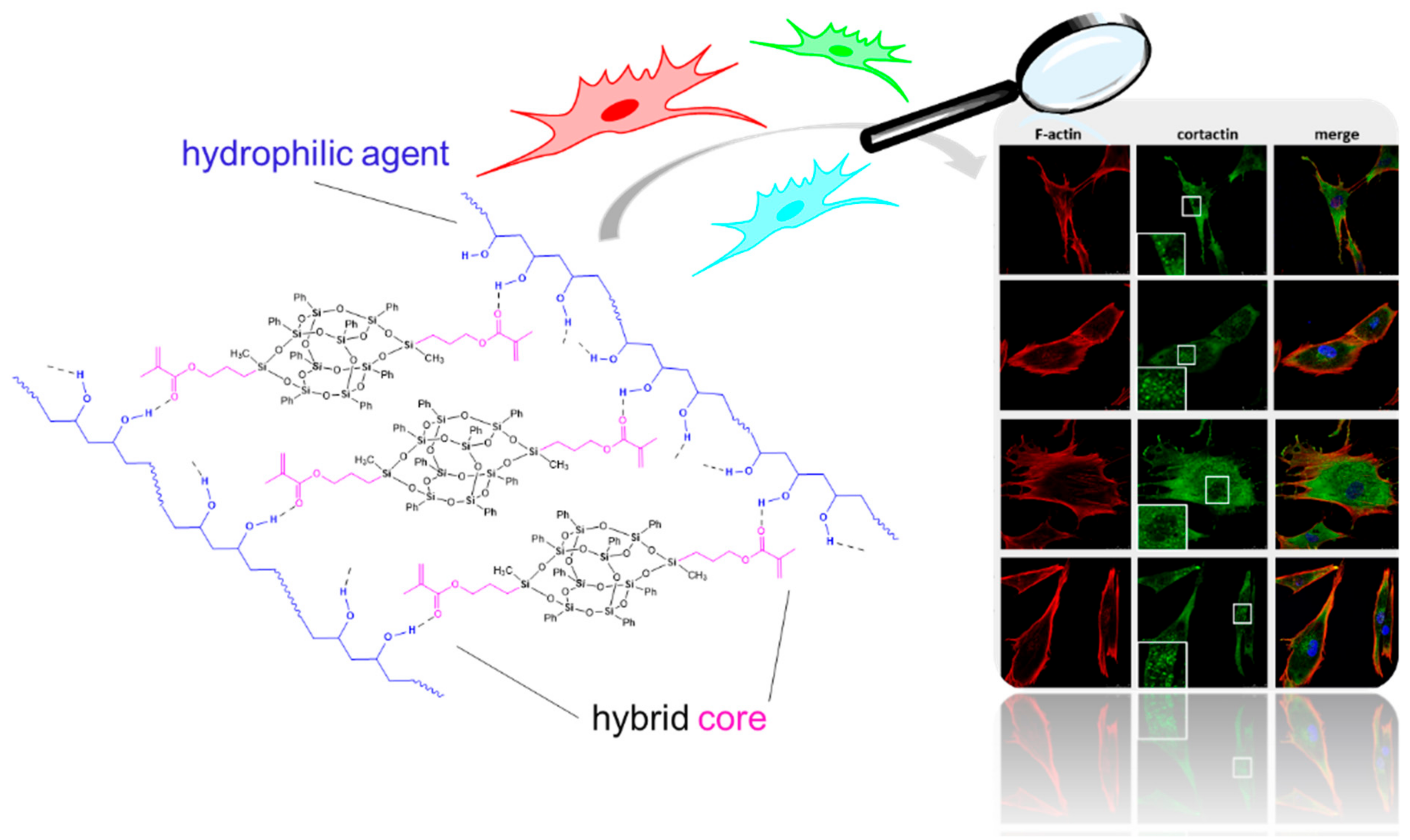

- Chi, H.; Wang, M.; Li, J.; Tian, H.; Chong, Y.T.; Lim, S.H.; Wang, Y.; Wang, F. Polyhedral oligomeric silsesquioxane as a polarity mediator and reinforced nanofiller for fabricating robust and hierarchical porous film for cell bioengineering. ACS Appl. Polym. Mater. 2022, 4, 5882. [Google Scholar] [CrossRef]

- Guerra, V.; Wan, C.; McNally, T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Prog. Mater. Sci. 2019, 100, 170. [Google Scholar] [CrossRef]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog. Mater. Sci. 2019, 103, 319. [Google Scholar] [CrossRef]

- Umoren, S.A.; Solomon, M.M. Protective polymeric films for industrial substrates: A critical review on past and recent applications with conducting polymers and polymer composites/nanocomposites. Prog. Mater. Sci. 2019, 104, 380. [Google Scholar] [CrossRef]

- Joshi, M.; Adak, B.; Butola, B.S. Polyurethane nanocomposite based gas barrier films, membranes and coatings: A review on synthesis, characterization and potential applications. Prog. Mater. Sci. 2018, 97, 230. [Google Scholar] [CrossRef]

- Mallakpour, S.; Naghdi, M. Polymer/SiO2 nanocomposites: Production and applications. Prog. Mater. Sci. 2018, 97, 409. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Dubois, P. Bio-based flame retardants: When nature meets fire protection. Mater. Sci. Eng. R 2017, 117, 1–25. [Google Scholar] [CrossRef]

- Fina, A.; Abbenhuis, H.C.; Tabuani, D.; Camino, G. Metal functionalized POSS as fire retardants in polypropylene. Polym. Degrad. Stabil. 2006, 91, 2275. [Google Scholar] [CrossRef]

- Franchini, E.; Galy, J.; Gerard, J.F.; Tabuani, D.; Medici, A. Influence of POSS structure on the fire retardant properties of epoxy hybrid networks. Polym. Degrad. Stabil. 2009, 94, 1728. [Google Scholar] [CrossRef]

- Raimondo, M.; Russo, S.; Guadagno, L.; Longo, P.; Chirico, S.; Mariconda, A.; Bonnaud, L.; Murariu, O.; Dubois, P. Effect of incorporation of POSS compounds and phosphorous hardeners on thermal and fire resistance of nanofilled aeronautic resins. RSC Adv. 2015, 5, 10974–10986. [Google Scholar] [CrossRef]

- Vannier, A.; Duquesne, S.; Bourbigot, S.; Castrovinci, A.; Camino, G.; Delobel, R. The use of POSS as synergist in intumescent recycled poly (ethylene terephthalate). Polym. Degrad. Stabil. 2008, 93, 818. [Google Scholar] [CrossRef]

- Didane, N.; Giraud, S.; Devaux, E.; Lemort, G. A comparative study of POSS as synergists with zinc phosphinates for PET fire retardancy. Polym. Degrad. Stabil. 2012, 97, 383. [Google Scholar] [CrossRef]

- Didane, N.; Giraud, S.; Devaux, E.; Lemort, G. Development of fire resistant PET fibrous structures based on phosphinate-POSS blends. Polym. Degrad. Stabil. 2012, 97, 879. [Google Scholar] [CrossRef]

- He, Q.; Song, L.; Hu, Y.; Zhou, S. Synergistic effects of polyhedral oligomeric silsesquioxane (POSS) and oligomeric bisphenyl A bis (diphenyl phosphate)(BDP) on thermal and flame retardant properties of polycarbonate. J. Mater. Sci. 2009, 44, 1308. [Google Scholar] [CrossRef]

- Chigwada, G.; Jash, P.; Jiang, D.D.; Wilkie, C.A. Fire retardancy of vinyl ester nanocomposites: Synergy with phosphorus-based fire retardants. Polym. Degrad. Stabil. 2005, 89, 85. [Google Scholar] [CrossRef]

- Vahabi, H.; Eterradossi, O.; Ferry, L.; Longuet, C.; Sonnier, R.; Lopez-Cuesta, J.M. Polycarbonate nanocomposite with improved fire behavior, physical and psychophysical transparency. Eur. Polym. J. 2013, 49, 319. [Google Scholar] [CrossRef]

- Kashiwagi, T. Progress in Flammability Studies of Nanocomposites with New Types of Nanoparticles. In Flame Retardant Polymer Nanocomposites; Morgan, A.B., Wilkie, C.A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007; Chapter 10; pp. 285–324. [Google Scholar]

- Wang, X.; Xuan, S.; Song, L.; Yang, H.; Lu, H.; Hu, Y. Synergistic effect of POSS on mechanical properties, flammability, and thermal degradation of intumescent flame retardant polylactide composites. J. Macromol. Sci. B 2012, 51, 255. [Google Scholar] [CrossRef]

- Gerard, C.; Fontaine, G.; Bellayer, S.; Bourbigot, S. Reaction to fire of an intumescent epoxy resin: Protection mechanisms and synergy. Polym. Degrad. Stabil. 2012, 97, 1366. [Google Scholar] [CrossRef]

- Gerard, C.; Fontaine, G.; Bourbigot, S. Synergistic and antagonistic effects in flame retardancy of an intumescent epoxy resin. Polym. Adv. Technol. 2011, 22, 1085. [Google Scholar] [CrossRef]

- Li, Y.C.; Mannen, S.; Schulz, J.; Grunlan, J.C. Growth and fire protection behavior of POSS-based multilayer thin films. J. Mater. Chem. 2011, 21, 3060. [Google Scholar] [CrossRef]

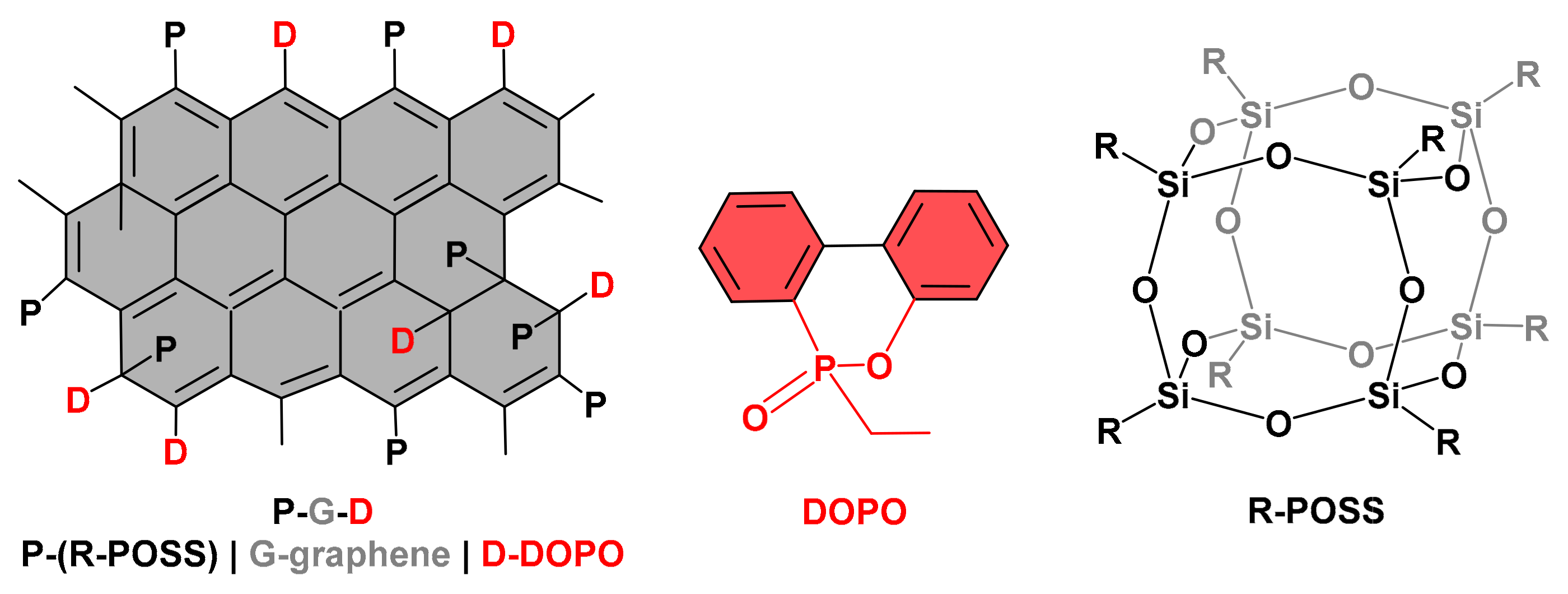

- Zhang, W.; Li, X.; Guo, X.; Yang, R. Mechanical and thermal properties and flame retardancy of phosphorus-containing polyhedral oligomeric silsesquioxane (DOPO/POSS)/ polycarbonate composites. Polym. Degrad. Stabil. 2010, 95, 2541. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, R. Synthesis of phosphorus-containing polyhedral oligomeric silsesquioxanes via hydrolytic condensation of a modified silane. J. Appl. Polym. Sci. 2011, 122, 3383. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Yang, R. Flame retardant mechanisms of phosphorus-containing polyhedral oligomeric silsesquioxane (DOPO-POSS) in polycarbonate composites. J. Appl. Polym. Sci. 2012, 124, 1848. [Google Scholar] [CrossRef]

- Zhang, W.; Li, X.; Yang, R. Novel flame retardancy effects of DOPO-POSS on epoxy resins. Polym. Degrad. Stabil. 2011, 96, 2167. [Google Scholar] [CrossRef]

- Guo, Z.; Ye, R.; Zhao, L.; Ran, S.; Fang, Z.; Li, J. Fabrication of fullerene-decorated graphene oxide and its influence on flame retardancy of high density polyethylene. Compos. Sci. Technol. 2016, 129, 123. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Wu, L. Preparation of a silica nanospheres/graphene oxide hybrid and its application in phenolic foams with improved mechanical strengths, friability and flame retardancy. RSC Adv. 2015, 5, 99907. [Google Scholar] [CrossRef]

- Song, P.A.; Zhao, L.P.; Cao, Z.H.; Fang, Z.P. Polypropylene nanocomposites based on C60-decorated carbon nanotubes: Thermal properties, flammability, and mechanical properties. J. Mater. Chem. 2011, 21, 7782. [Google Scholar] [CrossRef]

- Song, P.A.; Liu, L.N.; Huang, G.B.; Yu, Y.M.; Guo, Q.P. Largely enhanced thermal and mechanical properties of polymer nanocomposites via incorporating C60@graphene nanocarbon hybrid. Nanotechnology 2013, 24, 505706. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Song, L.; Yang, H.; Xing, W.; Kandola, B.; Hu, Y. Simultaneous reduction and surface functionalization of graphene oxide with POSS for reducing fire hazards in epoxy composites. J. Mater. Chem. 2012, 22, 22037. [Google Scholar] [CrossRef]

- Yuan, G.; Yang, B.; Chen, Y.; Jia, Y. Preparation of novel phosphorus-nitrogen-silicone grafted graphene oxide and its synergistic effect on intumescent flame retardant polypropylene composites. RSC Adv. 2018, 8, 36286. [Google Scholar] [CrossRef]

- Xu, J.D.; Zhang, W.H.; Jiang, Q.Y.; Mu, J.X. Synthesis and properties of poly(aryl ether sulfones) incorporating cage and linear organosiloxane in the backbones. Polymer 2015, 62, 77–85. [Google Scholar] [CrossRef]

- Wu, S.; Hayakawa, T.; Kakimoto, M.; Oikawa, H. Synthesis and characterization of organsoluble aromatic polyimides containing POSS in main chain derived from double-decker-shaped silsesquioxane. Macromolecules 2008, 41, 3481. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Y.; Song, L.; Xing, W.Y.; Lu, H.D. Thermal degradation behaviors of epoxy resin/POSS hybrids and phosphorus silicon synergism of flame retardancy. J. Polym. Sci. B 2010, 48, 693. [Google Scholar] [CrossRef]

- Liao, F.; Zhou, L.; Ju, Y.; Yang, Y.; Wang, X. Synthesis of a novel phosphorus nitrogen silicon polymeric flame retardant and its application in poly(lactic acid). Ind. Eng. Chem. Res. 2014, 53, 10015. [Google Scholar] [CrossRef]

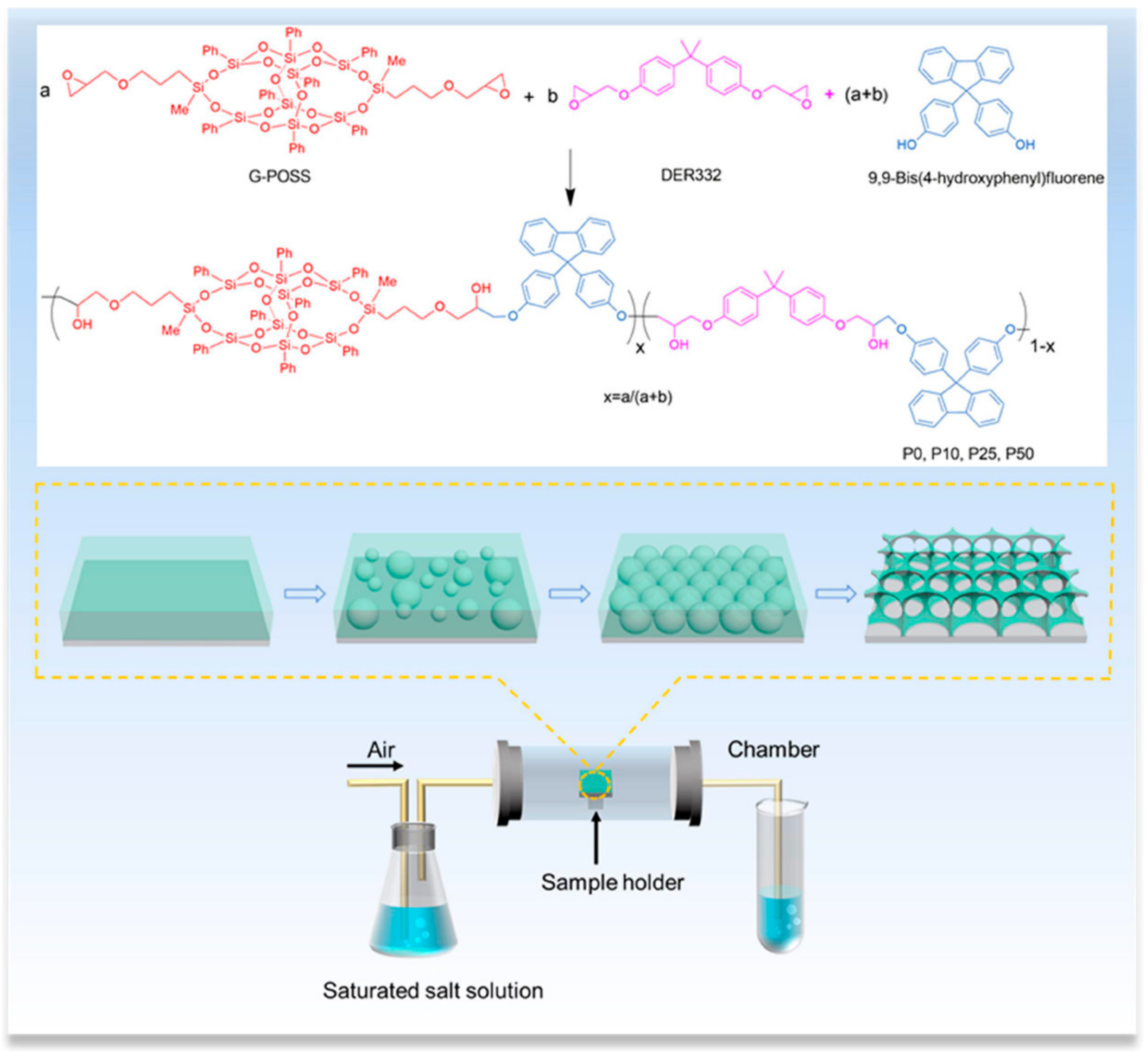

- Wang, L.; Zhang, C.; Zheng, S. Organic-inorganic poly (hydroxy ether of bisphenol a) copolymers with double-decker silsesquioxane in the main chains. J. Mater. Chem. 2011, 21, 19344. [Google Scholar] [CrossRef]

- Wei, K.; Wang, L.; Zheng, S. Synthesis and characterization of bead-like poly-(N-isopropyl acrylamide) copolymers with double-decker silsesquioxane in the main chains. Polym. Chem. 2014, 4, 1491. [Google Scholar] [CrossRef]

- Wei, K.; Wang, L.; Zheng, S. Organic-inorganic copolymers with double-decker silsesquioxane in the main chains by polymerization via click chemistry. J. Polym. Sci. A Polym. Chem. 2013, 51, 4221. [Google Scholar] [CrossRef]

- Zhang, W.; Li, Y.; Ma, H.; Song, W.; Lin, T.; Lu, C.; Nie, J.; Yang, G.; Chen, Z. Novel phosphorus-nitrogen-silicon copolymers with double-decker silsesquioxane in the main chain and their flame retardancy application in PC/ABS. Fire Mater. 2018, 42, 946. [Google Scholar]

- Song, W.; Zhang, W.; Li, Y.; Ma, H.; Lin, T.; Lu, C.; Nie, J.; Yang, C.; Chen, Z. Construction of novel silicon-phosphorus linear polymers with DDSQ and DOPO derivatives for effective flame retardancy of PC/ABS. Fire Mater. 2019, 43, 685. [Google Scholar] [CrossRef]

- Hoff, R. Handbook of Transition Metal Polymerization Catalysts, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018. [Google Scholar]

- Sobota, P.; Utko, J.; Lis, T.; John, Ł.; Petrus, R.; Drąg-Jarząbek, A. Unexpected reactions between Ziegler-Natta catalyst components and structural characterization of resulting intermediates. Inorg. Chem. 2016, 55, 4636. [Google Scholar] [CrossRef]

- Jerzykiewicz, L.B.; Utko, J.; John, Ł.; Duczmal, M.; Sobota, P. Titanium-manganese compound with a chiral Mn3Ti center. Inorg. Chem. 2007, 46, 9042. [Google Scholar] [CrossRef]

- John, Ł.; Utko, J.; Jerzykiewicz, L.B.; Sobota, P. Structural characterization of a methylaluminoxane (MAO)-magnesium dichloride cluster: Model of MAO grafted onto a MgCl2 support. Inorg. Chem. 2005, 44, 9131. [Google Scholar] [CrossRef] [PubMed]

- Klapper, M.; Joe, D.; Nietzel, S.; Krumpfer, J.W.; Müllen, K. Olefin Polymerization with Supported Catalysts as an Exercise in Nanotechnology. Chem. Mater. 2013, 26, 802. [Google Scholar] [CrossRef]

- Morra, E.; Giamello, E.; Van Doorslaer, S.; Antinucci, G.; D’Amore, M.; Busico, V.; Chiesa, M. Probing the coordinative unsaturation and local environment of Ti3+ sites in an activated highyield Ziegler-Natta catalyst. Angew. Chem. Int. Ed. Engl. 2015, 54, 4857. [Google Scholar] [CrossRef]

- Vittoria, A.; Meppelder, A.; Friederichs, N.; Busico, V.; Cipullo, R. Demystifying Ziegler-Natta Catalysts: The Origin of Stereoselectivity. ACS Catal. 2017, 7, 4509. [Google Scholar] [CrossRef]

- Correa, A.; Piemontesi, F.; Morini, G.; Cavallo, L. Key Elements in the Structure and Function Relationship of the MgCl2/TiCl4/Lewis Base Ziegler-Natta Catalytic System. Macromolecules 2007, 40, 9181. [Google Scholar] [CrossRef]

- Li, W.; Hui, L.; Xue, B.; Dong, C.; Chen, Y.; Hou, L.; Jiang, B.; Wang, J.; Yang, Y. Facile high-temperature synthesis of weakly entangled polyethylene using a highly activated Ziegler-Natta catalyst. J. Catal. 2018, 360, 145. [Google Scholar] [CrossRef]

- Liang, P.; Li, W.; Chen, Y.; Dong, C.; Zhou, Q.; Feng, Y.; Chen, M.; Dai, J.; Ren, C.; Jiang, B.; et al. Revealing the dynamic behaviours of tetrahydrofuran for tailoring the active species of Ziegler-natta catalysts. ACS Catal. 2021, 11, 4411. [Google Scholar] [CrossRef]

- Piovano, A.; Pletcher, P.; Velthoen, M.E.Z.; Zanoni, S.; Chung, S.H.; Bossers, K.; Jongkind, M.K.; Fiore, G.; Groppo, E.; Weckhuysen, B.M. Genesis of MgCl2-based Ziegler-Natta Catalysts as Probed with Operando Spectroscopy. ChemPhysChem 2018, 19, 2662. [Google Scholar] [CrossRef] [PubMed]

- Wada, T.; Takasao, G.; Piovano, A.; D’Amore, M.; Thakur, A.; Chammingkwan, P.; Bruzzese, P.C.; Terano, M.; Civalleri, B.; Bordiga, S.; et al. Revisiting the identity of δ-MgCl2: Part I. Structural disorder studied by synchrotron X-ray total scattering. J. Catal. 2020, 385, 76. [Google Scholar] [CrossRef]

- Piovano, A.; D’Amore, M.; Wada, T.; Cleto Bruzzese, P.; Takasao, G.; Thakur, A.; Chammingkwan, P.; Terano, M.; Civalleri, B.; Bordiga, S.; et al. Revisiting the identity of δ-MgCl2: Part II. Morphology and exposed surfaces studied by vibrational spectroscopies and DFT calculation. J. Catal. 2020, 387, 1–11. [Google Scholar] [CrossRef]

- Piovano, A.; D’Amore, M.; Thushara, K.S.; Groppo, E. Spectroscopic Evidences for TiCl4/Donor Complexes on the Surface of MgCl2-Supported Ziegler−Natta Catalysts. J. Phys. Chem. C 2018, 122, 5615. [Google Scholar] [CrossRef]

- Piovano, A.; Zarupski, J.; Groppo, E. Disclosing the Interaction between Carbon Monoxide and Alkylated Ti(3+) Species: A Direct Insight into Ziegler-Natta Catalysis. J. Phys. Chem. Lett. 2020, 11, 5632. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, P.; Yue, Z.; Li, W.; Dong, C.; Jiang, B.; Wang, J.; Yang, Y. Entanglement Formation Mechanism in the POSS Modified Heterogeneous Ziegler-Natta Catalysts. Macromolecules 2019, 52, 7593. [Google Scholar] [CrossRef]

- Li, Z.; Li, Z.; Hu, J.; Feng, X.; Zhang, M.; Duan, G.; Zhang, R. Self-Assembly of Poly(Janus particle)s into Unimolecular and Oligomeric Spherical Micelles. ACS Macro Lett. 2021, 10, 1563. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, H.; Zhang, J.; Liu, X.; Gu, Z.; Li, Y. Ultrasmall Nanoparticle ROS Scavengers Based on Polyhedral Oligomeric Silsesquioxanes. Chin. J. Polym. Sci. 2020, 38, 1149. [Google Scholar] [CrossRef]

- Li, Z.; Hu, J.; Yang, L.; Zhang, X.; Liu, X.; Wang, Z.; Li, Y. Integrated POSS-dendrimer nanohybrid materials: Current status and future perspective. Nanoscale 2020, 12, 11395. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

John, Ł.; Ejfler, J. A Brief Review on Selected Applications of Hybrid Materials Based on Functionalized Cage-like Silsesquioxanes. Polymers 2023, 15, 1452. https://doi.org/10.3390/polym15061452

John Ł, Ejfler J. A Brief Review on Selected Applications of Hybrid Materials Based on Functionalized Cage-like Silsesquioxanes. Polymers. 2023; 15(6):1452. https://doi.org/10.3390/polym15061452

Chicago/Turabian StyleJohn, Łukasz, and Jolanta Ejfler. 2023. "A Brief Review on Selected Applications of Hybrid Materials Based on Functionalized Cage-like Silsesquioxanes" Polymers 15, no. 6: 1452. https://doi.org/10.3390/polym15061452

APA StyleJohn, Ł., & Ejfler, J. (2023). A Brief Review on Selected Applications of Hybrid Materials Based on Functionalized Cage-like Silsesquioxanes. Polymers, 15(6), 1452. https://doi.org/10.3390/polym15061452